Patents

Literature

174results about How to "Reduce intermolecular forces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

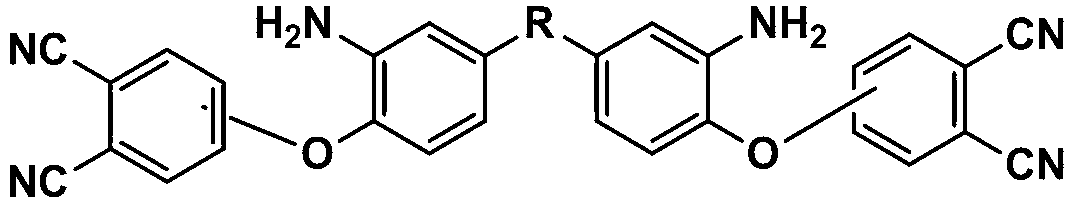

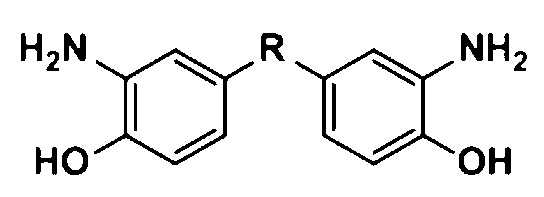

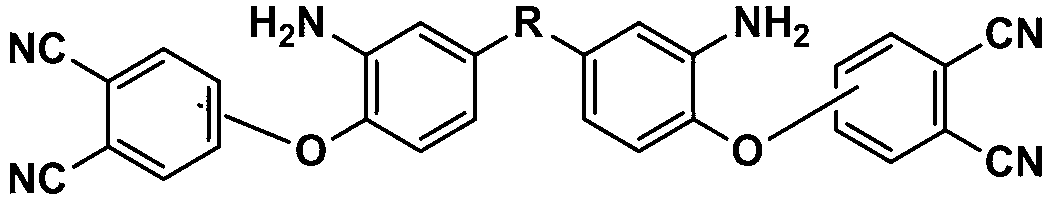

Aromatic diamine containing phthalonitrile side group and synthesis method and application thereof

InactiveCN102993070AIncrease typeBreak the rigid structureCarboxylic acid nitrile preparationOrganic compound preparationImidePolymer science

The invention discloses aromatic diamine containing phthalonitrile side group, which is characterized in that the structural formula is shown in the specification, wherein R is one of CF3CCF3, CH3CCH3, O, CO and S. A preparation method of the aromatic diamine containing phthalonitrile side group comprises the following steps of: adding 4-nitrophthalonitrile or 3-nitrophthalonitrile, a compound 1, potassium carbonate and a high-boiling point solvent into a reaction container; conducting reaction for 10-24 hours at room temperature under protection of nitrogen; and then precipitating, filtering and drying. The aromatic diamine containing phthalonitrile side group can be applied to the preparation of polyimide, polyamide and polyamide-imide.

Owner:SICHUAN UNIV

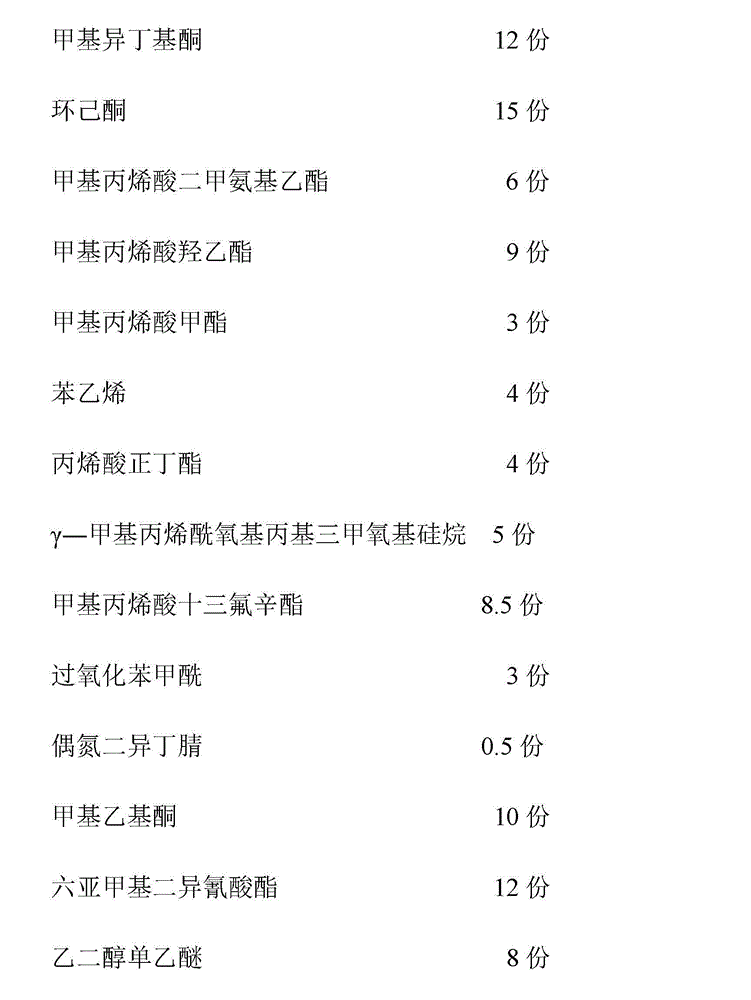

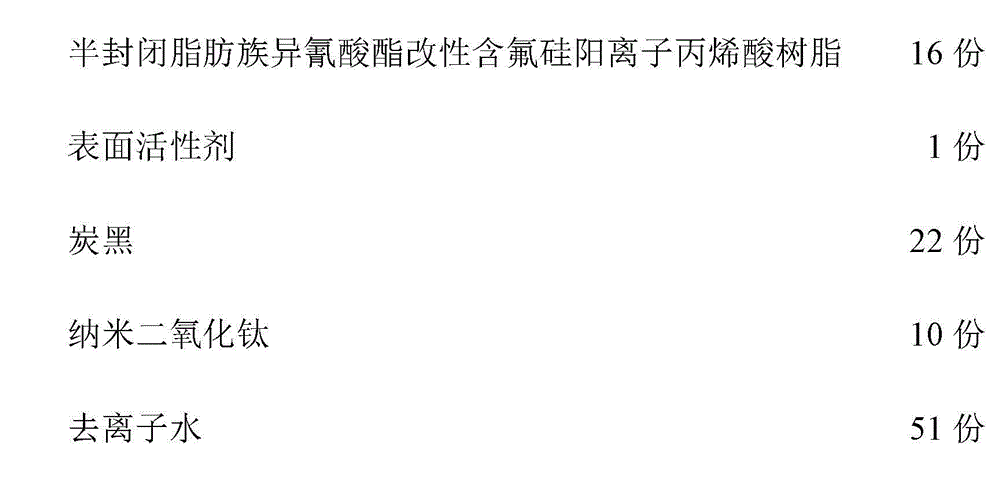

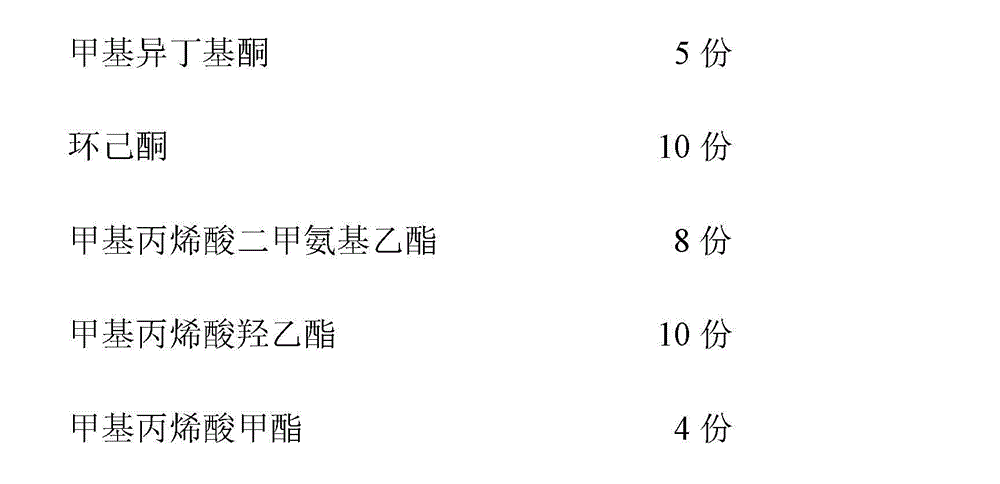

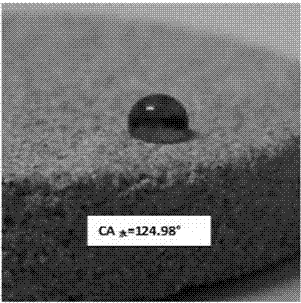

Self-cleaning fluorosilicone-modified acrylic acid cathode electrophoresis paint and preparation method thereof

ActiveCN103333596AImprove stain resistanceImprove stabilityPolyurea/polyurethane coatingsPaints for electrolytic applicationsPolymer scienceAcrylic resin

The invention relates to a self-cleaning fluorosilicone-modified acrylic acid cathode electrophoresis paint and a preparation method thereof. The paint is prepared from a fluorosilicone-modified acrylic acid emulsion and a nano silicon dioxide modified color paste in a ratio of 9:1, wherein the fluorosilicone-modified acrylic acid emulsion is prepared by stirring a semiclosed aliphatic isocyanate-modified fluorosilicone-containing cationic acrylic resin, a neutralizer and deionized water at high speed; and the nano titanium dioxide powder modified color paste is prepared by grinding a semiclosed aliphatic isocyanate-modified fluorosilicone-containing cationic acrylic resin, a surfactant and deionized water at high speed in a grinding tank. The paint provided by the invention has the advantages of high self stability and high tank liquor stability; and after the electrophoretic coating, the coating has the advantages of flat appearance, favorable mechanical properties, excellent acid and alkali resistance, high hydrophobicity and favorable pollution resistance (at most 10%), and the contact angle between the coating film surface and water can reach 130 degrees.

Owner:HAOLISEN COATING SHANGHAI +1

Welding flux for SnAgCu alloy solder powder and preparation method thereof

ActiveCN101508061AReduce intermolecular forcesImprove liquidityWelding/cutting media/materialsSoldering mediaRosinReflow soldering

The invention relates to a soldering flux for Sn-Ag-Cu alloy solder powder, which is characterized by comprising the following compositions in proportion by weight: 25 to 40 percent of organic solvent, 5 to 10 percent of activating agent, 30 to 55 percent of rosin, 5 to 10 percent of thixotropic agent, and 5 to 10 percent of plasticizing agent. The invention also provides a preparation method for the soldering flux. In the invention, the plasticizing agent strengthens the liquidity of residues, so that soldering paste prepared from the soldering flux and the Sn-Ag-Cu alloy solder powder has few residues after welding and can be well spread around welding spots; the residues are transparent so as to ensure good brightness of the welding spots; the corrosion of the residues to the welding spots and components and parts is greatly reduced at the same time; and the proper amount of thixotropic agent makes the soldering paste prepared from the soldering flux and the Sn-Ag-Cu alloy solder powder have high stability and good thixotropic property, and the soldering paste has good sagging resistance in printing and welding, and reduces solder balls generated around the welding spots in reflow soldering.

Owner:NICHE TECH KAISER SHANTOU

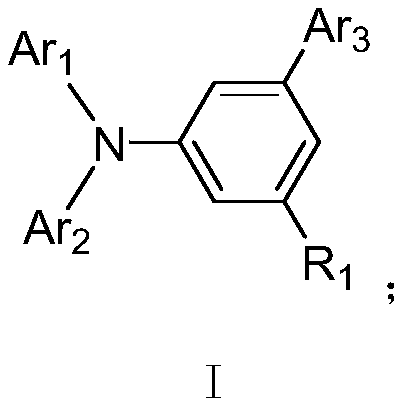

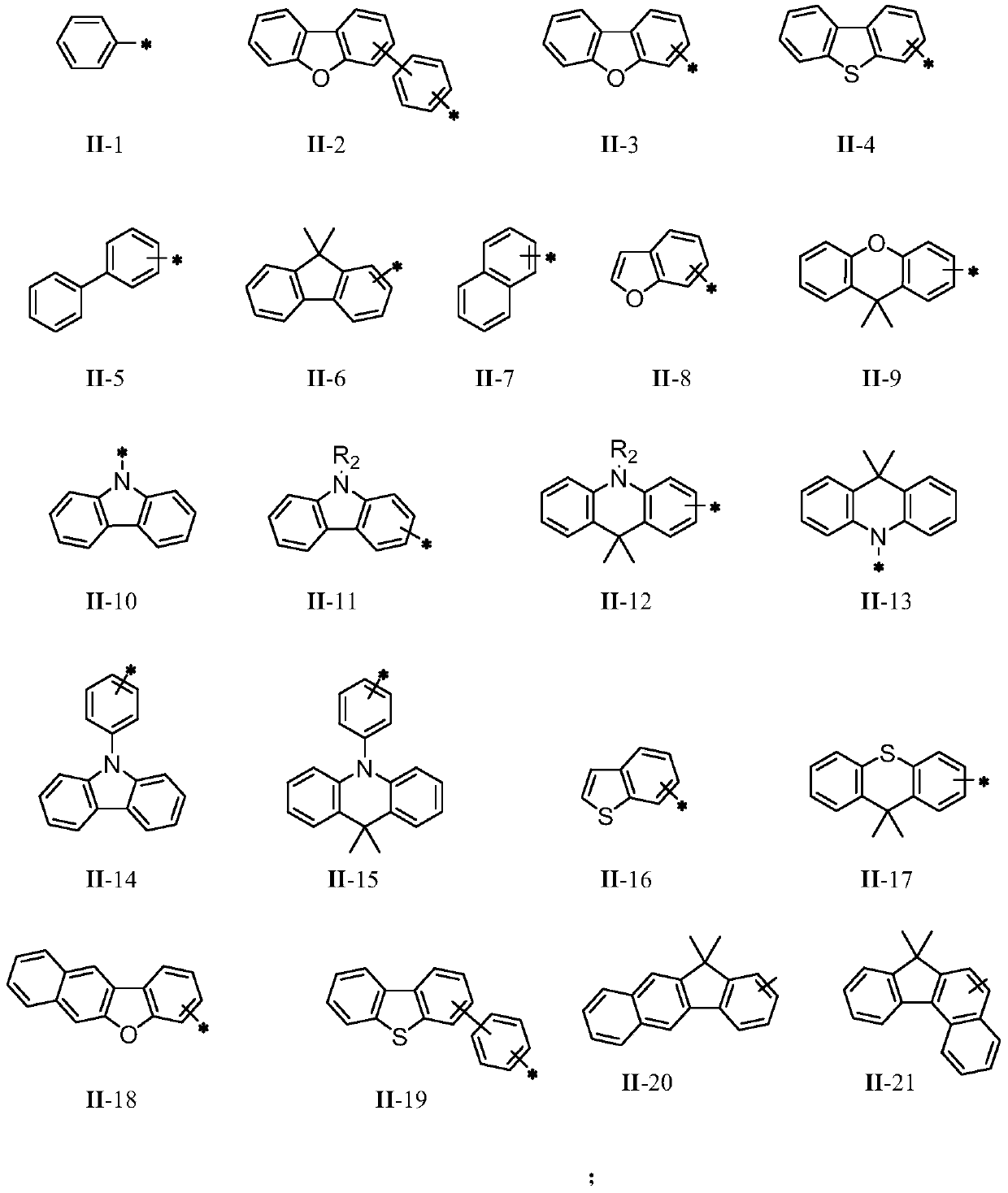

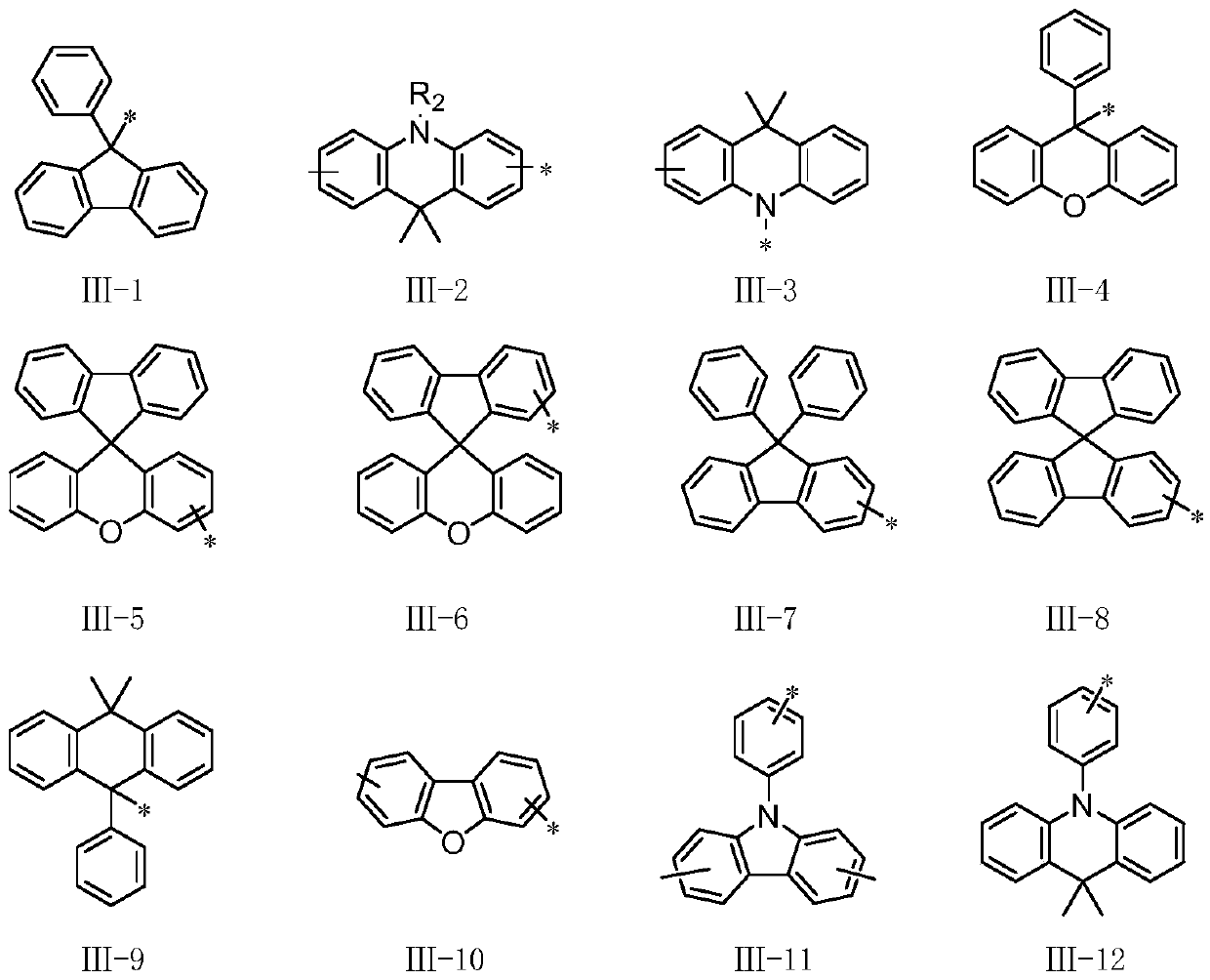

Luminescence auxiliary material, preparation method thereof and organic electroluminescent device

PendingCN111440156AHigh hole mobilityShort lifeOrganic chemistrySolid-state devicesChemical synthesisAryl

The invention discloses a luminescence auxiliary material, a preparation method thereof and an organic electroluminescence device, and belongs to the field of chemical synthesis and photoelectric materials. The structural general formula is shown in the specification, in the formula, Ar1, ar2 and Ar3 are each independently one or more of substituted or unsubstituted C1-C30 alkyl, substituted or unsubstituted C3-C30 cycloalkyl, substituted or unsubstituted 3-to 30-membered heterocycloalkyl, substituted or unsubstituted C6-C30 aryl, substituted or unsubstituted C1-C30 alkylamino, substituted orunsubstituted C1-C30 alkoxy, substituted or unsubstituted C6-C30 arylamino, substituted or unsubstituted 3-to 30-membered heteroaryl, substituted or unsubstituted C10-C30 fused ring group, substitutedor unsubstituted C5-C30 spiro ring group. The luminescent auxiliary material can improve the luminescent efficiency and the service life of the organic electroluminescent device.

Owner:JILIN OPTICAL & ELECTRONICS MATERIALS

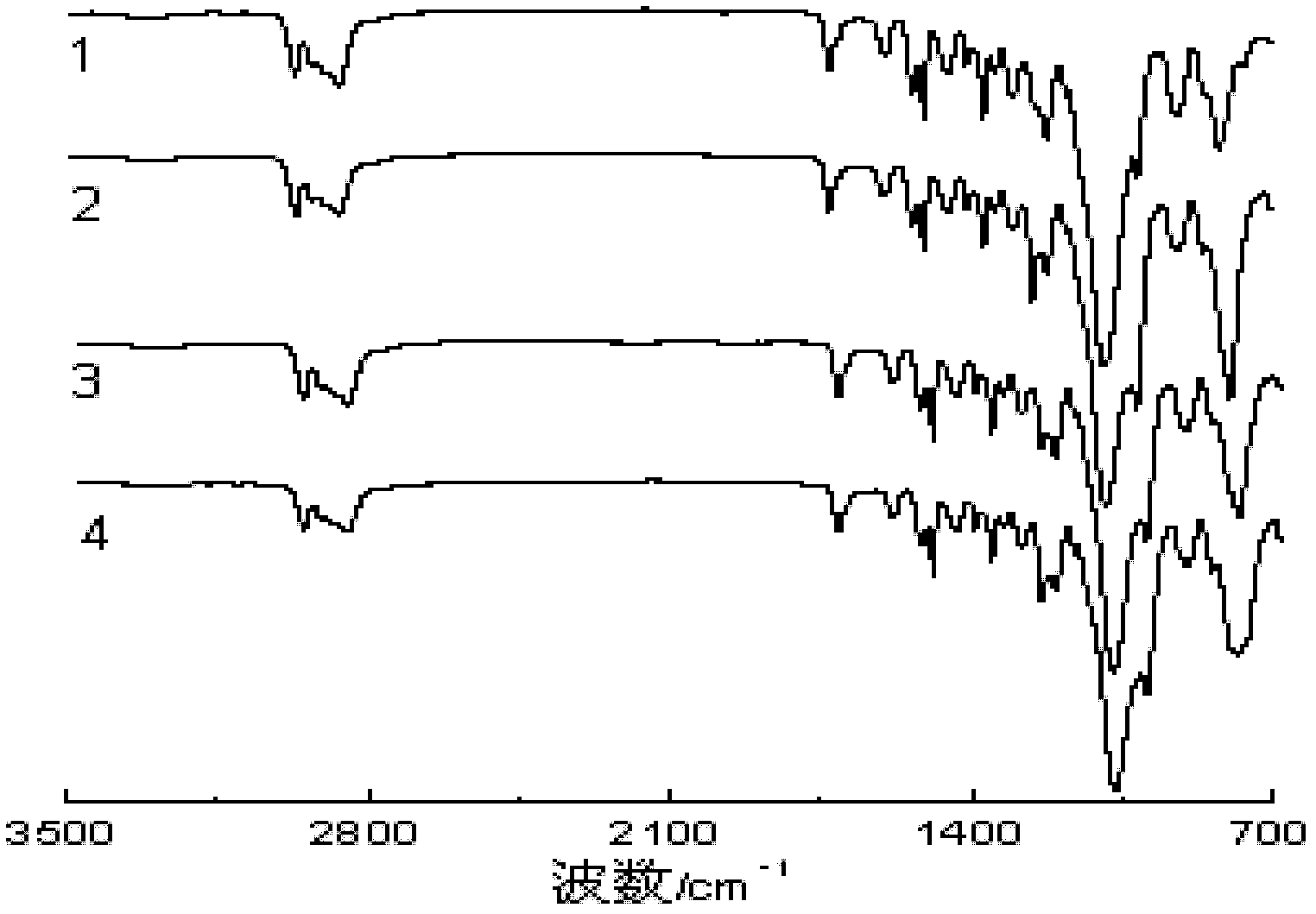

Polysiloxane modified polyurethane-epoxy resin polymer material, preparation method thereof and use thereof

The invention relates to a polysiloxane modified polyurethane-epoxy resin polymer material, a preparation method thereof and a use thereof. The preparation method comprises the following steps: 1, drying raw materials of a polyether, a bisphenol A type epoxy resin and a hydroxyl-terminated polysiloxane until water mass percentages of below 0.01%; 2, adding the polyester, the bisphenol A type epoxy resin and diisocyanate to a reaction vessel to generate a polyurethane-epoxy resin polymer system; 3, adding the hydroxyl-terminated polysiloxane to the polyurethane-epoxy resin polymer system, and reacting to generate a polysiloxane-polyurethane-epoxy resin prepolymer system; and 4, adding a curing agent and a catalyst before ending the reaction, uniformly stirring, dumping the obtained system to a die, and cure-molding. The polysiloxane modified polyurethane-epoxy resin polymer material has the advantage of the complementation of polyurethane-epoxy resin performances and also has the hydrophobic characteristic of the polysiloxane, so comprehensive properties of materials prepared from the polysiloxane modified polyurethane-epoxy resin polymer system are improved, thereby the polysiloxane modified polyurethane-epoxy resin polymer material is mainly applied to high damping materials, waterproof electronic packaging materials, medical materials, long-term storage materials and the like.

Owner:溧阳常大技术转移中心有限公司

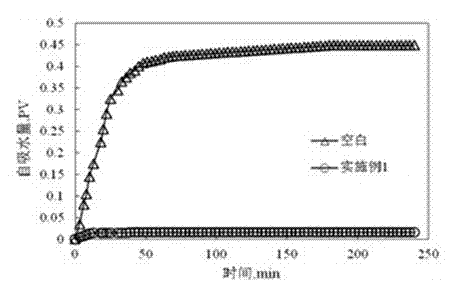

Anti-water-blocking agent for drilling fluid and preparation method thereof

ActiveCN102887974AGood weather resistanceImprove performanceDrilling compositionGas phaseWater block

The invention relates to an anti-water-blocking agent for drilling fluid and a preparation method thereof. The anti-water-blocking agent is a polymer containing a butyl acrylate (BA) monomer, a methyl methacrylate (MMA) monomer, a methacrylic acid (MAA) monomer, an acrylamide (AM) monomer and a 2-(perfluorohexyl)ethyl methacrylate (G06B) monomer, wherein the mol percent of a is 35.8-36.5%, the mol percent of b is 27.0-30.5%, the mol percent of c is 7.5-9.0% and the mol percent of d is 7.5-9.0%. According to the invention, the anti-water-blocking agent effectively reduces filtrate surface tension and oil-water interfacial tension, improves gas-phase relative permeability, has a good invading fluid draining effect and is beneficial to driving away resident fluid in near wellbore formations in a draining manner so as to better relieve the water blocking effect. The preparation method of the anti-water-blocking agent is safe and economic and has a high conversion rate; and a batch feeding method is used, so that the requirements for low dosage and high performance are met.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Single-component silane modified polyether sealant composition and sealant and preparation method thereof

ActiveCN108795360AGood weather resistanceIncreased durabilityNon-macromolecular adhesive additivesPolyether adhesivesSilanesUv absorber

The invention relates to the field of high molecular sealing materials and discloses a single-component silane modified polyether sealant composition and a sealant prepared from the single-component silane modified polyether sealant composition. The single-component silane modified polyether sealant composition disclosed by the invention is prepared from silane modified polyether resin, alkoxy terminated polydimethylsiloxane, a plasticizing agent, reinforcing filler, a water removal agent, a light stabilizing agent, an ultraviolet absorbent, a coupling agent and a catalyst. The sealant disclosed by the invention has the advantages of good smell, good ageing resistance, high recovery rate and the like.

Owner:浙江中天东方氟硅材料股份有限公司

Bi-component bisphenol A type epoxy resin structured fluid sealant and preparation thereof

InactiveCN101343524AImprove wear resistanceImprove thixotropyOther chemical processesEpoxy resin adhesivesPliabilityUltimate tensile strength

The invention discloses sealant of a dual-component and bisphenol A type epoxy resin structure and the preparation method, which comprises a first component and a second component, wherein, the first component comprises 75 parts to 95 parts of bisphenol A type epoxy resin, 8 parts to 22 parts of toughening agent, 75 parts to 95 parts of filling agent and 15 parts to 25 parts of plasticizing agent, the second component comprises 40 parts to 60 parts of curing agent, 45 parts to 55 parts of filling agent and 5 parts to 15 parts of ferric oxide powder. The preparation method comprises the followings: the preparation of the first component: the materials in the first component are poured into an agitating barrel according to the weight parts proportion, evenly stirring the materials, until grayish white fluid is obtained, namely the first component; the preparation of the second component: the materials in the second component are poured into the agitating barrel according to the weight part proportion, evenly stirring the materials, until grayish red fluid is obtained, namely the second component; the first component and the second component are mixed and evenly stirred according to the weight part of 2.8 to 3.2:1, and the sealant of the dual-component and bisphenol A type epoxy resin structure is obtained. The sealant has the advantages that the pliability is good, the stripping strength is strong, and the physical mechanical performance and the process performance are well improved.

Owner:SYST EQUIP CO LTD OF THE 28TH RES INST LI YANG

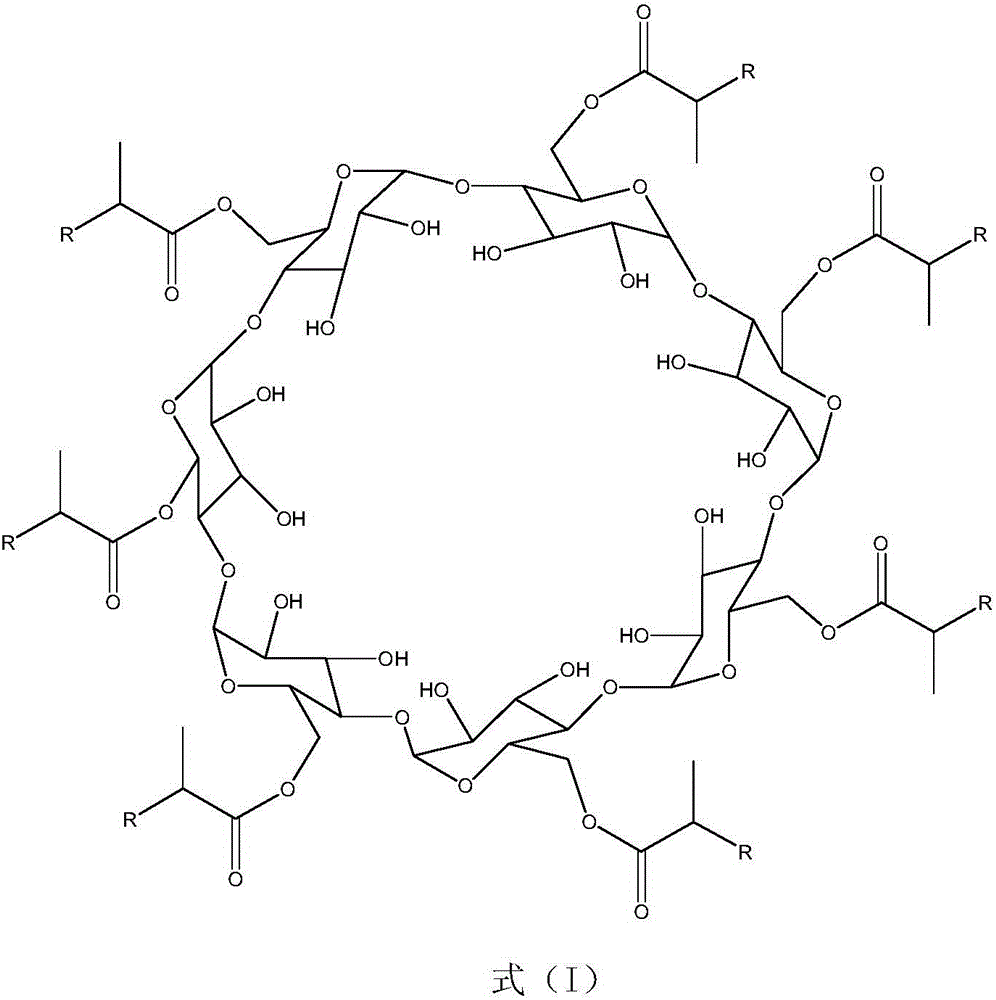

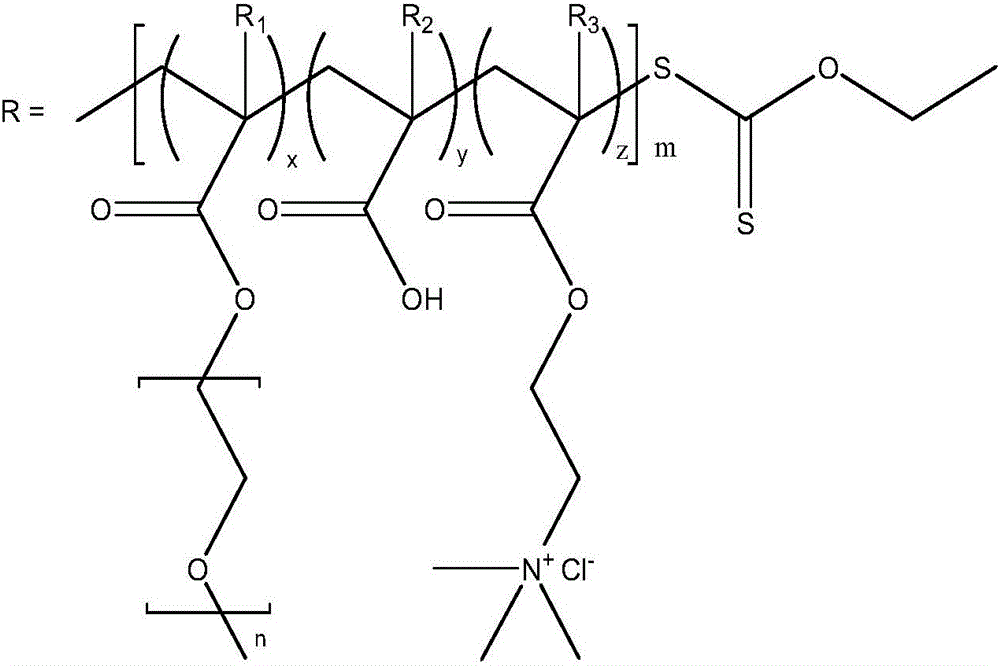

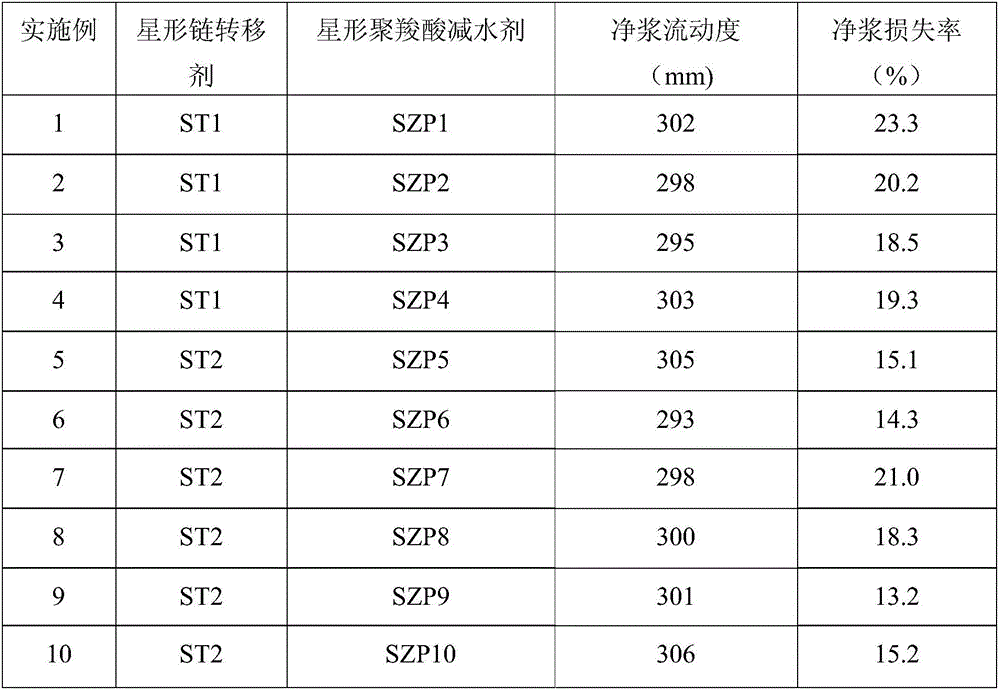

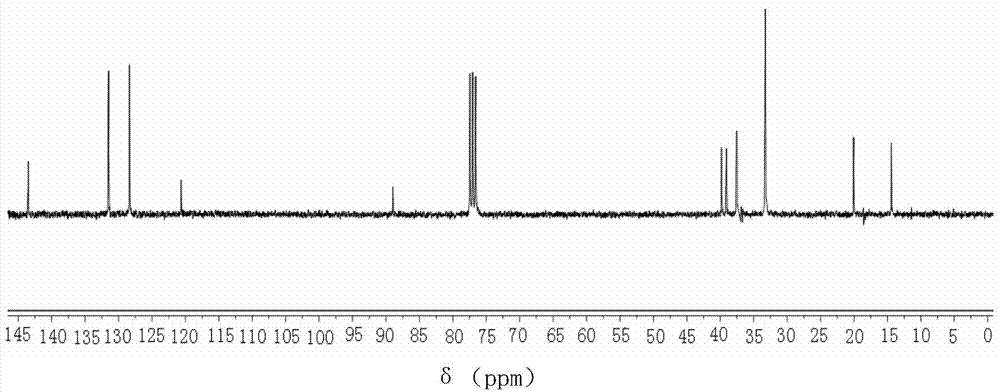

Star-like amphoteric polycarboxylate superplasticizer with efficient anti-mudding function and preparation method thereof

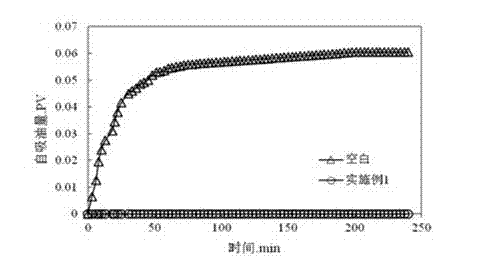

The invention discloses a star-like amphoteric polycarboxylate superplasticizer with efficient anti-mudding function and a preparation method thereof; the preparation method comprises: esterifying Beta-cyclodextrin and a dithioester compound with acyl halide groups to obtain star-structure reversible addition-fragmentation chain transfer agent (RAFT agent), initiating RAFT polymerization of (methyl)polyethylene glycol diacrylate, (methyl)acrylic acid and (methyl)acryloyloxyethyl trimethyl ammonium chloride under the action of the chain transfer agent and an initiator to obtain star-like amphoteric copolymer, and carrying out further processing to obtain the star-like amphoteric polycarboxylate superplasticizer having a solid content of 20% and efficient anti-mudding function. The polycarboxylate superplasticizer prepared herein has high water-reducing rate and efficient ant-mudding function and may meet high construction requirements.

Owner:SHANDONG JIAOTONG UNIV

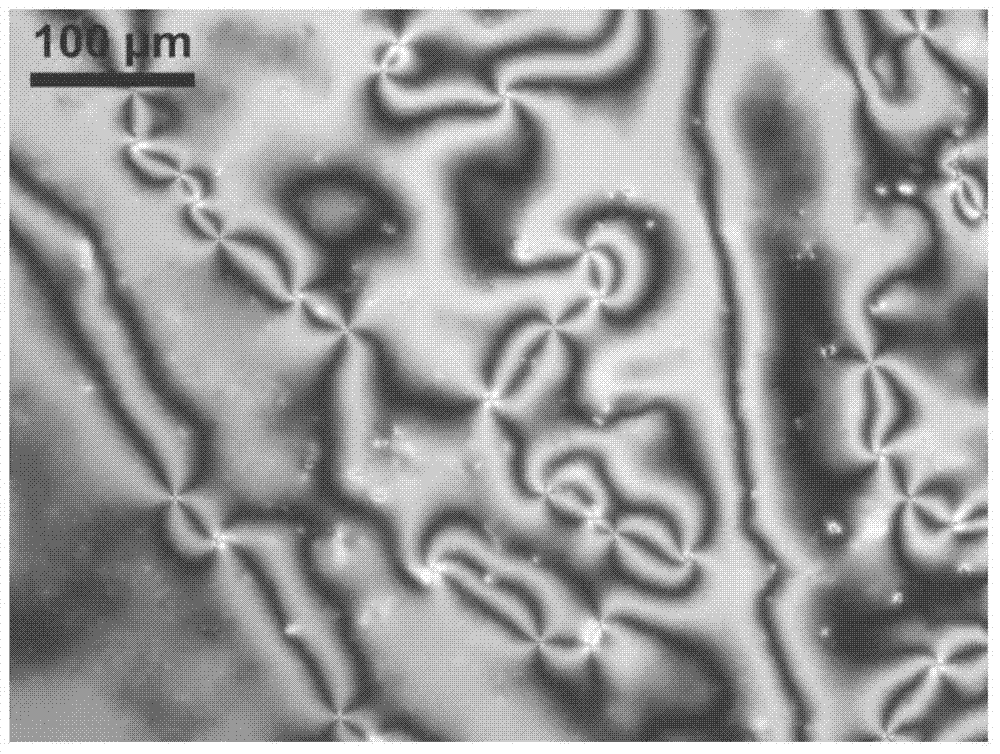

Dicyclohexyl ethylene group substituted diphenylacetylene liquid crystal compound and preparation method thereof

ActiveCN103805208ALow melting pointLow viscosityLiquid crystal compositionsHydrocarbonsCrystallographyLiquid-crystal display

The invention discloses a dicyclohexyl ethylene group substituted diphenylacetylene liquid crystal compound and a preparation method thereof. The structural general formula of the dicyclohexyl ethylene group substituted diphenylacetylene liquid crystal compound is shown in the specification, wherein (F)m, (F)n and (F)x respectively represent fluorine atom substitution, m, n and x represent substitution number of the fluorine atoms and the value of m, n and x is 0 or 1, and the cyclohexyl is trans-cyclohexyl; both R and R' represent C1-C15 alkyl, C1-C15 alkenyl, C1-C15 alkoxy, C1-C15 alkenyloxy, fluoro-substituted C1-C15 alkyl or fluoro-substituted C1-C15 alkenyl. The dicyclohexyl ethylene group substituted diphenylacetylene liquid crystal compound not only has high clearing point, wide nematic phase section, large birefringence, and low optical absorption coefficient, but also has low melting point, low viscosity and good intermiscibility, and can be used in liquid crystal optical elements; the dicyclohexyl ethylene group substituted diphenylacetylene liquid crystal compound with side fluorine can also be used in a double frequency liquid crystal display mode.

Owner:XIAN CAIJING OPTO ELECTRICAL SCI & TECH

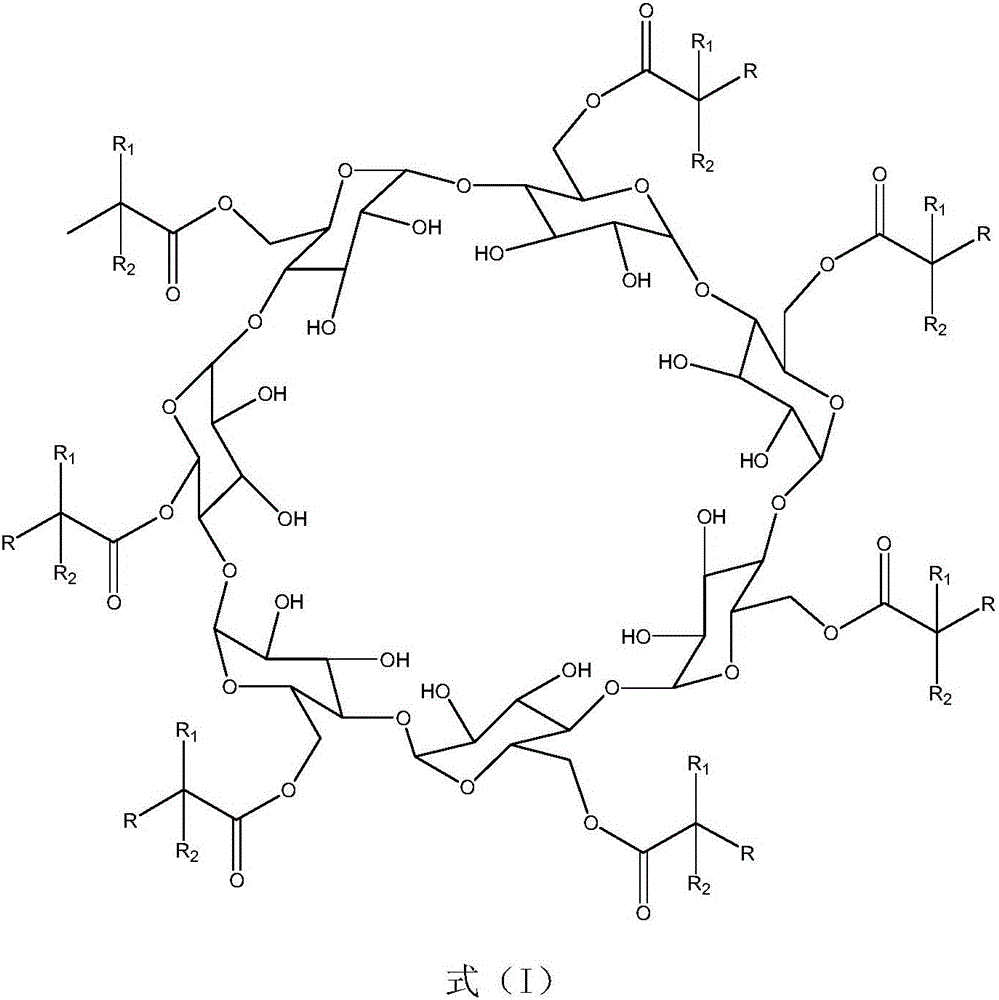

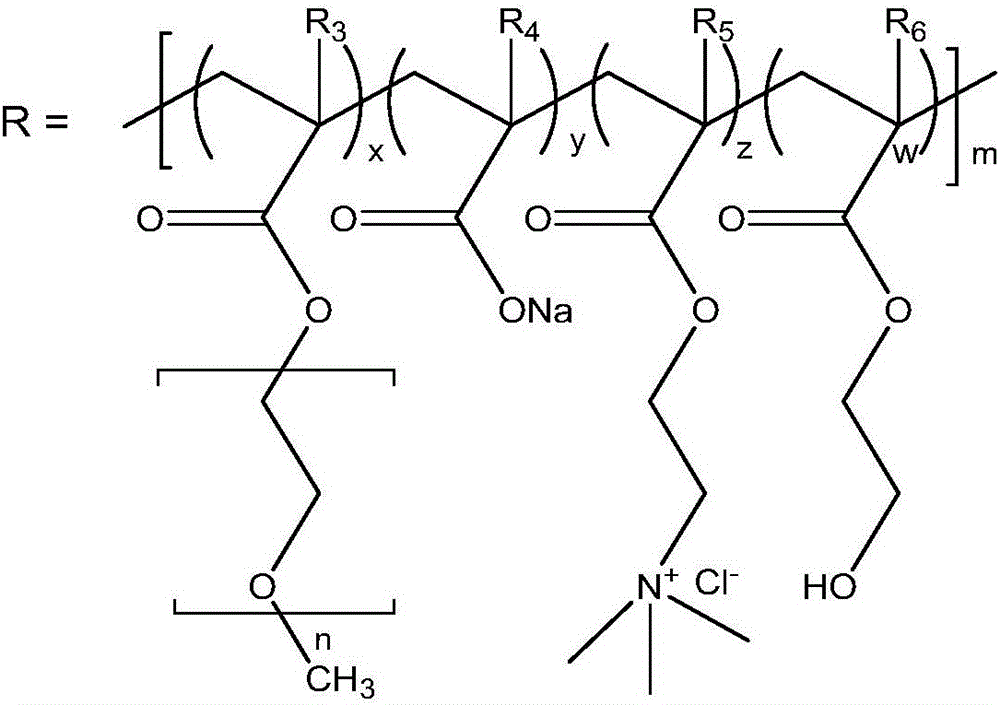

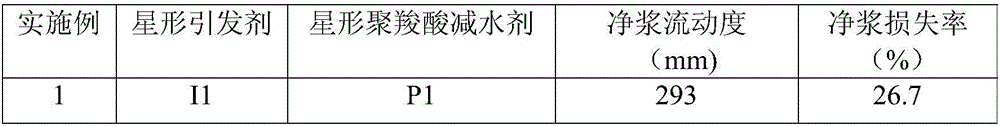

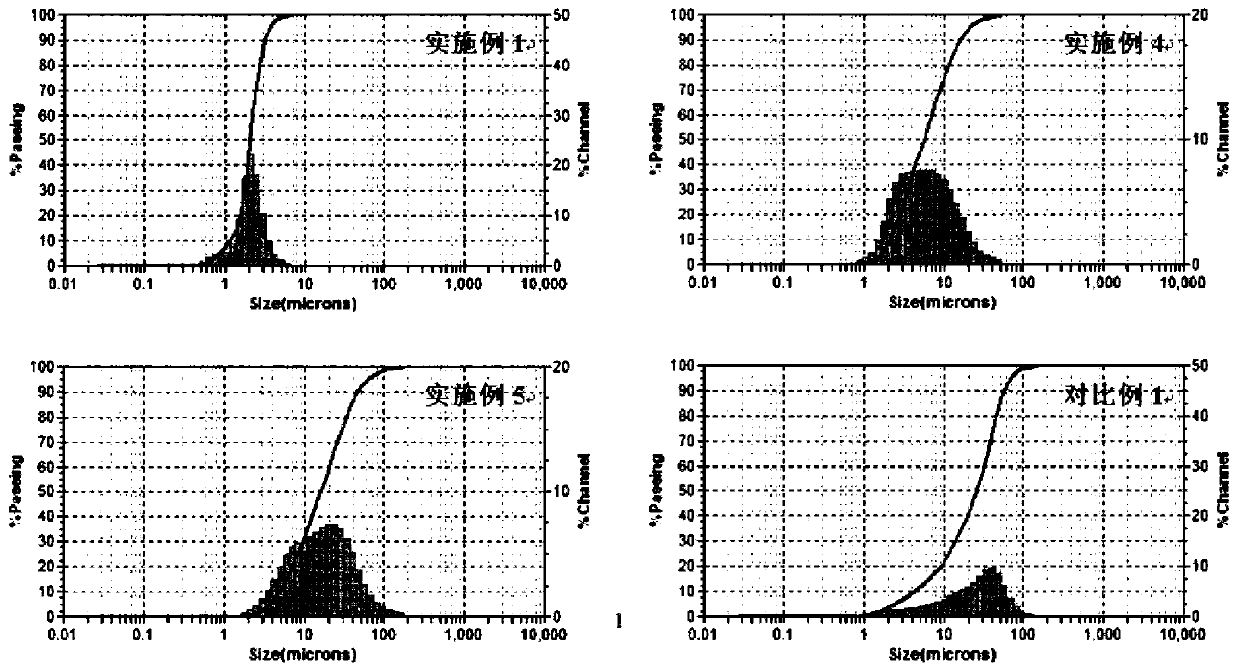

Star-shaped amphoteric polycarboxylate superplasticizer and preparation method thereof

The invention discloses a star-shaped amphoteric polycarboxylate superplasticizer and a preparation method thereof. The method includes: esterfying cyclodextrin to obtain a star-shaped initiator, initiating atom transfer radical polymerization of (methyl) polyethylene glycol acrylate, (methyl) sodium acrylate, (methyl) acryloyloxyethyl trimethyl ammonium chloride and (methyl) hydroxylethyl acrylate to obtain a star-shaped copolymer of the four monomers, and conducting further treatment to obtain a star-shaped amphoteric polycarboxylate superplasticizer with a solid content of 20%. The polycarboxylate superplasticizer prepared by the method provided by the invention has high water reducing rate and good mud resistance, meets high construction requirements, and has good application prospect.

Owner:SHANDONG JIAOTONG UNIV

Battery anode slurry, anode using same and battery manufacture method

ActiveCN101312243AImprove high temperature storage performanceGood conditionElectrode manufacturing processesSecondary cellsHigh temperature storagePhysical chemistry

Disclosed is positive slurry of lithium ion batteries, the positive slurry comprises positive materials and solvent, the positive materials comprise positive active substances, binder and a conductive agent, the solvent comprises polar solvent and non-polar solvent, wherein based on the gross weight of the positive materials, the content of the non-polar solvent is 20-80% by weight percentage, and the weight ratio of the polar solvent and the non-polar solvent is 1:1-10. The lithium ion batteries prepared by the positive slurry has fine high-temperature storage performance and high-temperature circulation performance.

Owner:SHANGHAI BYD

Production method of carboxymethyl cellulose acetate butyrate

ActiveCN105418770AImprove the uniformity of the reactionThorough responseCoatingsChemistryN-Butyrate

The invention discloses a production method of carboxymethyl cellulose acetate butyrate and aims to provide a continuous production process of carboxymethyl cellulose acetate butyrate that overcomes the existing difficulty that carboxymethyl cellulose acetate prepared by a traditional kneader method is inapplicable to the preparation of carboxymethyl cellulose acetate butyrate. The production method includes sodium carboxymethyl cellulose preparation, acidification, activation, esterification and purification. The production method has a short production period, the temperature is low, unit energy consumption is low, loss of raw materials is low, an operating process is simple, and manufacturing cost is greatly reduced; waterborne overlay coatings prepared based on the carboxymethyl cellulose acetate butyrate meet the requirement on environmental protection, are less harmful to the environment and human body and have excellent performance, and in the face of the requirement of automobile and aviation industries expanding day by day on waterborne overlay coatings, the carboxymethyl cellulose acetate butyrate has a promising application prospect and can also be made into different types of products according to different requirements, meeting requirements of a wider range.

Owner:CHONGQING LIHONG FINE CHEM +1

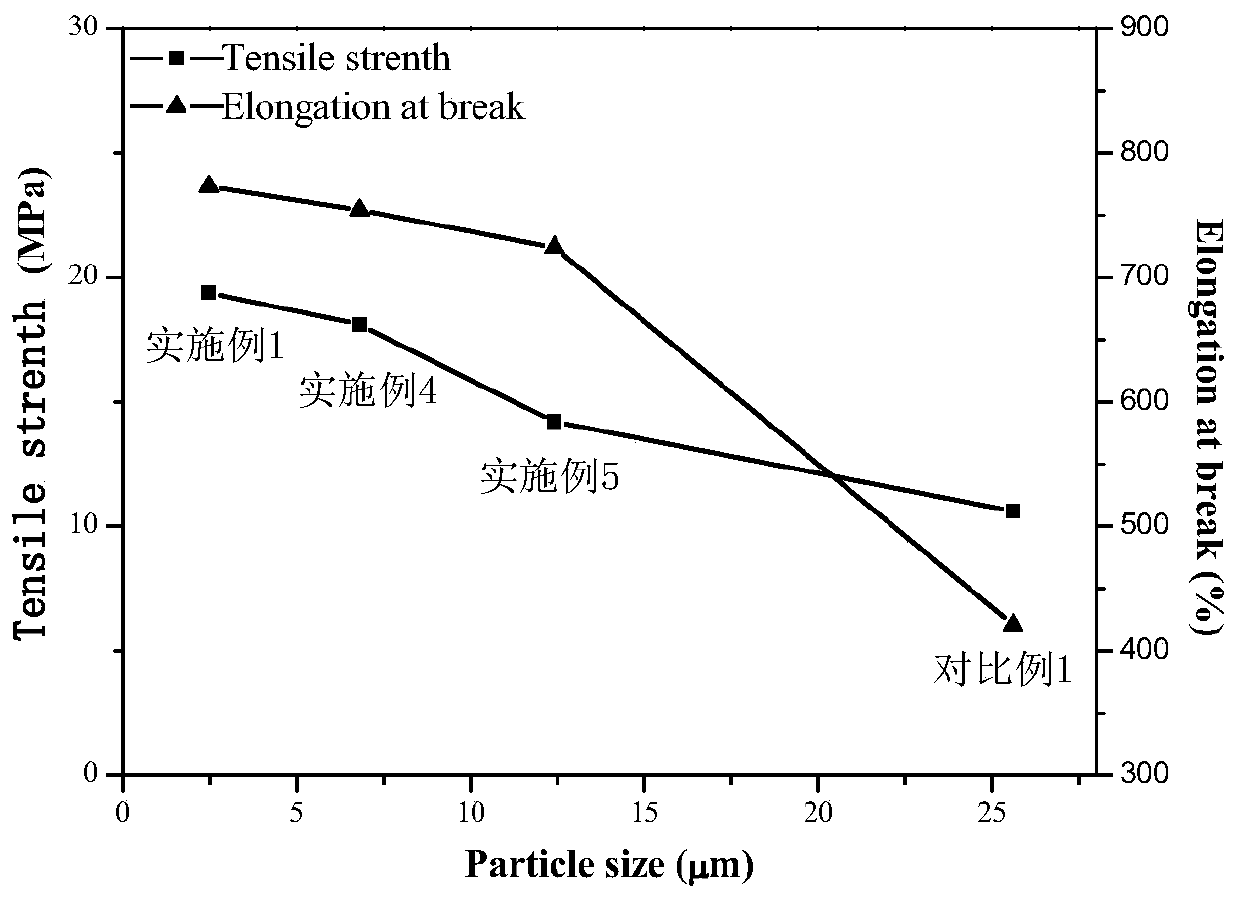

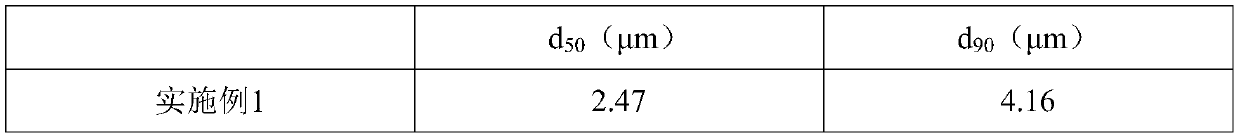

Lignin-unsaturated carboxylate composite reinforcing agent and application thereof in rubber

The invention discloses a lignin-unsaturated carboxylate composite reinforcing agent and application thereof in rubber. The lignin-unsaturated carboxylate composite reinforcing agent is obtained by adding lignin and unsaturated carboxylate into grinding equipment and adjusting the process until materials meet the required particle size. Compared with the prior art, according to the invention, thehigh-performance rubber reinforcing agent is prepared by adopting a reactive grinding mode of lignin and unsaturated carboxylate; metal ions in the unsaturated carboxylate and polar functional groupsin a lignin structure are used for generating a chelating effect, thereby facilitating dispersion of the lignin; meanwhile, the unsaturated carboxylate can be subjected to self-polymerization and grafting reaction with a rubber matrix in the vulcanization process to form ionic crosslinking chemical bonds, so that various mechanical properties of the vulcanized rubber are remarkably improved, and the reinforcing agent has a wide market application prospect.

Owner:NANJING UNIV OF TECH

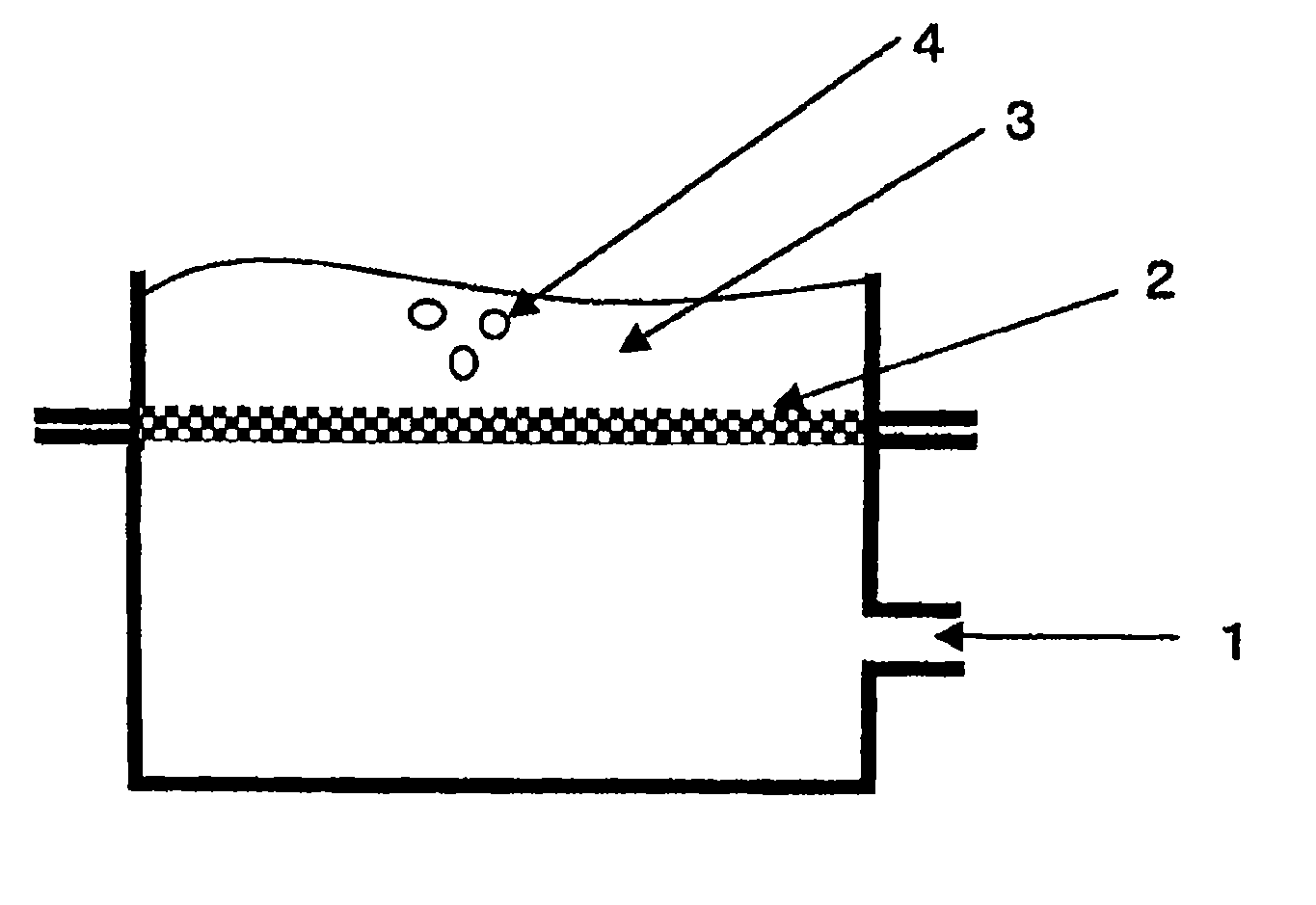

Process for producing microfiber assembly

InactiveUS20100001438A1Easy maintenanceReduce intermolecular forcesElectric discharge heatingNon-woven fabricsMetallic materialsEngineering

A process for producing a fiber assembly or agglomerate requiring micropores, such as for a battery separator or any of various filters, which is performed by electrostatic spinning and provides high productivity and ease of maintenance, is provided. The process for producing a microfiber assembly or agglomerate by electrostatic spinning includes continuously forming bubbles on a polymer solution or a polymer melt and applying high voltage to the formed bubbles. The bubbles can be formed by passing compressed air through porous material of one or a combination of two or more of plastic, ceramic and metal materials, or capillaries.

Owner:KANKYOKIKI CORP

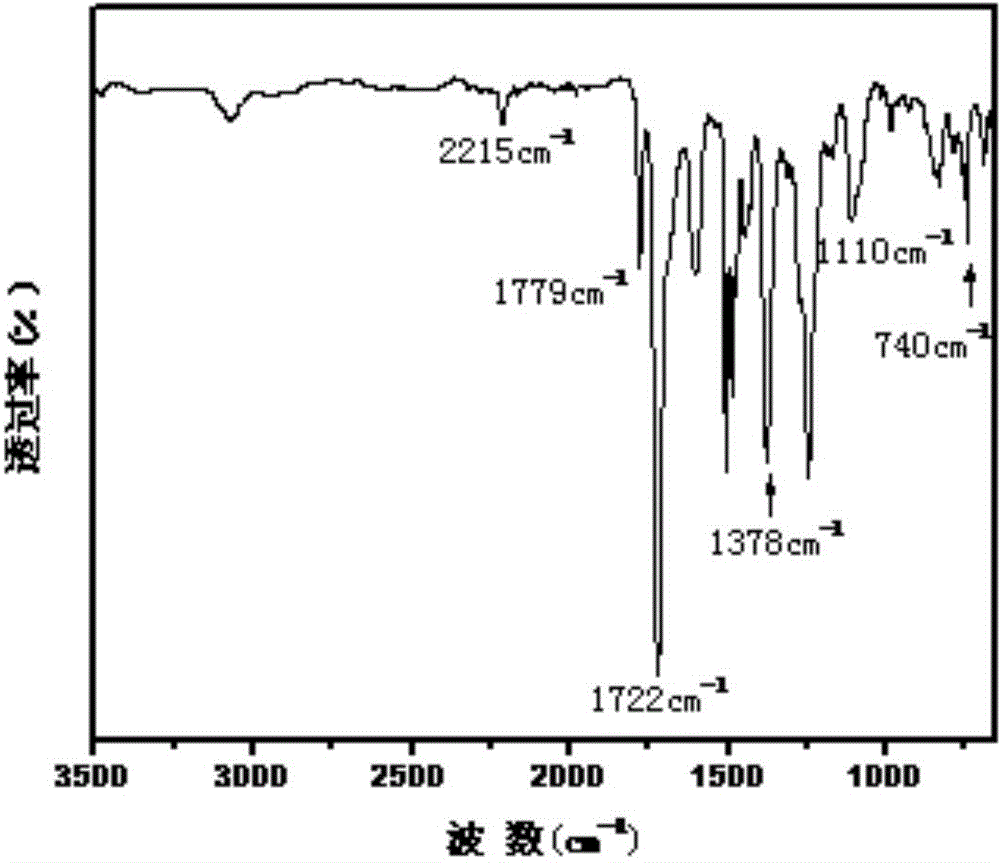

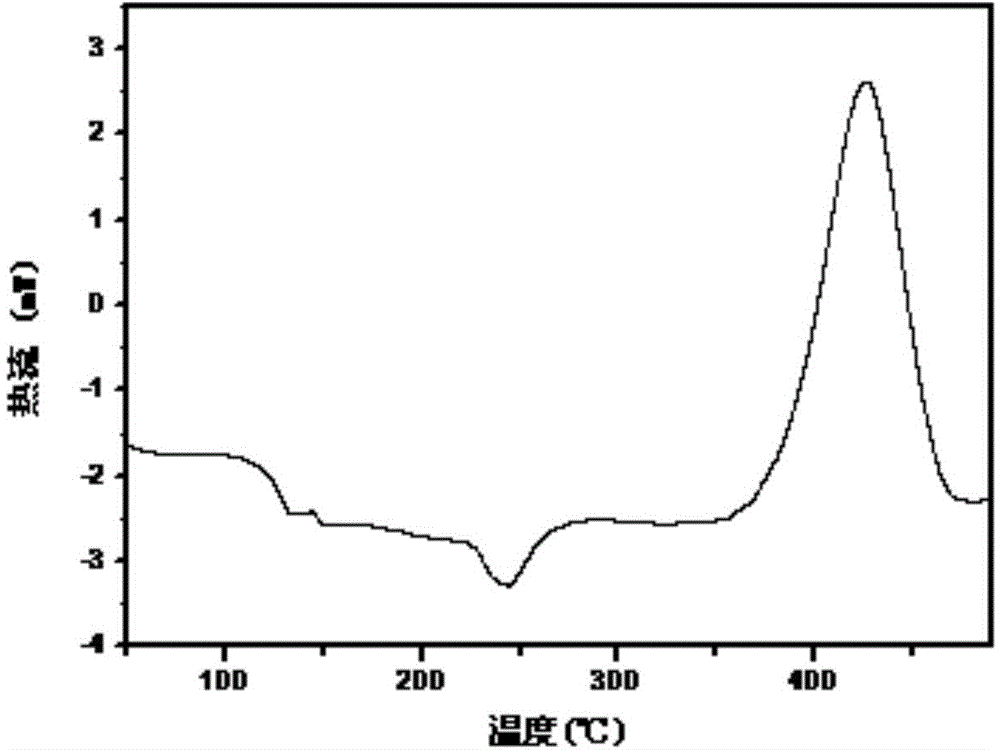

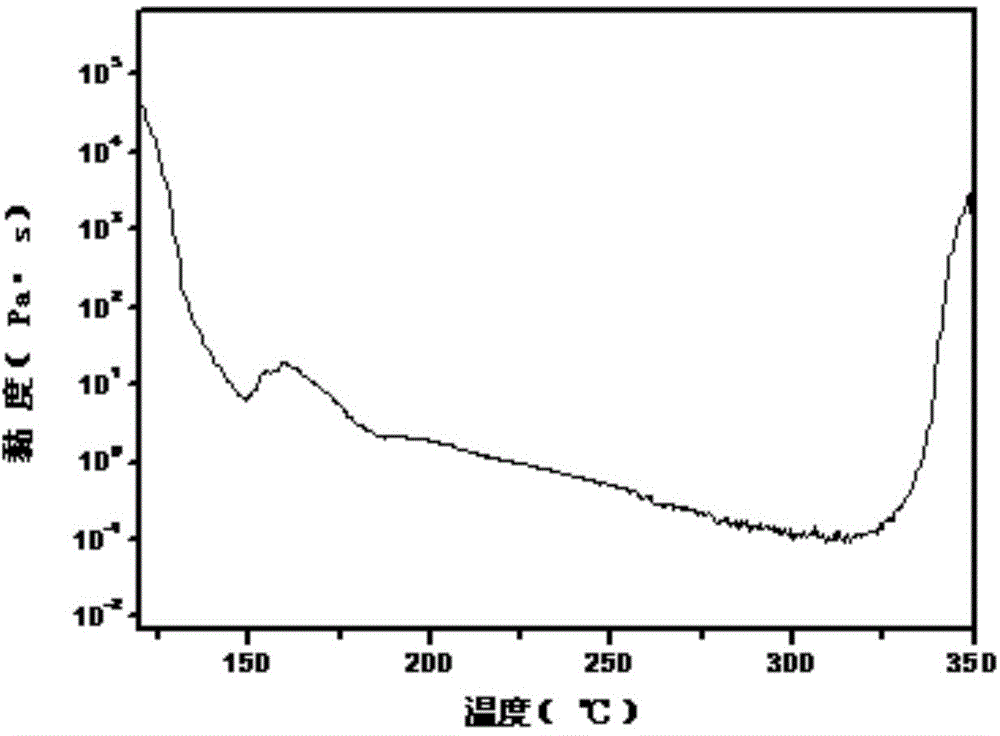

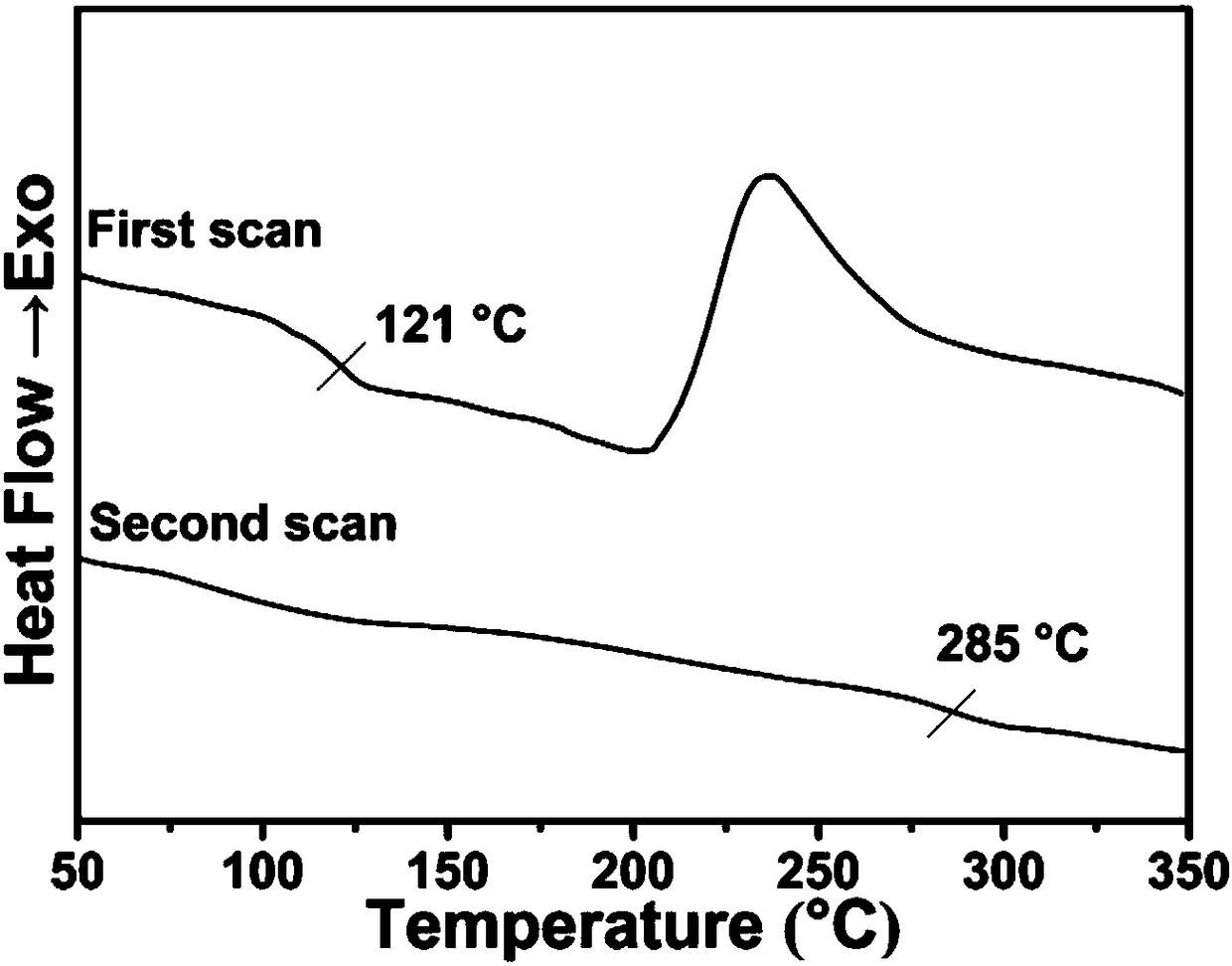

High-fluidity wide-processing-widow polyimide pre-polymer and preparation method thereof

ActiveCN104530429ALower glass transition temperatureProcessing window widthOrganic chemistryDiaminodiphenyl etherAdhesive

The invention relates to a high-fluidity wide-processing-widow polyimide pre-polymer and a preparation method thereof. A structural formula is shown in the description, wherein n is 1-20 and is an integer. The preparation method comprises the steps of dissolving 3,4'-diaminodiphenyl ether 3,4'-ODA in an organic solvent under the nitrogen protection condition, adding 2,3,3',4'-tetracarboxydiphthalic ether dianhydride a-ODPA after complete dissolution, meanwhile adding the organic solvent to enable the solid content of a solution to be 10%-40%, adding an end-capping reagent during reaction at the room temperature to continue to perform reaction, dropwise adding a dehydrating agent to perform reaction, washing, drying and smashing. The pre-polymer can be formed through compression molding, is well applicable to a resin transfer forming process and has potential application value on the aspect of preparation of high-performance composite materials, high-temperature-resisting adhesives and the like.

Owner:DONGHUA UNIV

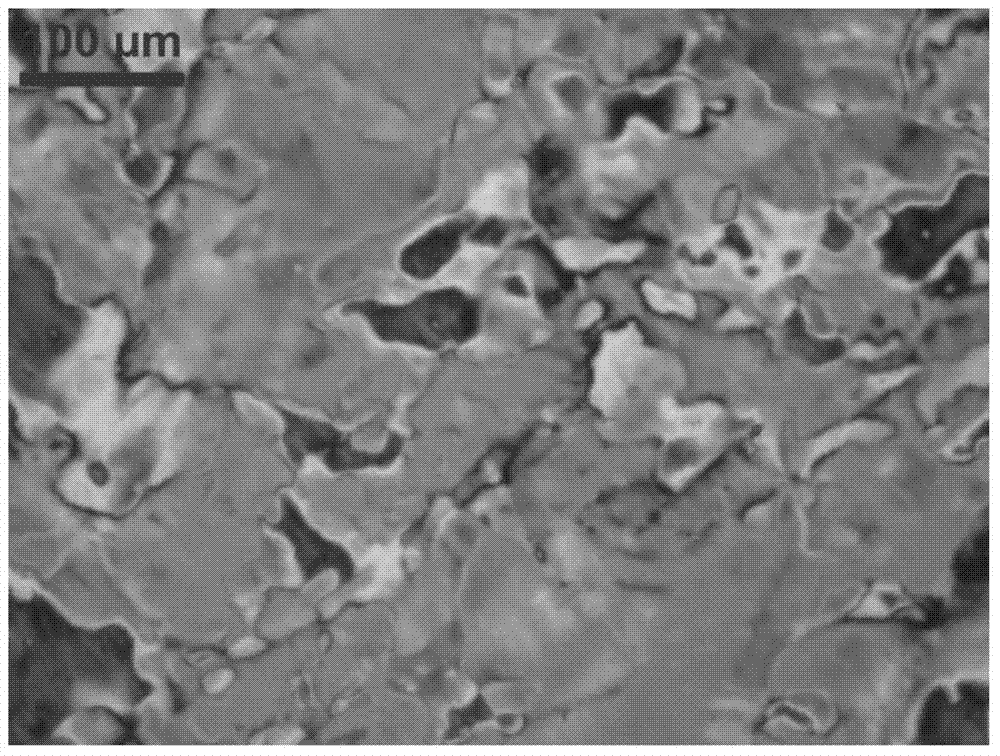

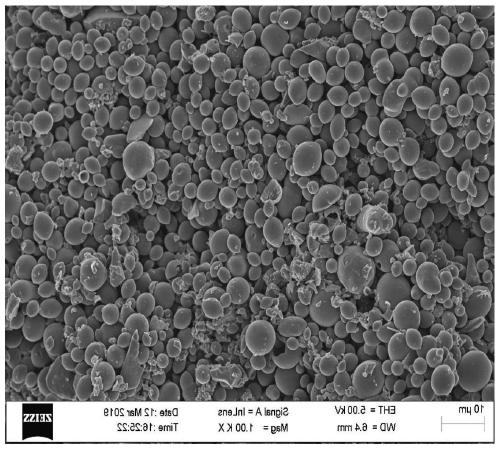

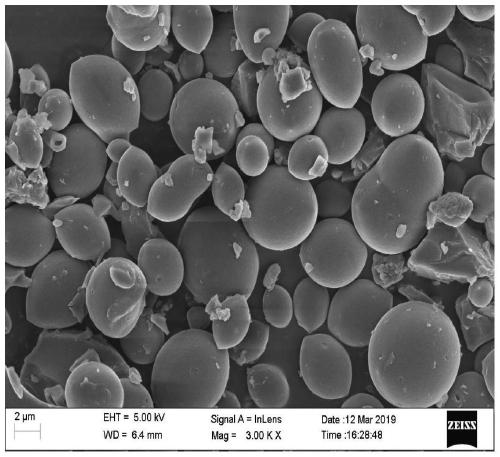

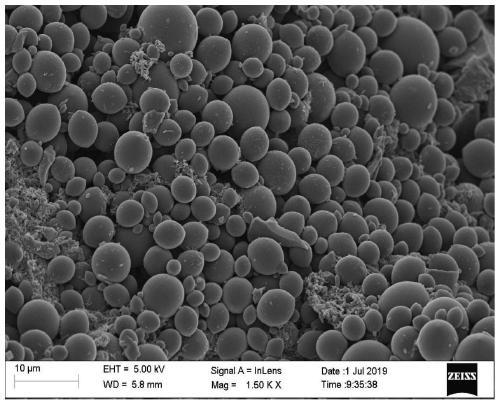

Method for preparing mesophase carbon microspheres with emulsification-hydrogenation-thermal polymerization ternary coupled system

ActiveCN110357069AEasy to shapeFlat surfaceCarbon preparation/purificationOrganic solventMicrosphere

The invention provides a method for preparing mesophase carbon microspheres with an emulsification-hydrogenation-thermal polymerization ternary coupled system and belongs to the technical field of preparation of mesophase carbon microspheres. The method comprises steps as follows: 1) an emulsification-hydrogenation-thermal polymerization ternary coupled solvent system is prepared from a hydrogen supply solvent, a modification catalyst and an emulsification solvent; 2) medium and low temperature coal tar asphalt with the fraction larger than 300 DEG C is added to the emulsification-hydrogenation-thermal polymerization ternary coupled solvent system, and mesophase asphalt is prepared; 3) the mesophase asphalt is subjected to extraction with an organic solvent, dried, pre-oxidized in the airatmosphere, carbonized in an N2 atmosphere and graphitized, and mesophase carbon microspheres are obtained. The preparation method of the mesophase carbon microspheres is a brand-new one-pot emulsification system, a good production environment is provided for growth of the mesophase carbon microspheres, and good sphericity degree, smooth surfaces, uniform size distribution and high graphitizationdegree of the prepared mesophase carbon microspheres are guaranteed.

Owner:NORTHWEST UNIV(CN)

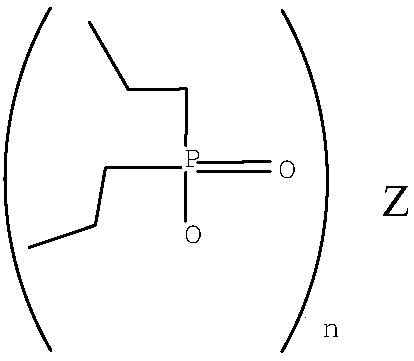

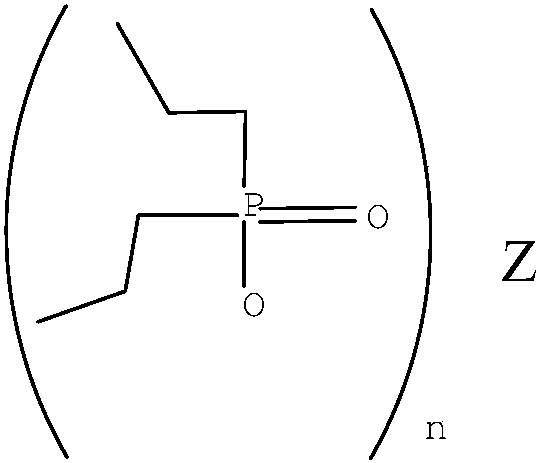

Flame-retardant superfine polyester and nylon island fiber and manufacturing method thereof

ActiveCN109355733AGood for alkali dissolutionInhibition of hydrogen bondingFlame-proof filament manufactureConjugated synthetic polymer artificial filamentsPolyesterFire retardant

The invention relates to the field of spinning, and discloses a flame-retardant superfine polyester and nylon island fiber and a manufacturing method thereof. The island component of the island fiberis PA6, and the sea component is PET, wherein the island component contains metal salt phosphorus flame retardant. The manufacturing method includes manufacturing flame-retardant PA6 chips by blendingthe flame retardant and the PA6 through double thread rods; melting flame retardant PA6 and the PET by threaded rods respectively; merging the melted flame retardant PA6 and the PET in a spinning boxby a metering pump; extruding the flame retardant PA6 and the PET into bundles by spinnerets; cooling; oiling; drafting and shaping; and finally winding the bundles into silk cakes. The metal elements contained in the modified flame retardant can increase the incompatibility between polyester and nylon components, so that the fiber is conductive to performing alkali deweighting treatment to obtain the superfine flame retardant polyester and nylon fiber.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

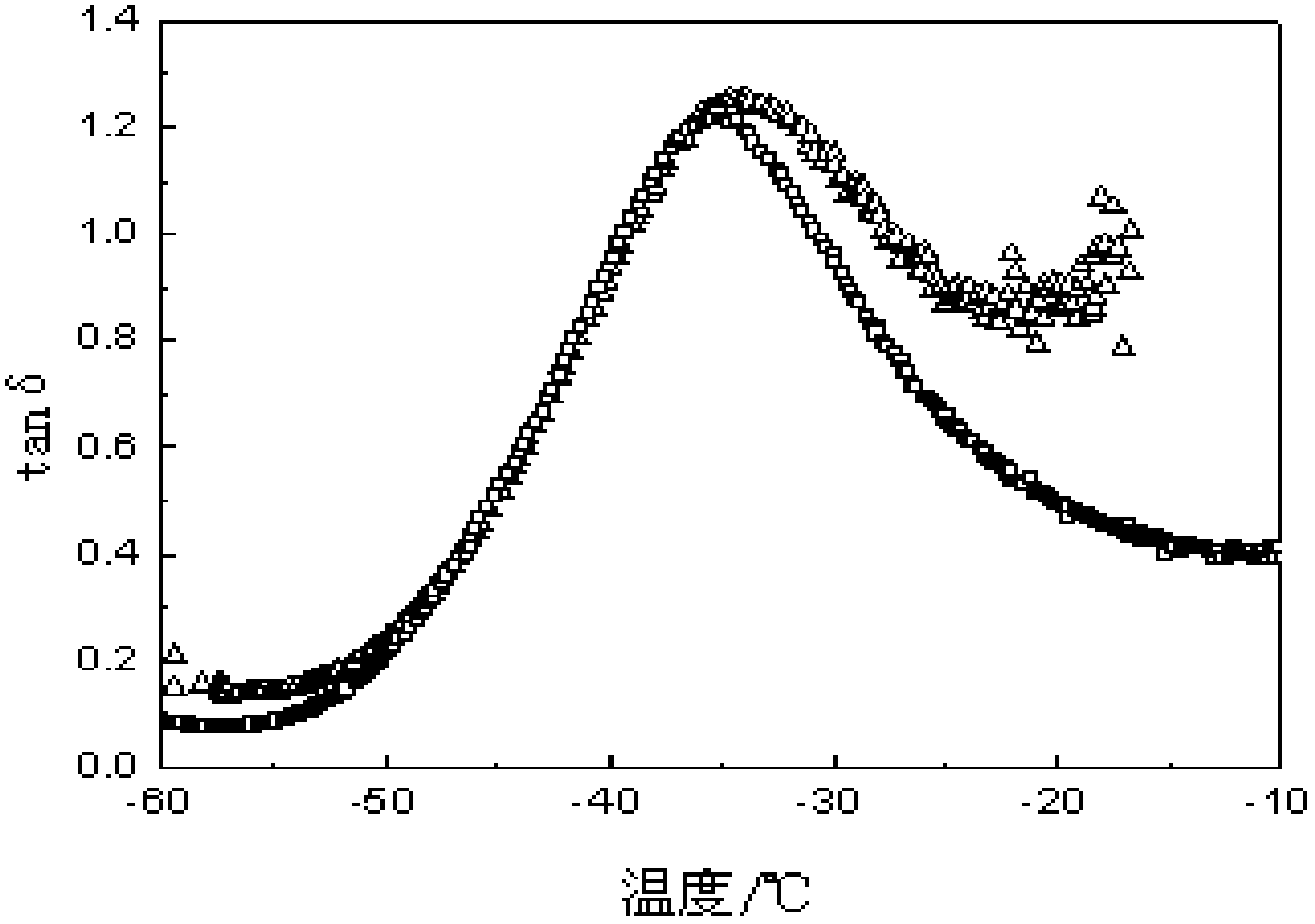

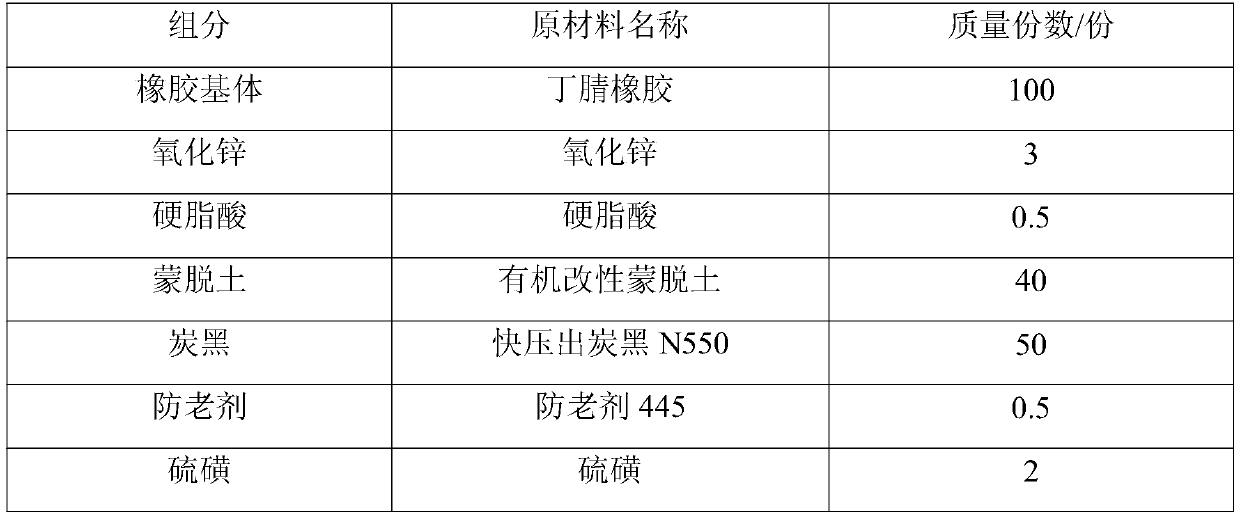

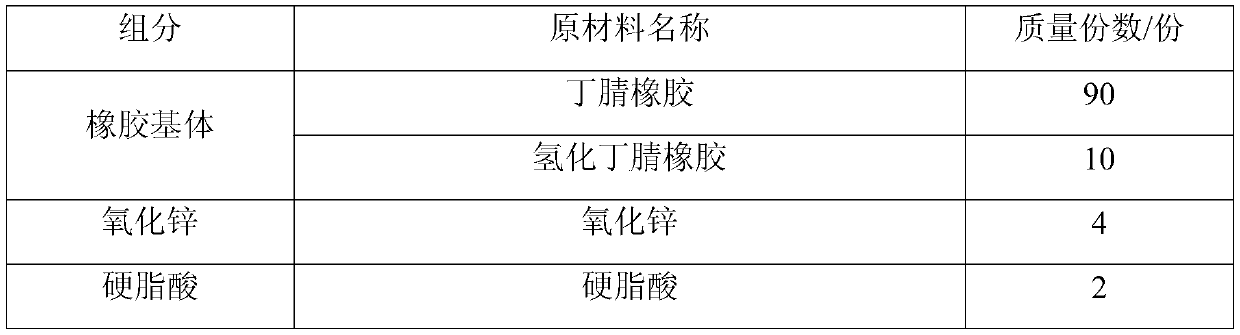

Low-temperature-resistant salt-spray-resistant rubber sealing material and preparation method thereof

InactiveCN111004420AExtended service lifePrevents and slows the oxidation processVulcanizationPlasticizer

The invention discloses a low-temperature-resistant salt-spray-resistant rubber sealing material and a preparation method thereof. The invention belongs to the technical field of rubber sealing materials. The sealing material comprises the following components in parts by mass: 100 parts of a rubber matrix, 3-5 parts of zinc oxide, 0.5-3 parts of stearic acid, 10-40 parts of montmorillonite, 5-50parts of carbon black, 0.5-3 parts of an anti-aging agent, 5-20 parts of a plasticizer, 1.5-3 parts of an accelerant, and 0-10 parts of a vulcanizing agent and an auxiliary of the vulcanizing agent. The raw materials are subjected to an open mill plastication process, an internal mixer mixing process, an open mill mixing process and a vulcanization process to prepare the rubber sealing material, and the rubber sealing material has low-temperature resistance and salt spray resistance and can meet the requirements of deck mechanical sealing and low-temperature pipeline system oil-resistant sealing on polar ships.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

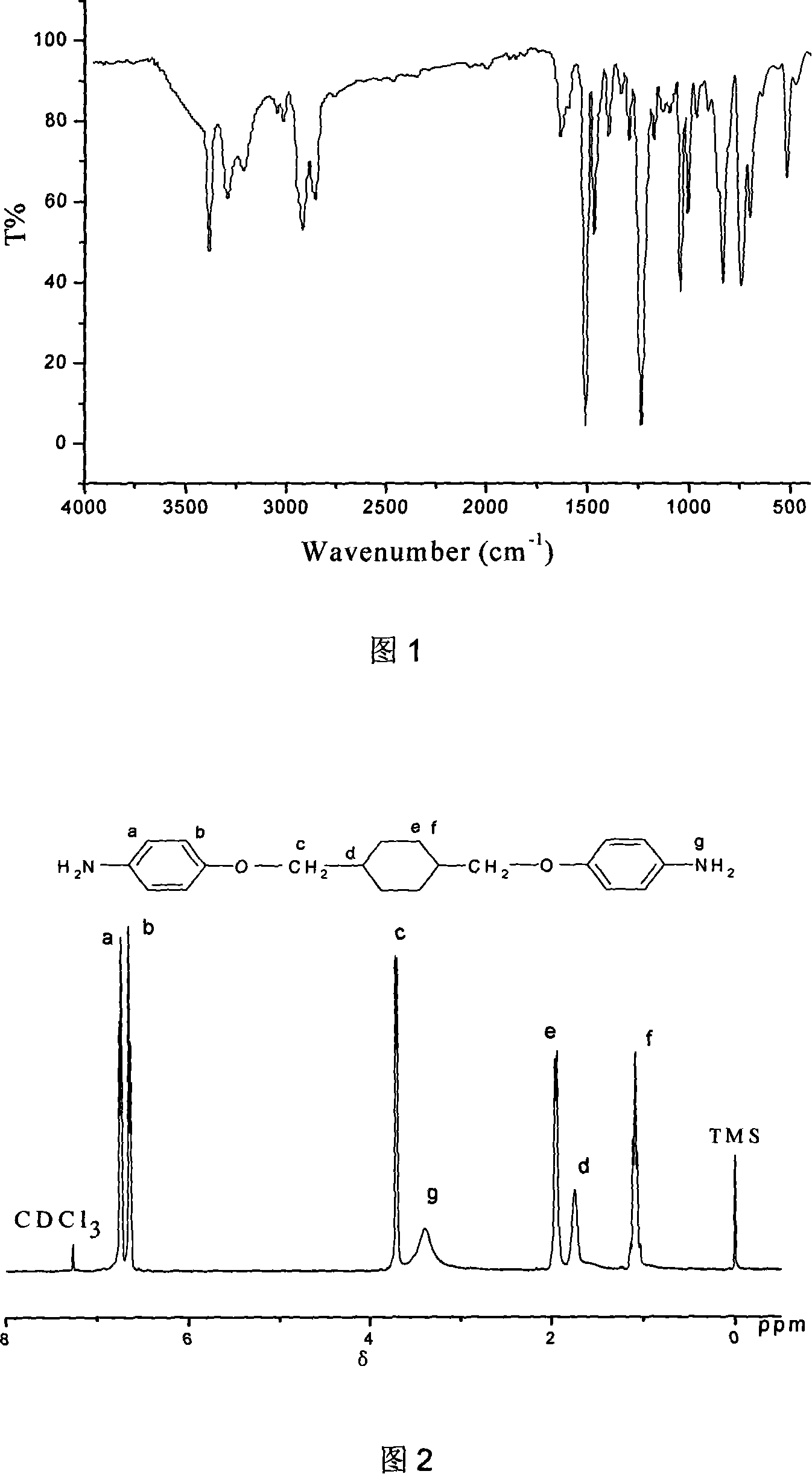

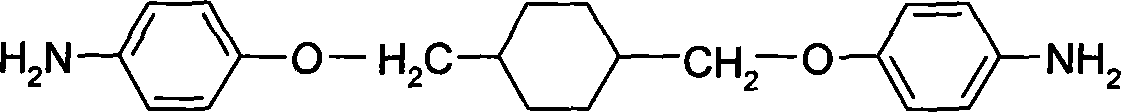

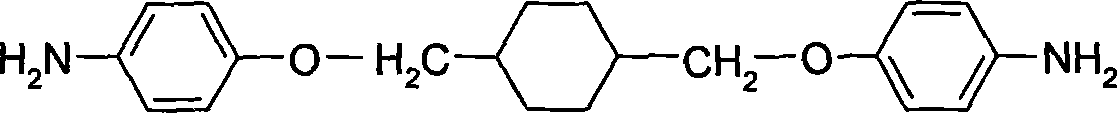

1,4-bis(4-amino-benzene oxymethylene) cyclohexyl and preparation and application thereof

InactiveCN101081819AReduce light lossHigh transparencyOrganic compound preparationAmino-hyroxy compound preparationChemical structureNitrobenzene

The present invention relates to 1, 4-bis(4-aminophenoxylmethylene)cyclohexane, which is white or light red crystal and has smelting point of 150-152 deg.c and chemical structure as shown. Its preparation process includes the reaction of 1, 4-cyclohexane dimethanol and p-halo nitrobenzene to obtain 1, 4-bis(4-nitrophenoxylmethylene)cyclohexane, and the further reaction with active carbon, ferric trichloride hexahydrate, anhydrous alcohol and hydrazine hydrate to obtain 1, 4-bis(4-aminophenoxylmethylene)cyclohexane. The compound 1, 4-bis(4-aminophenoxylmethylene)cyclohexane may be polymerized to form polyimide material with alicyclic ring structure, and the polyimide material may find its wide application in liquid crystal display, optical fiber communication and other hi-tech fields.

Owner:DONGHUA UNIV

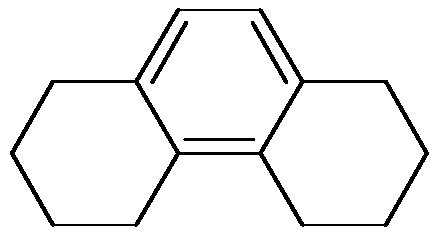

Preparation method of spinnable mesophase pitch

ActiveCN110776943AAvoid Ash ProblemsImprove adaptabilityWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansFiltrationHydrogen supply

A preparation method of spinnable mesophase pitch comprises the following steps: crushing high-softening-point petroleum pitch, carrying out hot extraction, and performing filtration to obtain purified petroleum pitch; mixing the purified petroleum pitch with octahydrophenanthrene or a hydrogen supply reagent containing octahydrophenanthrene, and carrying out a thermal polycondensation reaction; and reducing the pressure after the thermal polycondensation reaction is finished, and performing purging at 370-420 DEG C while stirring to obtain the mesophase pitch. The purified high-softening-point pitch and the hydrogen supply reagent octahydrophenanthrene are directly mixed to serve as a mesophase pitch raw material for thermal polycondensation, hydrogenation treatment and polymerization reaction are integrated, the hydrogen supply reagent does not need to be removed, so the technological process is simplified; and normal-pressure purging is carried out after thermal polycondensation, sothat the phenomenon that the melting of an intermediate phase is disturbed due to too fast escape of light components, caused by adopting a vacuum treatment mode, is avoided, the softening point of the system is also prevented from being increased too fast, and the light components with activity can be continuously retained in the reaction system to participate in polycondensation, thereby the product yield is increased.

Owner:SHAANXI TIANCE NEW MATERIAL TECH

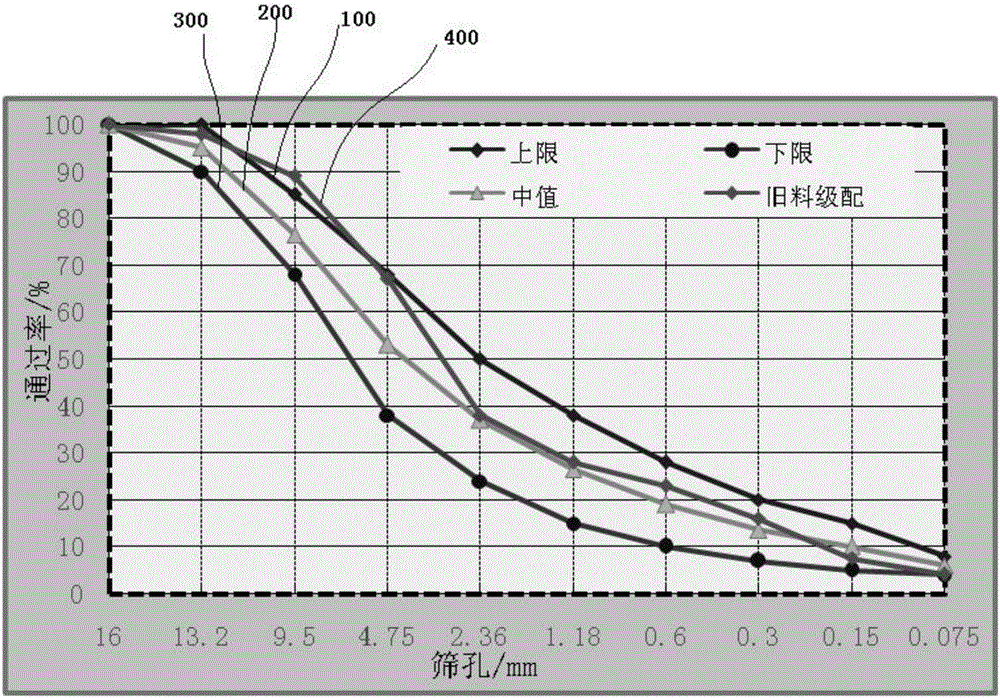

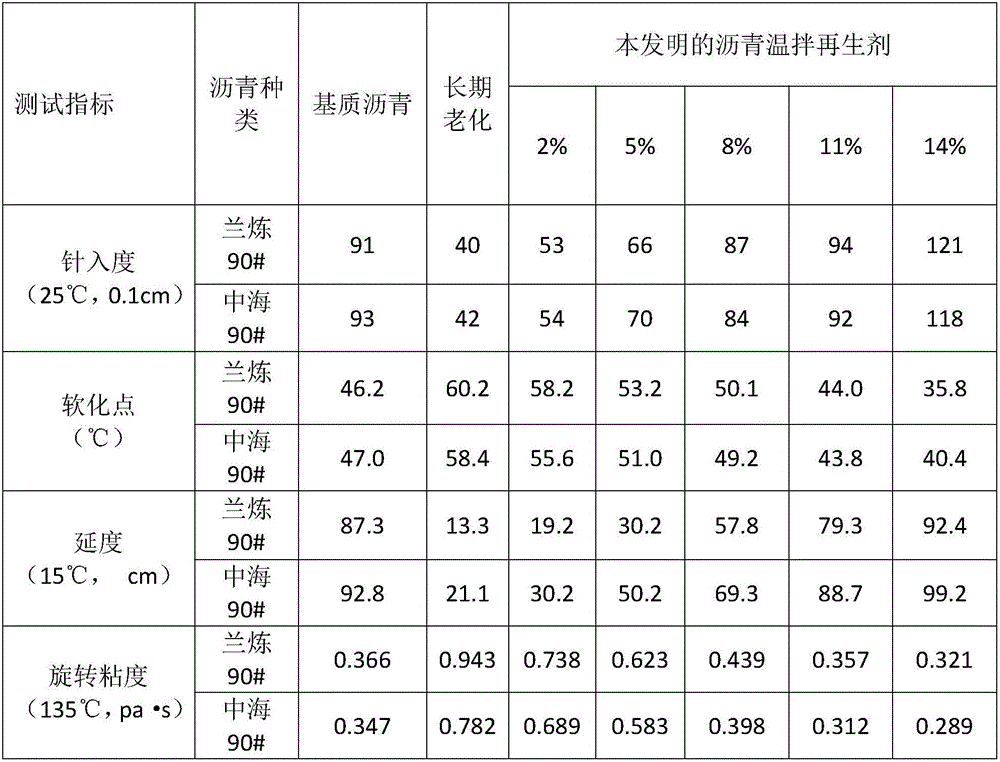

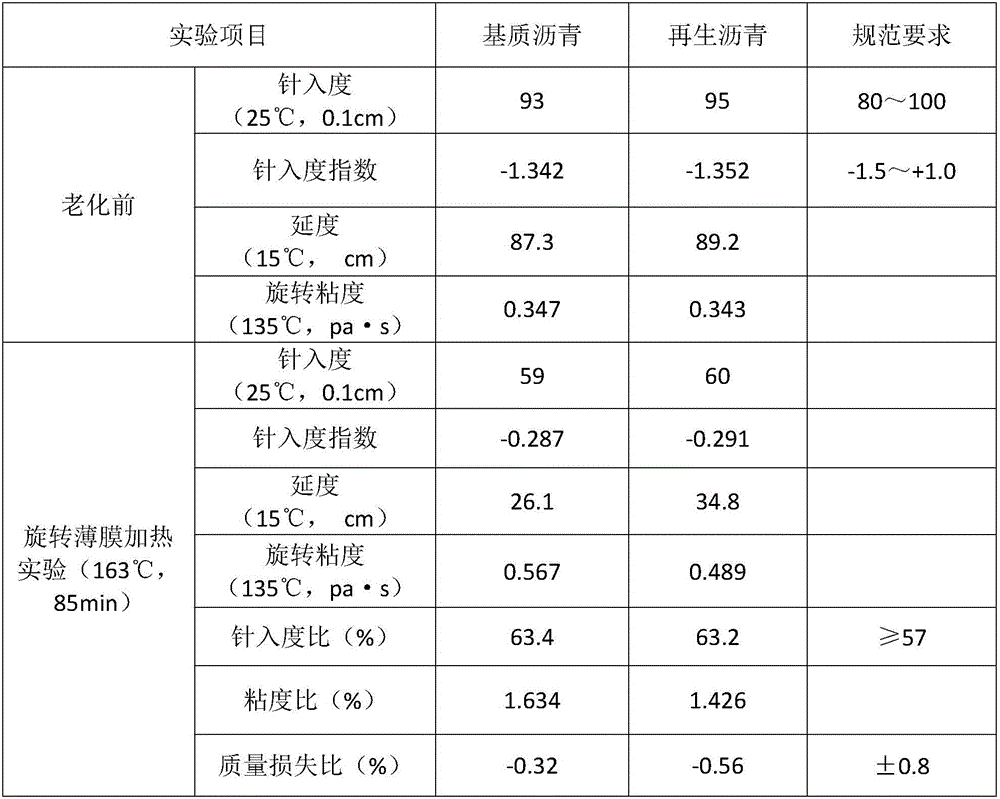

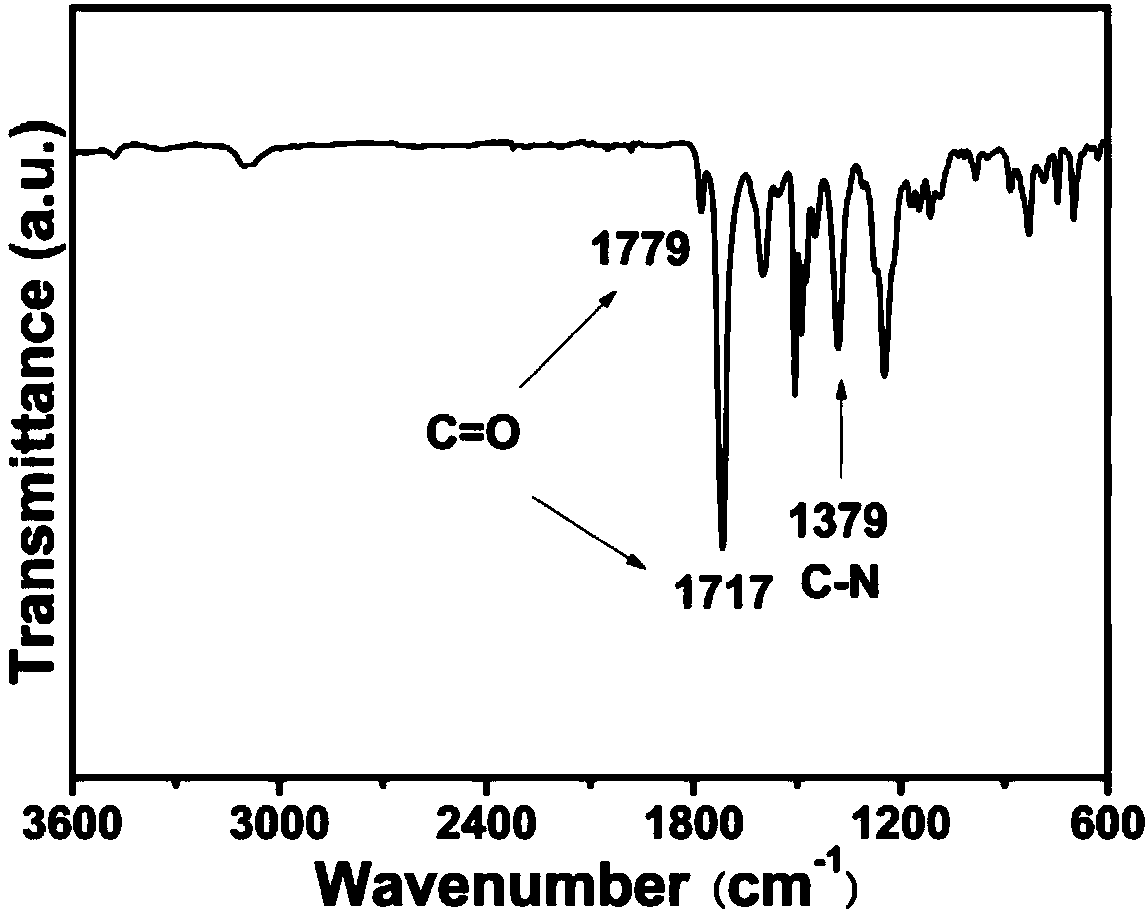

Asphalt warm-mixed modifier and preparation method thereof

InactiveCN106118078AGuaranteed regeneration effectGuaranteed regenerated miscibilityClimate change adaptationBuilding insulationsPetroleum resinLiquid state

The invention relates to an asphalt warm-mixed modifier and a preparation method of the asphalt warm-mixed modifier. The asphalt warm-mixed regenerant comprises the following raw materials in parts by weight: 10 to 20 parts of devulcanized rubber, 10 to 15 parts of ethylene bis oleamide, 50 to 70 parts of aromatic oil, 5 to 10 parts of dibutyl phthalate, 5 to 10 parts of petroleum resin, and 1 to 3 parts of performance improvements. The preparation method adopted by the invention comprises the following steps: 1) heating the aromatic oil to be 120 DEG C or above for later use; 2) heating the ethylene bis oleamide to be 120 DEG C or above in a liquid state, and putting into the aromatic oil obtained in step 1; 3) putting the dibutyl phthalate and the petroleum resin into the material obtained in the step 2 in sequence to be mixed and stirring uniformly; (4) putting the devulcanized rubber and the performance improvements in the material obtained in the step 3 in sequence, and stirring for 1 hour at the temperature of 120 DEG C to obtain the asphalt warm-mixed regenerant.

Owner:SHAANXI ZENITHS CHINA THERMAL REGENERATION ROAD MAINTENANCE CO LTD

Bismaleimide prepolymer with high solubility and good temperature resistant performance as well as preparation method and application thereof

PendingCN108395534AImprove solubilityThe regularity of the main chain is reducedAdhesivesSolubilityDiaminodiphenyl ether

The invention relates to a bismaleimide prepolymer and a preparation method. The material has the following structure formula shown in the description. The preparation method comprises the following steps of under the nitrogen gas protection, 3,4'-diaminodiphenyl ether are dissolved in an organic solvent; after complete dissolution, 2,3,3',4'-biphenyl tetracarboxylic dianhydride or 2,3,3',4'-diphenyl ether tetracarboxylic acid dianhydride are added; meanwhile, the organic solvent is added so that the solid content of the solution is 5 to 50 percent; room temperature reaction is performed; an end-capping reagent of maleic anhydride is added; reaction is continuously performed; then, dewatering agents and catalysts are added drip by drip; reaction, washing, drying and crushing are performedto obtain the bismaleimide prepolymer. The prepared bismaleimide material has good comprehensive performance; before crosslinking, the high dissolution degree, low vitrification conversion temperatureand higher temperature processing window are realized; after the heating curing, good temperature resistant performance is realized. The material can be prepared into films, high-performance resin-based composite materials and high-temperature-resistant structure bonding agents and the like, the bismaleimide prepolymer can be applied to the fields of aerospace, printed circuit boards, semiconductor encapsulation and the like.

Owner:常州杰铭新材料科技有限公司

Thermal oxidative aging resistant modified chlorinated polyethylene cable sheath material

InactiveCN104262803AImprove impact resistanceGood flexibilityInsulated cablesInsulatorsElastomerEpoxy

The invention discloses a thermal oxidative aging resistant modified chlorinated polyethylene cable sheath material prepared from the following raw materials in parts by weight: chlorinated polyethylene, nitrile butadiene rubber, thermoplastic polyamide elastomers, ethylene propylene grafted with maleic anhydride, ethylene vinyl acetate copolymer-polystyrene, organic modified montmorillonite, organic attapulgite, magnesium hydroxide, aluminum hydroxide, red phosphorus, pentaerythritol, glass beads, dicumyl peroxide, 1, 4-bis(tert-butyldioxyisopropyl)benzene, triallyl isocyanurate, triallyl cyanurate, trimethylolpropane trimethacrylate, an accelerant NA-22, sulphur, magnesium oxide, epoxy resin and a coupling agent. The thermal oxidative aging resistant modified chlorinated polyethylene cable sheath material disclosed by the invention is good in thermal oxidative aging resistance and flame retardance and long in service life.

Owner:ANHUI KAIBOER SPECIAL CABLES GRP

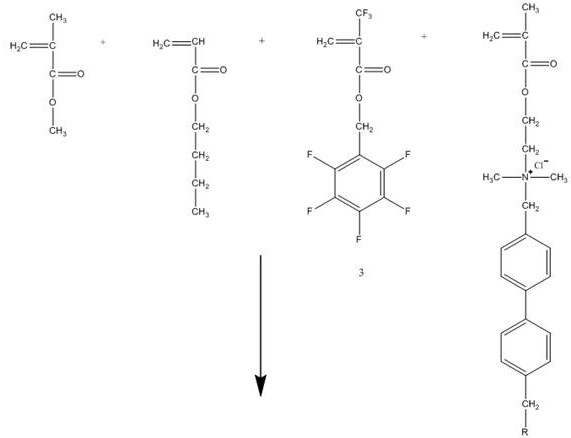

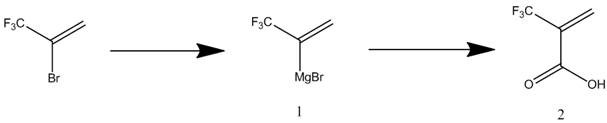

Antibacterial sanitary mobile phone film and preparation method thereof

ActiveCN113462250ANot easy to stainImprove cleanlinessAntifouling/underwater paintsFilm/foil adhesivesGlass chipMegasonic cleaning

The invention discloses an antibacterial sanitary mobile phone film and a preparation method thereof, and relates to the field of mobile phone films.The preparation method comprises the steps that an antibacterial antifouling emulsion, a curing agent, a cosolvent, deionized water, a coalescing agent, a flatting agent, a coupling agent and a defoaming agent are stirred to be uniform, then standing and filtering are conducted, and antibacterial sanitary coating is obtained; the antibacterial sanitary coating is sprayed to a rectangular glass sheet subjected to ultrasonic cleaning, an antibacterial sanitary coating is formed after drying, finally, rubberizing is carried out, packaging is carried out after inspection is qualified, and the antibacterial sanitary mobile phone film is obtained. The antibacterial and antifouling emulsion is formed by polymerization of four monomers including methyl methacrylate, butyl acrylate, an intermediate 3 and an intermediate 5, the intermediate 3 endows the antibacterial and antifouling emulsion with good stain-resistant and self-cleaning effects, a formed coating is not prone to being contaminated by stains and easy to clean, and the intermediate 5 endows the antibacterial and antifouling emulsion with good antibacterial and antiviral performance, so that the antibacterial and antifouling emulsion is good in anti-fouling and self-cleaning effects. Therefore, bacterium breeding is avoided, and the cleanliness of the mobile phone film is guaranteed.

Owner:江西昊泽光学膜科技有限公司

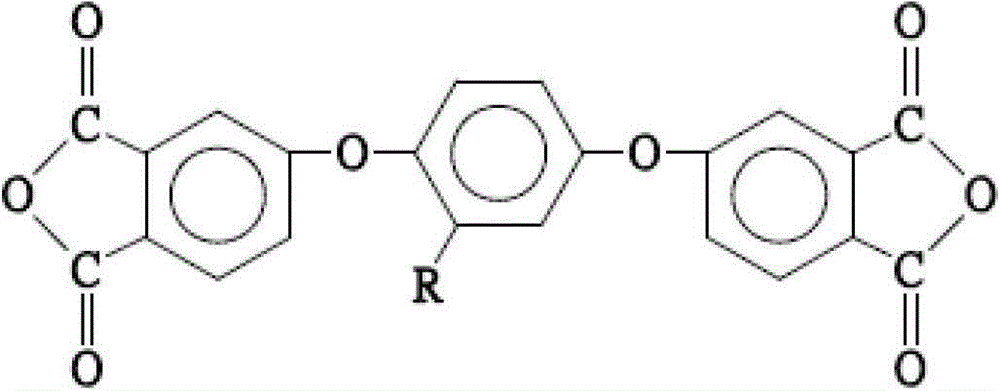

Dianhydride monomer and polyimide with side-chain radicals and preparation methods of dianhydride monomer and polyimide

The invention discloses a dianhydride monomer and polyimide with side-chain radicals and preparation methods of the dianhydride monomer and polyimide. The dianhydride monomer has the side-chain radical R, so that the structural asymmetry and arrangement irregularity of the dianhydride monomer can be improved. The dianhydride monomer has a structural formula as shown in the specification; the side-chain radical R is selected from a group consisting of the following radicals: cycloalkenes with alpha substituent of at least one tertiary carbon, cycloalkanes with a tertiary carbon, cycloalkenes with at least one tertiary carbon, benzene of alpha substituent, benzene, naphthalene of alpha substituent, naphthalene, anthracene of alpha substituent, anthracene, phenanthrene of alpha substituent, phenanthrene, aromatic hydrocarbon derivatives of alpha substituent, aromatic hydrocarbon derivatives, adamantane, adamantane of alpha substituent, cliademane and cliademane of alpha substituent.

Owner:UNIMICRON TECH CORP

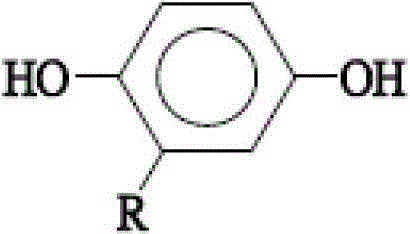

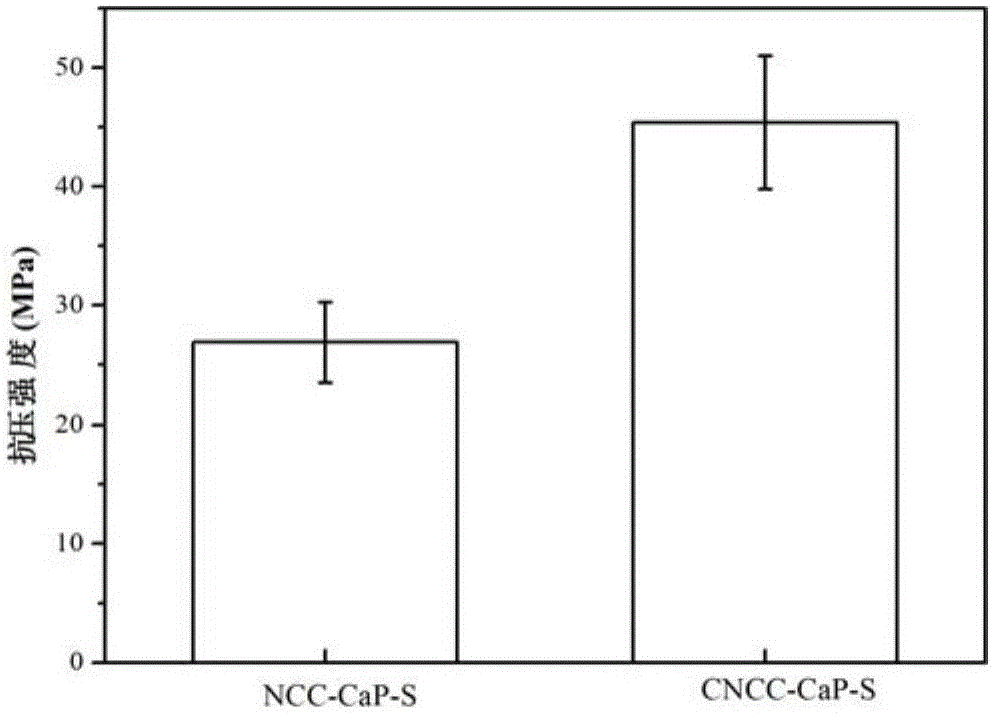

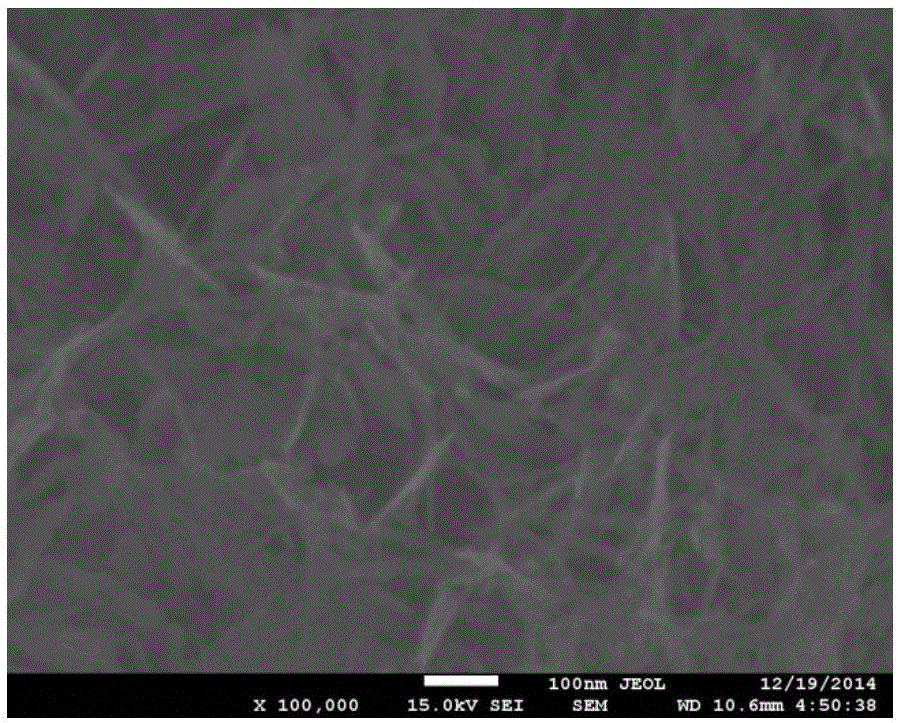

Preparation method of carboxylated nano-crystal cellulose enhanced calcium phosphate support

The invention relates to a preparation method of a carboxylated nano-crystal cellulose enhanced calcium phosphate support, which comprises the following steps: A)performing carboxylating modification on nano-crystal cellulose to obtain a carboxylated nano-crystal cellulose fluid suspension; B)preparation of composite powder: adding soluble calcium salt and a soluble phosphatic solution according to mol ratio of Ca and P being 1.67: 1 in order in the carboxylated nano-crystal cellulose fluid suspension; performing in situ synthesis to obtain hydroxyapatite in the carboxylated nano-crystal cellulose fluid suspension, washing, performing pumping filtration, and drying to obtain the carboxylated nano-crystal cellulose hydroxyapatite composite powder; and C)preparation of the support: individually taking the carboxylated nano-crystal cellulose hydroxyapatite composite powder as support solid phase powder, or uniformly mixing with other calcium salt powder to obtain the product being as the support solid phase powder; adding a support moulding liquid, and performing water-bath solidifying after moulding to obtain the product. The carboxylated nano-crystal cellulose enhanced calcium phosphate support has high compressive strength.

Owner:SOUTHWEST JIAOTONG UNIV

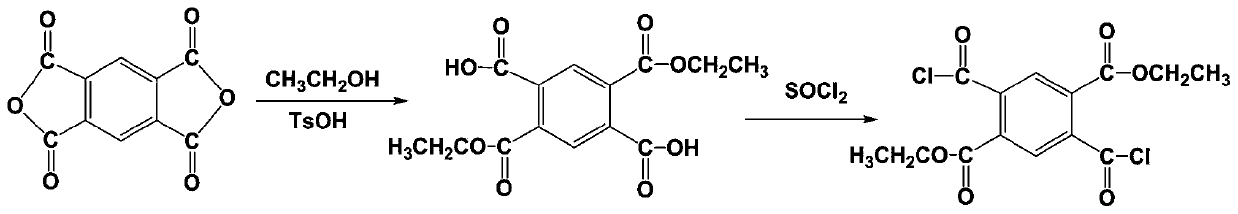

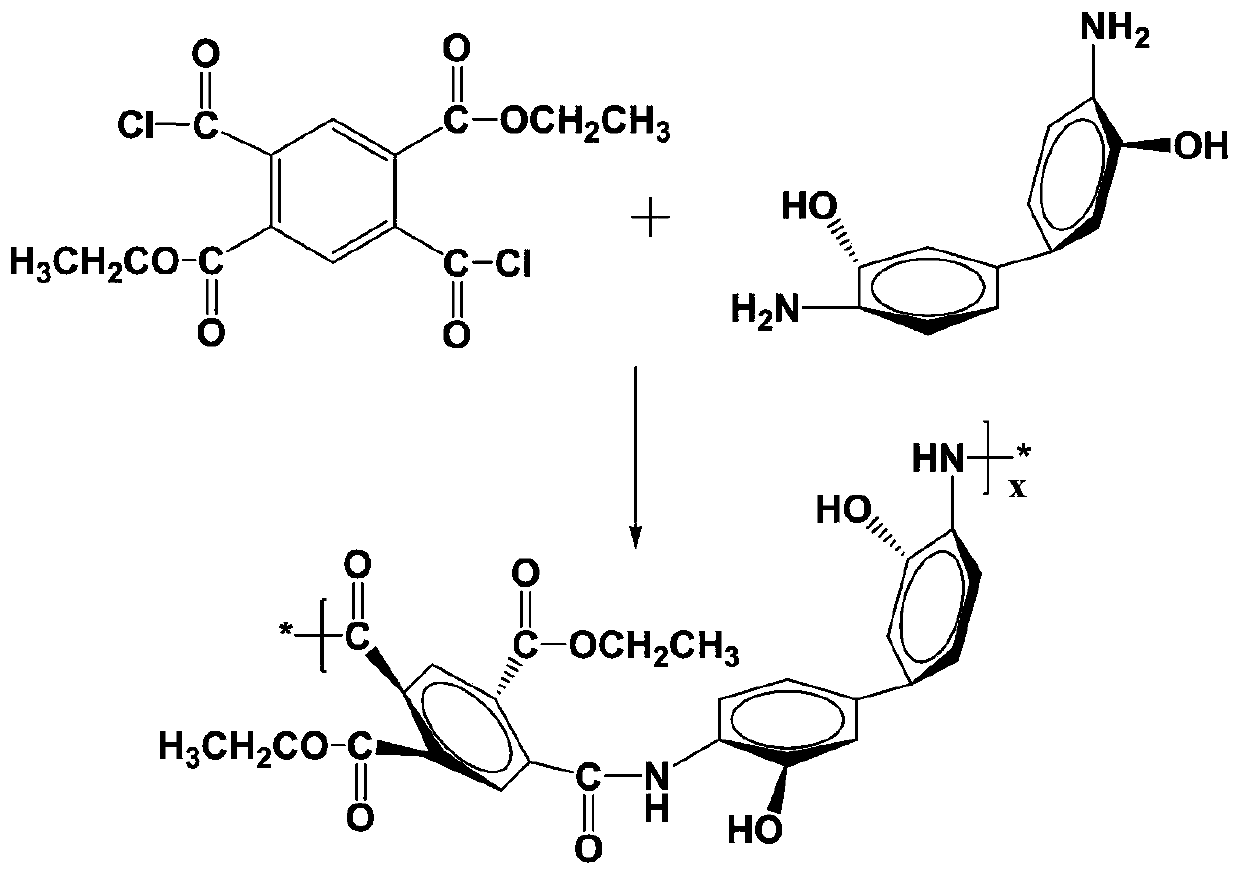

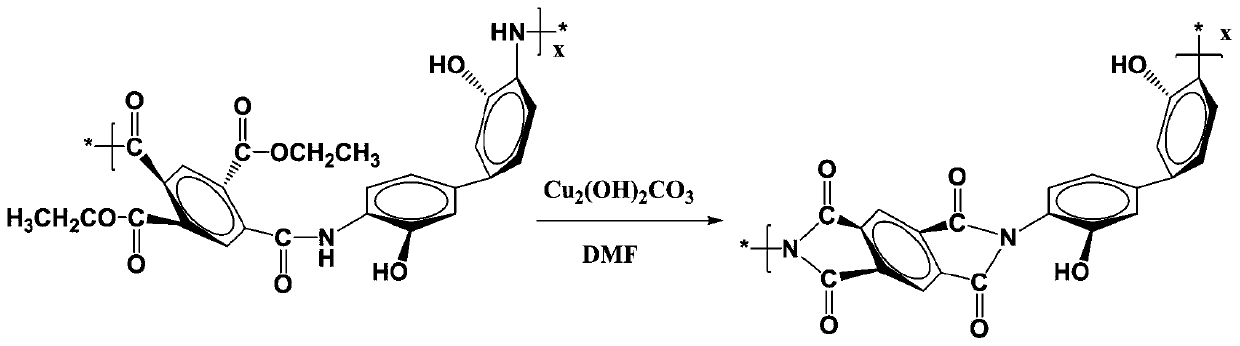

Soluble environment-friendly adhesive and preparation process thereof

InactiveCN110305314AImproves viscosity and bonding propertiesImprove bonding performancePolyamideChemistry

The invention discloses a soluble environment-friendly adhesive. The soluble environment-friendly adhesive comprises the following raw material components: 40-45 parts of dihydroxybiphenyl polyamide,80-90 parts of dimethylformamide, 4-7 parts of basic cupric carbonate, 34-38 parts of siloxane hydroxypyridine, 30-34 parts of boric acid and 120-130 parts of a solvent. The prepared adhesive not onlycan maintain the physical form at a high temperature of 500 DEG C for normal use, but also can be dissolved directly in an ethanol solvent at the same time; and meanwhile the bonding performance is high, and the peeling strength of the adhesive reaches 21.6 N.cm<-1>.

Owner:中著(杭州)知识产权运营有限公司

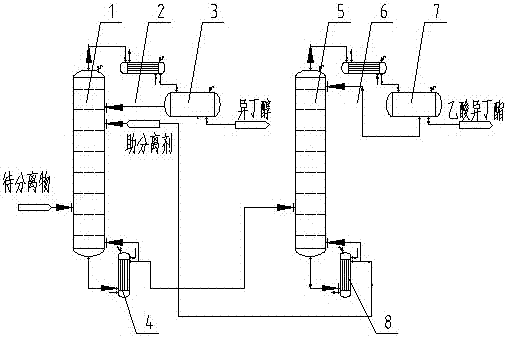

Method for separating isobutanol from isobutyl acetate

ActiveCN107337601AEasy to separateHigh purityOrganic compound preparationCarboxylic acid esters preparationIsobutanolIsobutyl acetate

The invention discloses a method for separating isobutanol from isobutyl acetate. According to the method, a screening separation promoter is added, an extraction distillation method is implemented to separate isobutanol from isobutyl acetate, the relative volatility of isobutanol and isobutyl acetate is changed, separation of isobutanol from isobutyl acetate is achieved, isobutanol and isobutyl acetate of relatively high purity are prepared, the added separation promoter can be recycled, and high-efficiency and high-purity separation of isobutanol from isobutyl acetate is achieved.

Owner:济南信兆昌化工科技有限公司

Preparation method and application of low-elasticity polyurethane resin

The invention relates to a preparation method and application of low-elasticity polyurethane resin. The preparation method of the low-elasticity polyurethane resin comprises the following steps: preparing the low-elasticity polyurethane resin; the preparation method comprises the following steps: mixing polyether polyol, polyester polyol, polyolefin polyol, a chain extender I (without carboxyl), achain extender II (with carboxyl) and diphenylmethane diisocyanate according to a certain molar ratio, and processing the mixture according to a preparation process of thermoplastic polyurethane resin, thereby preparing low-elasticity polyurethane resin A when the addition amount of the chain extender II is 0, otherwise, preparing low-elasticity polyurethane resin B. The application includes steps of: the low-elasticity polyurethane resin A and the low-elasticity polyurethane resin B are mixed to prepare a low-elasticity polyurethane resin mixture, and furthermore, the mixture is adopted to prepare the superfine fiber base cloth based on the low-elasticity polyurethane resin. The limitation that high-density embossed products are difficult to obtain from traditional polyurethane superfinefiber base cloth is overcome, and the applicability of the embossing technology to the synthetic leather field with high-density requirements such as rugby leather is improved.

Owner:HUAFON MICROFIBER SHANGHAI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com