Patents

Literature

52results about How to "Does not affect rheology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

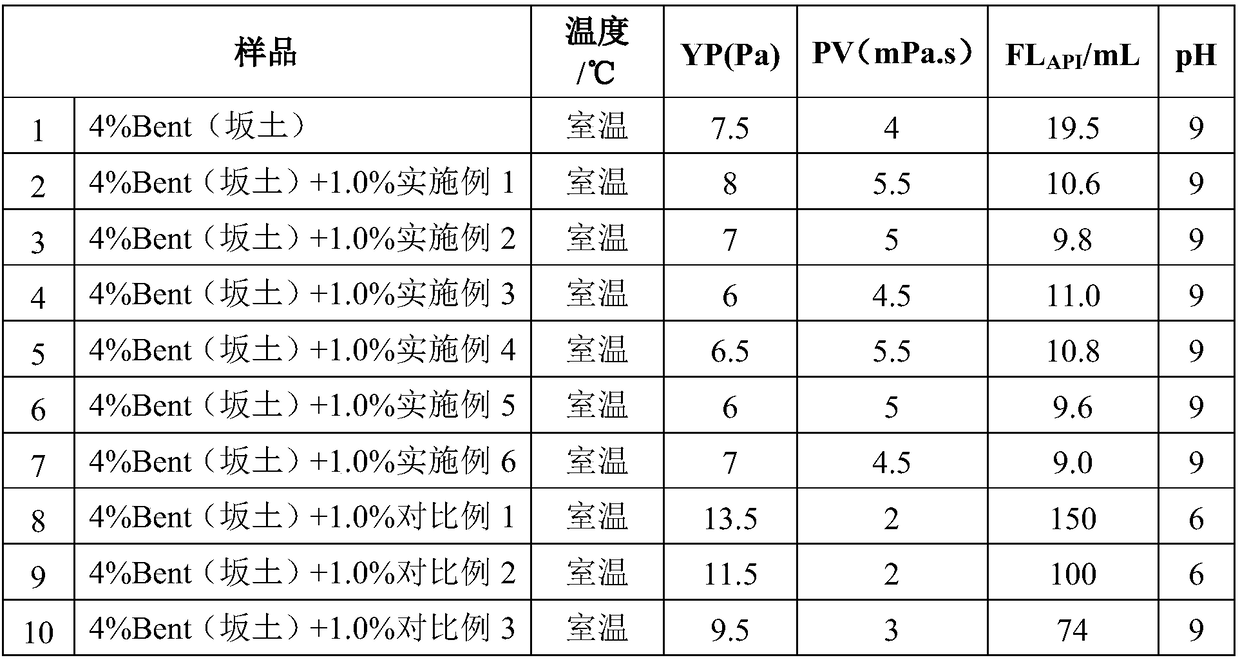

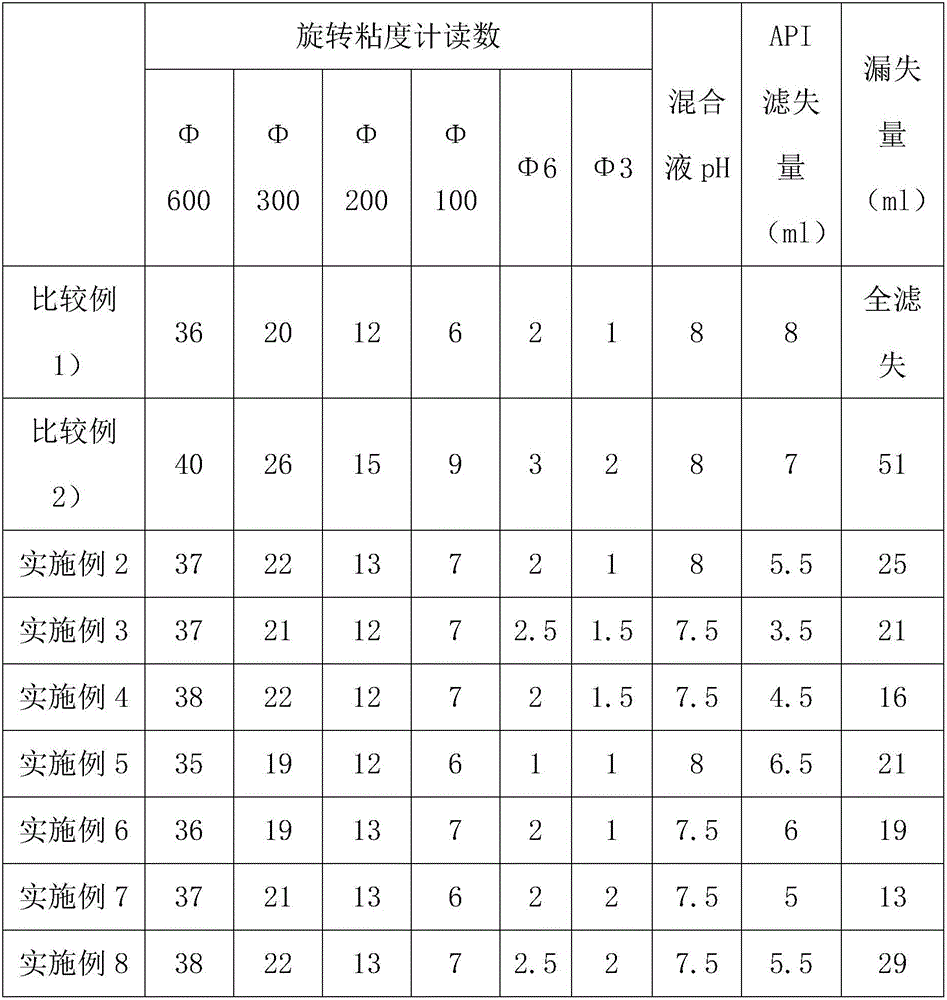

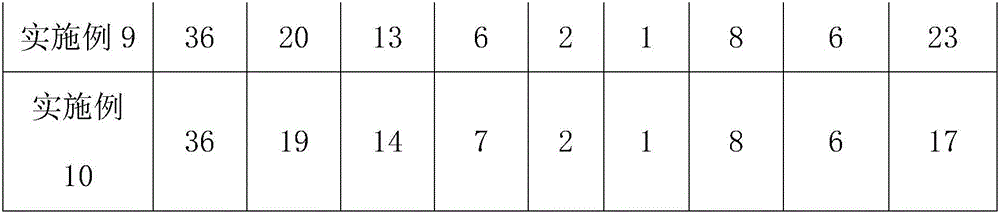

Follow-drilling plugging agent and its preparation method and use

The invention provides a leak preventer along with drilling and the method for its preparation, relating to the field of additive of boring fluid. Such leak preventer along with drilling contains: a) plant fiber without colloid or lignin, 100 weight shares; b) lime carbonate with calcium carbonate for at least 90 weight percent, 10-60 weight shares; c) oil-soluble resin of oil-soluble ratio no less than 95 weight percent and softening point 50-250 Deg. C, 3-30 weight shares. The leak preventer along with drilling is prepared by equably mixing the disintegrated ingredients which contains there substances above. It has a remarkable effect of leak prevention, which can be mixed with boring fluid to prevent leak while drilling, needing not stop drilling or stop laboratory sifter, improving the drilling speed and saving the drilling cost. And it also can release stoppage in acid solvent, oil solvent and negative pressure, and protect the reservoir. The leak preventer along with drilling is easy to spread, extensive sources of the material, low cost, and convenient technique.

Owner:CHINA PETROLEUM & CHEM CORP +1

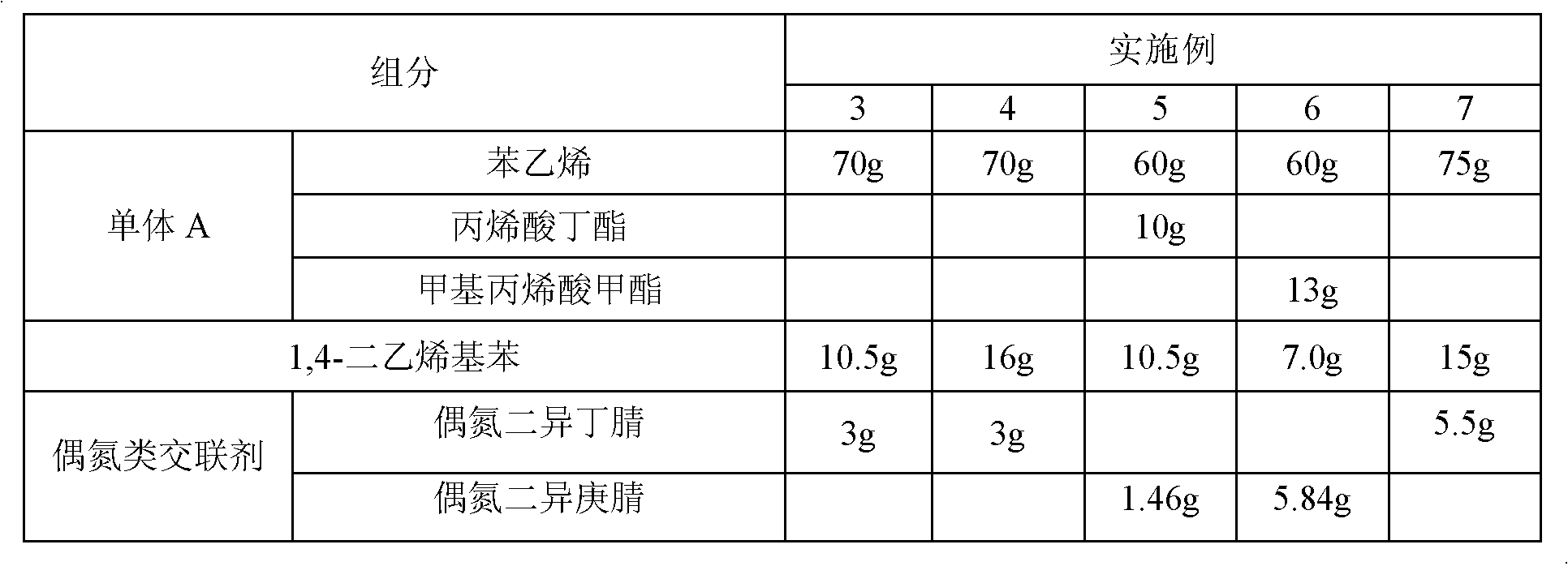

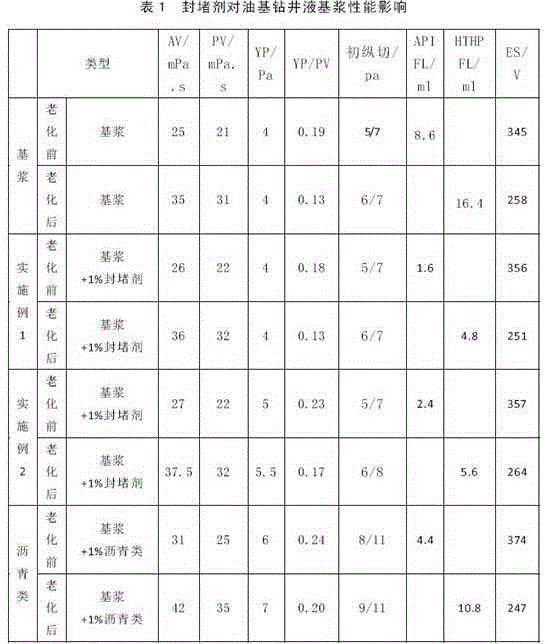

High-temperature-resistant while-drilling plugging agent and preparation method thereof

InactiveCN102603985AImprove temperature resistanceEnsure stabilityDrilling compositionTemperature resistancePollution

The invention relates to a high-temperature-resistant while-drilling plugging agent and a preparation method thereof and belongs to the technical field of oil field chemical drilling fluid treating agents. The method comprises the following steps: preparing a stable emulsion from an oil soluble monomer A, an oil soluble crosslinking agent B, an azo-type initiator, an organic hydroperoxide and water in the presence of an emulsifier, and polymerizing the stable emulsion to obtain a powder M; and swelling the powder M by use of a swelling agent, adding a water soluble monomer C, a water soluble crosslinking agent D and a reductive initiator into the swelled powder M, and polymerizing the mixture at the room temperature to obtain the high-temperature-resistant while-drilling plugging agent. The high-temperature-resistant while-drilling plugging agent is in a powder shape, has relatively high temperature resistance, can resist the temperature up to 180 DEG C, and can be used for performing while-drilling plugging on deep wells and supper deep wells. The while-drilling plugging agent can be used for quickly effectively plugging the permeability leak, the micro order crack and gap leak, avoiding the repeated leak, participating in the formation of a filter cake, keeping the stability of a well wall and obviously reducing the drilling filler loss and the pollution to a reservoir, has no influence on the rheological property of the drilling fluid and has the advantages of good compatibility with various drilling fluid systems and relatively good combination property.

Owner:CHINA PETROLEUM & CHEM CORP +1

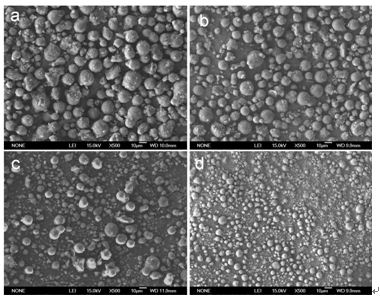

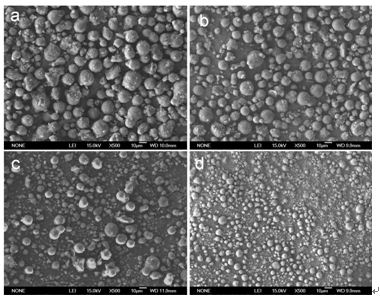

Resin type nanoparticle latex blocking agent for drilling fluids and preparation method of blocking agent

ActiveCN105462568AHigh blocking rateWide particle size distributionDrilling compositionBenzeneNanoparticle

The invention discloses a resin type nanoparticle latex blocking agent for drilling fluids. The blocking agent comprises raw materials in parts by weight as follows: 20 parts of alkenyl benzene, 15 parts of acrylate, 1 part of acrylates and 10 parts of hard inorganic materials, wherein the mass ratio of short-chain monomers to long-chain monomers in acrylate monomers is 3:1. The blocking agent is a composite product of the inorganic materials and organic materials, combines the hard materials with soft materials, has a higher blocking rate and is wide in particle size distribution and wider in application range; the rheological property of the drilling fluids are seldom influenced after the blocking agent is added to the drilling fluids, the blocking capacity of the drilling fluids can be remarkably improved, and the filter loss of the drilling fluids is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

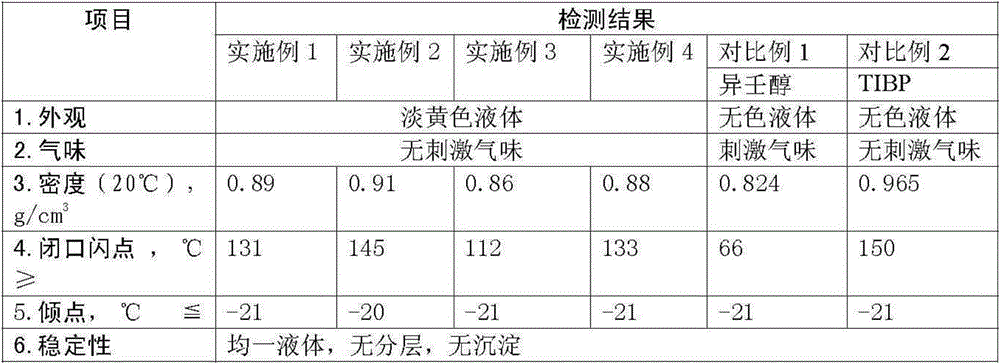

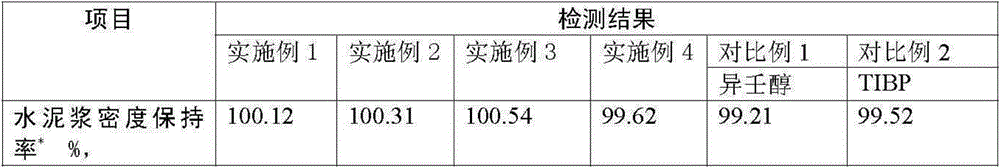

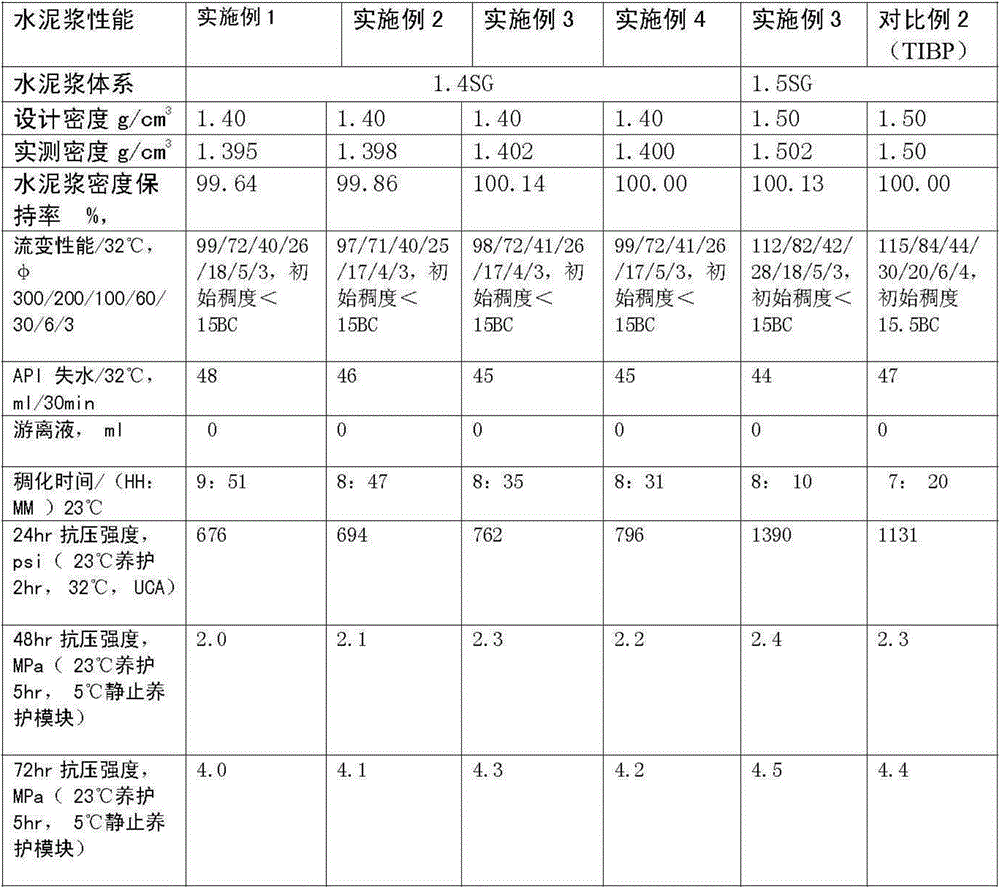

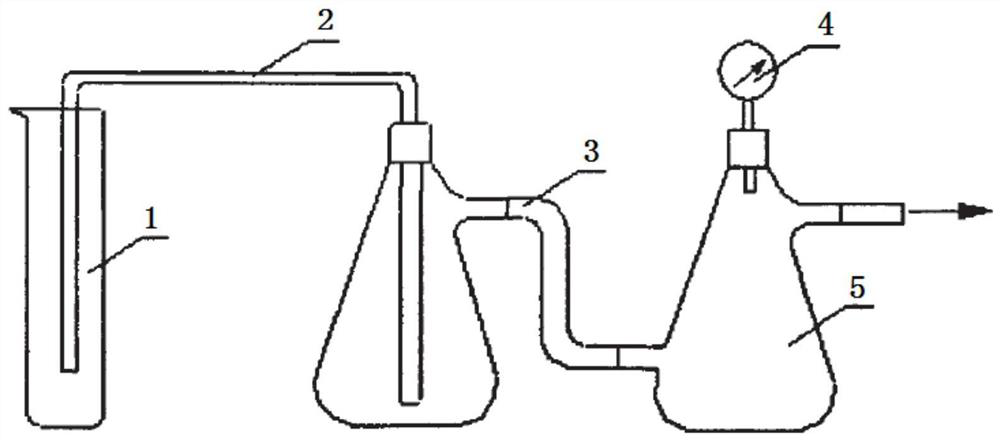

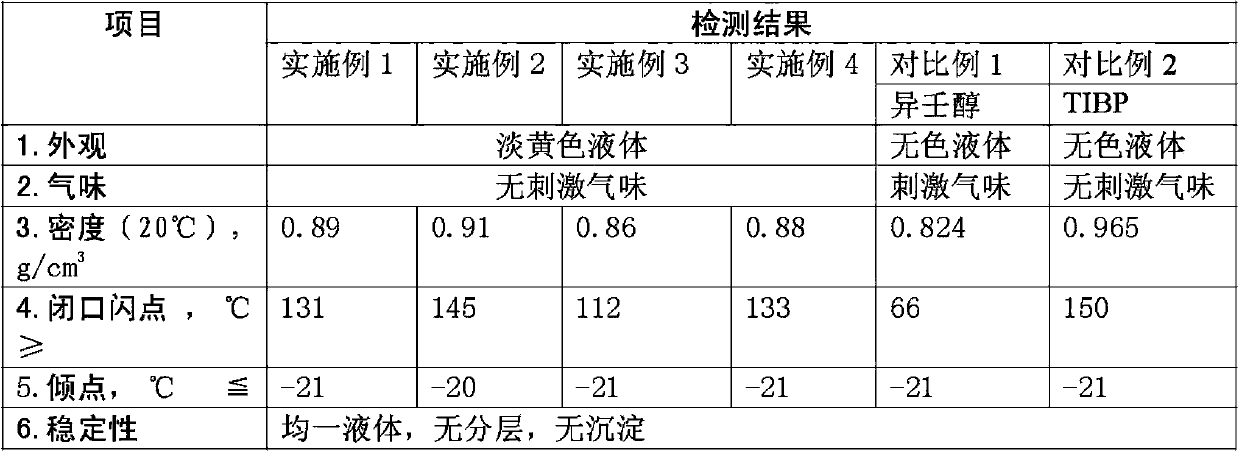

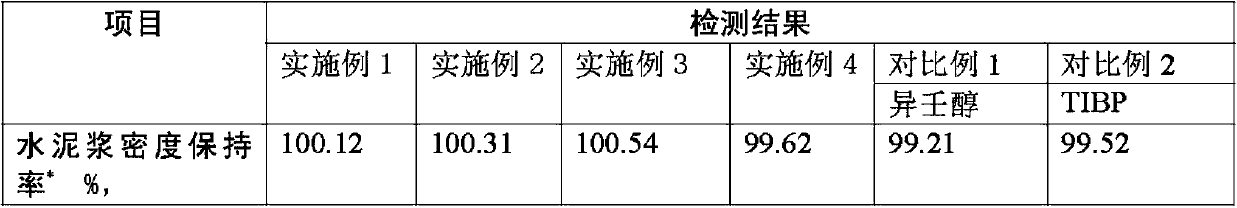

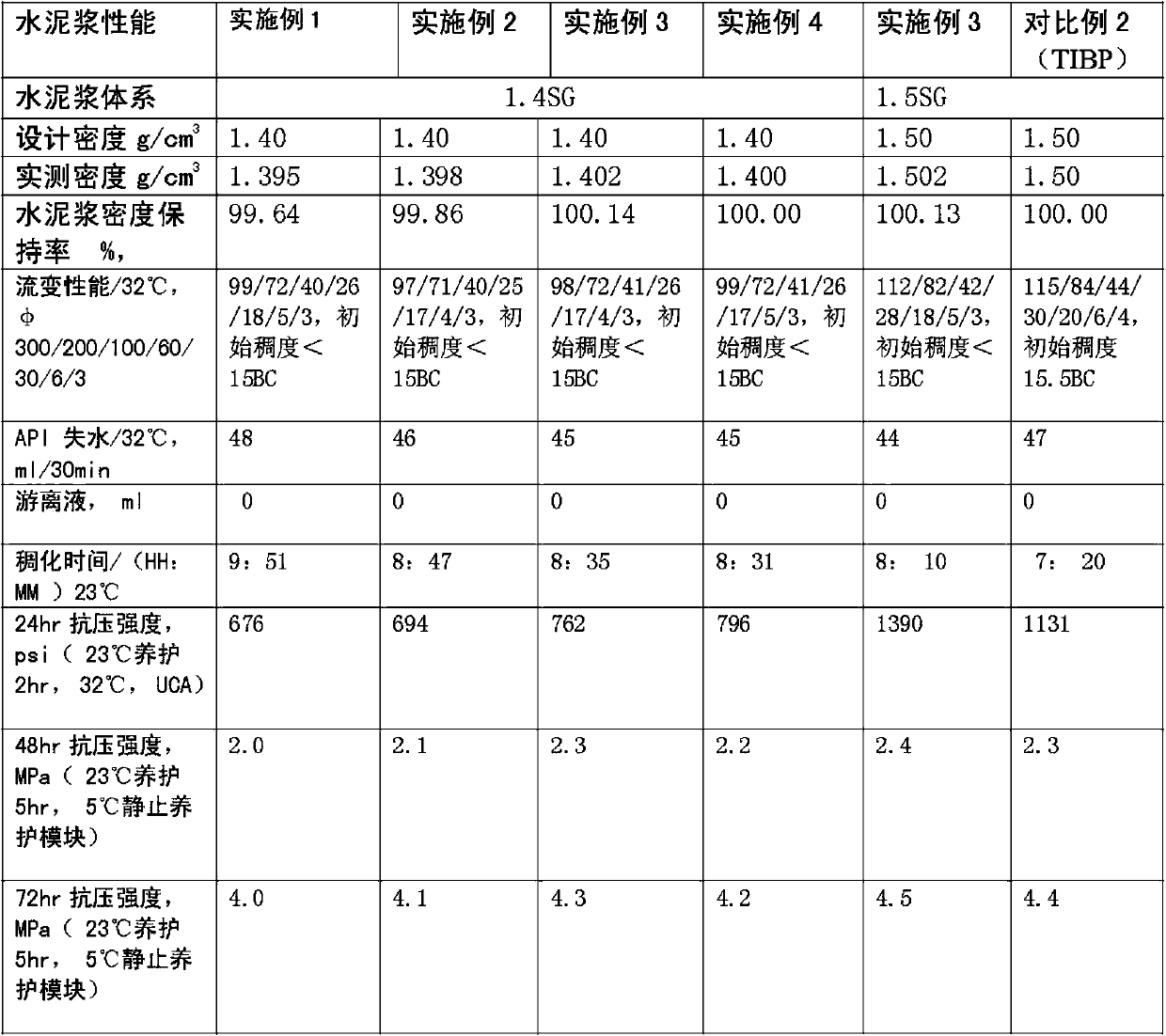

Efficient composite defoaming agent for oil well cement and preparation method thereof

The invention discloses an efficient composite defoaming agent for oil well cement and a preparation method thereof. The defoaming agent is applied to the defoaming and foam inhibition of various admixtures containing cement paste for well cementation in the processes of high-speed shearing and mixing. The defoaming agent comprises the following components in percentage by mass: 15-59.5% of mineral oil, 40-84.5% of polyol fatty acid ester, 0-15% of polyacid fatty alcohol ester and 0.5-15% of a defoaming auxiliary component, wherein the defoaming auxiliary component contains one or two of polyether and tri-isobutyl phosphate. The preparation method of the defoaming agent comprises the following steps: under the condition of stirring at room temperature, sequentially adding the mineral oil, the polyol fatty acid ester, the polyacid fatty alcohol ester and the defoaming auxiliary component into a batching kettle; mixing for 0.5-2.0 hours; filtering the obtained mixture, and discharging the obtained object; and carrying out measurement packing on the obtained product. Compared with common defoaming agents for oil well cement, the defoaming agent disclosed by the invention is low in cost and simple in manufacturing process, products are uniform and stable, and the defoaming agent concurrently has the functions of defoaming and foam inhibition, and does not affect the rheological property and thickening property of cement paste and the compressive strength and the like of cement.

Owner:NANJING YUNYUE NEW MATERIAL TECH CO LTD

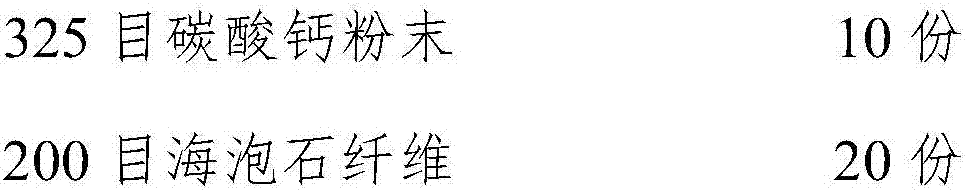

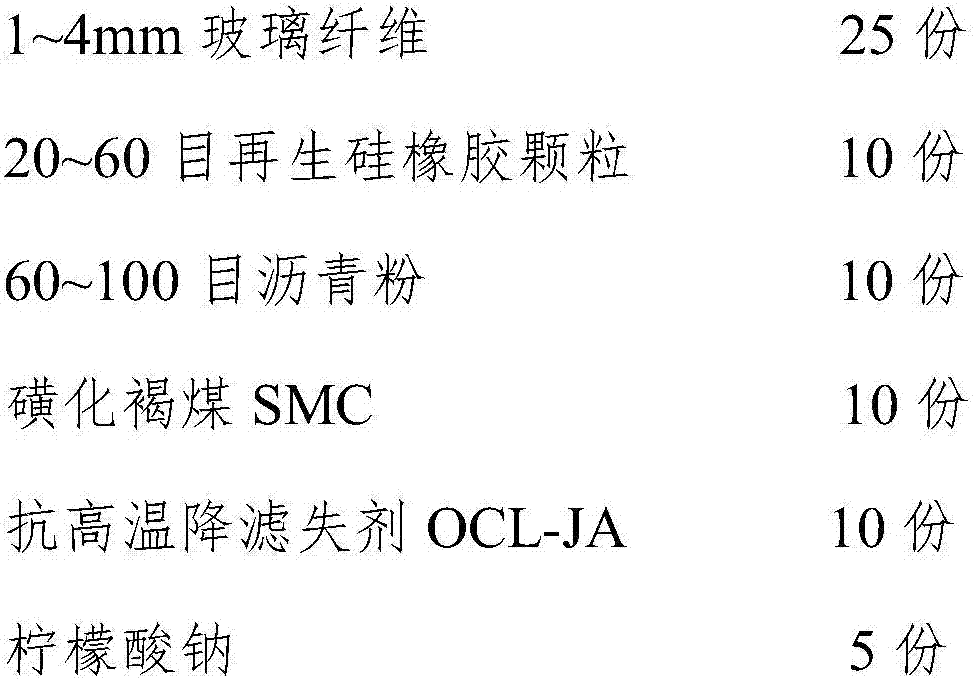

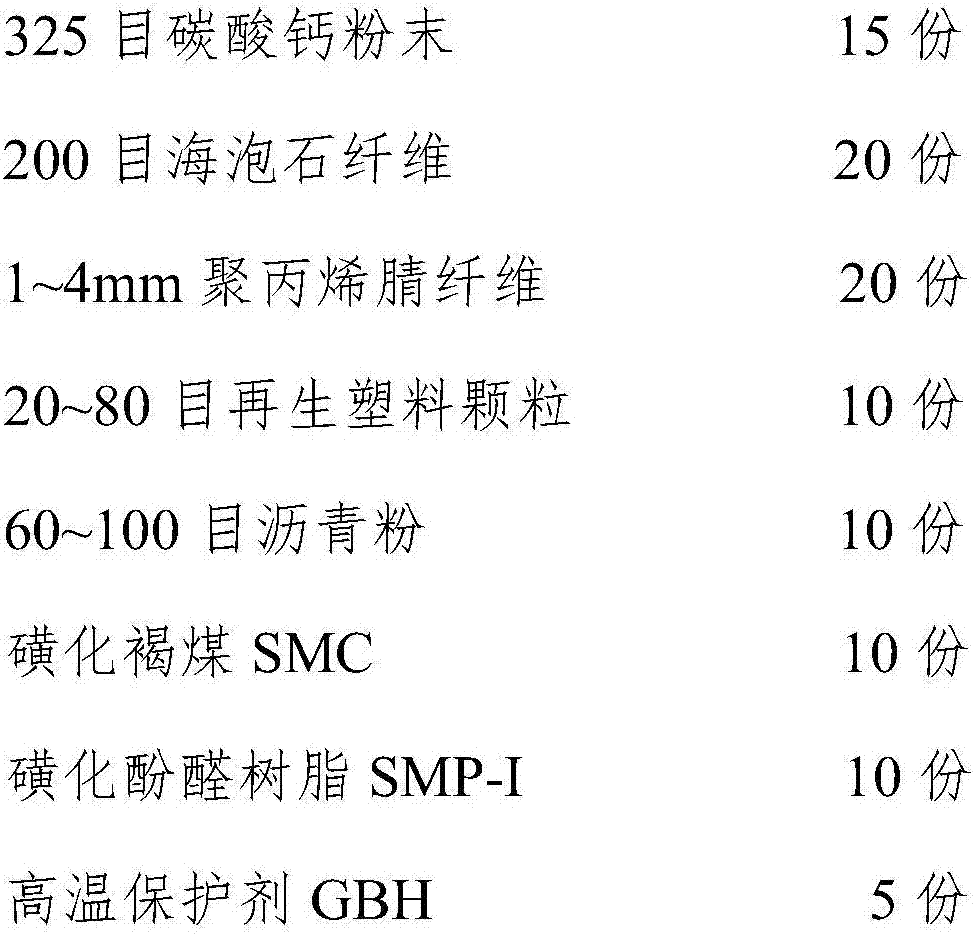

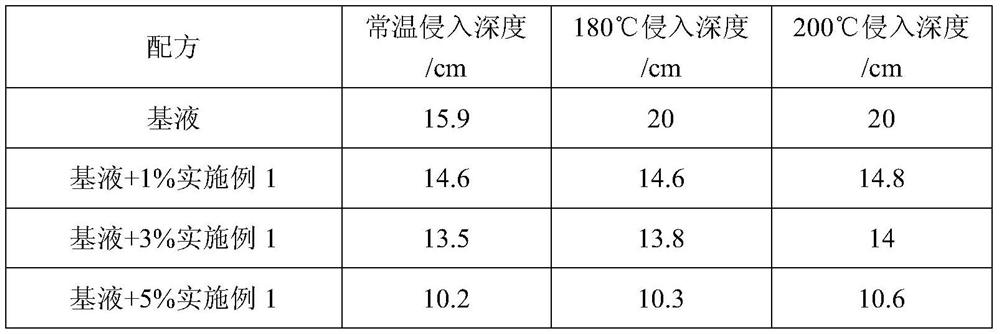

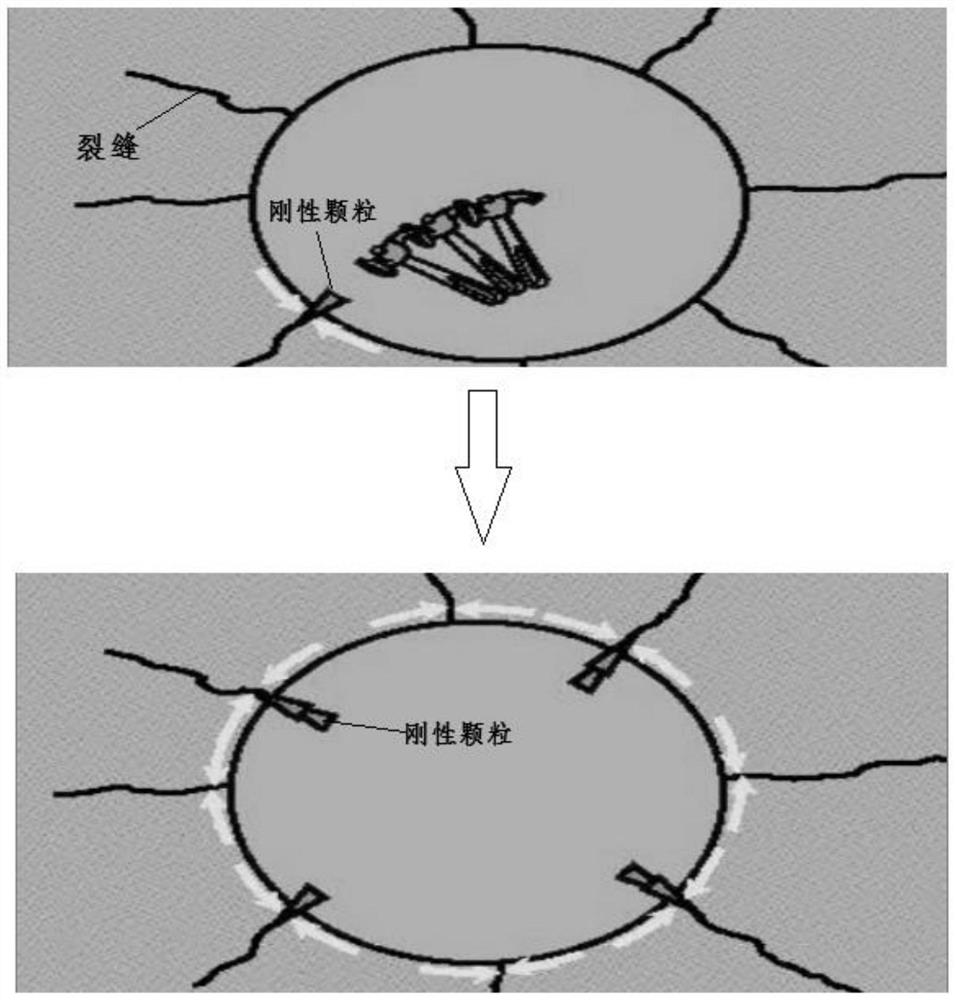

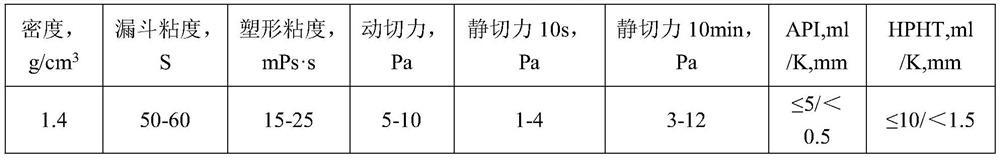

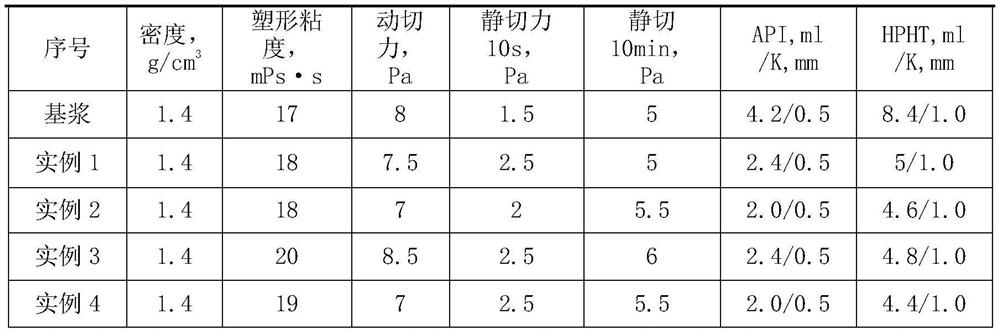

While-drilling blocking agent capable of resisting high temperature of 220 DEG C for drilling fluid and preparation method of while-drilling blocking agent

ActiveCN106978154ADoes not affect rheologyGood anti-high temperature plugging effectDrilling compositionMetallurgyScientific drilling

The invention discloses a while-drilling blocking agent capable of resisting high temperature of 220 DEG C for drilling fluid and a preparation method of the while-drilling blocking agent. The while-drilling blocking agent is prepared from the following components in parts by weight: 10 to 15 parts of rigid particles, 40 to 50 parts of a fiber material, 20 to 30 parts of deformable particles, 15 to 20 parts of a shield filtrate loss reduction material and 5 to 10 parts of a high-temperature protecting agent. The while-drilling blocking agent disclosed by the invention can resist the temperature of 220 DEG C, is good in high-temperature resistance and blocking performance, cannot affect the rheological property of the drilling fluid and is widely applicable to high-temperature dry hot rock, high-temperature geothermal and deep oil and gas drilling and deep scientific drilling.

Owner:BEIJING INST OF EXPLORATION ENG +1

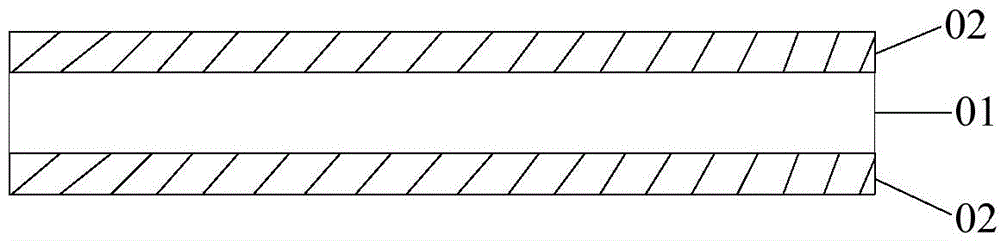

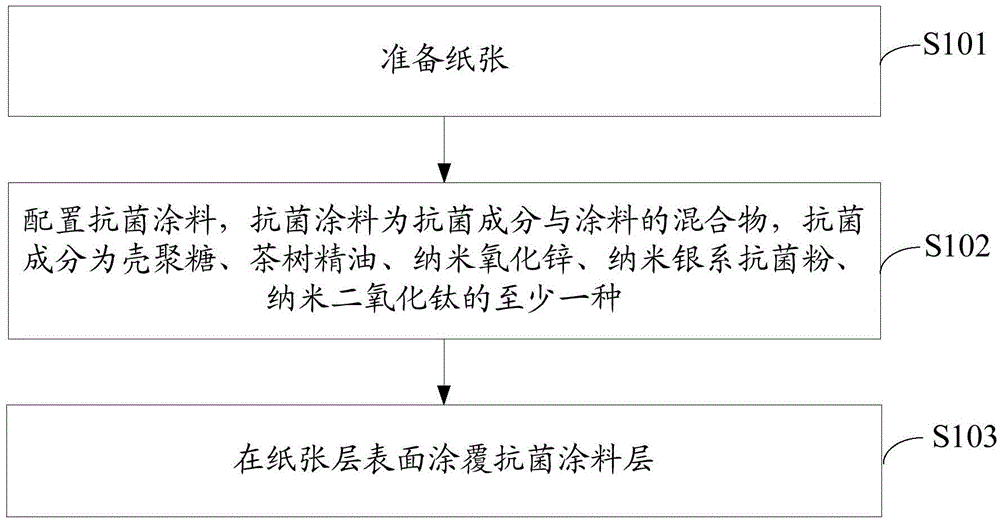

Antibacterial paint, antibacterial paper, preparation method of antibacterial paint, and preparation method of antibacterial paper

InactiveCN105088864ALong-lasting antibacterial effectGood antibacterial effectPaper coatingPaper/cardboardChemistryTitanium dioxide

The invention discloses an antibacterial paint, antibacterial paper, a preparation method of the antibacterial paint, and a preparation method of the antibacterial paper. The antibacterial paper comprises a paper layer and an antibacterial paint layer arranged on the surface of the paper layer, wherein the antibacterial paint layer is a mixture layer of antibacterial ingredients and paints, and the antibacterial ingredients contain one or more of chitosan, tea tree essential oil, nanometer zinc oxide, silver nanometer antibacterial powder and nanometer titanium dioxide. Through the manner, the antibacterial paper which is environmental-friendly and has a lasting favorable antibacterial effect can be obtained.

Owner:宁波中华纸业有限公司

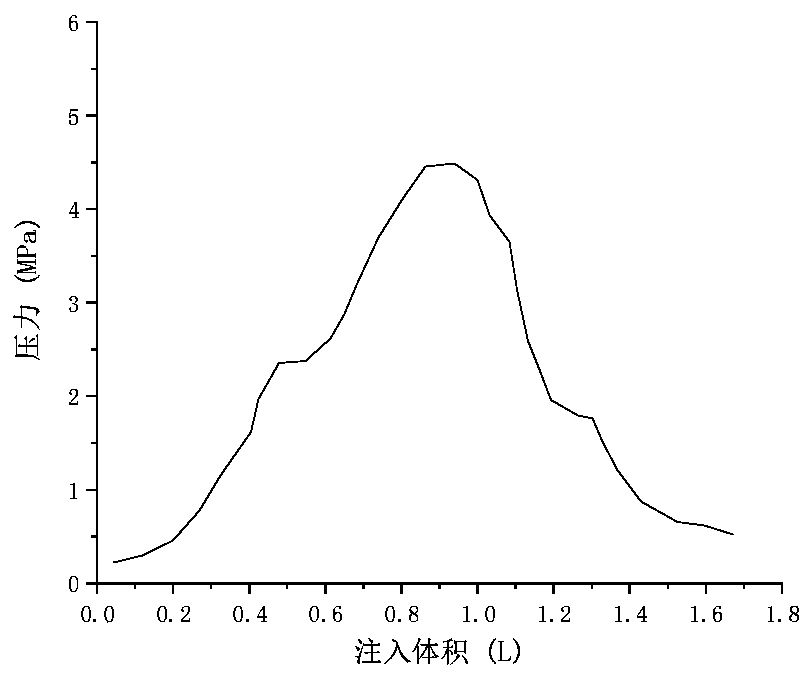

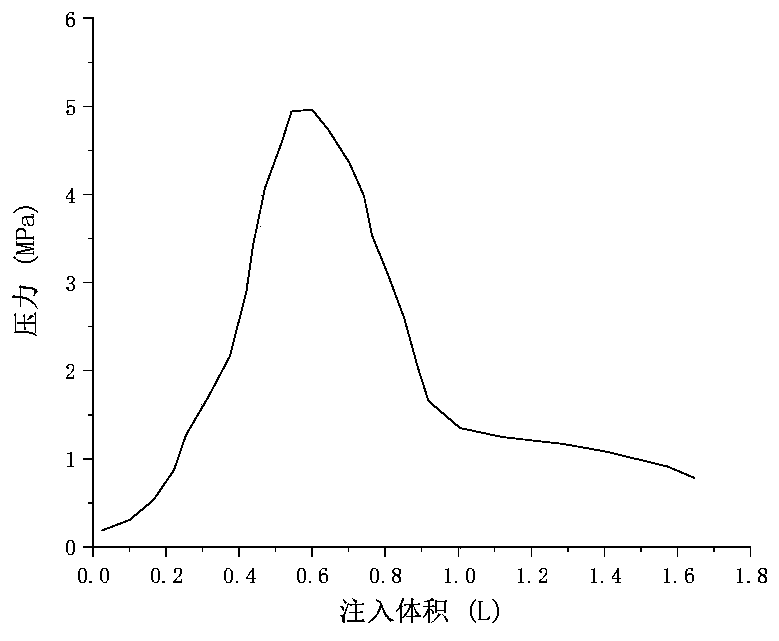

Hybrid gel particle while drilling plugging agent and preparation method thereof

ActiveCN110760296AEffective blockingImprove pressure bearing capacityDrilling compositionMeth-(Hydroxyethyl)methacrylate

The invention provides a hybrid gel particle while drilling plugging agent and a preparation method thereof. The hybrid gel particle while drilling plugging agent is prepared from the following raw materials in parts by mass: 20-35 parts of reactive monomer, 1.0-3.0 parts of a crosslinking agent, 0.3-0.5 part of an initiator, 3.0-5.0 parts of a silane coupling agent and 0.5-2.0 parts of nano-scalerigid particle; the reactive monomer is a composition of three or more than three kinds of methacrylamide, hydroxyethyl methacrylate, lauryl acrylate, tert-butyl methacrylate, dibutyl adipate, sodiump-styrene sulfonate, ethenyl-Benzenesulfonic acid or divinyl benzene; and the nano-scale rigid particle is a composition of one or more than two kinds of nano calcium carbonate, nano silicon dioxide,talcum powder or wollastonite powder. The gel particle plugging agent prepared by the preparation method has the advantages of high toughness, high temperature resistance, high pressure bearing capacity under high temperature and good plugging effect.

Owner:RES INST OF SHAANXI YANCHANG PETROLEUM GRP

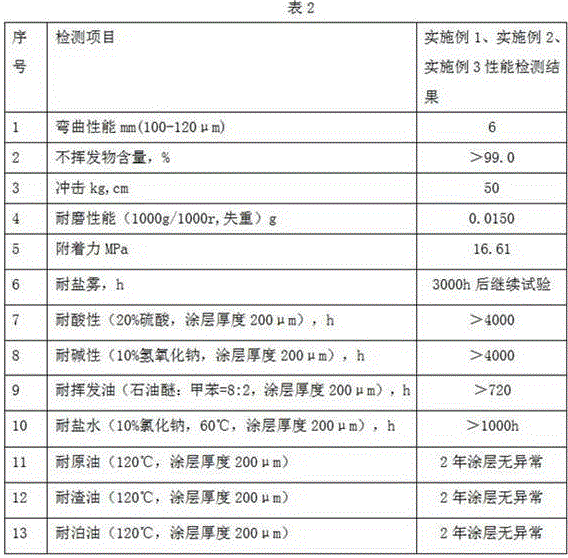

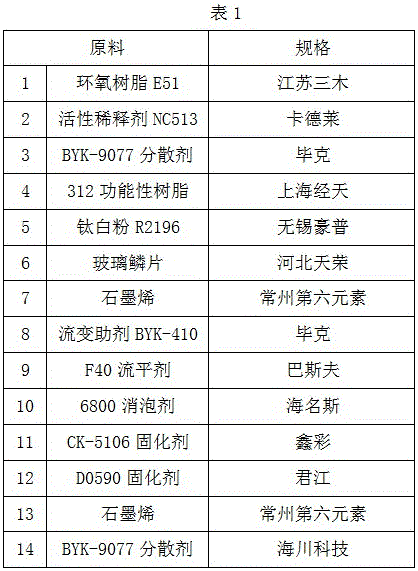

Low-viscosity solvent-free epoxy graphene glass-flake coating and preparation method thereof

ActiveCN106243922AEnsure structural dispersion stabilityGuaranteed flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

The invention discloses a low-viscosity solvent-free epoxy graphene glass-flake coating and a preparation method thereof, and aims to solve the problems that the conventional solvent-free epoxy graphene glass-flake coating has a high requirement on a construction thickness, is not ideal in corrosion resistance, needs to apply heating spraying and has a large number of coating working procedures. The coating consists of two components specifically as follows: the component I is prepared from the following raw materials in percentage by mass: 37 to 40 percent of epoxy resin E51, 2 to 4 percent of an active diluents NC513, 0.2 to 0.6 percent of a dispersing agent BYK-9077, 15 to 23 percent of functional resin 312, 14 to 15 percent of titanium dioxide R2196, 20 to 25 percent of glass flakes, 0.2 to 0.3 percent of graphene, 0.2 to 0.5 percent of a rheological agent BYK-410, 0.2 to 0.4 percent of a leveling agent F40 and 0.2 to 0.6 percent of a defoaming agent 6800; the component II is prepared from the following raw materials in percentage by mass: 75 to 94 percent of a curing agent CK-5106, 5.6 to 24.2 percent of a curing agent D0590, 0.2 to 1.5 percent of graphene and 0.2 to 1.0 percent of the dispersing agent BYK-9077. The coating can be directly used for coating by a conventional construction process without being heated, and the construction is rapid, simple and convenient.

Owner:西北永新涂料有限公司

VOC (volatile organic compounds)-free ultraviolet curing gravure printing ink and preparation method thereof

The invention discloses VOC (volatile organic compounds)-free ultraviolet curing gravure printing ink and a preparation method thereof. The ink comprises components of a formula in parts by weight as follows: 5-15 parts of unsaturated acrylic resin, 30-70 parts of dispersing monomers, 10-30 parts of dilution monomers, 3-6 parts of a photoinitiator 1173, 2-6 parts of a photoinitiator 369, 5-16 parts of pigment and 2-5 parts of an auxiliary. The preparation method is as follows: the unsaturated acrylic resin, the dispersing monomers, the photoinitiators, the pigment and part of the auxiliary are mixed, stirred at a high speed and pre-dispersed; and the well pre-dispersed material is dispersed and ground to stipulated grain size through combined use of a sand mill and a three-roller machine. The VOC-free ultraviolet curing gravure printing ink and the preparation method have the benefits as follows: the problem of environmental pollution caused by volatilization of a large quantity of VOC in conventional ink and the problems that ink products introduced in conventional related ultraviolet curing gravure printing ink patents are high in viscosity and slow to dry and is not matched with conventional gravure printing or the ink still contains a solvent and is not environment-friendly are solved; and meanwhile, the production process is improved, and the production efficiency is increased.

Owner:杭华油墨股份有限公司

Light solidified rare earth red flruorescence anti-forge printing ink and preparation process thereof

InactiveCN1560148AResolve features that do not disperse evenlyDistributed protectionInksFluorescenceComplex materials

The invention is a photocurable rare-earth red fluorescent anti-falsification printing ink and its preparing method, using 'in situ process' wet-chemical technique, adopting 'in situ process' to synthesize rare-earth complex material in photocurable resin substrate, according to the components in the photocurable resin, synthesizing Eu-TTA-AA-Phen rare-earth complex in diphenol A epoxy acrylic ester substrate, where the new generated complex uniformly disperses in the resin substrate so as to make the rare-earth complex obtain high uniform dispersivity in the photocurable substrate, and the complex is fixed in the substrate network, under the protection of the substrate material, not only preventing the formation of congeries particles but also the automatic congregation of the complex, preventing the formation of congeries, thus obtaining the optical-transparency and high-lighting efficiency high-molecular material of photocurable fluorescent anti-falsification printing ink.

Owner:SECTION OF SCI & TECH DEV

Drilling fluid lubricating agent composition containing lubricating capsules, preparation method of drilling fluid lubricating agent composition, water-based drilling fluid and application thereof

InactiveCN109135690ALow costImproves oxidation stability and lubricityDrilling compositionGas industryPetroleum

The invention belongs to the technical field of drilling fluid in petroleum and natural gas industry and relates to a drilling fluid lubricating agent composition containing lubricating capsules, a preparation method of the drilling fluid lubricating agent composition, water-based drilling fluid and application thereof. The lubricating agent composition comprises the capsules, a dispersing agent,an anti-wear reagent at extreme pressure and a defoaming agent and is characterized in that each capsule comprises a capsule shell and a lubricating substance arranged in the capsule shell, the capsule shell is prepared by sulfonated polyimide, dimethyl diallyl ammonium chloride and ceric ammonium nitrate through polymerization reaction, and the lubricating substance is one or more of modified vegetable oil, biodiesel, surfactant and polyol non-ionic emulsifier. The lubricating agent composition has the advantages that the composition can achieve targeting release under pressure control, a drilling fluid lubricating agent can perform 'targeting positioning and lubricating according to needs' on underground high-friction-drag and high-torque parts, the efficient friction and resistance reducing effect of the lubricating agent is brought into full play, and the drilling fluid lubricating agent composition is good in friction resistance, good in turbidity point stability, easy in biodegradation, green, environmentally friendly and promising in application prospect.

Owner:SINOPEC SSC +2

Plugging agent for oil-base drilling fluid and preparation method

InactiveCN108977181AGood plugging effectImprove temperature resistanceDrilling compositionCalcium carbonateFiber

The invention provides a plugging agent for an oil-base drilling fluid with high crack matching ability. The plugging agent is composed of elastic sponge, regenerated fiber, adsorbent, calcium carbonate superfine powder and flexible graphite. Specifically, the components in parts by weight added into 100 parts of oil-base drilling fluid are as follows: 0.1-0.8 part of elastic sponge, 0.1-1.5 partsof regenerated fiber, 3-8 parts of adsorbent, 5-10 parts of calcium carbonate superfine powder and 3-8 parts of flexible graphite. The plugging agent for the oil-base drilling fluid provided by the invention can easily enter into cracks and form bridges in the cracks; high-temperature resisting materials and high-temperature resisting inert materials are high in dispersity in the oil-base drilling fluid, so that the success rate of plugging can be effectively increased and the happening of re-leakage can be avoided; the plugging construction process is simplified by adopting the plugging agent; the plugging material has excellent temperature resistance, does not lose efficacy under high temperature and has an excellent plugging effect for fracture-cavity type leakage.

Owner:SINOPEC SSC +2

Special high-temperature suspending agent for oil well cement and preparation method thereof

InactiveCN111154034AHigh application temperatureNo effect on other performanceDrilling compositionPotassium persulfateMeth-

The invention discloses a special high-temperature suspending agent for oil well cement and a preparation method thereof. The suspending agent is prepared from the following components in parts by weight: 10 to 20 parts of 2-acrylamide-2-methylpropanesulfonic acid, 5 to 10 parts of vinyl pyrrolidone, 5 to 10 parts of acrylamide crystals, 60 to 80 parts of deionized water, 0.01 to 0.05 part of potassium persulfate, 0.01 to 0.05 part of formaldehyde sodium sulfoxylate, 2 to 5 parts of sodium hydroxide and 60 to 80 parts of magnesium aluminum silicate. The method is simple in principle, reliablein technology and easy and convenient to operate, the prepared high-temperature suspending agent is high in application temperature, has no influence on other properties of cement paste, is good in compatibility, particularly does not influence the rheological property of the cement paste at low temperature, can be well suitable for a high-temperature cement paste system, and overcomes the defectsof an existing oil well cement paste high-temperature suspending agent.

Owner:四川安钮诺斯油气能源技术有限公司

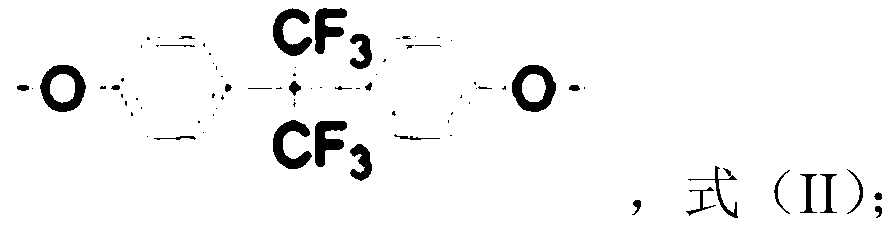

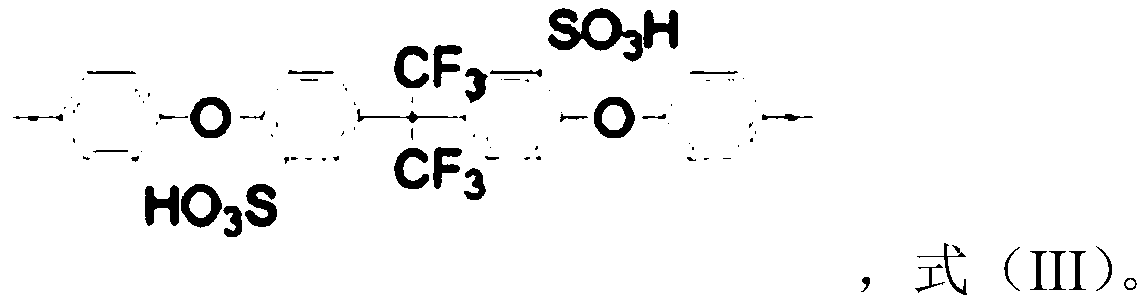

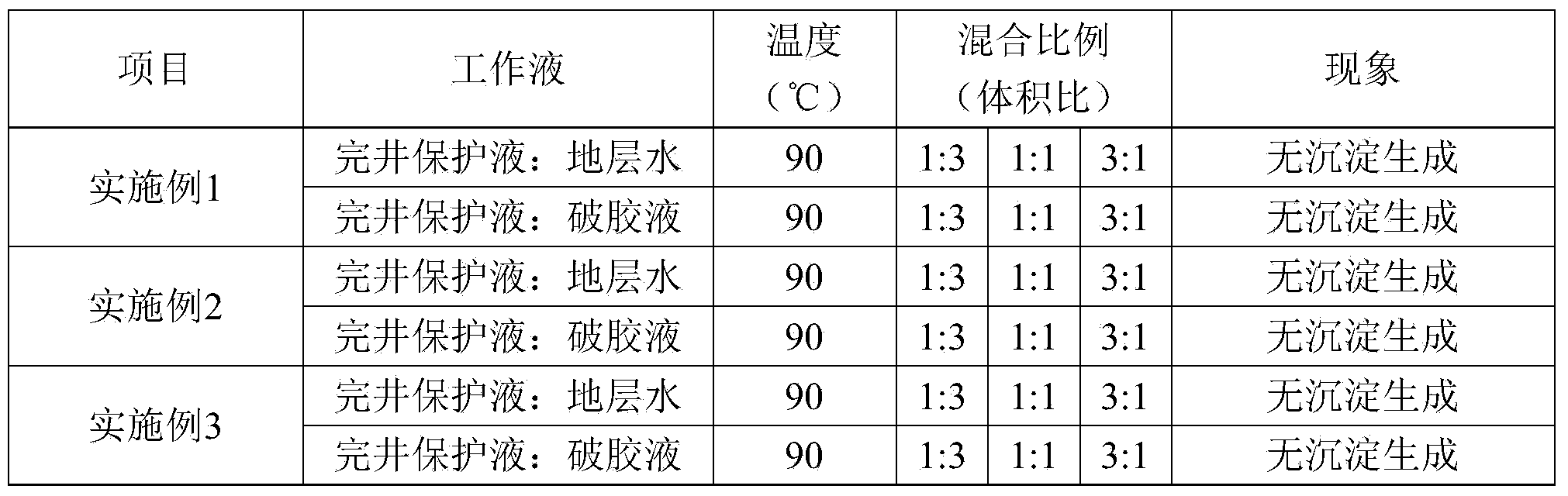

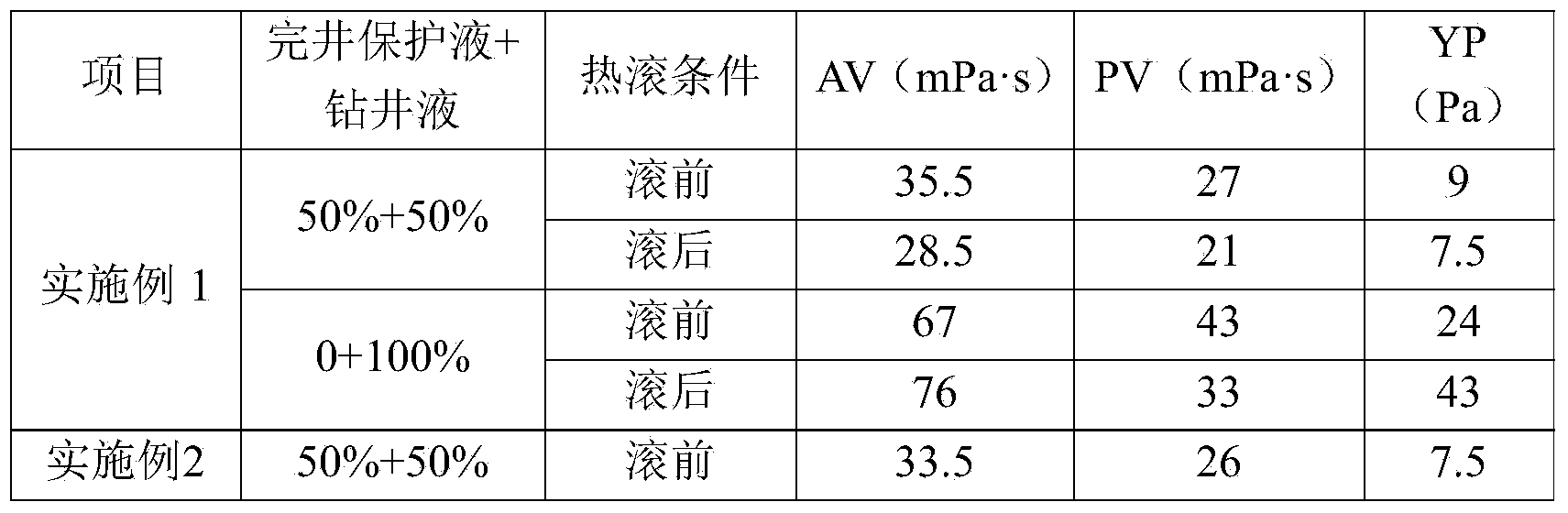

Solid-free slurry-replacing well completion protective fluid and preparation method thereof

The invention discloses a solid-free slurry-replacing well completion protective fluid and a preparation method thereof, which belongs to the technical field of exploitation of oil and gas fields. The completion protective fluid comprises, by weight, 100 parts of a formate-based liquid, 0.2 to 0.4 part of a thickening agent, 1 to 3 parts of a high temperature high temperature, 0.2 to 3 parts of a clay stabilizing agent and 0.2 to 1 part of a waterproof locking agent. The completion protective fluid has the following advantages: (1) the completion protective fluid has no solid phase, so solid phase settlement does not exist; (2) the completion protective fluid has good rheological properties and a low shearing force value; (3) the completion protective fluid has an excellent hydrocarbon reservoir protection function; (4) the completion protective fluid has good high temperature resistance and salt resistance stability, and a system has good displacement and carrying capability under reservoir temperature; (5) the completion protective fluid is safe, nontoxic, easily degradable and compatible with the environment; (6) the completion protective fluid has good compatibility with a drilling fluid and a fracturing fluid, and the rheological properties of the completion protective fluid are not influenced after mixing; (7) the completion protective fluid has little corrosivity and greatly reduces corrosivity of a saline solution to downhole tools; and (8) the completion protective fluid has great specific gravity and no solid phase and is applicable to areas with abnormal high temperature and high-pressure area.

Owner:CHINA PETROLEUM & CHEM CORP +1

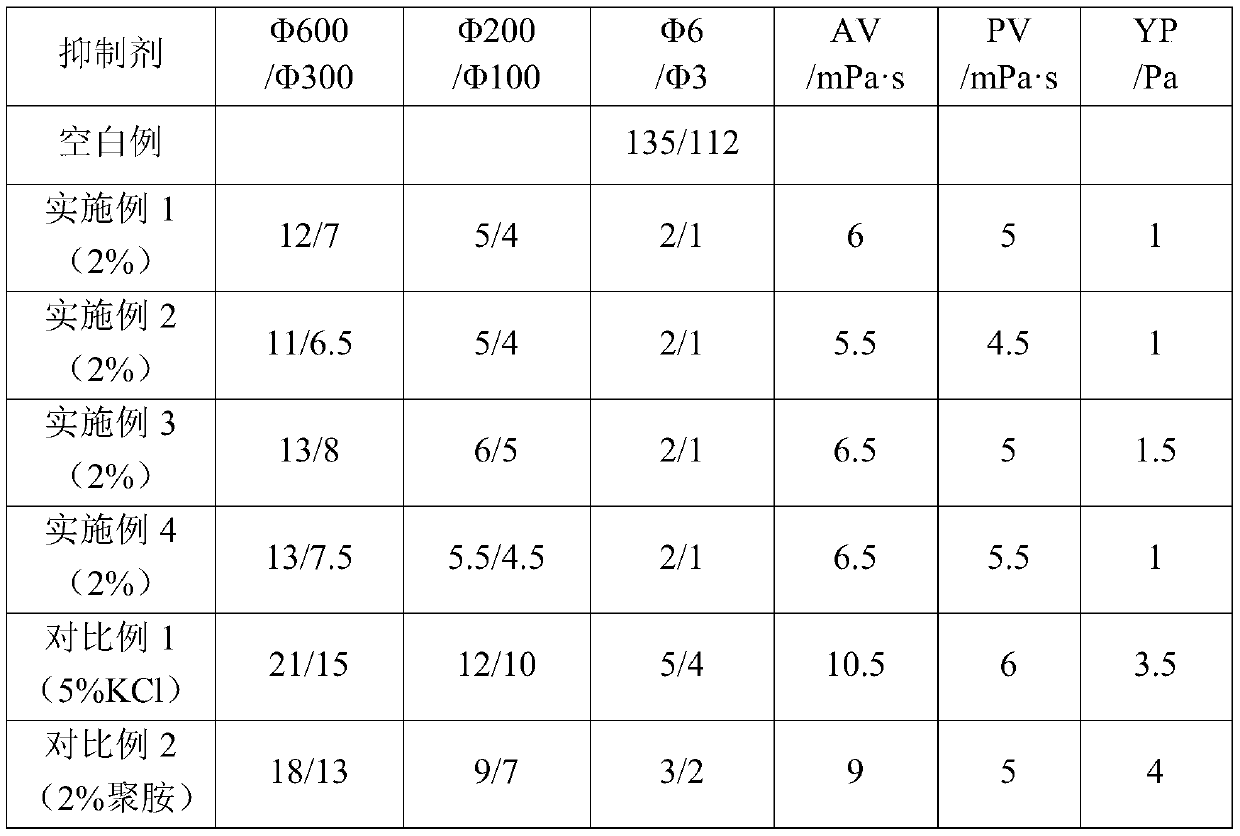

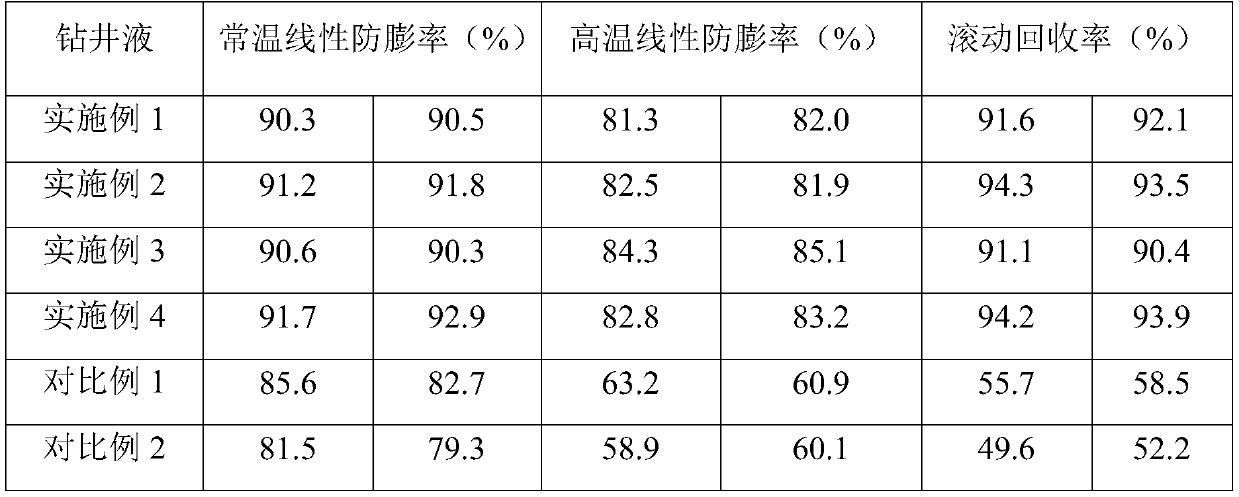

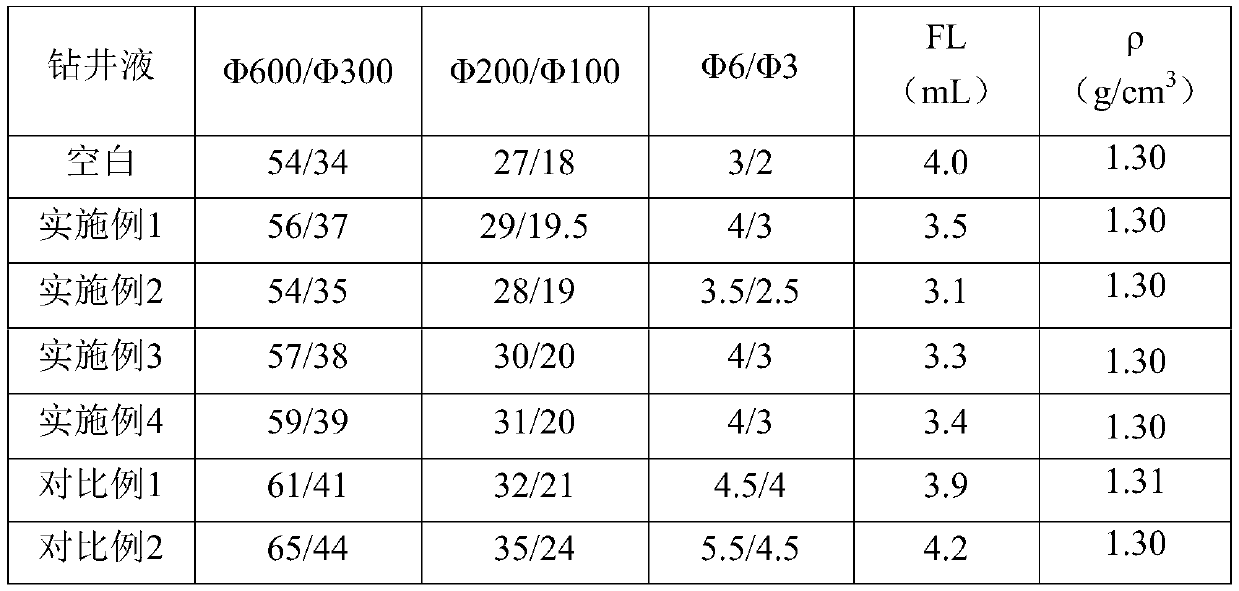

Preparation method of polyamine inhibitor for drilling fluid

InactiveCN106190064AEnhanced inhibitory effectGood compatibilityDrilling compositionTetramineReaction temperature

The invention discloses a preparation method of a polyamine inhibitor for drilling fluid. The method comprises the following steps: an amine compound of low molecular weight and heterocyclic compounds are reacted in a setting condition for synthesis, and the amine compound is one of triethylene tetramine, trimethylethylamine hydroxide, N-methylethylamine, and trimethylhexamethylenediamine; the heterocyclic compound is 1,2-epoxypropane or 2,3-epoxybutane or 1,3-epoxybutane; the setting condition is as follows: alkali metal is used as a catalyst, and the reaction temperature is 80-100 DEG C; charging mol ratio between the amine compound and the heterocyclic compound is 1:2.5; the mass ratio between the amine compound and the alkali metal catalyst is 1200:1. The inhibitor has high inhibition capability for shale, and has good compatibleness to other common drilling fluid additives; the inhibitor is nontoxic and environmentally friendly.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Aluminum base blocking treatment agent for drilling fluid and preparation method thereof

ActiveCN108728064AEasy to synthesizeEffective blockingDrilling compositionCelluloseSODIUM METAPHOSPHATE

The invention relates to an aluminum base blocking treatment agent for drilling fluid and a preparation method thereof in the field of an oil gas field chemical auxiliary agent. The aluminum base blocking treatment agent for the drilling fluid is prepared from ingredients including inorganic aluminum, surface modifying agents and dispersing agents, wherein the mass ratio of the inorganic aluminumto the surface modifying agent is (10 to 500):1; the weight ratio of the organic aluminum to the dispersing agents is (50 to 500):1; the surface modifying agents are selected from at least one kind ofmaterials from stearic acid, sodium stearate, magnesium stearate, sodium dodecyl benzene sulfonate, sodium metaphosphate and sodium pyrophosphate; the dispersing agents are selected from at least onekind of materials from starch, sodium carboxymethyl starch, sodium carboxymethylcellulose, polyanionic cellulose and xanthan gum. The aluminum base blocking treatment agent for the drilling fluid isof a liquid type; the use is easy; the dust problem cannot occur; the difficult problem of obvious matching problem of the existing aluminum base treatment agent in a drilling well system can be effectively solved.

Owner:CHINA PETROLEUM & CHEM CORP +1

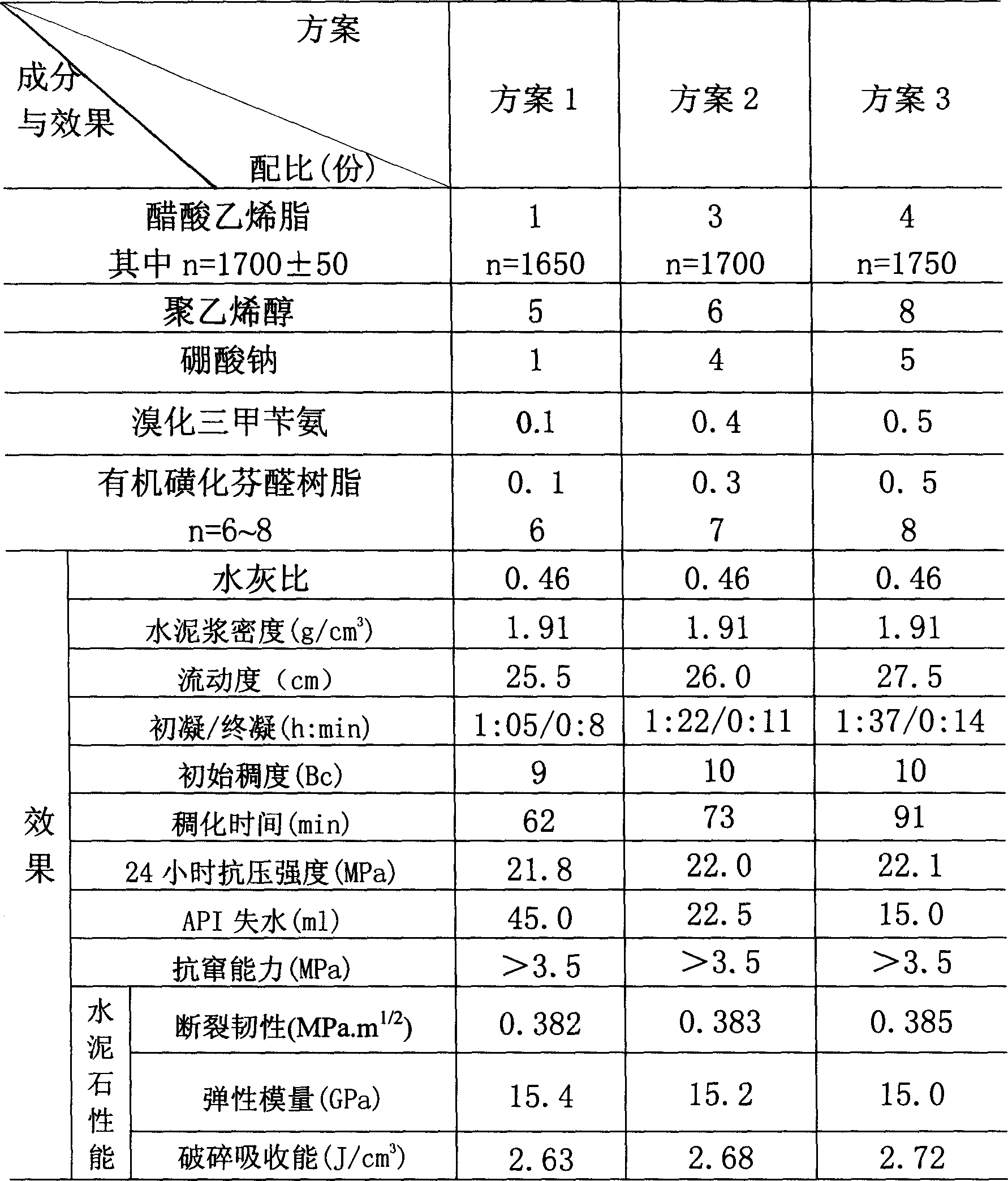

Tough impact admixture for oil well cement

The present invention relates to tough impact admixture for oil well cement for oil field well drilling and fixing. The present invention features that the tough impact admixture for oil well cement consists of vinyl acetate 1-4 (in weight portions, the same below), polyol 5-8, inorganic sodium salt 0.1-0.5, binary hydroxycarboxylic acid 0.1-0.3 and naphthalenesulfonate 0.1-0.5. The tough impact admixture has the features of fast solidification, waterproofing and antiseeping, low water loss, quick increase of coagulation strength, and powerful looseness resisting strength. It can raise the compact strength of cement ring and well fixing quality.

Owner:DAQING PETROLEUM ADMINISTRATION

Thermosetting foam profile control agent and application thereof

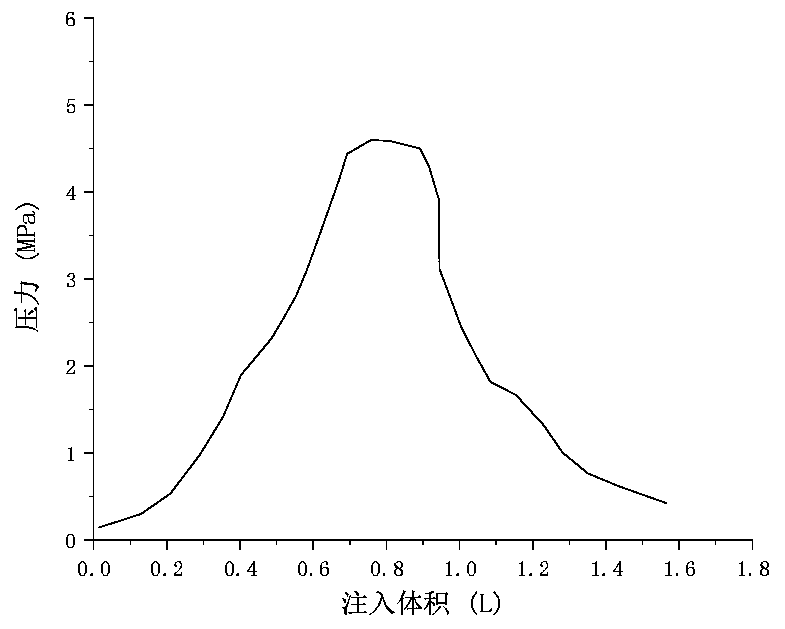

ActiveCN111826143APerformance is not affectedDoes not affect formationDrilling compositionSealing/packingPhenolformaldehyde foamPolymer science

The invention discloses a thermosetting foam profile control agent and application thereof. The thermosetting foam profile control agent comprises a foam fixing agent, a curing agent and a foaming agent, wherein the foam fixing agent is a resin prepolymer, and the curing agent is water-soluble temperature control decomposition type slow-release acid. According to the invention, by researching anddeveloping water-soluble temperature-controlled decomposition slow-release acid and a temperature-resistant foaming agent, an underground cross-linked thermosetting phenolic foam plastic (wet method)meeting a thick oil thermal recovery plugging control construction process is modified and researched; a low-molecular resin prepolymer and a curing agent stably exist in a foam liquid film, so that the foaming volume and the half-life period are not influenced; and a curing agent is decomposed to generate an acid at a high temperature, hydrophilic resin hydroxymethyl bonds are catalyzed to be subjected to condensation polymerization to form hydrophobic resin methylene bonds, free water bound by a space net structure and coated with a liquid film is formed, and the foam liquid film is converted into a thermosetting resin hard shell, so that the influence of high temperature, stratum pore size and injected water dilution scouring on foam plugging strength, heat stability and validity periodis avoided.

Owner:PETROCHINA CO LTD

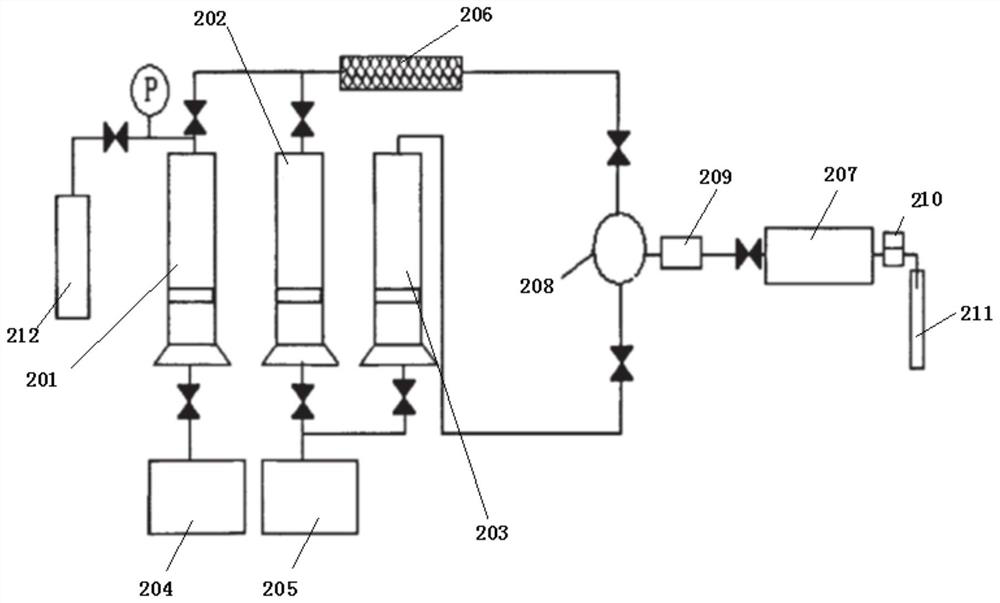

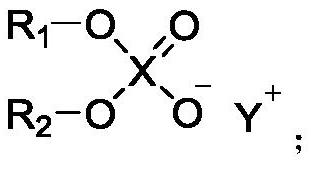

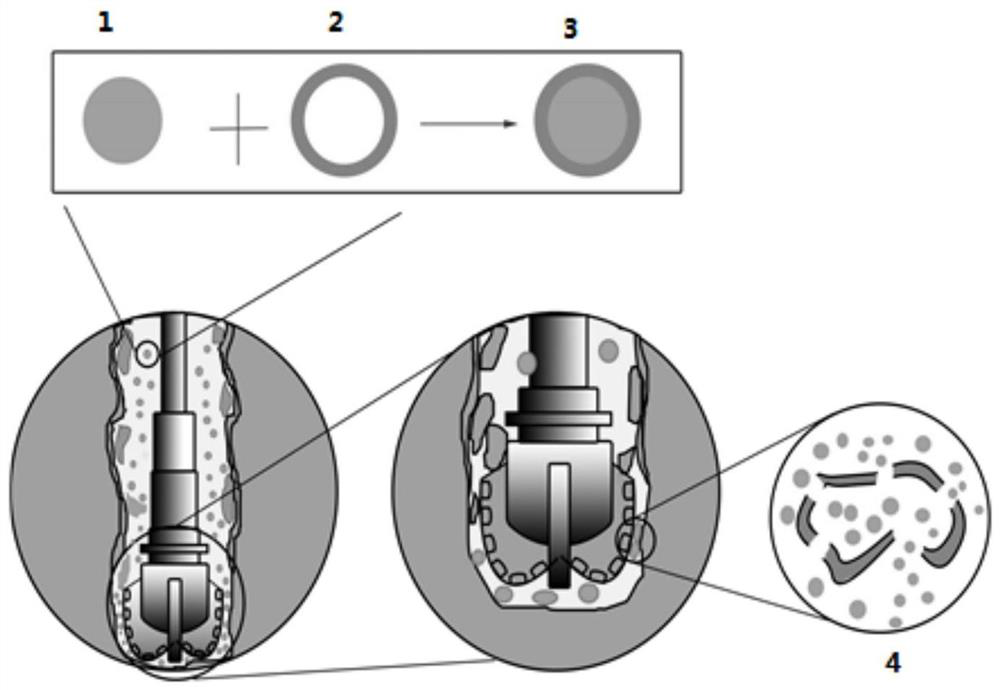

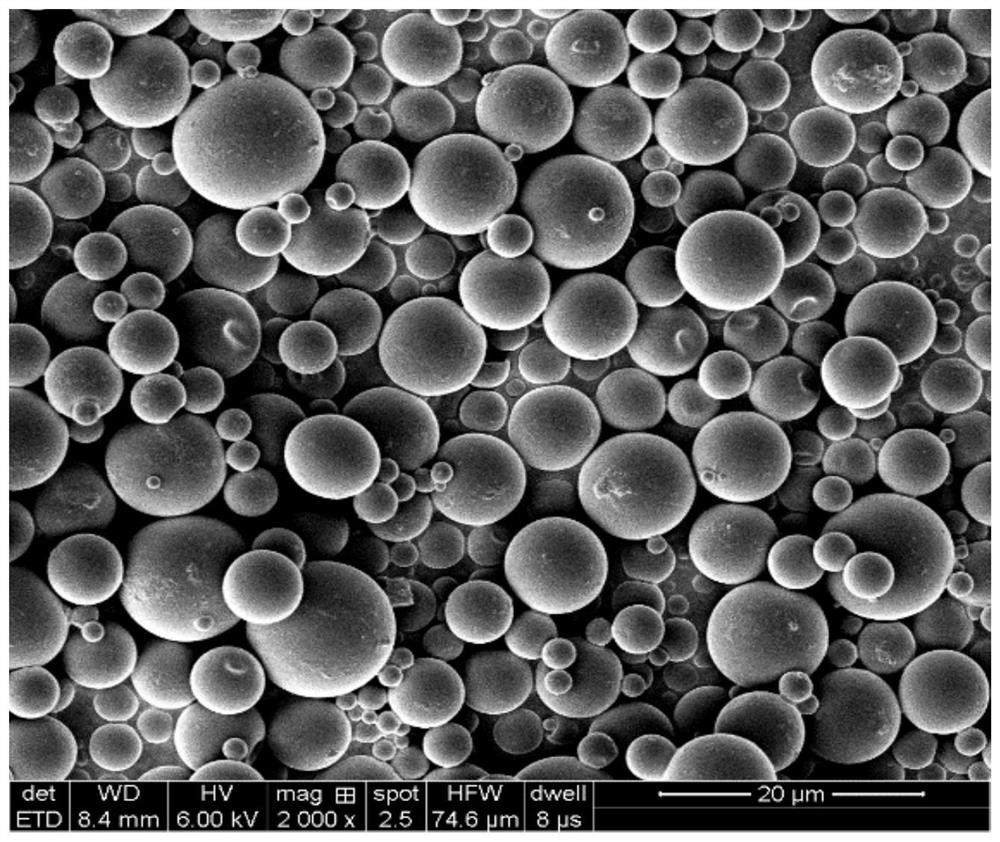

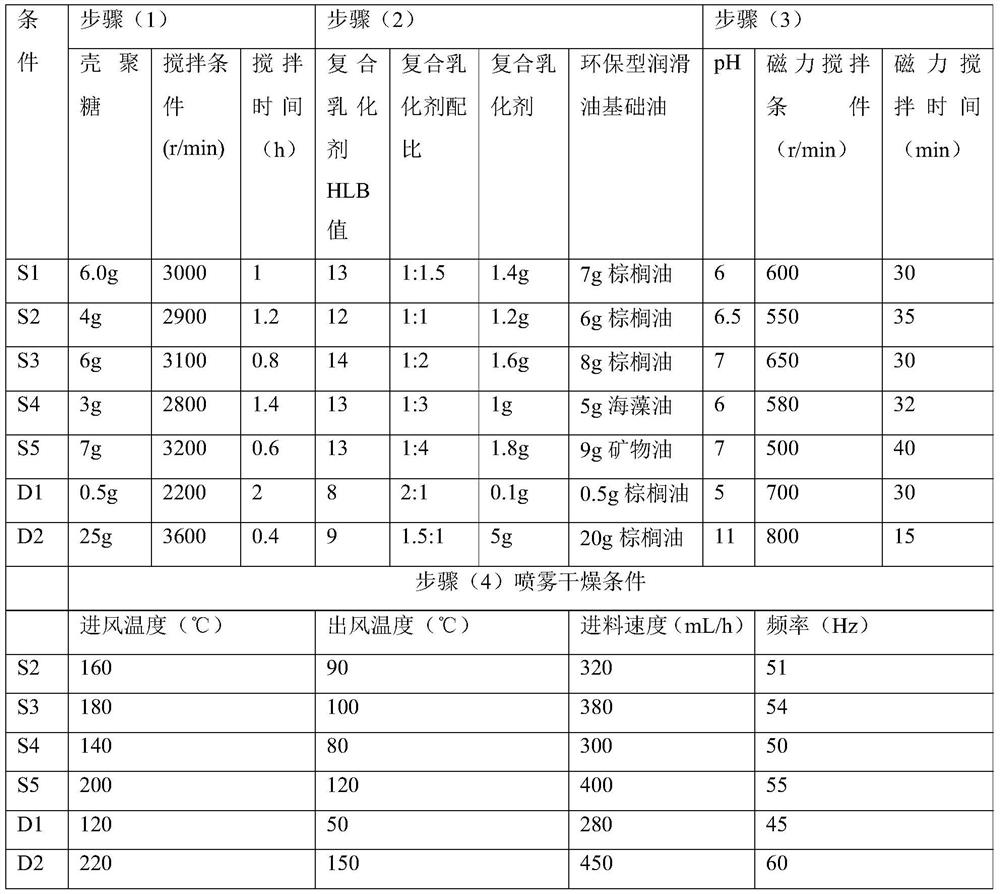

Capsule lubricant for drilling fluid, preparation method thereof, water-based drilling fluid and application

ActiveCN111826139ADoes not affect rheologyReduced extreme pressure lubrication coefficientDrilling compositionFirming agentSpray dried

The invention relates to the technical field of lubricant preparation, and discloses a capsule lubricant for drilling fluid, a preparation method thereof, water-based drilling fluid and application. The capsule lubricant comprises a core component and a wall component coating the outer surface of the core component, and on the basis of the total weight of the capsule lubricant, the content of thecore component is larger than or equal to 75 wt%, and the content of the wall component is smaller than or equal to 25 wt%. The capsule lubricant is prepared by the following method: in the presence of a curing agent, carrying out phase separation reaction on an oil-in-water emulsion and a wall component solution, and carrying out spray drying treatment on a reaction product; the oil-in-water emulsion includes a lubricant base oil, a composite emulsifier, and water, and the wall component solution includes a polysaccharide polymer and an acid. When the addition amount of the capsule lubricantis 1%, the reduction rate of the lubrication coefficient is basically 70% or above.

Owner:中石化石油工程技术服务有限公司 +2

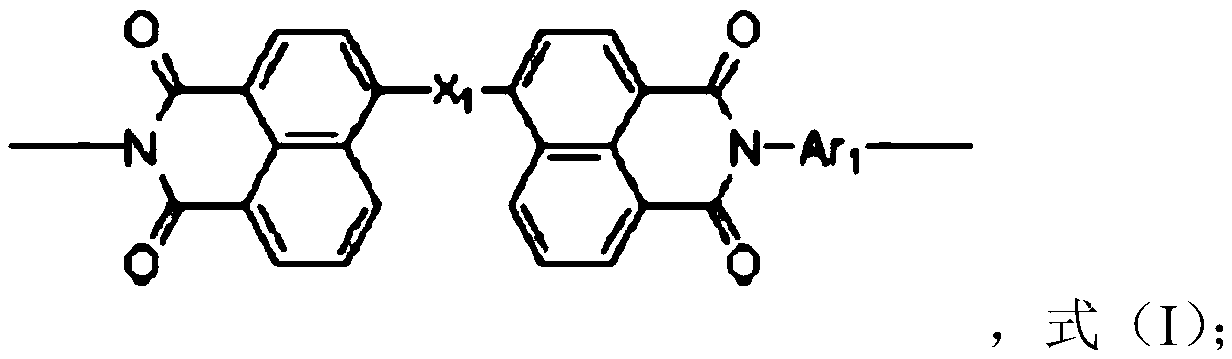

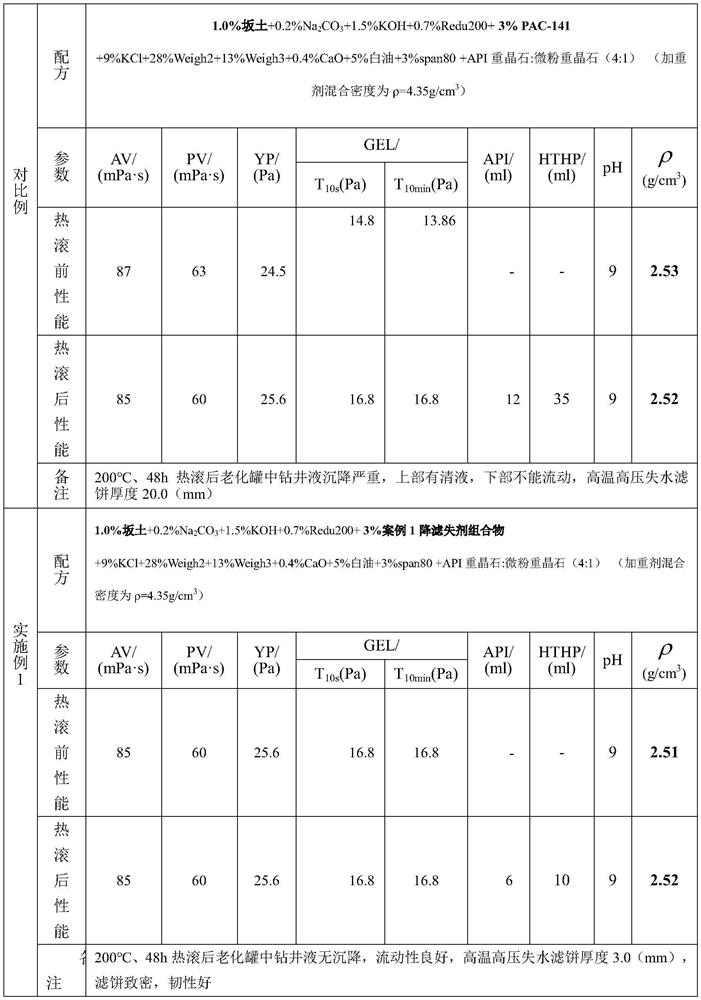

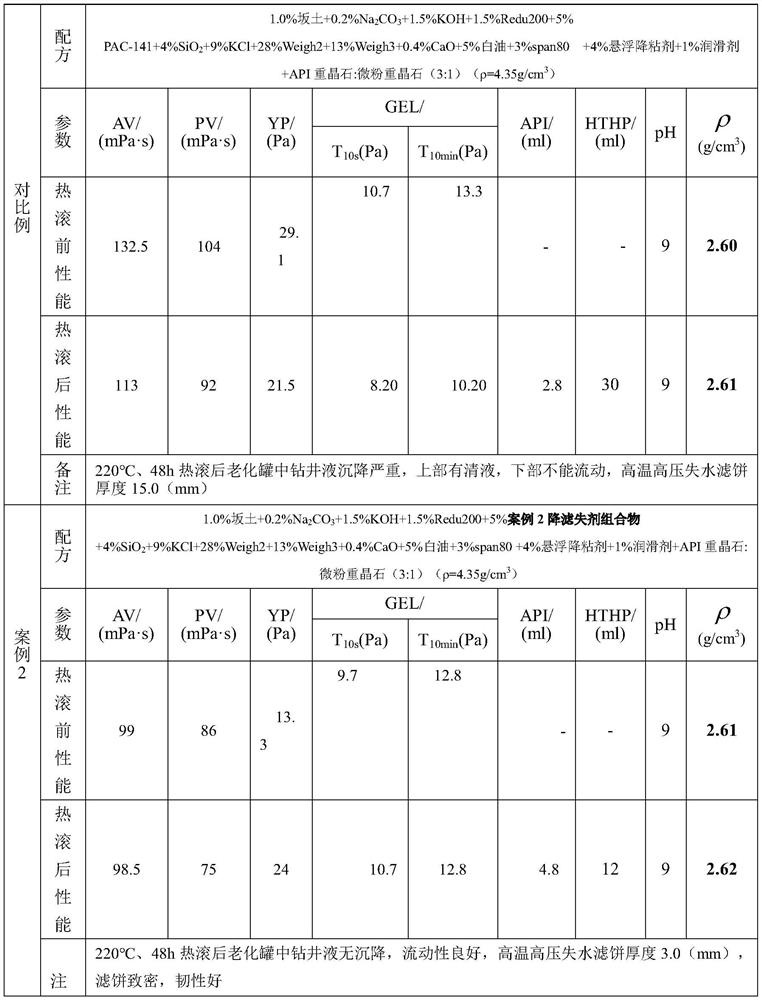

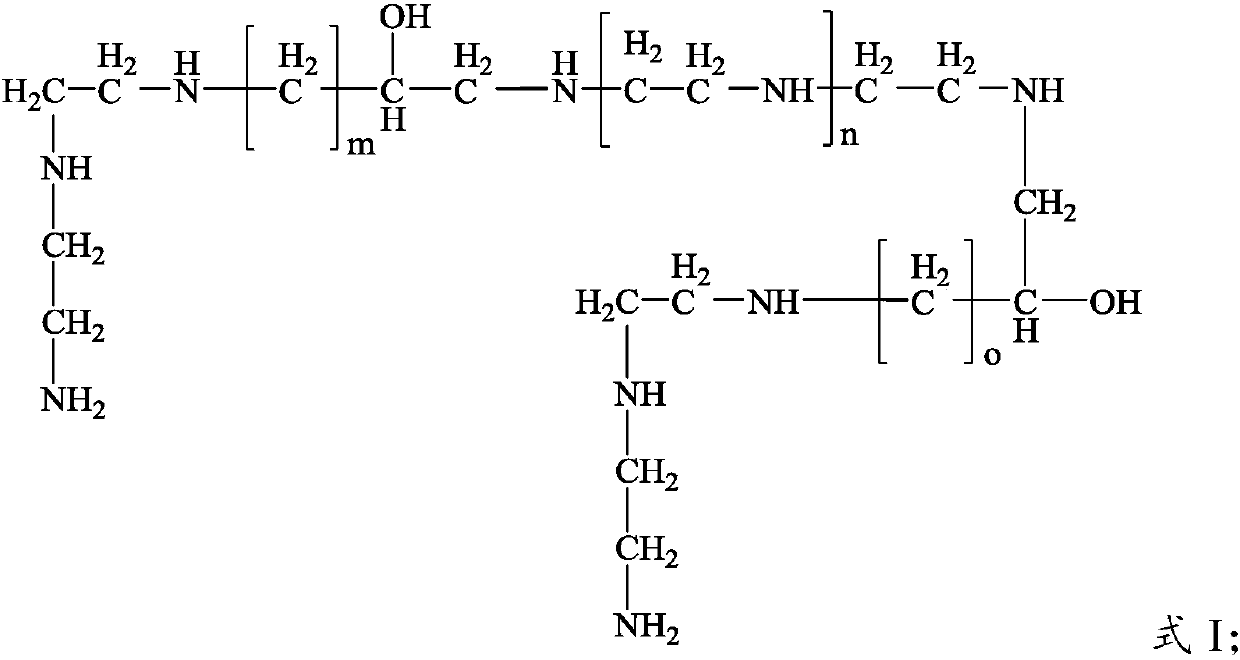

Preparation method of high-temperature high-density water-based drilling fluid filtrate reducer composition

PendingCN114736659AIncrease resistance to movementAvoid curlDrilling compositionHydrophilic monomerMicrosphere

The invention discloses a preparation method of a high-temperature and high-density water-based drilling fluid filtrate reducer composition, which belongs to the technical field of oilfield chemical agents, and is characterized in that the filtrate reducer composition is formed by combining a low-molecular-weight linear polymer and temperature-sensitive polymer particle microspheres, the preparation method of the low-molecular-weight linear polymer comprises the following steps: reacting an acrylamide hydrophilic monomer, a sulfonic acid group-containing temperature-resistant monomer, a rigid hydrophobic monomer, a cationic monomer, an initiator I and a polymerization inhibitor under a deoxidizing condition, washing a reaction product, drying and crushing to obtain the low-molecular-weight linear polymer. The preparation method of the temperature-sensitive polymer particle microspheres comprises the following steps: dissolving a temperature-sensitive monomer, a cationic monomer, a dispersing agent, a cross-linking agent and an initiator II in a mixed solution of deionized water and polyethylene glycol, reacting under a deoxidizing condition, and washing and drying a reaction product to obtain the polymer particle microspheres. The method is mainly used for synthesizing the high-temperature high-density water-based drilling fluid filtrate reducer composition.

Owner:YANGTZE UNIVERSITY +1

Polyamine mud shale inhibitor for drilling fluids, and preparation method thereof, and drilling fluid

InactiveCN109694697AEnhanced inhibitory effectImprove stabilityDrilling compositionEthylenediamineWell drilling

The invention provides a preparation method of a polyamine mud shale inhibitor for drilling fluids, wherein the polyamine mud shale inhibitor for drilling fluids is obtained by carrying out a reactionon a chlorinated epoxide, an acidic catalyst, polyethylene polyamine, ethanolamine, thionyl chloride and ethylenediamine. According to the present invention, the polyamine mud shale inhibitor is prepared by using the specific raw materials, and particularly thionyl chloride is added to the preparation components, such that the prepared polyamine mud shale inhibitor for drilling fluids has good shale inhibition property and good clay stabilizing performance; the prepared polyamine mud shale inhibitor has good lubricating property and good compatibility, and does not have biological toxicity; and the prepared polyamine mud shale inhibitor can be used in drilling fluids, and is suitable for strong water-sensitivity mud shale with high requirements, mud-containing rock and other easily collapsed stratums, and the well boring construction of shale gas horizontal wells. The invention further provides a polyamine mud shale inhibitor for drilling fluids.

Owner:SINOPEC SSC +1

Environmentally-friendly sand-in-water colorful paint and preparation method thereof

The present invention provides environmentally-friendly sand-in-water colorful paint and a preparation method thereof, color particles are innovatively introduced in conventional paint, by formula optimization and process improvement, excellent natural stone particulate matter simulation effect of the color particles can be ensured, the obtained color particles are added into the paint to give the paint excellent stone simulation characteristic, at the same time, performance is stable, the rheological property of the paint is not affected, and decorative effect can be significantly improved. The environmentally-friendly sand-in-water colorful paint is prepared by use of a new concept and a new technology based on the principle of production of sand-in-water colorful paint, so that a multicolored coating with rough surface granite effect can be obtained only by once spraying, the coating not only has permeability, the particles are mutually infiltrated and superimposed, and simulation degree is high. Good technical effect can be realized by innovative technical improvement, and the environmentally-friendly sand-in-water colorful paint is low in cost, easy to realize, so that the environmentally-friendly sand-in-water colorful paint has wide application prospect.

Owner:TIANJIN RONGXIN BUILDNG DECORATION PAINT

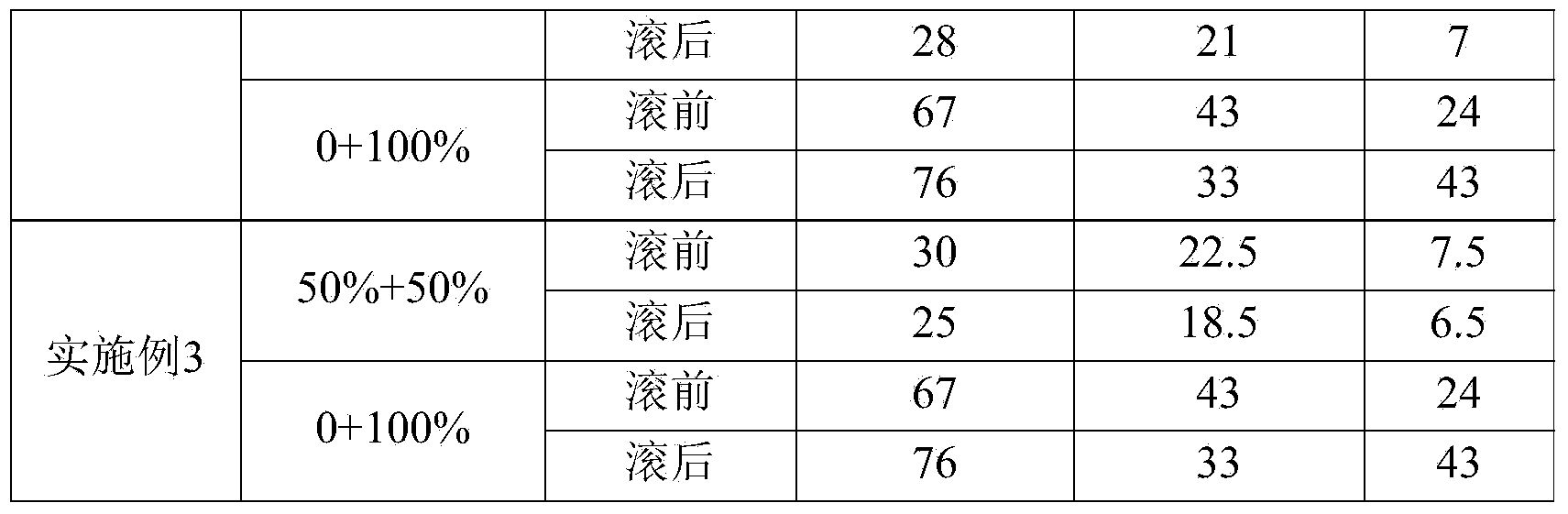

Double-fiber fine blocking agent along with drilling, and preparation method thereof

The present invention provides a double-fiber fine blocking agent along with drilling, wherein the components comprise, by mass, 100 parts of mica, 30-80 parts of wood fiber, and 20-60 parts of brucite fiber. According to the present invention, the double-fiber fine blocking agent along with drilling provides good rapid leakage blocking effects for osmotic leakage loss or micro-fracture leakage loss, especially for the leakage loss in the Luohe Formation stratum and the Liujiagou formation stratum, can prevent the leakage loss of the drilling fluid in the low pressure bearing stratum, has characteristics of easily available raw material, simple preparation process and low use cost, and does not affect the rheology of the drilling fluid.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

Hydrocarbon reservoir protective agent and preparing method thereof

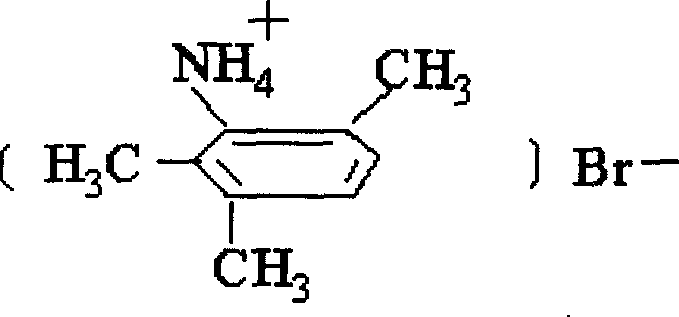

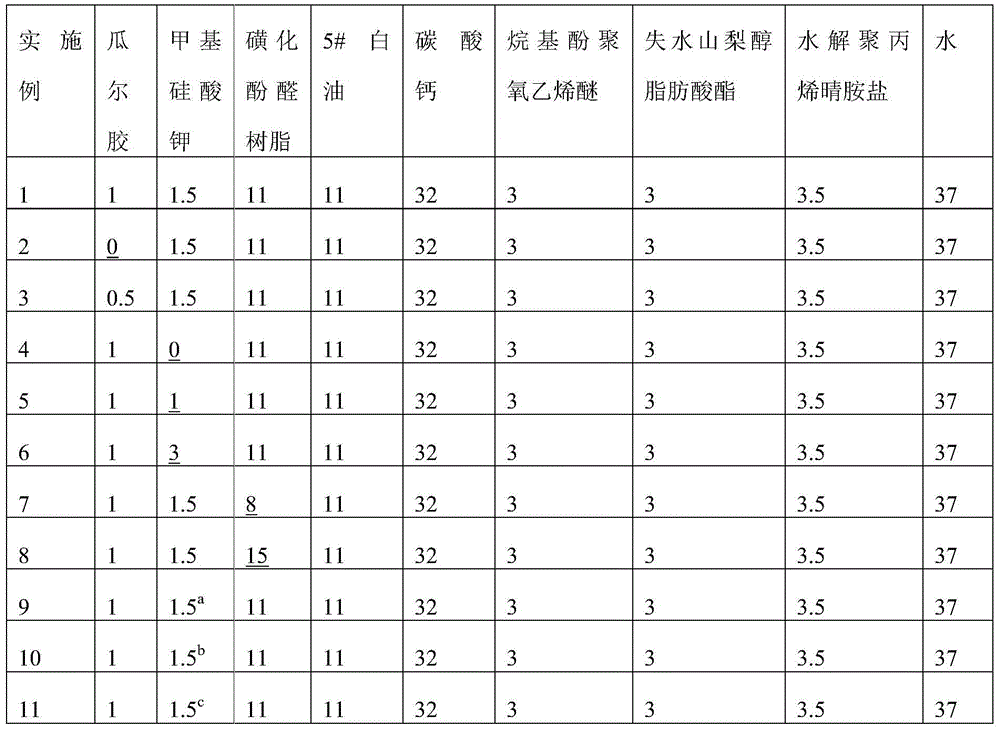

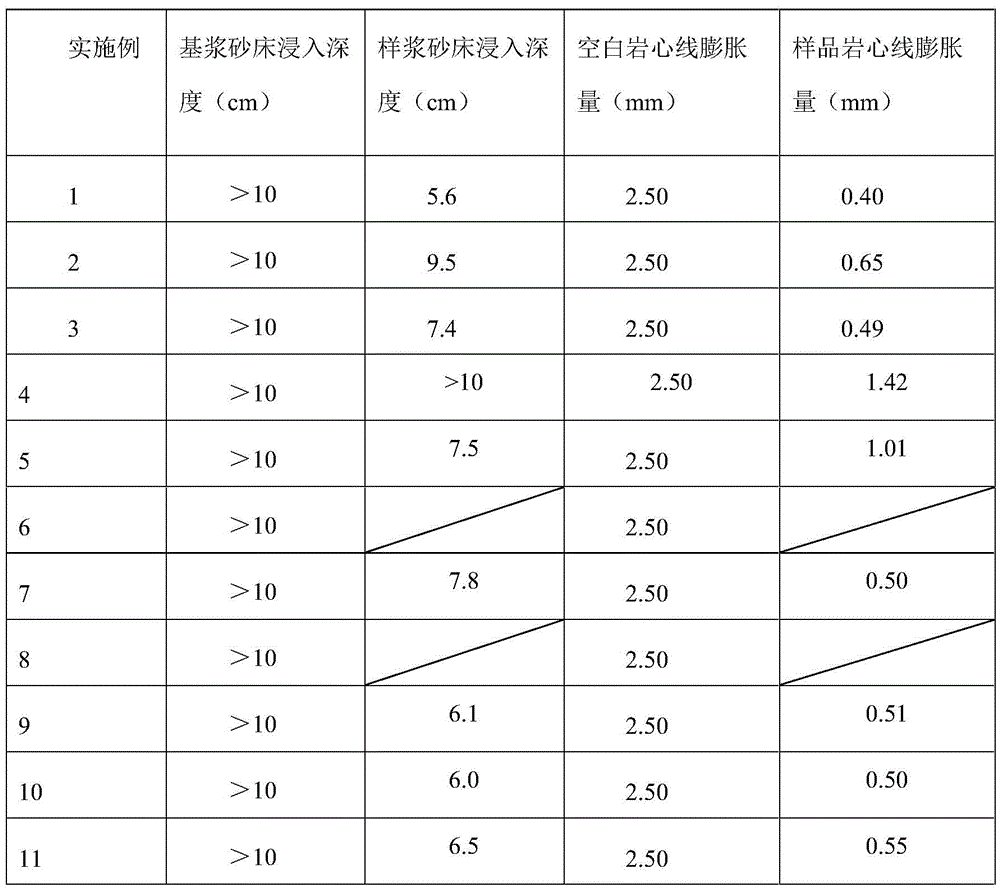

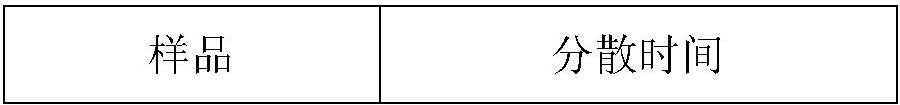

ActiveCN105670581ADoes not affect rheologyInhibition of hydrationDrilling compositionAlkylphenolHydrolysis

The invention relates to a hydrocarbon reservoir protective agent and a preparing method thereof.The hydrocarbon reservoir protective agent contains guar gum, organosilicate, sulfomethal phenolaldehy resin, white oil, calcium salt, alkylphenol ethoxylates, sorbitan fatty acid ester, hydrolysis polyacrylonitrile amine salt and water.The preparing method comprises the steps of 1, heating and evenly mixing water, guar gum, white oil, alkylphenol ethoxylates and sorbitan fatty acid ester to obtain a first mixture; 2, adding sulfomethal phenolaldehy resin, calcium salt, methyl silicate and hydrolysis polyacrylonitrile amine salt to the first mixture and conducting stirring to obtain the hydrocarbon reservoir protective agent.The hydrocarbon reservoir protective agent has high shale hydration expansion inhibiting capacity and dispersing capacity, does not affect the rheological property of drilling fluid, can effectively prevent or delay entering of drilling filtrate into the stratum and prevent or delay pressure increase of formation pores, and prolongs the hole-wall collapsing period.

Owner:四川泓华油气田工程科技有限公司

Low-density high-temperature plugging agent as well as preparation method and application thereof

PendingCN113969148ALow densityIncreased Microfoam LifespanDrilling compositionSilane couplingPorous network

The invention relates to the technical field of leakage-proof and plugging working fluid for drilling engineering, in particular to a low-density and high-temperature plugging agent, and a preparation method and application thereof. The plugging agent comprises the following components in parts by volume: 20-40 parts of liquid glass, 5-18 parts of resin and 2-5 parts of a silane coupling agent. The preparation method comprises the following steps: converting the liquid glass into silicon dioxide gel, modifying the surface of the silicon dioxide gel by using the silane coupling agent, and combining the above with the low-density resin to form the low-density high-temperature plugging agent. A nano-porous network structure exists in particles of the protective agent, and the protective agent is light in weight and low in density which is smaller than or equal to 1.65 g / cm < 3 >; the temperature resistance is higher than or equal to 200 DEG C; inorganic rigid and organic flexible elastic plugging is achieved, and the micro-foam fluid invasion depth reduction rate before and after the plugging agent is added is larger than or equal to 65.7%; the stability of the micro-foam fluid can be improved; and the plugging agent can be applied to high-temperature leakage strata, and the plugging property and stability of low-density fluid are improved.

Owner:SINOPEC SSC +2

Plugging agent for drilling fluid and preparation method thereof

The invention discloses a plugging agent for drilling fluid and a preparation method thereof. The plugging agent is prepared from the following components in parts by weight: 100 parts of matrix asphalt, 10-40 parts of a microcapsule modifier, 1-20 parts of a dispersing agent, 5-20 parts of a curing agent, 0.5-5 parts of an accelerant and 100-200 parts of water. The plugging agent can effectively reside at entrances of malignant leakage strata such as large cracks and karst caves to form solid sealing, and particularly, the retention plugging capacity and the water washing resistance are improved at high temperature and high pressure, so that the plugging success rate is increased.

Owner:CHINA PETROLEUM & CHEM CORP +1

Micro-nano rigid resin anti-collapse blocking agent

InactiveCN112375547AImprove pressure-bearing sealing capacityReduce lossesDrilling compositionHigh densityBasalt fiber

The invention discloses a micro-nano rigid resin anti-collapse blocking agent, which comprises the following components in percentage by mass: 50-65% of rigid resin particles, 20-25% of mineral fibers, 10-15% of inorganic powder and 5-10% of a surface treating agent, wherein the rigid resin particles are thermoplastic acrylic and are formed by compounding 3000-mesh rigid resin particles, 2000-meshrigid resin particles and 1000-mesh rigid resin particles according to the mass ratio of (4-5): (2-3): (1-2); the mineral fibers are brucite fibers or basalt fibers or a mixture of the brucite fibersand the basalt fibers; the length-diameter ratio of the mineral fiber is 10-20, and the diameter of the mineral fiber is 0.5-9 microns; and the inorganic powder is calcite with the particle size of 1500 meshes. The anti-collapse blocking agent is suitable for being applied to high-density drilling fluid, can prevent solid phases or liquid phases in the drilling fluid from damaging oil and gas reservoirs, and achieves oil and gas reservoir protection.

Owner:台前县天宏化工有限公司

A kind of high-efficiency composite defoamer for oil well cement and preparation method thereof

The invention discloses a high-efficiency composite defoamer for oil well cement and a preparation method thereof, which are used for defoaming and foam suppression in the process of high-speed shear mixing of cement slurry containing various admixtures. In terms of mass percentage, it consists of 15-59.5% mineral oil, 40-84.5% polyol fatty acid ester, 0-15% polybasic acid fatty alcohol ester and 0.5-15% defoaming auxiliary component, said defoaming auxiliary component Contains one or both of polyether and triisobutyl phosphate. The preparation method of the defoamer is as follows: under stirring at room temperature, successively add mineral oil, polyhydric alcohol fatty acid ester, polybasic acid fatty alcohol ester and defoaming auxiliary components to the batching kettle, stir and mix for 0.5-2.0 hours, filter out Material, measurement and packaging. Compared with ordinary oil well cement defoamers, the defoamer of the present invention has low cost, simple production process, uniform and stable product, and has both defoaming and foam suppression functions, and does not affect the rheology, thickening performance and compressive resistance of cement slurry. performance such as strength.

Owner:NANJING YUNYUE NEW MATERIAL TECH CO LTD

Yellowing-resistant UV (ultraviolet) antibacterial coating

InactiveCN107641352AHas antibacterial propertiesHas anti-yellowing propertiesAntifouling/underwater paintsPaints with biocidesAcrylic resinSolvent

The invention relates to a yellowing-resistant UV (ultraviolet) antibacterial coating. The yellowing-resistant UV antibacterial coating is prepared from the following components in parts by weight: 20to 50 parts of yellowing-resistant additive, 1.5 to 4 parts of natural antibacterial agent, 15 to 20 parts of monomer, 1.2 to 2.5 parts of photoinitiator, 3.5 to 5 parts of flatting agent, and 35 to50 parts of inert solvent, wherein the yellowing-resistant additive consists of acrylic resin and alkyd resin; the natural antibacterial agent is chitosan and / or tea tree essential oil. The yellowing-resistant UV antibacterial coating has the advantages that by adding the yellowing-resistant additive and the natural antibacterial agent into the UV coating, the prepared UV coating has the antibacterial and yellowing-resistant properties, and the yellowing and aging degrading of the coating film under the long-time radiation by ultraviolet rays can be delayed or prevented; the yellowing-resistant additive is compounded by the acrylic resin and the alkyd resin, so that the good yellowing-resistant effect is realized.

Owner:桂林市漓江机电制造有限公司

Environment-friendly inhibitor for drilling fluid, and preparation method thereof

PendingCN111205833AInhibitory requirements are metImprove adsorption capacityOrganic phosphatic fertilisersDrilling compositionO-Phosphoric AcidEnvironmental engineering

The invention discloses an environment-friendly inhibitor for a drilling fluid, and a preparation method thereof, and relates to the field of drilling fluids in petroleum and natural gas and geological exploration and development. The environment-friendly inhibitor for the drilling fluid is prepared from, by mass, 25 to 35 parts of amino acids, 3 to 5 parts of a strong base, 15 to 25 parts of phosphoric acid, 10 to 20 parts of choline, 7 to 12 parts of urea and 50 to 70 parts of water. The inhibitor has excellent clay hydration expansion and dispersion inhibition effects, can be firmly adsorbed on the surface of clay, is not prone to desorbing, has a long-acting inhibition effect, is completely made of environment-friendly materials, is environment-friendly and easy to degrade, meets the requirements of national environmental protection laws, solves the problems that common inhibitors do not meet the environmental protection requirements and are difficult to degrade, and is suitable for mining operation in part of domestic severe ocean areas.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com