Resin type nanoparticle latex blocking agent for drilling fluids and preparation method of blocking agent

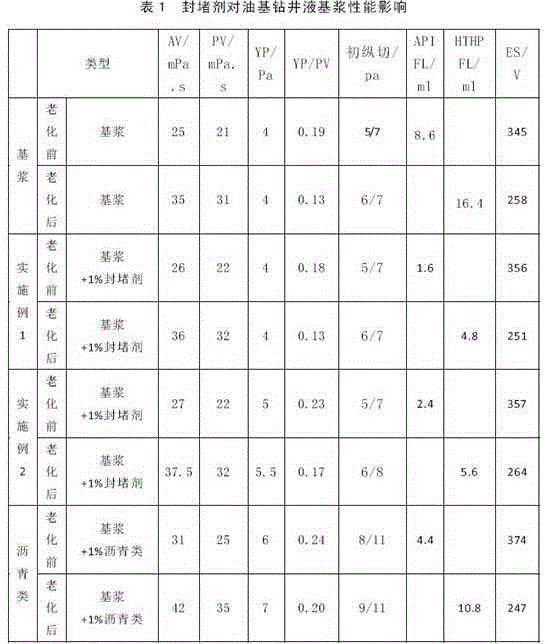

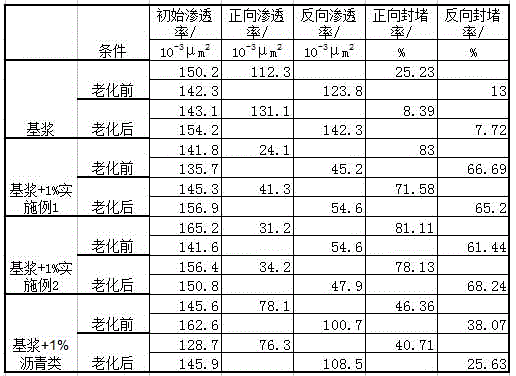

A nanoparticle and resin technology is applied in the field of resin nanoparticle latex plugging agent for drilling fluids, which can solve the problem of high cost and achieve the effects of high plugging rate, improving plugging ability and reducing filtration loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] As the best embodiment of the present invention, it discloses a kind of resin nano particle latex plugging agent for drilling fluid, which is composed of the following raw materials in parts by weight:

[0032] Alkenylbenzene: 20;

[0033] Acrylate: 15;

[0034] acrylic: 1;

[0035] Hard Inorganic Materials: 10;

[0036] The mass ratio of long-chain monomers to short-chain monomers in the acrylate monomers is 3:1.

[0037] The alkenyl benzene monomer is one of styrene, propylene toluene and vinyl toluene.

[0038] The acrylic monomer is methyl methacrylate, butyl acrylate, lauryl methacrylate, two or more mixtures in any proportion of stearyl methacrylate, wherein the long-chain monomer is specifically ( Lauryl methacrylate, octadecyl methacrylate), short-chain monomers specifically (methyl methacrylate, butyl acrylate).

Embodiment 2

[0040] As the best implementation mode of this preparation method, its steps are as follows:

[0041] 1) Add 10g of alkylphenol polyoxyethylene ether ammonium sulfate to 200ml of distilled water, add 40g of alkenylbenzene, 30g of acrylate, 2g of acrylic acid, and 20g of hard inorganic material in sequence, and use a shear emulsifier to cut for 30 minutes to form a pre- lotion;

[0042] 2), adding a 15% sodium bicarbonate aqueous solution to the pre-emulsion, stirring at a constant speed, adjusting the pH of the pre-emulsion to be weakly alkaline, and the pH range is 7-8;

[0043] 3) Stir at a constant speed, slowly add 2% saturated solution of initiator ammonium persulfate dropwise, finish adding in 30 minutes, raise the temperature to 70°C-85°C, and keep warm for 4h;

[0044] 4) After cooling the reactant to 30°C-40°C, add 5% ammonia solution, adjust the pH value of the reactant to be weakly alkaline, and the pH range is 7-8, and stir for 10 minutes to obtain resin nanoparti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com