Patents

Literature

45results about How to "Improve processing thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nylon composite material special for electric wire and cable jacket and preparation method thereof

ActiveCN102020842AImprove heat resistanceImprove light aging resistanceInsulated cablesInsulated conductorsPropanoic acidPhenol

The invention provides a nylon composite material special for an electric wire and cable jacket, which is prepared from the following components by mass percent: 86-100% of nylon 6, 0.1-2.0% of main antioxygen, 0.1-2.0% of auxiliary antioxygen, 0.1-2.0% of lubricant release agent, 0.1-2.0% of light stabilizer, 0.1-2.0% of lubricant, 0.1-2.0% of nucleating agent and 0.3-2.0% of tackifier, wherein the main antioxygen is a hindered phenol antioxygen, the auxiliary antioxygen is thiodi-propionic acid diester or phosphite ester, the lubricant release agent is calcium stearate, the light stabilizer is a hindered amine light stabilizer, the lubricant is ethylene double hard ester amide (EBS), silicone powder or a compositor of the ethylene double hard ester amide (EBS) and silicone powder, the nucleating agent is nano talcum powder, and the tackifier is nylon 6 containing reactive groups. The nylon composite material has the advantanges of simple formula and cheap, easily available components and low cost, and the electric wire and cable jacket prepared from the nylon composite material can prevent white ants and mousse, has abrasion resistance and corrosion resistance, is durable in use and is non-toxic and environment-friendly.

Owner:辰东意普万新材料(广东)有限公司

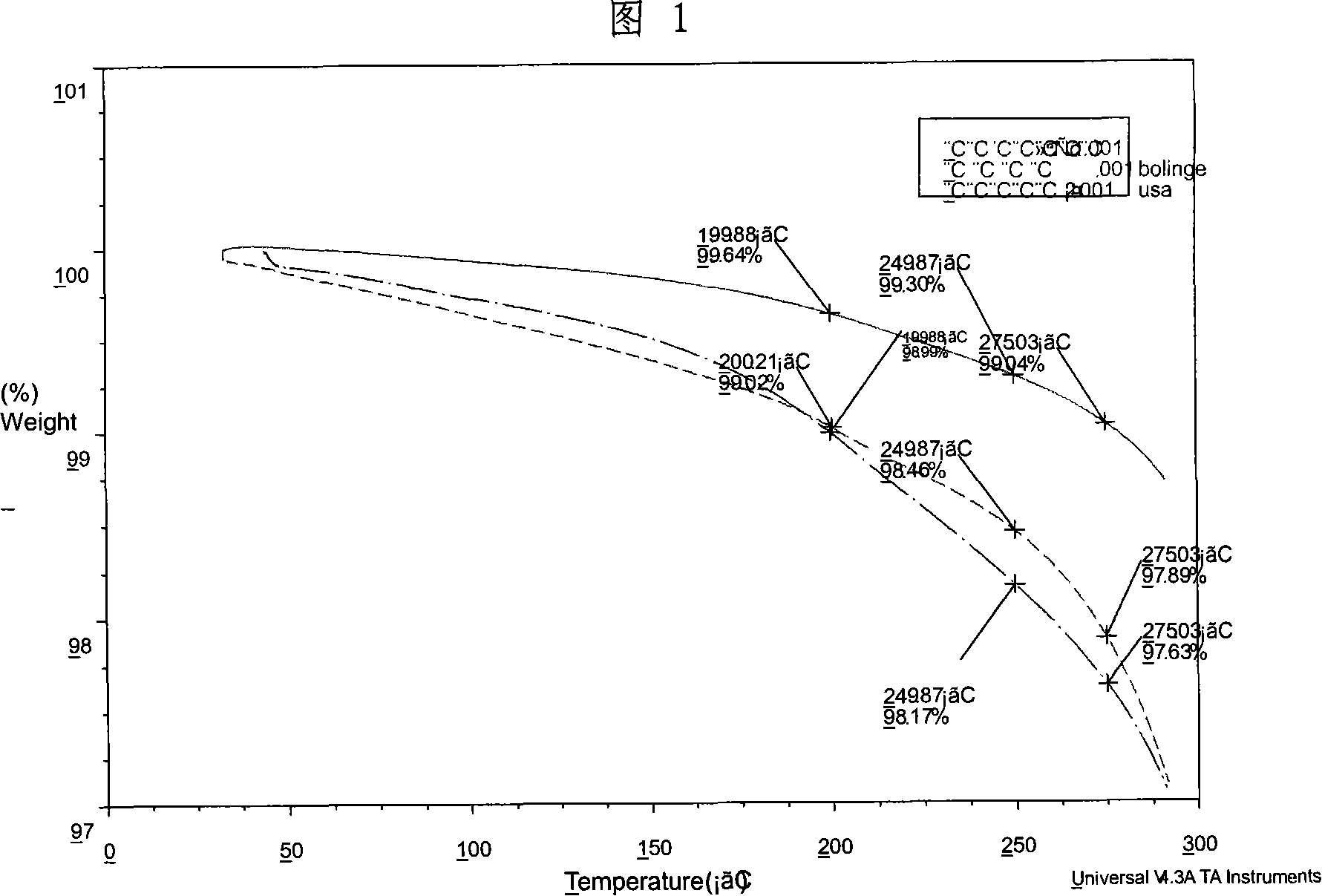

Method for preparing poly (lactic-co-glycolic acid)

The invention provides a preparation method of a lactic and glycolic acid. The method comprises a catalyst containing three compounds of a catalytic induction system. The catalyst catalyzes and induces ring cleavage copolymerization between diglycolide and lactide to synthesize lactic and glycolic acid. The monomer to catalyst (mol ratio) is at 20,000 to 500,000 and the reaction temperature is 100 to 220 DEG C for 1 to 200 hours with inert gas protection or in vacuum. The invention has the advantages of high transformation ration, low catalyst contents of products, high molecular weight, narrow molecular weight disposition, good heat stability, small degradation of high temperature molten, good uniformity of materials, and is provided with excellent biological degradability and biological compatibleness. The lactic and glycolic acid prepared by the invention can be widely used for surgical operation suture, internal fixation of fracture, tissue repair, plastic surgery, anti-organic conglutination, medical slow release, organic engineering, etc.

Owner:HUIZHOU HUAYANG MEDICAL EQUIP

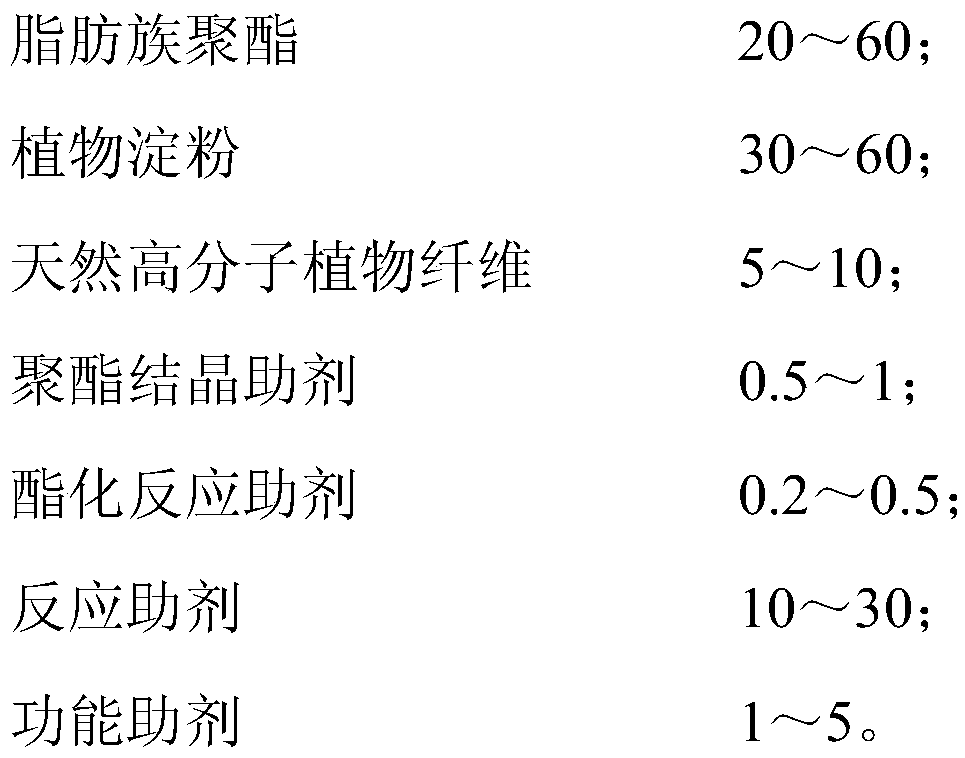

Starch and plant fiber composite biodegradable polyester film-blowing grade resin and preparation method

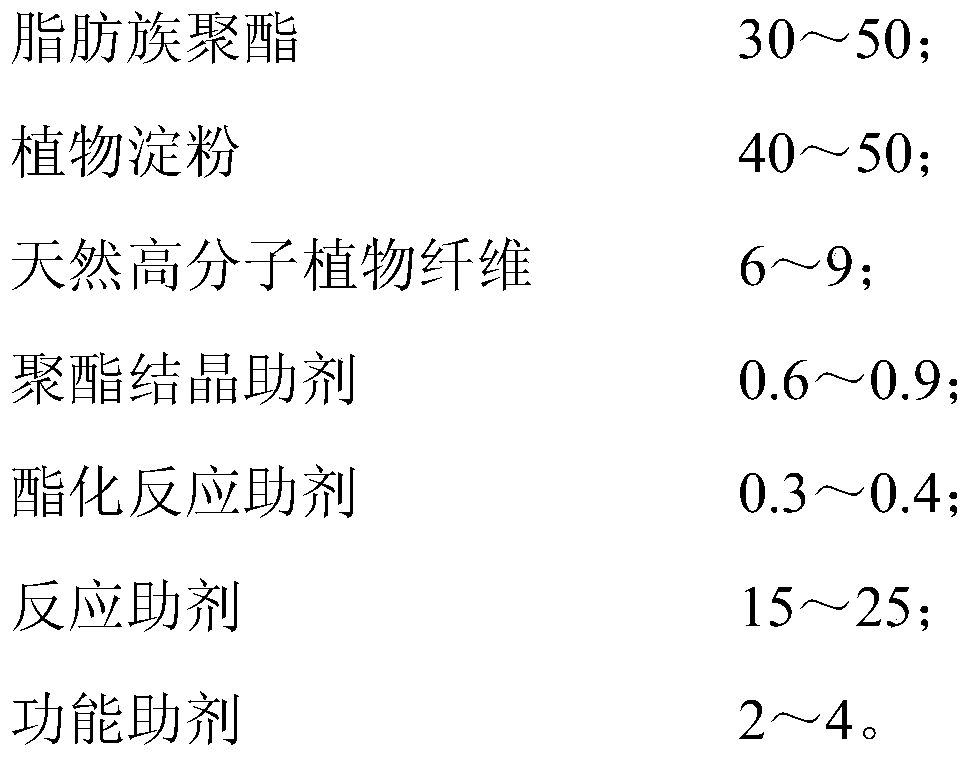

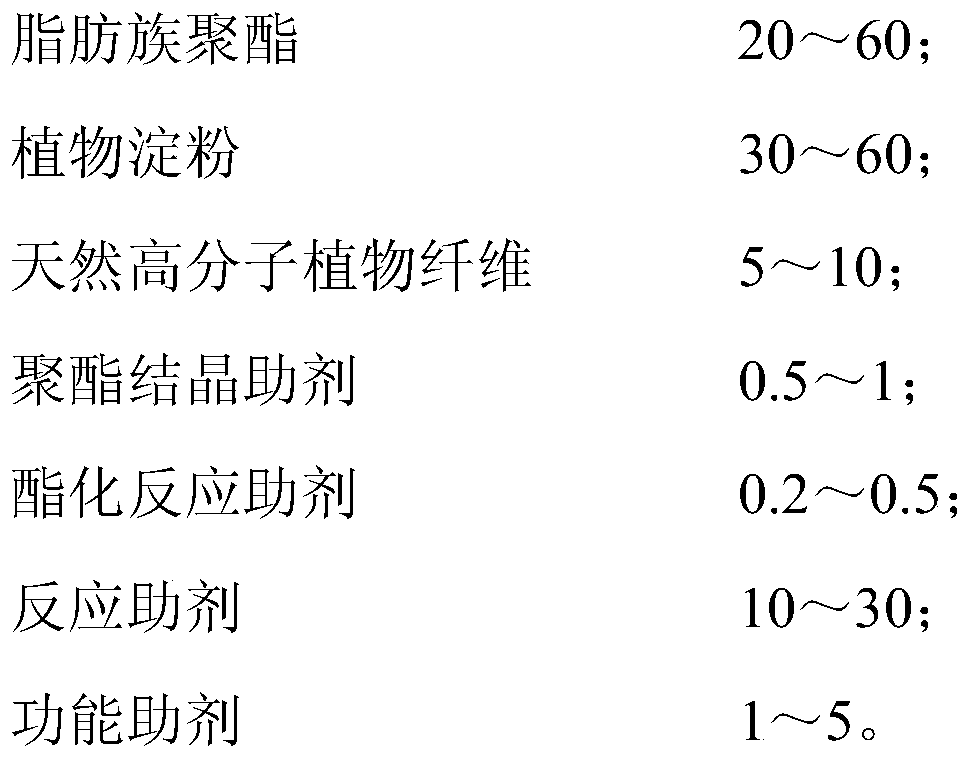

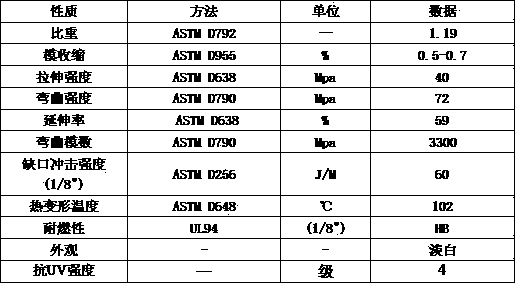

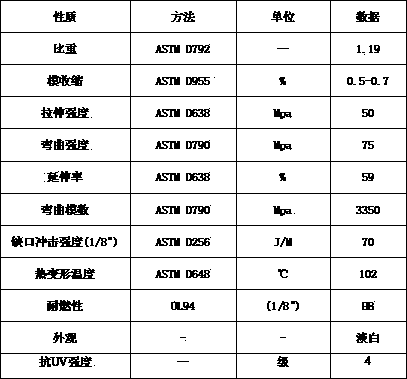

The invention belongs to the technical field of film-blowing resin, and particularly relates to starch and plant fiber composite biodegradable polyester film-blowing grade resin. The starch and plant fiber composite biodegradable polyester film-blowing grade resin is prepared from, by weight, 20-60 parts of aliphatic polyester, 30-60 parts of plant starch, 5-10 parts of natural polymer plant fiber, 0.5-1 part of polyester crystallization auxiliary, 0.2-0.5 part of esterification reaction auxiliary, 10-30 parts of reaction auxiliaries and 1-5 parts of functional auxiliaries. According to the starch and plant fiber composite biodegradable polyester film-blowing grade resin, esterification treatment is conducted on the plant starch and the natural polymer plant fiber through the esterification reaction auxiliary, a transesterification reaction is further conducted through esters and aliphatic polyester in the blending extrusion process, starch graft aliphatic polyester copolymer is generated, and therefore the compatibility between the starch and the aliphatic polyester in a blend is improved.

Owner:东莞市酬勤包装制品有限公司

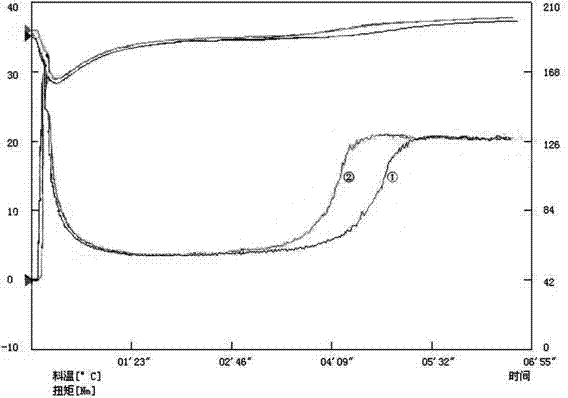

PVC resin with ultra-low degree of polymerization and manufacturing method thereof

ActiveCN101665548AImproved particle morphology and molecular weight distributionImprove processing thermal stabilityChemistryPlasticizer

The invention discloses a PVC resin with ultra-low degree of polymerization and a manufacturing method thereof. In the invention, a polymerization method is adopted to carry out polymerization reaction, the reaction temperature is 60-64 DEG C, and the reaction pressure is less than 1.0 MPa; a first chain transfer agent is added when the polymerization reaction is carried out for 0-30min, and then0.005-0.012% of vinyl chloride monomer (VCM) is added; a second chain transfer agent is added when the polymerization reaction is carried out for 60-90min, and then 0.005-0.02% of monomer is added toobtain the PVC resin with ultra-low degree of polymerization. The PVC resin manufactured by the invention has the advantages of the average degree of polymerization below 500, high apparent density, low melting and gelatinization temperature, low melt viscosity, good transparency, short plasticization time and favorable processability and the like, and the phenomenon of accelerating products agingdue to the transfer of plasticizer does not appear in machining process.

Owner:SICHUAN JINLU GRP

PMMA light diffusion agent and light diffusion PMMA material

The invention discloses a PMMA light diffusion agent. Raw materials of the PMMA light diffusion agent comprise frozen micro-grounded polysiloxane particles, a light diffusion agent 1, a light diffusion agent 2, a curing agent and a compatilizer. By adopting a low-temperature freezing and ultrasonic grinding method, market available polysiloxane particles are converted into low-temperature micro-grounded polysiloxane particles. The low-temperature micro-grounded polysiloxane particles are added in the PMMA material, and enable the PMMA material to gain an excellent atomization effect. The low-temperature micro-grounded polysiloxane particles overcome influences of an organosilicone light diffusion agent to the PMMA material, so that the prepared light diffusion PMMA material can keep excellent performances such as impact resistance, oxidation resistance and processing heat stability.

Owner:广西海枫光学材料科技有限公司

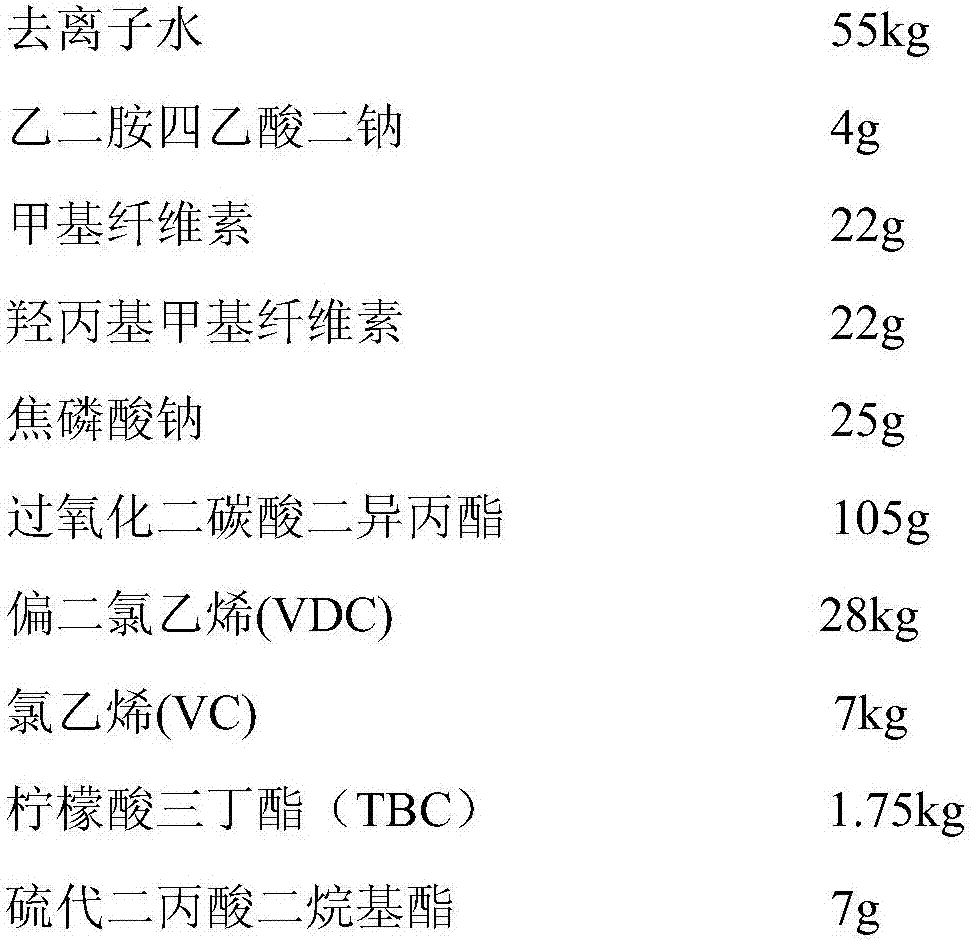

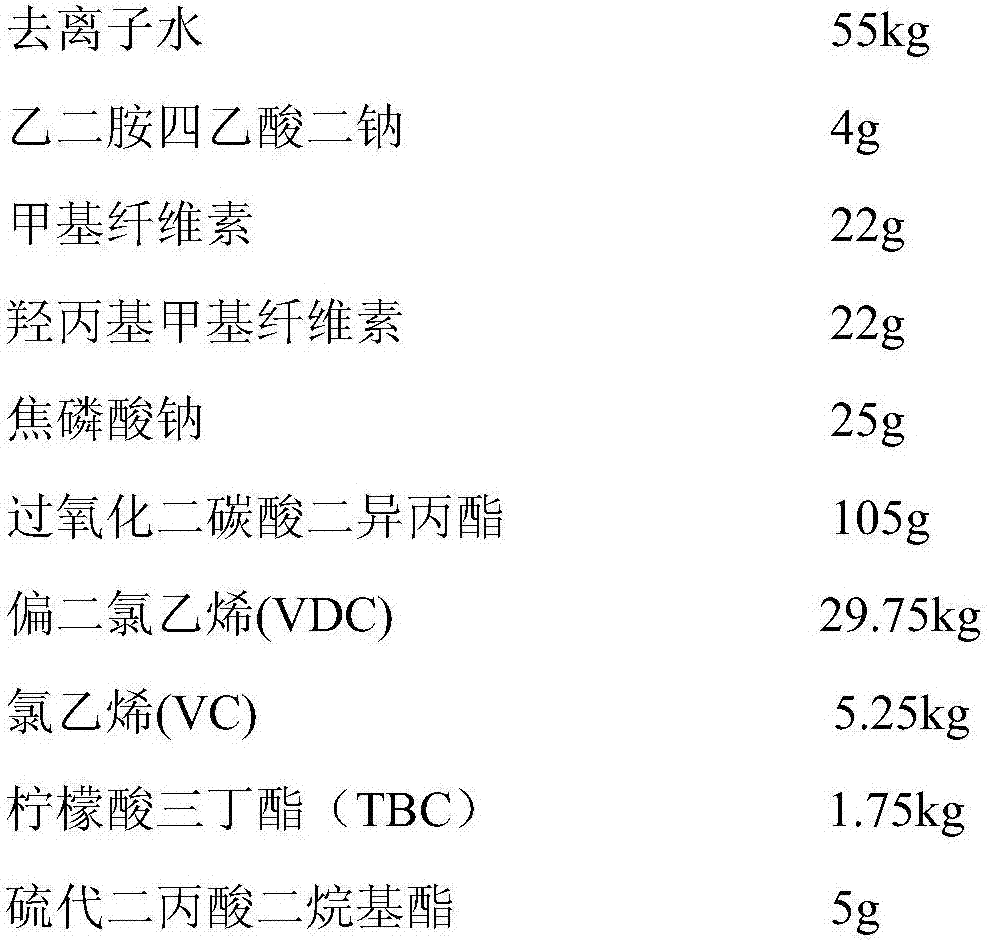

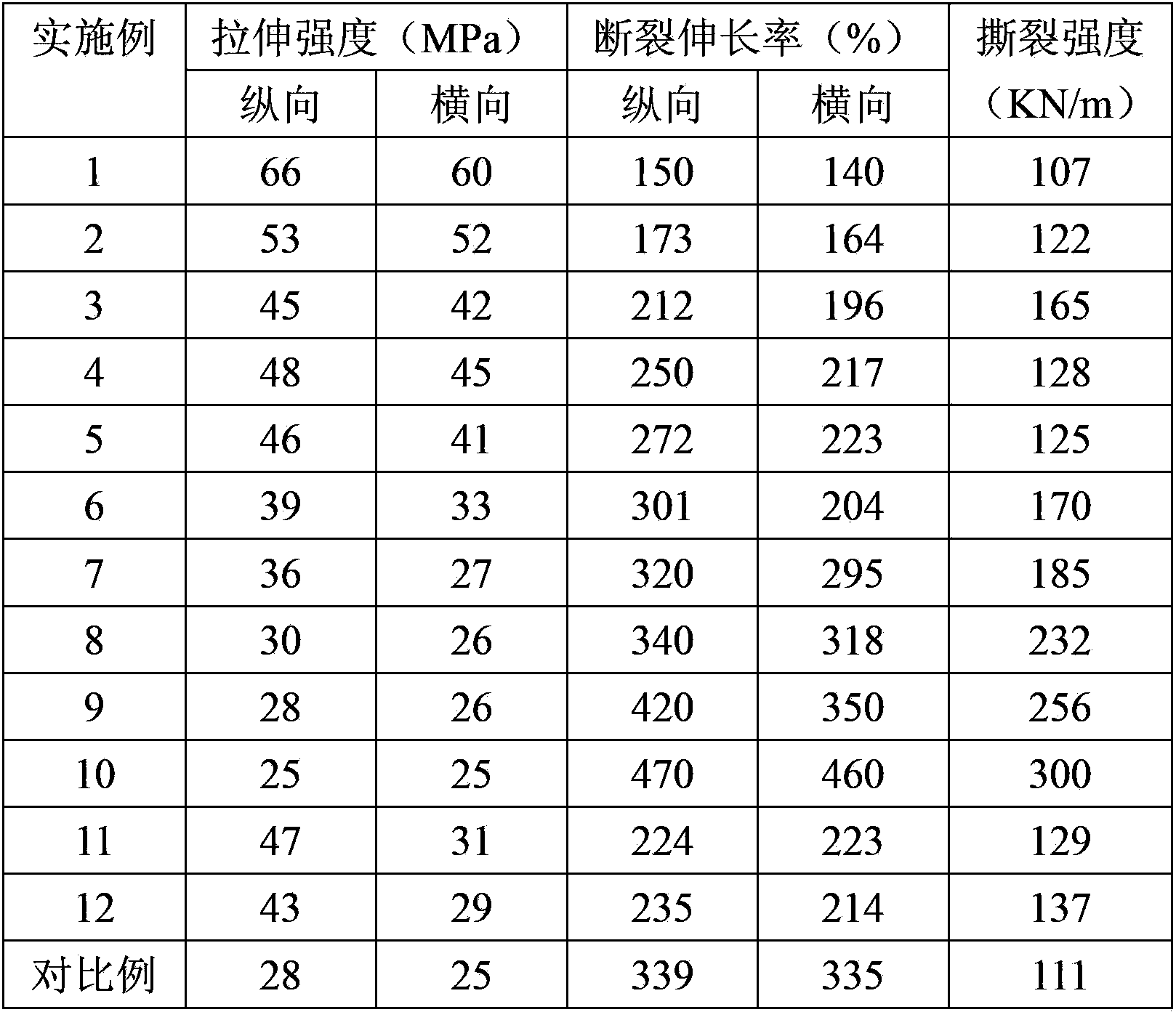

Preparation method of PVDC composition by VDC/MA copolymerization

The invention provides a preparation method of a PVDC composition by VDC / MA copolymerization. The preparation method comprises the following steps: putting mixing monomer, chelating agent, dispersing agent, deionized water, pH regulator, thermostability plasticizing agent and composite initiating agent into a polymeric kettle, carrying out cold dispersion on the mixture for 30 minutes, starting polymerization when raising temperature fast to 65 DEG C at the agitator speed of 120rpm, then stirring at the speed of 8rpm / h to 20rpm / h and 3 DEG C / h to 5 DEG C / h and raising the temperature to 80 DEG C to 85 DEG C at the agitator speed of 170rpm to 180rpm, finally at the agitator speed of 170rpm to 180rpm, raising the temperature to 90 DEG C at the speed of 2.5 DEG C / h to 6 DEG C / h, reacting for 1h to 2h at constant temperature, stopping polymerization, separating residual monomer in vacuum, reducing temperature, discharging materials, centrifugating, drying, adding post processing auxiliary agent, raising the temperature to 80 DEG C at the speed of 25 DEG C / h to 30 DEG C / h, mixing, curing and obtaining the composition. The PVDC composition has good forming processing thermostability and can be used for packing low-and-medium temperature food by multi-layer coextrusion film or coextrusion casting film.

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +1

Light rare-earth hydrotalcite-curcumin composite heat-stable assistant and preparation method thereof

InactiveCN103740004AImprove processing thermal stabilityImprove melt fluidityPolyvinyl chloridePhysical chemistry

The invention relates to the field of polyvinyl chloride molding and processing, and particularly relates to a composite heat-stable assistant for VC molding and processing and a preparation method thereof. The stable assistant comprises the following raw materials in parts by weight: 100-120 parts of light rare-earth magnesium hydrotalcite, 20-90 parts of curcumin and 20-40 parts of calcium stearate. The preparation method comprises the following steps: evenly premixing light rare-earth hydrotalcite with calcium stearate; mechanically stirring and mixing at 100-120 DEG C for 3 hours, wherein the rotating speed of an agitator is 400-800r / min; cooling the material to 40-60 DEG C, so as to obtain a material pre-mixture; evenly mixing the curcumin with the material pre-mixture; mechanically stirring and mixing at 40-60 DEG C for 2 hours, wherein the rotating speed of the agitator is 300-500r / min; cooling the materials to room temperature, so as to obtain the composite heat-stable assistant. The light rare-earth hydrotalcite-curcumin composite heat-stable assistant is wide in raw material source, low in cost, and friendly to environment, and has excellent strength and toughness.

Owner:TANGSHAN NORMAL UNIV

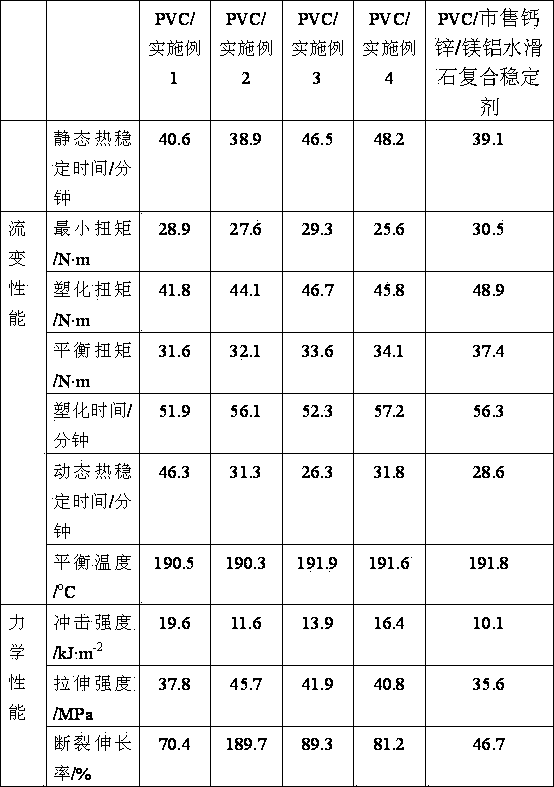

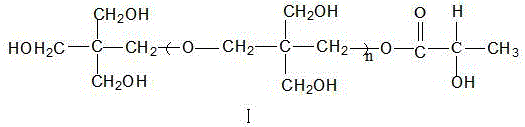

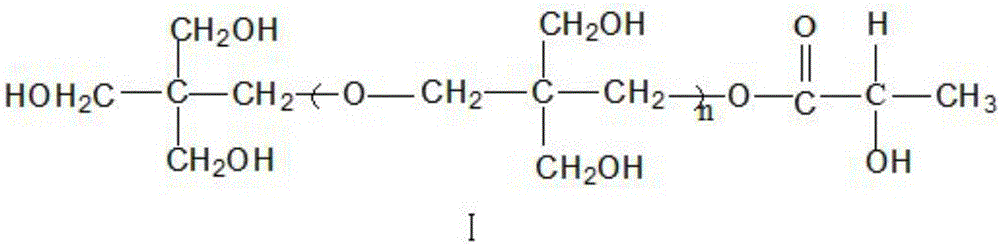

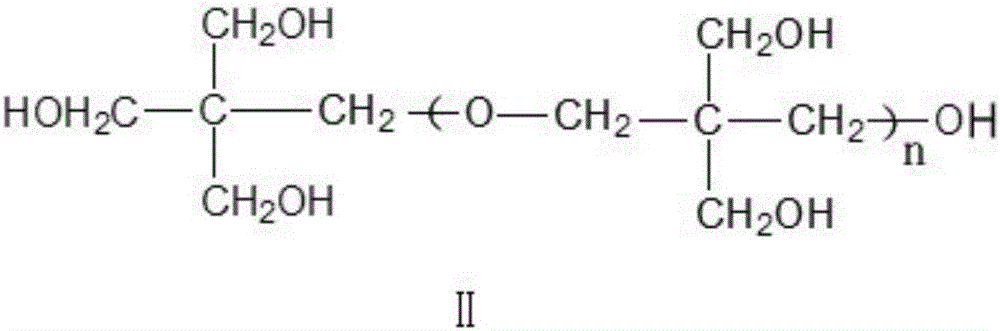

Lactic acid polyol esters and preparation method and application thereof in processing halogenated vinyl polymers

ActiveCN106631778AInhibit or weaken the phenomenon of zinc burningLow priceOrganic compound preparationCarboxylic acid esters preparationPolyolThermal stability

The invention discloses lactic acid polyol esters, a preparation method of the lactic acid polyol esters and application of the lactic acid polyol esters in processing halogenated vinyl polymers. The lactic acid polyol esters are prepared by carrying out esterification on polyols or a mixture of polyols and lactic acid in the presence of a catalyst. The product of the invention is good in compatibility with the halogenated vinyl polymers, especially PVC and not easy to precipitate, and has a very good function of assisting to improve the processing thermal stability of the halogenated vinyl polymers (especially PVC), and further can inhibit or reduce the 'zinc burning phenomenon' of a zinc containing heat stabilizer, and has very good application prospects in the processing field of the halogenated vinyl polymers, especially PVC.

Owner:济南金昌树新材料科技有限公司

High-light-color-fastness transfer printing method

ActiveCN102797173AImproved gripping abilityTightly bondedTransfer printing processDyeing processBinding forceAqueous solution

The invention relates to a high-light-color-fastness transfer printing method. An ink for transfer printing comprises the following components in percentage by mass: 40-70% of black disperse dye, 10-30% of red disperse dye, 12-15% of methanol and / or isobutanol, 5-10% of polyvinyl butyral and 3-5% of photostabilizer 622. The transfer printing method comprises the following steps: soaking a textile to be printed in a polyoxyethylene or polyoxypropylene water solution, and carrying out transfer printing. The invention has the advantages of simple technique and low cost; and the printed pattern has the advantages of high binding force with cloth, high light color fastness and high durability.

Owner:WUXI SAILITE TEXTILE TECH

Preparation method for highly thermal stable CPVC blend composition

The invention provides a preparation method for a highly thermal stable CPVC blend composition. The preparation method comprises steps of heating and mixing materials and cooling, wherein in the heating and mixing step, hydrotalcite, a tin ethyl thermal stabilizer compound, CPVC and additives are heated and blended in a mixing machine. The thermal stability of CPVC is improved, less tin ethyl thermal stabilizer is used at the same time, and the problems that CPVC is difficult to process and the thermal stabilizer is high in cost are solved.

Owner:杭州电化新材料有限公司

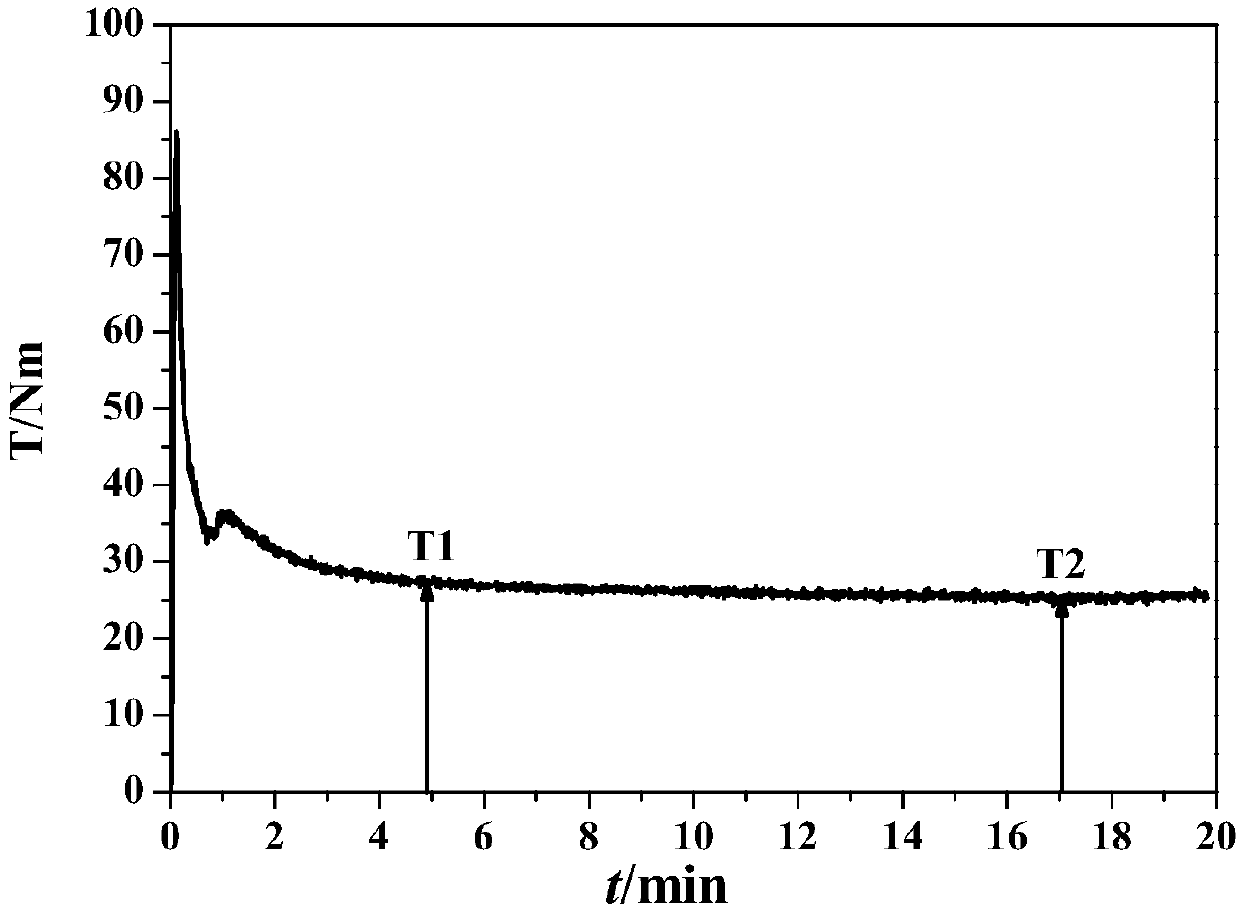

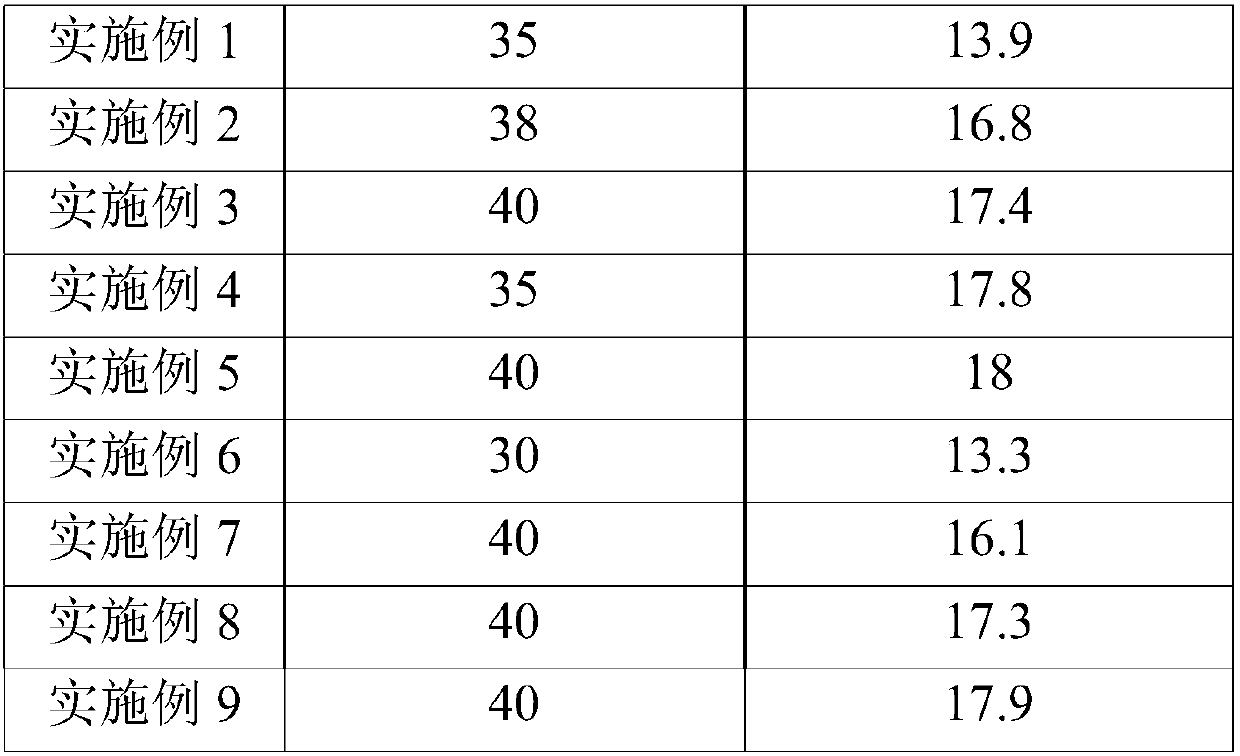

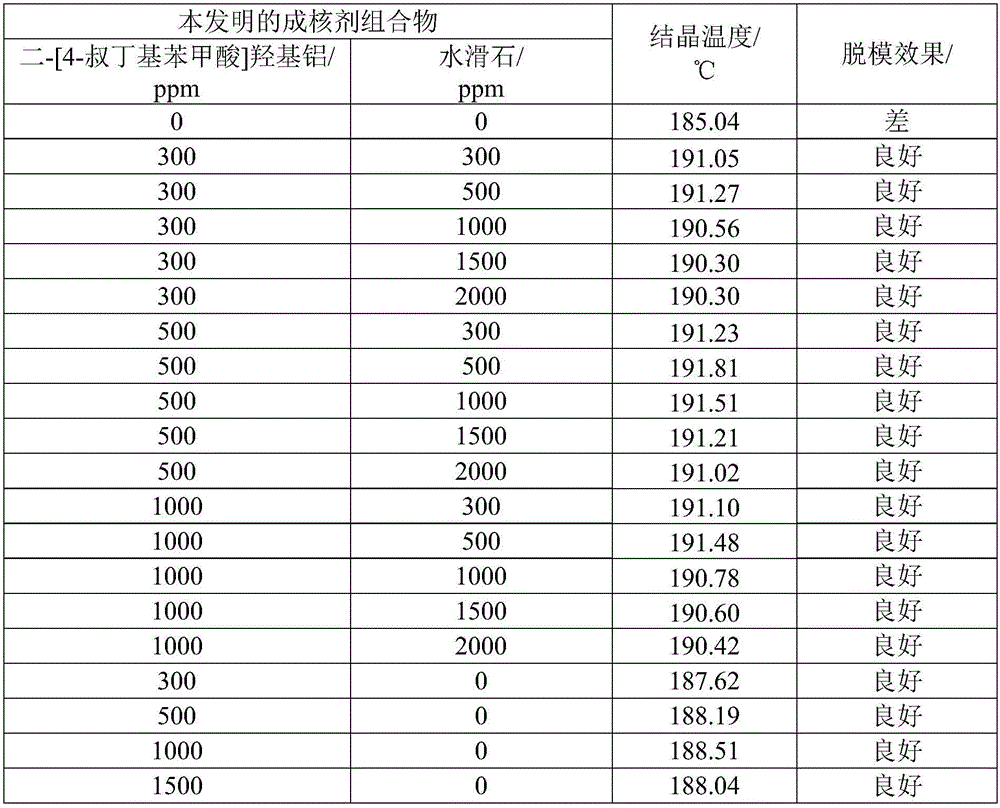

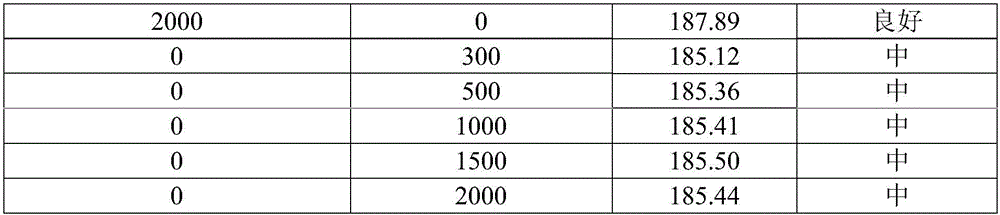

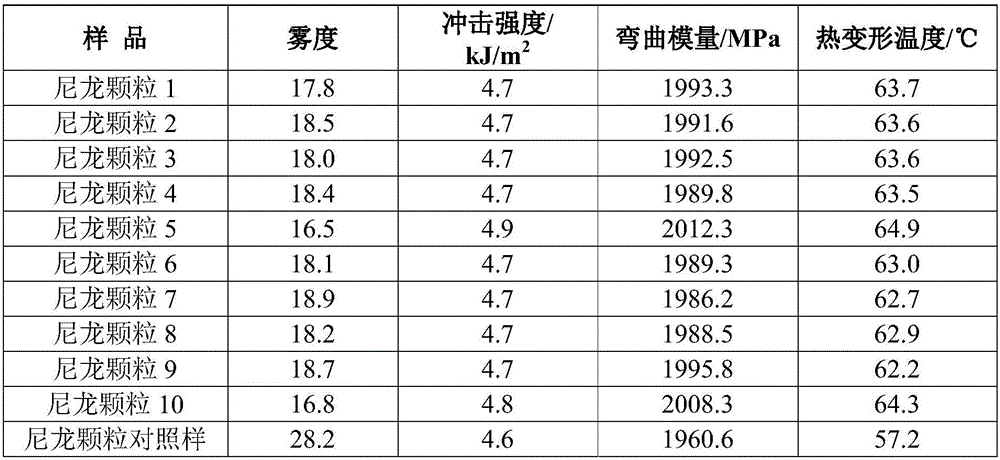

Hydrotalcite-containing stiffening nucleating agent composition

ActiveCN105754142AGive full play to the functional advantagesImprove processing thermal stabilityBenzoic acidThermoplastic

The invention relates to a hydrotalcite-containing stiffening nucleating agent composition and also relates to a thermoplastic plastic containing the nucleating agent composition and particularly relates to nylon containing the nucleating agent composition. The nucleating agent composition contains di-[4-tert-butyl benzoic acid]hydroxyl aluminium in a weight ratio of (5:1)-(1:5). The nucleating agent composition has a better nucleating effect, and the obtained nylon product has high tensile and bending strength, low loss of impact strength, good heat resistance and the like. By adopting the nucleating agent provided by the invention, the demoulding property in the nylon processing process is improved, the injection moulding cycle is shortened, and the production efficiency is improved; and moreover, the dimensional stability of the product is higher, the shrinkage is reduced, and the mechanical properties, product transparency and heat-resistance temperature of the product are improved.

Owner:GCH TECH

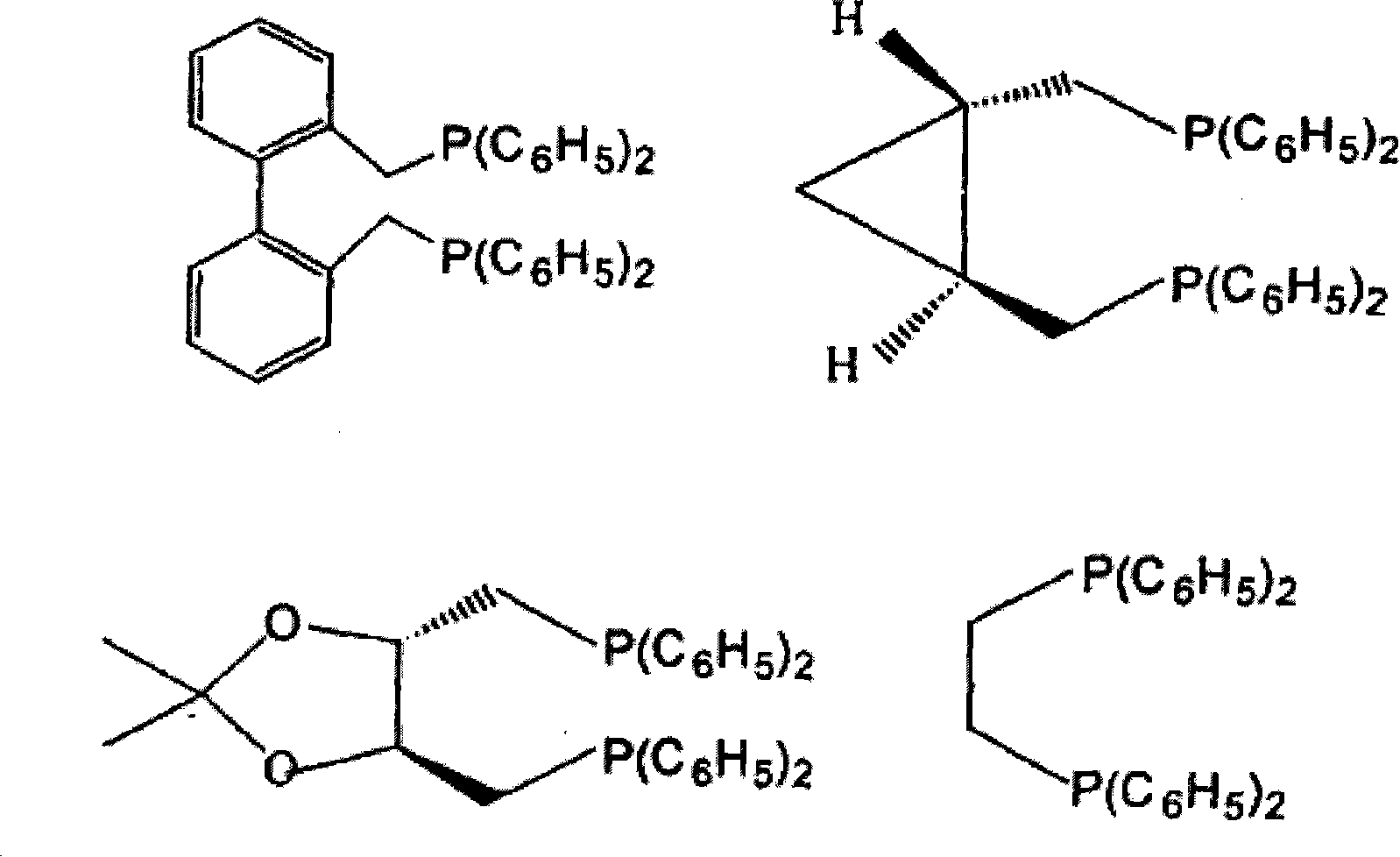

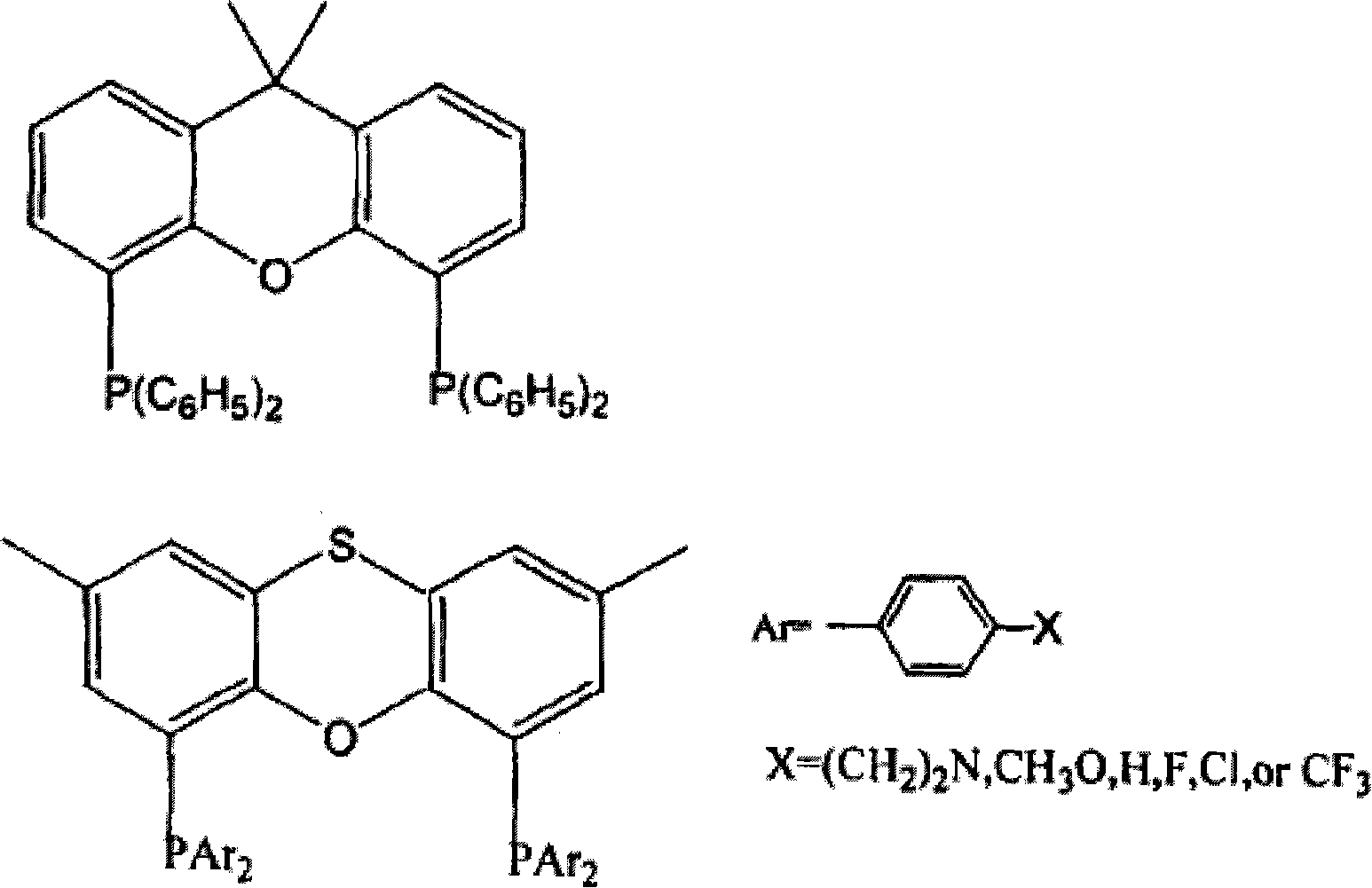

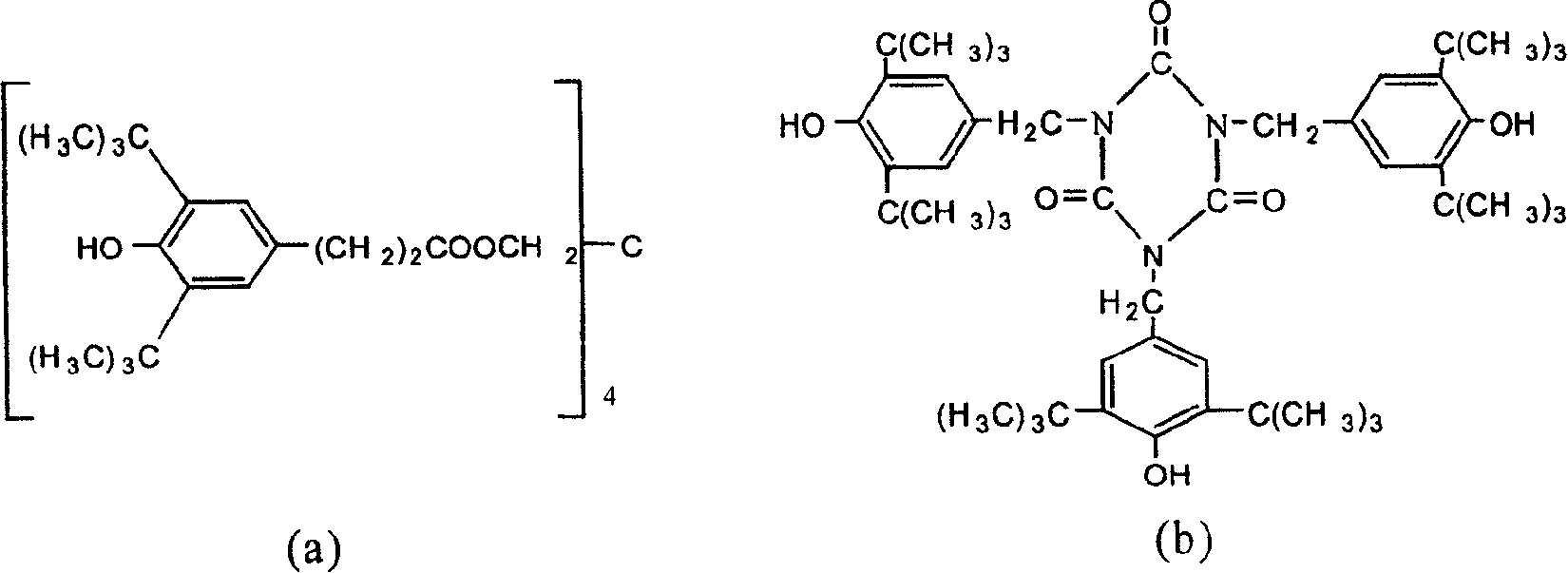

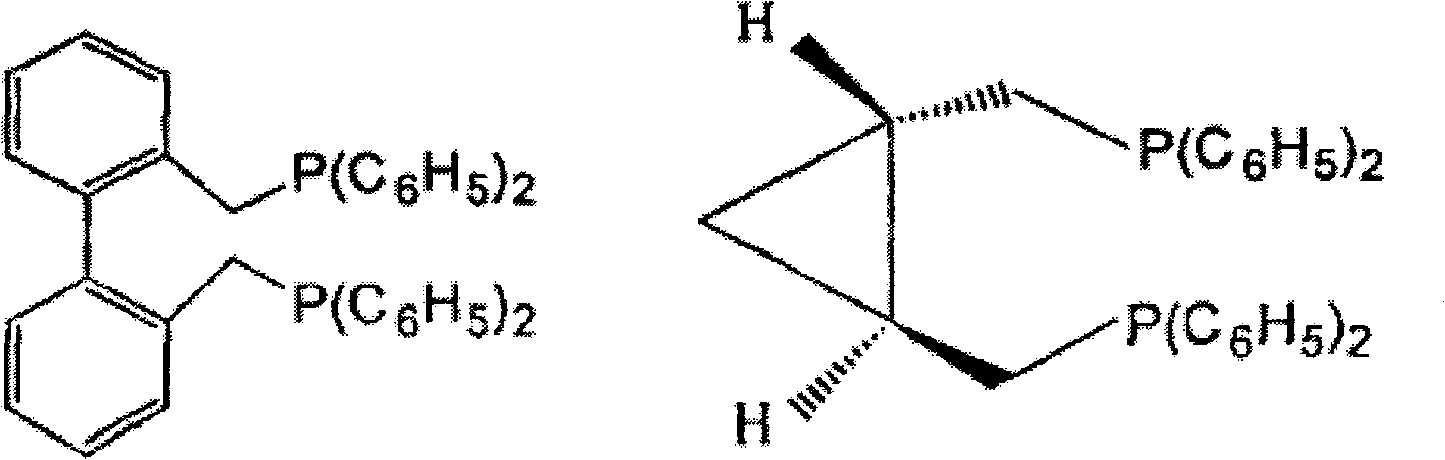

Combination of stabilizing agent in use for producing polyolefine resin

A composite stabilizer used for preparing the polyolefine resin contains hindered phenol as primary antioxidizing agent, phosphite as secondary antioxidizing agent and deacidifying agent.

Owner:宁波金海雅宝化工有限公司

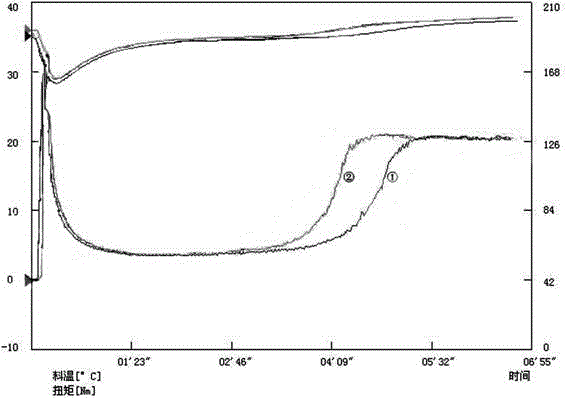

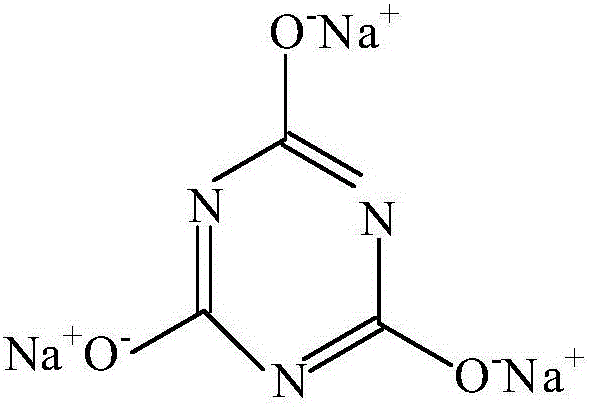

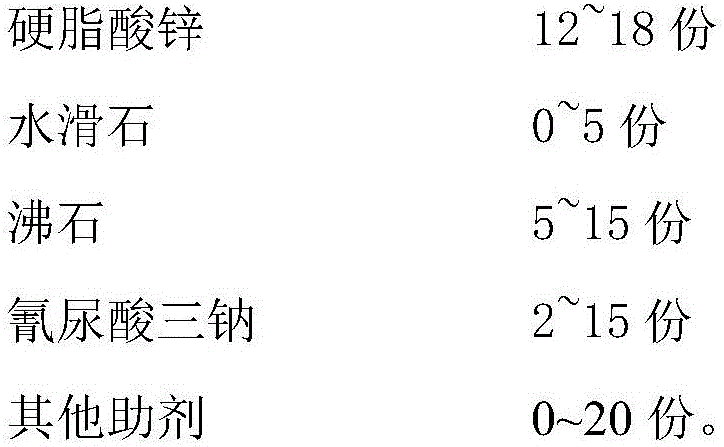

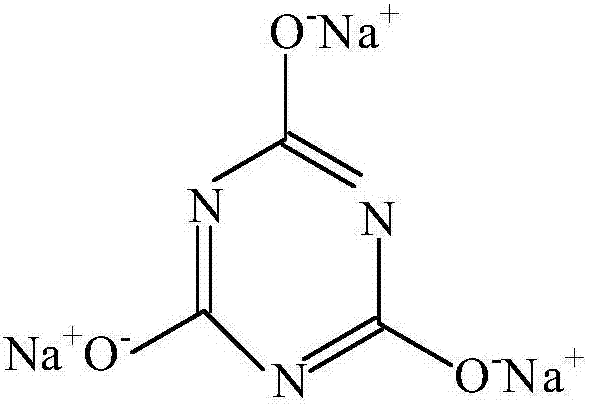

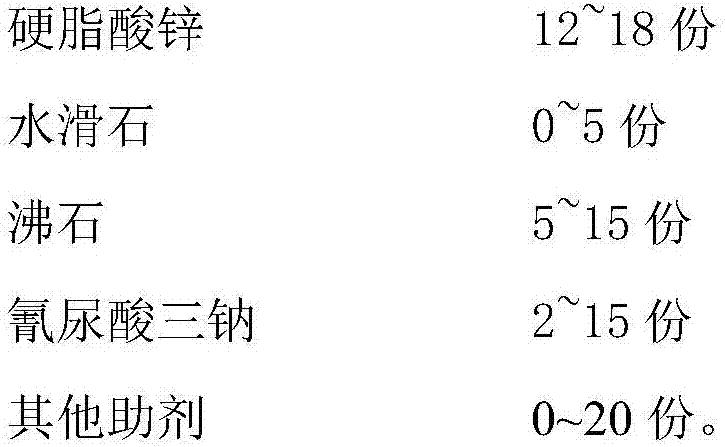

Application of trisodium cyanurate to increasing of PVC thermostability and composite heat stabilizer containing trisodium cyanurate

ActiveCN106117882AImprove thermal stabilityImprove weather resistanceTrisodium citrateWeather resistance

The invention discloses application of trisodium cyanurate to the increasing of PVC thermostability and a composite heat stabilizer containing the trisodium cyanurate. The trisodium cyanurate can be used for assisting a heat stabilizer and can increase the thermostability of PVC during processing when being combined with the heat stabilizer containing zinc during use. When the trisodium cyanurate is combined with the heat stabilizer containing zinc during use, the thermostability of the PVC during processing can be increased, product weather resistance can be increased, and 'zinc burning' can be inhibited at the same time. The composite heat stabilizer formed by the trisodium cyanurate and the heat stabilizer containing zinc keeps the advantages of nontoxicity and environment protection of the heat stabilizer containing zinc, satisfies the requirement of environment protection and is suitable for being popularized and used.

Owner:济南金昌树新材料科技有限公司

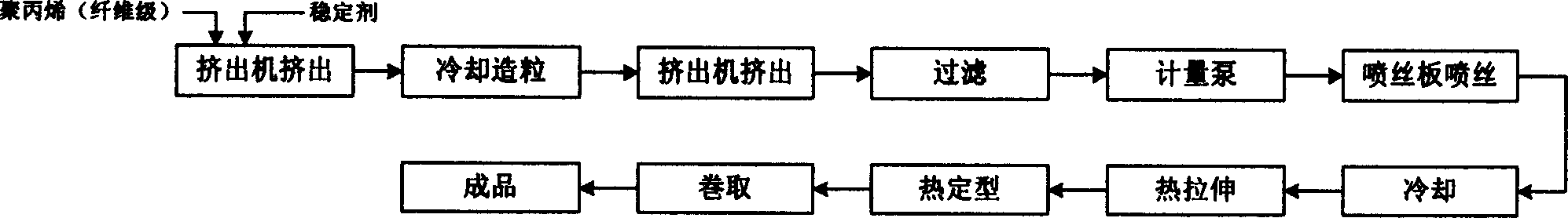

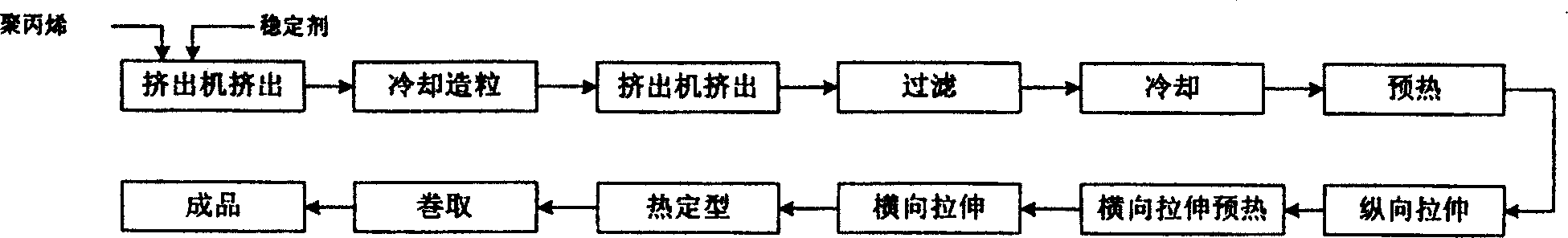

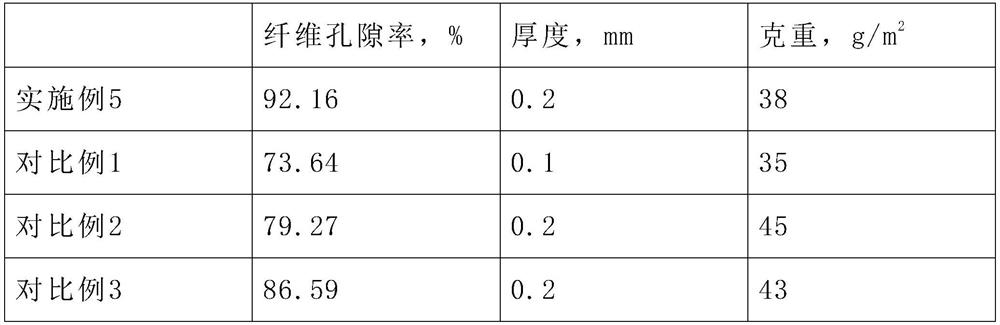

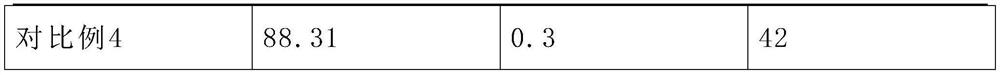

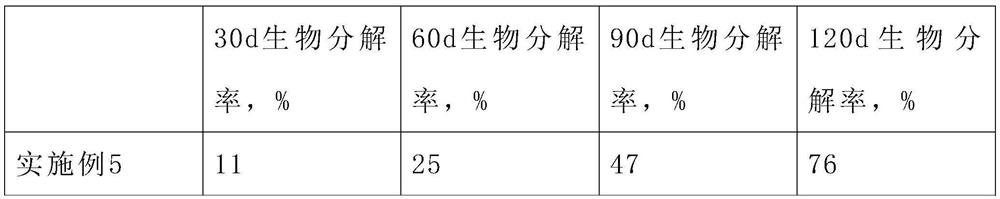

Biodegradable mulch dust suppression net and preparation method thereof

PendingCN109610034ALow lignin contentLower quality contentBuilding material handlingMonocomponent polyesters artificial filamentMasterbatchFlax fiber

The invention discloses a degradable mulch dust suppression net. The degradable mulch dust suppression net is prepared from the following raw materials: polylactic acid, bagasse fibers, flax fibers, masterbatch and calcium carbonate. The invention also discloses a preparation method of the degradable mulch dust suppression net. The degradable mulch dust suppression net has the advantages of greatenvironmental significance, significantly better durability and mechanical strength than those of existing similar polylactic acid products and lower cost.

Owner:SHANDONG JINGUAN NET

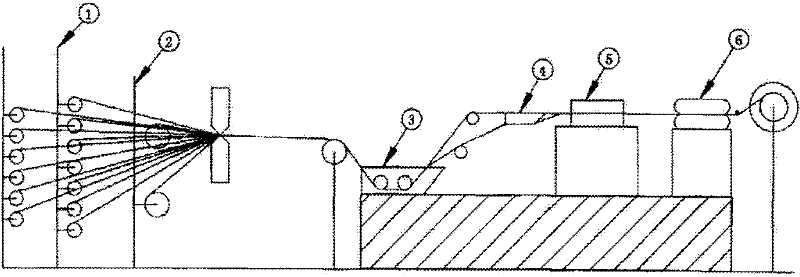

Composite material cable core

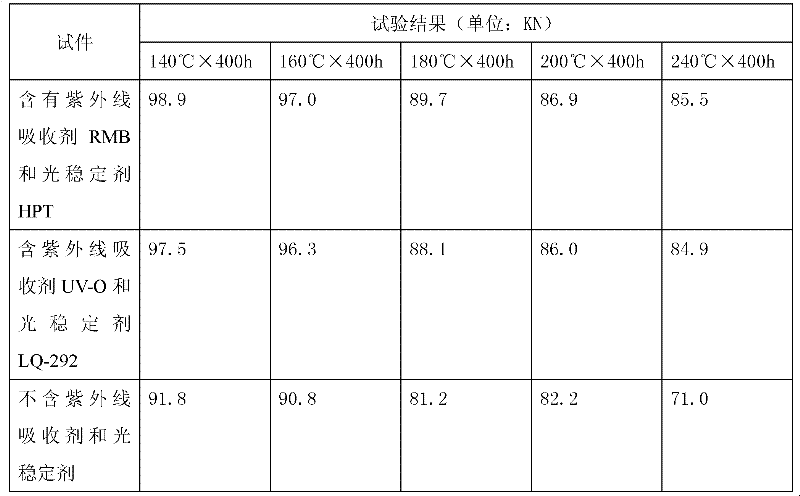

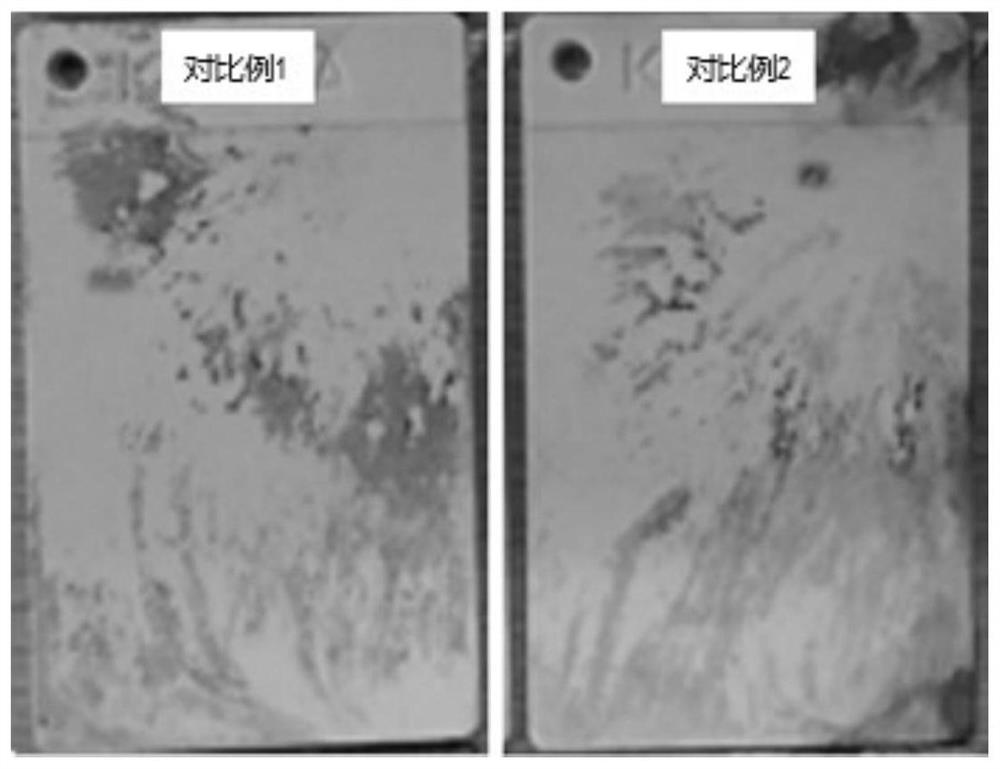

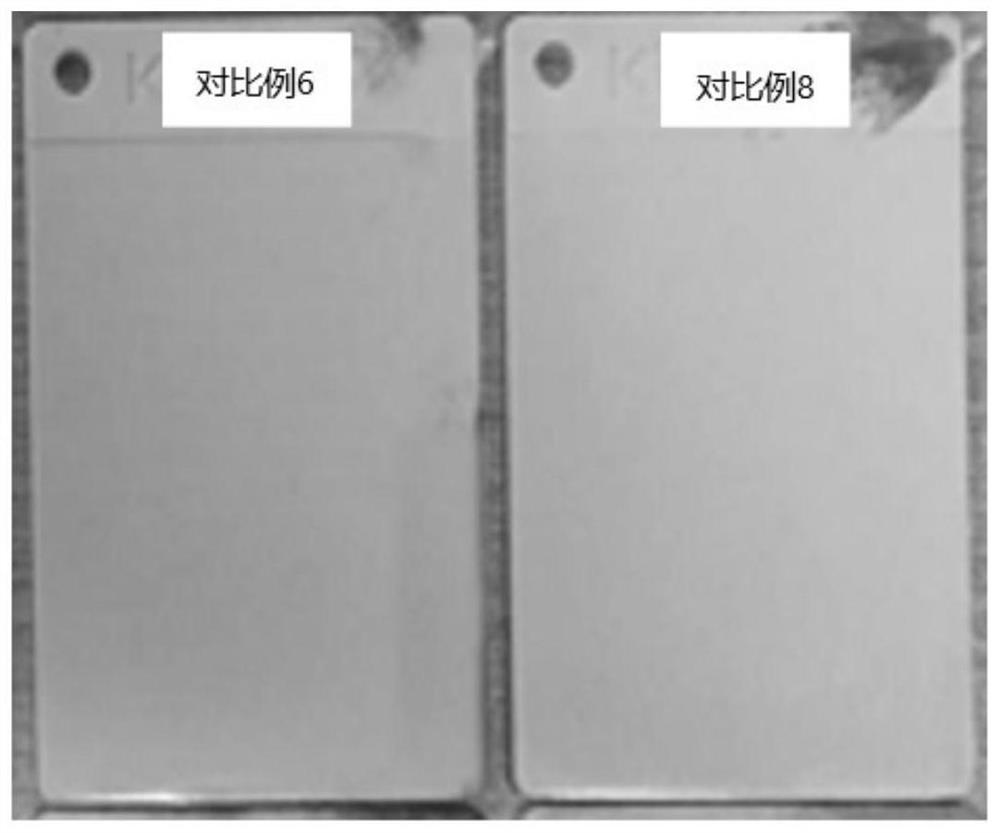

InactiveCN102222542AGood processing thermal stabilityImprove heat resistanceInsulated cablesInsulated conductorsLow elastic modulusFiber

The invention relates to a composite material cable core which is composed of an inner layer and an outer layer; heat-resisting resin is taken as a matrix for the inner layer, and a high-strength ultra-long continuous fiber is taken as a reinforcing material; and hindered anime light stabilizers and ultraviolet absorbers are added in the heat-resisting resin of the inner layer and the outer layer. The cable core provided by the invention has favorable performances of ultraviolet resistance, aging resistance and even heat resistance.

Owner:CHANGZHOU HONGZELAN WIRE & CABLE

Preparation method of PVDC composition by VDC/MA copolymerization

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +1

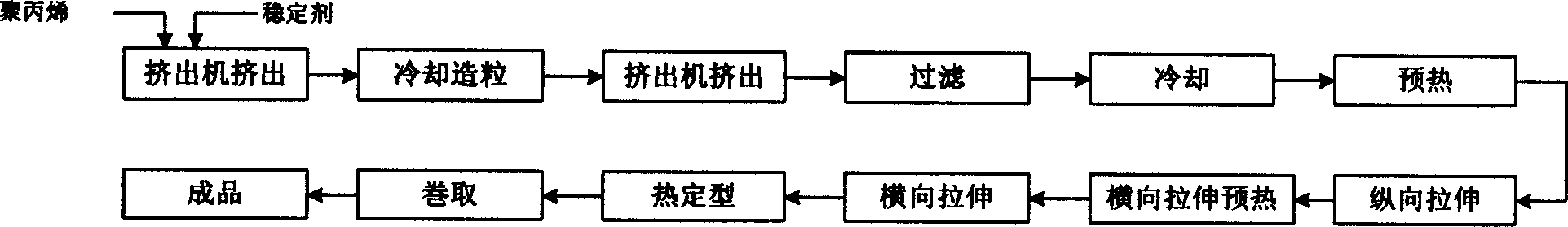

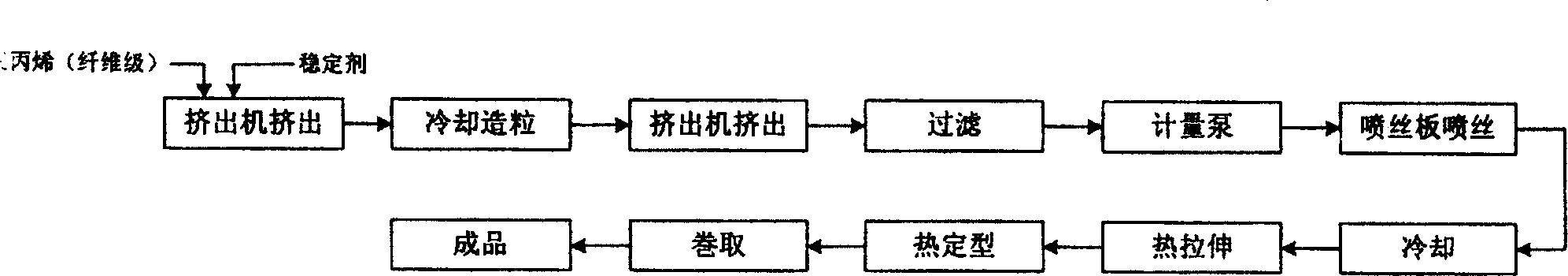

Polylactic acid nonwoven cloth and preparation method and application thereof

InactiveCN108130652AReduce polarityImprove toughnessMelt spinning methodsNon-woven fabricsYarnPolymer science

The invention relates to polylactic acid nonwoven cloth and a preparation method and application thereof. The preparation method comprises the following steps; (1) adding montmorillonoid into an ethylalcohol solution of polyphosphoric acid, stirring, and filtering; (2) adding filter cake obtained in step (1) into an ethyl alcohol solution of dopamine, stirring after adding is completed, filtering, and drying, so as to obtain the modified montmorillonoid; (3) uniformly mixing the modified montmorillonoid and polylactic acid, so as to obtain a mixture; (4) feeding the mixture into a screw extruder, extruding, and granulating, so as to obtain a complex; (5) treating the complex by a melting and spraying method so as to obtain nascent fibers, drawing and extending the nascent fibers by air flow to form net-shaped fibers with uniformly paved long yarns, and adhering the net-shaped fibers by a heat roll, so as to obtain the polylactic acid nonwoven cloth. The preparation method has the advantages that the montmorillonoid is easily compatible with the polylactic acid, and the polylactic acid can be easily crystallized. The polylactic acid nonwoven cloth has the advantages that the toughness and anti-impact property are higher, the heat stability in processing is good, and the like.

Owner:北京泰洋泉生物科技有限公司

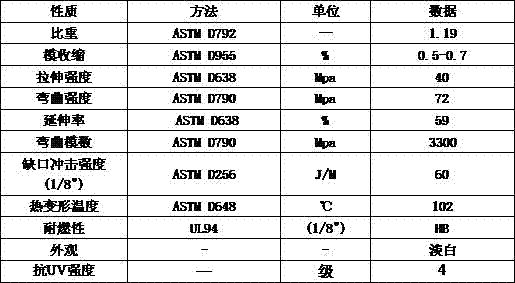

High-heat-resistance flame-retardant nylon 66 composite material

The invention provides a high-heat-resistance flame-retardant nylon 66 composite material and a preparation method thereof. The high-heat-resistance flame-retardant nylon 66 composite material comprises the following components in percentage by mass: 40-75.5% of polyamide 66 resin; 12-19% of a decabromodiphenyl ethane flame retardant; 2-8% of antimonous oxide; 4-10% of a synergistic flame retardant; 10-40% of chopped glass fibers; 0.5-3.0% of an acid acceptor; and 0.3-1.0% of a lubricant. The invention creatively provides the flame-retardant nylon 66 composite material with high processing thermal stability, the material has excellent processing thermal stability, the composite material is continuously produced under the conditions of normal extrusion processing temperature and injection molding processing temperature, and the industrial production requirements are met.

Owner:TIANJIN KINGFA NEW MATERIAL

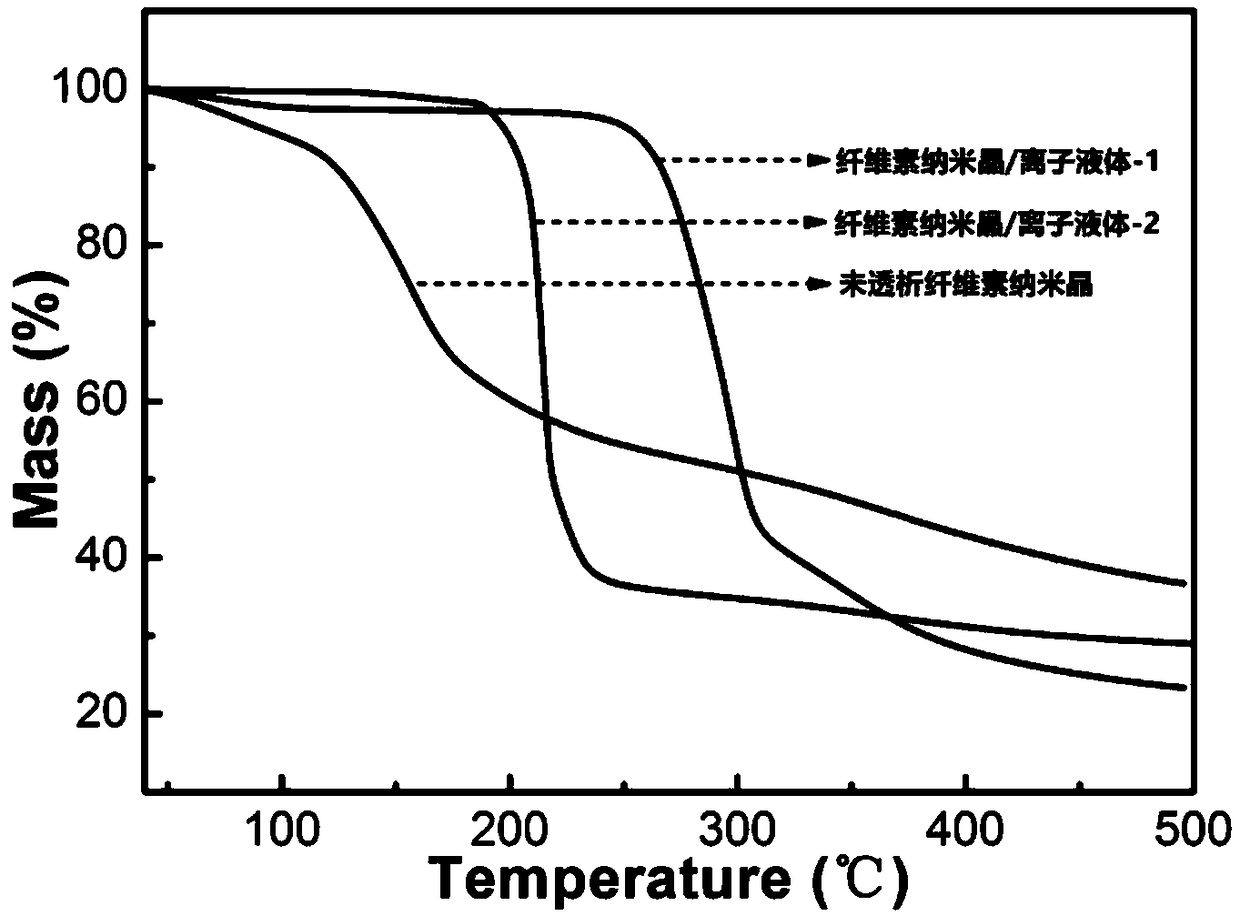

High heat-resistant redispersible powder cellulose nanocrystal and preparation method thereof

Owner:QINGDAO UNIV OF SCI & TECH

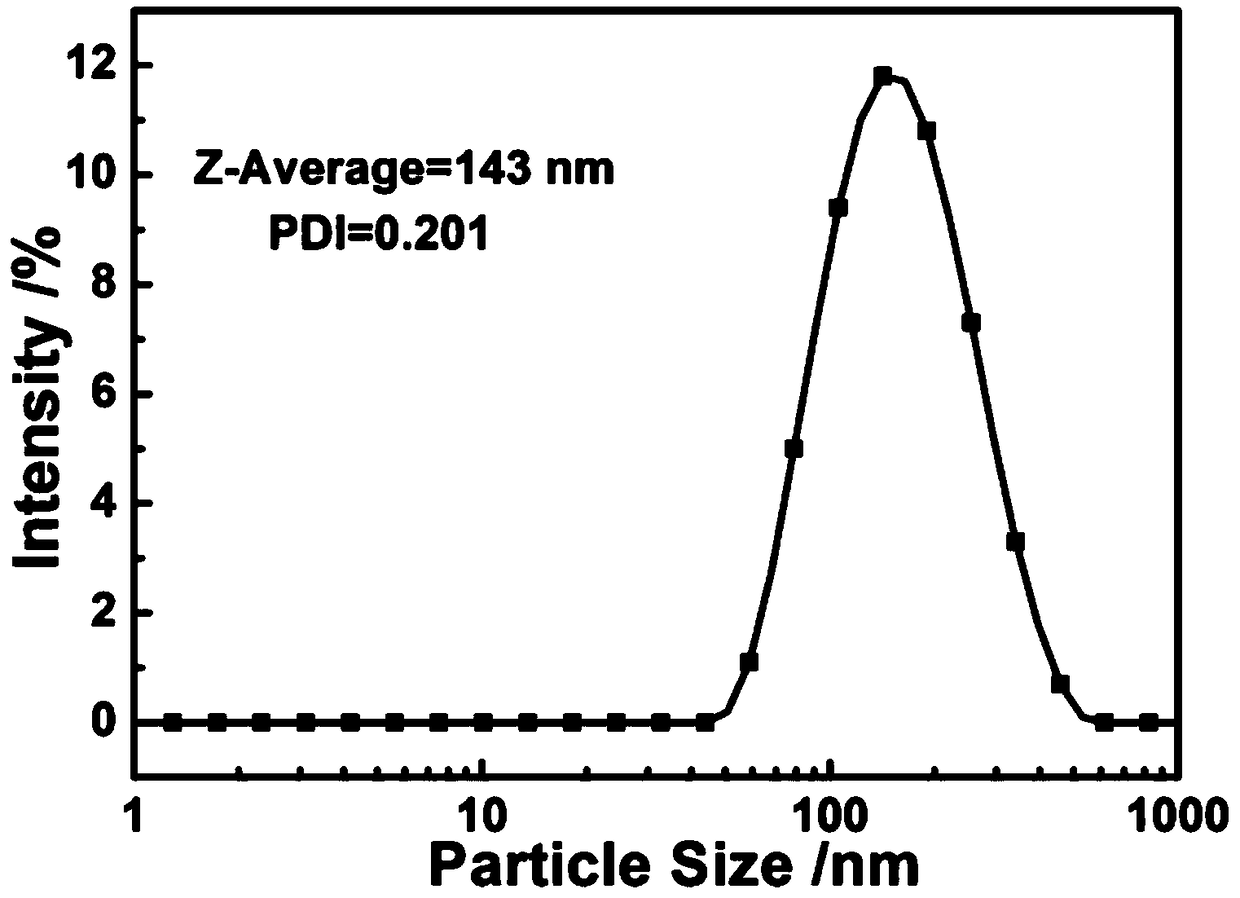

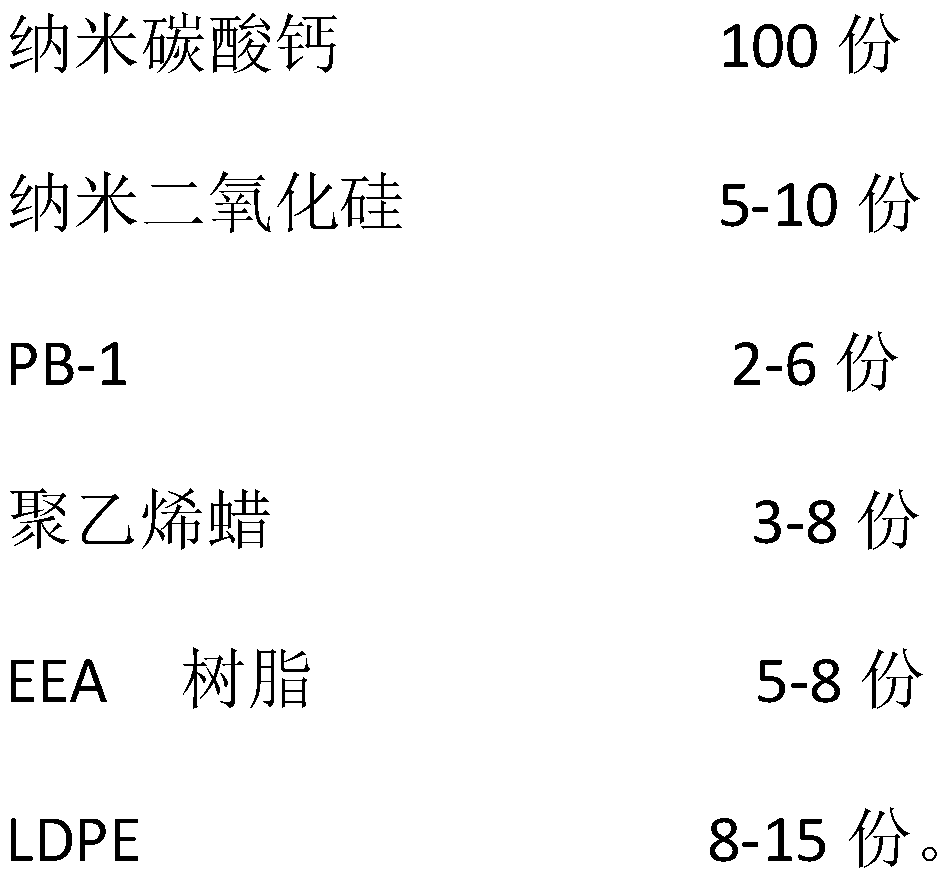

Polyolefin and nano calcium carbonate composite master batch and production method thereof

The invention discloses a polyolefin and nano calcium carbonate master batch and a production method thereof. The polyolefin and nano calcium carbonate master batch comprises the following componentsin parts by mass: 100 parts of nano calcium carbonate, 5-10 parts of nano silicon dioxide, 2-6 parts of PB-1, 3-8 parts of polyethylene wax, 5-8 parts of EEA resin and 8-15 parts of LDPE. Materials ofall the components are kneaded, mixed, kneaded and pressed into a distributed and dispersed composite molten mass in a homodromous parallel line-shaped three-screw extruder, and obtaining the completely molten and plasticized polyolefin nano calcium carbonate composite molten mass through molten mass exhausting; feeding the polyolefin nano calcium carbonate composite molten mass into a conical single-screw extruder with a double-bowl feeding machine; and controlling the temperature of the molten mass through the water temperature of a single-screw mandrel to 96-120 DEG C, performing compact compression extrusion molding, and performing surface grinding and hot cutting to obtain the polyolefin nano calcium carbonate composite master batch.

Owner:上海心尔新材料科技股份有限公司

PVC resin with ultra-low degree of polymerization and manufacturing method thereof

ActiveCN101665548BParticles in good shapeHigh Molecular Weight DistributionApparent densityPolymer science

The invention discloses a PVC resin with ultra-low degree of polymerization and a manufacturing method thereof. In the invention, a polymerization method is adopted to carry out polymerization reaction, the reaction temperature is 60-64 DEG C, and the reaction pressure is less than 1.0 MPa; a first chain transfer agent is added when the polymerization reaction is carried out for 0-30min, and then0.005-0.012% of vinyl chloride monomer (VCM) is added; a second chain transfer agent is added when the polymerization reaction is carried out for 60-90min, and then 0.005-0.02% of monomer is added toobtain the PVC resin with ultra-low degree of polymerization. The PVC resin manufactured by the invention has the advantages of the average degree of polymerization below 500, high apparent density, low melting and gelatinization temperature, low melt viscosity, good transparency, short plasticization time and favorable processability and the like, and the phenomenon of accelerating products aging due to the transfer of plasticizer does not appear in machining process.

Owner:SICHUAN JINLU GRP

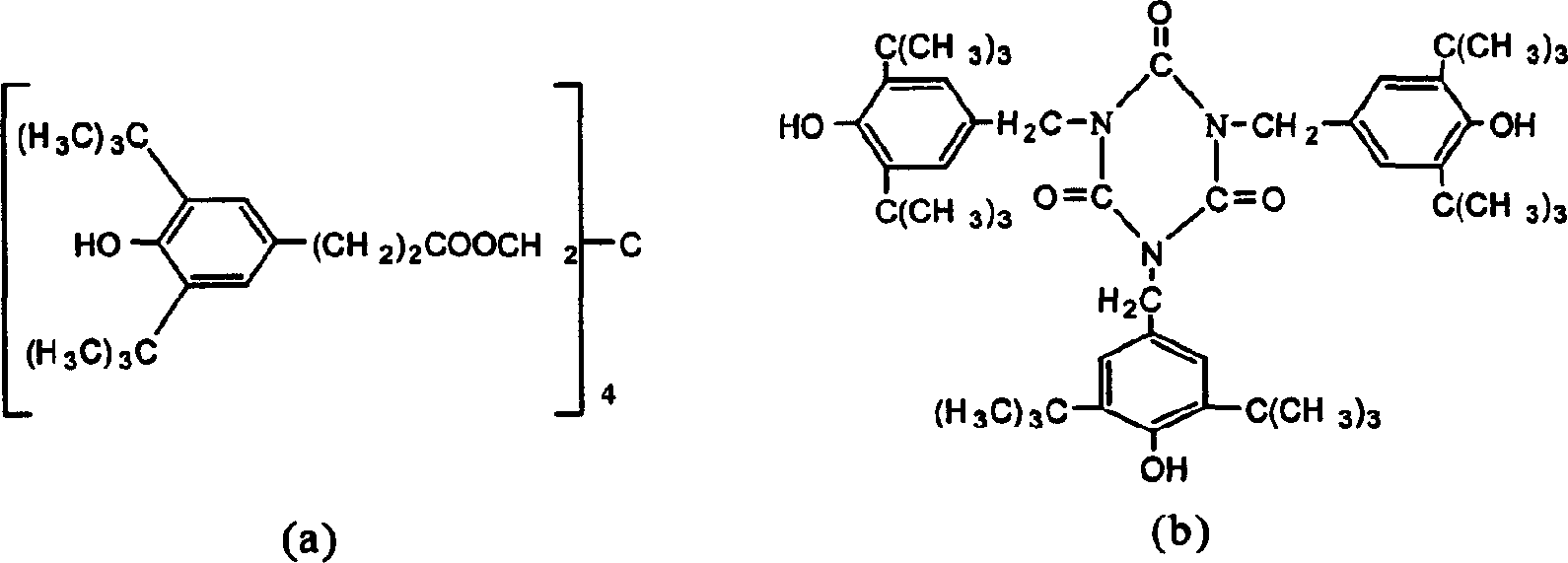

Preparation method of curcumin rare earth complex, composite heat stabilizer for rigid PVC (polyvinyl chloride) and preparation method of composite heat stabilizer

ActiveCN104892653AImprove processing thermal stabilityImprove rheologyGroup 3/13 element organic compoundsFiltrationRare earth

The invention provides a preparation method of a curcumin rare earth complex, a composite heat stabilizer for rigid PVC (polyvinyl chloride) and a preparation method of the composite heat stabilizer. The preparation method of the curcumin rare earth complex comprises steps as follows: curcumin and absolute ethyl alcohol are added to a flask and heated until curcumin is dissolved completely; a rare earth nitrate solution is dropwise added to the flask, and the pH value is regulated to 6.0 plus or minus 0.2; the mixture is continuously stirred and flows back, after the reaction is finished, the mixture is cooled to the room temperature and is subjected to extraction filtration, precipitates obtained through extraction filtration are washed with absolute ethyl alcohol and subjected to extraction filtration and vacuum drying, and the curcumin rare earth complex is obtained. The composite heat stabilizer for rigid PVC comprises components in parts by weight as follows: 100 parts of the curcumin rare earth complex, 0-20 parts of an antioxidant 1010, 5-20 parts of glyceryl monostearate, 5-20 parts of glyceryl tristearate, 15-50 parts of calcium stearate and 5-10 parts of zinc stearate. The composite heat stabilizer for rigid PVC has excellent heat stabilizing effect on processing of a PVC product, and meanwhile, the PVC product has excellent rheological properties and mechanical properties.

Owner:TANGSHAN NORMAL UNIV

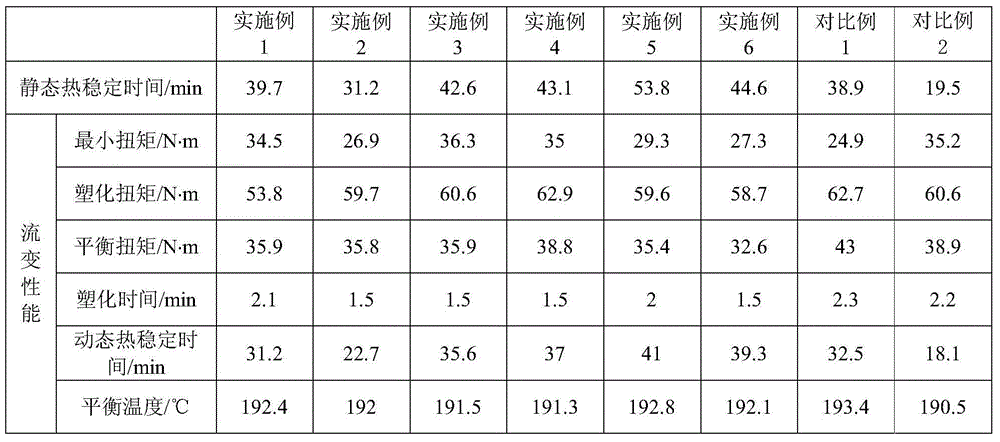

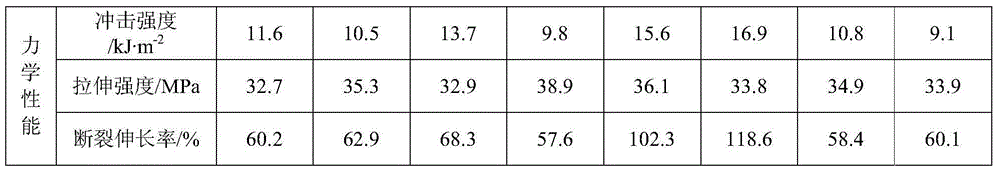

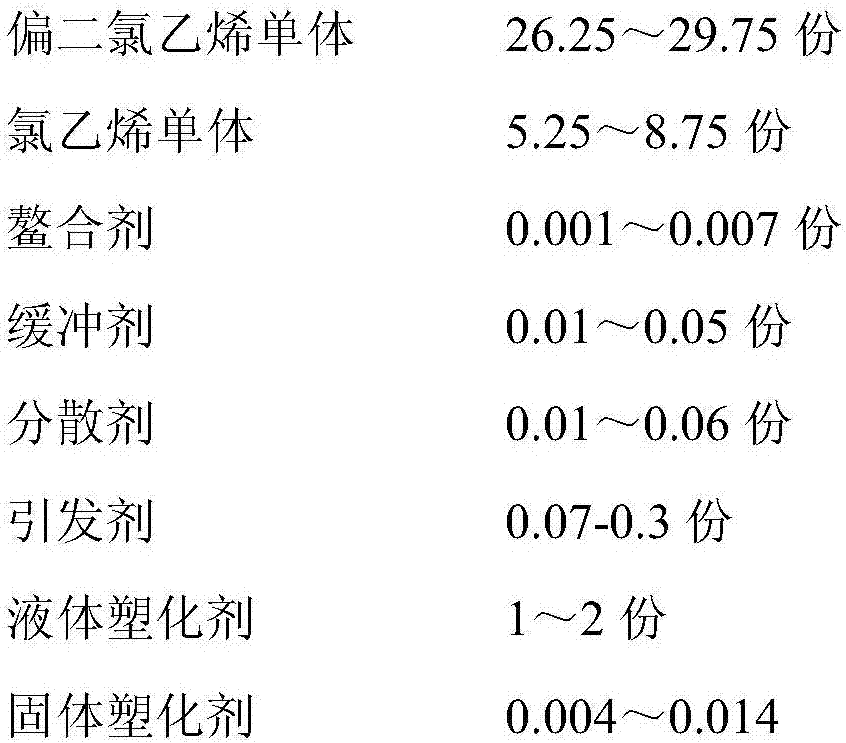

Polyvinylidene chloride composition capable of prolonging food shelf life

The invention discloses a polyvinylidene chloride composition capable of prolonging food shelf life. The polyvinylidene chloride composition comprises, by weight, 26.25-29.75 parts of polyvinylidene chloride monomer, 5.25-8.75 parts of vinyl chloride monomer, 0.001-0.007 part of chelating agent, 0.01-0.05 part of buffer agent, 0.01-0.06 part of dispersing agent, 0.07-0.3 part of initiator, 1-2 parts of liquid plasticizer and 0.004-0.014 part of solid plasticizer. The polyvinylidene chloride composition has the advantages that the composition is excellent in processability, and a thin film prepared through a screw extruder is high in transparency and barrier property, applicable to food fresh-keeping packaging and capable of prolonging the food shelf life.

Owner:ZHEJIANG QUZHOU JUSU CHEM IND CO LTD +1

Biodegradable material containing aliphatic polycarbonate, and preparation method and application thereof

The invention relates to a biodegradable material containing aliphatic polycarbonate, and a preparation method and an application thereof. The biodegradable material is obtained by the following steps of mixing 20-90 parts by weight of aliphatic polycarbonate, 10-80 parts by weight of aliphatic polyester, 0.01-1 part by weight of an organic peroxide, 0.05-1 part by weight of a cross-linking agent, 3-15 parts by weight of a compatilizer, 0.3-5 parts by weight of a plasticizer, 0.1-5 parts by weight of a heat stabilizer and 0.01-1 part by weight of an auxiliary agent uniformly; adding the above mixture in a double-screw extruder for melt blending, stretching the blended mixture into strips; pelletizing the strips to obtain granular mixing resin slices; and vacuum drying the slices and removing water from the slices. The biodegradable material can be used for preparing completely biodegradable film which has various excellent performances of conventional films, can keep relatively good transparency, has relatively high tensile strength, can provide high toughness and tearing strength, and has good thermal stability, etc.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Dull polishing sheet and manufacture process thereof

InactiveCN102942752BIncrease the plasticizing processImprove toughnessProcedure AgentsPolyvinyl chloride

The invention provides a dull polishing sheet and manufacture process thereof. The dull polishing sheet is manufactured by the following raw materials, by weight, 100 parts of polyvinyl chloride (PVC), 1-5 parts of talcum powder, 1-3 parts of organic tin stabilizer, 3-10 parts of modifier, 0.5-1.5 parts of processing agent, 0.05-0.15 part of calcium stearate and 0.1-0.7 part of lubricant for the inside and outside. An optical haze degree and adhesive plaster sheet toughness are improved, production cost is saved, simultaneously convenience for maintaining of the device and the like is brought, device performance is improved, and productivity effect of enterprises is improved.

Owner:ZHEJIANG XINYUANFANG PLASTIC

Stabilizing agent composition in use for producing polyolefine resin

Owner:宁波金海雅宝化工有限公司

Application of trisodium cyanurate in improving the heat stability of PVC and composite heat stabilizer containing trisodium cyanurate

ActiveCN106117882BImprove processing thermal stabilityGood weather resistanceWeather resistanceThermal stability

The invention discloses application of trisodium cyanurate to the increasing of PVC thermostability and a composite heat stabilizer containing the trisodium cyanurate. The trisodium cyanurate can be used for assisting a heat stabilizer and can increase the thermostability of PVC during processing when being combined with the heat stabilizer containing zinc during use. When the trisodium cyanurate is combined with the heat stabilizer containing zinc during use, the thermostability of the PVC during processing can be increased, product weather resistance can be increased, and 'zinc burning' can be inhibited at the same time. The composite heat stabilizer formed by the trisodium cyanurate and the heat stabilizer containing zinc keeps the advantages of nontoxicity and environment protection of the heat stabilizer containing zinc, satisfies the requirement of environment protection and is suitable for being popularized and used.

Owner:济南金昌树新材料科技有限公司

Method for preparing poly (lactic-co-glycolic acid)

The invention provides a preparation method of a lactic and glycolic acid. The method comprises a catalyst containing three compounds of a catalytic induction system. The catalyst catalyzes and induces ring cleavage copolymerization between diglycolide and lactide to synthesize lactic and glycolic acid. The monomer to catalyst (mol ratio) is at 20,000 to 500,000 and the reaction temperature is 100 to 220 DEG C for 1 to 200 hours with inert gas protection or in vacuum. The invention has the advantages of high transformation ration, low catalyst contents of products, high molecular weight, narrow molecular weight disposition, good heat stability, small degradation of high temperature molten, good uniformity of materials, and is provided with excellent biological degradability and biologicalcompatibleness. The lactic and glycolic acid prepared by the invention can be widely used for surgical operation suture, internal fixation of fracture, tissue repair, plastic surgery, anti-organic conglutination, medical slow release, organic engineering, etc.

Owner:HUIZHOU HUAYANG MEDICAL EQUIP

A kind of pmma light diffusing agent and a kind of light diffusing pmma material

ActiveCN104109385BPromote atomizationPerformance impactHexadecyltrimethylammonium bromideThermal stability

A PMMA light-diffusing agent, including frozen micro-pulverised polysiloxane particles, light-scattering agents 1 and 2, a curing agent, and a compatibilising agent, wherein the compatibilising agent is a mixture of hexadecyltrimethylammonium bromide and ethyl acetoacetate, and the curing agent is a mixture of a persulphate and tetrahydrofuran.

Owner:广西海枫光学材料科技有限公司

Preparation method of impact-resistant easily-degradable environment-friendly non-woven fabric

PendingCN112048829AImprove toughnessHigh impact strengthConjugated synthetic polymer artificial filamentsNon-woven fabricsPolymer sciencePolybutylene

The invention discloses a preparation method of an impact-resistant easily-degradable environment-friendly non-woven fabric. The preparation method of the impact-resistant easily-degradable environment-friendly non-woven fabric comprises the following steps that polylactic acid, epoxy resin, carbon nanotubes and acetone are mixed, ultrasonic treatment is carried out for 2-4 hours, ultrasonic poweris 300W-500W, the acetone is removed, a curing agent and montmorillonite are added, and reacting is carried out at 130DEG C-150DEG C for 10-20 minutes to obtain pretreated polylactic acid; the pretreated polylactic acid, polybutylene adipate-co-terephthalate resin, an inorganic filler and a plasticizer are uniformly mixed, twin-screw extrusion is carried out, and then sequential cooling, drying and crushing are carried out to obtain a premix; the premix is extruded and melted at the extruding and melting temperature of 160DEG C-168 DEG C, the temperature of the melt is adjusted to 185DEG C-190 DEG C, nascent fibers are sprayed through a 0.4mm-0.5mm spray head, the nascent fibers are stretched through air flow, the nascent fibers are uniformly laid into a fiber net, and the fiber net is bound through a 130 DEG C-140DEG C hot roller to obtain the impact-resistant easily-degradable environment-friendly non-woven fabric.

Owner:温岭市妮珂芙服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com