Composite material cable core

A technology of cable core and heat-resistant resin, which is applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of easy aging, etc., and achieve the effects of excellent high temperature resistance, improved heat resistance, and excellent processing thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

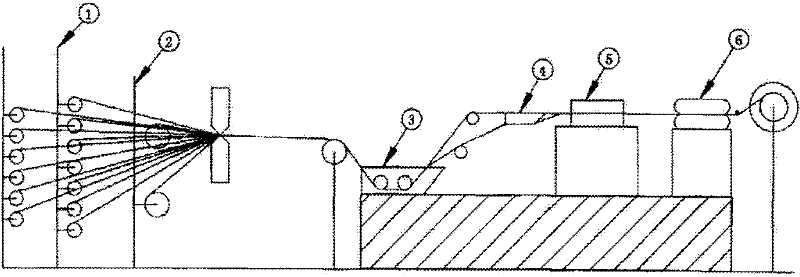

[0017] The preparation of embodiment 1 cable core

[0018] Pass the carbon fiber untwisted yarn through the creel 1, enter the storage tank 3 filled with epoxy resin glue through the guide felt plate 2, and dip in the glue. The ultraviolet absorber RMB and light stabilizer HPT in the glue are 0.1% of the epoxy resin quality. %, 0.1%, the quality of the acid anhydride curing agent is the sum of the quality of the ultraviolet absorber RMB, light stabilizer HPT, and epoxy resin, and then enters the preforming mold 4.

[0019] The reinforcing material coming out of the preforming mold 4 enters the forming mold 5 with a heating plate for curing. The forming mold 5 is 650mm long and has a cavity diameter of 4.5mm, and is divided into three temperature zones: 140°C, 170°C, and 140°C. After solidification, pull out from the forming mold 5 by the pulling machine 6, and obtain the inner layer of the cable core.

[0020] Pass the glass fiber untwisted yarn through the creel 1, enter th...

Embodiment 2

[0022] The preparation of embodiment 2 cable core

[0023] Pass the carbon fiber untwisted yarn through the creel 1, enter the storage tank 3 filled with phenolic resin glue through the guide felt plate 2, and dip in the glue. The ultraviolet absorber UV-O and light stabilizer LQ-292 in the glue are the quality of phenolic resin. 3%, 3%, the quality of the anhydride curing agent is the sum of the quality of the ultraviolet absorber UV-O, the light stabilizer LQ-292, and the phenolic resin, and then enters the preforming mold 4.

[0024] The reinforcing material coming out of the preforming mold 4 enters the forming mold 5 with a heating plate for curing. The forming mold 5 is 650mm long and has a cavity diameter of 4.5mm, and is divided into three temperature zones: 140°C, 170°C, and 140°C. After solidification, pull out from the forming mold 5 by the pulling machine 6, and obtain the inner layer of the cable core.

[0025] Pass the glass fiber untwisted yarn through the cre...

Embodiment 3

[0026] The reinforcing material coming out from the preforming mold 4 enters the forming mold 5 with a heating plate to solidify. Forming mold 5 is long 650mm, and mold cavity diameter is 6.5mm. After solidification, pull out from the forming mold 5 by the pulling machine 6, and obtain the inner layer of the cable core. Example 3 Cable core heat resistance (aging) performance test

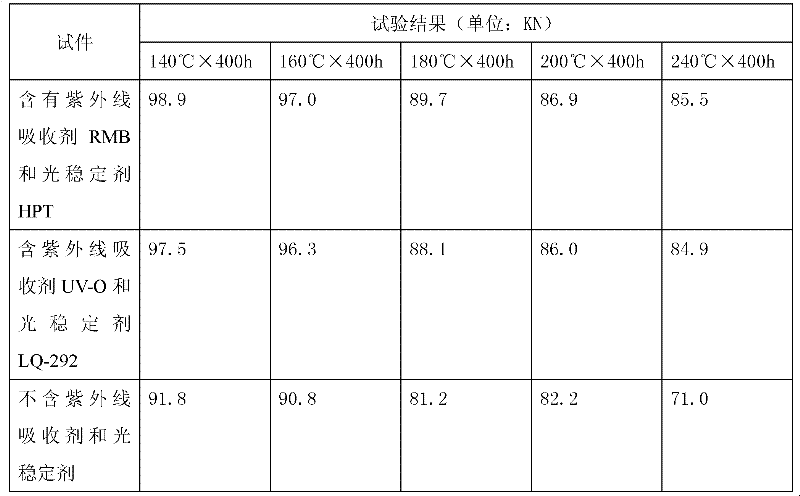

[0027] Put the cable core containing ultraviolet absorber and light stabilizer, and the cable core without ultraviolet absorber and light stabilizer into ovens with temperatures of 140°C, 160°C, 180°C, 200°C, and 240°C for 400 hours; After heating, take it out and let it cool naturally in the air to room temperature; install wedge-shaped tension clamps at both ends of the cable and test the tensile force on a 500KN tensile testing machine. The test results are shown in the table below. The tensile force of the former is higher than that of the latter, indicating that the cable core containing ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com