Patents

Literature

63results about How to "Does not affect formation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Prepn of lateral hydroxyl group containing polyimide/SiO2 hybrid film

InactiveCN1436815AHigh molecular weightThe structure of the main chain is flexible and changeableEpoxyRoom temperature

The preparation process of lateral hydroxyl group containing polyimide / SiO2 hybrid film includes dissolving polyamido acid containing lateral hydroxyl group or polyimide in 1-1400 portions in solvent to compound 5-15 % concentration solution, adding silane coupling agent containing epoxy radical in 0-250 portions for reaction at 120-150 deg.c in the presence of catalyst in 0.1-10 portions of 2-4 hr; cooling to room temperature, adding n-silicate ester in 1-1000 portions through stirring for 6-24 hr, flow casting to form film, and processing at 0.1 atm negative pressure and 60 deg.c for 12 hr, and 160 deg.C for 2 hr, at 200 deg.c for 2 hr, at 260 deg.c for 1 hr and at 300 deg.c for 0.5 hr to obtain the lateral hydroxyl group containing polyimide / SiO2 hybrid film.

Owner:SICHUAN UNIV

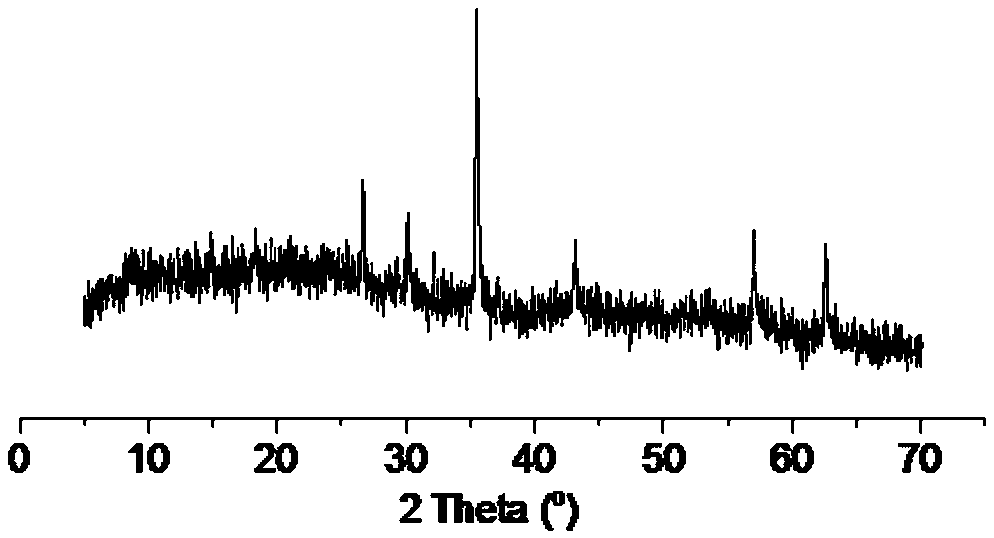

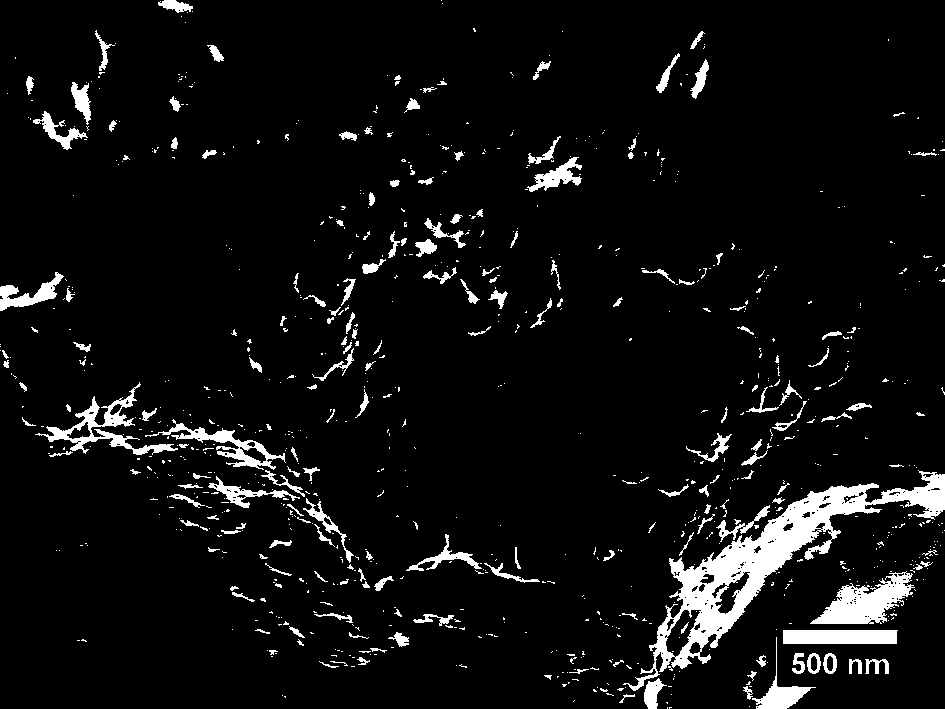

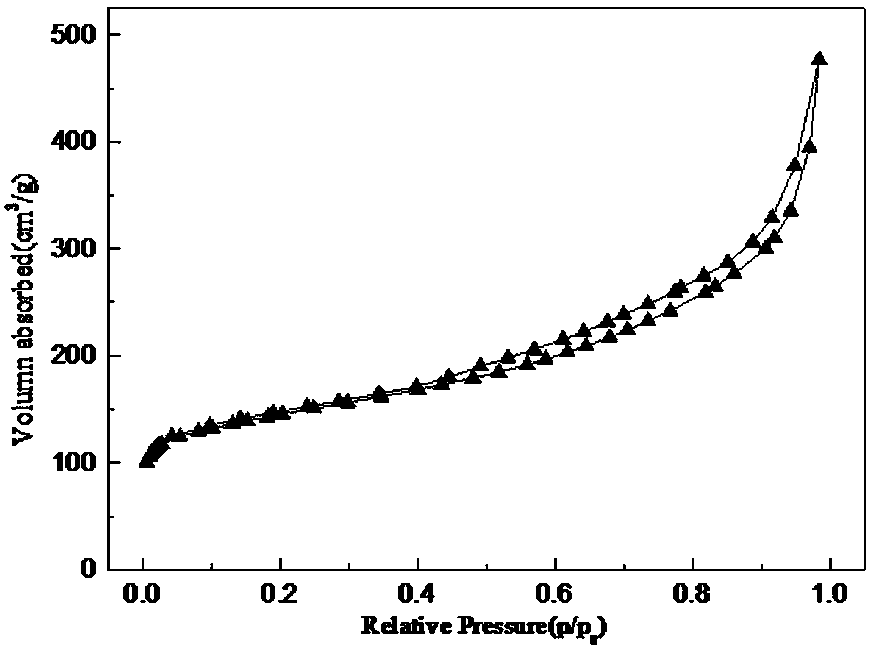

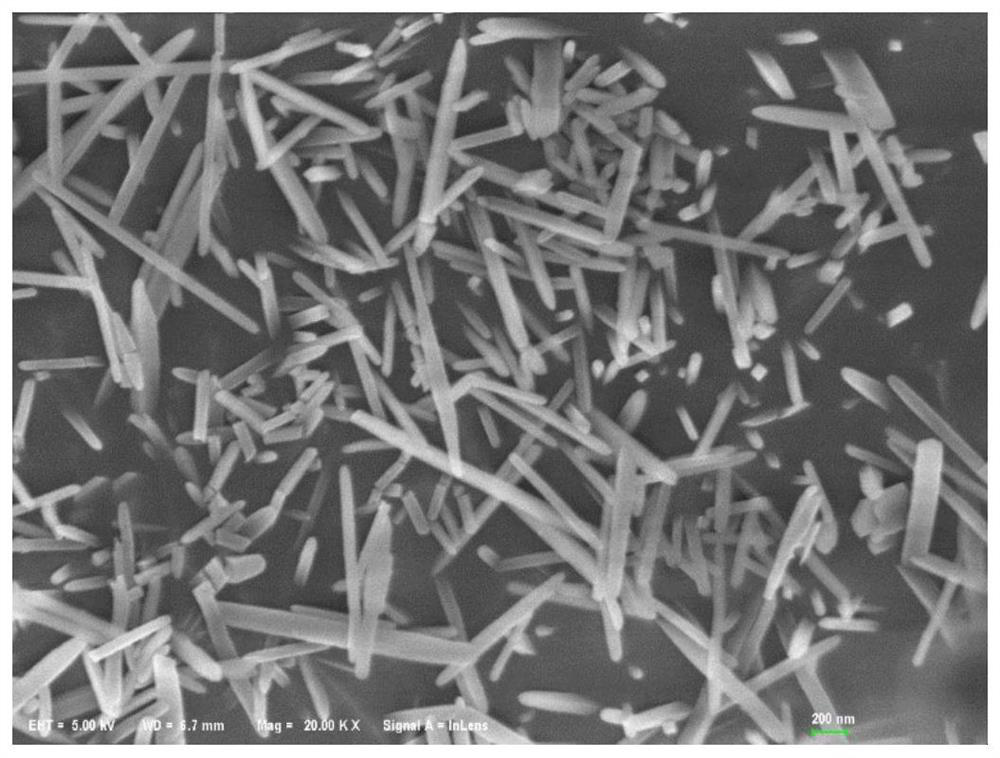

Preparation method of nano-metal oxide and porous activated carbon composite

InactiveCN108097210AWide variety of sourcesIncrease profitOther chemical processesAlkali metal oxides/hydroxidesActivated carbonNanotechnology

The invention discloses a preparation method of a nano-metal oxide and porous activated carbon composite. The preparation method has the universality and is suitable for the composite process of different nano-metal oxides and an activated carbon material; the produced composite is stable in performance, and the nano-metal oxides can be uniformly distributed in an activated carbon structure. In the nano-metal oxide and porous activated carbon composite prepared by the preparation method provided by the invention, the metal oxides are uniformly distributed in the activated carbon component in anano-particle form, introduction of metal oxide nano-particles does not influence formation of an activated carbon pore canal, and thus the prepared composite is stable in performance.

Owner:海宁瑞创新材料有限公司

Cigar mildewproof additive and using method thereof

InactiveCN101797071ADoes not affect quality styleDoes not affect the formation of quality styleTobacco preparationTobacco treatmentYeastAntioxidant

The invention relates to an additive for cigar mildewproof treatment. The additive comprises the following components in part by weight: 50 to 100 parts of natamycin, 50 to 150 parts of solubilizer, 0.1 to 2 parts of antioxidant and 0.1 to 3 parts of surfactant. The components are dissolved in 100 parts of water after being mixed uniformly, the pH value of the solution is adjusted to 3 to 7, and the solution is stirred for 30 minutes. The additive, which uses water as diluent, is applied on the surface of cigar tobacco in a soaking or spray manner. The additive has the advantages of special inhibitory action on fungi and yeasts which cause mildew, prevention of cigar mildew, no influence on normal operation of alcoholized fermentation, no adverse effect on the quality of the cigar, high efficiency, environmental protection, low cost, effective reduction in the risks of the cigar mildew and improvement on the quality of the cigar.

Owner:CHINA TOBACCO CHUANYU IND

Preparation of lateral hydroxyl group containing polyimide/SiO2 hybrid film

InactiveCN1218999CHigh molecular weightThe structure of the main chain is flexible and changeableEpoxyRoom temperature

The preparation process of lateral hydroxyl group containing polyimide / SiO2 hybrid film includes dissolving polyamido acid containing lateral hydroxyl group or polyimide in 1-1400 portions in solvent to compound 5-15 % concentration solution, adding silane coupling agent containing epoxy radical in 0-250 portions for reaction at 120-150 deg.c in the presence of catalyst in 0.1-10 portions of 2-4 hr; cooling to room temperature, adding n-silicate ester in 1-1000 portions through stirring for 6-24 hr, flow casting to form film, and processing at 0.1 atm negative pressure and 60 deg.c for 12 hr, and 160 deg.C for 2 hr, at 200 deg.c for 2 hr, at 260 deg.c for 1 hr and at 300 deg.c for 0.5 hr to obtain the lateral hydroxyl group containing polyimide / SiO2 hybrid film.

Owner:SICHUAN UNIV

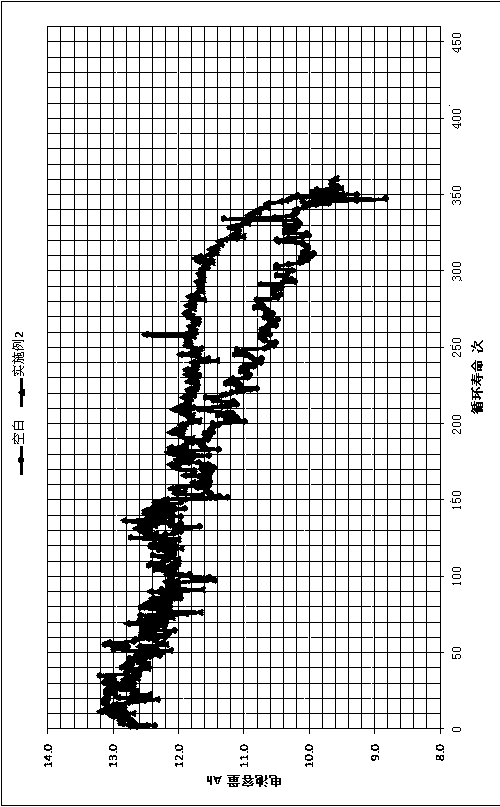

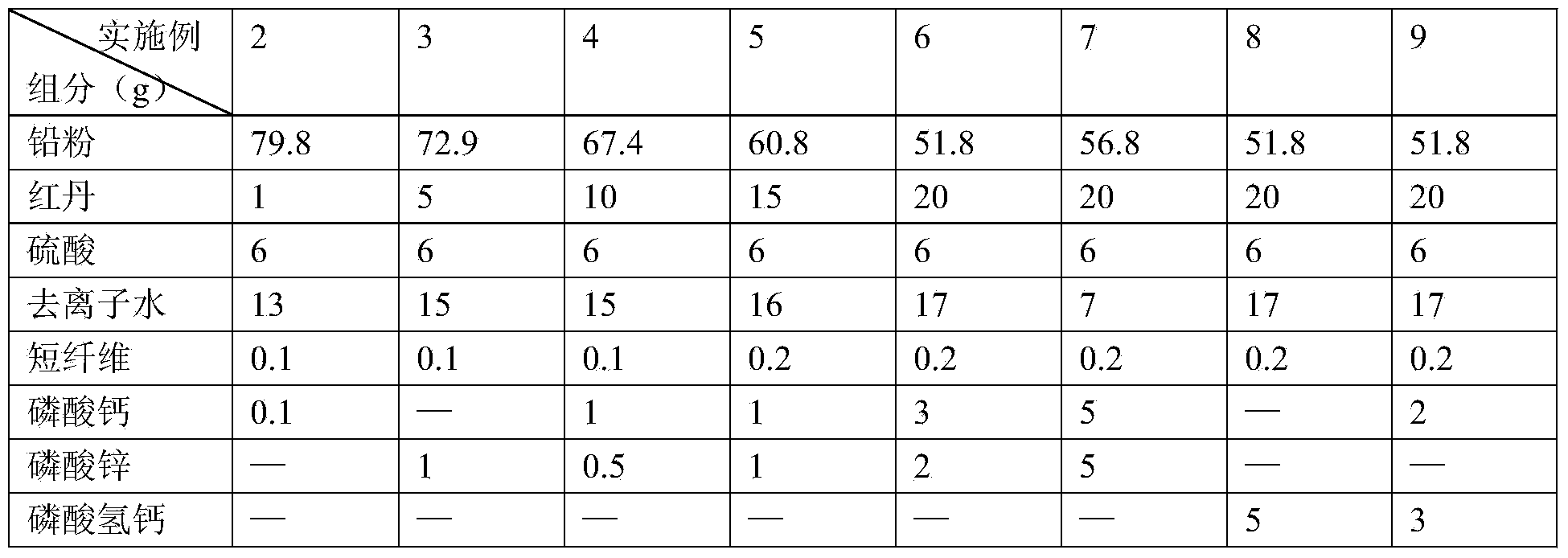

Anode lead plaster of lead-acid accumulator

ActiveCN104241641ADoes not affect formationDoes not affect the early electrical performanceCell electrodesFiberZinc phosphate

The invention relates to an anode lead plaster of a lead-acid accumulator. The anode lead plaster comprises the following components in percentage by weight: 1-25% of red lead, 3-15% of sulfuric acid, 5-20% of water, 0.05-2% of short fibers, 0.01-10% of phosphate and the balance of lead powder. According to the anode lead plaster, by adding the slightly soluble phosphate into the formula, phosphate radical are slowly released during usage of the cell; not only are the forming process and early-stage performance of the cell not influenced, and also the problem that an electrode plate is softened at the later usage stage of the cell is overcome; the phosphate can be selected from common phosphate with stable property, such as calcium phosphate and zinc phosphate.

Owner:CHAOWEI POWER CO LTD

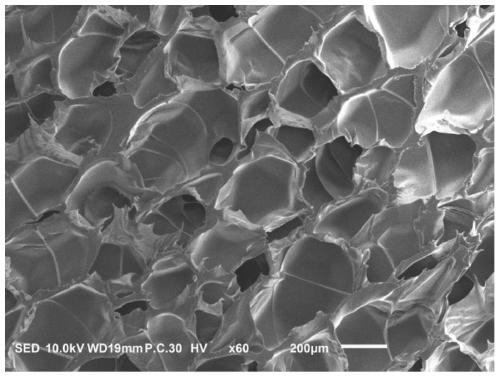

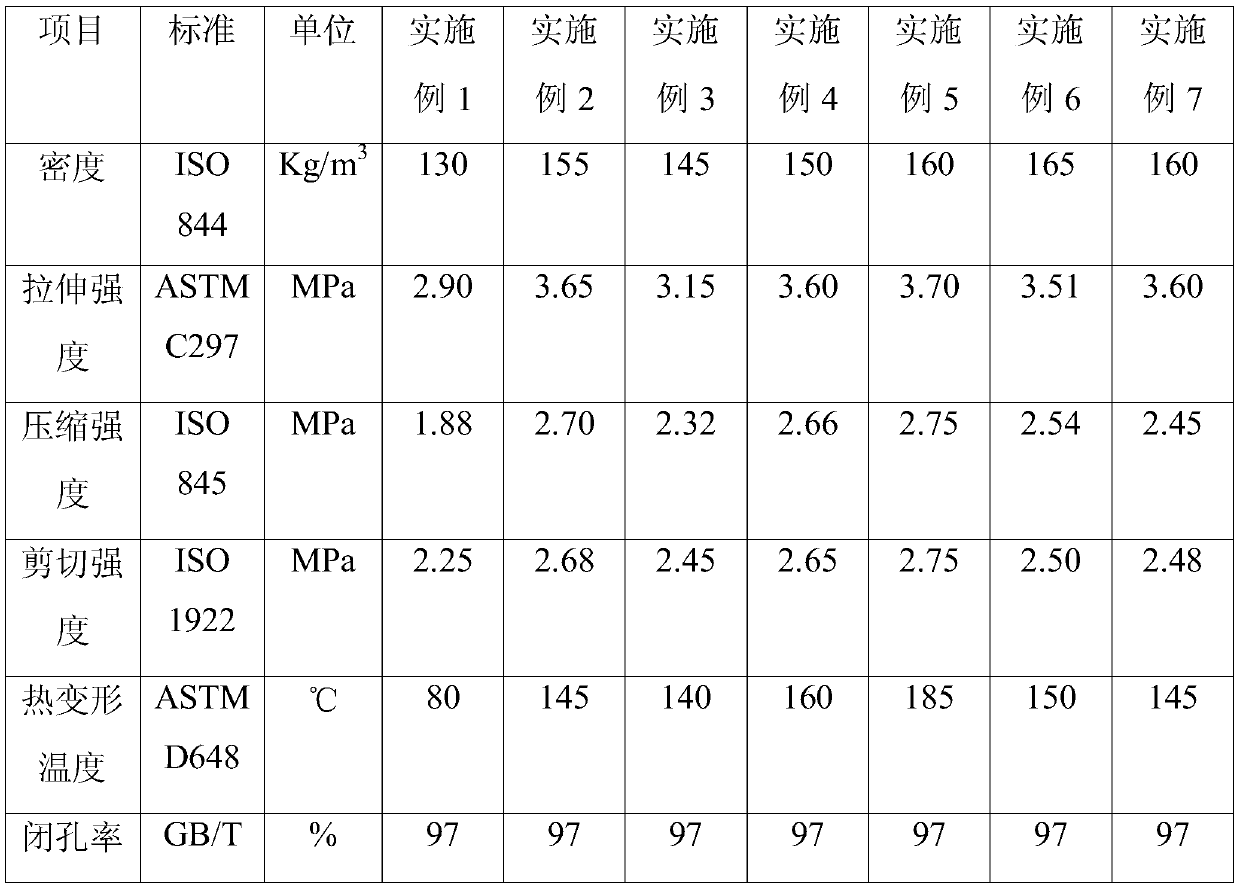

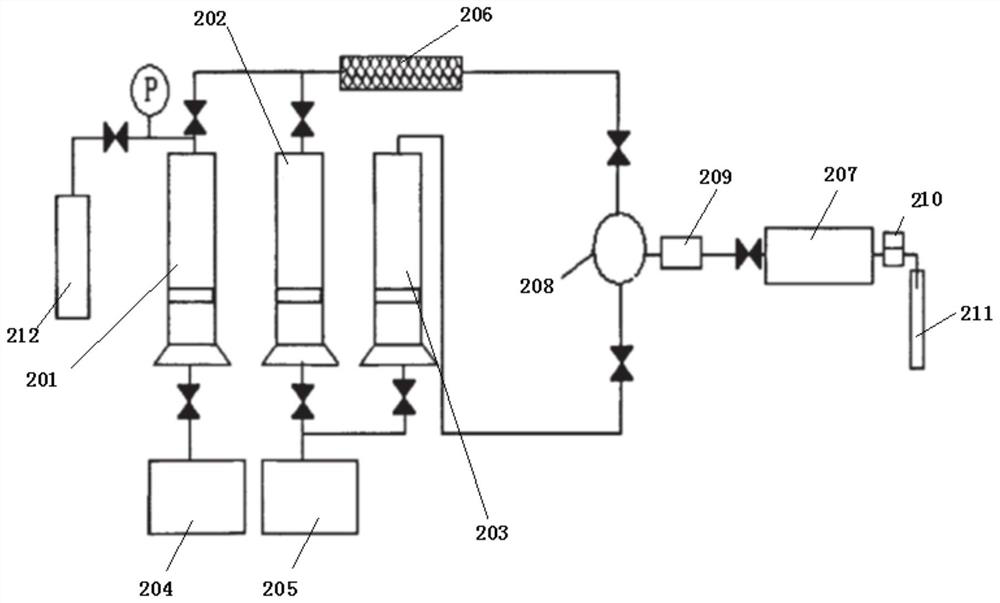

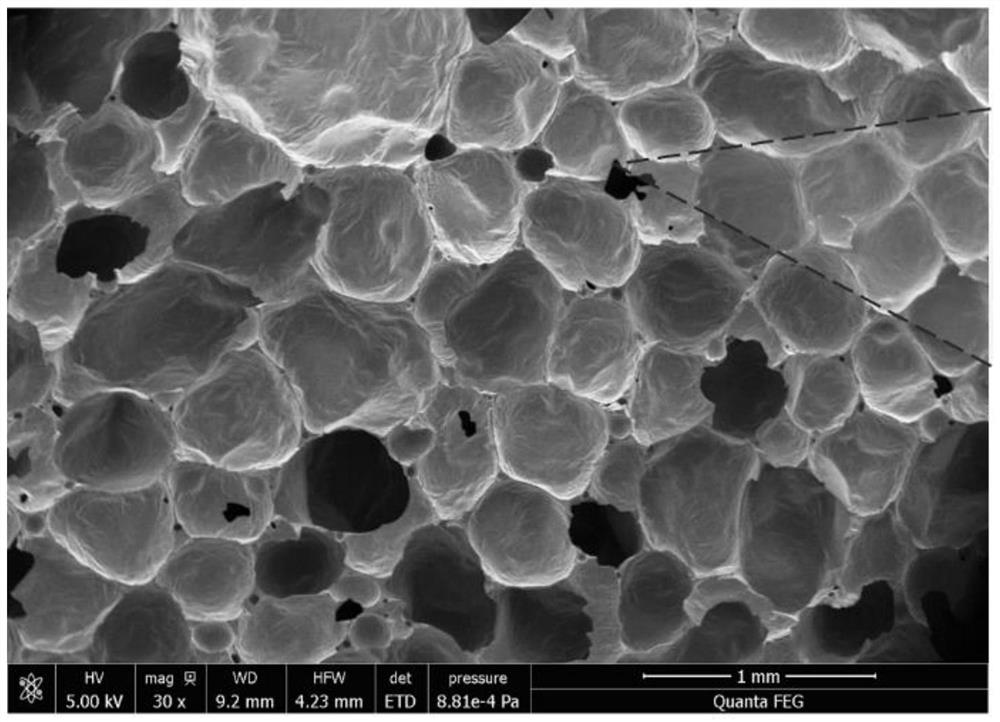

Supercritical fluid continuous extrusion high-performance recyclable PA foam material and preparation method thereof

The invention relates to a supercritical fluid continuous extrusion recyclable high-performance nylon foam material and a preparation method thereof. The high-performance PA foam material is preparedfrom the following raw materials in parts by weight: 69-98 parts of nylon PA resin, 1-30 parts of fibers, 0.5-2 parts of a chain extender and 0.5-2 parts of a nucleating agent through supercritical fluid double-step (double screws are connected in series with a single screw) extrusion foaming device. The fibers added in the foaming process do not influence the formation of the basic structure of the closed-cell foam, and the foamed fibers are uniformly distributed on the cell walls to play a role of a reinforcement phase. The prepared thermoplastic nylon foam material is high in forming efficiency, capable of achieving continuous production, controllable in foaming ratio, economical, environmentally friendly and recyclable, and generated foam edge cutting materials or unqualified foam products can be crushed, recycled and foamed again. The material has high mechanical properties, thermal stability and creep resistance, and can be applied to the fields of aerospace, wind power, rail transit transportation, buildings and the like.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD

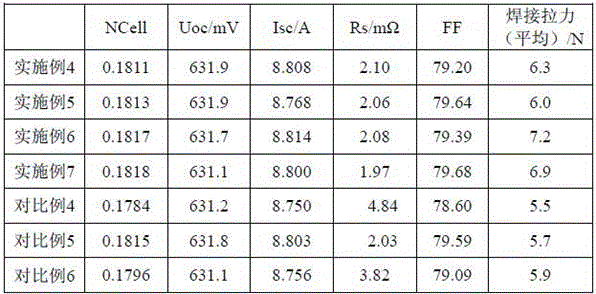

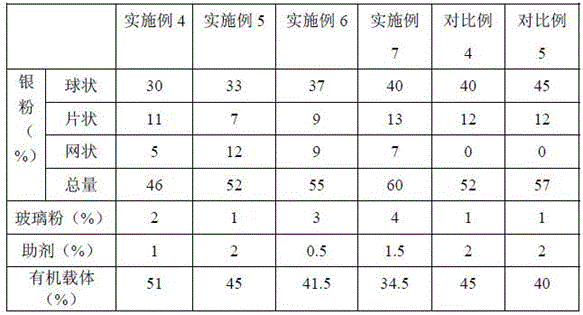

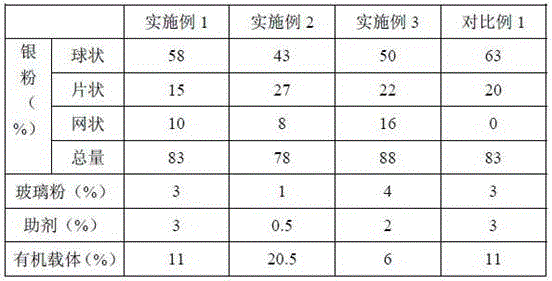

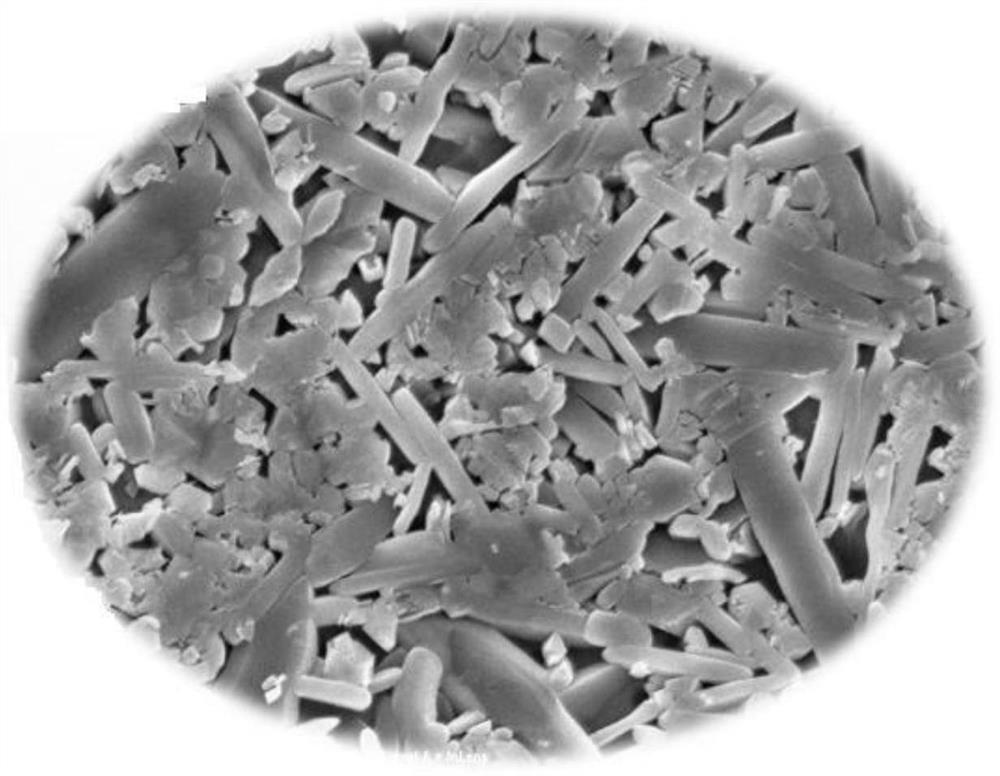

Crystalline silicon solar cell silver paste with low silver content and preparation method thereof

ActiveCN105913897AReduce meltingReduce silver contentNon-conductive material with dispersed conductive materialPhotovoltaic energy generationMicro nanoSilver paste

The invention discloses crystalline silicon solar cell silver paste with a low silver content and a preparation method thereof. The crystalline silicon solar cell silver paste is composed of: silver powder, an organic carrier and an auxiliary agent. An organic solvent and a thickening agent are mixed to form the organic carrier. Micro-nano netted silver powder, spherical silver powder and sheet-shaped silver powder are mixed to form the silver powder. With 100% of the mass of the crystalline silicon solar cell silver paste, the mass percent of the micro-nano netted silver powder is 5-16%. According to the invention, a proper amount of micro-nano netted silver powder is added to conventional silver paste, the micro-nano netted silver powder has a porous characteristic, and compared with other entity silver powder with the same particle size, the fusion speed of the micro-nano netted silver powder is low and can relatively well maintain the structure characteristic in an existing paste flash burning process, so that the purpose of lowing the silver content of the paste is achieved.

Owner:JIANGSU HOYI TECH

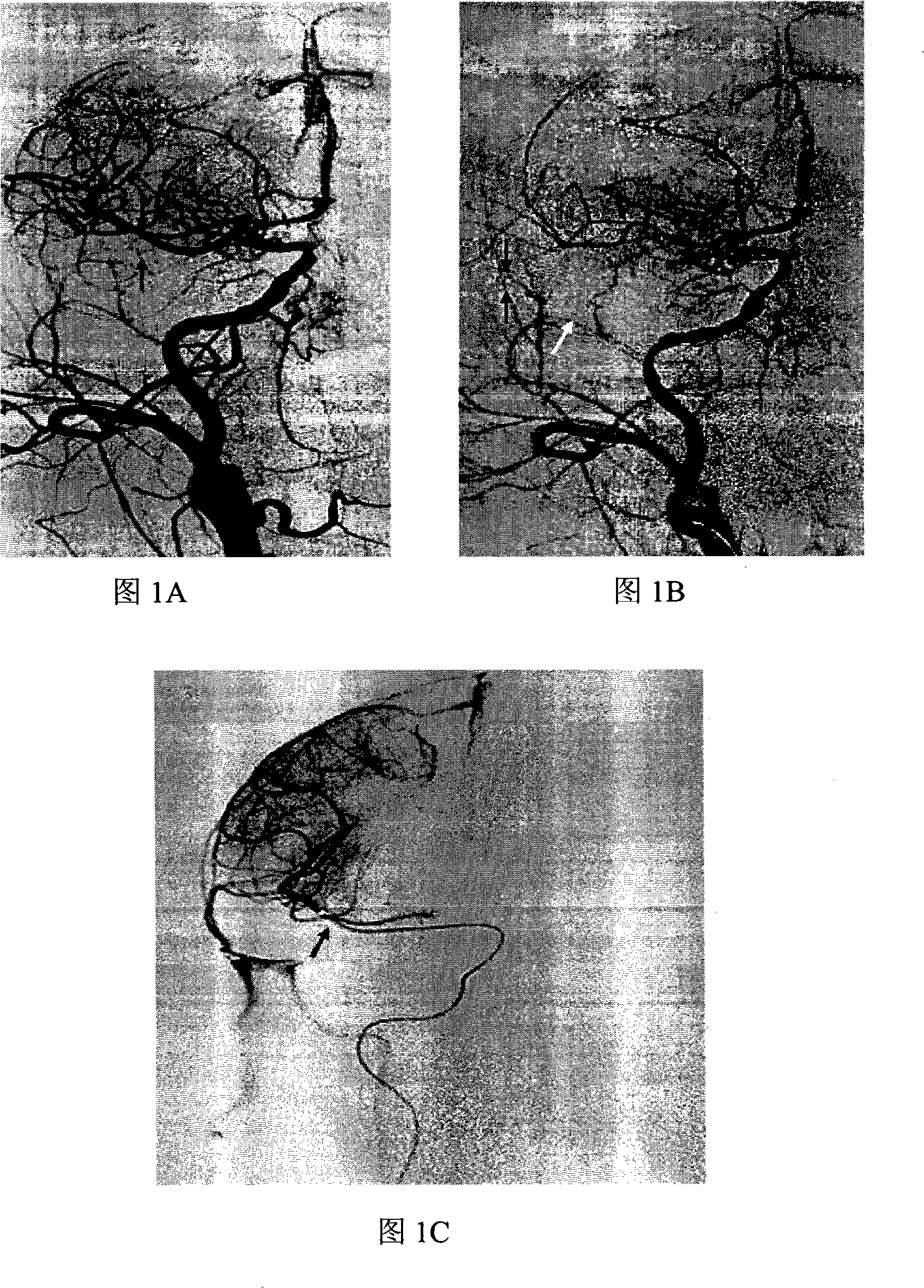

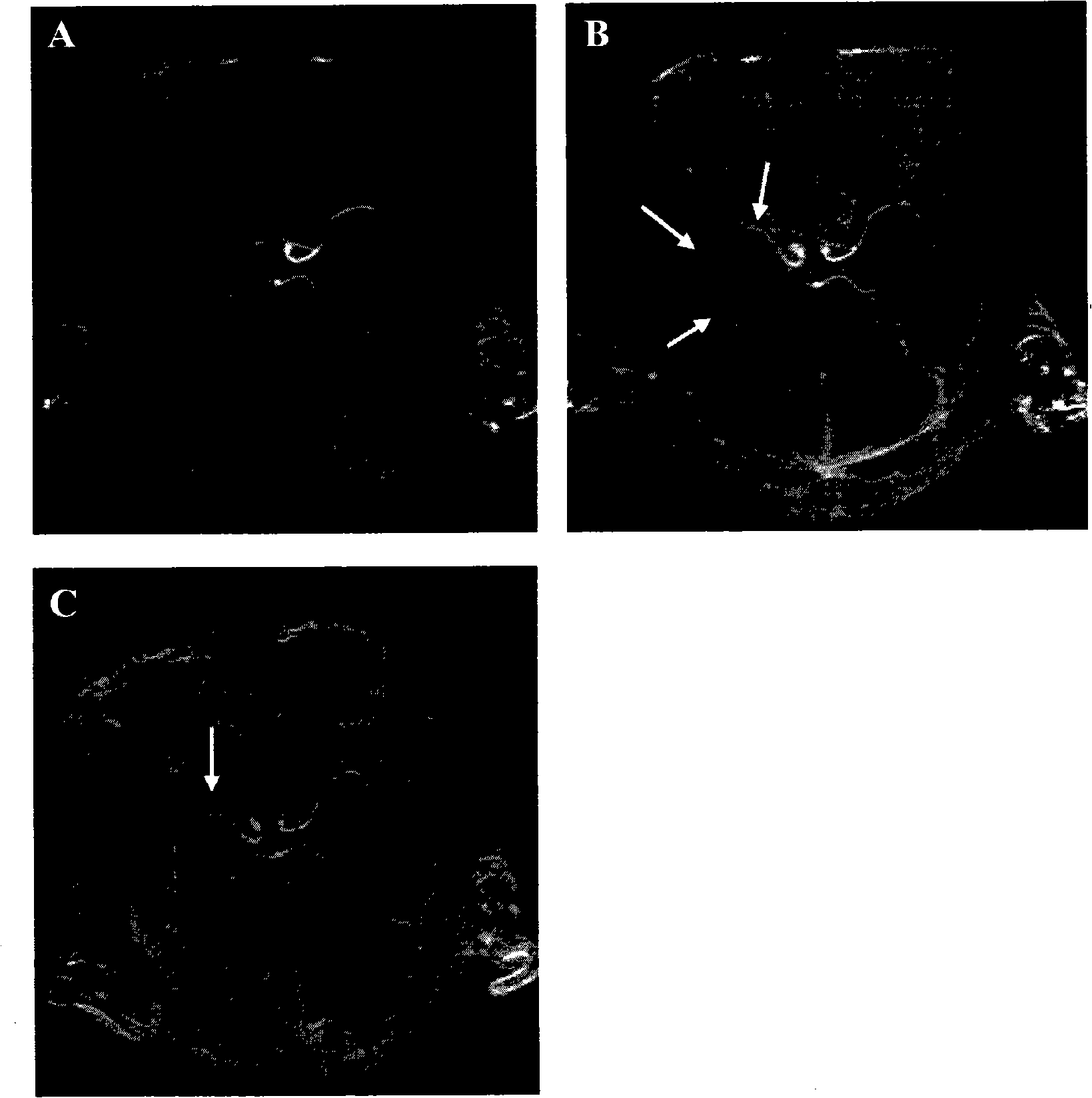

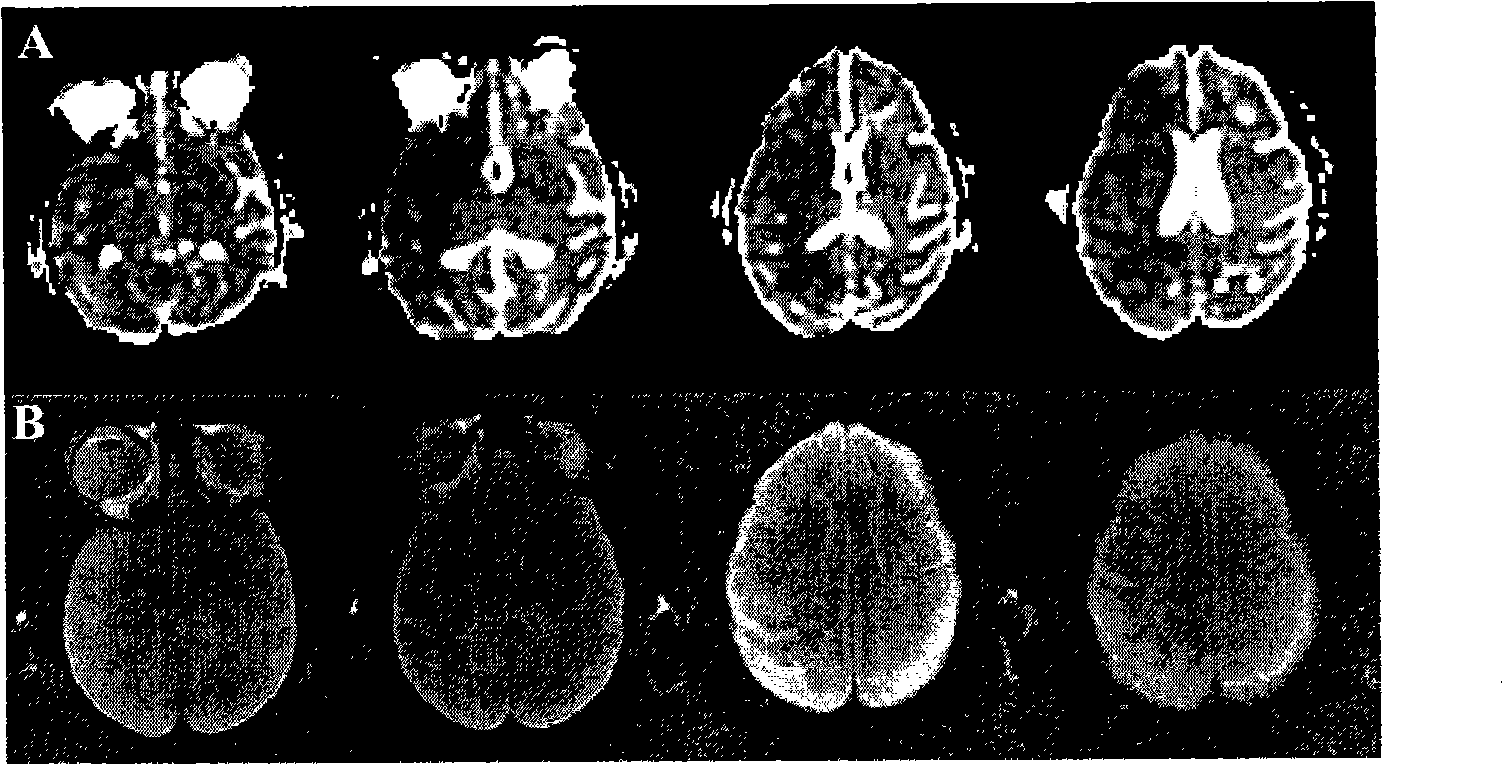

Method for establishing artery ischemia model of brain of rhesus monkey and evaluation method

InactiveCN101653378ADoes not affect formationImprove controllabilityDiagnosticsSurgeryClinical manifestationBasic research

The invention relates to a method for establishing an artery ischemia model of a brain of a rhesus monkey and an evaluation method. The constructing method adopts the mode of directly puncturing femoral arteries of an experimental monkey to perform the intravascular interventional operation under the direct view of a digital subtraction angiography, and establishes the chronic cerebral infarctionprimate model by using a micro-catheter to block the arteries in the brain of the experimental monkey and controlling ischemia time. The model is a quite reasonable cerebral ischemia-reperfusion animal model, and the pathological characteristics of the monkey cerebral injury model established by the method are similar to clinical manifestation; and moreover, the model is stable and reliable and issuitable for all kinds of curing therapeutic research and related basic research.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV +1

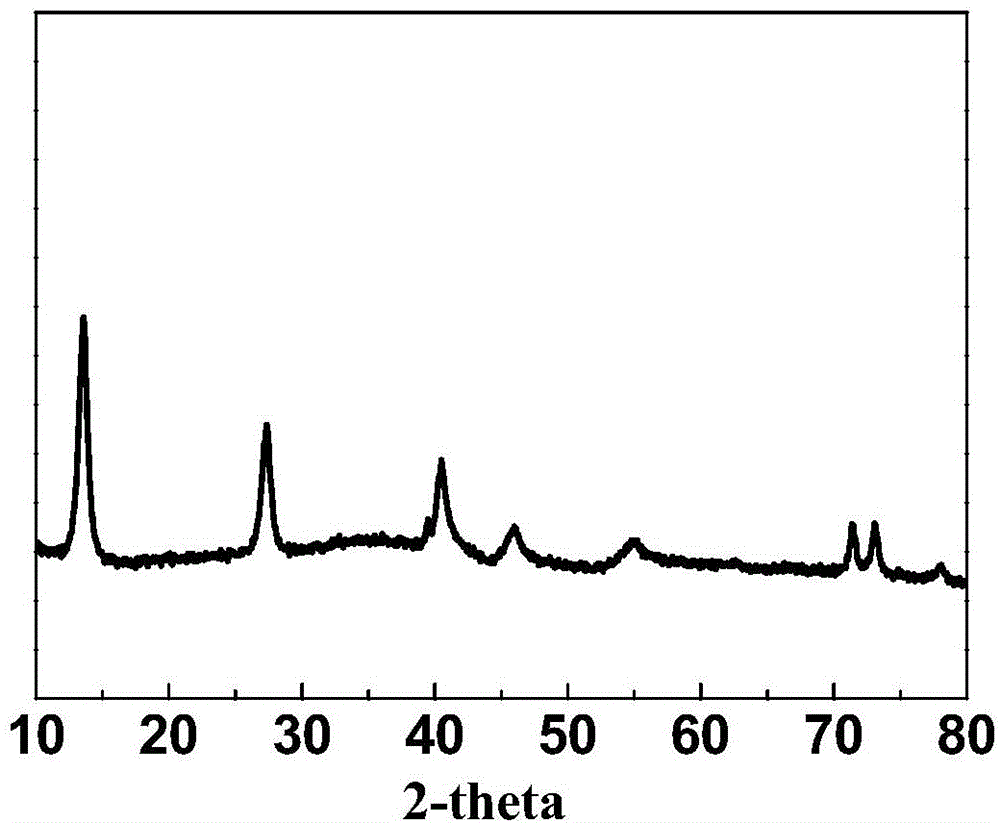

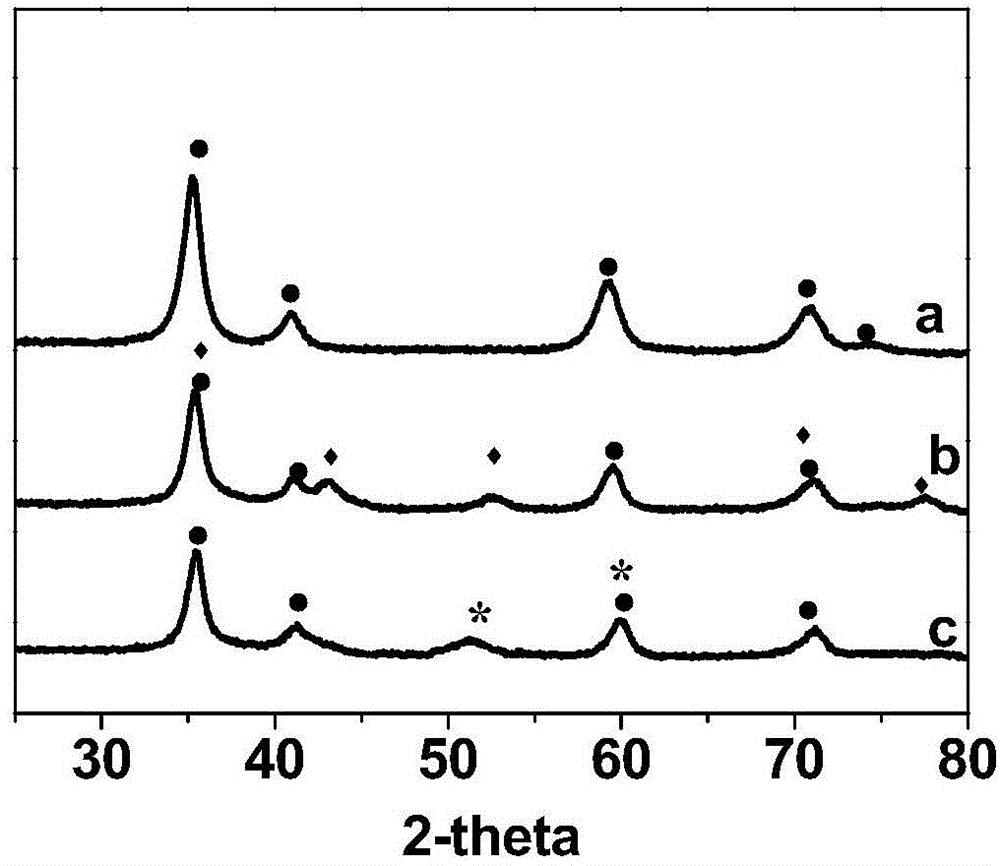

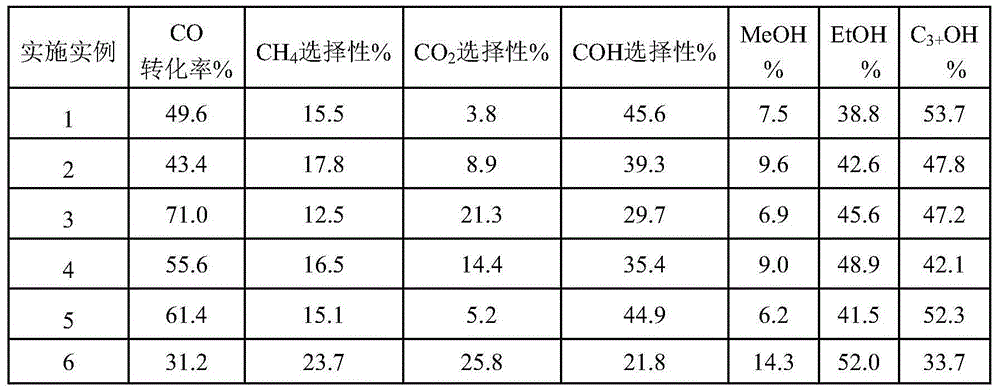

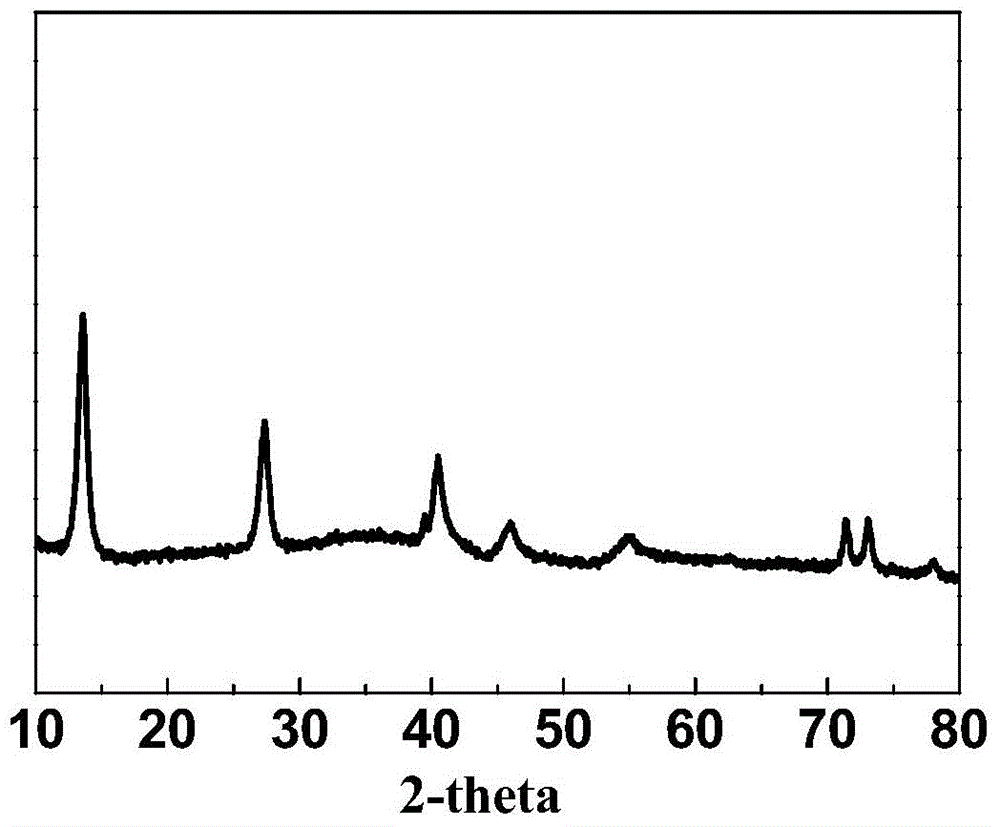

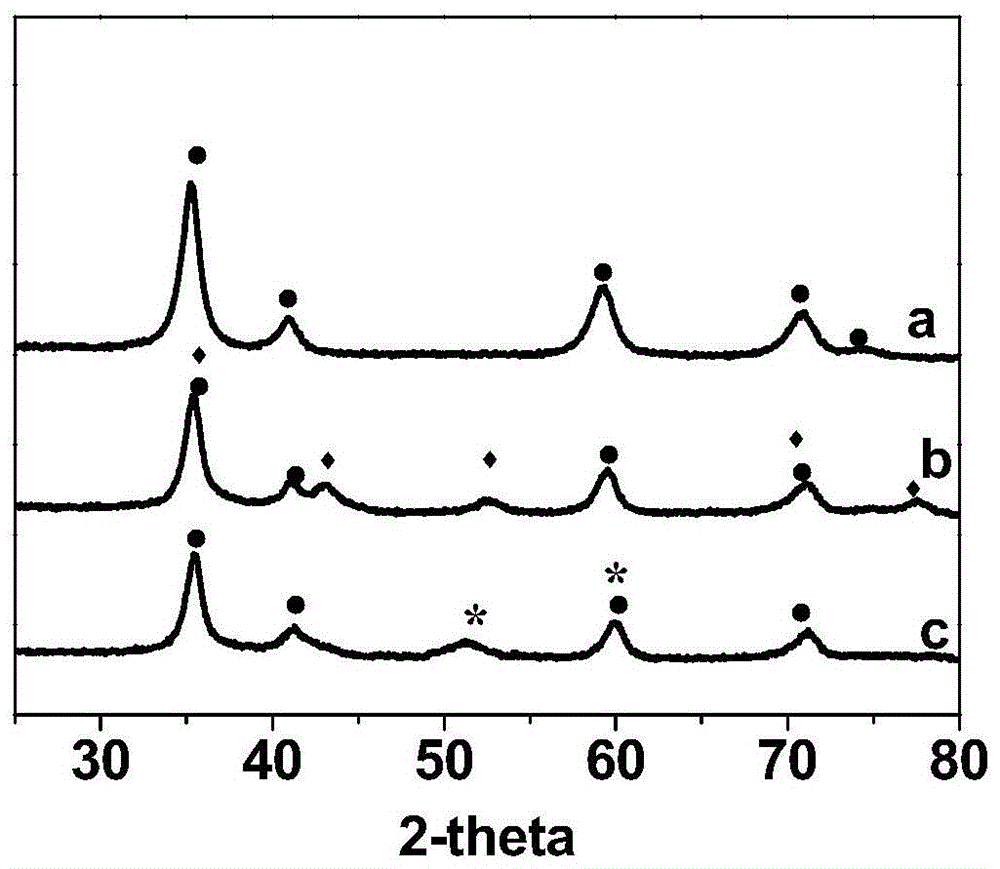

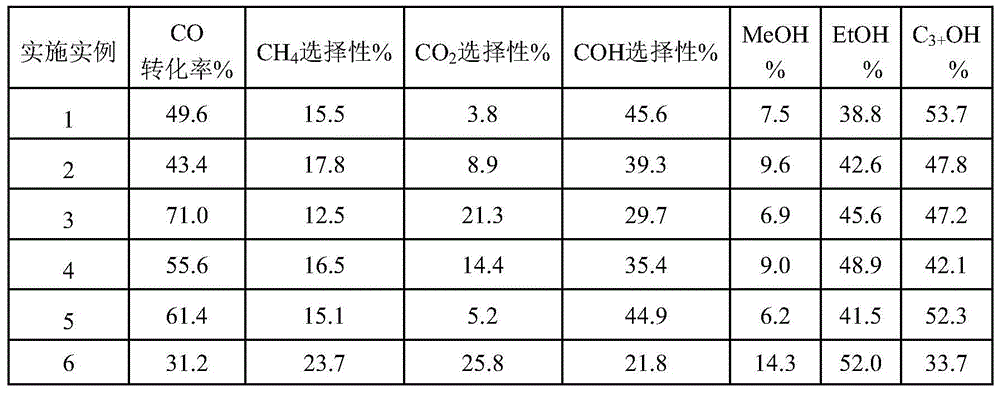

Preparation method and application of mixed oxide-doped nano copper-cobalt alloy catalyst

ActiveCN104645991AReduce contentGood dispersionOrganic compound preparationHydroxy compound preparationMixed oxideActive component

The invention relates to a preparation method and application of a mixed oxide-doped nano copper-cobalt alloy catalyst. According to the catalyst, CuCo serves as an active component and mixed oxide serves as a carrier, wherein Cu accounts for 5-25% in the catalyst in percentage by mass, Co accounts for 5-25% in the catalyst in percentage by mass, Al2O3 accounts for 13-25% in the catalyst in percentage by mass, and one of SiO2, ZrO2, CeO2 or TiO2 accounts for the balance. The mixed oxide-doped nano copper-cobalt alloy catalyst is obtained by calcinating and reducing a hydroxide-doped hydrotalcite-like precursor. Since silicon, zirconium, cerium and titanium ions cannot enter a hydrotalcite-like laminate, the dispersion of copper and cobalt on the surface is improved, the dispersion degree of active components is increased, and the formation of a hotspot in a reaction process of synthesizing low-carbon alcohol is relieved. The catalyst is relatively high in low-carbon alcohol selectivity and low-temperature activity, easy to operate, and low in cost and is applicable to industrial production.

Owner:TIANJIN UNIV

Coal tar hydrorefining catalyst and preparation method thereof

ActiveCN101905163AHydrogenation benefitsImprove water absorptionCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOrganic chemistry

The invention discloses a coal tar hydrorefining catalyst and a preparation method thereof. Alumina is used as a carrier, VIB and VIII metal elements are used as active constituents, and the content of the active constituents in the catalyst is 25%-60% by weight relative to oxides. The preparing method comprises the following steps of: taking pseudoboehmite dry gel powder used as a carrier raw material; roasting part of the pseudoboehmite dry gel powder at the temperature of 800-1200 DEG C, and uniformly mixing with the rest of unroasted pseudoboehmite dry gel powder; and mixing the mixture and the solution containing an active constituent compound, pulping, filtering, drying, crushing, forming, drying and roasting to obtain the final hydrorefining catalyst. Compared with the prior art, the catalyst has high content of active constituents, larger pore volume and specific surface, a proper amount of large pores, suitable distribution of active constituents, and high activity and good stability when used for hydrogenating and refining the coal tar.

Owner:胜帮科技股份有限公司

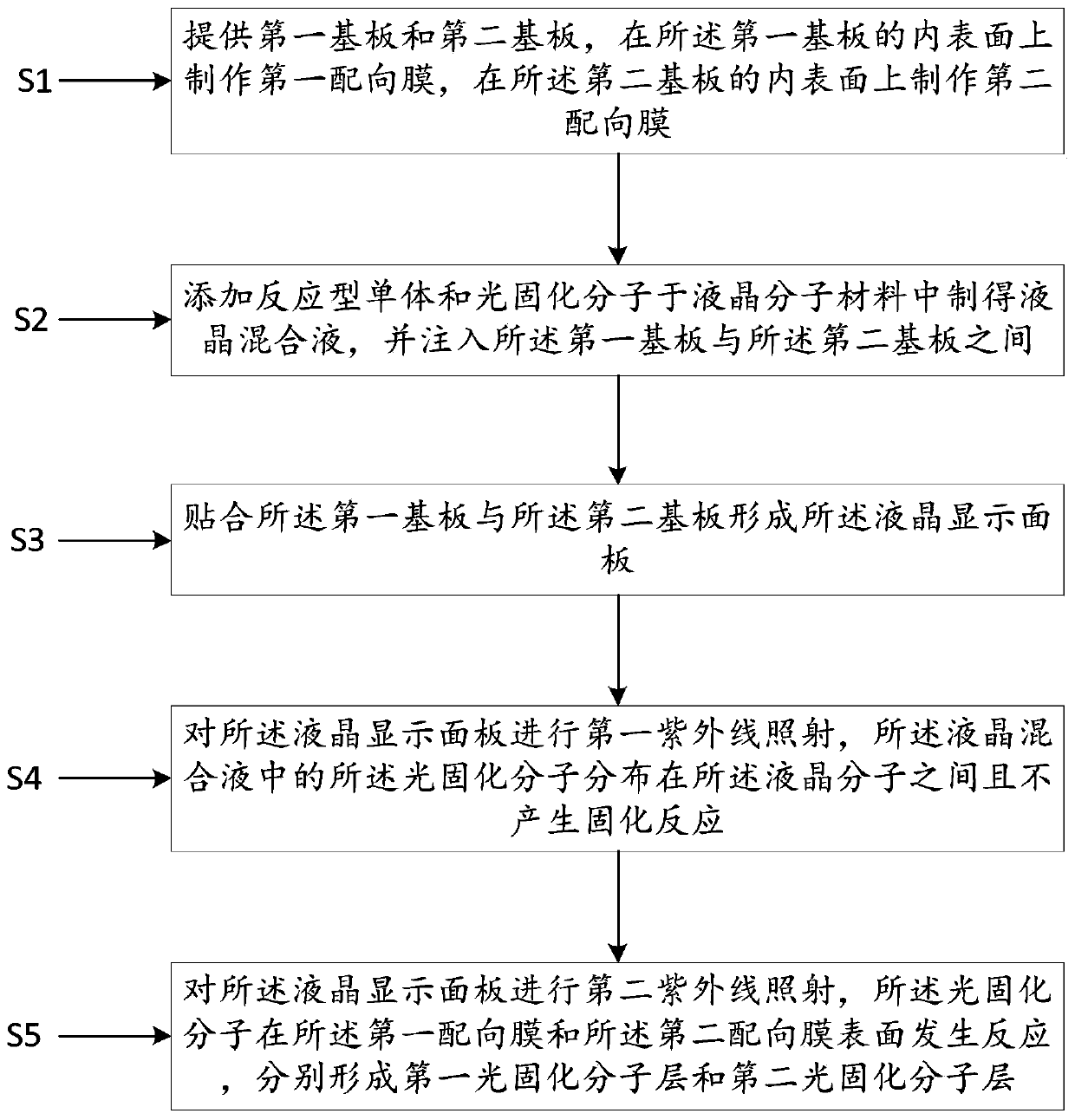

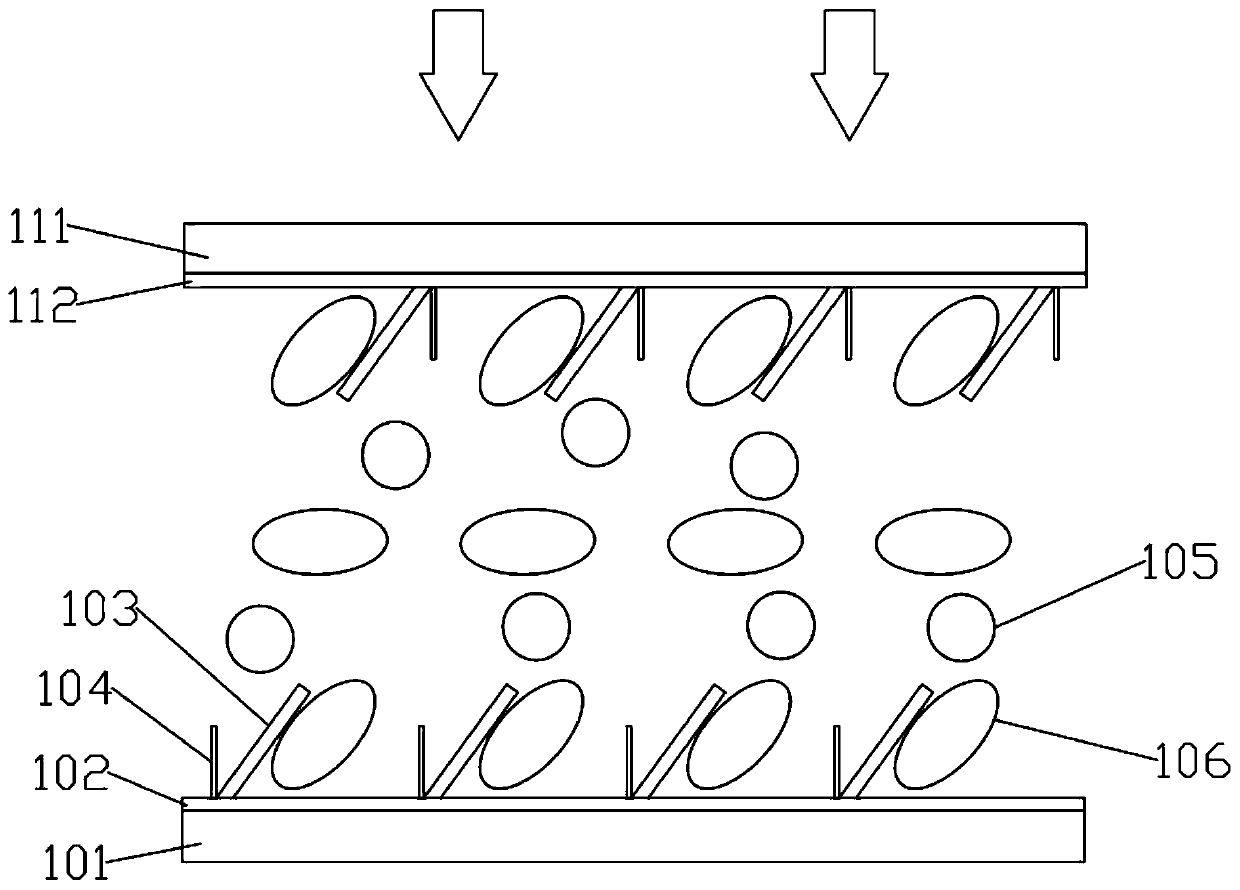

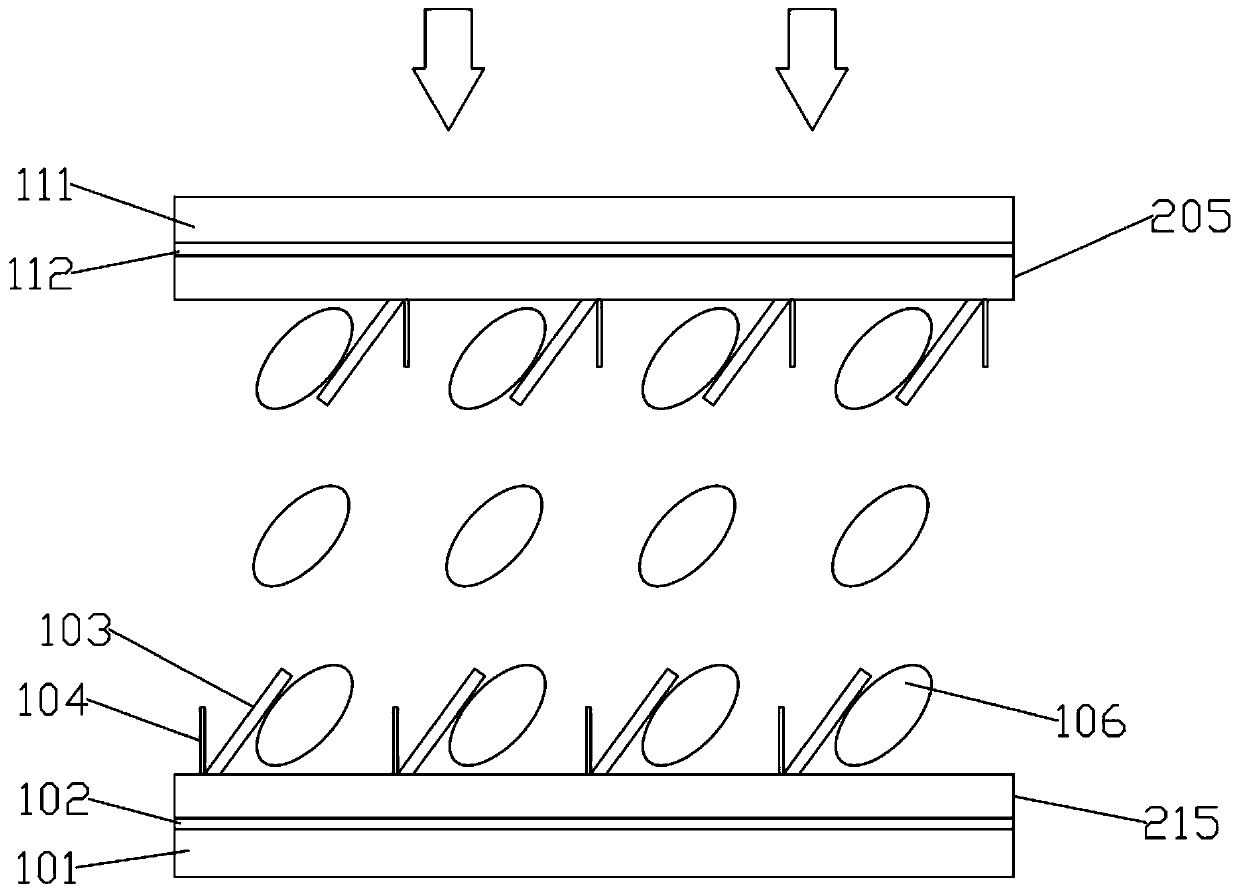

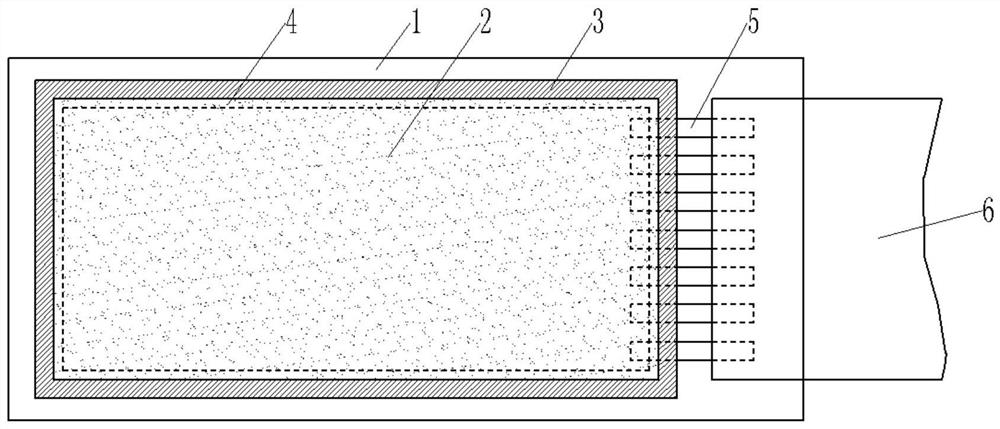

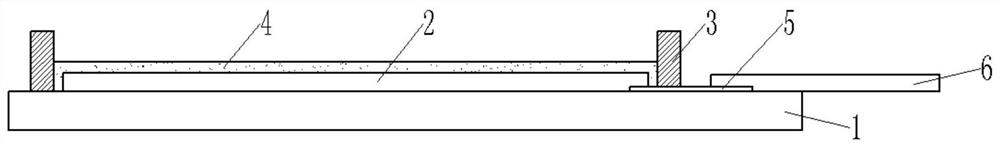

Liquid crystal display panel and manufacturing method thereof

ActiveCN110794619ADoes not affect formationImprove stabilityNon-linear opticsCrystallographyPhoto irradiation

Embodiments of the present invention disclose a liquid crystal display panel and a manufacturing method thereof. The liquid crystal display panel comprises: a first substrate, wherein a first alignment film is disposed on a surface; a second substrate, wherein the second substrate is disposed opposite to the first substrate, and a second alignment film is disposed on a surface of the second substrate; and a liquid crystal layer, wherein the liquid crystal layer is disposed between the first alignment layer and the second alignment layer, and the liquid crystal layer comprises liquid crystal molecules, a reactive monomer and a photo-curing material. According to the embodiments of the present invention, the photo-curing material is added, and a curing reaction may occur by irradiating UV light of a particular wavelength on photo-curing molecules, to form a solidified layer and a fixed side chain, so that side chain robustness is improved, tilt angle stability is enhanced, and black-level mura generation in a dark state is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

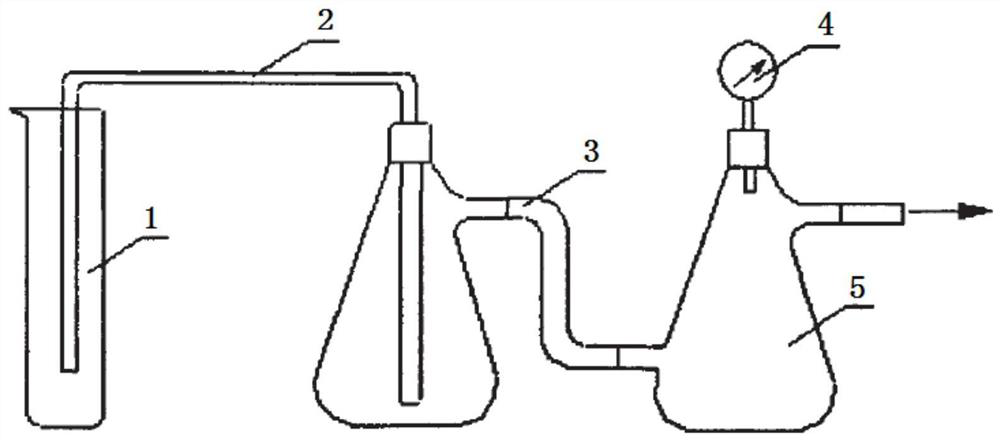

Environment-friendly process for preparing carbon black by utilizing tar

ActiveCN104629497ADoes not affect formationReduce pollutantsPigmenting treatmentDispersed particle separationTarChemistry

The invention relates to an environment-friendly process for preparing carbon black by utilizing tar, and relates to a tail gas denitrification process in a carbon black production process. The tail gas denitrification process needs to utilize a reaction device, a preheating device and a granulating device; the reaction device comprises a reaction furnace, a venturi, a reaction chamber and a cooling section; the preheating device comprises an air preheater and an oil preheater; and the granulating device comprises a carbon black grading device, the granulating device and a drying device. The tail gas denitrification process mainly comprises four steps of feed gas pyrolysis, carbon black smoke gas high-temperature denitrification, preheating of high-temperature carbon black smoke gas on air and an oil material, carbon black smoke gas separation and carbon black granulation respectively. Compared with the prior art, the tail gas denitrification process disclosed by the invention can perform denitrification treatment on the carbon black smoke gas at the manufacturing stage of the carbon black, is free of influencing the formation of the carbon black and can be used for transforming nitrogen oxide contained in a tail gas into nitrogen and decreasing the pollutants contained in the tail gas.

Owner:NINGBO DETAI CHEM

Thermosetting foam profile control agent and application thereof

ActiveCN111826143APerformance is not affectedDoes not affect formationDrilling compositionSealing/packingPhenolformaldehyde foamPolymer science

The invention discloses a thermosetting foam profile control agent and application thereof. The thermosetting foam profile control agent comprises a foam fixing agent, a curing agent and a foaming agent, wherein the foam fixing agent is a resin prepolymer, and the curing agent is water-soluble temperature control decomposition type slow-release acid. According to the invention, by researching anddeveloping water-soluble temperature-controlled decomposition slow-release acid and a temperature-resistant foaming agent, an underground cross-linked thermosetting phenolic foam plastic (wet method)meeting a thick oil thermal recovery plugging control construction process is modified and researched; a low-molecular resin prepolymer and a curing agent stably exist in a foam liquid film, so that the foaming volume and the half-life period are not influenced; and a curing agent is decomposed to generate an acid at a high temperature, hydrophilic resin hydroxymethyl bonds are catalyzed to be subjected to condensation polymerization to form hydrophobic resin methylene bonds, free water bound by a space net structure and coated with a liquid film is formed, and the foam liquid film is converted into a thermosetting resin hard shell, so that the influence of high temperature, stratum pore size and injected water dilution scouring on foam plugging strength, heat stability and validity periodis avoided.

Owner:PETROCHINA CO LTD

Silicon carbide high temperature vibration sensor with high sensitivity, high frequency response and anti-overload

ActiveCN109764954AHigh sensitivityAnti-overloadSubsonic/sonic/ultrasonic wave measurementUsing electrical meansCantileverHigh frequency

The invention discloses a silicon carbide high temperature vibration sensor with high sensitivity, high frequency response, and anti-overload. The silicon carbide high temperature vibration sensor comprises a silicon carbide chip, a silicon carbide bonding sheet, an insulation layer, a packaging shell, and a kovar pin; the silicon carbide chip comprises a supporting sheet body, a cantilever beam,and a mass block; the supporting sheet body and the silicon carbide bonding sheet form a bonding body; the mass block and the cantilever beam are arranged insidea cavity of the bondingbody, and the cantilever beam is provided with a chip circuit; and the kovar pin extends into a bonding material along through holes arranged on the package shell, the insulation layer and the silicon carbide bondingsheet, and is connected with the chip circuit. The high temperature vibration sensorhas the characteristics of high sensitivity, high frequency response and anti-overload, and the accurate and timelymeasurement of vibration signals in the high temperature environment can be realized.

Owner:XI AN JIAOTONG UNIV

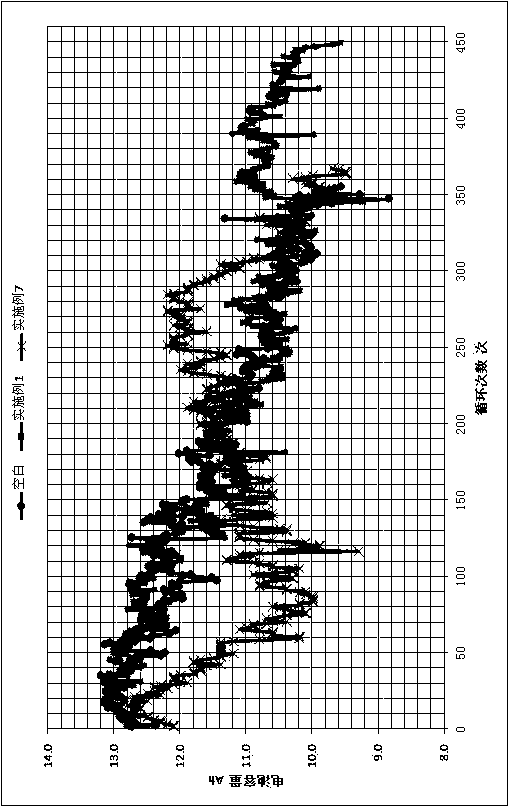

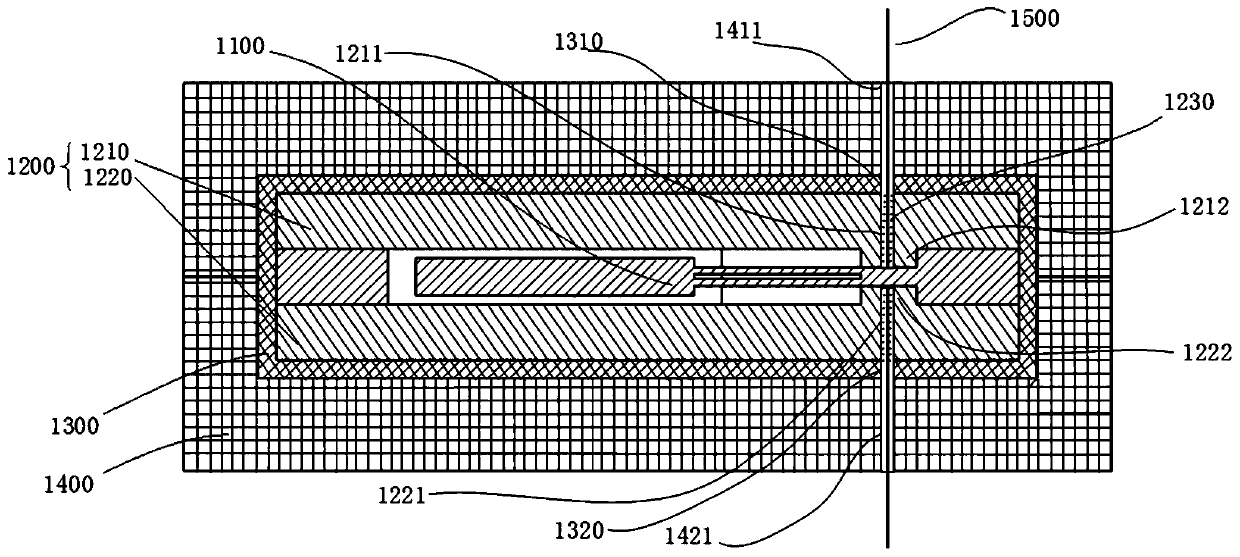

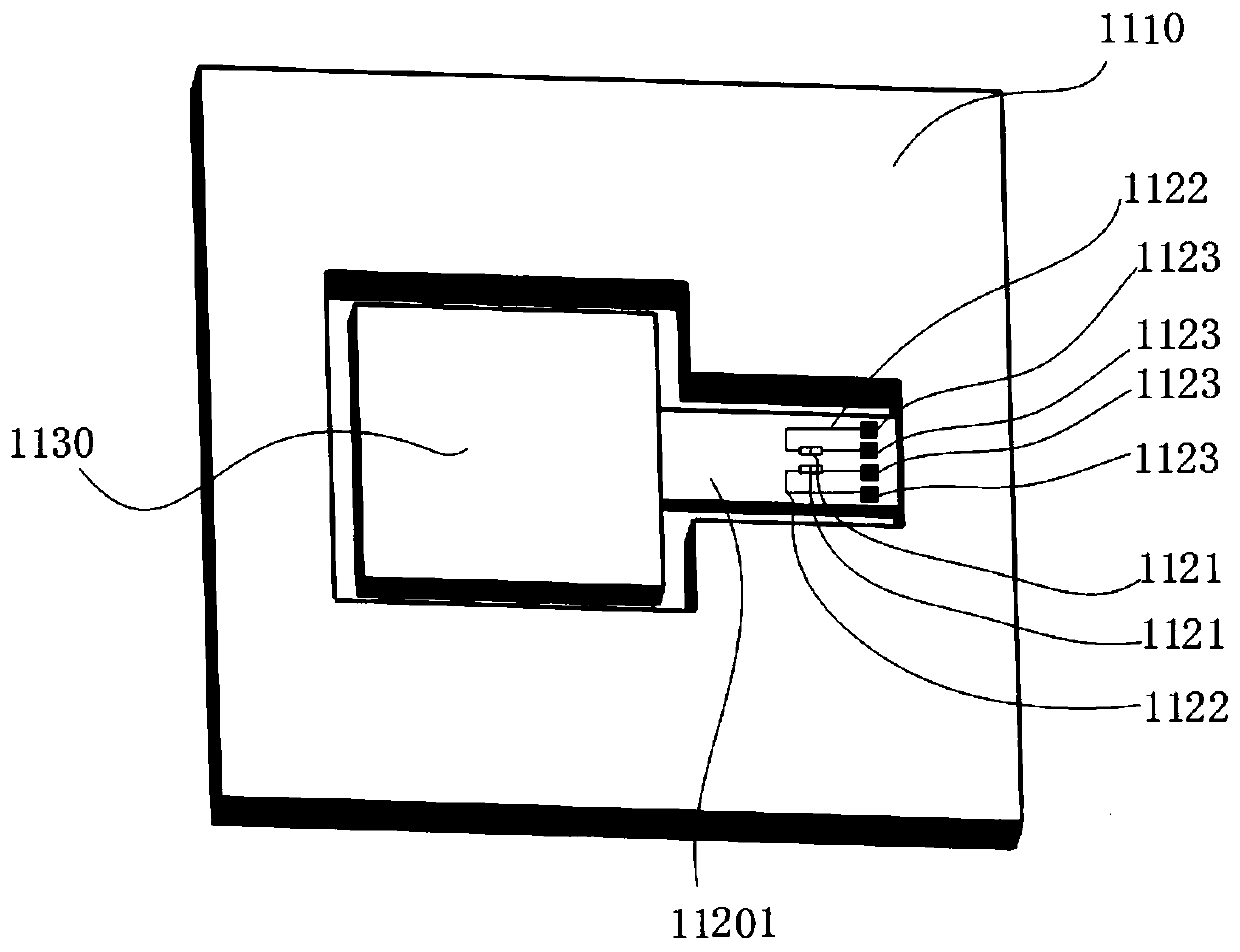

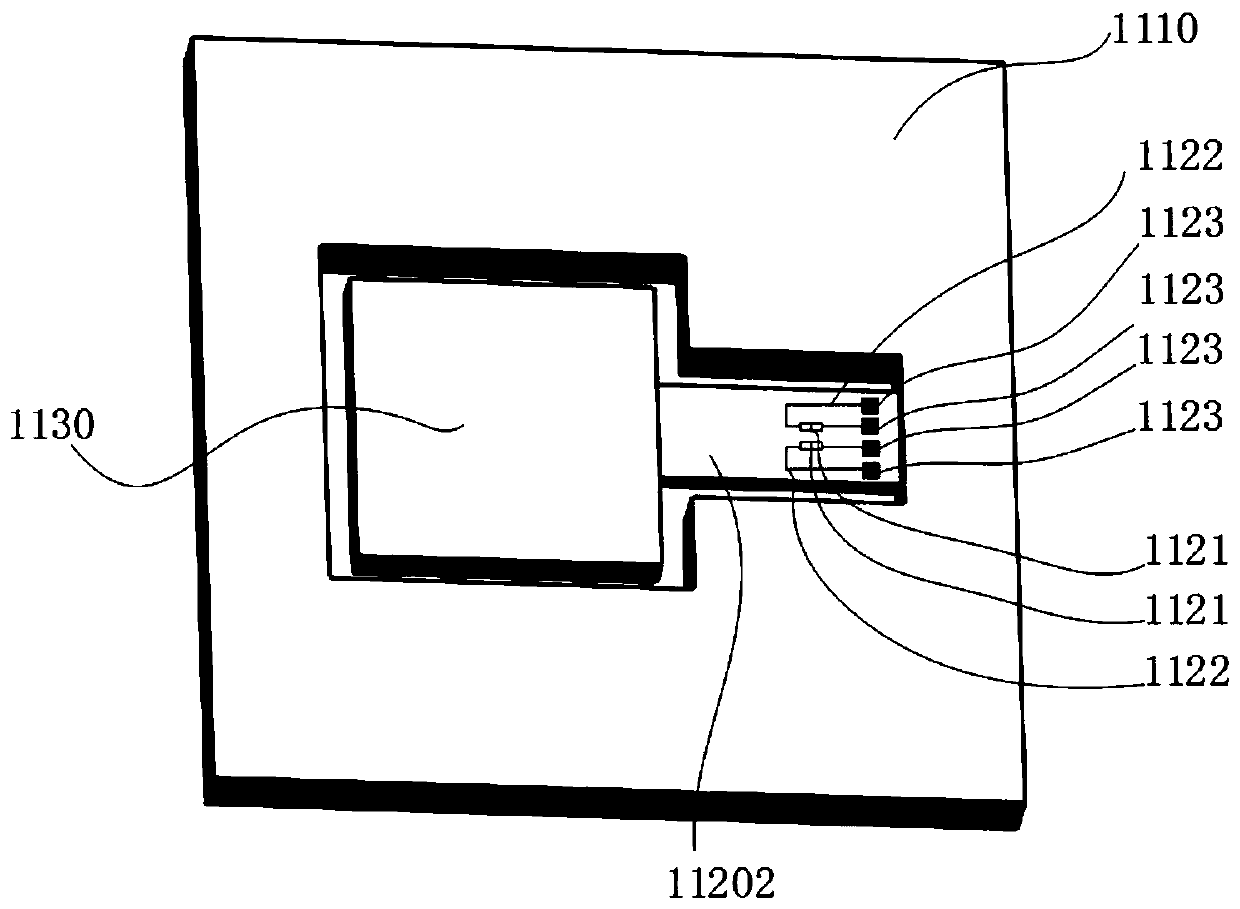

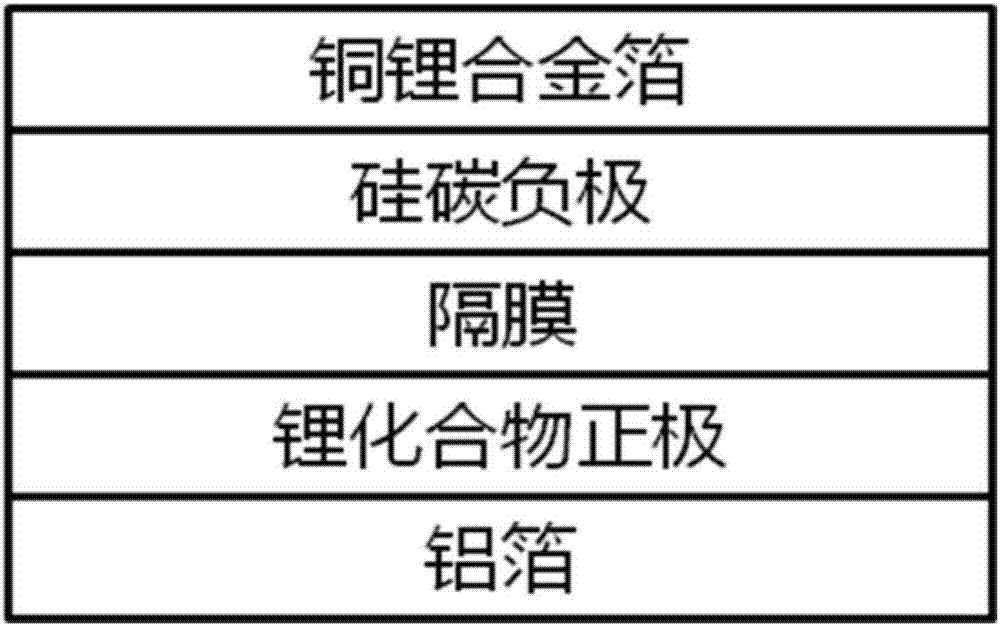

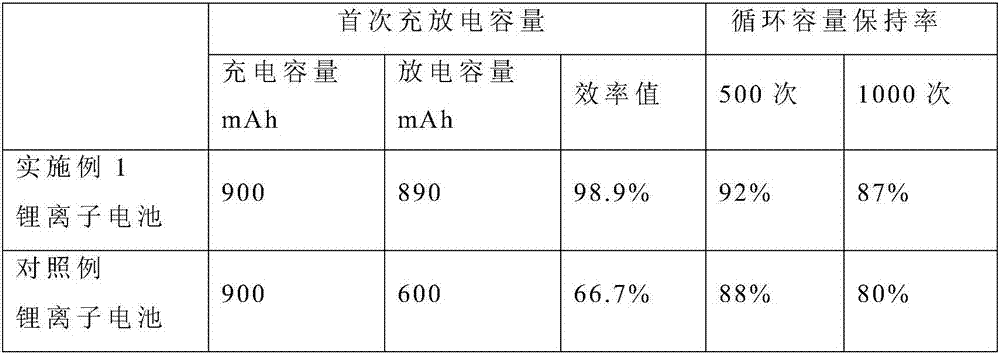

Lithium ion battery and preparation method thereof

InactiveCN107069041ARestore original capacityImprove charge and discharge efficiencyFinal product manufactureElectrode carriers/collectorsCapacity lossEngineering

The invention provides a lithium ion battery and a preparation method thereof. A negative pole piece of the battery consists of a copper-lithium alloy current collector and a silicon-carbon negative material, and the negative pole piece is assembled with a membrane and a positive pole piece to form the battery. According to the battery, the capacity loss after first circulation is avoided, the utilization rate of positive active materials is improved, and the battery has excellent circulation capacity and long service life.

Owner:SUZHOU SAIFU DEBEI TRADE CO LTD

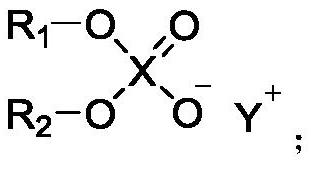

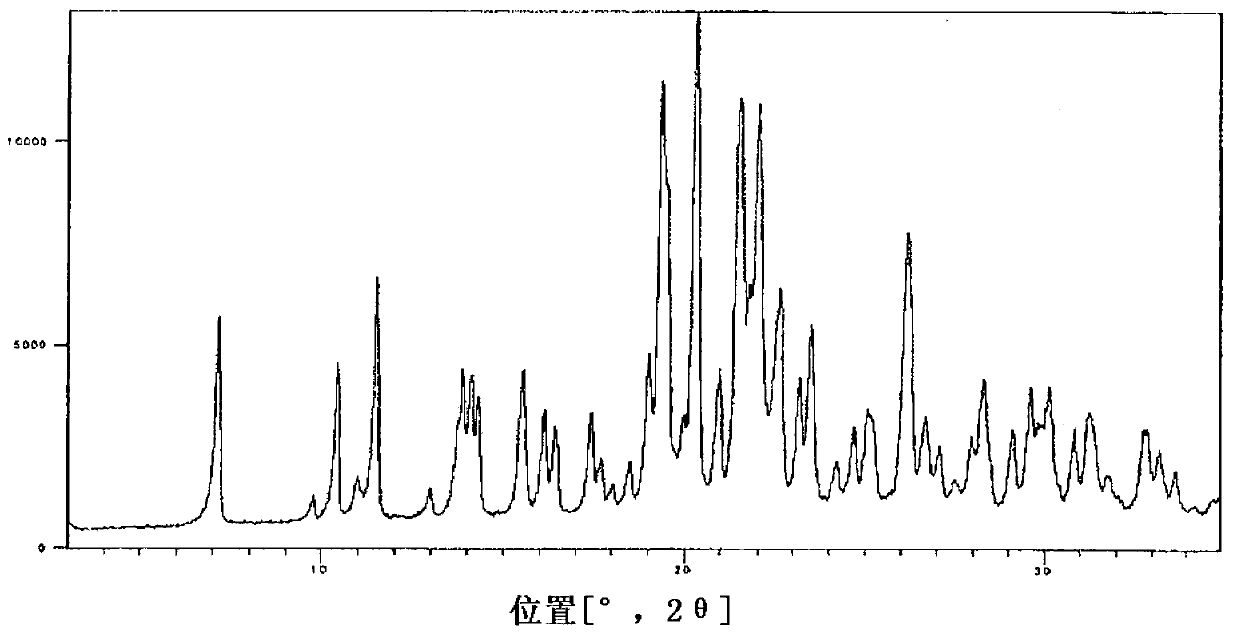

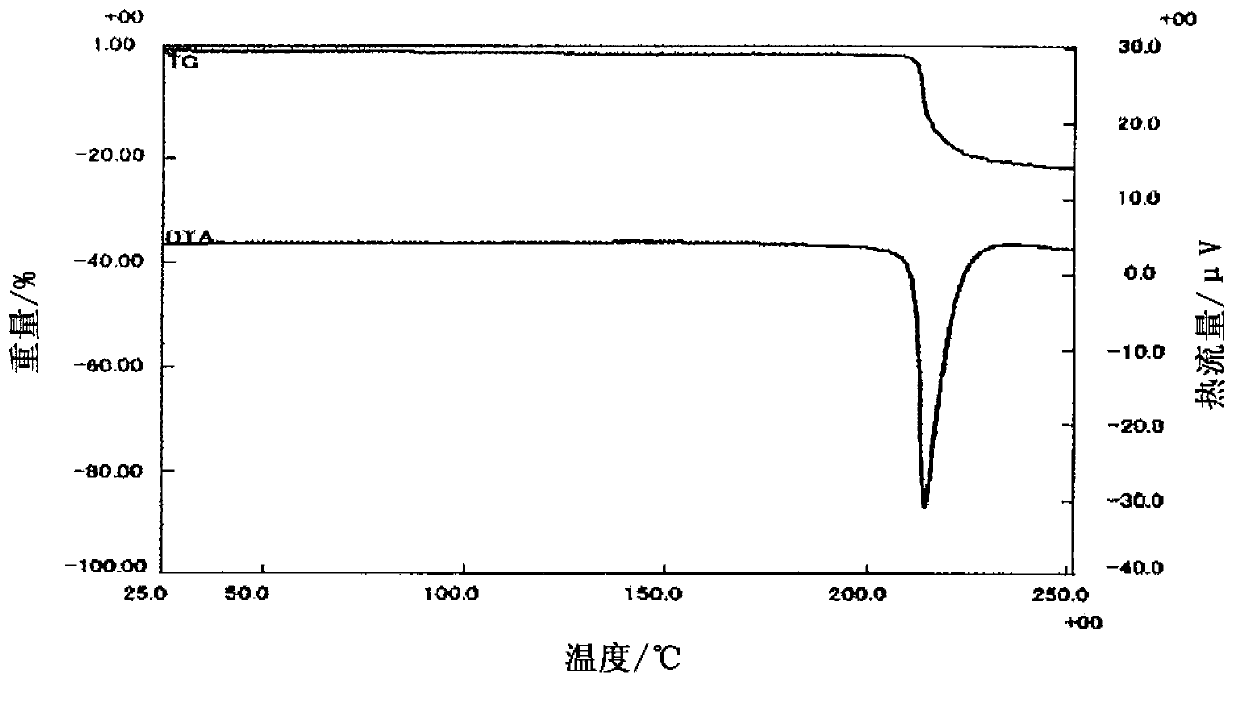

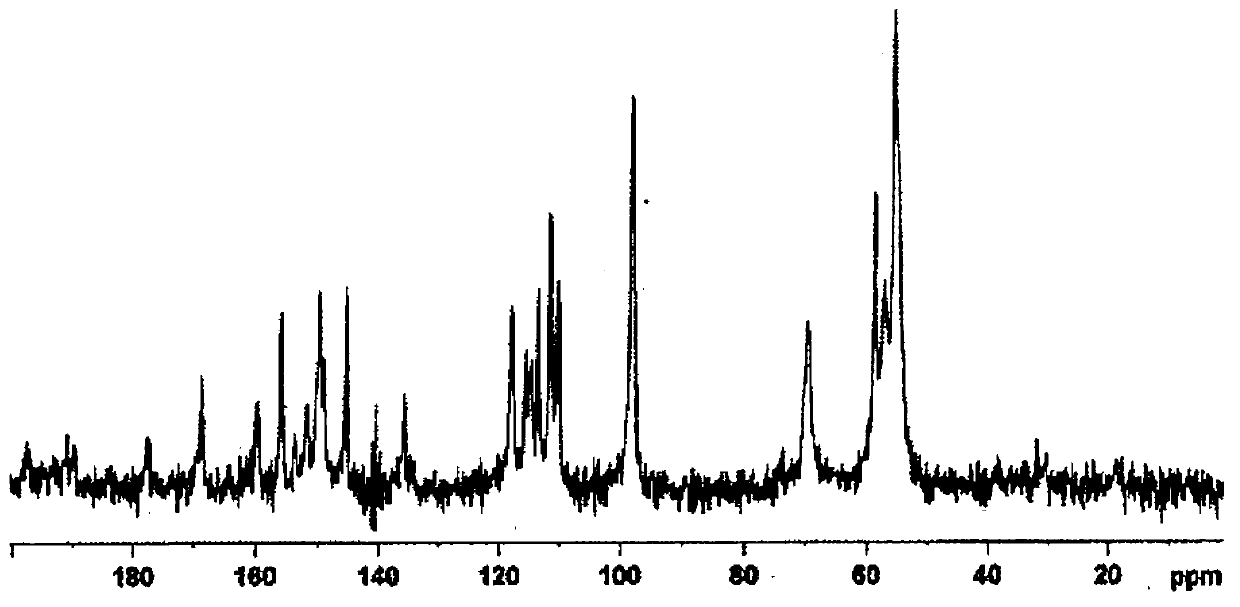

Salt of fused heterocyclic derivative and crystal thereof

ActiveCN102753557AHigh crystallinityGood storage stabilityNervous disorderOrganic chemistry methodsCarboxylic acidPerylene derivatives

Owner:KISSEI PHARMA

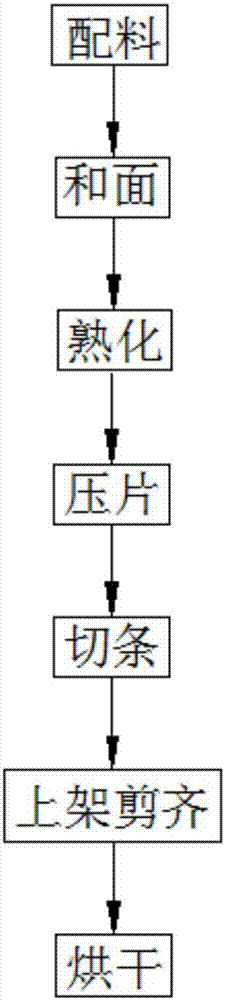

Black corn fine dried noodles and production method thereof

InactiveCN107183529ADoes not affect formationSatisfy the contentFood scienceCorn flourMixed materials

The present invention provides black corn fine dried noodles and a production method thereof, wherein the raw materials comprise, by weight, 6-10 parts of black corn powder, 2-6 parts of tapioca starch, 0.5-1.5 parts of salt, 0.05-0.15 part of sodium carbonate, and 85-89 parts of flour. Compared to the fine dried noodles in the prior art, the black corn fine dried noodles of the present invention have the following characteristics that the weight part ratio of various raw materials can meet the black corn content in the fine dried noodles, the characteristics of the wheat powder can be retained in the mixed material, and the formation of the fine dried noodles is not affected.

Owner:HUAIBEI XUYUAN FOOD CO LTD

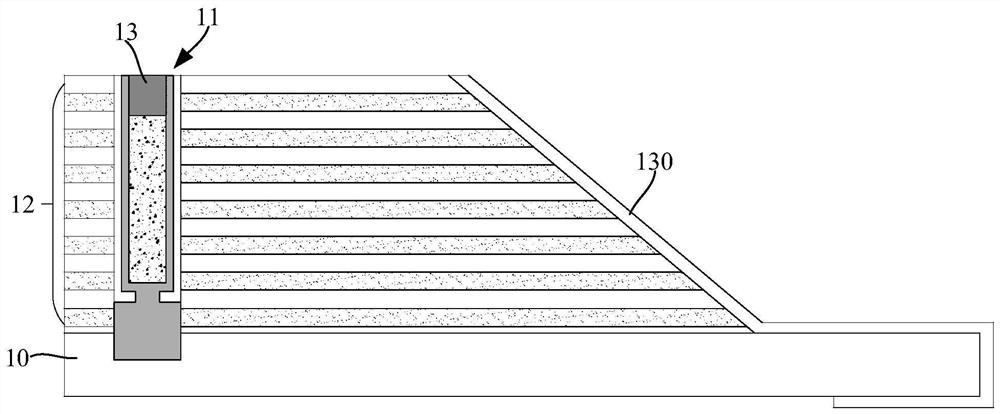

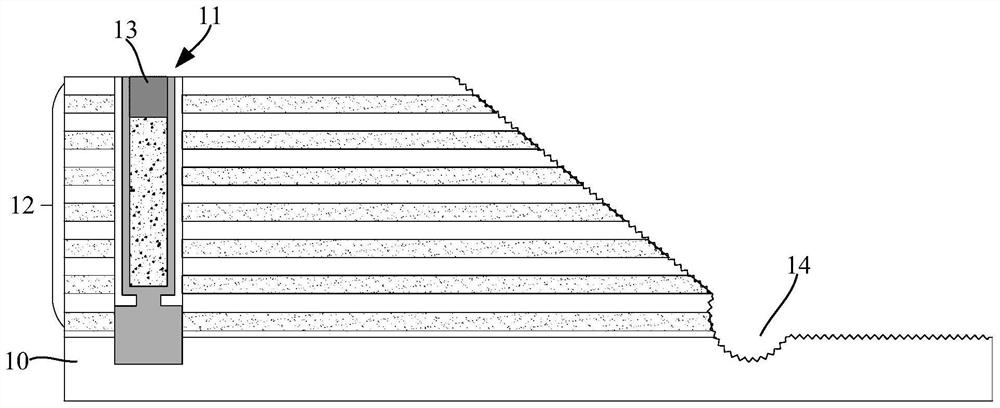

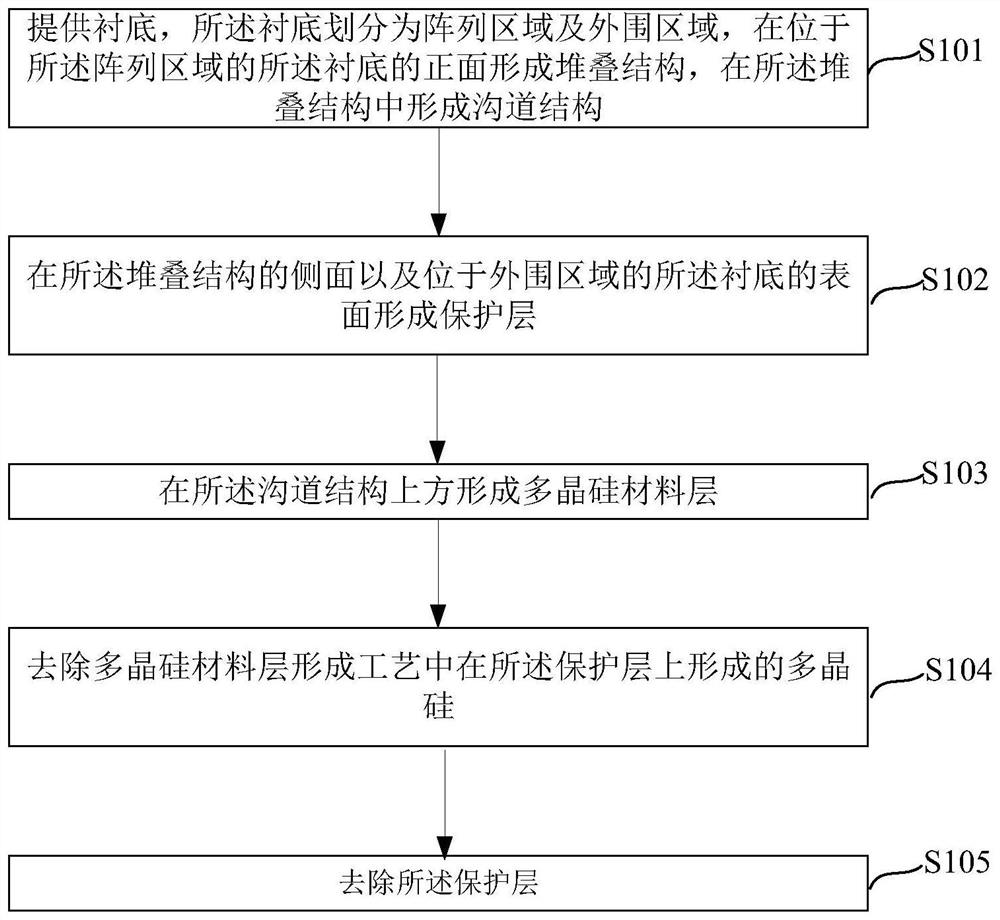

Polycrystalline silicon material filling method in semiconductor device structure and preparation method of 3D NAND memory

PendingCN112466888AImprove performanceImprove etch selectivitySolid-state devicesSemiconductor devicesDevice materialPhysical chemistry

The invention provides a filling method of a polycrystalline silicon plug material in a semiconductor device structure and a preparation method of a 3D NAND memory, and the method comprises the steps:forming a channel structure in a stacked structure of an array region of a substrate, and then forming a protection layer on the side wall of the stacked structure and the surface of the substrate located in a peripheral region, wherein the protective layer has a sufficiently high etch selectivity ratio relative to polysilicon, for example, may be a carbon thin film; and forming a trench at the top of the channel structure and depositing polycrystalline silicon. When redundant polycrystalline silicon is removed, due to the fact that the etching selection ratio of the protective layer to the polycrystalline silicon is high enough, the stacked structure and the substrate cannot be etched, the defect that substrate grooves are formed in the cross section of the stacked structure and the cross section of the substrate is overcome, and the performance of the device can be improved. And the protective layer is removed through ashing treatment, so that no by-product residue exists, and meanwhile, the substrate is not damaged. The preparation method of the 3D NAND memory also adopts the method to form the polycrystalline silicon plug, so that the 3D NAND memory also has the above beneficial effects.

Owner:YANGTZE MEMORY TECH CO LTD

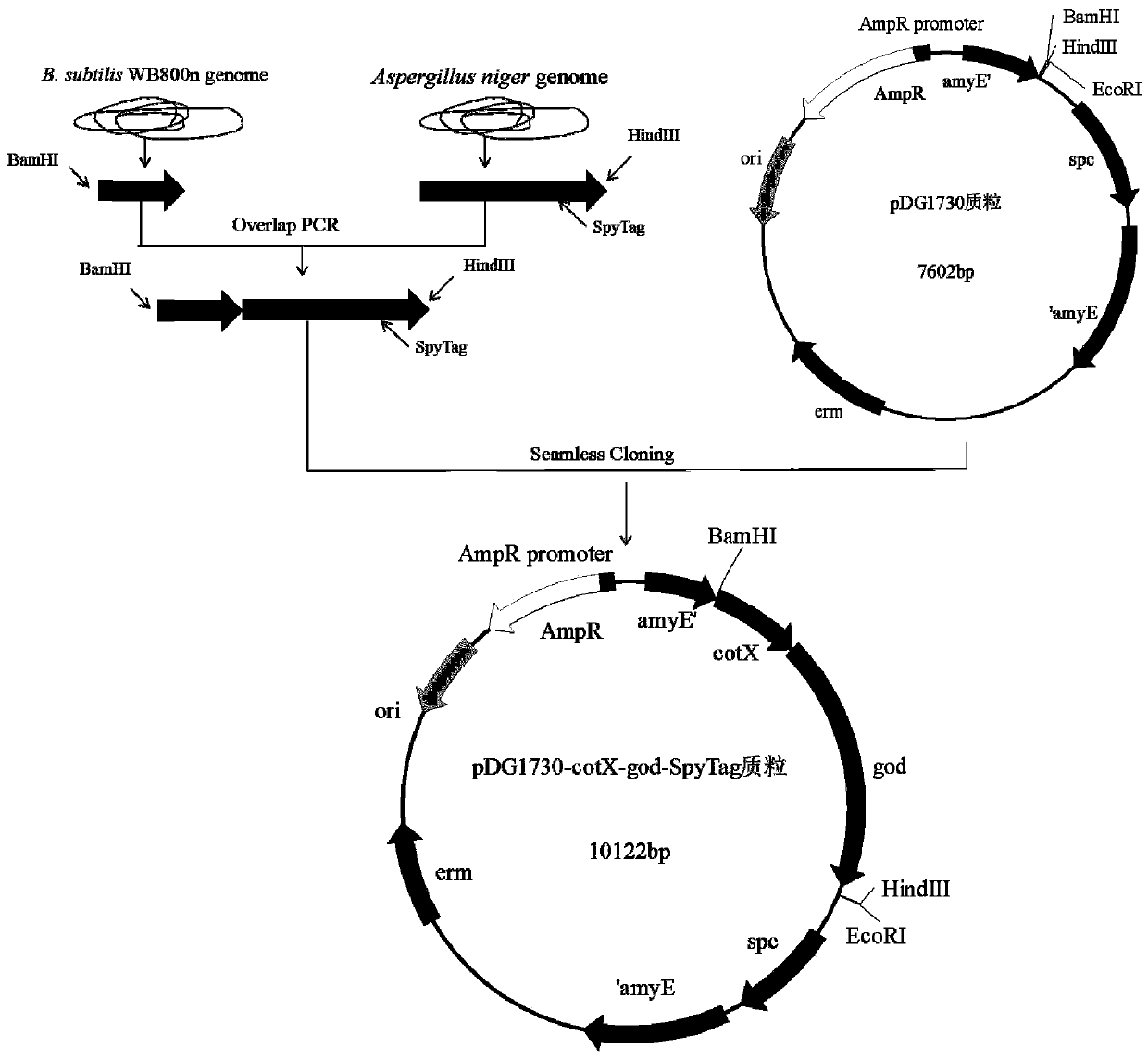

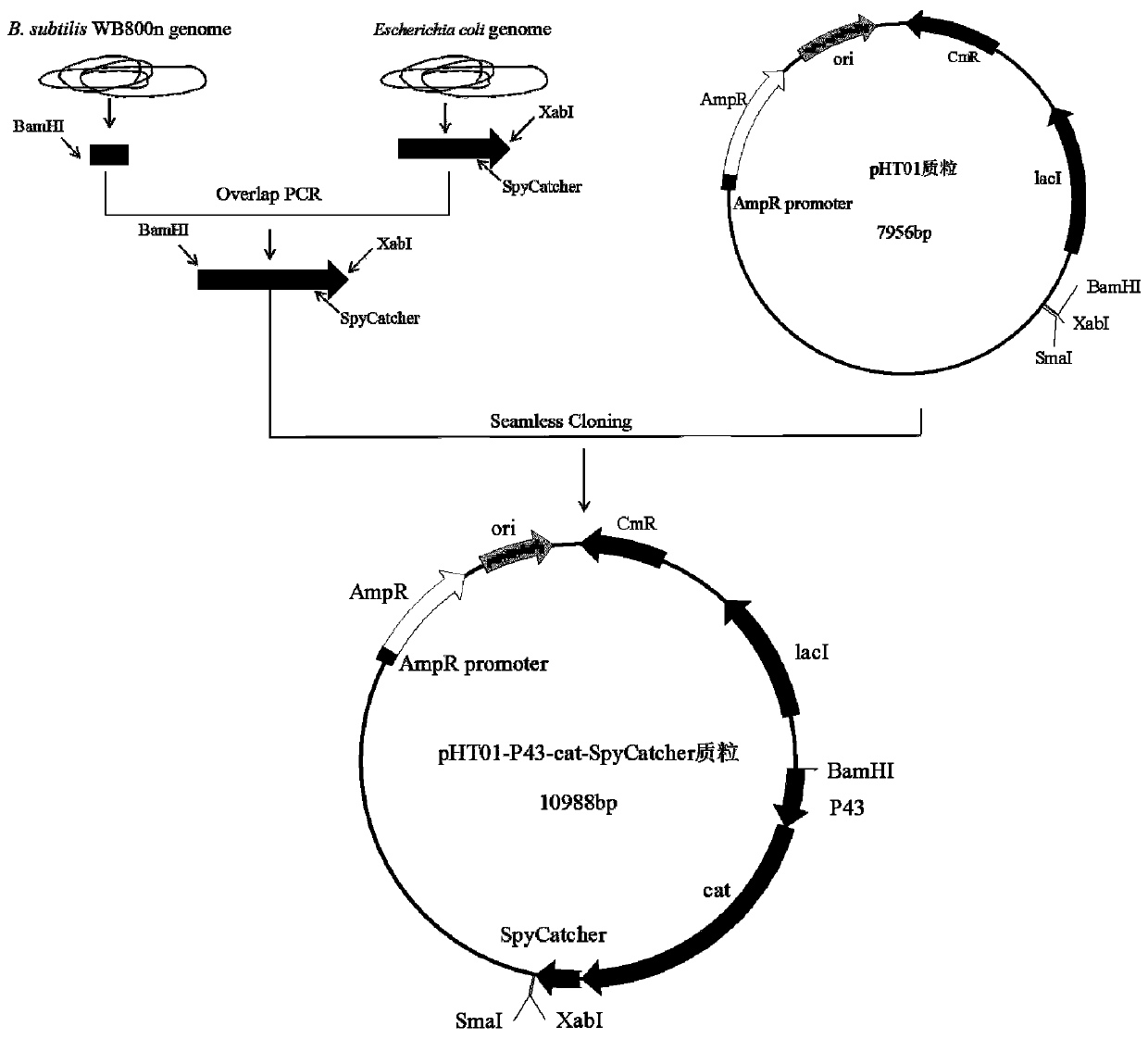

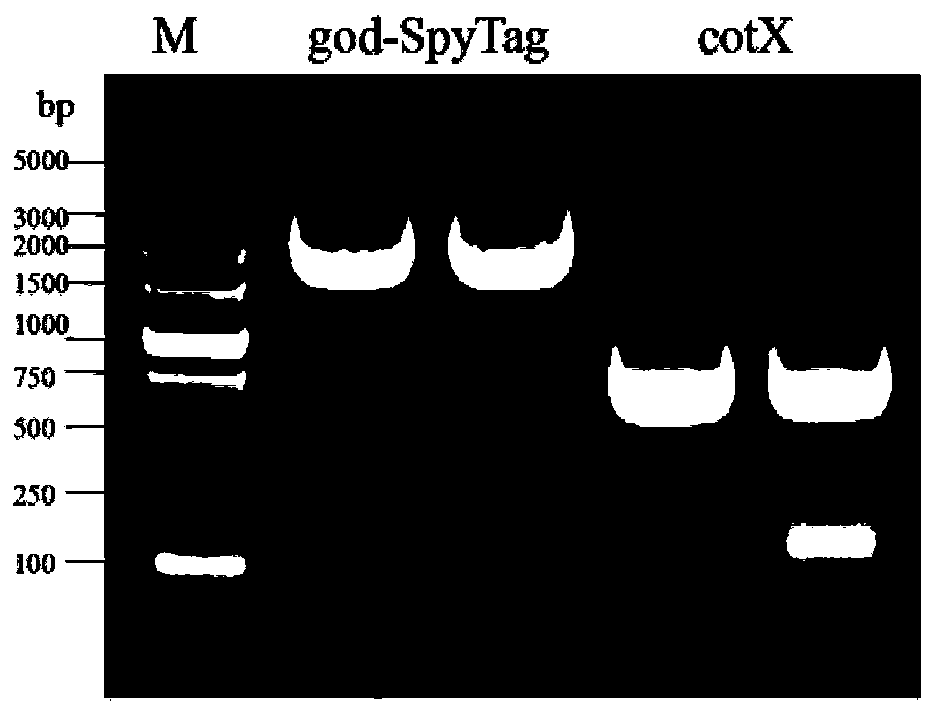

Engineering strain for co-displaying glucose oxidase and catalase on spore surface and application of engineering strain

ActiveCN110499273AChanges in enzymatic propertiesWide temperatureBacteriaMicroorganism based processesSporeCompetent cell

The invention relates to an engineering strain for co-displaying glucose oxidase and catalase on spore surface and application of the engineering strain. According to an engineering strain of bacillussubtilis, a prepared fusion gene fragment cotX-god-SpyTag is transformed into bacillus subtilis WB800n, recombinant bacillus subtilis WB800n-cotX-god-SpyTag is obtained, then a fusion gene fragment P43-cat-SpyCatcheris electro-transformed into recombinant bacillus subtilis WB800n-cotX-god-SpyTag competent cells; and namely the engineering strain is obtained. The experiment shows that the interaction peptide has no effect on the glucose oxidase and the catalase linked by SpyTag / SpyCatcher, and the enzymatic properties of the expressed glucose oxidase and the catalase are obviously changed, theadaptive range of the temperature and pH is wide, and the temperature and acid resistant properties are improved.

Owner:QILU UNIV OF TECH

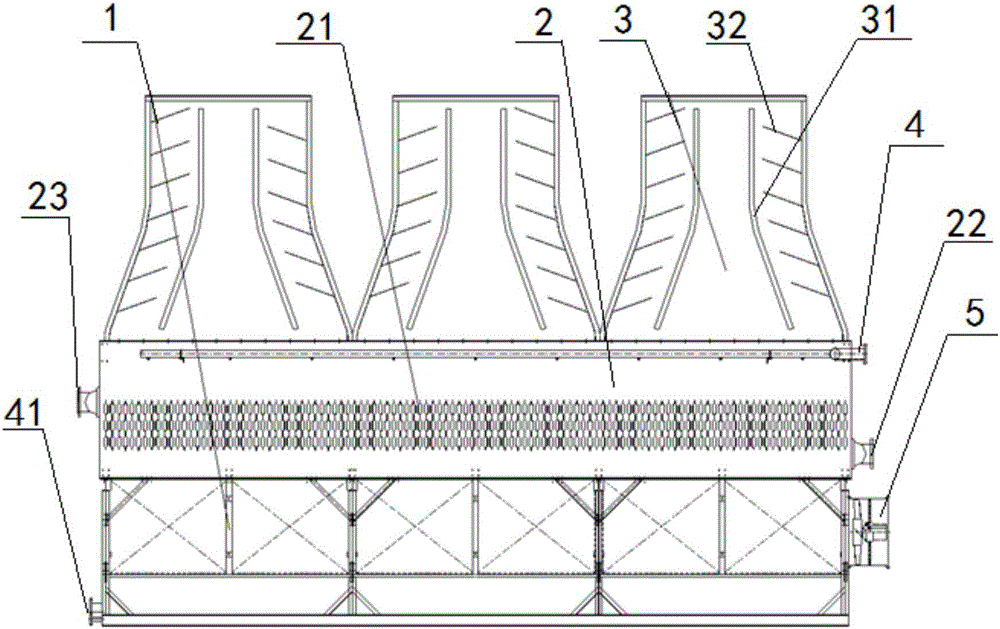

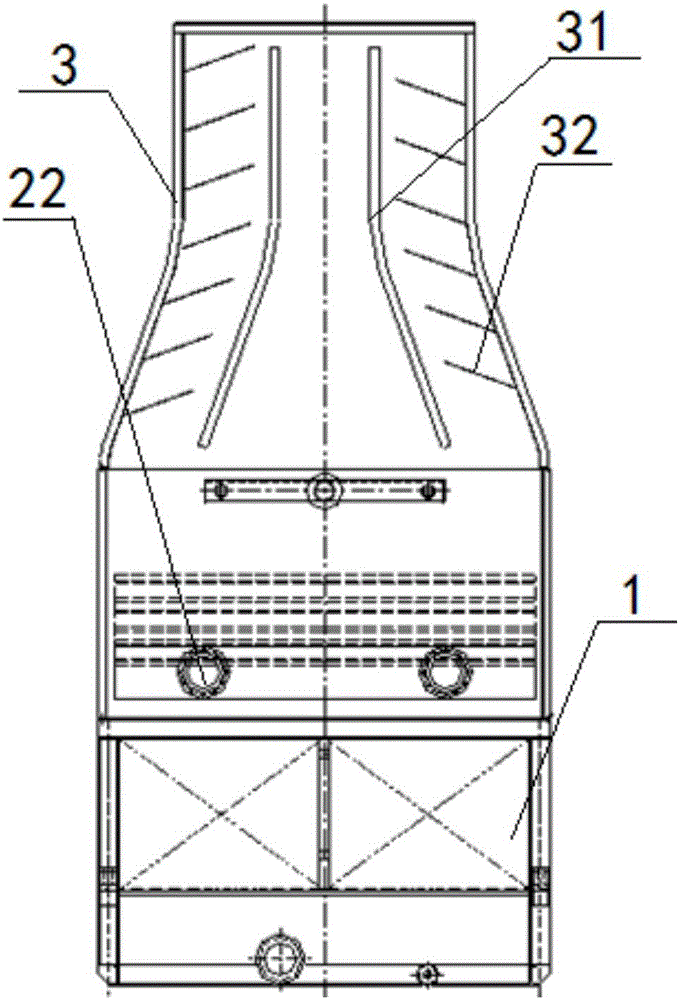

Shell-and-plate blast furnace evaporation air cooling system using soft water closed recirculation cooling system and plate scale treatment method thereof

ActiveCN106403652AReduce water consumptionReduce the total installed capacityEnergy industryStationary conduit assembliesCooling towerCooling effect

The invention discloses a shell-and-plate blast furnace evaporation air cooling system using a soft water closed recirculation cooling system and a plate scale treatment method thereof and belongs to the technical field of blast furnace iron making production. The shell-and-plate blast furnace vaporation air cooling system using the soft water closed recirculation cooling system comprises a base, a shell body which is over the base and is fixedly connected with the base, a cooling plate set which is a vertical layered layout is arranged in the shell body in a fixation mode, and induced air cooling towers which are connected with the shell body in a fixation mode and right above the shell body. Through replacing an induced air motor with an air suction function with the induced air cooling towers, installed gross and production running cost are lowered, there is no need to frequently change and maintain a soggy and fragile fan motor, and the induced air cooling towers are capable of being at a normal working state for a long time and saves electric energy and water consumption of refrigerant water. Physical descaling can be conducted periodically in the whole operational process of the system through the plate scale treatment method, and also thorough descaling can be conducted in a stopping process. The induced air cooling towers are flexible and mobile and through in treatment effect. The heat exchange and cooling effects of the whole system are improved, and the continuous working period and service life are prolonged.

Owner:安徽马钢输送设备制造有限公司

High-strength foamed ceramic and preparation method thereof

The invention discloses a high-strength foamed ceramic and a preparation method thereof, and the preparation method comprises the following steps: (1) preparing a foamed ceramic raw material and an auxiliary agent into slurry, and drying to prepare powder; in the auxiliary agent, silicon carbide is used as a foaming agent, chromic oxide and / or a substance containing chromic oxide are / is used as a nucleating agent, and inorganic chopped fibers are used as a reinforcing agent; (2) putting the powder into a mold, and sintering; and (3) after firing, cooling and demolding to obtain the high-strength foamed ceramic. According to the preparation method, Cr2O3 is adopted as a nucleation agent and is cooled to a crystallization temperature point for heat preservation, so that a glass phase in a matrix is promoted to form high-strength mullite and quartz crystals, the strength of the matrix is improved, formation and growth of pores in a melt at a high temperature are not affected, and the prepared foamed ceramic has a good pore structure and excellent mechanical properties.

Owner:WUHAN UNIV OF TECH

Photocurable/thermosetting inkjet composition, and printed wiring board using same

ActiveCN103403106AImprove heat resistanceGood chemical resistanceDuplicating/marking methodsInksInsulation layerGlycylxylidide

Provided is a photocurable / thermosetting inkjet composition characterized in comprising: a monomer having a (meth)acryloyl group and a glycidyl group in the molecule thereof, and having a viscosity of 10 mPa°s or less at 25°C; a trifunctional or higher acrylate monomer; a heat-curing catalyst; and a photopolymerization initiator. Also provided is a photocurable / thermosetting inkjet composition obtained by including titanium oxide in the composition described above, and characterized in being used to draw a pattern on a resin insulation layer formed on a printed wiring board.

Owner:TAIYO INK MFG

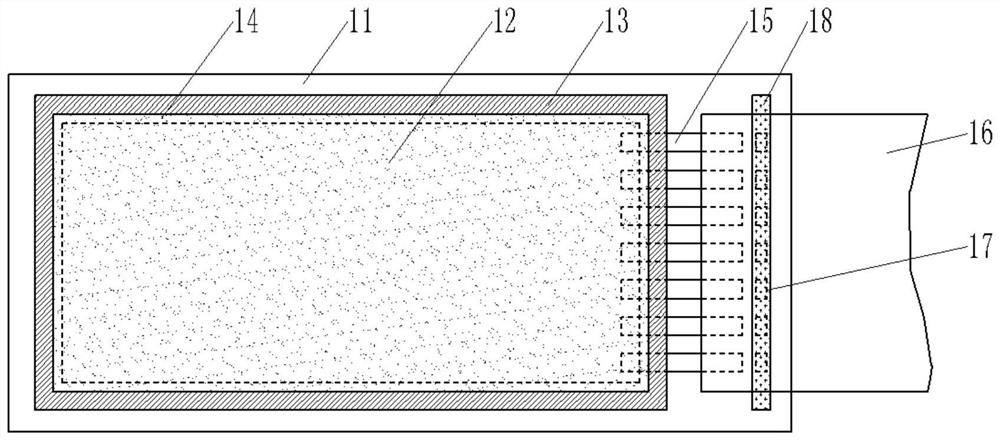

Display device

InactiveCN111987132AGuaranteed joint forceDoes not affect formationSemiconductor/solid-state device detailsSolid-state devicesPhysicsThin membrane

The invention provides a display device, which utilizes a pressing wall arranged in a non-display area to penetrate through a plurality of openings of a chip on film to ensure the bonding force between the chip on film and a substrate as well as between the chip on film and a driving electrode. The display device has a simple structure, and does not influence the formation of an encapsulation layer in a display area. Furthermore, in other embodiments, the wall pressing structure can be replaced by the side walls of a cofferdam, the structure can be simplified, and materials can be saved.

Owner:山东傲晟智能科技有限公司

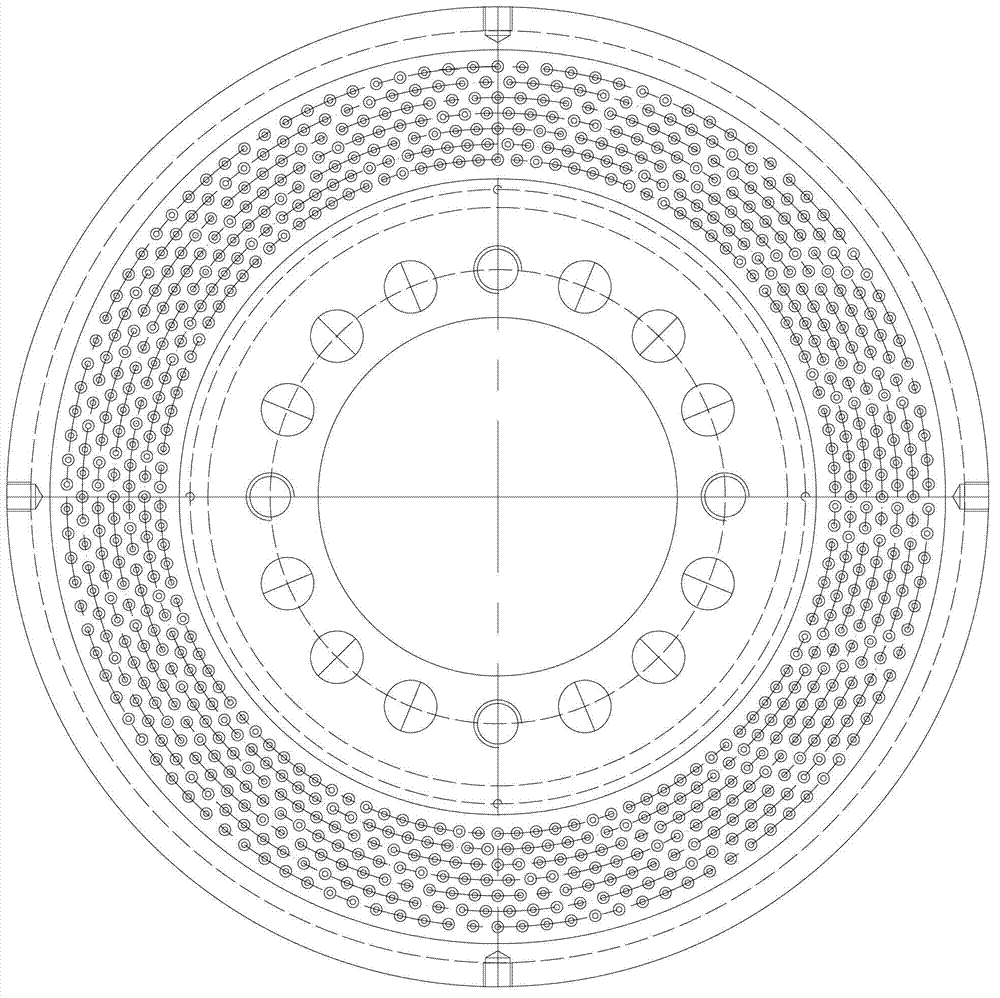

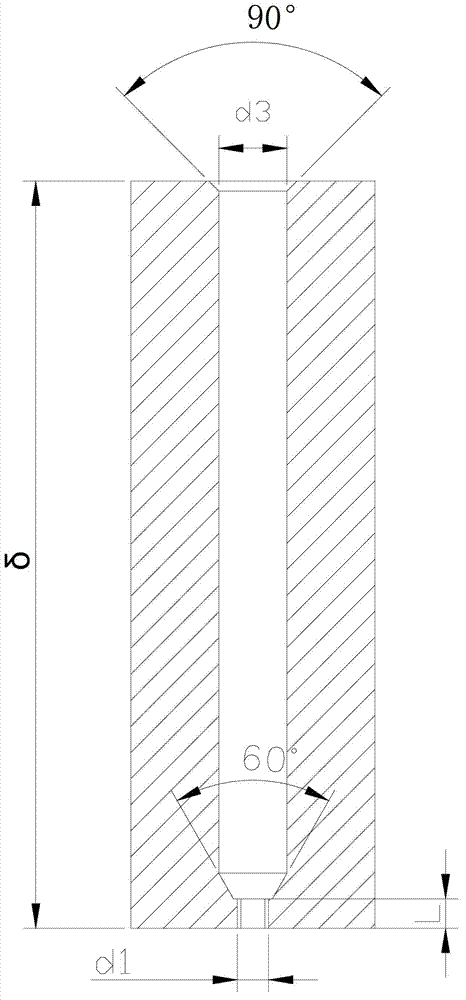

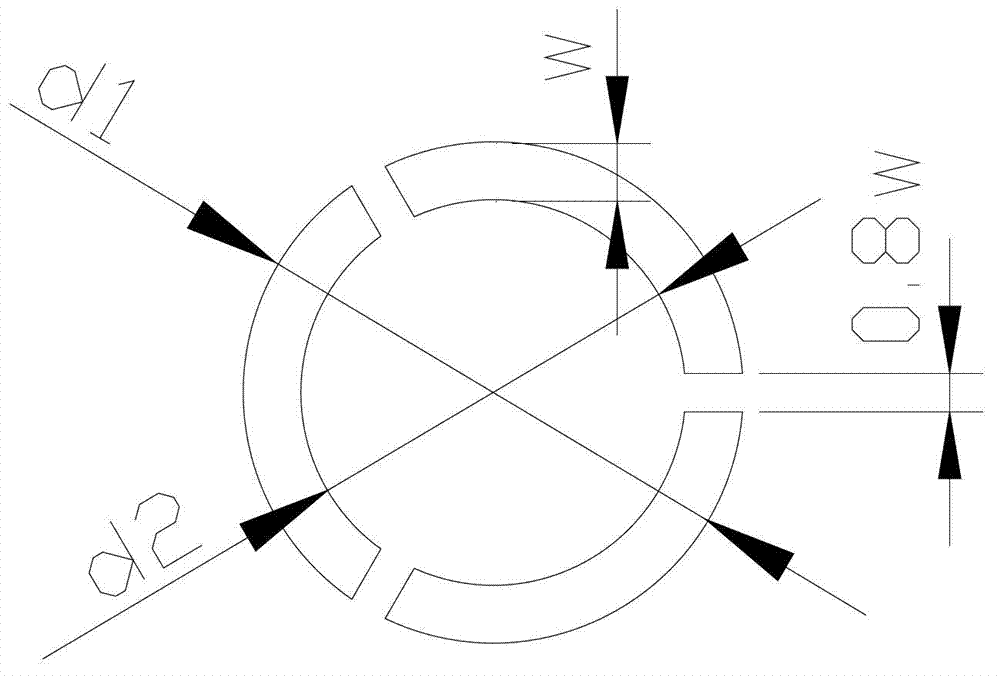

High-viscosity melt spinning spinneret plate

InactiveCN102926004AGuaranteed spinnabilityGood compatibilityHollow filament manufactureEngineeringMelt spinning

The invention relates to a spinneret plate and particularly relates to a high-viscosity polyester melt spinning spinneret plate with the intrinsic viscosity ranging between 0.74dL / g-0.78dL / g. The overall shape of the spinneret plate is in a cylindrical shape, a plurality of spinneret orifices are arranged evenly on the spinneret plate in a circular mode, each of the spinneret orifice comprises a guide hole and a micro hole, the guide hole is connected with the micro hole, the shape of a cross section of the micro hole is a circular ring with three openings, the three openings are distributed on the circular ring evenly, the outer diameter d1of the circular ring ranges between 2.25mm and 2.45mm, the inner diameter d2 ranges between 1.5mm and 2.0mm, the width of the openings is 0.70-0.90 time of the width w of the circular ring, the length L of the micro hole ranges between 1.5mm and 2.0mm, the diameter d3 of the guide hole ranges between 4.0mm and 5.5mm, and the thickness Delta of the spinneret plate ranges between 35mm and 40mm. The spinneret plate has the advantages that coarse denier three-dimensional crimp polyester produced by the spinneret plate is low in spinning speed, good in spinnability, high in filling power, sufficient in stiffness and good in compression elasticity.

Owner:NINGBO DAFA CHEM FIBER

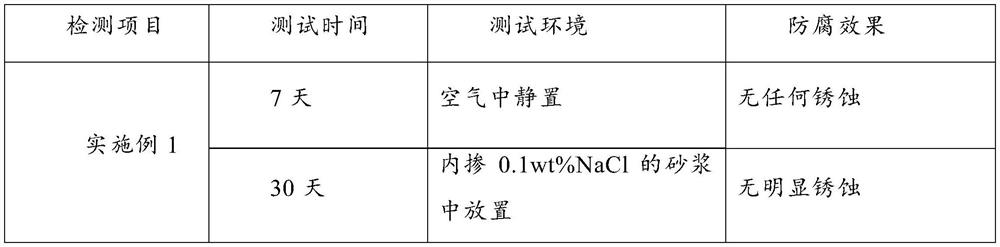

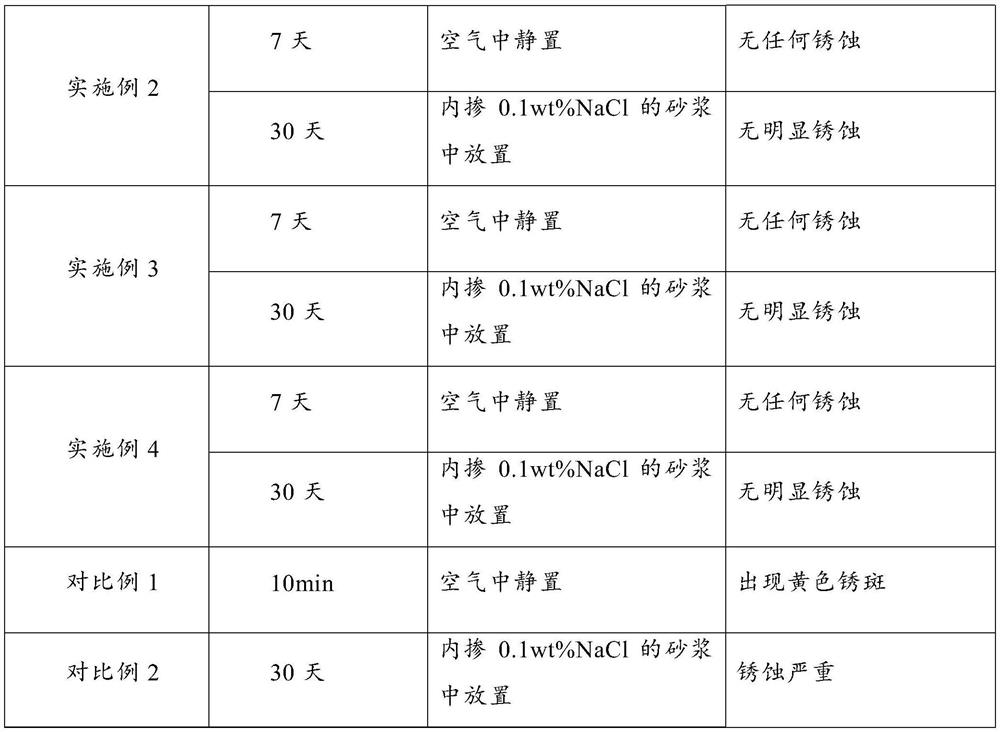

Graphene enhanced phytic acid-based passivator, preparation method and application

ActiveCN113265651AImprove crack resistanceImprove compactnessMetallic material coating processesPhytic acidZinc nitrate

The invention belongs to the field of marine reinforced concrete engineering corrosion inhibitors, and particularly relates to a graphene reinforced phytic acid-based passivator, a preparation method and an application. The passivator is an alkaline aqueous solution and is prepared from the following components in percentage by mass: 0.1 to 1.0 percent of phytic acid, 0.1 to 0.5 percent of zinc nitrate and 0.05 to 0.1 percent of amination modified graphene. According to the invention, by compounding a modified graphene material and a phytic acid material, amination modification is performed on active sites of the graphene material, so that the bonding capacity between graphene and phytic acid heteroatom groups is enhanced, and based on a layer-by-layer self-assembly reaction among a chelating agent, a nano functional structure material and a metal matrix, a graphene / phytic acid composite chemical conversion film with a spatial three-dimensional structure is constructed, so that steel bar passivation is achieved, and meanwhile, no crack and long-term corrosion resistance of the film layer are achieved, and the service life of a reinforced concrete structure is greatly prolonged.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

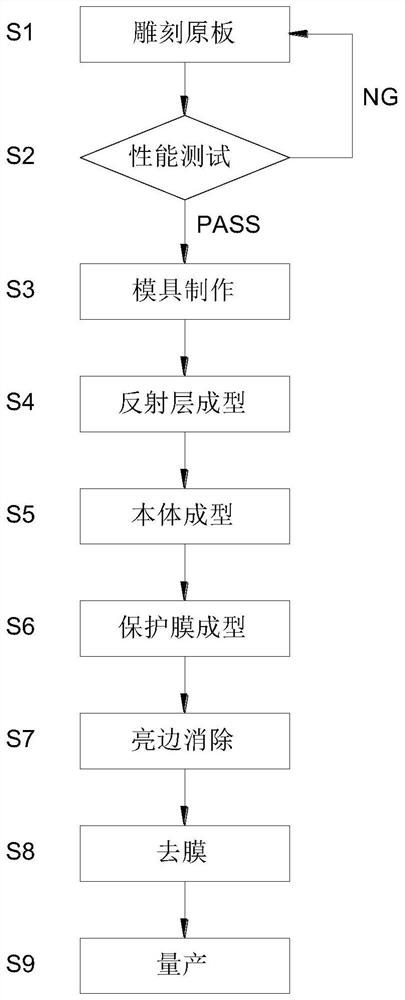

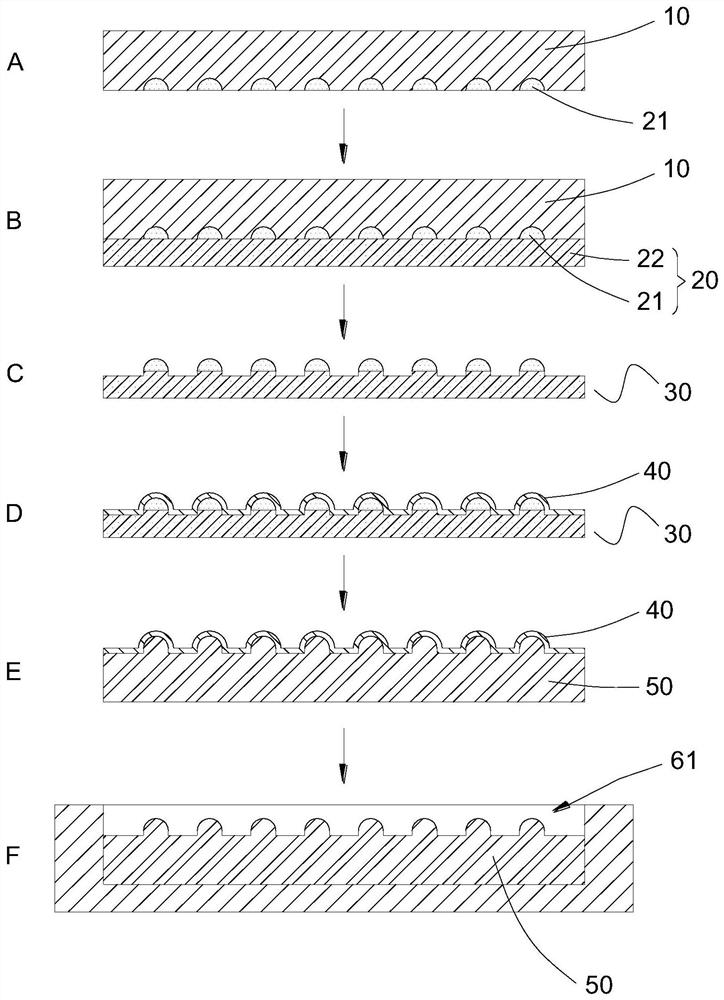

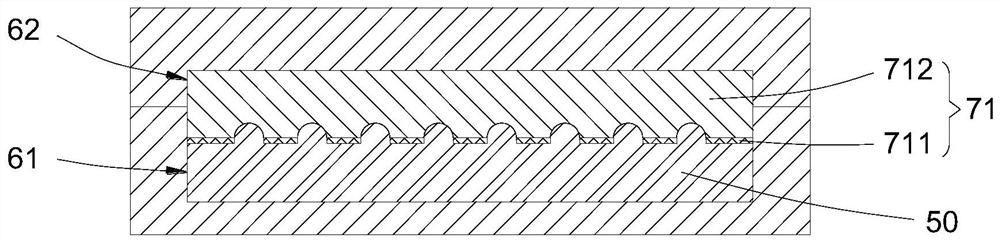

Light guide plate forming production method

ActiveCN112406002AGuaranteed accuracyImprove consistencyOptical articlesCoatingsCorrosionEngineering

The invention provides a light guide plate forming production method. The light guide plate forming production method comprises the following steps of carving an original plate; performance testing; mold manufacturing, and specifically filling light guide dots with corrosion-resistant material, and forming a corrosion-resistant block after curing; connecting one side of the corrosion-resistant block fixedly with an etching plate to form a primary template; etching the primary template to obtain a secondary template; electroplating the top surface of the secondary template to obtain a metal film, wherein the back surface of the metal film clings to the secondary template; separating the secondary template from the metal film, and molding on the back surface of the metal film to obtain a mold core; forming a reflecting layer, and injecting reflecting molten metal into the lower die cavity; forming a body; forming a protective film; eliminating bright edges, and forming a frosting layer through sand blasting; removing the film; and mass production. According to the method, high consistency between the light guide dots of the finished light guide plate obtained by mass production and the original light guide dots can be ensured, and the production efficiency can be improved; the light guide plate is integrally formed to obtain the reflecting layer, and production time can be effectively shortened; and the frosting layer obtained by coarsening can effectively improve the light emitting uniformity.

Owner:DONGGUAN XINJU OPTRONICS INC

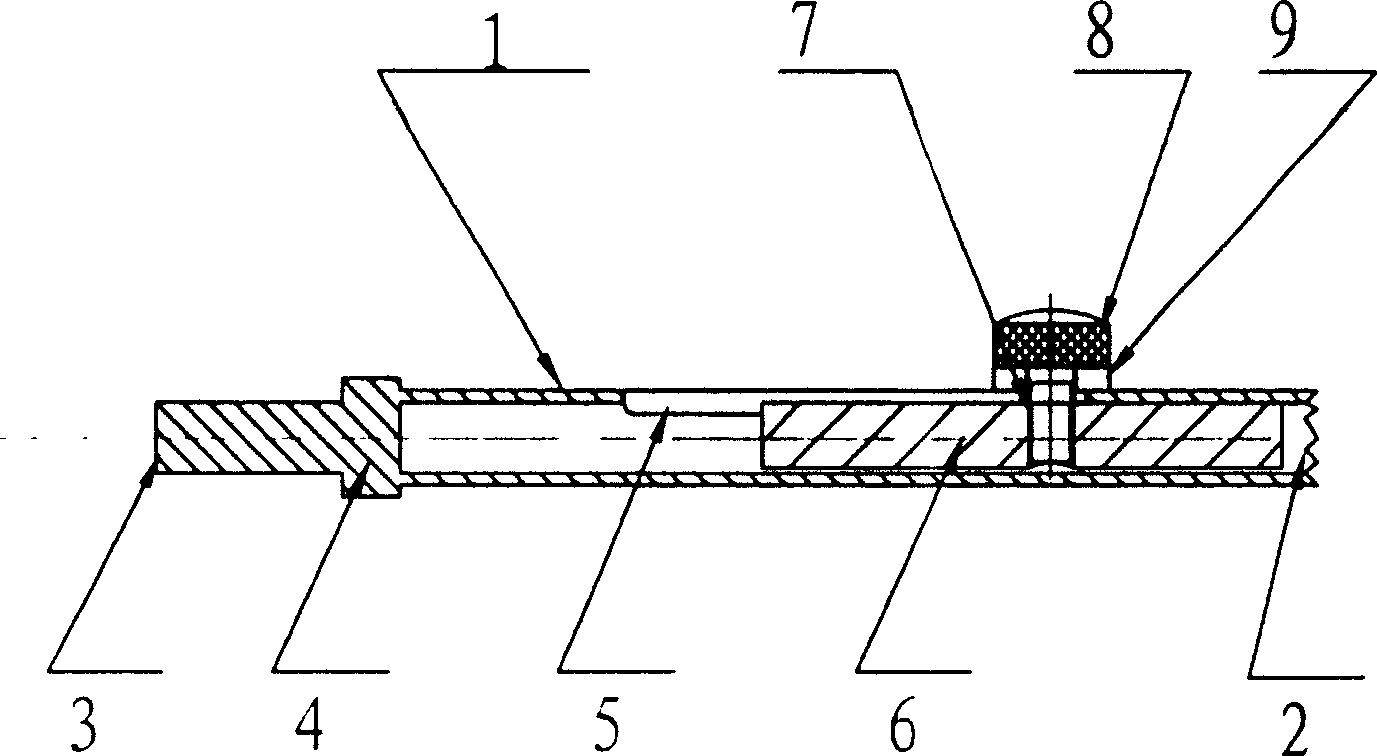

Means for taking-out broken nail from inner-bone

An intrabony broken nail taking-off device is composed of main tubular body, front saw end, tail end, buffering node, force releasing window, push rod, screw bolt and nut. Its advantages are convenient operation, simple structure, and no damage to tissue and bone.

Owner:沈先刚

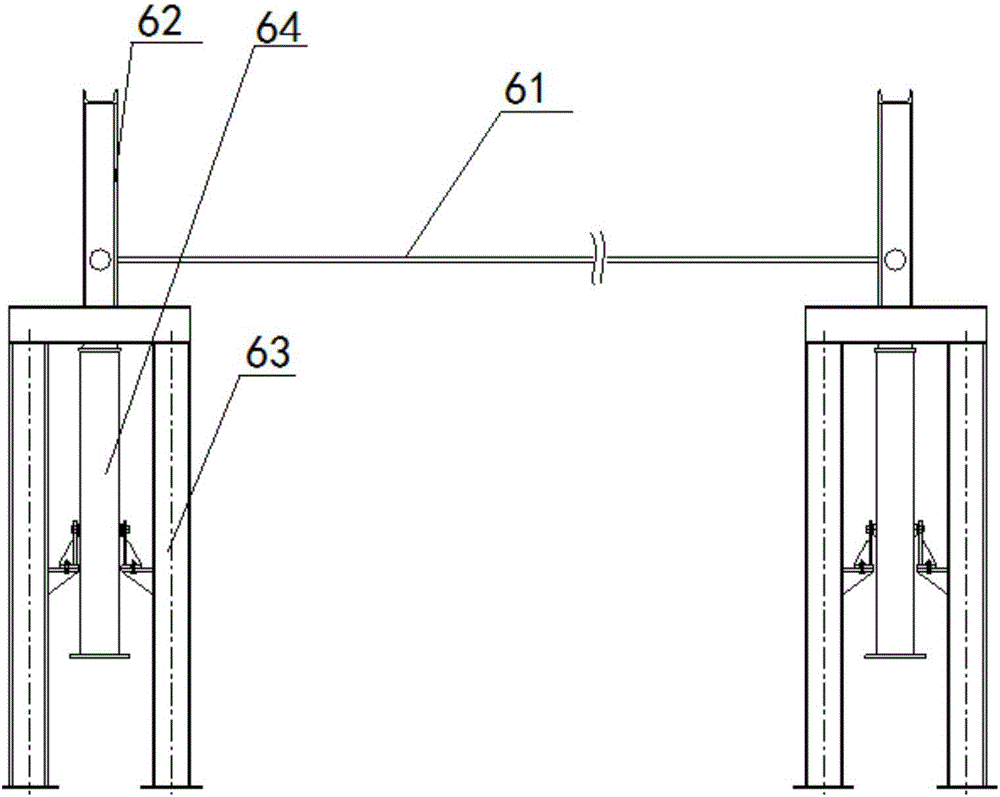

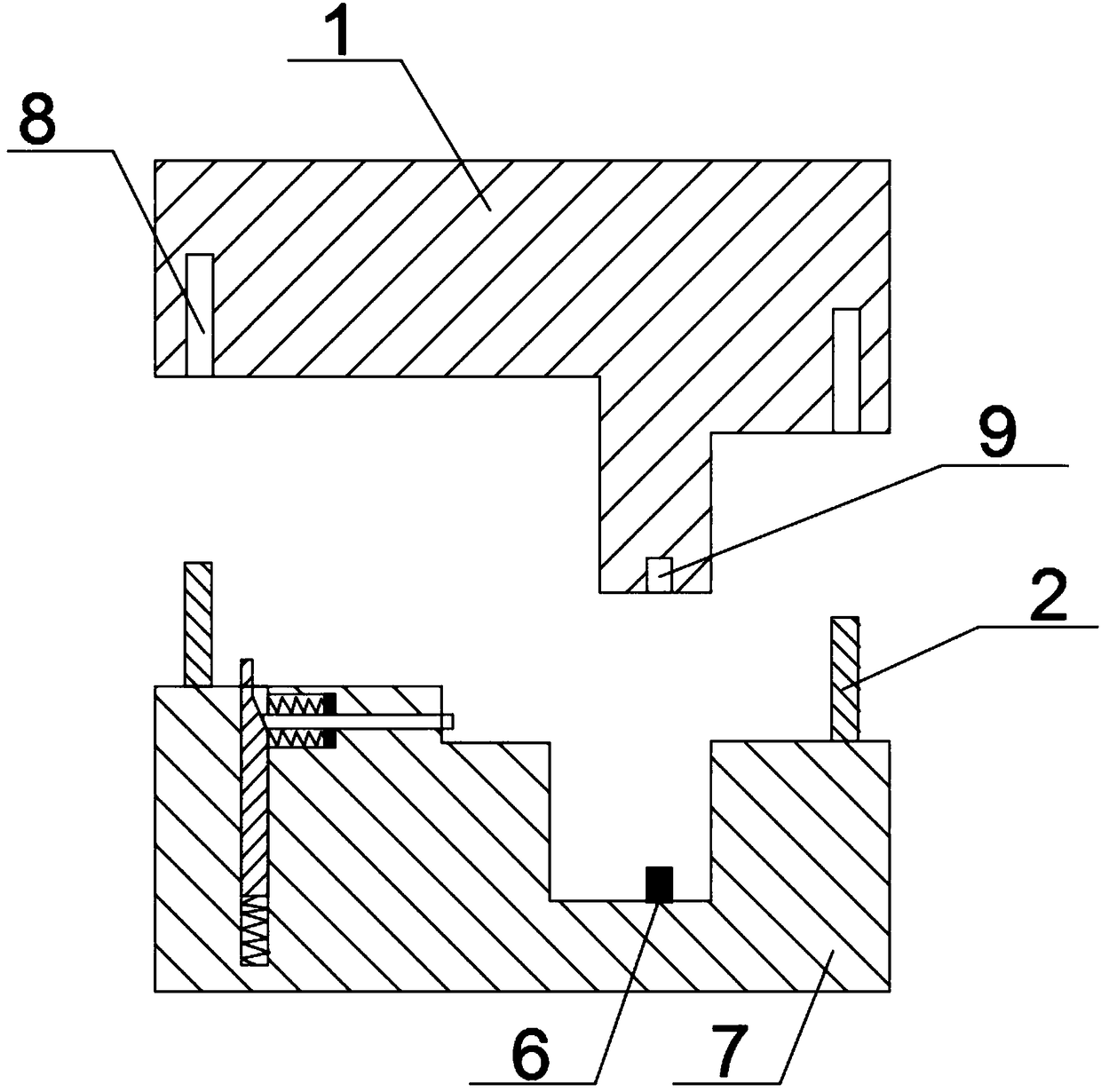

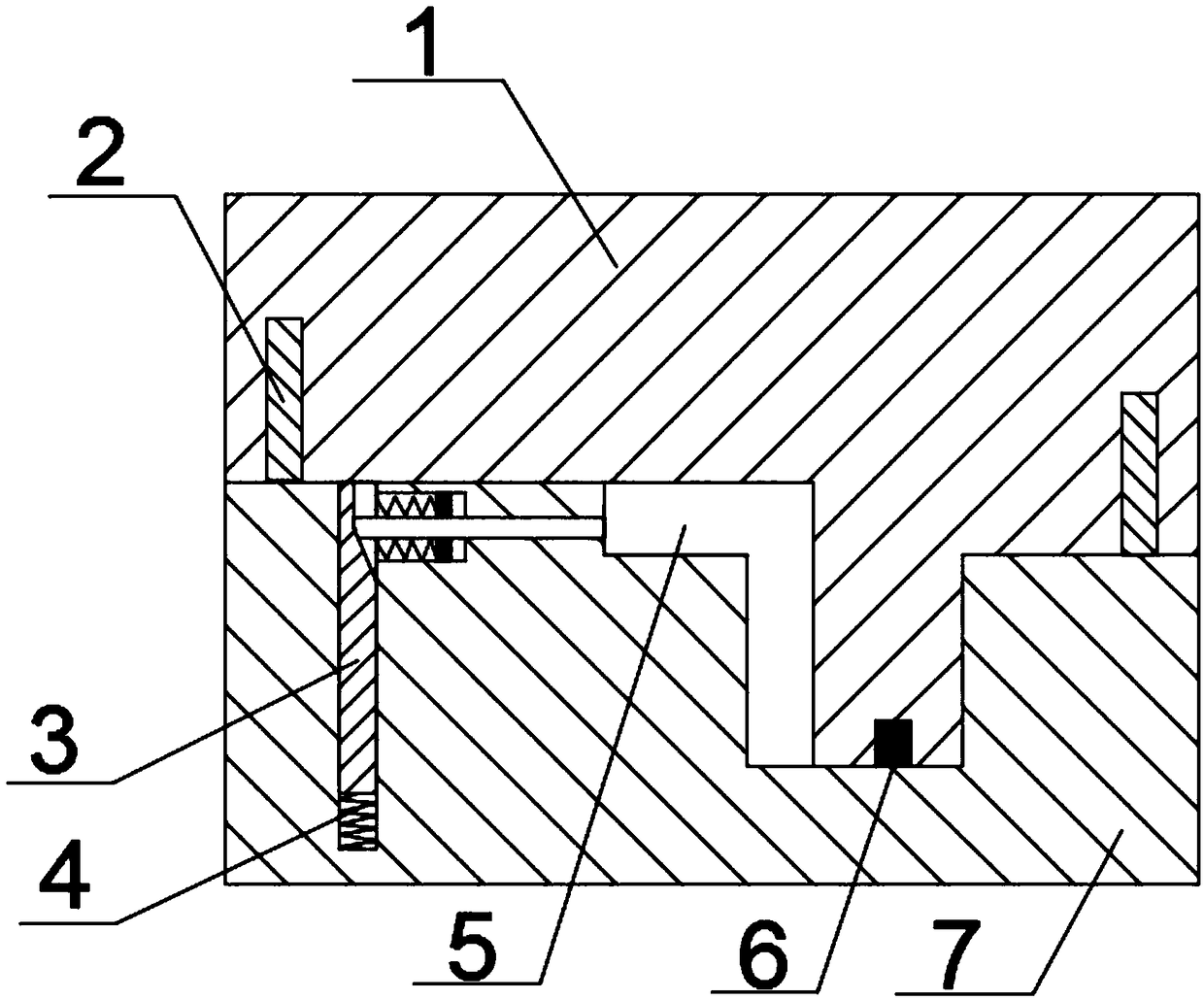

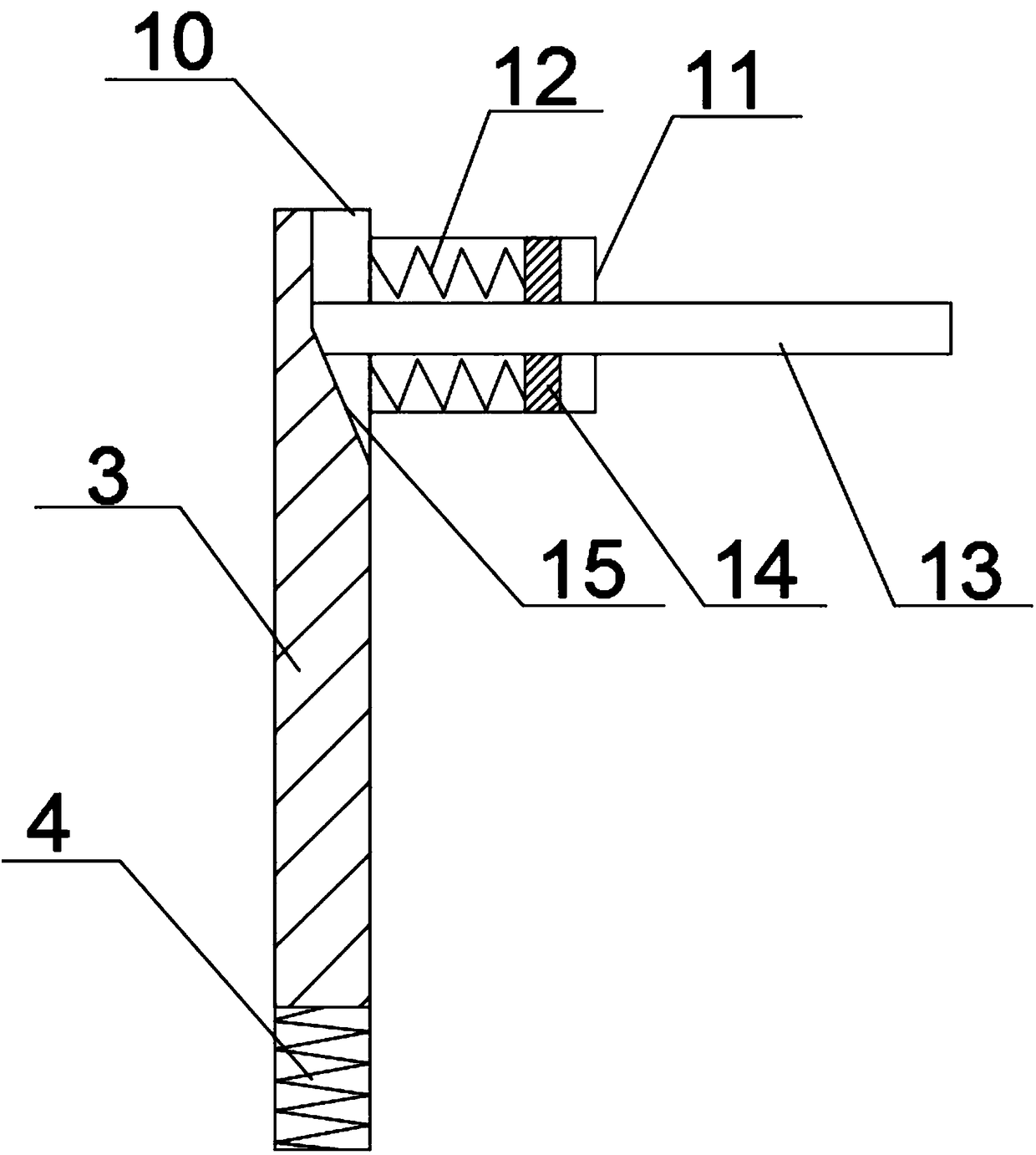

A bend pipe forging die with spring material device

ActiveCN106925709BImprove forging processing efficiencyReduce labor intensityForging/hammering/pressing machinesEngineeringUltimate tensile strength

A bend pipe forging die with a springing device comprises a fixed die body and a movable die body, wherein the movable die body is arranged below the fixed die body; a convex die body is arranged on a forging surface of the fixed die body; a concave die body which is matched with the convex die body is arranged on a forging surface of the movable die body; the convex die body is matched with the concave die body to form a forging cavity of which the shape is matched with that of a bend pipe; the springing device is arranged in the movable die body; a downward blind hole is formed in the forging surface of the movable die body; the springing device comprises a first spring arranged at the bottom of the blind hole and a pressure lever arranged on the first spring; the upper end of the pressure lever extends out of the blind hole; the upper part of the pressure lever is a wedge-shaped surface; a through hole is formed in a position, which corresponds to the forging cavity, of the wedge-shaped surface; a push rod which is matched with the wedge-shaped surface of the pressure lever is arranged in the through hole; and a resetting spring is arranged on the push rod. The springing device is arranged in the movable die body, so that a finished bend pipe can be unloaded from the die when stripped from the die; the labor intensity of workers is reduced; and the forging efficiency of the bend pipe is improved remarkably.

Owner:JIANGSU MINGGE FORGING EQUIP CO LTD

Preparation and application of mixed oxide-doped nano-copper-cobalt alloy catalyst

ActiveCN104645991BReduce contentGood dispersionOrganic compound preparationHydroxy compound preparationPtru catalystMixed oxide

Owner:TIANJIN UNIV

Moringa oleifera product used for replacing traditional cigarettes

The invention provides a moringa oleifera product used for replacing traditional cigarettes, belonging to the technical field of tobacco substitutes. According to the moringa oleifera product, moringa oleifera leaves and moringa oleifera thin branches are taken as raw materials; a preparation method comprises the following steps: carrying out airing, carrying out fermentation, carrying out re-airing, carrying out steam heating, and carrying out shredding. The aroma and color of the obtained product are similar to those of the traditional flue-cured tobacco, the obtained product does not contain nicotine or tar, causes no harm of passive smoking, and contains no addictive ingredients; moringa oleifera contains abundant nutritional ingredients, and can emit various aroma after being repeatedly aired, the ideal smoking and sucking feelings can be obtained under the natural condition that no additives are added, no throat irritation exists, no dryness exists, the sweet taste is obtained through the conversion of the bitter taste, the secretion of saliva or body fluid is promoted, the habit of people for the traditional cigarettes is well reserved, and thus the moringa oleifera product has better substitutability; the preparation of the raw materials adopts sunlight and does not need baking, thus the loss of the energies including coal, electricity and the like is small, and therefore, the energy and cost are saved; as the fast growing species, moringa oleifera has strong adaptability and high yield.

Owner:红河万年堂生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com