Environment-friendly halogen-free flame-retardant masterbatch and preparation method thereof

A flame-retardant masterbatch and environmentally friendly technology, applied in the field of materials, can solve the problems of nervous system and immune system poisoning, unsuitable for production and use, environmental hazards, etc., achieve excellent compatibility and dispersibility, no precipitation performance, strong The effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

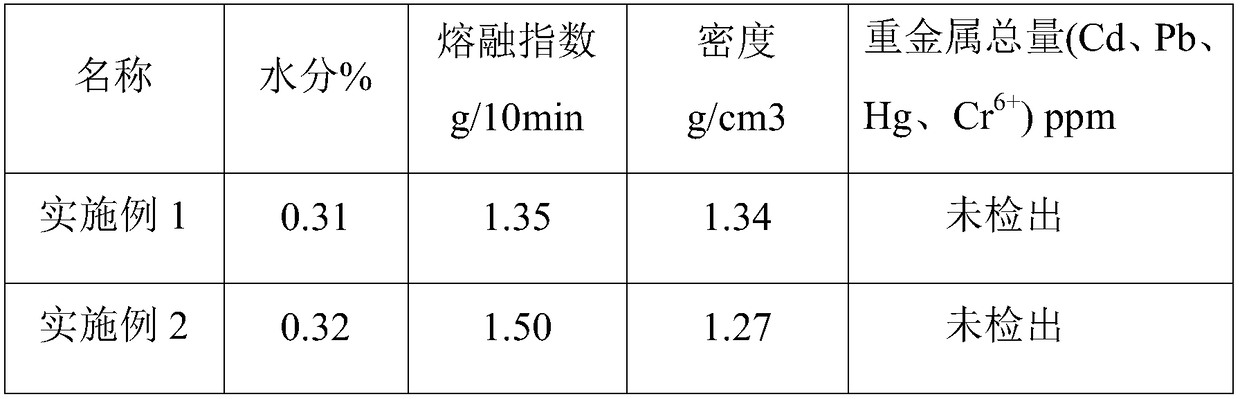

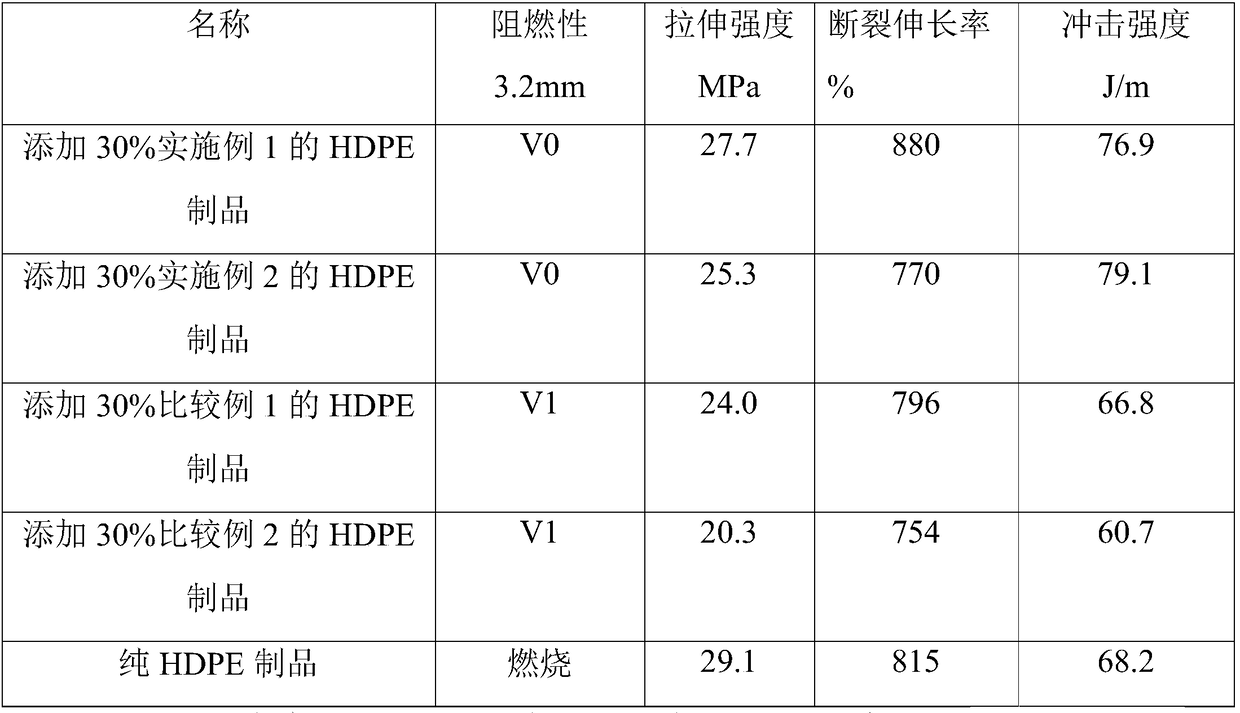

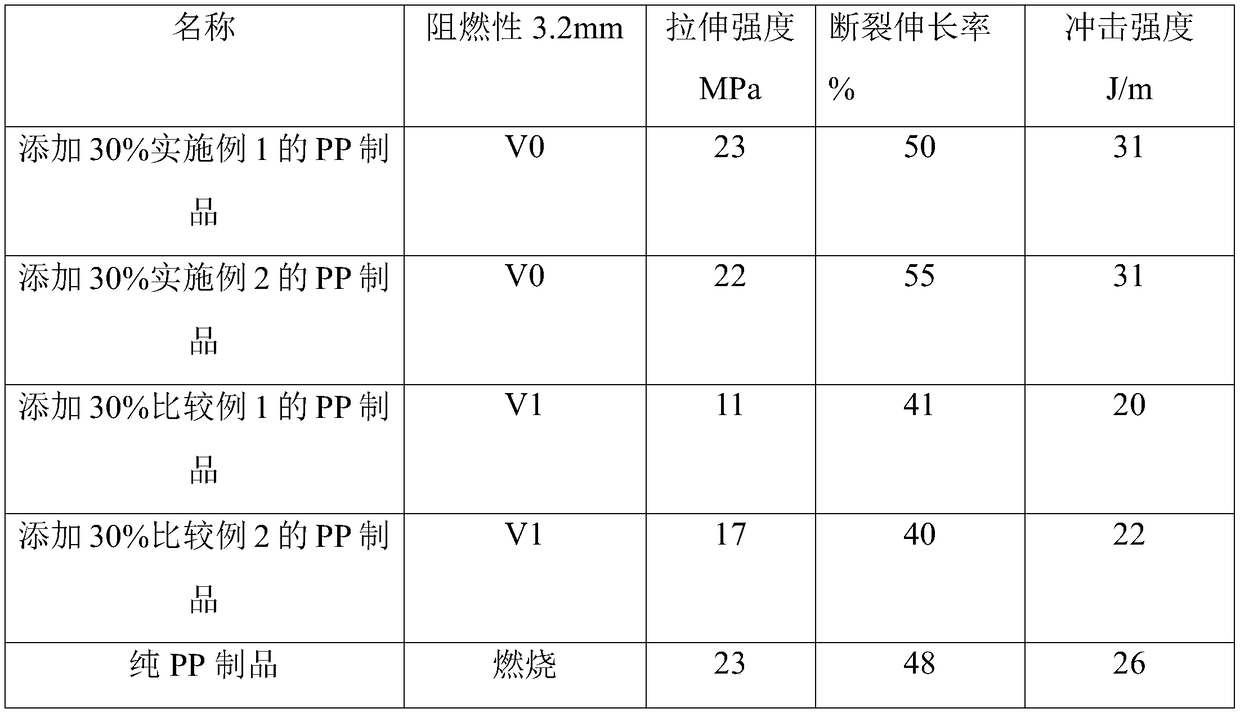

Embodiment 1

[0038] An environmentally friendly halogen-free flame retardant masterbatch, comprising the following raw materials in parts by weight:

[0039] Polyethylene 108 parts;

[0040] Antioxidant 1076 0.12 parts;

[0041] Composite modified halogen-free flame retardant powder 94 parts;

[0042] Polyethylene wax H110 4.5 parts;

[0043] Composite modified halogen-free flame retardant powder, including the following raw materials in parts by weight:

[0044] Silane coupling agent KH550 1.8 parts;

[0045] Stearic acid Indonesia 1801 1.2 parts;

[0046] 57 parts of hydrotalcite powder;

[0047] 24 parts of aluminum hydroxide powder;

[0048] Talcum powder 15 parts.

[0049] The MRF of the polyethylene is 2-4g / 10min.

[0050] The D97 of the hydrotalcite powder is ≤ 1 μm; the D97 of the aluminum hydroxide powder is ≤ 10 μm; the D97 of the talc powder is ≤ 0.5 μm.

[0051] The preparation method of the environment-friendly halogen-free flame retardant masterbatch is:

[0052] S1...

Embodiment 2

[0065] An environmentally friendly halogen-free flame retardant masterbatch, comprising the following raw materials in parts by weight:

[0066] 95 parts of polypropylene;

[0067] Antioxidant 1076 0.22 parts;

[0068] Composite modified halogen-free flame retardant powder 80 parts

[0069] 4.1 parts of polypropylene wax;

[0070] The composite modified halogen-free flame retardant powder includes the following raw materials in parts by weight:

[0071] Silane coupling agent KH550 1.6 parts;

[0072] Stearic acid Indonesia 1801 1.0 parts;

[0073] 52 parts of hydrotalcite powder;

[0074] 25 parts of aluminum hydroxide powder;

[0075] Talcum powder 12 parts.

[0076] The MRF of the polypropylene is 3-4 g / 10 min.

[0077] The D97 of the hydrotalcite powder is ≤ 1 μm; the D97 of the aluminum hydroxide powder is ≤ 10 μm; the D97 of the talc powder is ≤ 0.5 μm.

[0078] The preparation method of the environment-friendly halogen-free flame retardant masterbatch is:

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com