Reinforcing

A technology of reinforcing ribs and steel bars, which is applied in the direction of building reinforcements, key connections, rod connections, etc., can solve problems such as increased corrosion, excessive longitudinal slip, cracking, etc., and achieve the effect of reducing constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

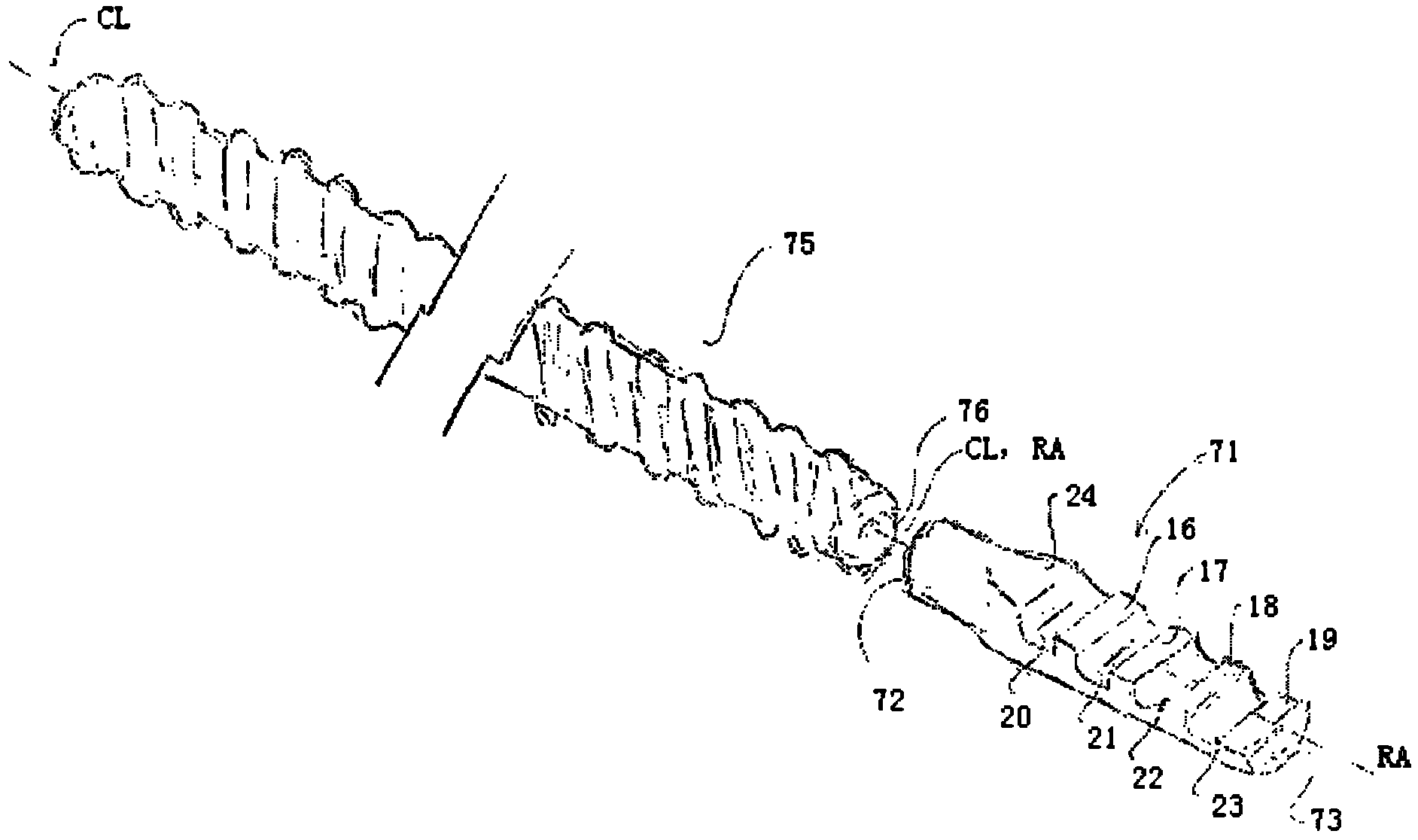

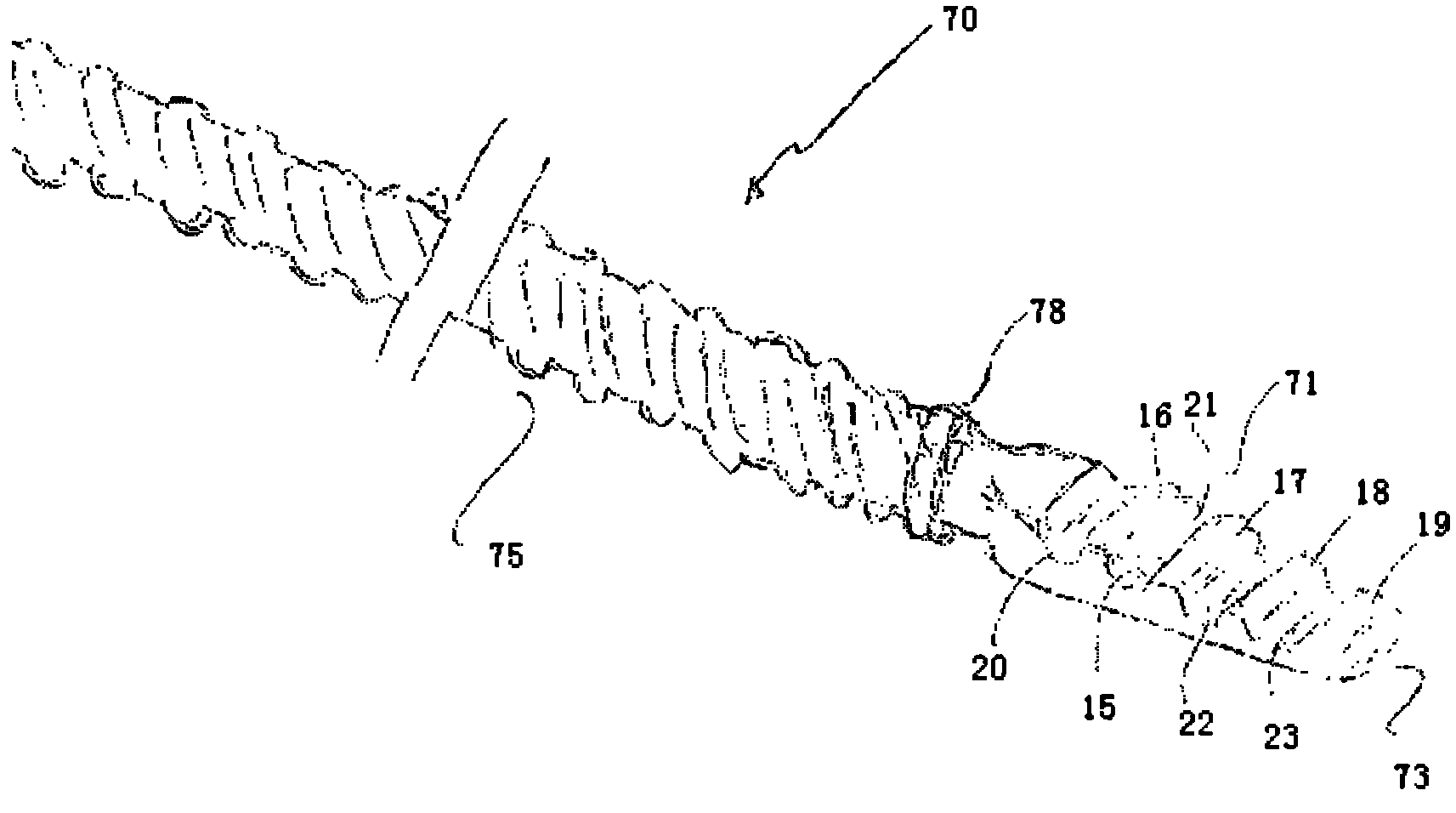

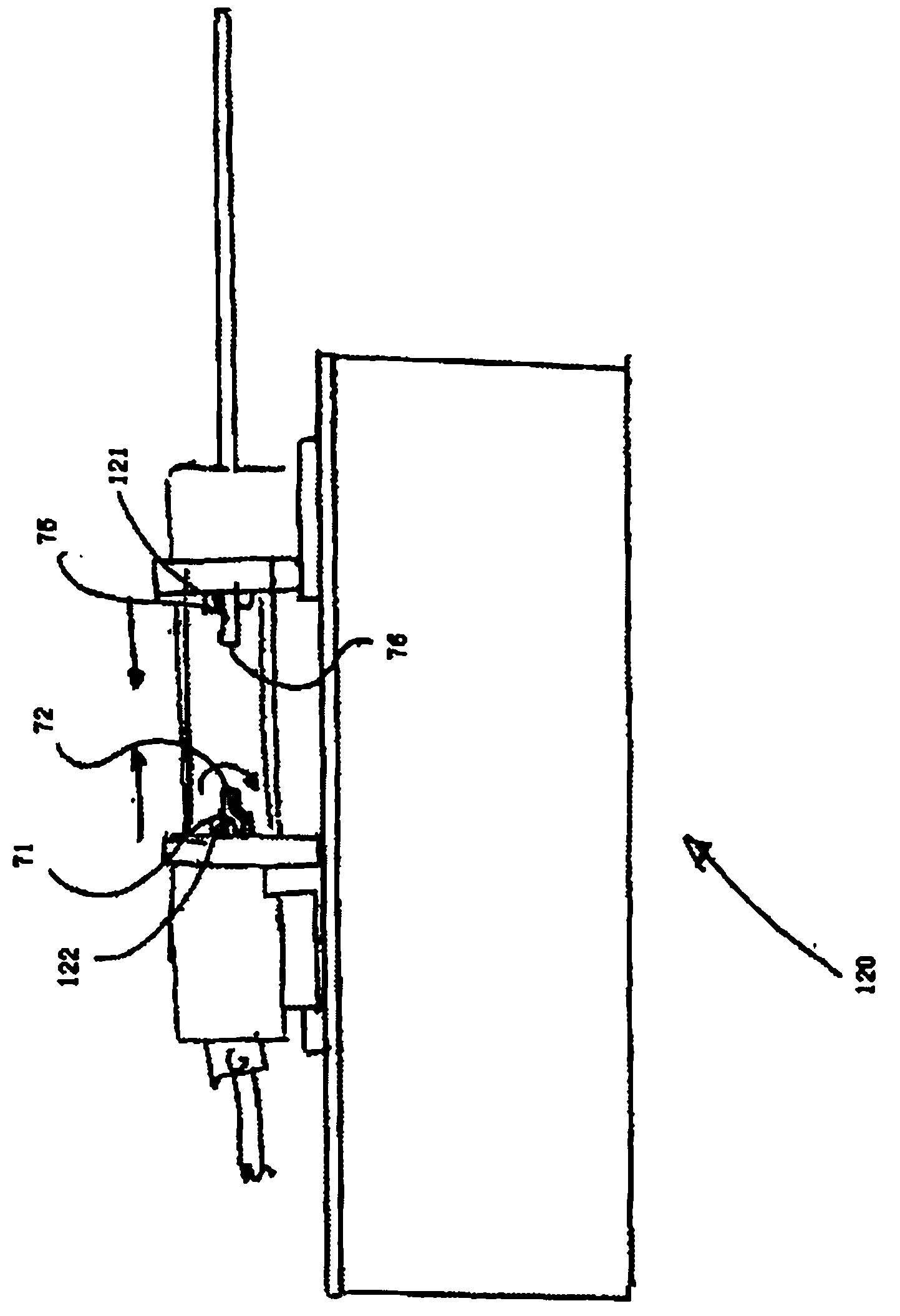

[0055] first as Figures 1 to 3 As shown in the partial view of the reinforcing bar 10 , the reinforcing bar 10 generally made of steel includes an axis 11 extending along the length of the reinforcing bar 10 . Only a small part of the shaft 11 is shown, it being noted that the shaft can extend for several meters. Rebar is manufactured in continuous lengths and cut to different sizes according to specific needs. Furthermore, the shaft 11 is shown as flat for convenience. It is worth noting that the shaft can contain threads, such bars are often referred to as deformed bars.

[0056] The bar 10 also includes a terminating structure 12 extending along the end of the bar to an end 13 of the bar 10, the terminating structure 12 is shown integral with the axis 11 and enlarged compared to the axis 11 (i.e. it is defined by the central axis of the bar). The distance extending radially outward is greater than the distance extending outward of the shaft 11 ), and a transition zone 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com