Production process of damping underwater acoustic transmission plastic functional master batch

A technology of functional masterbatch and production process, which is applied in the field of production process of damping underwater sound-transmitting plastic functional masterbatch, can solve the problem that sound transmission, pressure resistance, vibration reduction, weather resistance, corrosion resistance are difficult to achieve balance, and polyurethane resistance is difficult to achieve. Poor aging performance, poor rubber aging resistance and other problems, to achieve the effect of improving processing performance, reducing extrusion viscosity, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

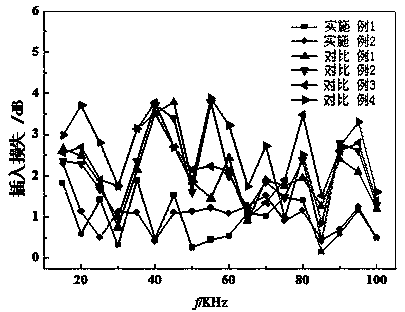

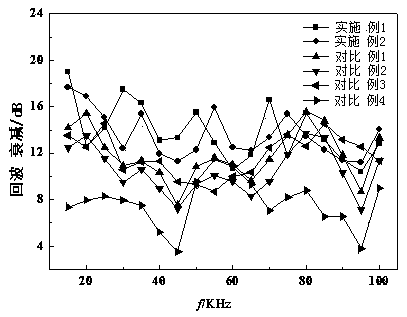

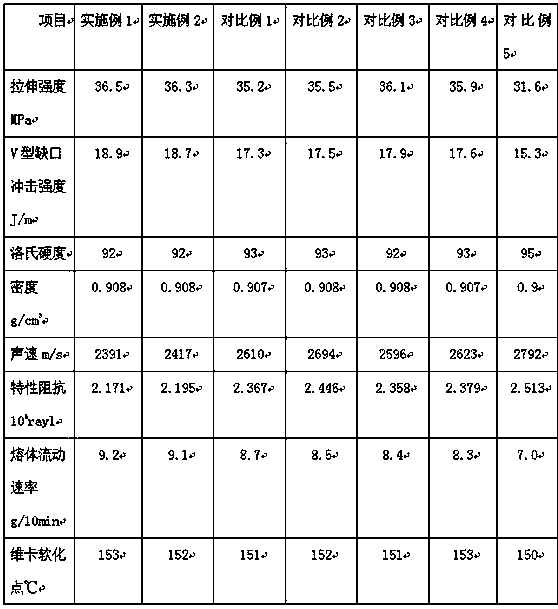

Examples

Embodiment 1

[0022] The first step is to pulverize the raw material SEBS on a pulverizer, then wash it with ethanol for 4 hours, and then dry it in an oven at 60°C. The irradiation conditions will treat the processed SEBS powder at room temperature in an air atmosphere. 60CO-γ-ray irradiation, the irradiation dose is: 60kGy, the irradiated powder is placed in a low-temperature box, and stored at −24°C for 12 hours to obtain the irradiated powder, and 100 parts by weight are weighed. The powder is placed in a reaction kettle containing 100 parts of methacrylic acid aqueous solution with a mass fraction of 6%, and 0.6 parts of 4mmol / L copper chloride aqueous solution is added as a polymerization inhibitor, sealed with nitrogen gas for 15 minutes, and stirred in a constant temperature stirring water bath at 60°C Carry out the grafting reaction for 20 minutes, filter the material, extract it with a mixed solution of ethanol and water for 48 hours, and then dry it in a vacuum oven at 60°C to a c...

Embodiment 2

[0024] The first step is to pulverize the raw material SEBS on a pulverizer, then wash it with ethanol for 4 hours, and then dry it in an oven at 60°C. The irradiation conditions will treat the processed SEBS powder at room temperature in an air atmosphere. 60 CO-γ-ray irradiation, the irradiation dose is: 60kGy, put the irradiated powder into a low-temperature box, and store it at −24°C for 10 hours to obtain the irradiated powder. Weigh 100 parts of the irradiated powder by weight. The powder is placed in a reaction kettle containing 100 parts of methacrylic acid aqueous solution with a mass fraction of 6%, and 0.6 parts of 4mmol / L copper chloride aqueous solution is added as a polymerization inhibitor, sealed with nitrogen gas for 10 minutes, and stirred in a constant temperature stirring water bath at 50°C Carry out the grafting reaction for 20 minutes, filter the material, extract it with a mixed solution of ethanol and water for 24 hours, and then dry it in a vacuum oven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com