Carbon fiber composite foam core sandwich structure wind tunnel fan blade and molding method

A technology of sandwich structures and composite materials, applied in liquid fuel engines, components of pumping devices for elastic fluids, non-variable displacement pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

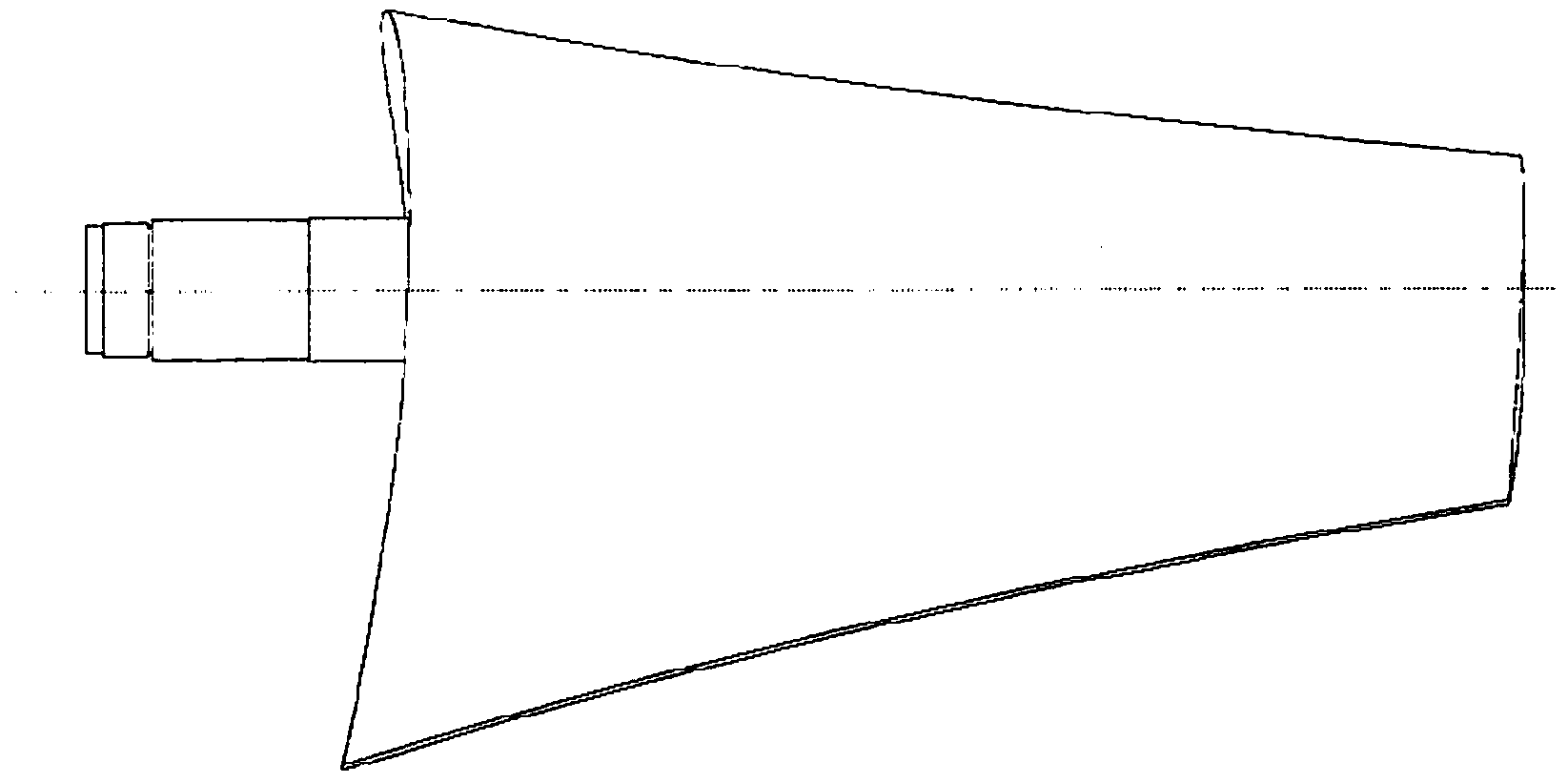

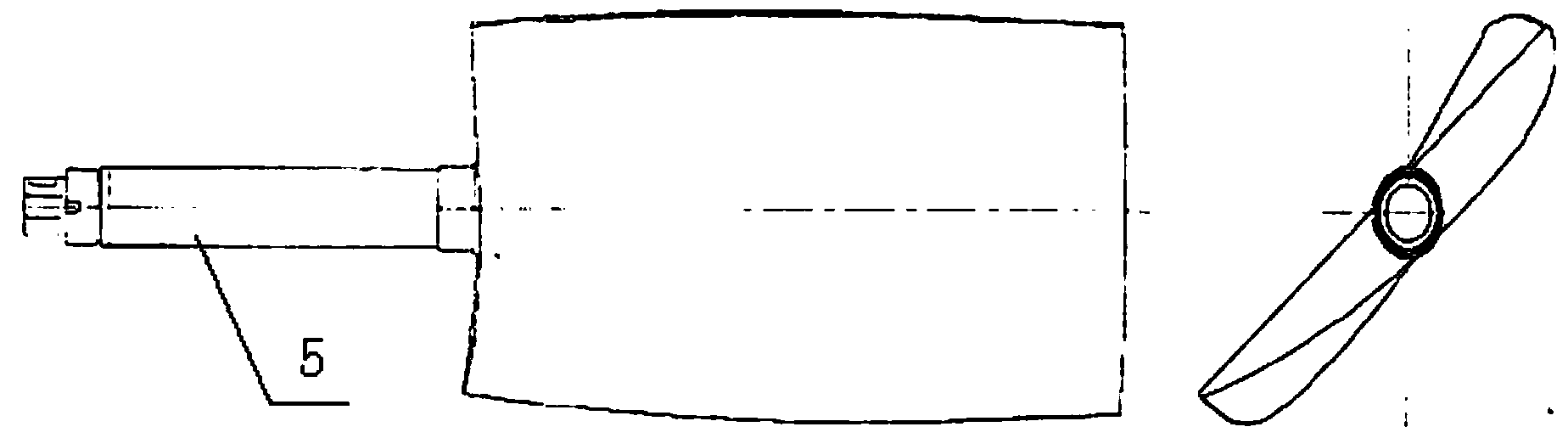

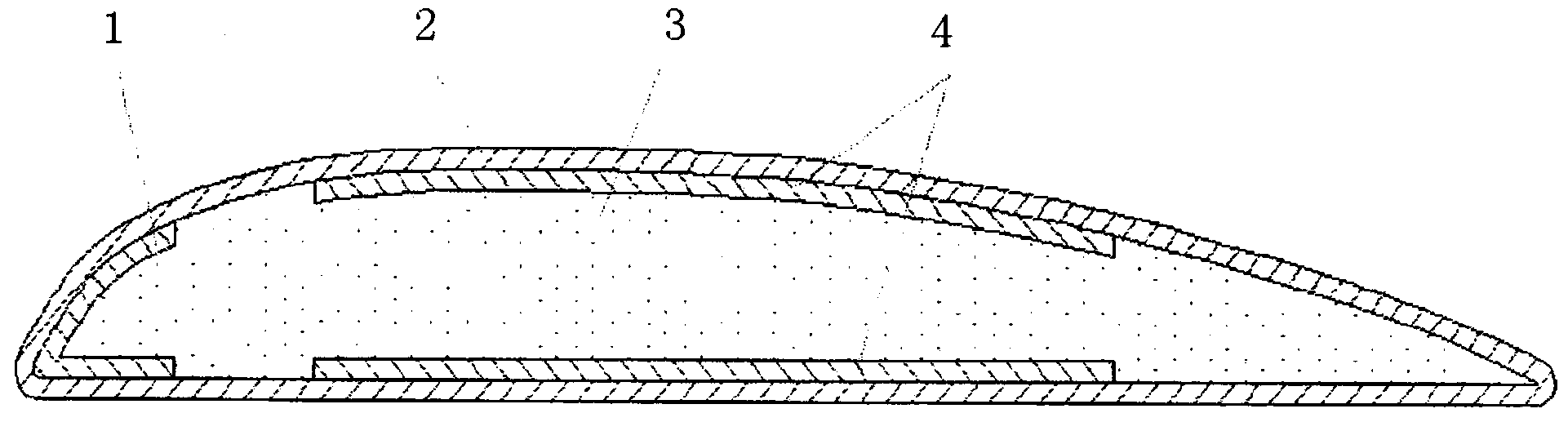

[0032] Such as Figure 1 to Figure 3 As shown, a carbon fiber composite material foam sandwich structure wind tunnel fan blade according to the present invention, the blade is an integral foam sandwich structure, the blade root is connected to a metal petiole 5; the blade includes a skin 2, a leading edge reinforcement area 1 , the main load-bearing beam 4 and the foam core material 3, wherein the outer part is the skin 2, the inner front end of the skin 2 is connected to the front edge reinforcement area 1, the inner middle of the skin 2 is connected to the main load-bearing beam 4, and the foam core material 3 is filled in the cover The inner space formed by the skin 2, the front edge reinforcement area 1 and the main bearing beam 4; the skin 2 is divided into an inner skin and an outer skin, and the inner skin is covered with an outer skin;

[0033] The thickness of the main bearing beam 4 transitions from 9.75mm at the blade root to 3.75mm at the blade tip, and the gradual...

Embodiment 2

[0053] Such as Figure 1 to Figure 3 As shown, a carbon fiber composite material foam sandwich structure wind tunnel fan blade according to the present invention, the blade is an integral foam sandwich structure, the blade root is connected to a metal petiole 5; the blade includes a skin 2, a leading edge reinforcement area 1 , the main load-bearing beam 4 and the foam core material 3, wherein the outer part is the skin 2, the inner front end of the skin 2 is connected to the front edge reinforcement area 1, the inner middle of the skin 2 is connected to the main load-bearing beam 4, and the foam core material 3 is filled in the cover The inner space formed by the skin 2, the front edge reinforcement area 1 and the main bearing beam 4; the skin 2 is divided into an inner skin and an outer skin, and the inner skin is covered with an outer skin;

[0054] The thickness of the main bearing beam 4 transitions from 8 mm at the root of the blade to 2 mm at the tip of the blade, and t...

Embodiment 3

[0074] Such as Figure 1 to Figure 3 As shown, a carbon fiber composite material foam sandwich structure wind tunnel fan blade according to the present invention, the blade is an integral foam sandwich structure, the blade root is connected to a metal petiole 5; the blade includes a skin 2, a leading edge reinforcement area 1 , the main load-bearing beam 4 and the foam core material 3, wherein the outer part is the skin 2, the inner front end of the skin 2 is connected to the front edge reinforcement area 1, the inner middle of the skin 2 is connected to the main load-bearing beam 4, and the foam core material 3 is filled in the cover The inner space formed by the skin 2, the front edge reinforcement area 1 and the main bearing beam 4; the skin 2 is divided into an inner skin and an outer skin, and the inner skin is covered with an outer skin;

[0075] The thickness of the main bearing beam 4 transitions from 10 mm at the root of the blade to 4 mm at the tip of the blade, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com