Transparent resin laminate

A laminated body and resin technology, applied in the direction of synthetic resin layered products, coatings, layered products, etc., can solve problems such as insufficient warpage and deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0040] Hereinafter, manufacturing examples, examples, etc., are illustrated to describe the present invention in detail. However, the present invention is not limited to the illustrated manufacturing examples, examples, etc., and can be modified as long as it does not significantly deviate from the content of the present invention. Any method to implement.

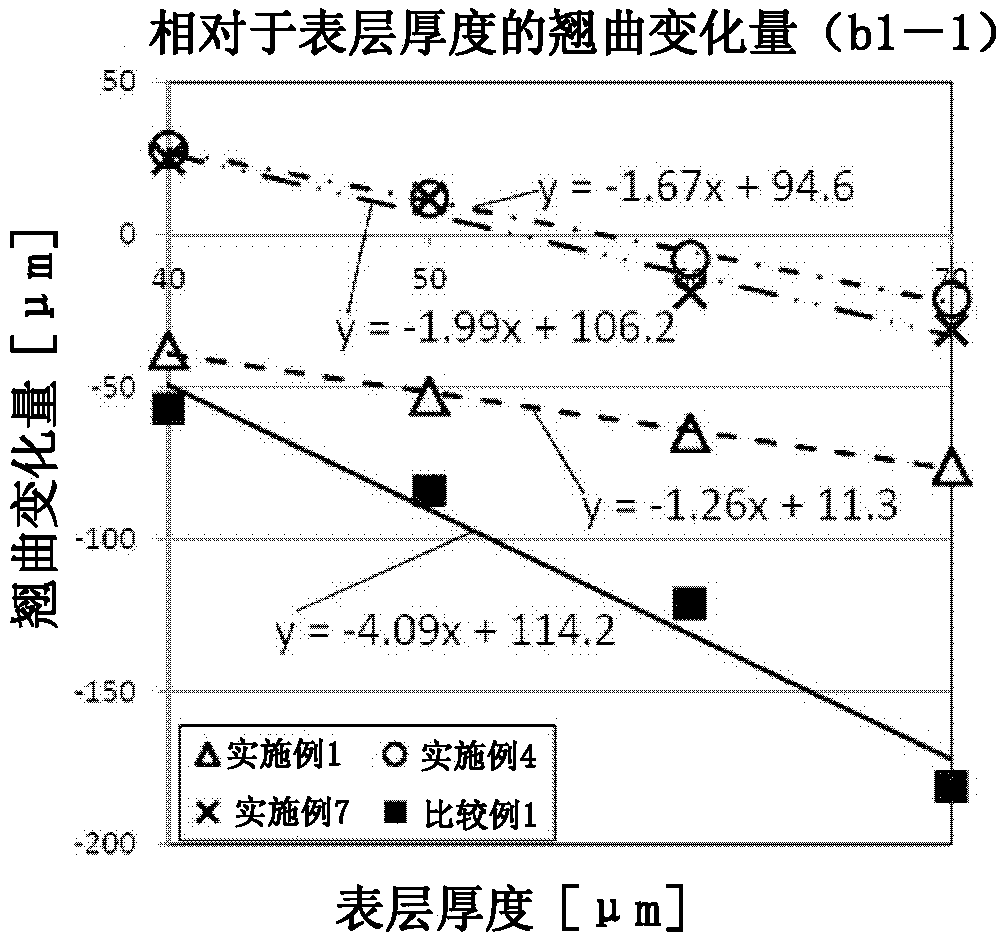

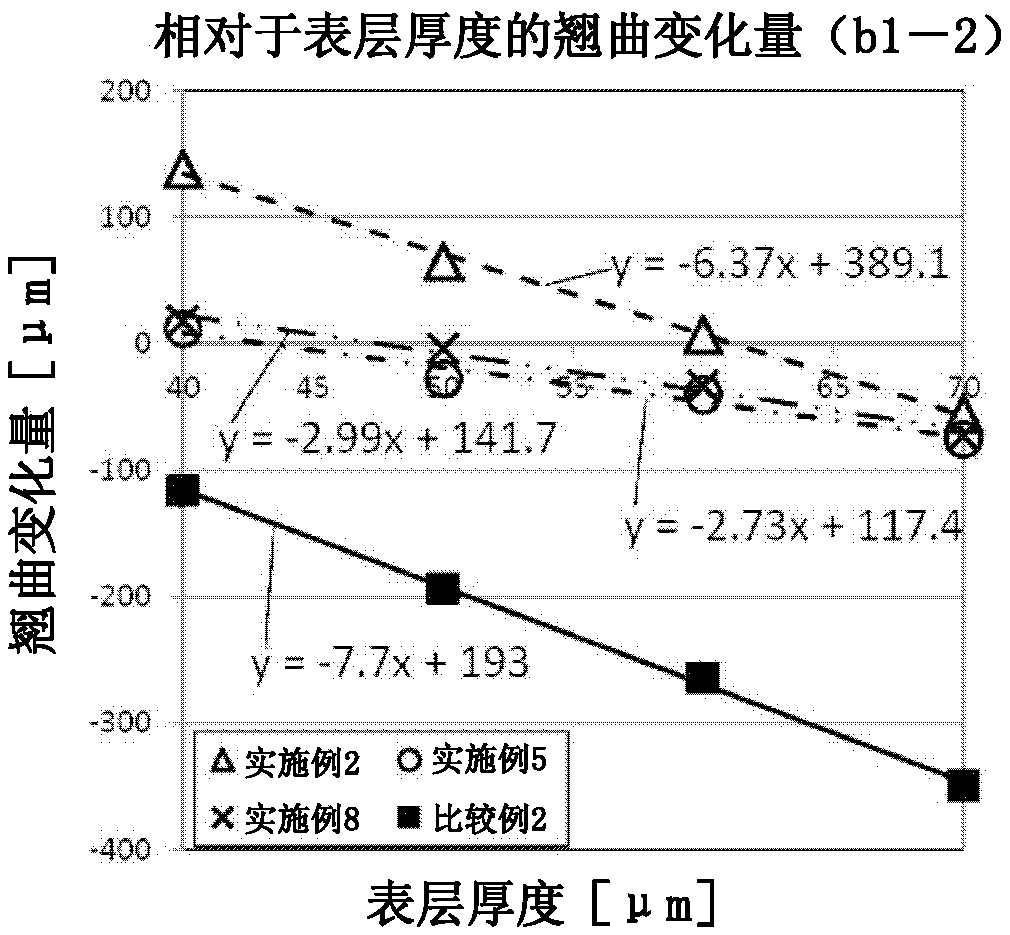

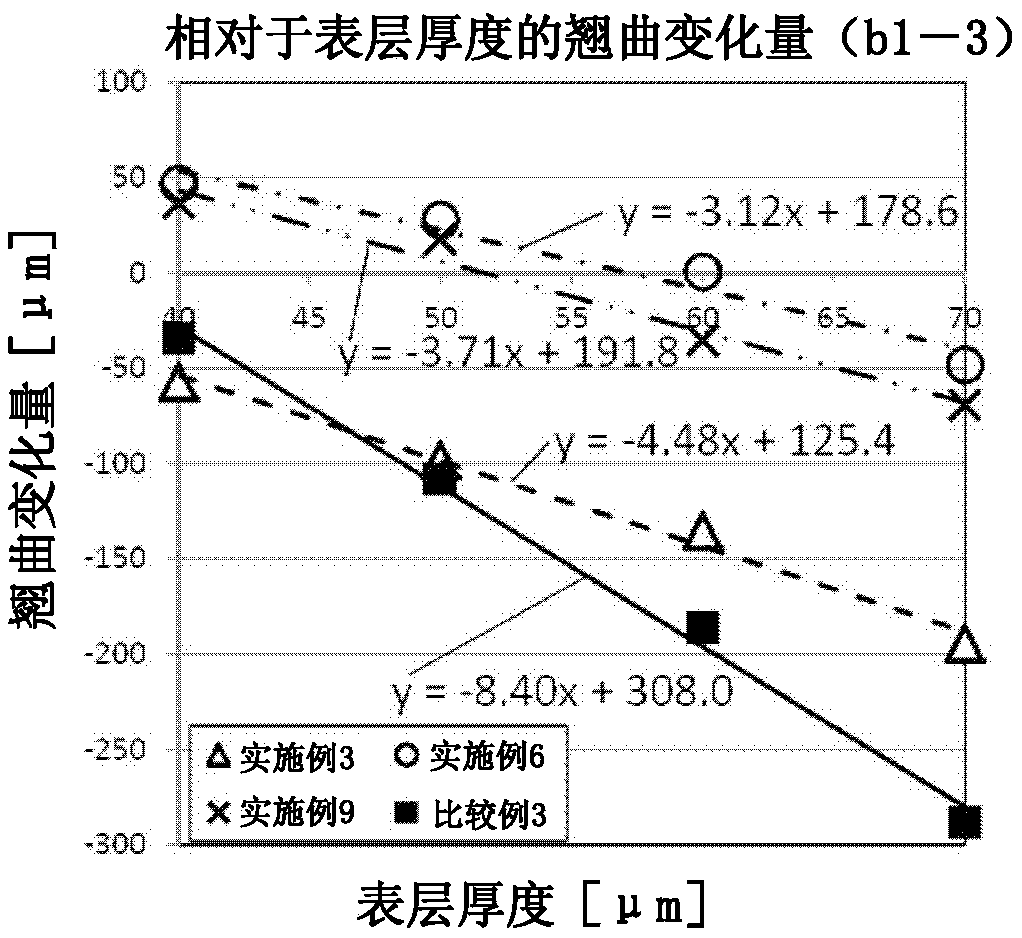

[0041] The present invention relates to a resin laminate characterized in that it is a resin obtained by laminating a thermoplastic resin (B) on at least one surface of a polycarbonate resin sheet (A) containing polycarbonate resin as a main component A laminate in which the thermoplastic resin (B) contains the copolymer (b1) and contains any one of the copolymer (b2) and the copolymer (b3), and the copolymer (b1) contains an aromatic vinyl monomer unit 45 ~85% by mass, 5-50% by mass of unsaturated dicarboxylic anhydride monomer units, and 5 to 35% by mass of acrylic compound monomer units. The copolymer (b2) contains 1-30% b...

Embodiment

[0113] Hereinafter, the present invention will be specifically explained through examples. However, the present invention is not limited in any way by these examples.

[0114] The physical property measurement of the laminated resin obtained in the manufacturing example and the evaluation of the synthetic resin laminated body obtained in the Example and the comparative example were performed as follows.

[0115]

[0116] A test piece of 10 cm in length and 6 cm in width was cut out from the vicinity of the center of the resin laminate. The test piece was set on a two-point support type holder, put into an environmental testing machine set at a temperature of 23° C. and a relative humidity of 50% for 24 hours or more, and after adjusting the state, the warpage was measured. Let the value at this time be the value of the amount of warpage before processing. Next, the test piece was set in a holder, put into an environmental testing machine set at a temperature of 85°C and a relativ...

manufacture example 1

[0127] Production Example 1 [Production of resin (B11) pellets]

[0128] Relative to R100 (b1-1) as copolymer (b1) (mass ratio of styrene:maleic anhydride:MMA=65:15:20, weight average molecular weight: 170,000) 75 parts by mass and as copolymer (b2) DELPET PM120N(b2-1) (mass ratio of styrene:N-phenylmaleimide:MMA=4:15:81, weight average molecular weight: 113,000) 25 parts by mass total 100 parts by mass, add 500ppm Phosphorus-based additive PEP-36 (manufactured by ADEKA Co., Ltd.) and 0.2% by mass of stearic acid monoglyceride (product name: H-100, manufactured by Riken VITAMIN Co., Ltd.), mixed with a blender for 20 minutes, and then screwed 26mm diameter twin-screw extruder (manufactured by Toshiba Instruments Co., Ltd., TEM-26SS, L / D≒40), melted and kneaded at a barrel temperature of 240°C, extruded into strands and pelletized using a pelletizer 化. The pellets were manufactured stably.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com