Medium-high temperature oil reservoir phenolic gel self-degradation temporary plugging agent and preparation method thereof

A temporary plugging agent, medium and high temperature technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of complex oil field construction, incomplete gel breaking of temporary plugging agent, high polymer cost, etc., to achieve gel breaking Controllable time, high plugging rate and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

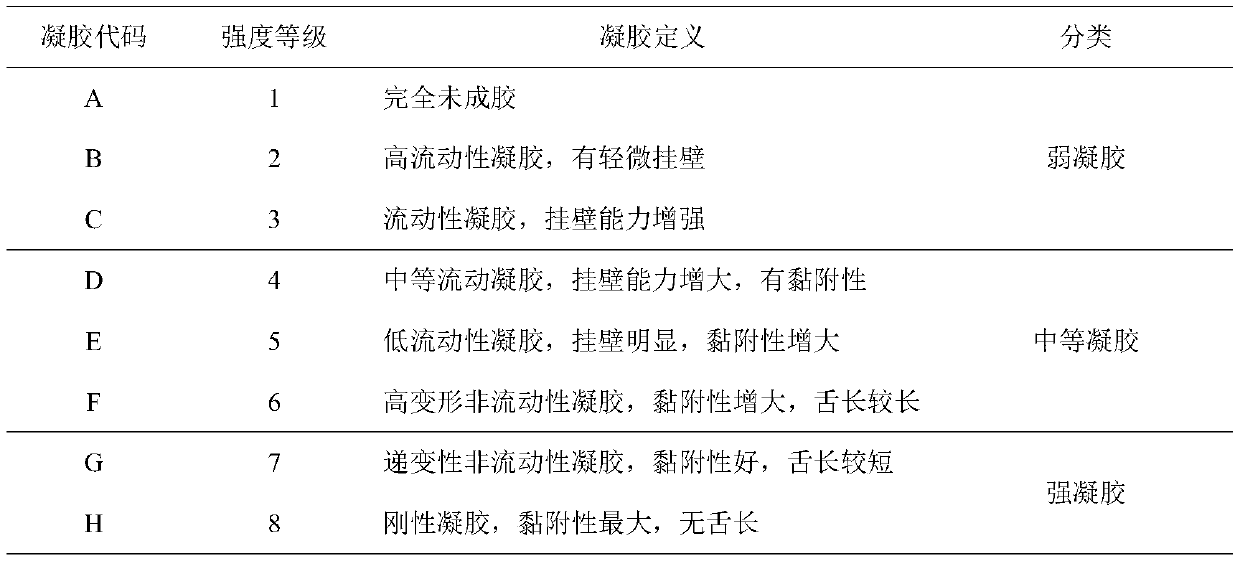

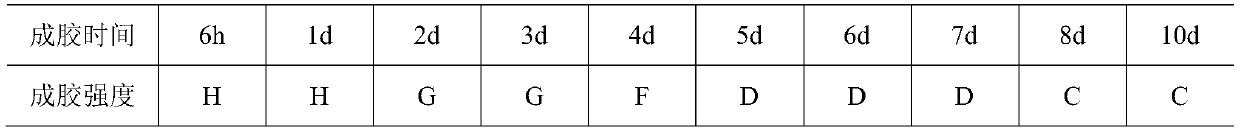

[0041] Add 62.5g polymer mother liquor, 0.2g resorcinol, 0.4g urotropine, 36.25g water into the beaker, stir well, then add 0.05g aluminum sol, 0.1g acetic acid, 0.5g malonic acid and stir Until all the medicines are dissolved in the aqueous solution, the jelly temporary plugging agent of the present invention is obtained. Put it into an ampoule bottle and seal it, then place it in a high-temperature tank at 100°C for aging, and observe the change in jelly strength at different time points. The gelling time of the temporary plugging agent at 100°C is 5 hours, and the strength remains above F for 1 to 4 days (the strength is G at 72 hours). It degrades from the fifth day, and the strength gradually decreases, and the strength drops to C, has better fluidity. The jelly strength changes are shown in Table 2 below.

[0042] Table 2 Changes in jelly strength with time at 100°C after adding 0.5% gel breaker to the gelling solution

[0043]

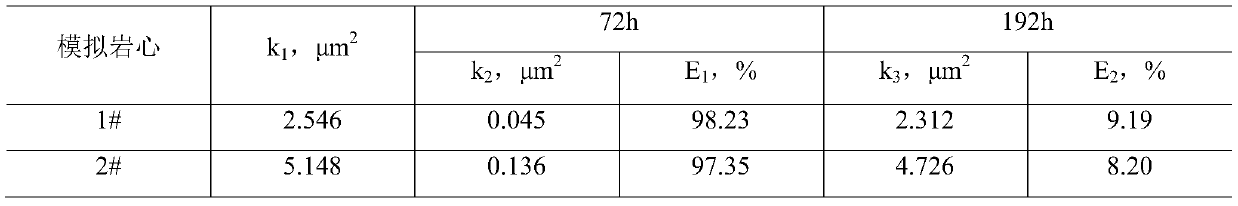

[0044] Blocking ability test:

[0...

Embodiment 2

[0049] Add 62.5g polymer mother liquor, 0.2g resorcinol, 0.4g urotropine, 36.0g water into the beaker, stir well, then add 0.05g aluminum sol, 0.1g acetic acid, 0.75g malonic acid and stir Until all the medicines are dissolved in the aqueous solution, the jelly temporary plugging agent of the present invention is obtained. Put it into an ampoule bottle and seal it, place it in a 90°C water bath for aging, and observe the change in jelly strength at different time points. The gelling time of the temporary plugging agent at 90°C is 5 hours, and the strength remains above F for 1 to 4 days (the strength is G at 72 hours). It degrades from the fifth day, and the strength gradually decreases, and the strength drops to C, has better fluidity. The jelly strength variation is shown in Table 4 below.

[0050] Table 4 Changes in jelly strength with time at 90°C after adding 0.75% gel breaker to the gelling solution

[0051]

[0052] Blocking ability test:

[0053] Investigate the...

Embodiment 3

[0057] Add 62.5g polymer mother liquor, 0.2g resorcinol, 0.4g urotropine, 36.0g tap water into the beaker, stir well, then add 0.05g aluminum sol, 0.1g acetic acid, 0.75g malonic acid and stir Until all the medicines are dissolved in the aqueous solution, the jelly temporary plugging agent of the present invention is obtained. Put it into an ampoule bottle and seal it, then place it in an 80°C water bath for aging, and observe the change in jelly strength at different time points. The gelling time of the temporary plugging agent at 80°C is 6 hours, and the strength remains above F for 1 to 6 days (the strength is G at 96 hours). It degrades from the 7th day, and the strength gradually decreases. On the 10th day, the strength drops to C, has better fluidity. See table 6 below for jelly strength changes.

[0058] Table 6 Changes in jelly strength with time at 80°C after adding 0.75% gel breaker to the gelling solution

[0059]

[0060] Blocking ability test:

[0061] Inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| core plugging rate | aaaaa | aaaaa |

| core plugging rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com