Nano cellulose based biological aerogel and preparation method and application thereof

A technology of nanocellulose and nanoscale cellulose, applied in chemical instruments and methods, colloid chemistry, colloid chemistry, etc., can solve the problems of easy re-dispersion, etc., and achieve the effect of strong practicability, high surface area and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

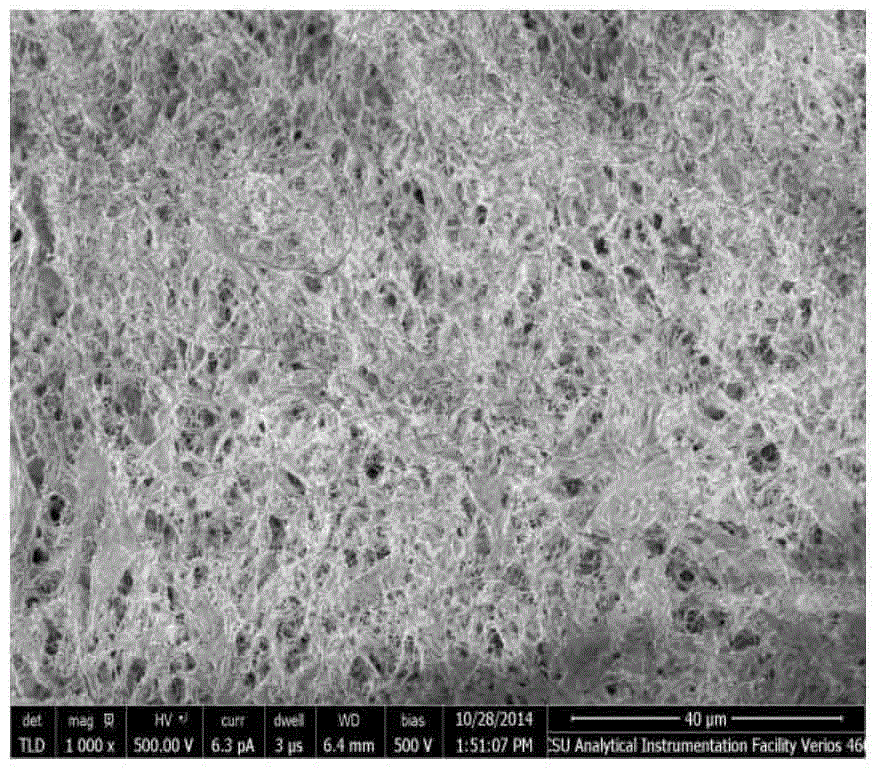

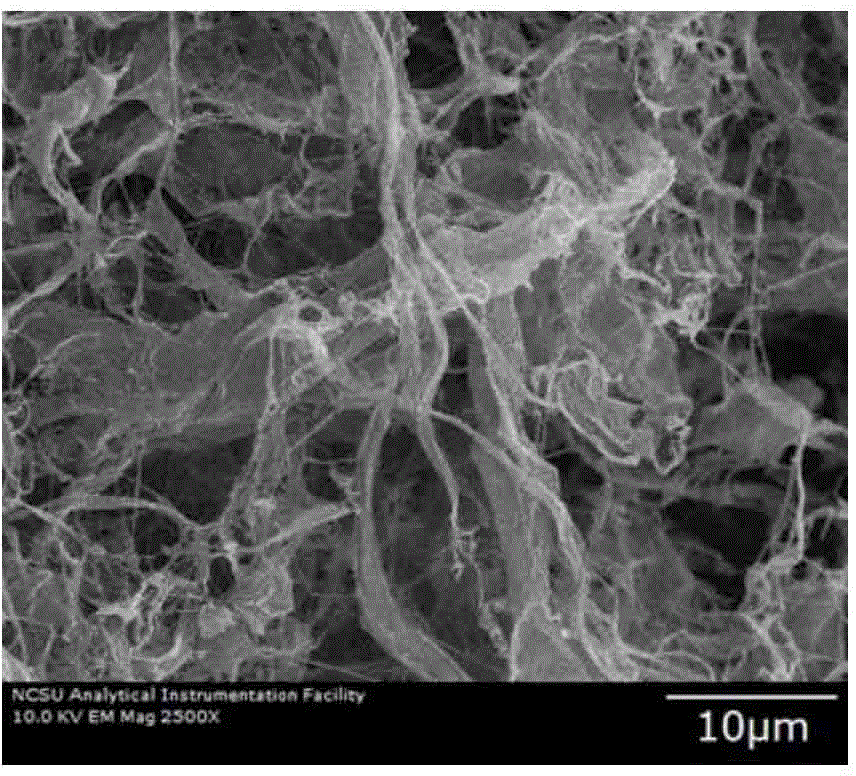

Image

Examples

Embodiment 1

[0035] The preparation method of bioaerogel of the present invention comprises the following steps:

[0036] (1) Fully bleached softwood pulp adopts chemical mechanical method to prepare nanocellulose dispersion;

[0037] Nano-scale cellulose dispersion: In this example, a chemical-mechanical method is used to prepare a nano-scale cellulose dispersion, and the fiber is first subjected to an appropriate oxidative degradation pretreatment using a chemical degradation method. For example, sodium hydroxide solution can be used for pretreatment, and then A high-pressure homogenizer is used for homogenization treatment to obtain the nanocellulose dispersion in this example.

[0038] (2) Chitosan is prepared into a 1% solution with 2% acetic acid solution;

[0039] The preparation method of chitosan: use clean shrimp and crab shells as raw materials, decalcify them with hydrochloric acid, and then digest them with caustic soda to deproteinize them to obtain chitin, and then use conc...

Embodiment 2

[0046] The preparation method of bioaerogel of the present invention comprises the following steps:

[0047] (1) The fully bleached broadleaf pulp is prepared by mechanical method and chemical combination method; the preparation method is the same as in Example 1.

[0048] (2) chitosan is prepared into 1% solution with 0.01mol / L hydrochloric acid solution;

[0049] The preparation method of chitosan: use clean shrimp and crab shells as raw materials, decalcify them with hydrochloric acid, and then digest them with caustic soda to deproteinize them to obtain chitin, and then use concentrated lye to deacetylate chitin to obtain the final Chitosan, and chitosan is prepared into 1% solution with 0.01mol / L hydrochloric acid solution, obtains the chitosan solution of the present embodiment.

[0050] (3) The cellulose in the nanoscale cellulose dispersion prepared in (1) is mixed with the chitosan in the chitosan solution prepared in (2) with a ratio of 1:0.05, mechanically stirred ...

Embodiment 3

[0055]The preparation method of bioaerogel of the present invention comprises the following steps:

[0056] (1) Unbleached broadleaf pulp adopts mechanical method to prepare micron cellulose dispersion;

[0057] In this embodiment, a high-pressure homogenizer is used to prepare a micron cellulose dispersion, that is, the reciprocating pump of the high-pressure homogenizer transports a certain concentration of fiber slurry to the working valve area, and the pressure drops rapidly. The strong cavitation effect similar to the explosion effect is generated in the narrow area composed of the former, and accompanied by the shearing action of the slurry passing through the slit between the valve core and the valve seat and the high-speed impact of the impact ring, the fiber Filaments are disintegrated and the fibers are miniaturized.

[0058] (2) Chitosan is prepared into 1% solution with 2% acetic acid solution (preparation method is identical with embodiment 1);

[0059] (3) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com