Preparation method of magnesium hydroxide flame retardant

A magnesium hydroxide and flame retardant technology, applied in the field of flame retardants, can solve problems such as inability to meet industrial production needs, and achieve good industrial application prospects, good dispersion and compatibility, and qualified flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

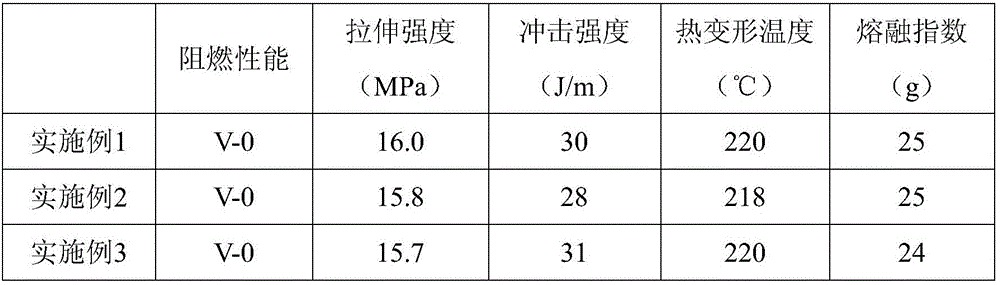

Examples

Embodiment 1

[0027] A preparation method of magnesium hydroxide flame retardant of the present invention, comprises the following steps:

[0028] (1) adding magnesium sulfate to water, be mixed with the magnesium sulfate solution that concentration is 0.8mol / L;

[0029] (2) Add acetone to 1,7,7-trimethylbicyclo[2,2,1]heptan-2-one to prepare a mixed solution I with a concentration of 400g / L;

[0030] (3) Add the mixed solution I obtained in step (2) into the magnesium sulfate solution obtained in step (1), stir and disperse to form mixed solution II, in which 1,7,7-trimethylbicyclo[2 ,2,1] the concentration of heptan-2-one is 20g / L;

[0031] (4) adding sodium hydroxide to the mixed solution II obtained in step (3) as a precipitating agent, carrying out a precipitation reaction to form a slurry, the molar ratio of magnesium ions and hydroxide ions in the slurry is 1:2;

[0032] (5) Aging the slurry obtained in step (4), the aging time is 3h, then filtering, washing the filter cake with abs...

Embodiment 2

[0037] A preparation method of magnesium hydroxide flame retardant of the present invention, comprises the following steps:

[0038] (1) adding magnesium sulfate to water, be mixed with the magnesium sulfate solution that concentration is 0.9mol / L;

[0039] (2) Add acetone to 1,7,7-trimethylbicyclo[2,2,1]heptan-2-one to prepare a mixed solution I with a concentration of 440g / L;

[0040] (3) Add the mixed solution I obtained in step (2) into the magnesium sulfate solution obtained in step (1), stir and disperse to form mixed solution II, in which 1,7,7-trimethylbicyclo[2 ,2,1] the concentration of heptan-2-one is 22g / L;

[0041] (4) adding sodium hydroxide to the mixed solution II obtained in step (3) as a precipitating agent, carrying out a precipitation reaction to form a slurry, the molar ratio of magnesium ions and hydroxide ions in the slurry is 1:2.1;

[0042] (5) Aging the slurry obtained in step (4), the aging time is 3.5h, then filtering, washing the filter cake with...

Embodiment 3

[0047] A preparation method of magnesium hydroxide flame retardant of the present invention, comprises the following steps:

[0048] (1) adding magnesium sulfate to water, be mixed with the magnesium sulfate solution that concentration is 1.0mol / L;

[0049] (2) Add acetone to 1,7,7-trimethylbicyclo[2,2,1]heptan-2-one to prepare a mixed solution I with a concentration of 480g / L;

[0050] (3) Add the mixed solution I obtained in step (2) into the magnesium sulfate solution obtained in step (1), stir and disperse to form mixed solution II, in which 1,7,7-trimethylbicyclo[2 ,2,1] the concentration of heptan-2-one is 25g / L;

[0051] (4) adding sodium hydroxide to the mixed solution II obtained in step (3) as a precipitating agent, carrying out a precipitation reaction to form a slurry, the molar ratio of magnesium ions and hydroxide ions in the slurry is 1:2.1;

[0052] (5) Aging the slurry obtained in step (4), the aging time is 4h, then filtering, washing the filter cake with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com