Patents

Literature

211results about How to "Reduce melting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

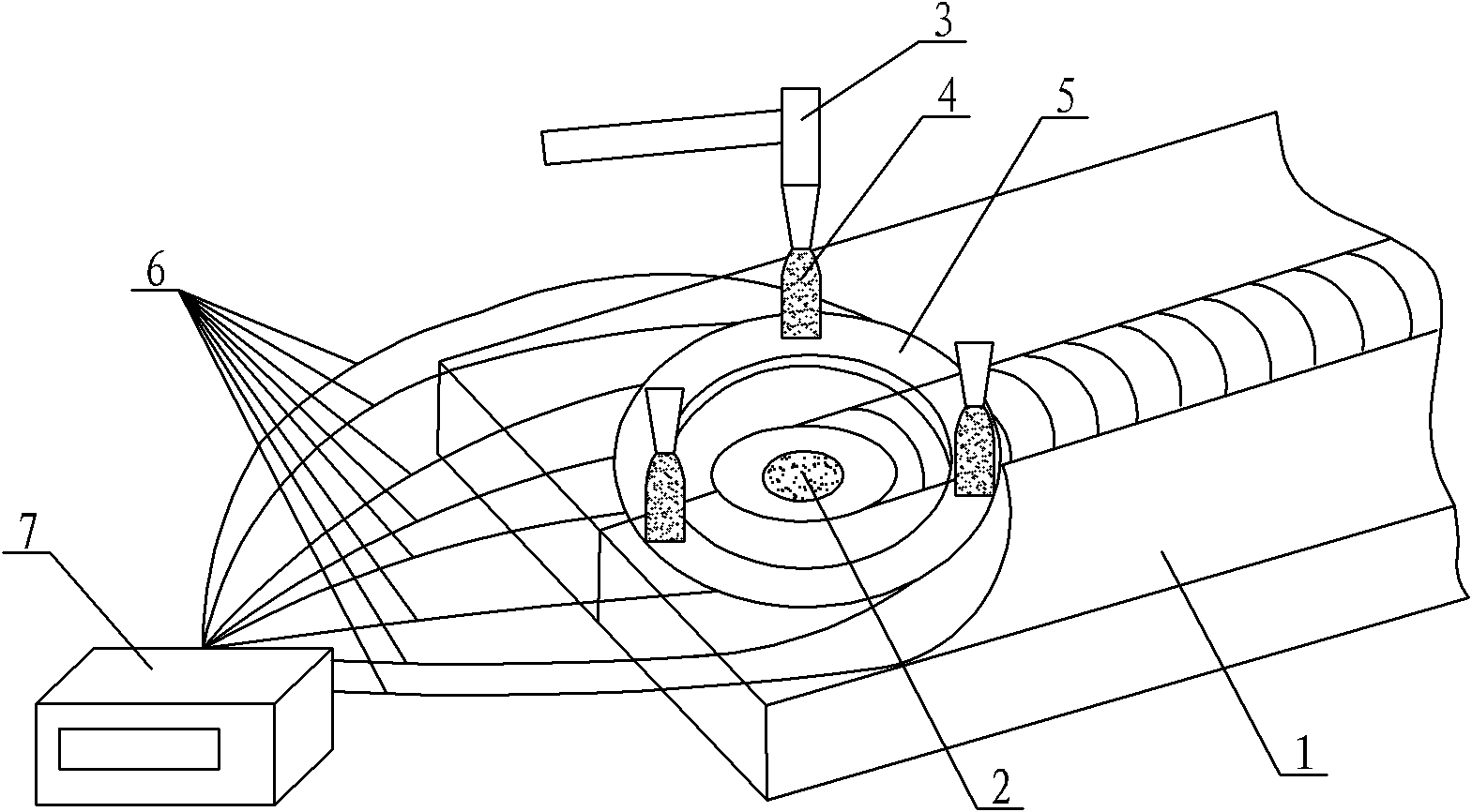

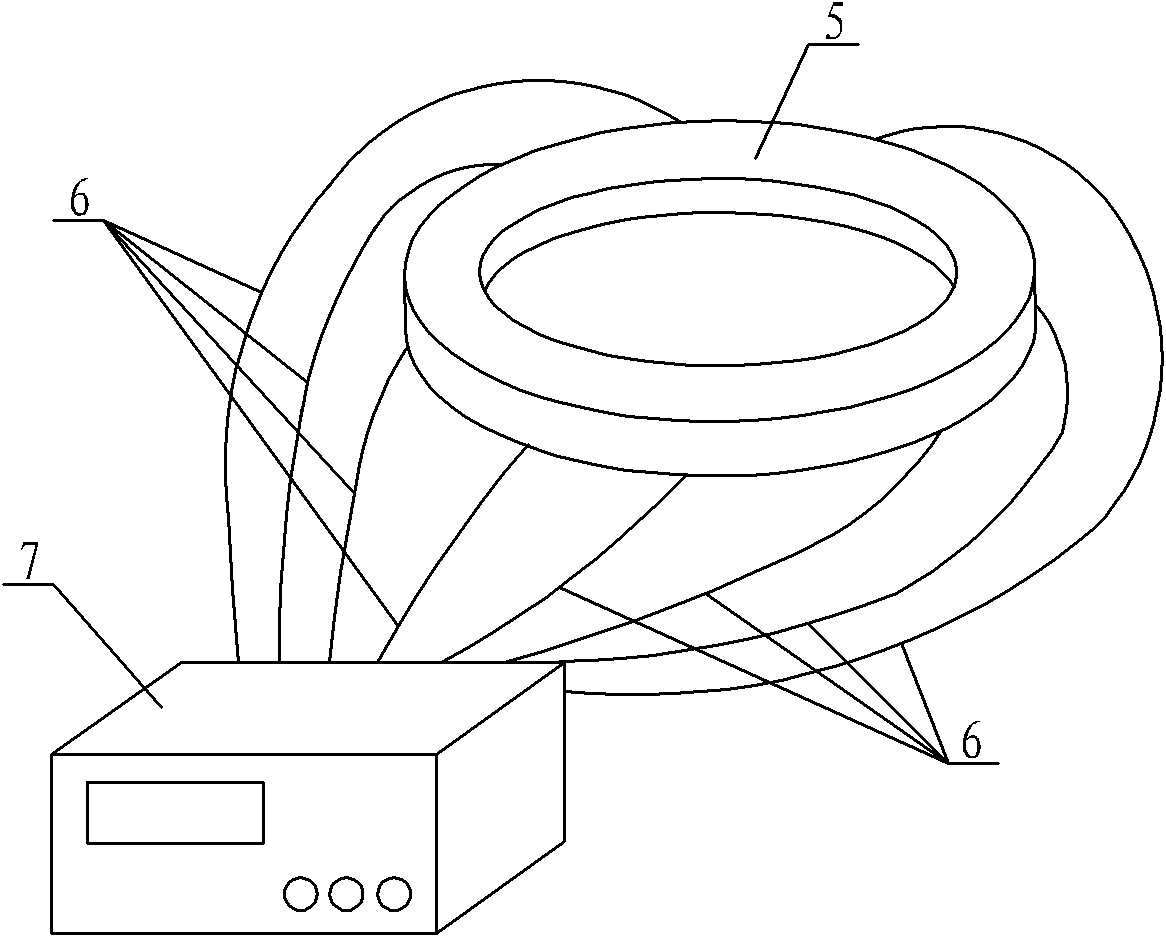

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

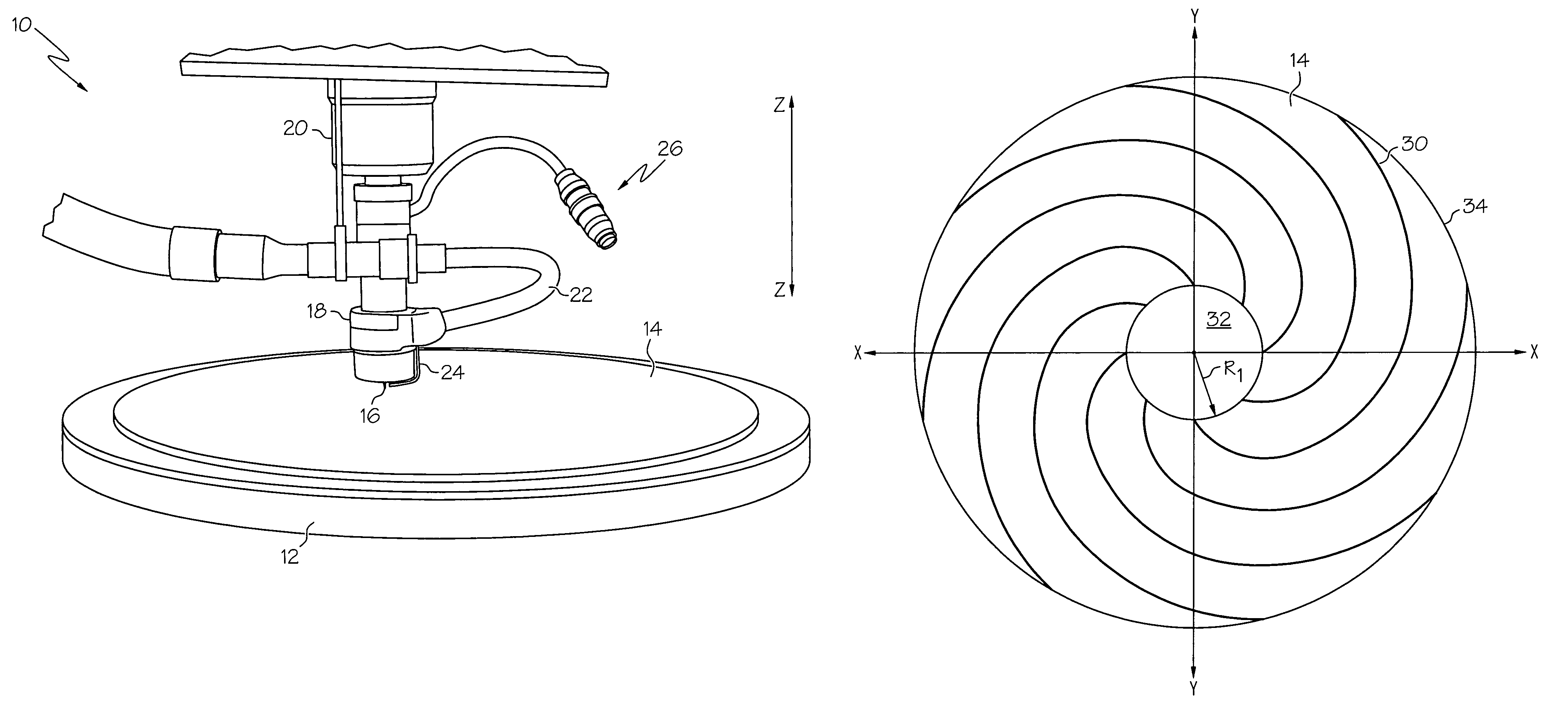

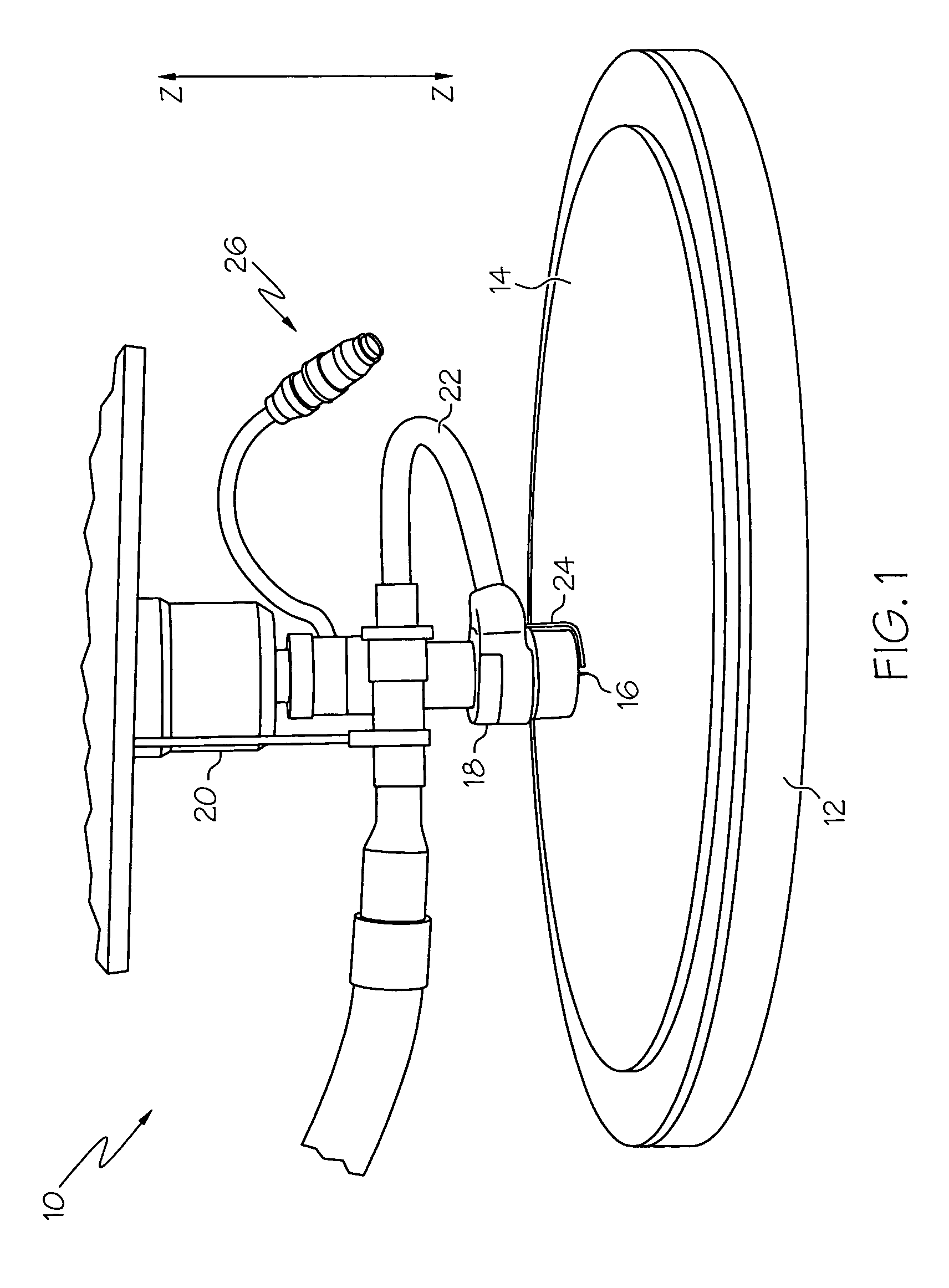

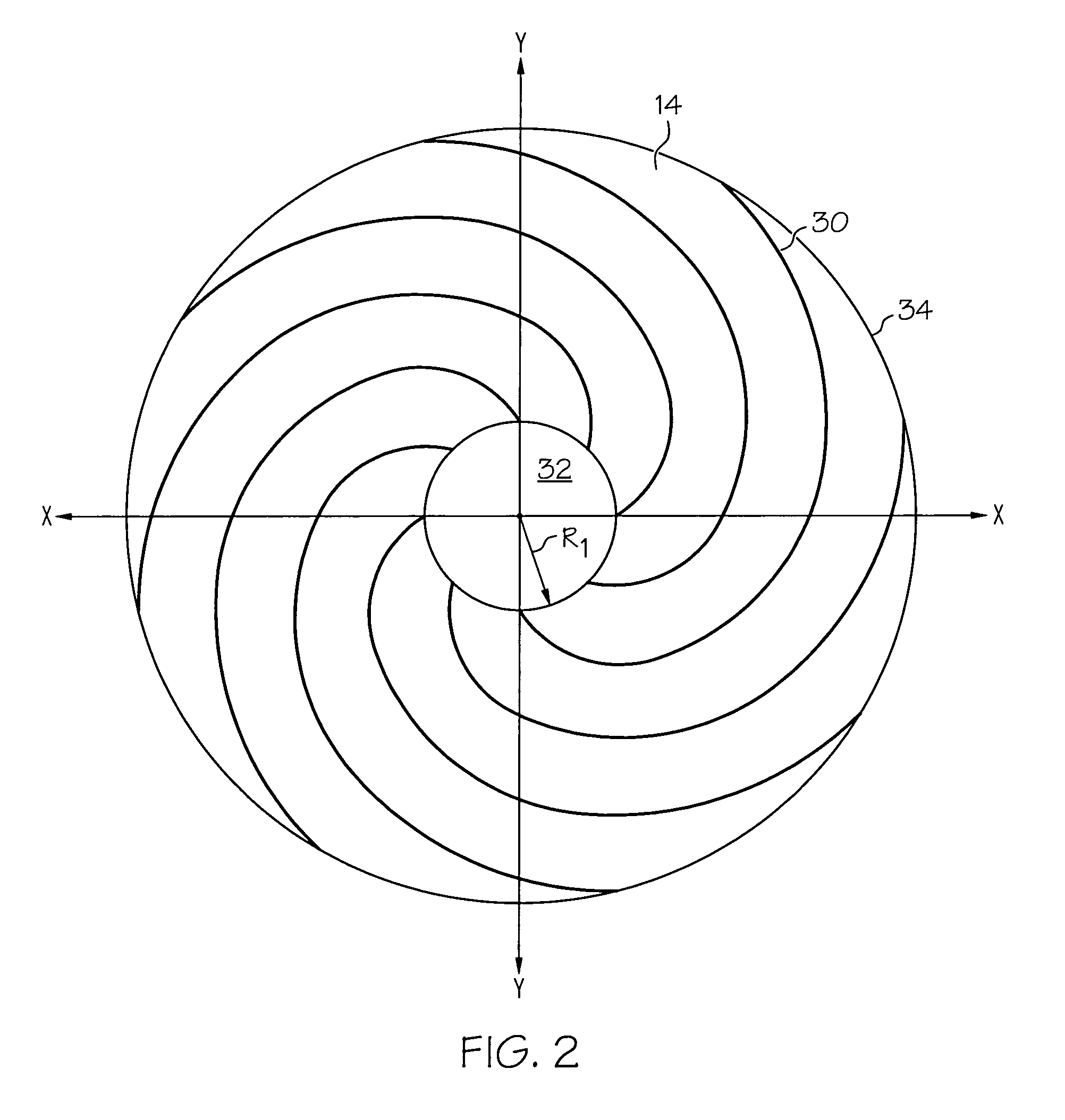

Curved grooving of polishing pads

ActiveUS7234224B1Improve productivityEfficiently formedMilling cuttersAbrasion apparatusHigh rateEngineering

A method is provided for forming grooves in a polishing pad useful for planarizing a substrate in a chemical mechanical planarization process. The method maintains average velocity as a function of bit diameter to enable groove formation using a rotating bit, whereby grooves can be formed at a higher rate while maintaining high groove quality and low defectivity.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

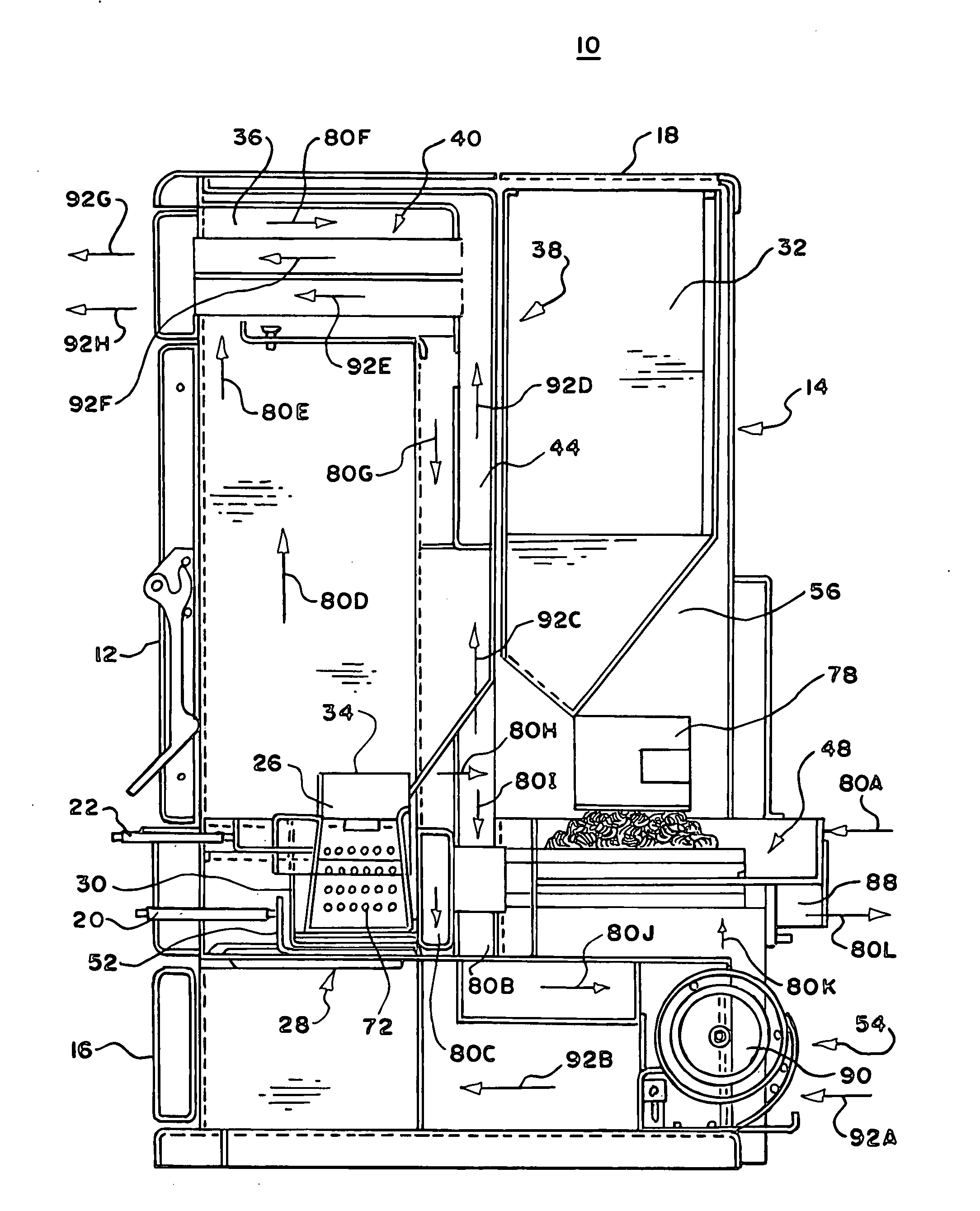

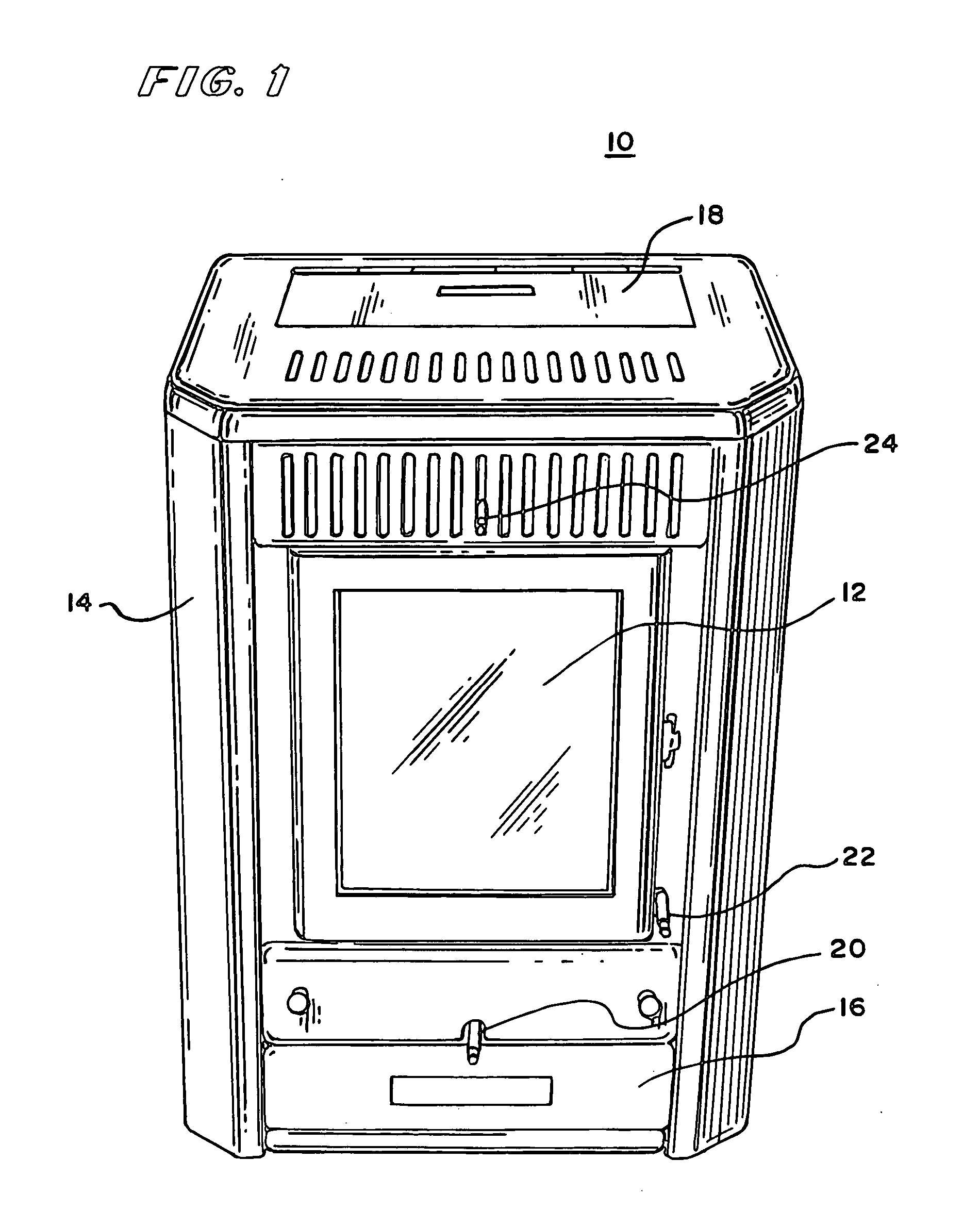

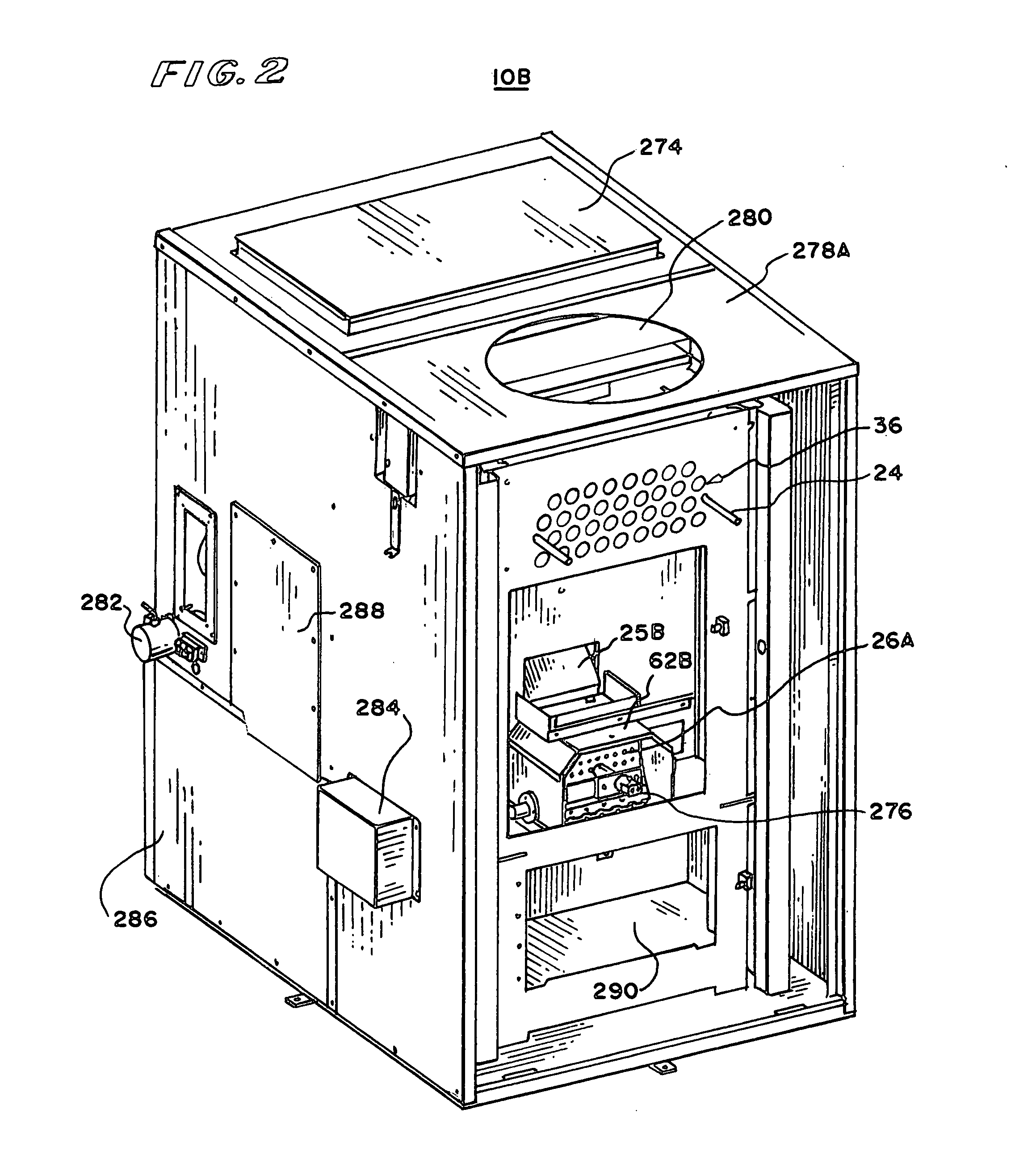

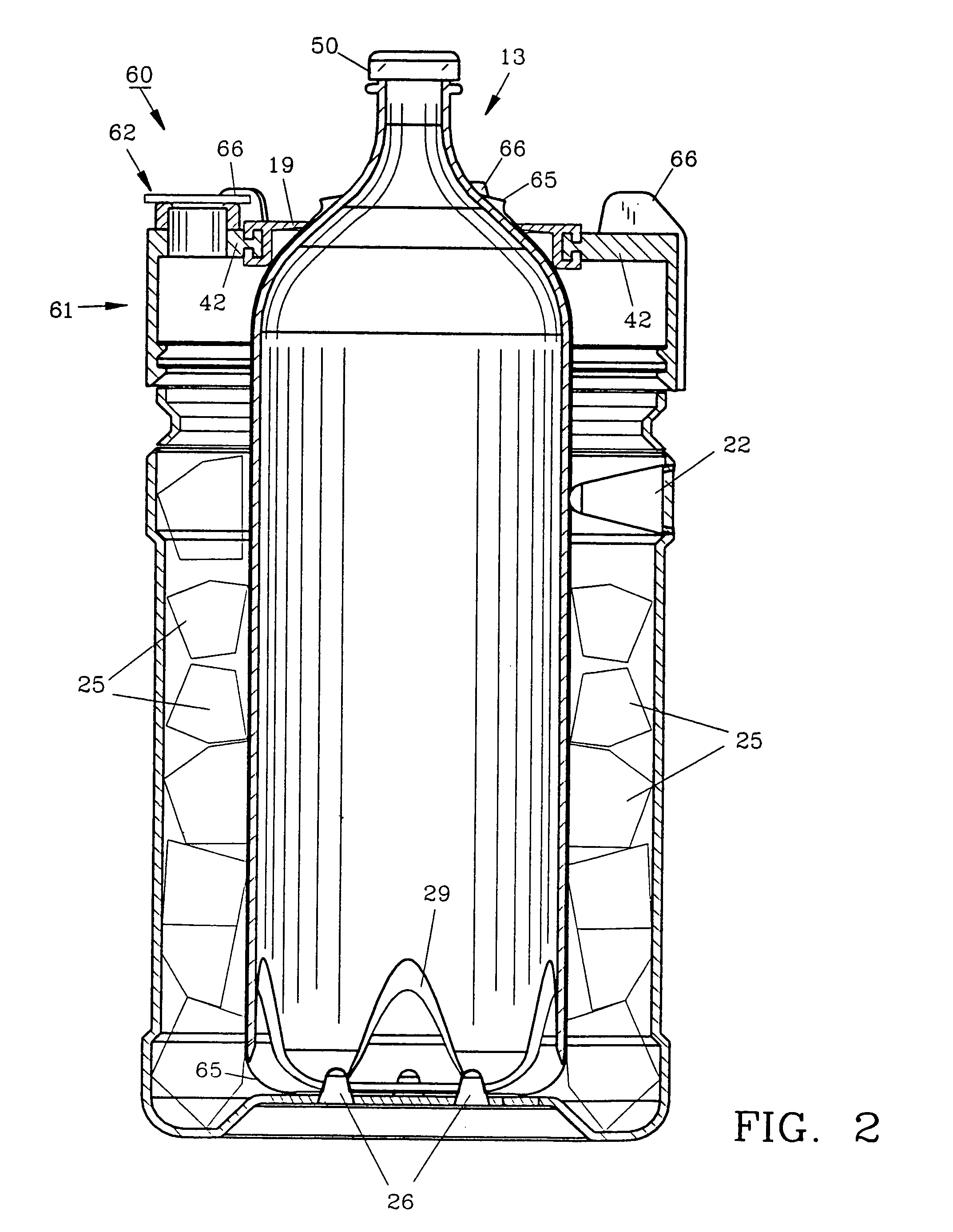

Apparatus and method for combustion

InactiveUS20070215021A1Avoid heat concentrationControl flowGratesPulverulent fuel combustion burnersCombustion chamberEngineering

To enable a burnpot for a corn burning stove to be continuously operated, the burnpot has either: (1) an openable bottom with at least a first and second position, one of the at least first and second positions being substantially closed to enable a body of combustible fuel to burn on its upper surface, the other of the at least first and second positions providing an opening, burnpot side wall portions and a top of the burnpot being shaped so as to permit a solid clinker to drop out of the opening in the openable bottom when the openable bottom is in its second position; or (2) a bottom formed as one of a series of sections of a rotatable member so that as the member rotates, it carries ash with it away from the bottom of the burnpot. A combustion volume is provided between the openable bottom or rotatable bottom, the side surfaces and the top, the combustion volume having an upper portion and a lower portion whereby a fire on a combustion surface in the lower portion burns upwardly toward the upper portion so that byproducts of combustion build on the combustion surface to cause burning fuel to burn at a higher level; the higher level having a smaller cross sectional area than the lower portion whereby the byproducts of combustion may drop as a unit out of the burnpot bottom opening. Easy to ignite fuel is moved from one hopper into the burnpot and ignited. When the temperature is high enough to ignite the harder to ignite fuel it is moved into the burnpot and the flow of easy to ignite fuel stopped.

Owner:EVENTEMP

Low-dielectric-constant glass fiber and glass fiber fabric made thereof

InactiveUS6846761B2Maintain good propertiesImprove meltabilityWoven fabricsCircuit susbtrate materialsTO-18Glass fiber

Low-dielectric-constant glass fibers having a glass composition comprising, by weight %, 50 to 60% of SiO2, 10 to 18% of Al2O3, 14% to less than 20% of B2O3, 1% to less than 6% of MgO, 2 to 5% of CaO, 0.5 to 5% of TiO2, 0 to 0.3% of Li2O, 0 to 0.3% of Na2O, 0 to 0.5% of K2O and 0 to 2% of F2, the content of MgO+CaO being 4 to 11% and the content of Li2O+Na2O+K2O being 0 to 0.6%. The glass fiber has a low dielectric constant and a low dielectric tangent, is excellent in productivity and workability and is also excellent in water resistance, and the glass fiber is suitable for reinforcing printed wiring boards for high-density circuits.

Owner:NITTO BOSEIKI CO LTD

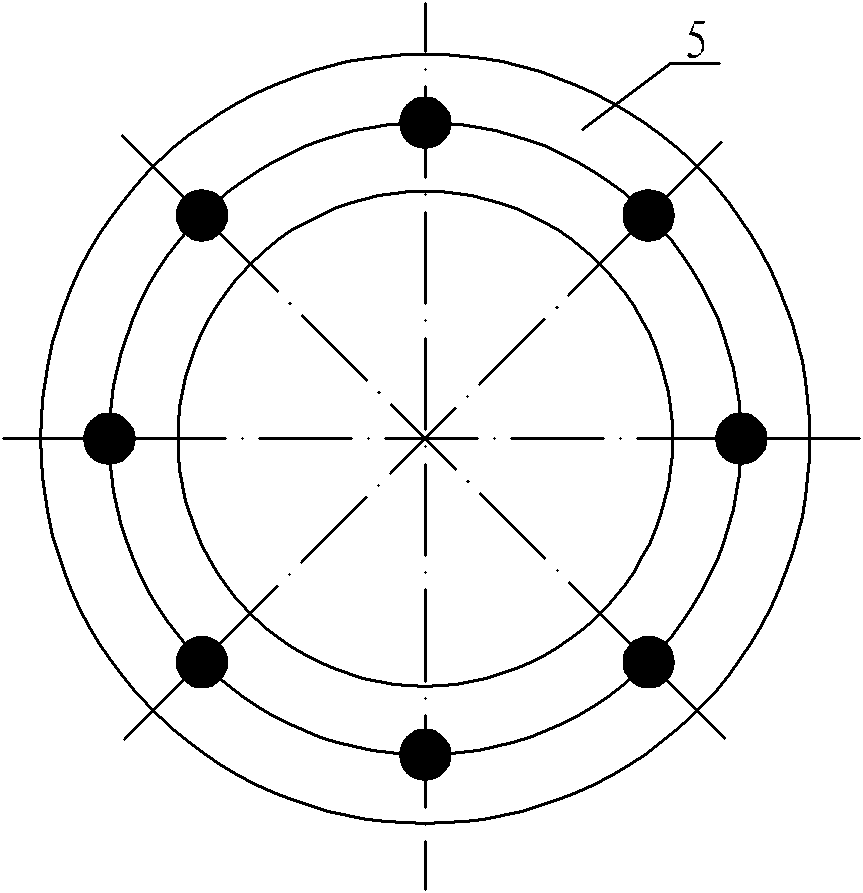

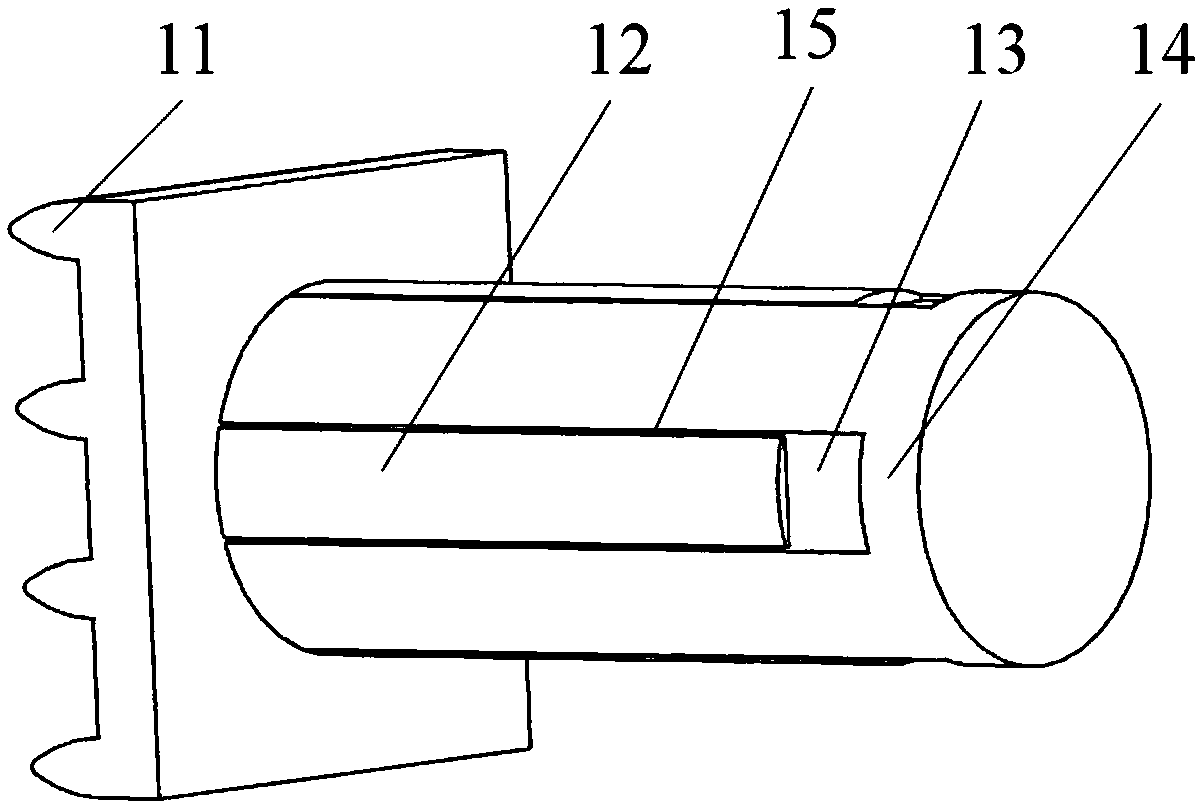

Electric arc preheating repair welding method for stir friction plug

InactiveCN101966621AFull plastic flowSufficient plastic flow, the stirring needle is not easy to breakNon-electric welding apparatusFriction weldingPore diameter

The invention discloses an electric arc preheating repair welding method for a stir friction plug, relates to a repair welding method for the stir friction plug and aims to solve the problem of poor continuous flowability of a material because a stirring needle is broken before complete plastic deformation and flow under the action of strong resisting force of a material at a repair welding position of the stir friction plug. The method comprises the following steps of: 1, performing electric arc preheating on a key hole left by friction stir welding or secondary friction stir welding repairing, namely, putting a circular ring at a key hole position until the center of the circular ring is coincided with that of the key hole, performing electric arc heating on the circular ring by using a tungsten electrode argon arc welding machine at the temperature of between 180 and 200 DEG C and transferring heat to a region needing repair welding after the circular ring is heated so as to preheat the key hole in the region needing repair welding, wherein the central pore diameter of the circular ring is greater than that of the key hole; and 2, performing repair welding on the key hole, namely, during repair welding, moving a welding tool towards a welding direction by 1 to 5 millimeters and allowing the stirring needle to undergo plastic deformation and flow so as to fill the key hole. The method is used for performing repair welding on the weld defects of the stir friction welding and the key hole.

Owner:HARBIN INST OF TECH

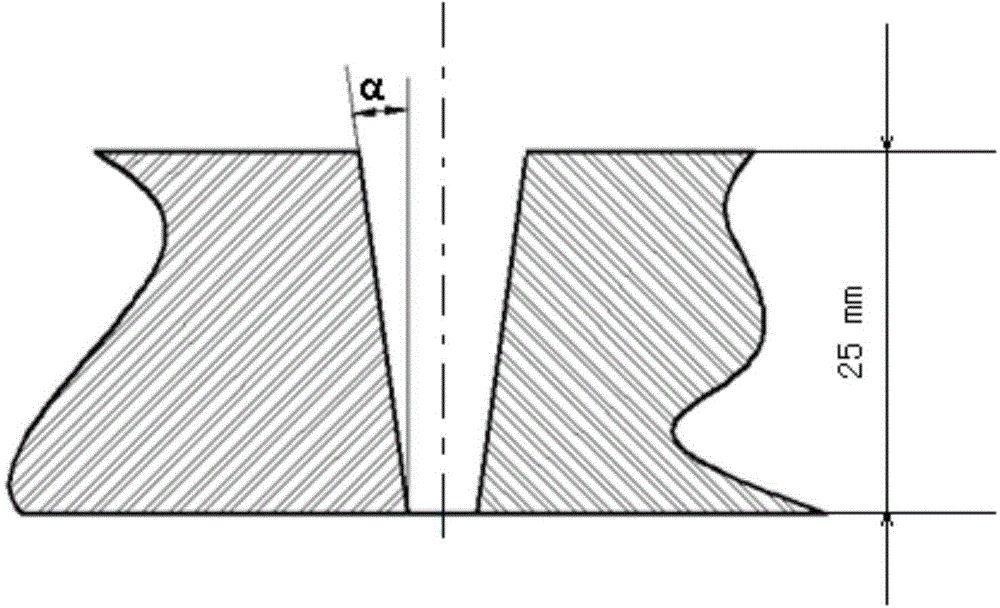

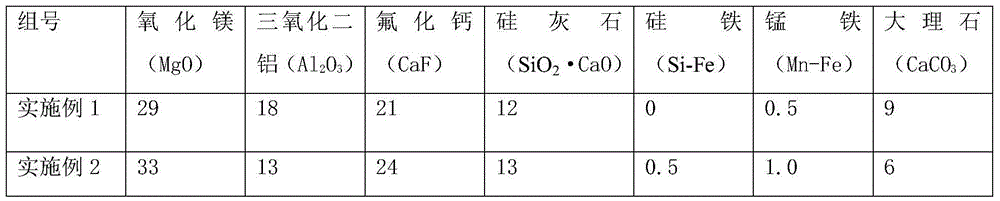

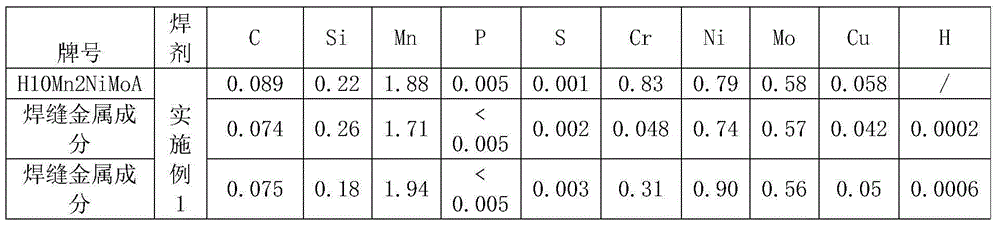

Submerged-arc welding flux for low-alloy-steel narrow-gap welding and preparation method thereof

ActiveCN104668816AExcellent transition abilityEasy transitionWelding/cutting media/materialsSoldering mediaSlagMechanical property

The invention relates to a submerged-arc welding flux for low-alloy-steel narrow-gap welding and a preparation method thereof. A high-alkalinity MgO-CaO-Al2O3-CaF slag system is adopted, and the submerged-arc welding flux is mainly made from raw materials including calcium fluoride, aluminum oxide, wollastonite, marbles, silicon iron and ferromanganese iron. The preparation method of the submerged-arc welding flux mainly comprises the steps of 1 dry mixing in proportion, 2 impurity removal, 3 bonding agent adding for wet mixing and 4 baking and high-temperature sintering. The alkalinity of the welding flux ranges from 2.0 to 3.0, low-hydrogen and low-oxygen deposited metal containing ultra low P and S impurity contents can be obtained through welding, and accordingly it can be ensured that the deposited metal has excellent comprehensive mechanical property. When the submerged-arc welding flux is matched and welded with a low-purity low-alloy steel welding wire, S and P are not added into the deposited metal by adopting the welding flux. The submerged-arc welding flux has excellent alloy transition capacity.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

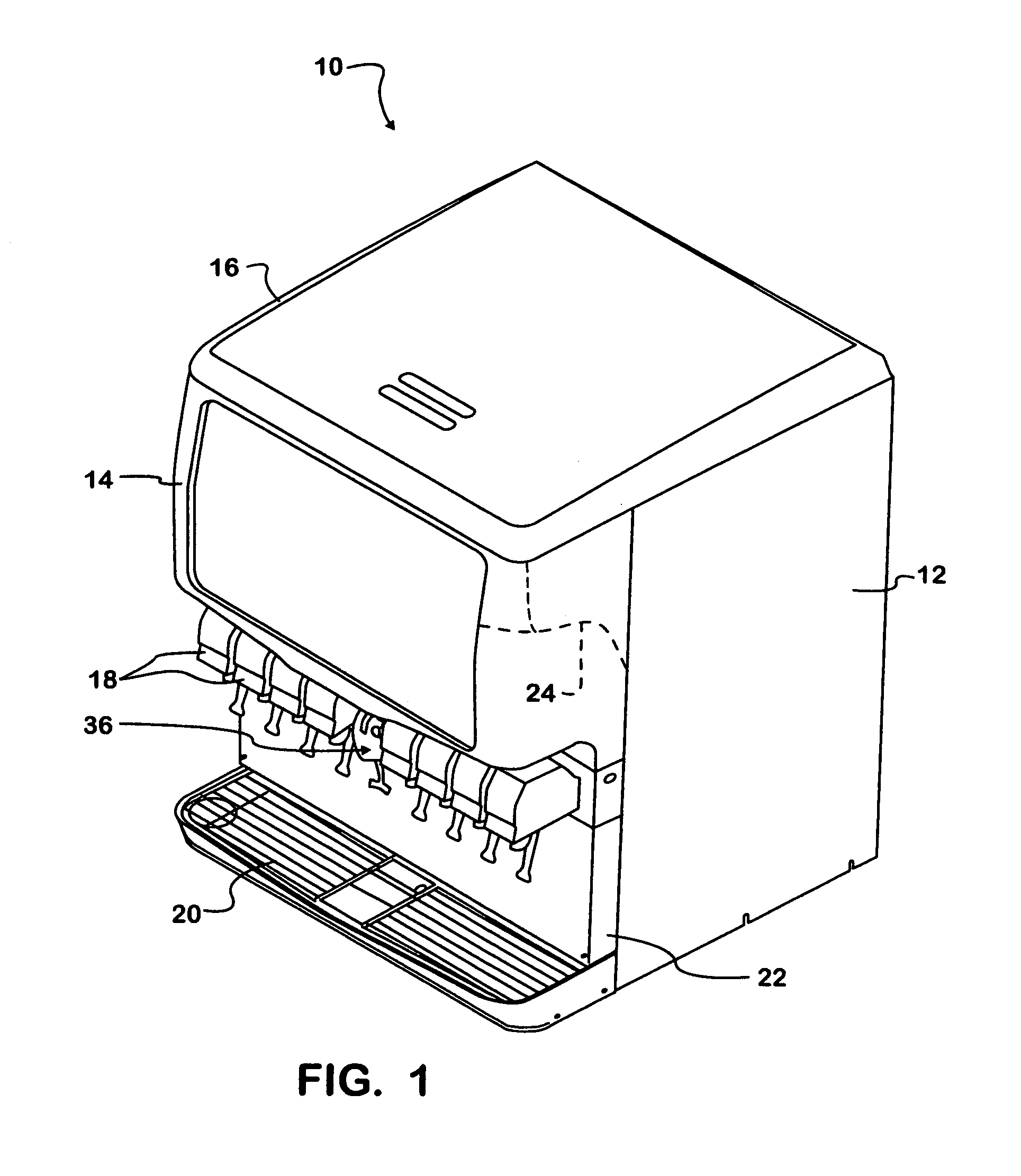

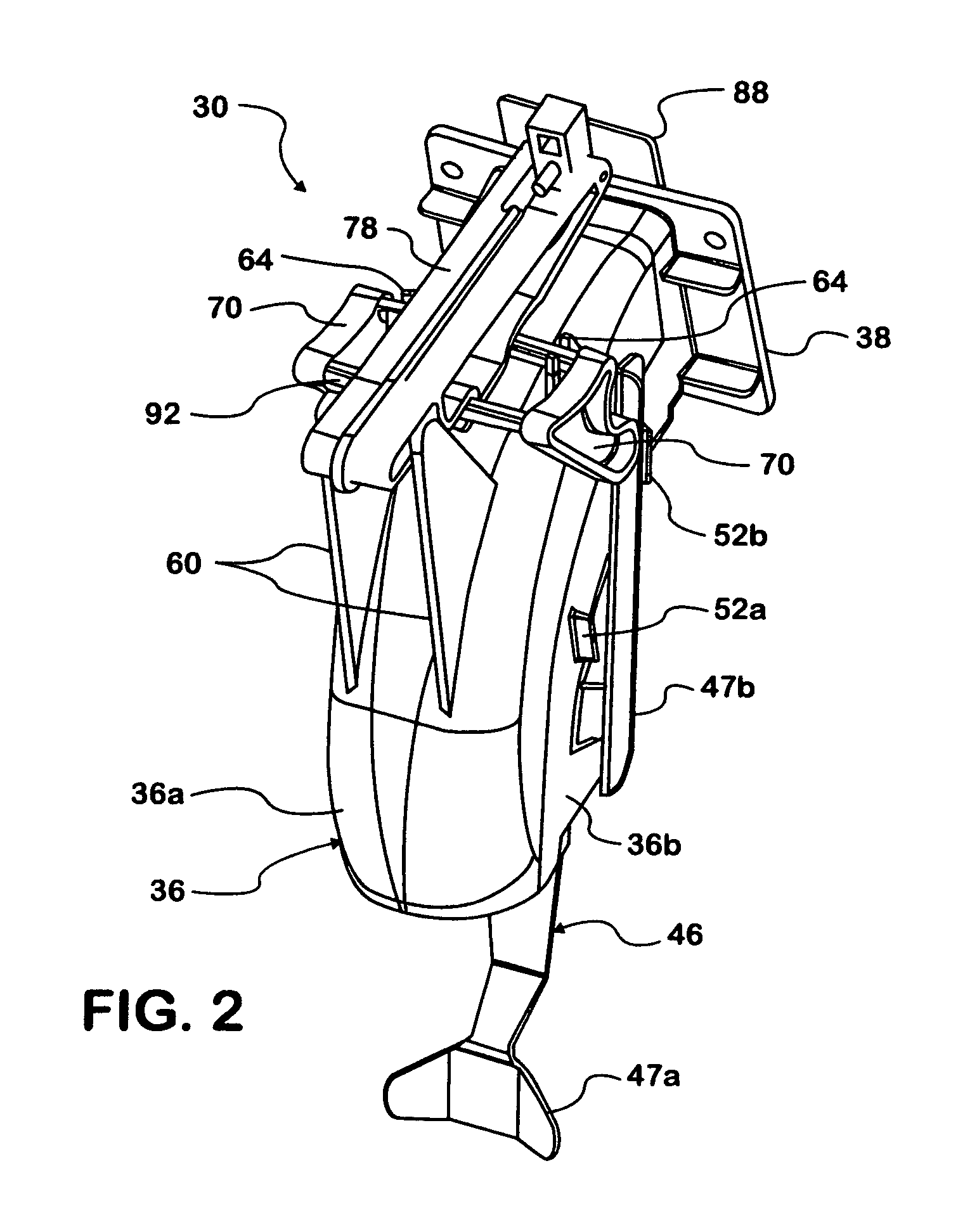

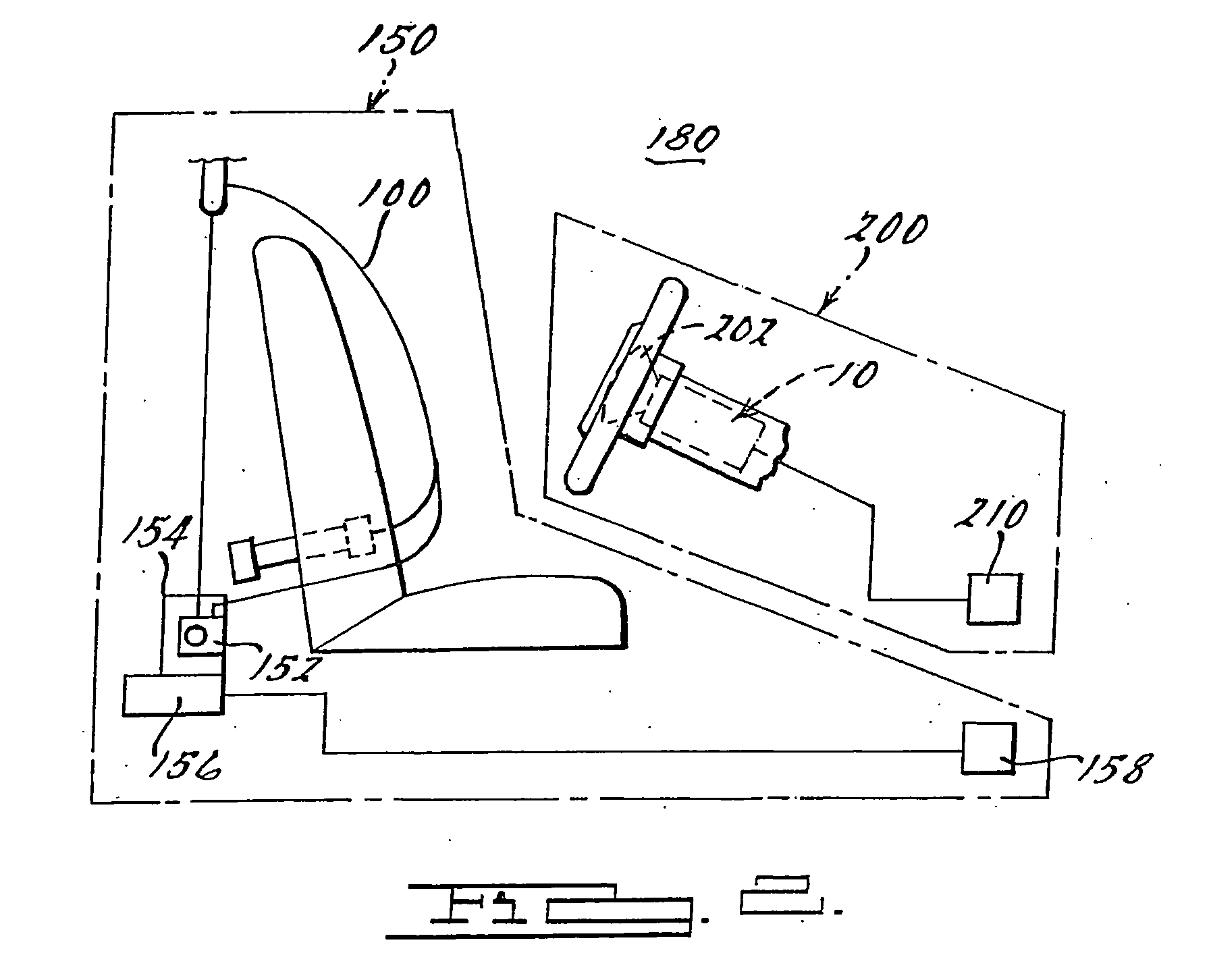

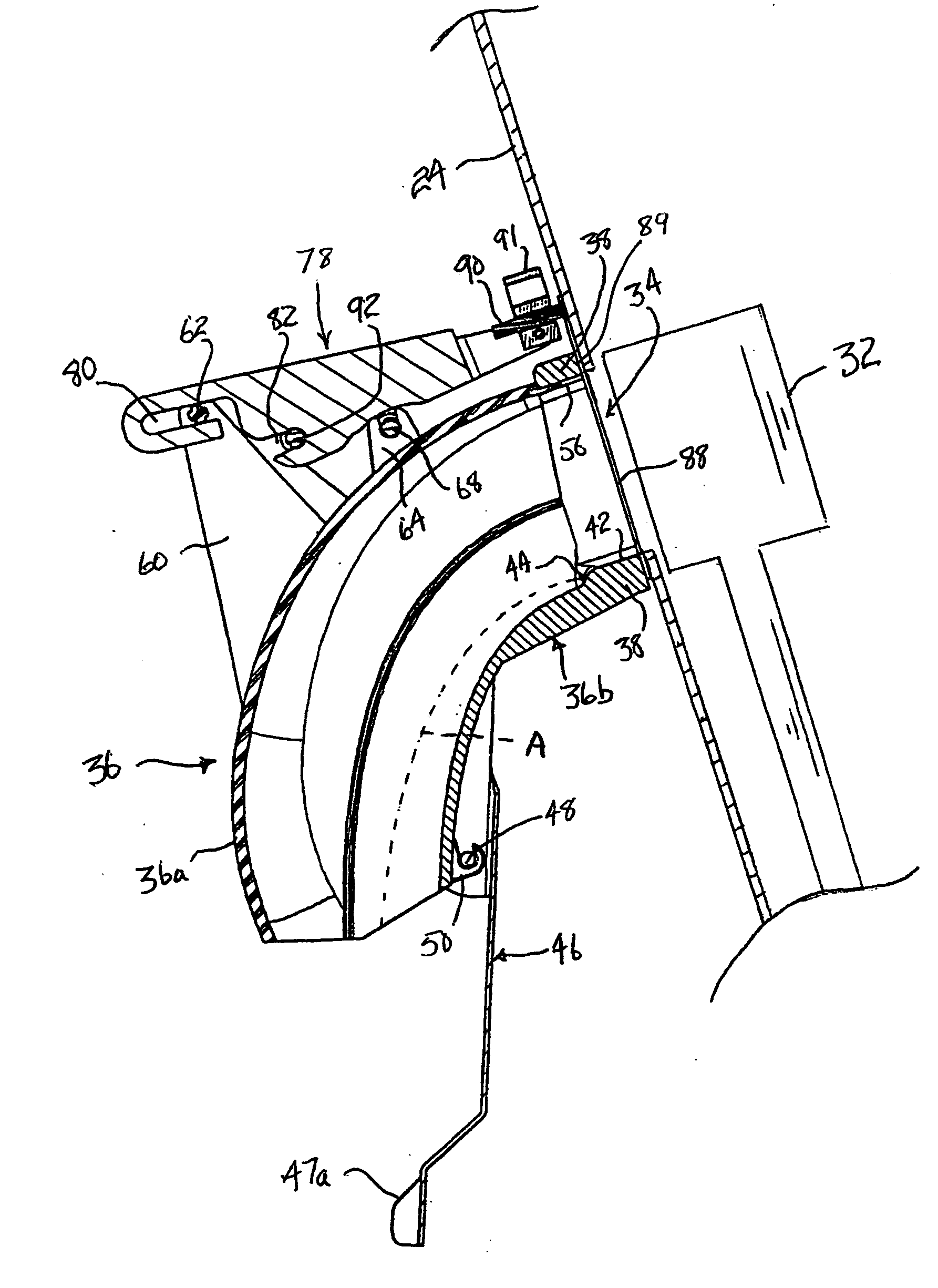

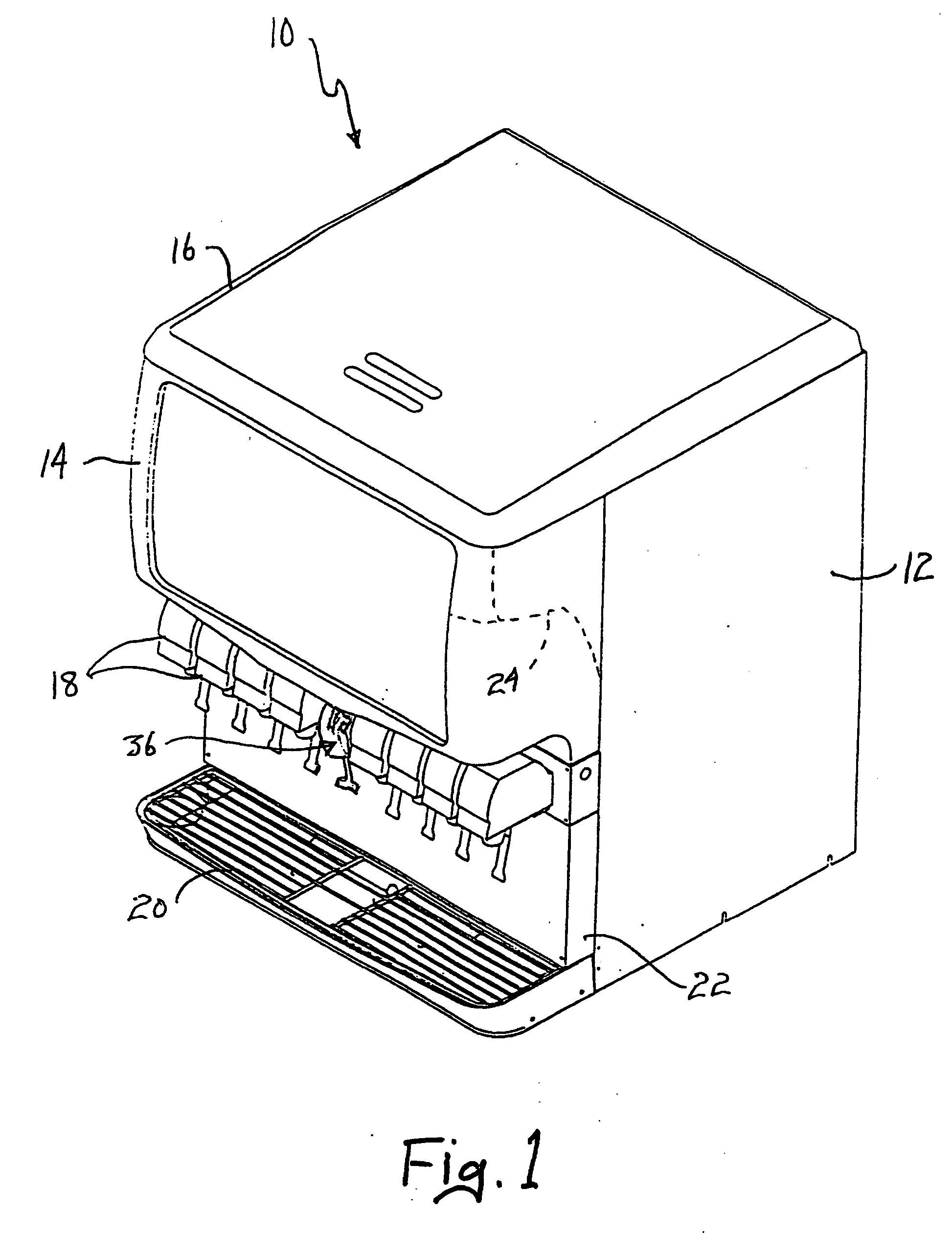

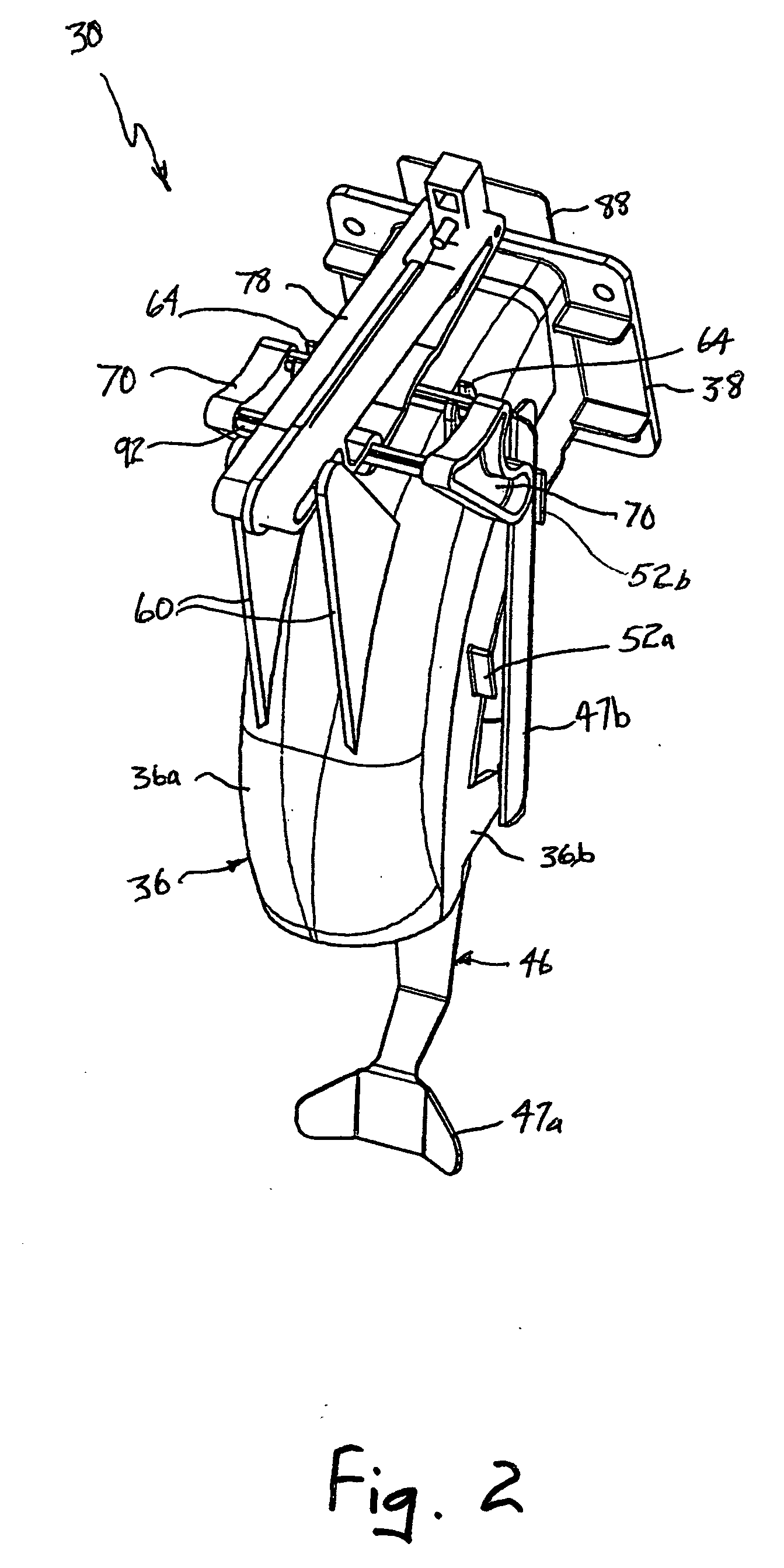

Ice dispensing chute

ActiveUS6964351B2Easy to separateLess wetLighting and heating apparatusLiquid flow controllersLinear motionMarine engineering

An ice dispensing chute mechanism is characterized by an ice chute adapted for attachment at an upper ice inlet end to an ice retaining bin at an ice outlet from the bin. An actuating arm is pivotally mounted on the ice chute and has a lower end for being contacted and moved by a receptacle into which ice is to be dispensed from a lower ice discharge end of the chute and an upper end for contacting and moving a linkage mechanism upon rotation of the actuating arm by the receptacle. The linkage mechanism is pivotally mounted on the ice chute and is coupled to an ice gate that is linearly moved by the linkage mechanism between open and closed positions that establish and interrupt communication between the upper inlet to the chute and the ice outlet opening from the bin. Movement of the linkage mechanism by the actuating arm operates the linkage mechanism to translate the rotational movement of the actuating arm into linear movement of the ice gate between its open and closed positions to dispense ice and to cease dispensing ice into the receptacle. The ice chute consists of two halves that snap together in a releasable manner to permit easy disassembly of the ice chute for cleaning, repair or replacement of parts. The upper inlet to the ice chute is configured to impart to ice particles a trajectory through the chute that guides the ice particles into the receptacle while preventing the vast majority of the ice particles from contacting interior surfaces of the chute.

Owner:MARMON FOODSERVICE TECH INC

Water-permeable ceramic waste brick and production method thereof

InactiveCN106854085AImprove workabilityPrevent poor plasticityCeramic materials productionCeramicwareScrapSintering

The invention discloses a water-permeable ceramic waste brick and a production method thereof. The water-permeable ceramic waste brick comprises, by weight, 71-79% of ceramic wastes, 3-4% of clay, 8-13% of feldspar and 10-12% of water glass. The water-permeable brick product is obtained through burdening, crushing, mixing, molding, drying, sintering and heat insulation of all above components. The water-permeable brick produced in the invention has the advantages of low sintering temperature, simple production technology, high water-permeable intensity, excellent performances, and greenness and environmental protection.

Owner:SOUTHWEST JIAOTONG UNIV

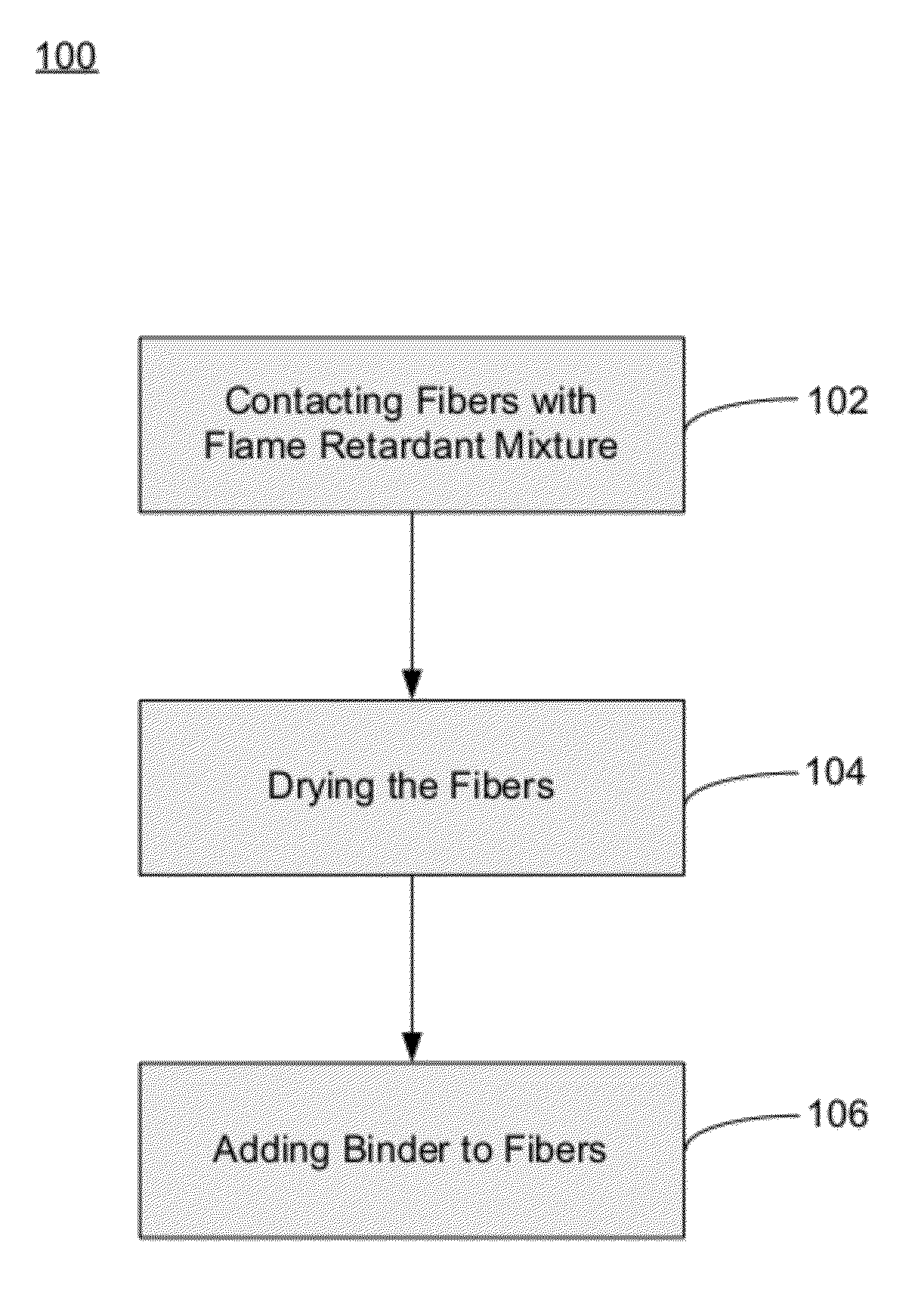

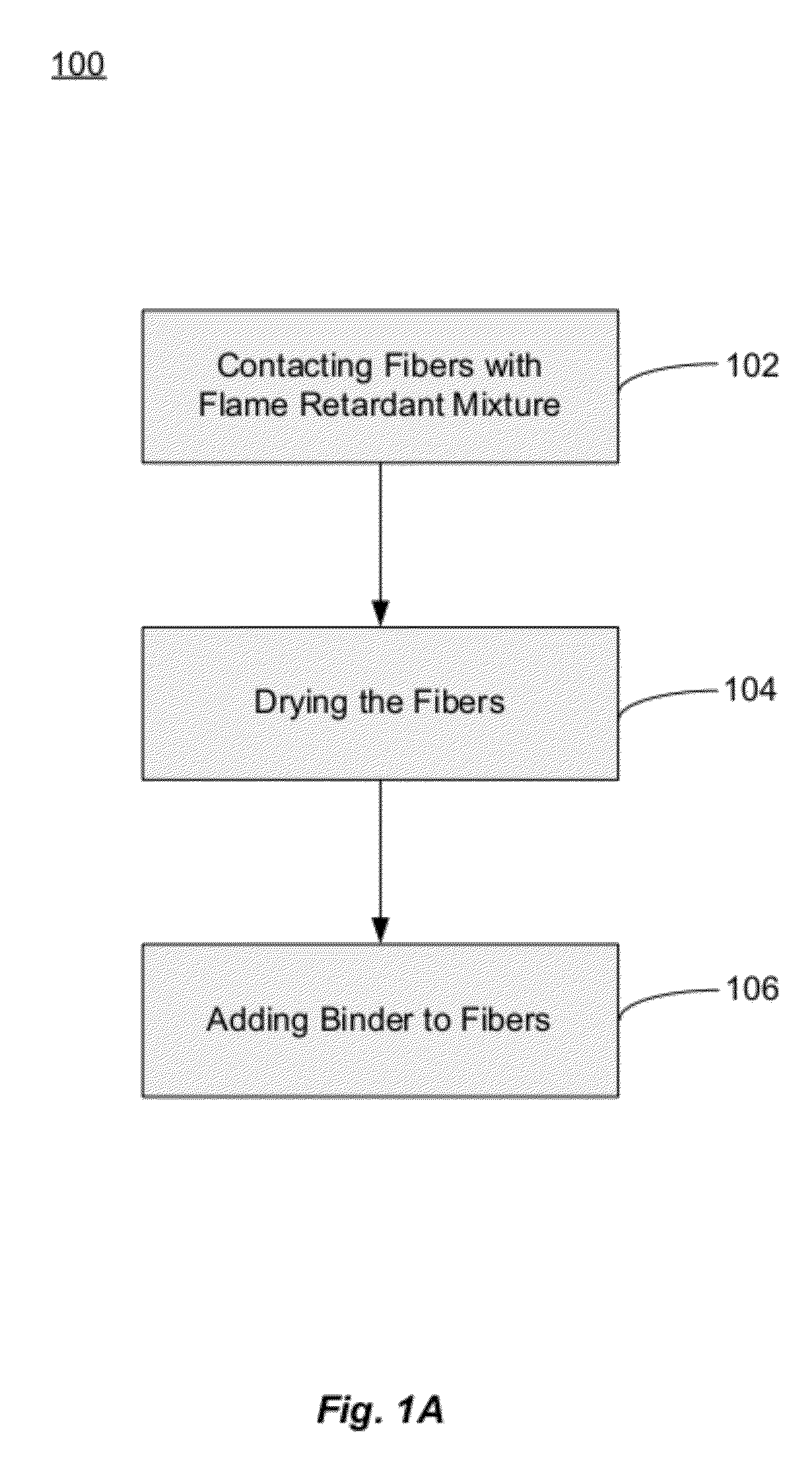

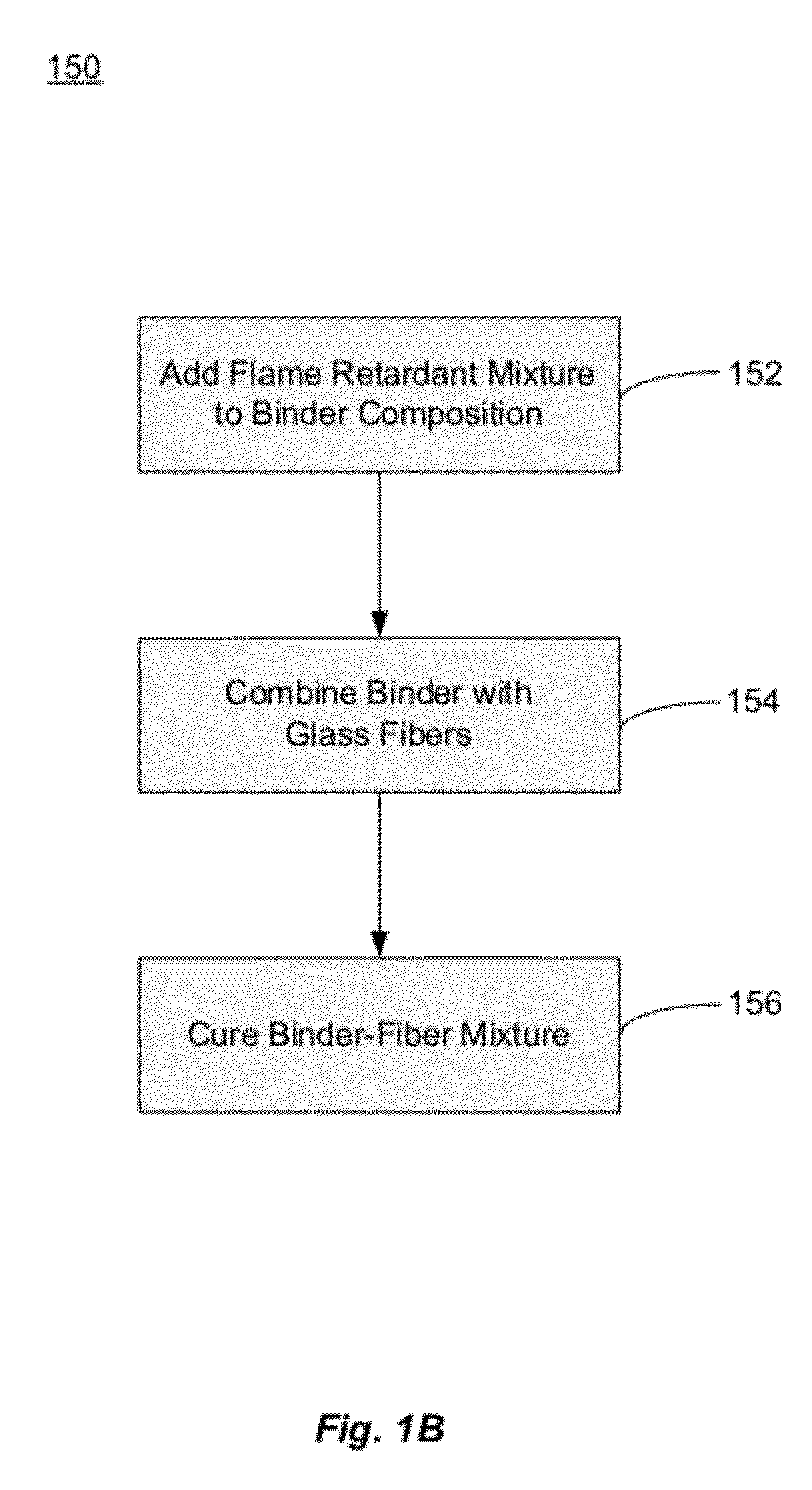

Fiberglass composites with improved flame resistance from phosphorous-containing materials and methods of making the same

InactiveUS20120315458A1Improve flame retardant performanceReduce meltingLayered productsPretreated surfacesGlass fiberOrganophosphorous compounds

Fiberglass products with increased flame resistance are described. The products may include fiberglass-containing thermal insulation that include a plurality of glass fibers coated with a phosphorous-containing flame retardant. The flame retardant may include an organophosphorous compound having a substituted or unsubstituted organophosphorous group bonded to a substituted or unsubstituted amide group by a substituted or unsubstituted alkyl group. The fiberglass products may further include fiberglass composites that are about 50 wt. % to about 98 wt. % glass fibers, about 2 wt. % to about 50 wt. % of a binder; and a phosphorous-containing flame retardant. Also described are methods of making fiberglass products with increased flame resistance. These methods may include the steps of contacting glass fibers and / or fiberglass products with a flame retardant mixture that includes a phosphorous-containing compound.

Owner:JOHNS MANVILLE CORP

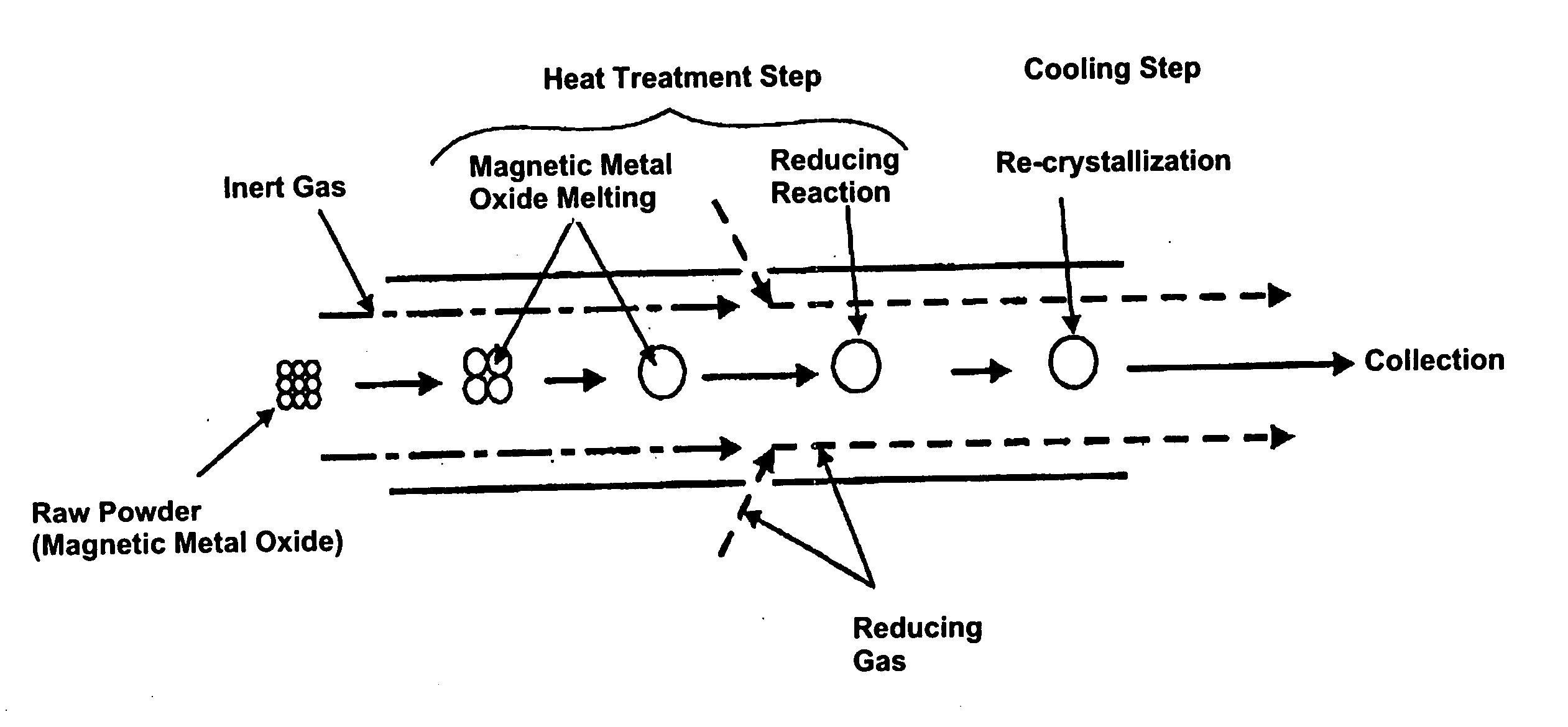

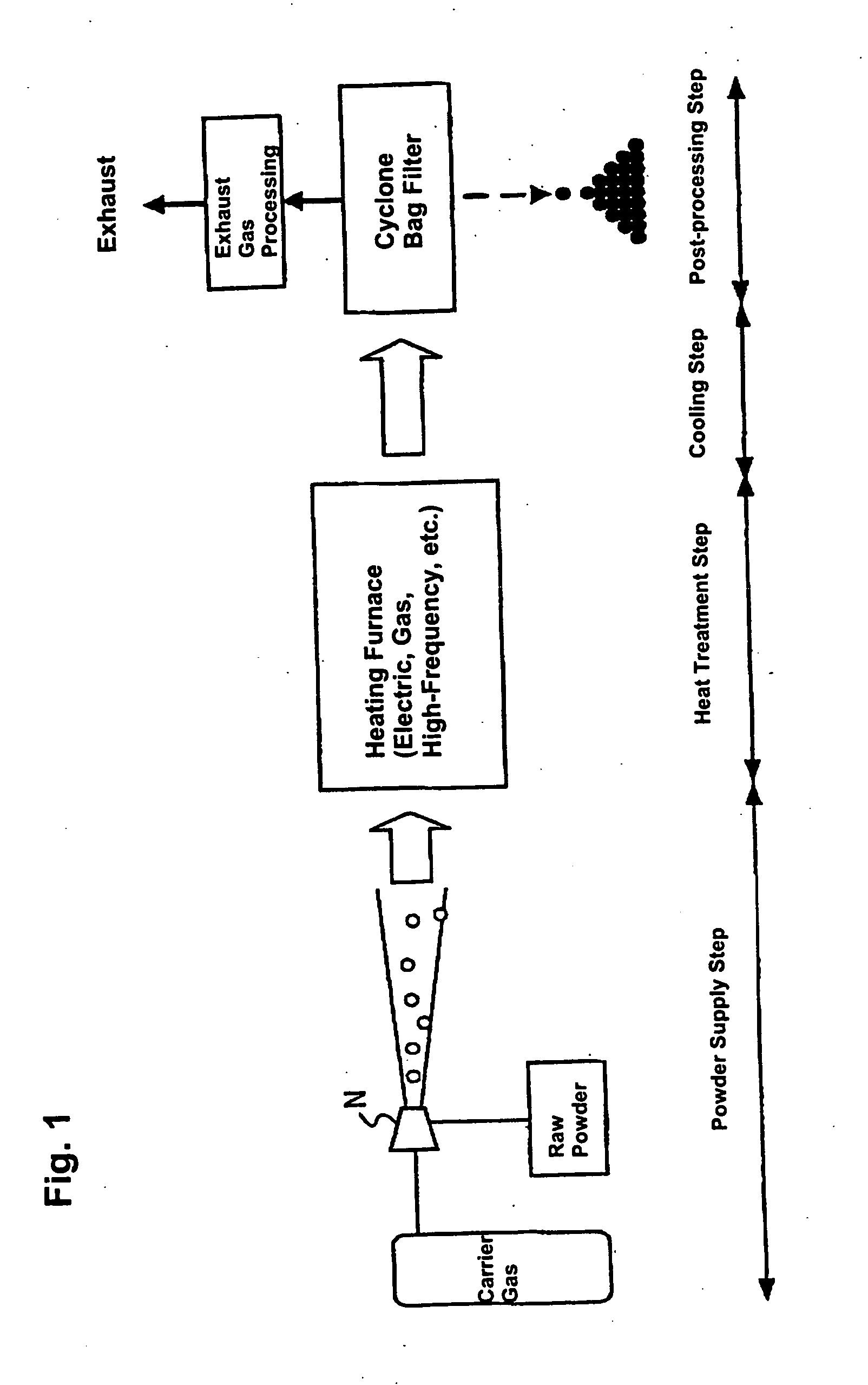

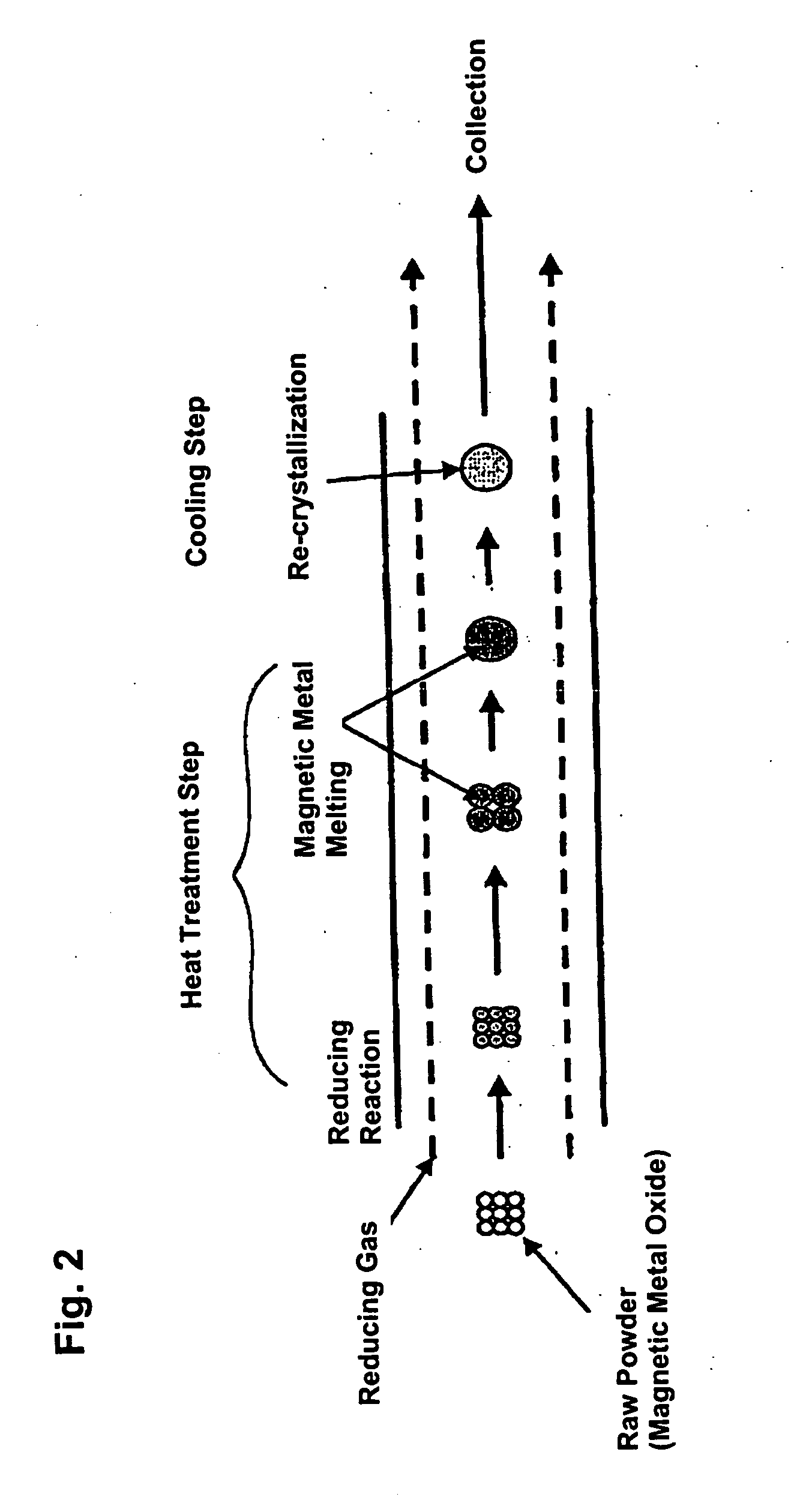

Method for manufacturing magnetic metal powder, and magnetic metal powder

InactiveUS20050056347A1Excellent magnetic propertiesLess heat energyRecord information storageInorganic material magnetismSingle crystalMetal particle

A method for manufacturing magnetic metal powder is provided. In the method, a powdered magnetic metal oxide is supplied to a heat treatment furnace with a carrier gas composed of a reducing gas. The heat treatment furnace is maintained at temperatures above a reducing action starting temperature for the powdered magnetic metal oxide and above a melting point of the magnetic metal in the powder. The powdered magnetic metal oxide is subject to a reducing process, and then magnetic metal particles, the resultant reduced product, is melted to form a melt. The melt is re-crystallized in a succeeding cooling step, to obtain single crystal magnetic metal power in substantially spherical form.

Owner:TDK CORPARATION

Glass composition fluorescent at infrared wavelengths

InactiveUS20060199721A1Reduce the temperatureReduce meltingGlass shaping apparatusActive medium materialFluorescenceDivalent metal

The present invention provides a glass composition that exhibits a fluorescence function and an optical amplification function in a wide wavelength range. This glass composition includes a bismuth oxide, an aluminum oxide, and a glass network former. The glass network former includes an oxide other than silicon oxides as its main component. The glass composition emits fluorescence in an infrared wavelength region through irradiation of excitation light, with bismuth contained in the bismuth oxide functioning as a fluorescent source. A preferable glass network former is B2O3 or P2O5. This glass composition further may contain a univalent or divalent metal oxide.

Owner:NIPPON SHEET GLASS CO LTD

Method for preparing polyester/nano calcium carbonate mixture

The invention relates to a preparation method for a mixed material of polyester / nanometer calcium carbonate, which includes the steps as follows: when polyester chips, nanometer calcium carbonate particles, a reactive monomer and other additives are mixed at a high speed in a high-speed mixing machine simultaneously, the temperature of a mixed system is raised to the temperature of 145 DEG C by utilizing a method of mixed heating or added heating to soften the polyester chips and to lead the nanometer calcium carbonate as well as the other additives to be uniformly stuck on the polyester chips; while no serious conglutination exists between the particles of the polyester chips. The mixed material of polyester / nanometer calcium carbonate prepared by the invention has excellent processing properties and can be used for manufacturing fibers, films or reinforced plastics used for weaving by melt blowing or melt spinning.

Owner:DONGHUA UNIV +1

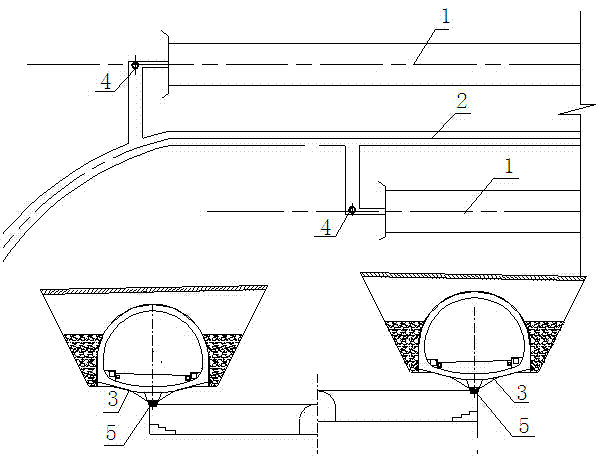

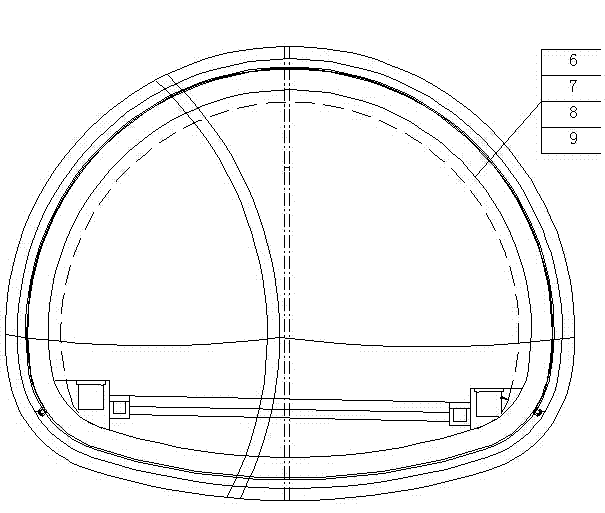

Summer-time face excavation construction method for high and cold permafrost ultra-long highway tunnel

The invention discloses a summer-time face excavation construction method for a high and cold permafrost ultra-long highway tunnel. The summer-time face excavation construction method comprises the steps of tunnel portal excavation and side slope and heading slope protection, shallow-buried tunnel portal permafrost follow-pipe shed construction, shallow-buried tunnel trunk section permafrost excavation and supporting and frozen-earth-section tunnel trunk lining. Before a frozen-earth-section tunnel portal is excavated, a heat-preservation blind drain and a water retaining drive part are arranged in the outside 5 m away from the top of a heading slope and 2 m away from the tops of side slopes in a 'front-cut rear-drive' mode. A positive benching tunneling method is adopted at a frozen-earth tunnel portal section to perform layered and sectioned excavation and supporting, a tunnel portal is pre-reinforced by adopting a large advancing pipe shed, a mining method is adopted at a hidden hole shallow-buried section for construction, a three-bench seven-step excavation method is adopted for excavation, C30 low-temperature early-strength steel fiber sprayed concrete and primary-formwork-lining C30 low-temperature early-strength concrete are adopted to form a double-layer preliminary-supporting structure, and C45 concrete is adopted for secondary formwork lining. By means of the summer-time face excavation construction method, the hole forming difficulty problem can be solved, construction cost can be reduced, a construction period can be shortened, and the like.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

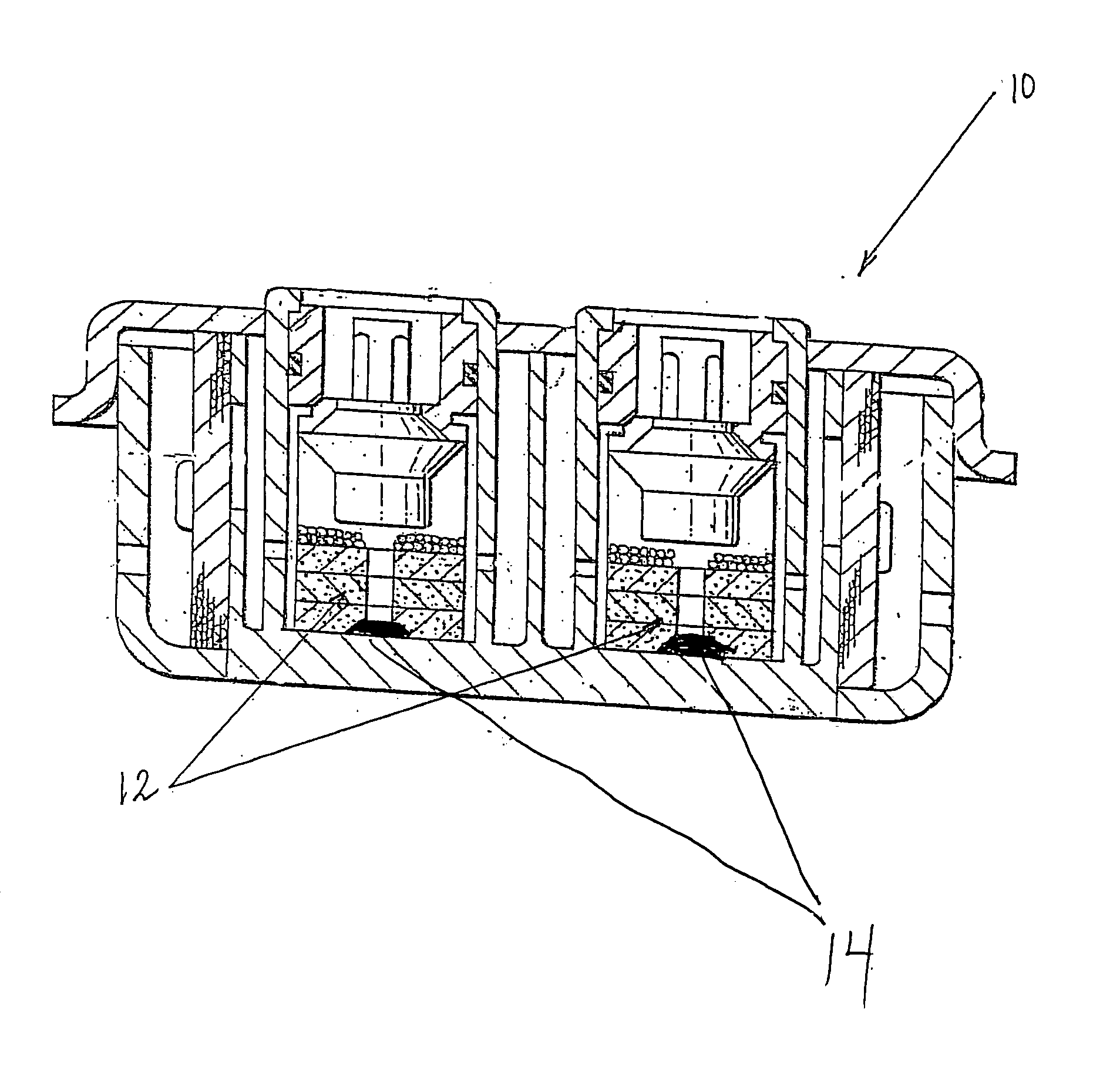

Autoignition compositions

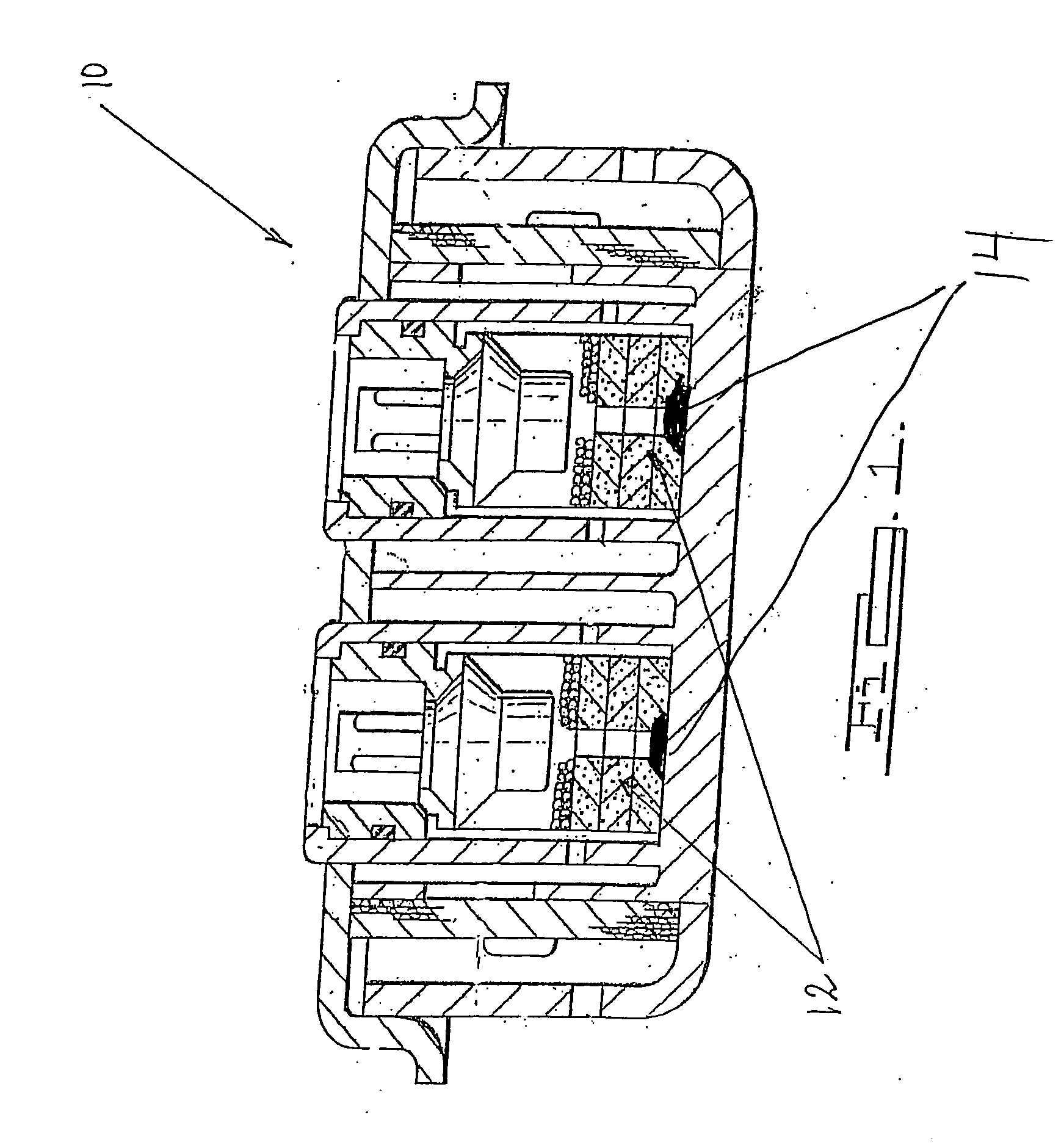

InactiveUS20070044675A1Reduce meltingSurface area availableAlkali metal salt explosive compositionsIgnitorsCombustionCarboxylic acid

An autoignition composition 14 is provided to manage the safe combustion of a primary gas generant composition 12. The autoignition composition 14 contains carboxylic acid and potassium chlorate. A method of managing the safe combustion of the primary gas generant composition 12 is also provided.

Owner:AUTOMOTIVE SYST LAB

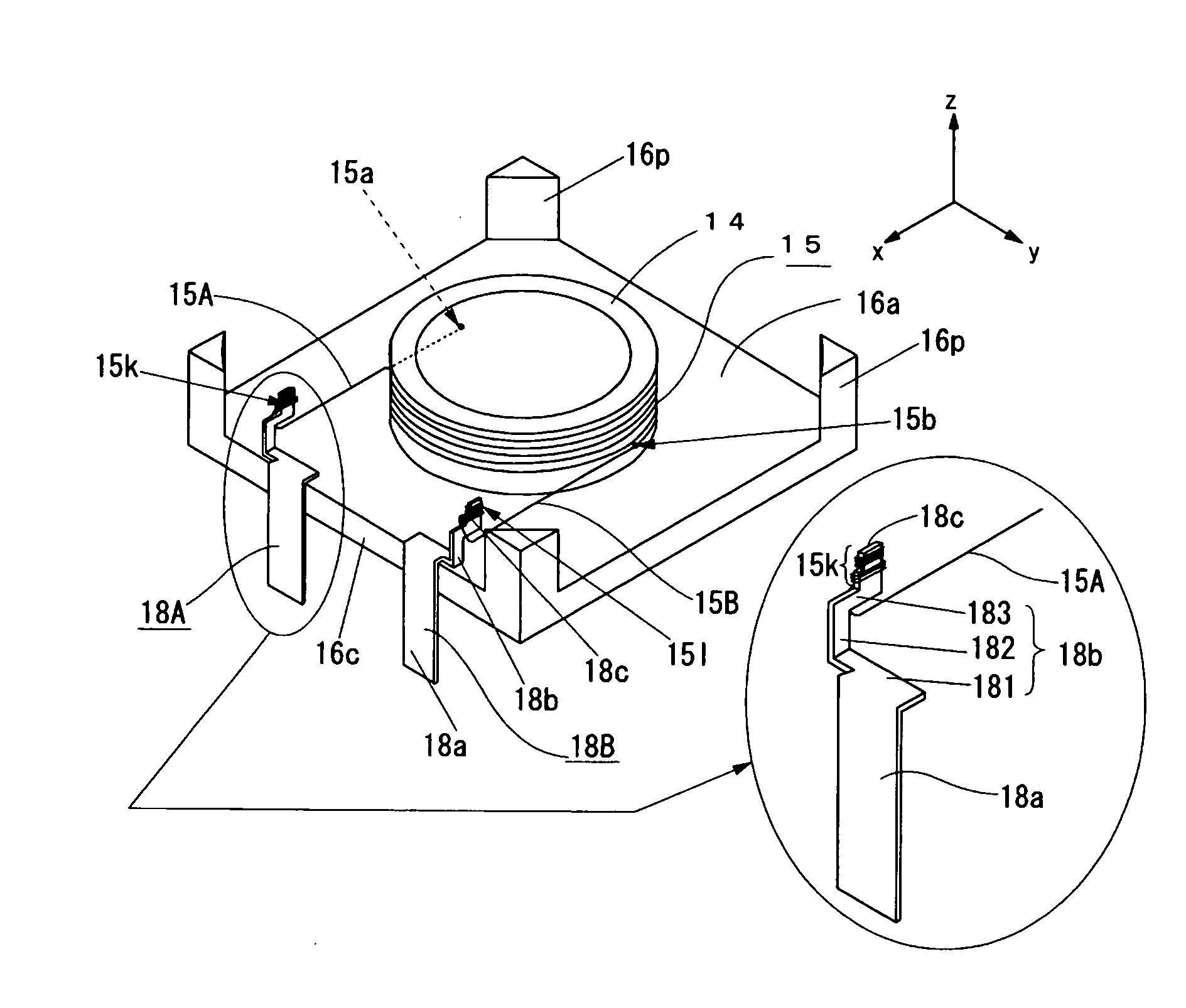

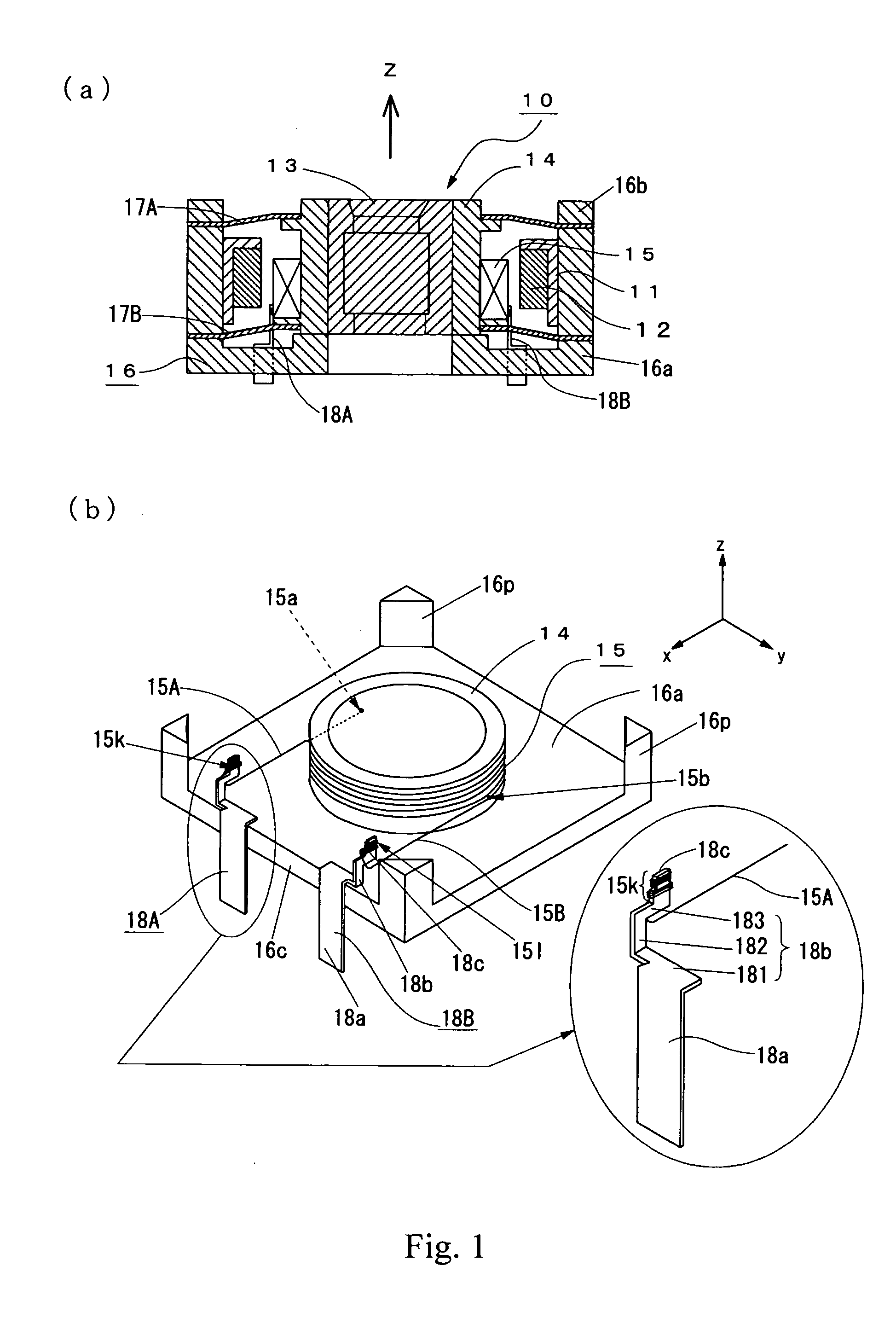

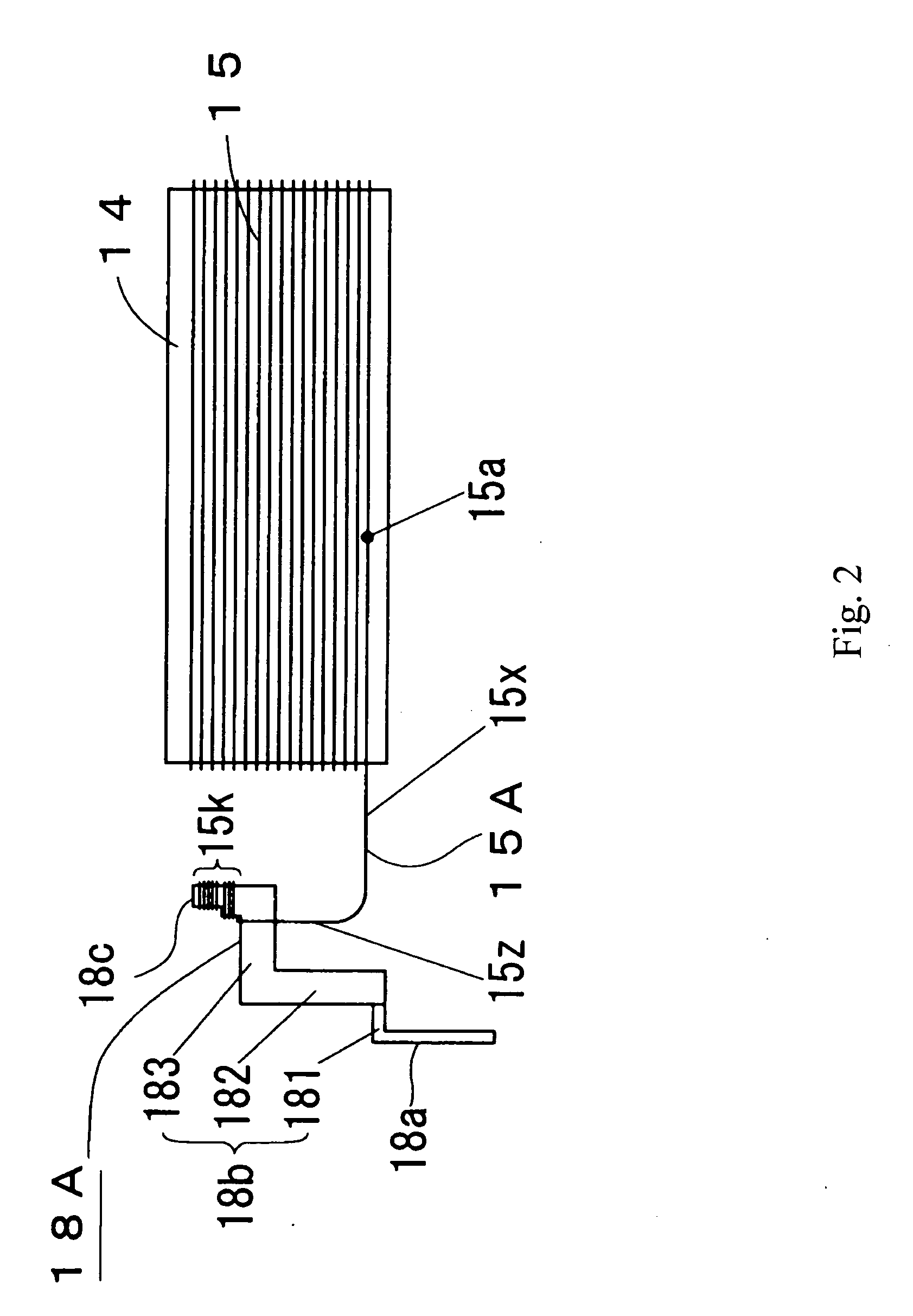

Lens driving device

This invention provides a lens driving device with a driving coil connected thereto that can avoid possible damages on the ends of the driving coil and any adverse effect on the spring members or the lens holder. When the ends of the driving coil are connected to the electric terminals mounted on a casing respectively, the coiling pull start section of the driving coil which begins from the beginning end of the driving coil to the electric terminal and the coiling pull finish section of the driving coil which begins from the finish end of the driving coil to the electric terminal are made into L-shaped structures. Such L-shaped structure comprises a lens holder lateral section extending horizontally and a terminal lateral section extending vertically.

Owner:MICRO WIN TECH +2

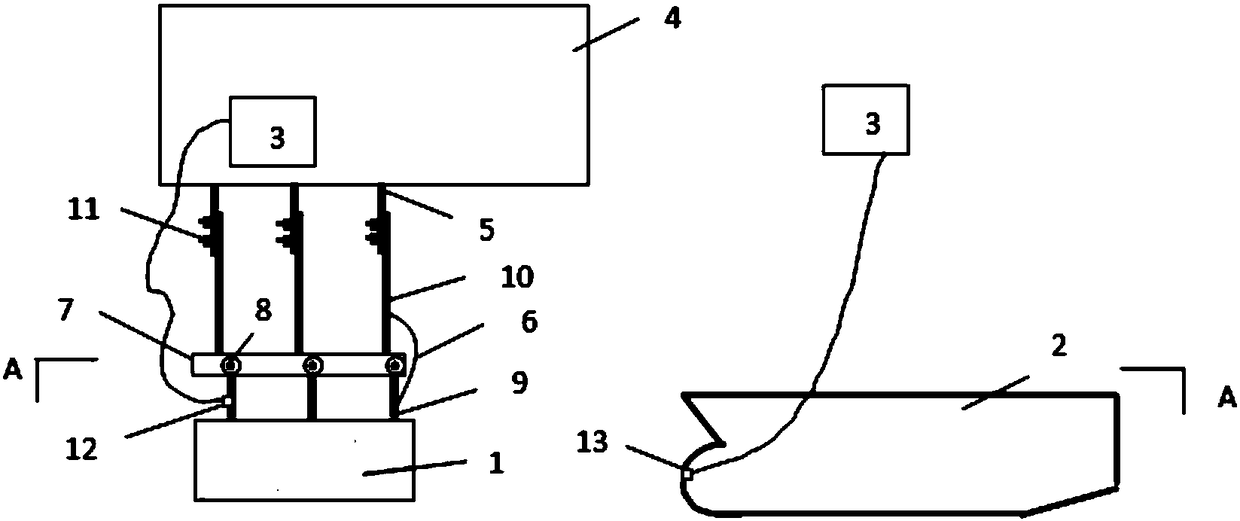

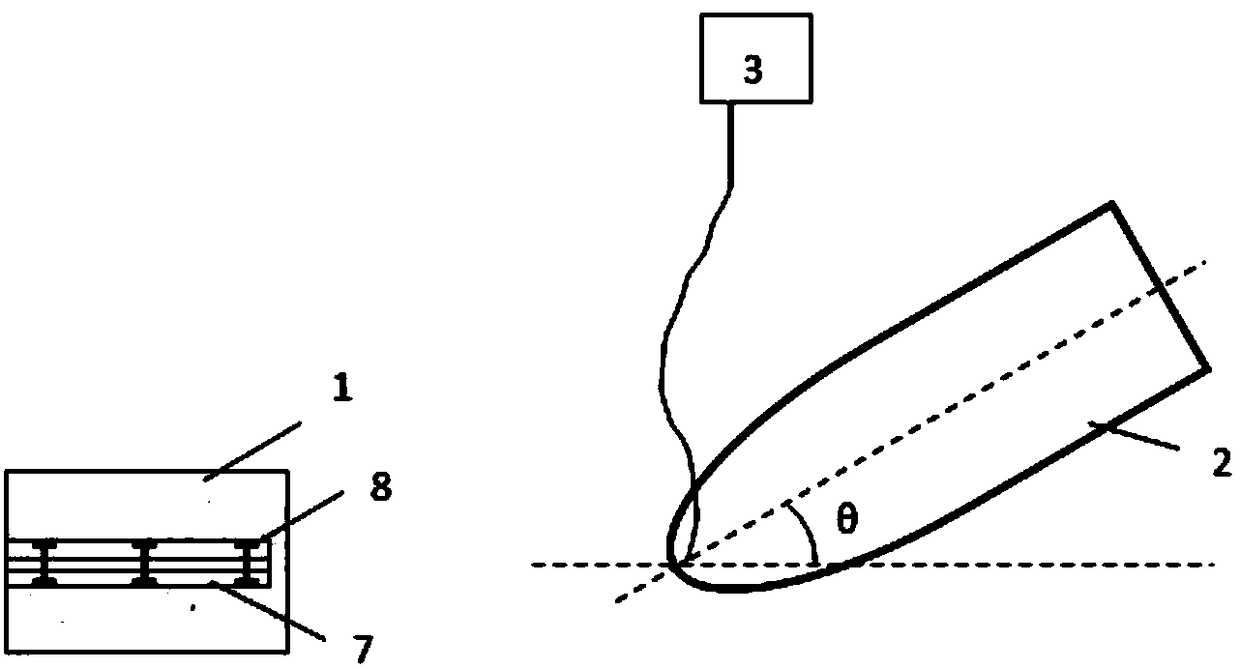

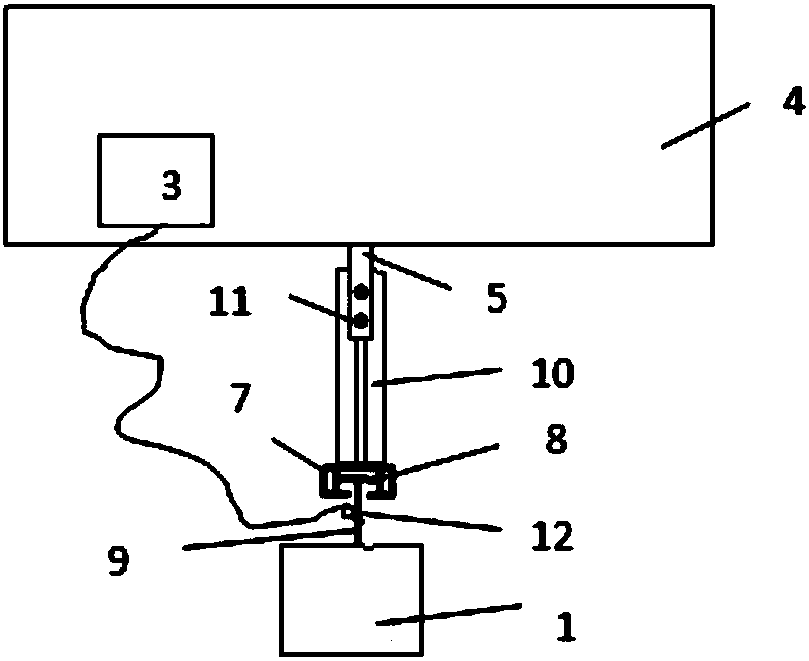

Ship ice model tank collision experiment device and experiment method

The invention discloses a ship ice model tank collision experiment device. The ship ice model tank collision experiment device comprises a water tank, wherein a ship model and an ice body are arrangedin the water tank; the ice body is fixedly connected with a pull rod; the pull rod is fixedly mounted on a connecting rod of a pulley; the pulley is positioned in a guide rail; the guide rail is connected with a connecting plate; the connecting plate is fixedly connected with a towing assembly; the pulley is fixed on the guide rail through a connecting device; a strain gage is mounted at the endpart of the ship model; the strain gage is sequentially connected with a charge amplifier, a multichannel information acquisition instrument and a computer; the motion of the towing assembly drives the pulley and the guide rail to move, thereby driving the pull rod to move; and when the ice body collides the ship model, the strain gage collects collision data. The ship ice model tank collision experiment device can perform structural response validation on mechanical properties, ice body shapes, ice body mass, ice body speed, and collision positions of different ice materials, ship model flotation conditions and collision angles, properly reflects real situations of collision between ships and ice, and is low in cost, easy to operate and low in risk.

Owner:JIANGSU UNIV OF SCI & TECH

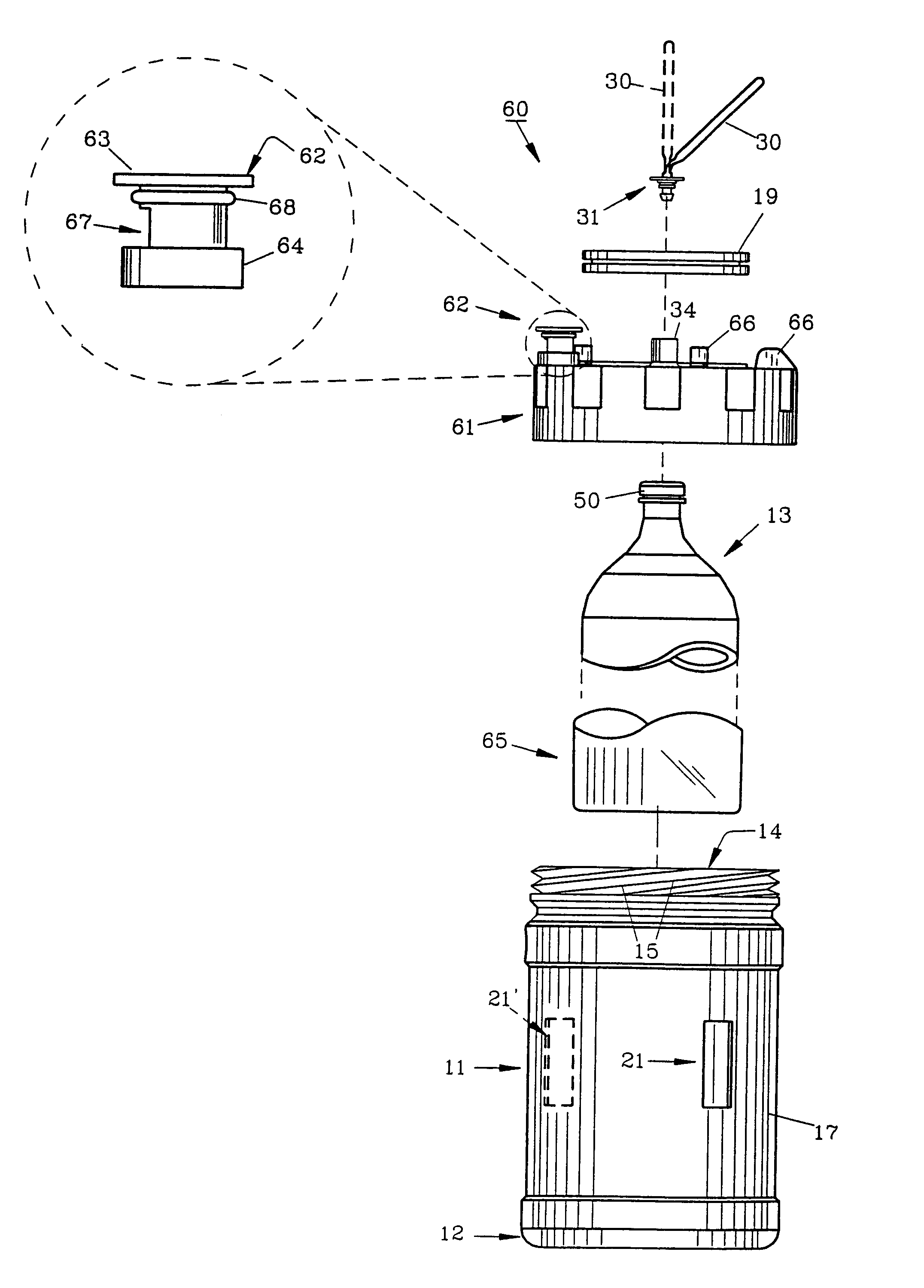

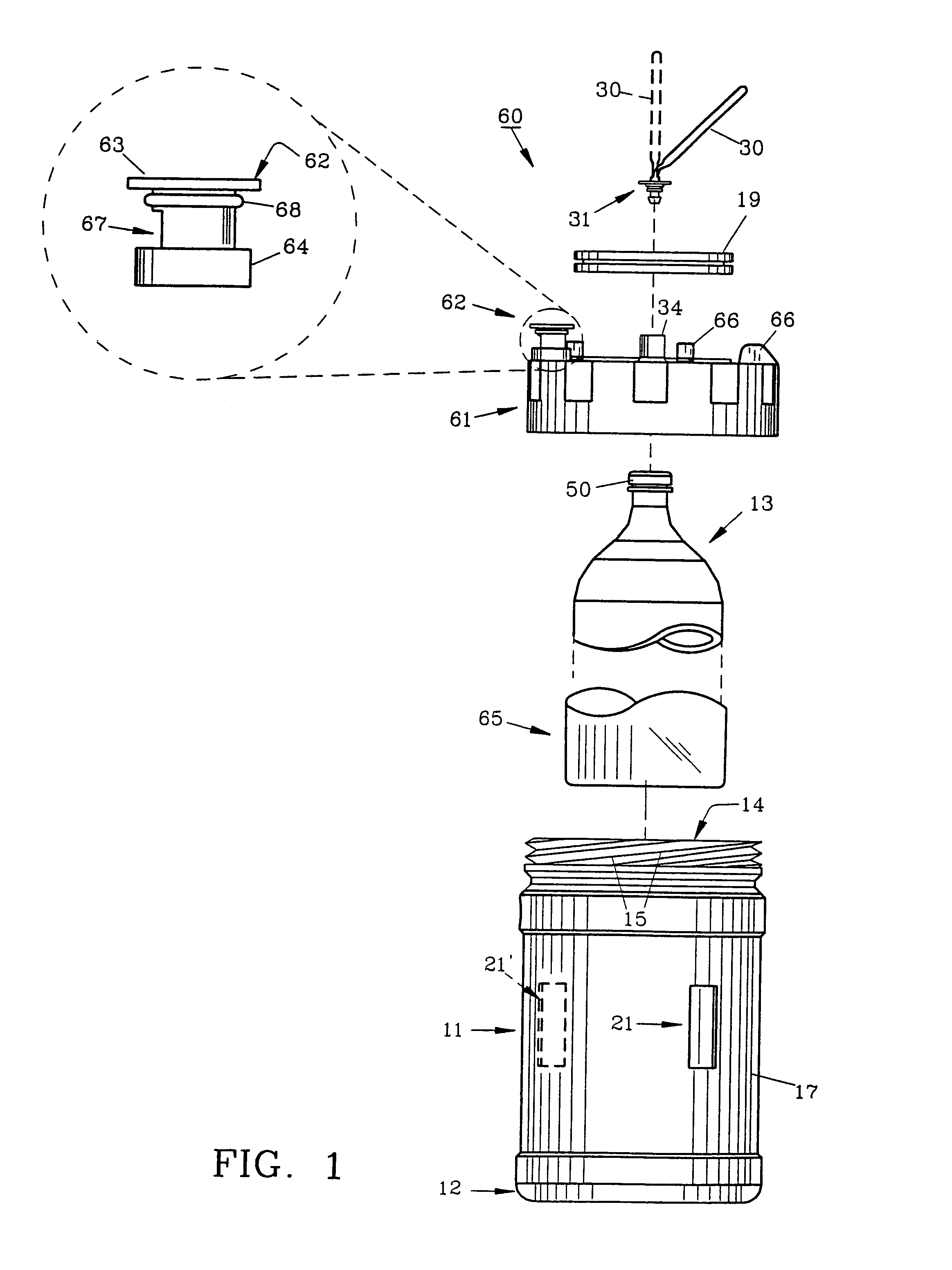

Bottle carrier/cooler

InactiveUS7032409B1Reduce usagePrevent overflowLighting and heating apparatusLiquid dispensingPotable waterEngineering

A bottle carrier / cooler is provided for easy, convenient transportation, cooling and storage of a single conventional plastic beverage bottle. The bottle carrier / cooler is configured to substantially contain one standard bottle while exposing the bottle neck and bottle cap. The body of the bottle carrier / cooler is of a diameter sufficient to maintain ice, water or other refrigerants so the bottled beverage will remain at a desirable low temperature. The beverage which may be a soft drink, can be poured from the bottle without removing the bottle from the carrier / cooler. A seal connected to the carrier / cooler lid prevents leakage of the refrigerant while the beverage is poured and in conjunction with projections along the bottom of the carrier / cooler stabilize the bottle longitudinally. In the preferred embodiment of the invention a lid having a pour spout and finger tabs is provided. A cover or sleeve is utilized to surround the bottle before placement within the carrier / cooler to maintain the refrigerant placed therein free from dirt and debris. The pour spout provides access to the potable water contained therein as the ice melts.

Owner:21ST CENTURY PROD INC

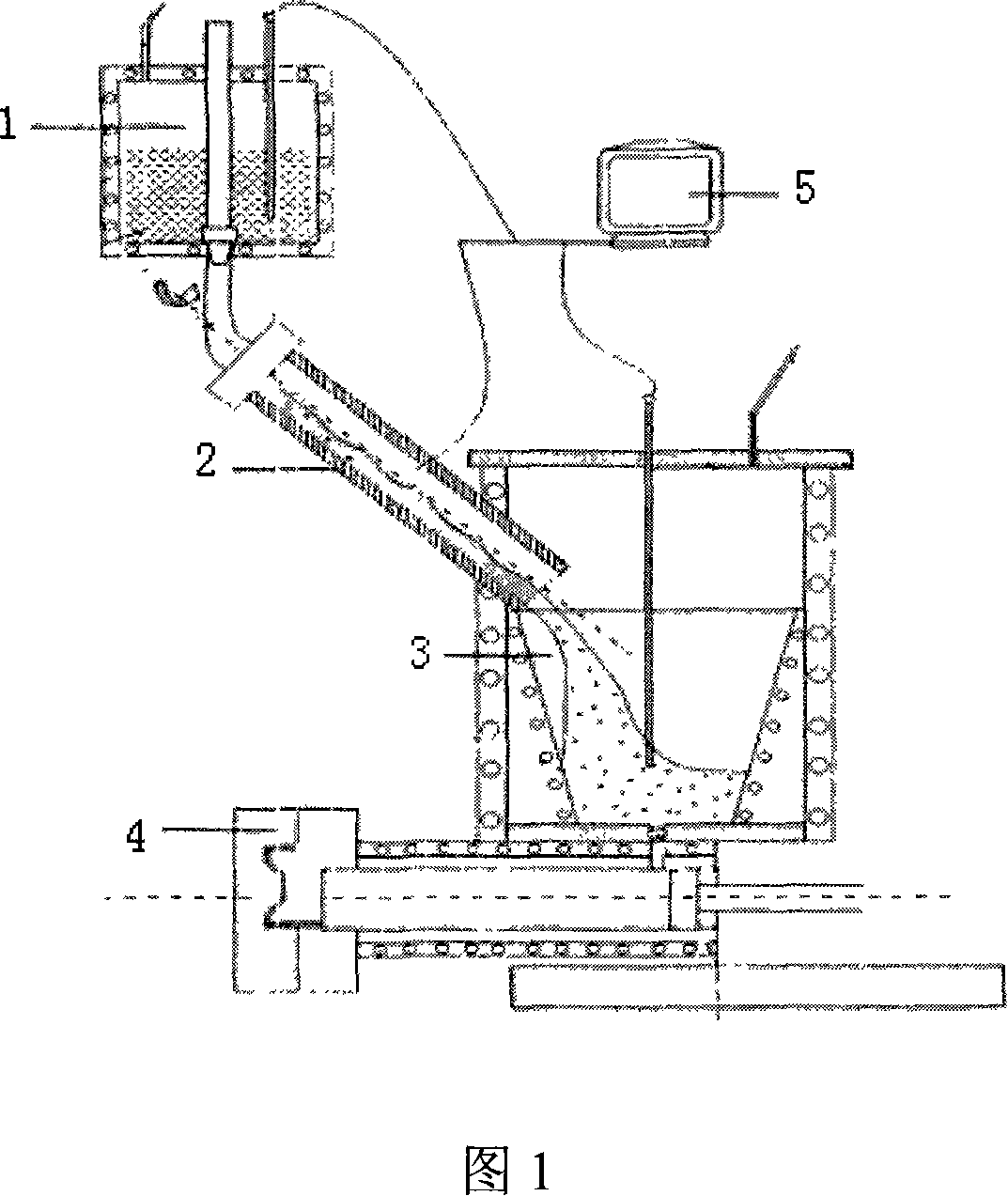

Low-temperature shearing rheological die casting technology

The present invention relates to a low-temperature shearing rheopectic die-casting process. It is characterized by that said process includes the following steps: (1), making alloy melt be passed through feeding device and be fed into turning conveying pipe, and adopting conveying pipe with low rotating speed to control cooling and implement splat cooling of molten metal and stirring of primary stage of coagulation; (2), making the melt with lots of crystal nucleus be flowed into a crystallization furnace, utilizing slurry microstructure on-line detection technique to control and detect growth form of nascent phase and solid-phase rate of slurry; and (3), making the slurry be injected into pressure chamber of die-casting machine to make directly-forming.

Owner:NANCHANG UNIV

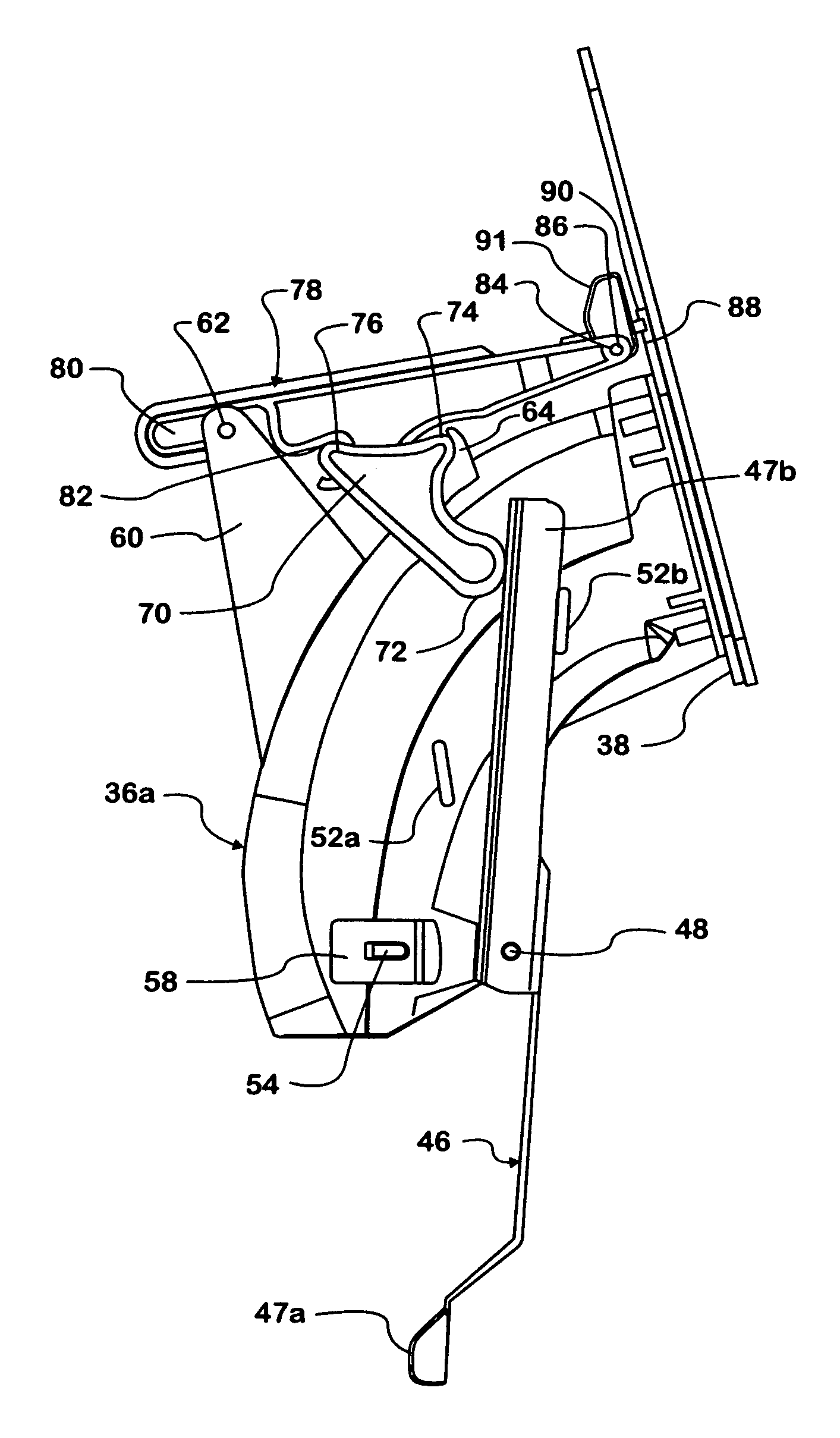

Ice dispensing chute

ActiveUS20050006406A1Easily separateLess wetLighting and heating apparatusLiquid flow controllersEngineeringLinkage concept

An ice dispensing chute mechanism is characterized by an ice chute adapted for attachment at an upper ice inlet end to an ice retaining bin at an ice outlet from the bin. An actuating arm is pivotally mounted on the ice chute and has a lower end for being contacted and moved by a receptacle into which ice is to be dispensed from a lower ice discharge end of the chute and an upper end for contacting and moving a linkage mechanism upon rotation of the actuating arm by the receptacle. The linkage mechanism is pivotally mounted on the ice chute and is coupled to an ice gate that is linearly moved by the linkage mechanism between open and closed positions that establish and interrupt communication between the upper inlet to the chute and the ice outlet opening from the bin. Movement of the linkage mechanism by the actuating arm operates the linkage mechanism to translate the rotational movement of the actuating arm into linear movement of the ice gate between its open and closed positions to dispense ice and to cease dispensing ice into the receptacle. The ice chute consists of two halves that snap together in a releasable manner to permit easy disassembly of the ice chute for cleaning, repair or replacement of parts. The upper inlet to the ice chute is configured to impart to ice particles a trajectory through the chute that guides the ice particles into the receptacle while preventing the vast majority of the ice particles from contacting interior surfaces of the chute.

Owner:MARMON FOODSERVICE TECH INC

PVC resin with ultra-low degree of polymerization and manufacturing method thereof

ActiveCN101665548AImproved particle morphology and molecular weight distributionImprove processing thermal stabilityChemistryPlasticizer

The invention discloses a PVC resin with ultra-low degree of polymerization and a manufacturing method thereof. In the invention, a polymerization method is adopted to carry out polymerization reaction, the reaction temperature is 60-64 DEG C, and the reaction pressure is less than 1.0 MPa; a first chain transfer agent is added when the polymerization reaction is carried out for 0-30min, and then0.005-0.012% of vinyl chloride monomer (VCM) is added; a second chain transfer agent is added when the polymerization reaction is carried out for 60-90min, and then 0.005-0.02% of monomer is added toobtain the PVC resin with ultra-low degree of polymerization. The PVC resin manufactured by the invention has the advantages of the average degree of polymerization below 500, high apparent density, low melting and gelatinization temperature, low melt viscosity, good transparency, short plasticization time and favorable processability and the like, and the phenomenon of accelerating products agingdue to the transfer of plasticizer does not appear in machining process.

Owner:SICHUAN JINLU GRP

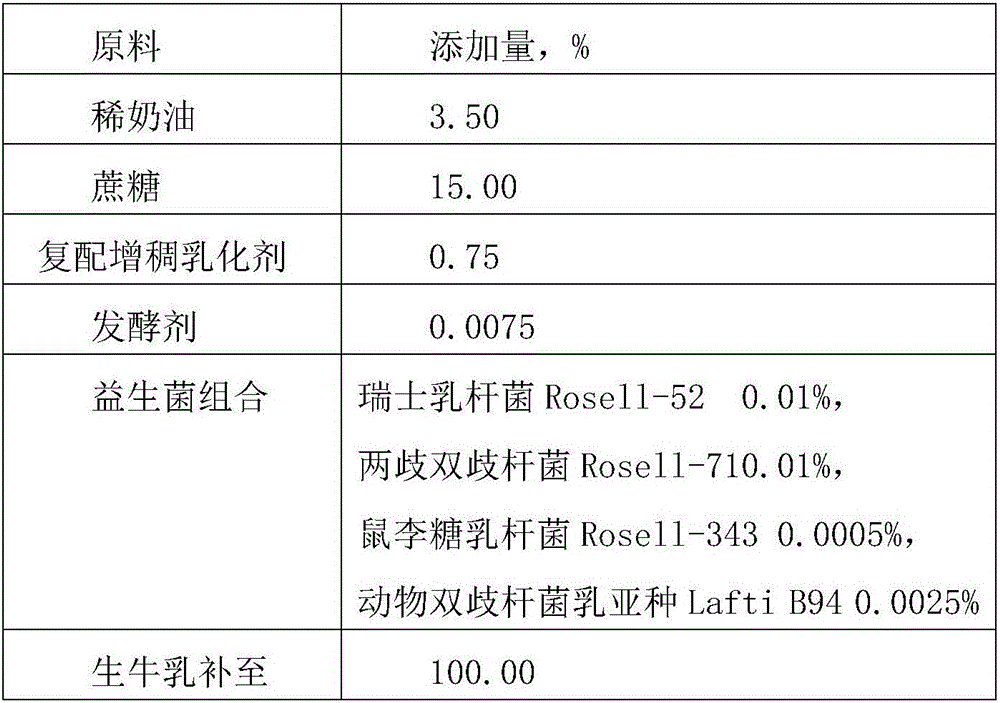

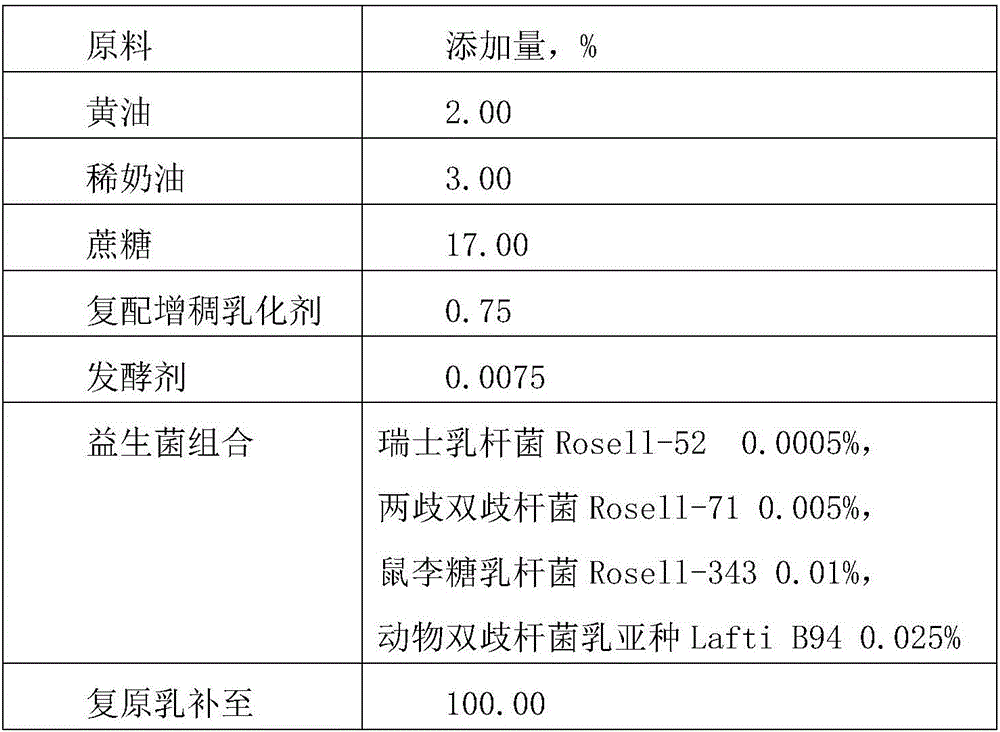

Fermented yoghourt soft ice cream milk sauce containing various probiotics, and production method of milk slurry

InactiveCN106359592AFine and even textureEntrance smoothMilk preparationFrozen sweetsSlurrySweetness

The invention discloses a fermented yoghourt soft ice cream milk sauce containing various probiotics. The milk sauce comprises, by mass, 70-85% of raw milk or reconstituted milk, 10-30% of a sweetener, 0.3-1.2% of a compounded thickening emulsifier, 0-5% of oil, 0-10% of a dairy product raw material, 0.005-0.02% of a starter and 0.0085-0.065% of probiotics, and the sum of the mass percentages of all above raw materials is 100%. The invention also discloses a production method of the milk sauce. The shelf life of the milk sauce stored at 4-10 DEG C can reach 21 d; the shelf life of the milk sauce stored in a refrigeration manner can reach 12 months; and ice cream obtained by using the milk sauce has the advantages of smooth and fine texture, smooth mouthfeel, and sour-sweet and tasty taste.

Owner:XUZHOU YITONG FOOD IND CO LTD

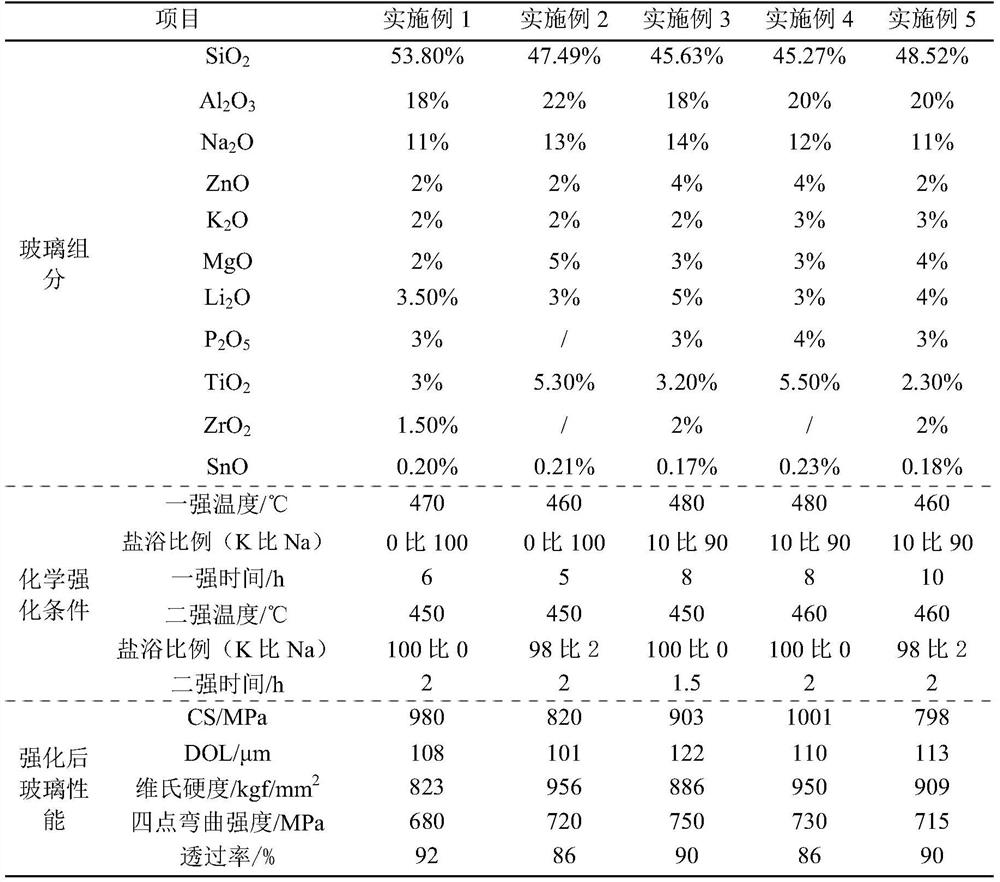

Lithium-aluminum-silicon microcrystalline glass as well as strengthening method and application thereof

InactiveCN112919813AGood chemical stabilityModerate melting temperatureGlass tempering apparatusTelephone set constructionsPotassium nitrateIon exchange

The invention discloses lithium-aluminum-silicon microcrystalline glass as well as a strengthening method and application thereof. The glass comprises the following components in percentage by mass: 45%-75% of SiO2, 10%-25% of Al2O3, 0-4% of ZrO2, 3%-5% of Li2O, 10%-18% of Na2O, 0-5% of K2O, 0-6% of P2O5, 0-7% of TiO2, 2%-7% of MgO, 0-10% of ZnO and 0-1% of SnO. The strengthening method comprises the following steps: preparing raw materials, and performing melting and molding to obtain mother glass; carrying out heat treatment to obtain microcrystalline glass; carrying out ion exchange on the microcrystalline glass in molten salt at the temperature of 390-500 DEG C for 3-10 hours to obtain primarily strengthened microcrystalline glass; and finally, soaking the glass ceramic subjected to primary strengthening in molten salt consisting of potassium nitrate and sodium nitrate for 1-2.5 hours to obtain the lithium-aluminum-silicon glass ceramic.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

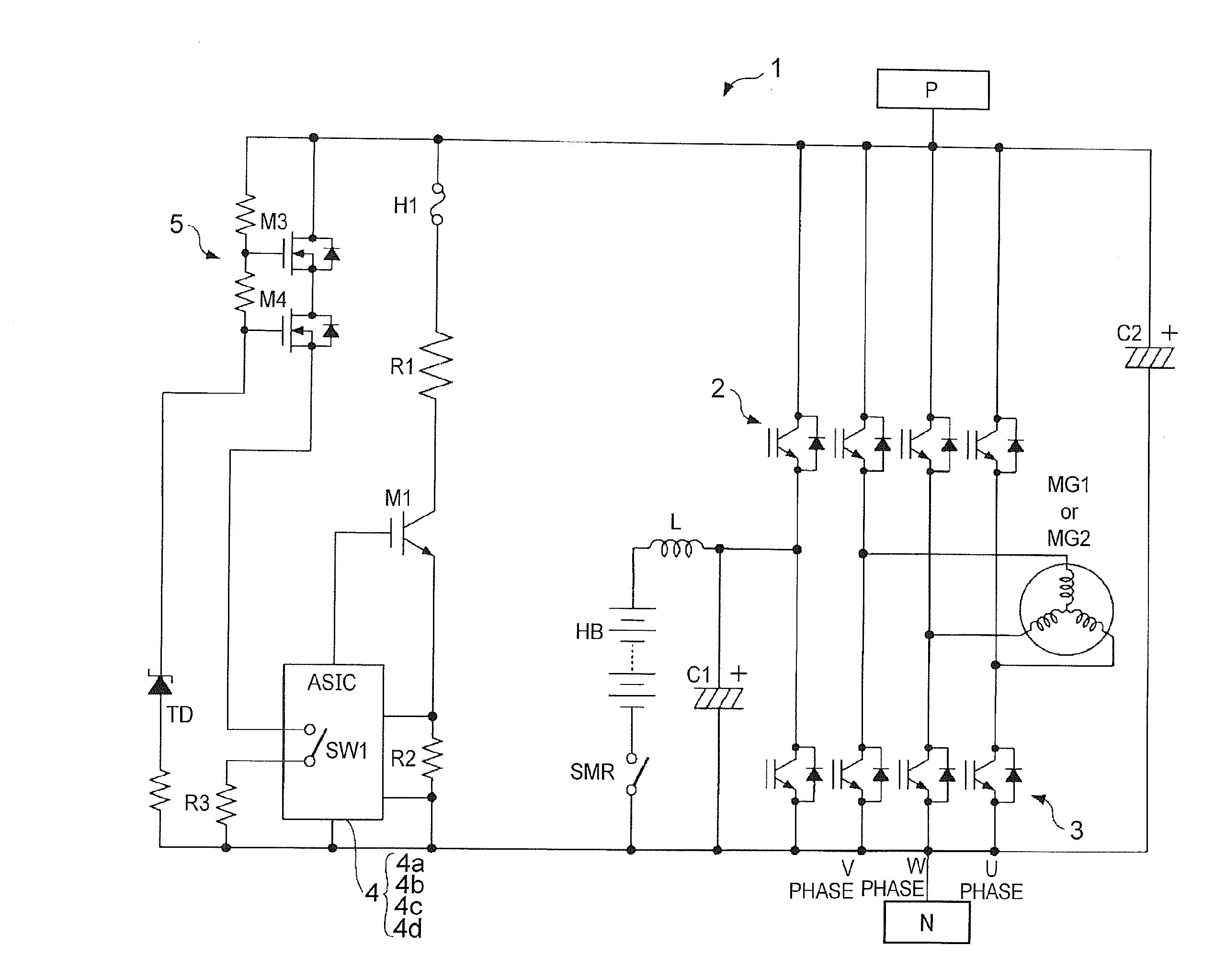

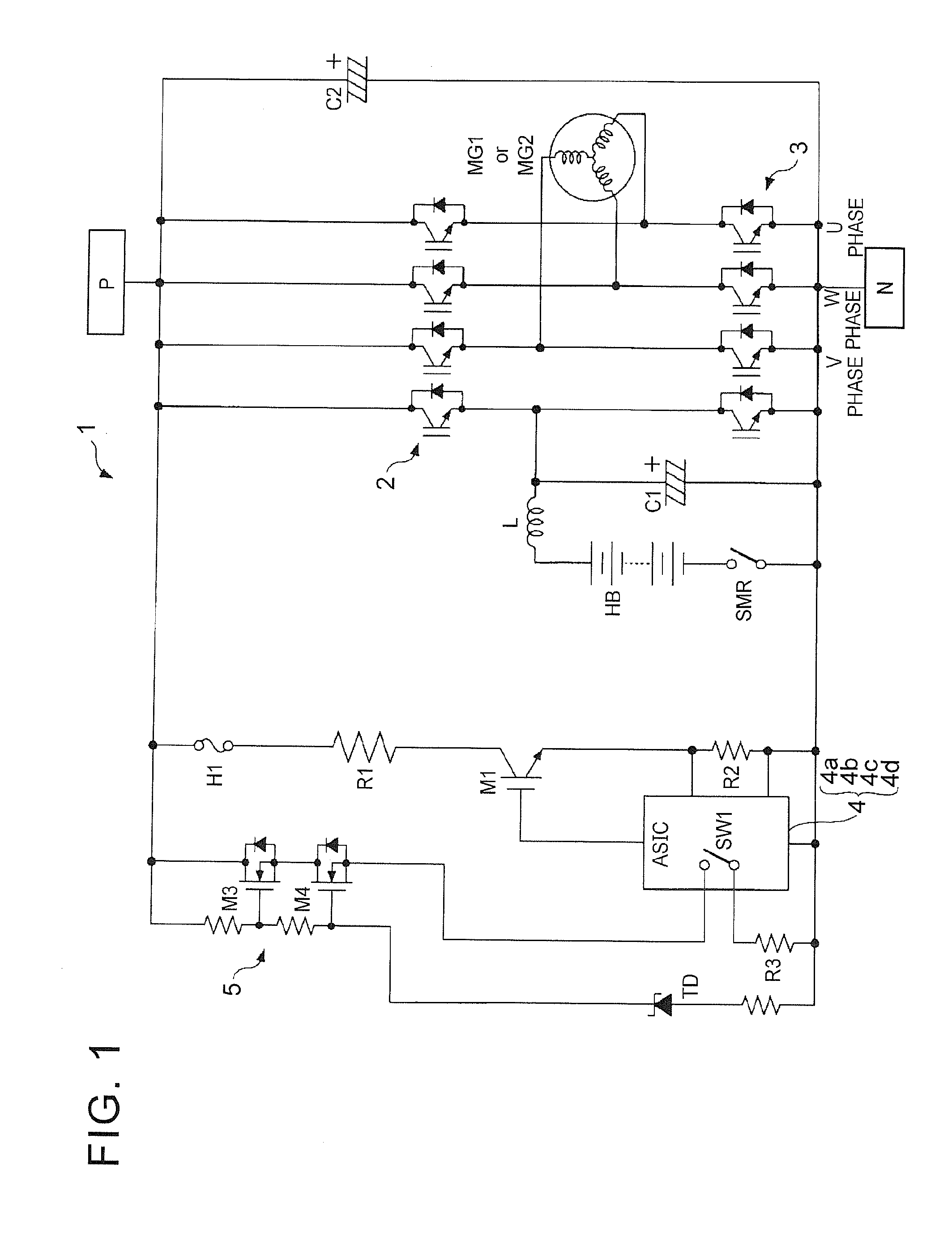

Overcurrent protection device, overcurrent protection method, and non-transitory medium

ActiveUS20140177119A1Sufficient protectionMelt the fuse element can beHybrid vehiclesElectric devicesPower flowEngineering

An overcurrent protection device includes a fuse element and an auxiliary circuit. Power is applied from a high-voltage unit of a main circuit to the fuse element. The auxiliary circuit includes a component which heats the fuse element. An amount of electric current flowing in the fuse element when the fuse element melts is controlled by heat generated by the component.

Owner:TOYOTA JIDOSHA KK

Rotary kiln lime roasting process

The invention discloses a rotary kiln lime roasting process comprising the following steps: (1), putting a raw material namely lime into a preheater for preheating at first, guiding the flue gas generated by pulverized coal combustion in a rotary kiln into the preheater to preheat the lime by using waste heat, and then discharging the lime, wherein the preheater is communicated with the kiln tail of the rotary kiln; and (2), roasting the preheated lime discharged from the preheater in the rotary kiln which is heated by burner nozzle pulverized coal injection, adding the roasted lime into a cooler from the kiln head to perform cooling, and finally discharging the cooled lime from the bottom of the cooler, wherein in the step (1), a pulverized coal spray gun is arranged at the lower part of the preheater to spray the pulverized coal accounting for 5-30% of the coal spraying quantity of the burner nozzle of the original rotary kiln into the preheater so as to improve the preheating temperature in the preheater, and the pulverized powder sprayed into the preheater is independently measured.

Owner:JIANGSU ZHONGSHENGYUAN TECH CO LTD

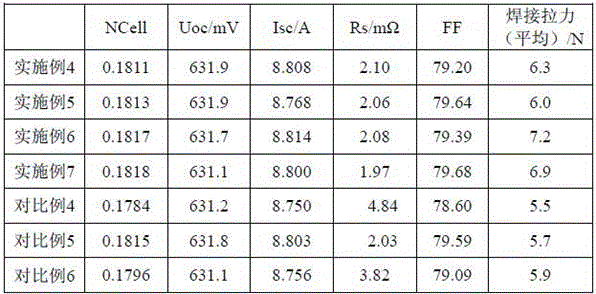

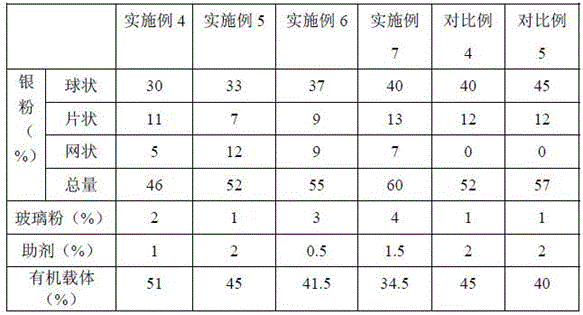

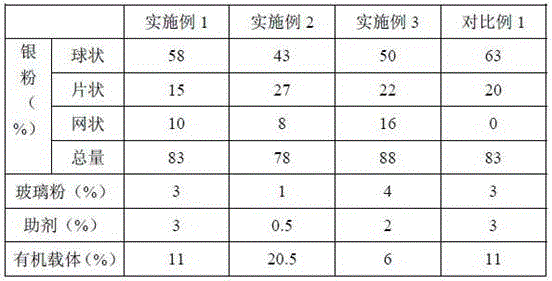

Crystalline silicon solar cell silver paste with low silver content and preparation method thereof

ActiveCN105913897AReduce meltingReduce silver contentNon-conductive material with dispersed conductive materialPhotovoltaic energy generationMicro nanoSilver paste

The invention discloses crystalline silicon solar cell silver paste with a low silver content and a preparation method thereof. The crystalline silicon solar cell silver paste is composed of: silver powder, an organic carrier and an auxiliary agent. An organic solvent and a thickening agent are mixed to form the organic carrier. Micro-nano netted silver powder, spherical silver powder and sheet-shaped silver powder are mixed to form the silver powder. With 100% of the mass of the crystalline silicon solar cell silver paste, the mass percent of the micro-nano netted silver powder is 5-16%. According to the invention, a proper amount of micro-nano netted silver powder is added to conventional silver paste, the micro-nano netted silver powder has a porous characteristic, and compared with other entity silver powder with the same particle size, the fusion speed of the micro-nano netted silver powder is low and can relatively well maintain the structure characteristic in an existing paste flash burning process, so that the purpose of lowing the silver content of the paste is achieved.

Owner:JIANGSU HOYI TECH

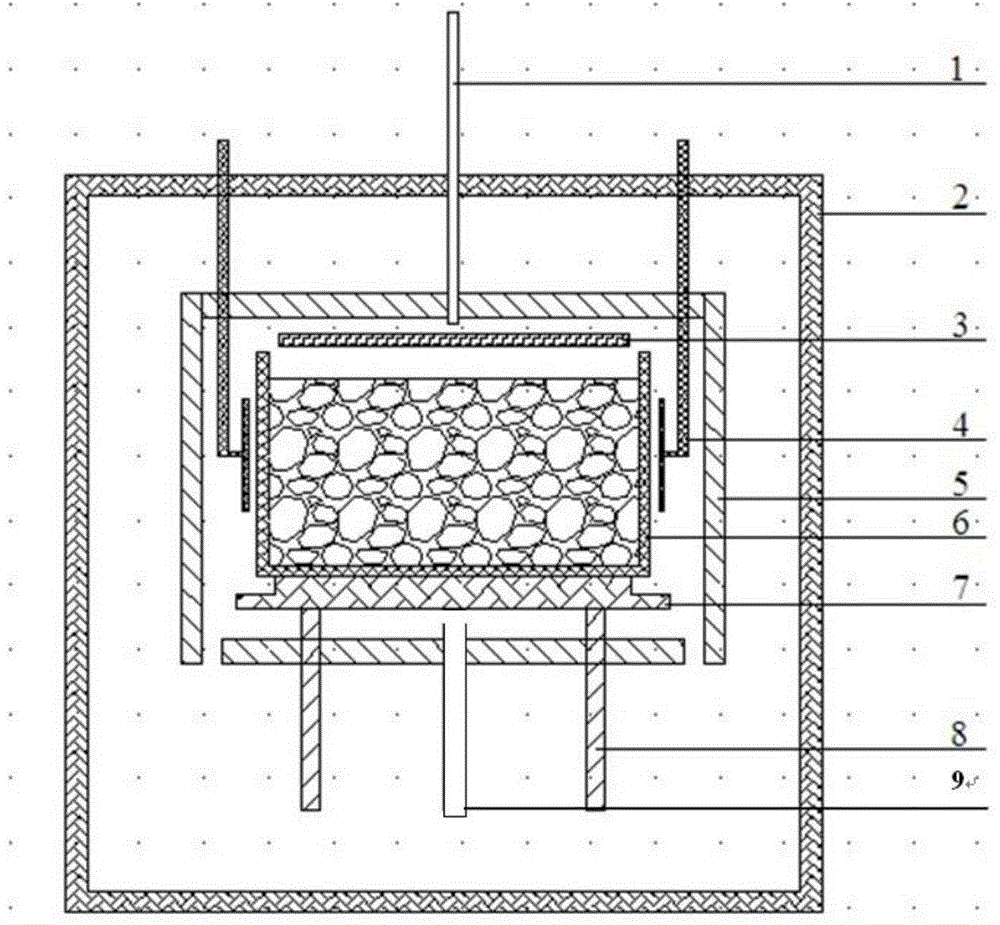

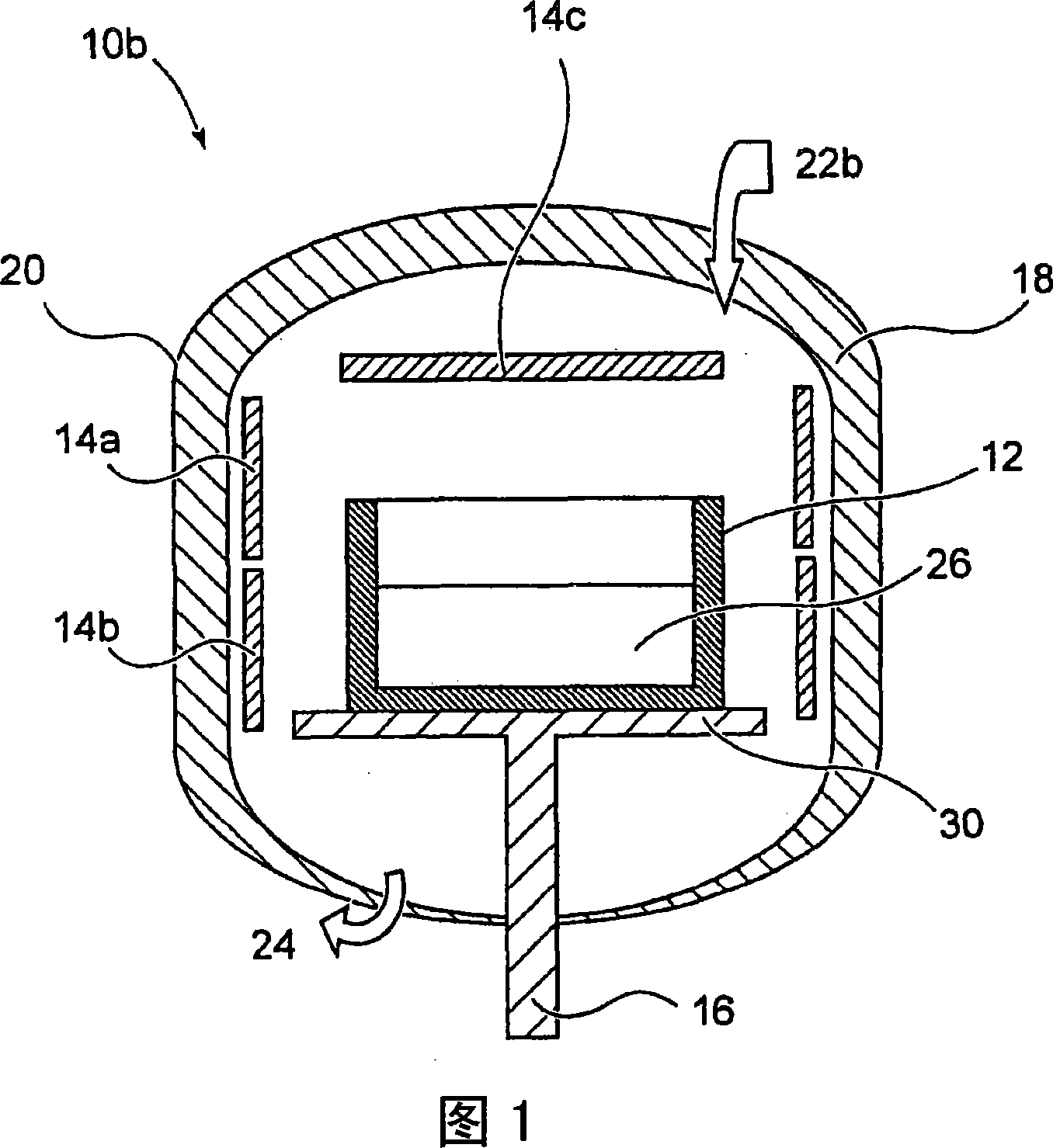

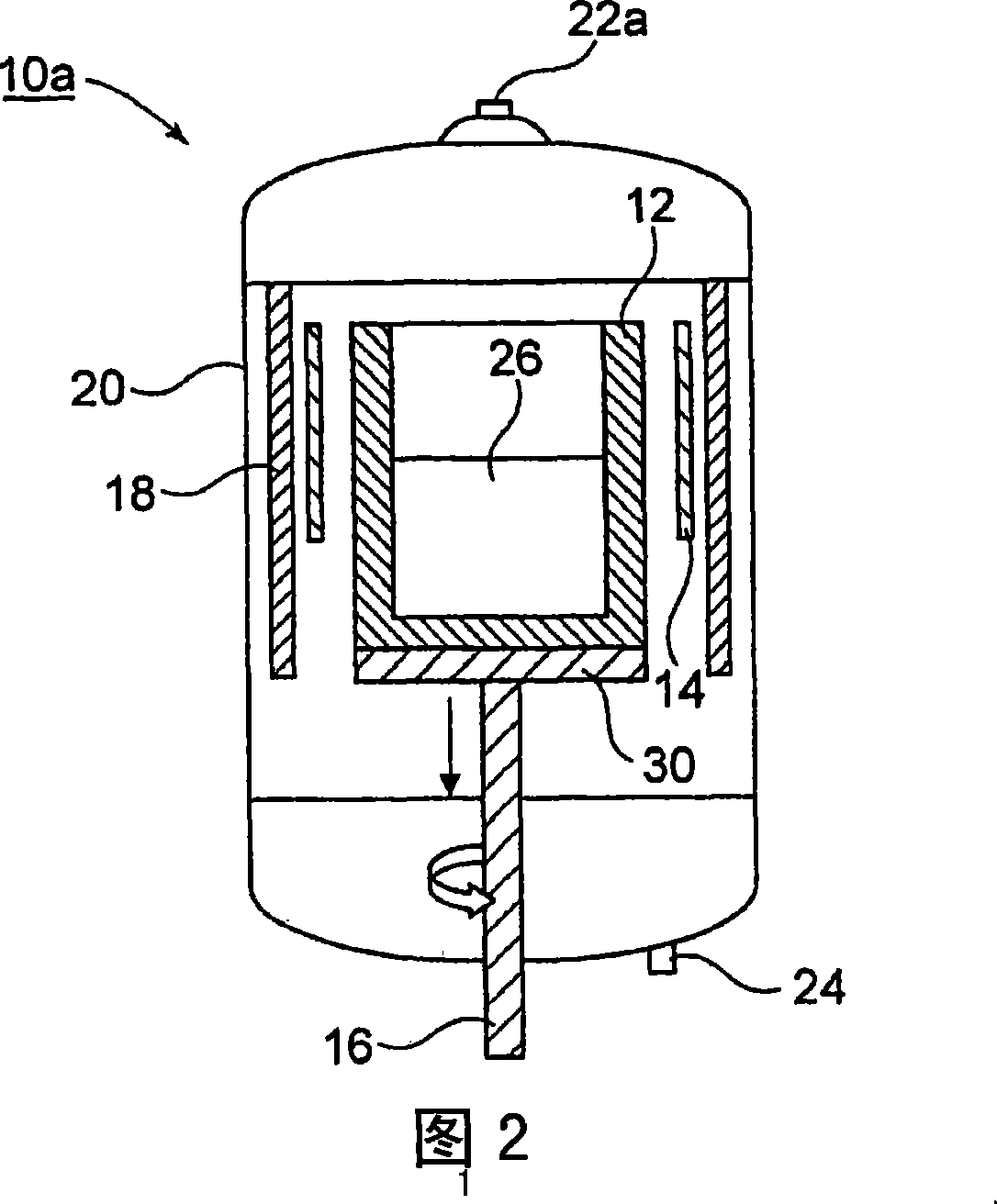

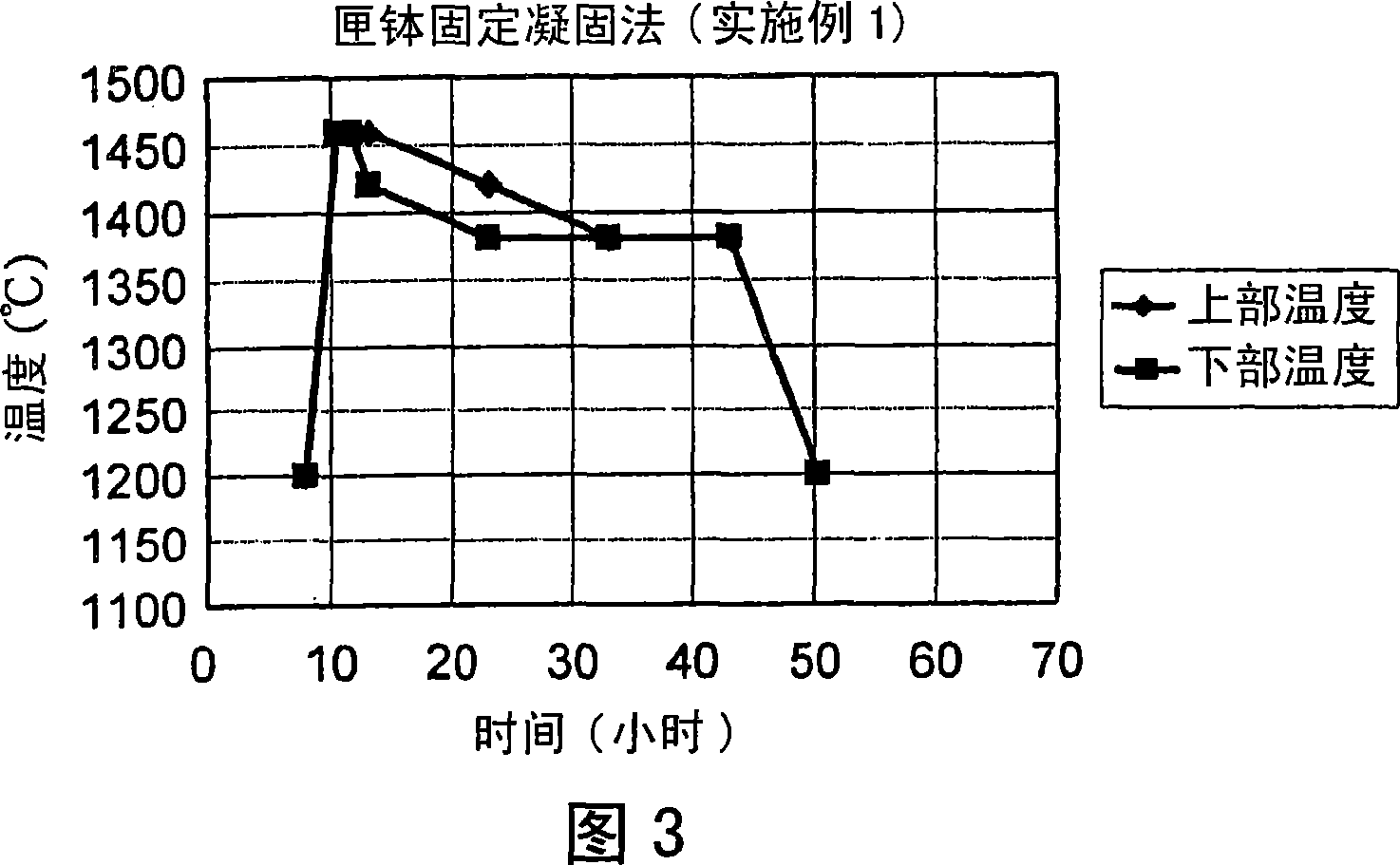

Polysilicon semi-fusion casting device adopting bottom air cooling and technology using the same

InactiveCN104131345ASave heat field costReduce labor costsPolycrystalline material growthSingle crystal growth detailsTime efficientCrucible

The invention relates to a polysilicon semi-fusion casting device adopting bottom air cooling and a technology using the same, and belongs to the field of polysilicon preparation. The polysilicon semi-fusion casting device adopting bottom air cooling comprises a furnace body, a directional solidification block in the furnace body and a crucible on the directional solidification block, a ventilation bottom pipe (9) is arranged in the center below the directional solidification block, and the opening of the bottom pipe is 2-5cm away from the directional solidification block. The polysilicon semi-fusion casting device reduces a furnace body heat field cost, a labor cost and energy consumption in a fusion phase, reduces a production cost by 5%, reduces semi-fusion technology melting, crystallization and cooling time by about 4h and saves a time cost by 5%.

Owner:DALIAN UNIV OF TECH

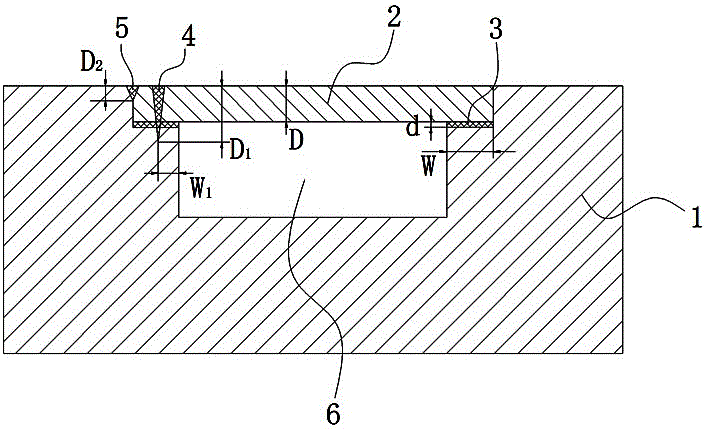

Moderate-strength aluminum liquid cooled shell welding method

The invention relates to a moderate-strength aluminum liquid cooled shell welding method. The method comprises the following steps: step S1, machining welding parts; step S2, pre-treating the parts; step S3, welding, wherein the distance from a seal weld to the inner wall of a liquid cooling flow channel is W1; the fusion depth D1 of the electron beam EB1 weld is equal to the summation of the thickness D of a cover plate, the thickness d of a solder material and (3-4)mm; a surface focus is adopted for welding; the scanning amplitude value of the electron beams is 0.2mm to 0.4mm; a finished weld adopts defocusing welding; the fusion depth D2 of the finished electron beam EB2 weld is 2mm to 4mm; the appearance condition of the electron beam weld is checked after welding; step S4, performing vacuum braze welding treatment; step S5, machining the shell after welding until a final product is obtained. The method disclosed by the invention has the advantages of realizing reliable welding of an embedded cover plate and a chamber body by adopting a reasonable joint design and electron beam welding and vacuum braze welding techniques, and greatly improve the maturity of a preparation technique of a liquid cooling project.

Owner:CHENGDU SIWI HIGH TECH IND GARDEN

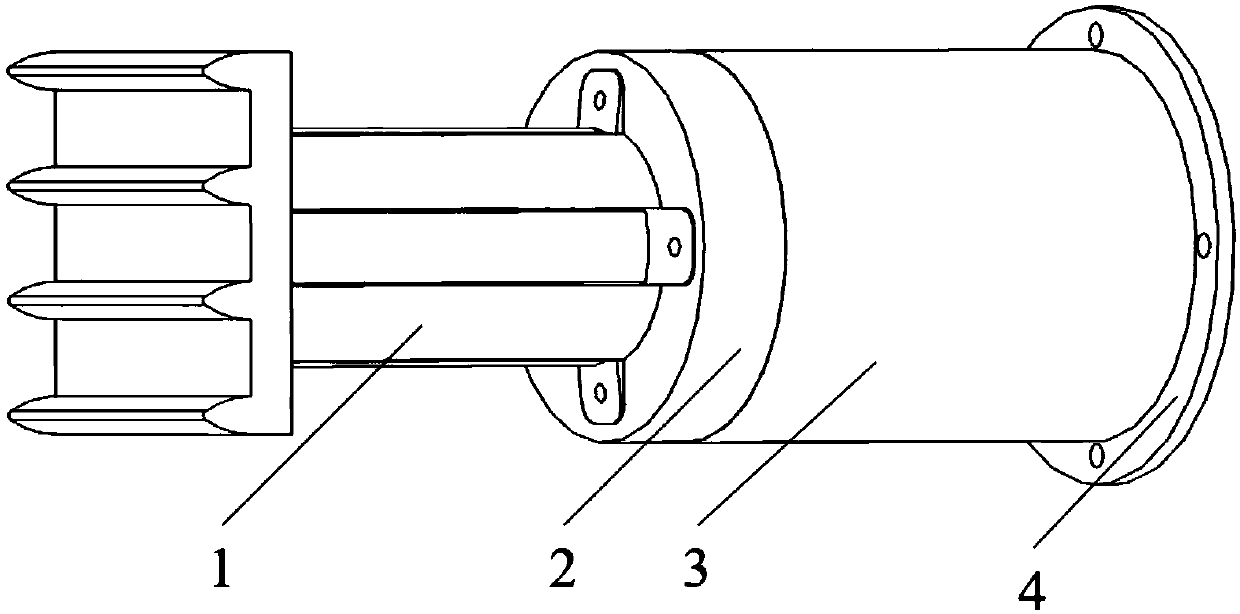

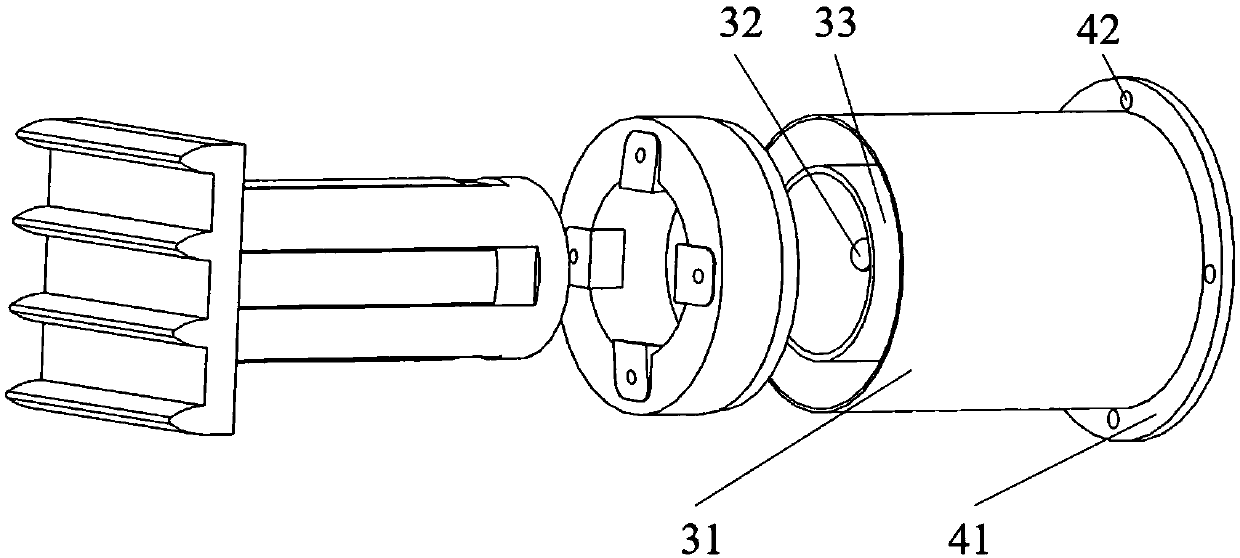

Composite type energy-absorbing anti-creeper of rail vehicle

ActiveCN109515468AImprove stabilityHigh energy absorption efficiencyRailway wheel guards/bumpersRailway transportLoad resistanceEnergy absorption

The invention discloses a composite type energy-absorbing anti-creeper of a rail vehicle. The composite type energy-absorbing anti-creeper comprises a piston rod, a flange, an inner sleeve and an outer sleeve, wherein the inner sleeve is arranged in the outer sleeve in a sealing mode; damping liquid is arranged in the inner sleeve; one end of the piston rod is equipped with a piston which can be in sliding connection to the inner sleeve; a damping hole is formed in the inner sleeve; a damping hole sealer is arranged on the damping hole; a guide hole which is in sliding connection to the pistonrod is formed in the flange; one side of the flange is fixedly connected to one end of the inner sleeve and one end of the outer sleeve; the other side of the flange is equipped with a cutting tool;and the cutting tool extends into a guide slot in the piston rod. According to the anti-creeper disclosed by the invention, a cut cutting part pushes the piston to extrude the damping liquid to absorbenergy, so that energy absorption and electric load resistance of the device are greatly improved, and therefore, the anti-creeper is high in collision force stability and energy-absorbing efficiency, and is good in energy-absorbing adjustability; and damping hole sealers of different specifications are selected, so that rail vehicle collision working conditions under different speed grades can be met, and therefore, collision resistance of the rail vehicle are improved.

Owner:CENT SOUTH UNIV

Process for producing polycrystalline silicon bar

InactiveCN101061065AHigh melting concentrationReduce solubilityPolycrystalline material growthSiliconHydrogen atmosphereCrystallographic defect

Owner:COSMOSS ENERGY JAPAN CO LTD +1

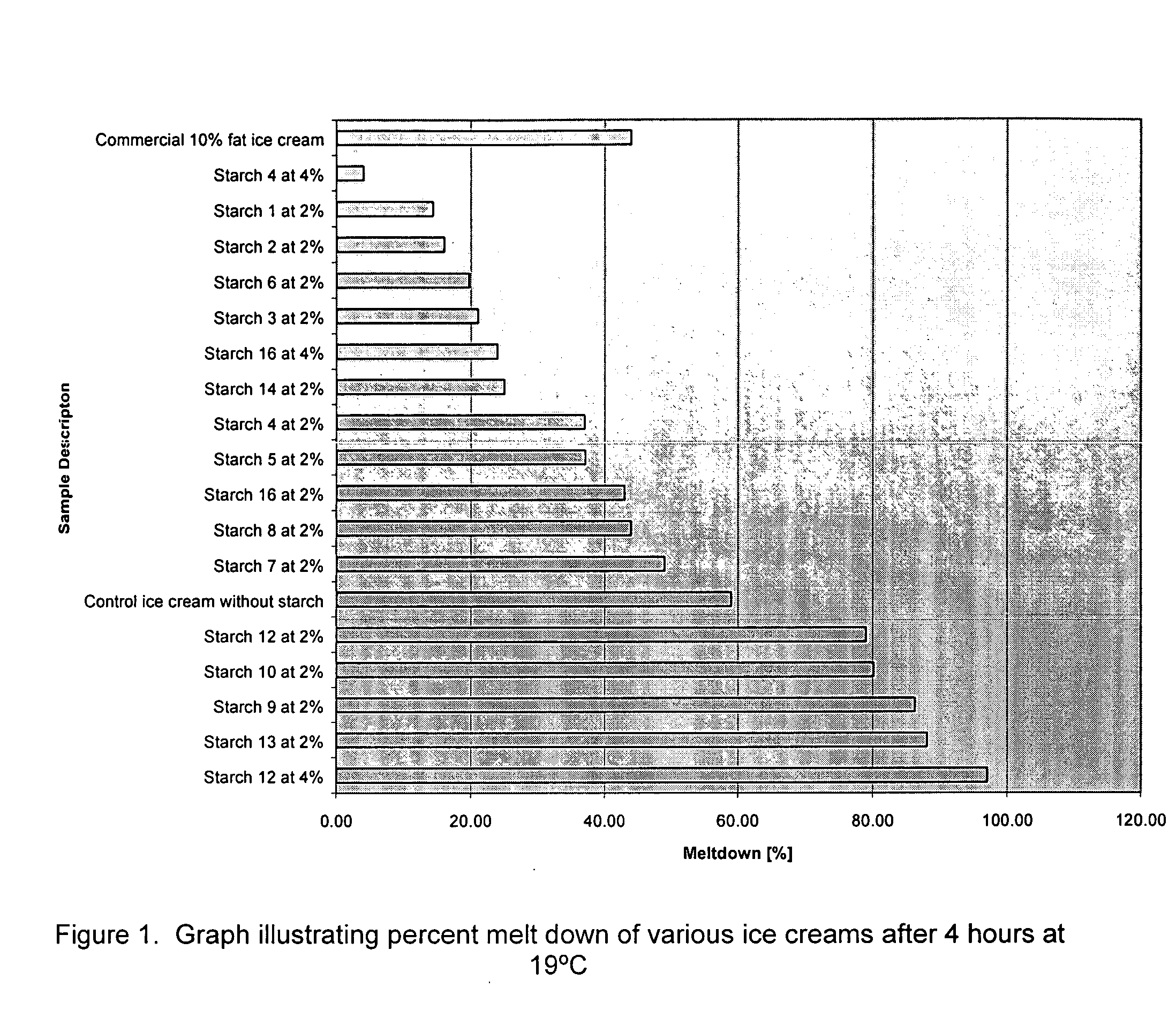

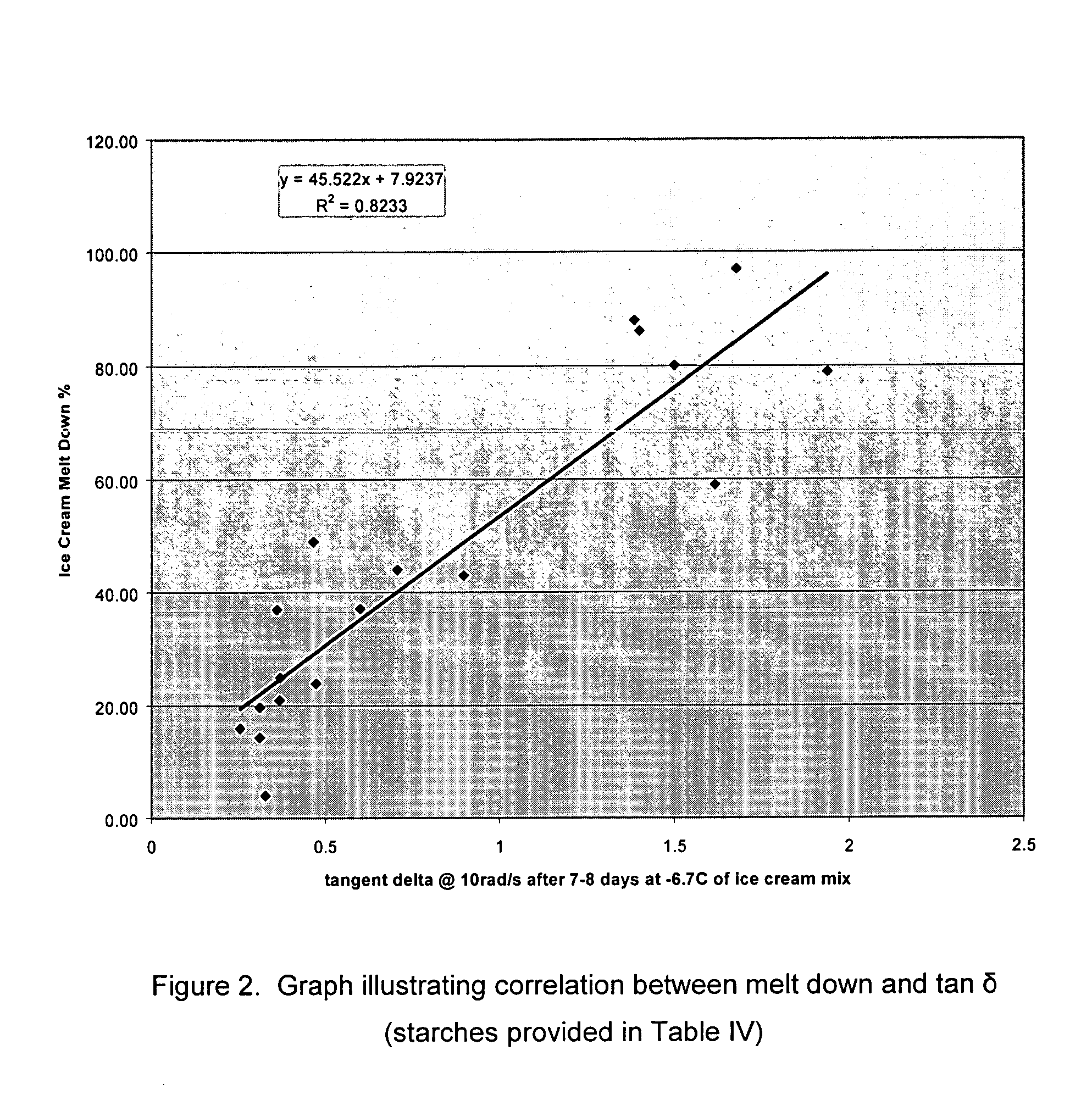

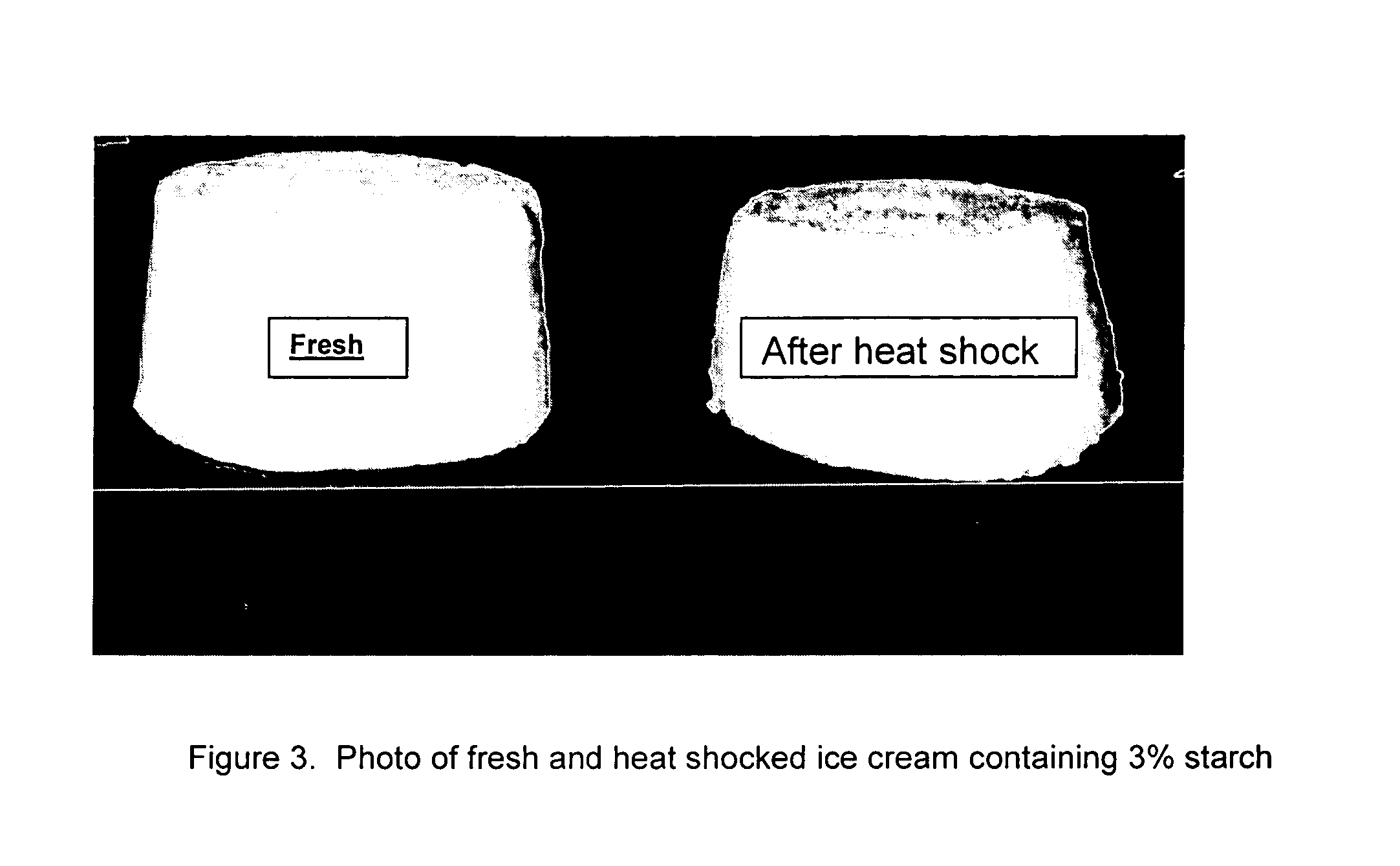

Starch for frozen desserts

InactiveUS20050048168A1Low shrinkageImprove structural propertiesFrozen sweetsConfectioneryHeat shockIce crystals

Use of starch(es) and starch derivatives in frozen desserts for improved meltdown and shape retention, including reduced expansion and contraction of the frozen dessert when transported at high altitudes, e.g., over mountain ranges. These improved characteristics are retained in the frozen dessert even after multiple heat shock cycling. The starch(es) and starch derivatives inhibit ice crystal formation in frozen after heat shock cycling.

Owner:BRUNOB II BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com