Self-cleaning fluorosilicone-modified acrylic acid cathode electrophoresis paint and preparation method thereof

A cathodic electrophoretic coating and fluorine-silicon modification technology, which is applied in electrophoretic coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of increased cleaning costs and high pollution on the product surface, and achieve convenient coating and smooth coating. Excellent liquid stability and improved stain resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

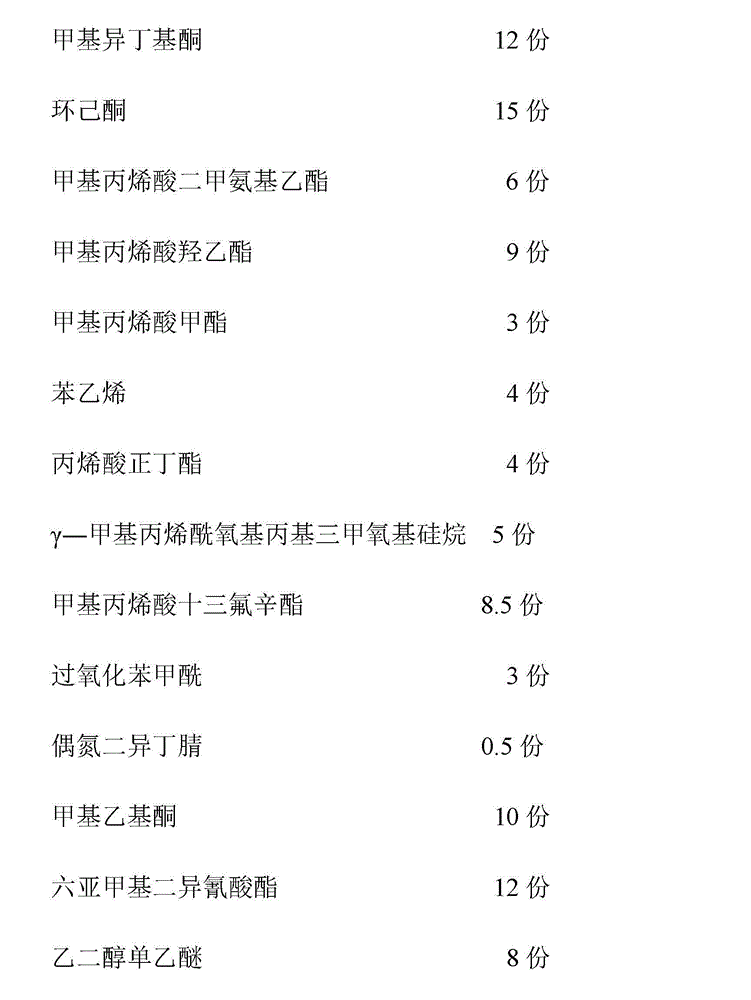

[0028] 1) The formula of the semi-blocked aliphatic isocyanate modified fluorine-containing silicon cationic acrylic resin:

[0029]

[0030] Add methyl ethyl ketone and hexamethylene diisocyanate into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen gas, raise the temperature to 75°C, add ethylene glycol monoethyl ether dropwise, and drop it in 1 hour. After 2 hours of heat preservation, the temperature was lowered to below 45°C and the material was discharged to obtain a semi-blocked aliphatic isocyanate, which was put into a desiccator for later use. Dimethylaminoethyl methacrylate, hydroxyethyl methacrylate, methyl methacrylate, styrene, n-butyl acrylate, γ-methacryloxypropyltrimethoxysilane, methyl Tridefluorooctyl acrylate and benzoyl peroxide are mixed evenly for use, which is called mixed solution 1; azobisisobutyronitrile and 1 part of cyclohexanone are mixed evenly for use, called mixed solution 2 . Add methyl isobu...

Embodiment 2

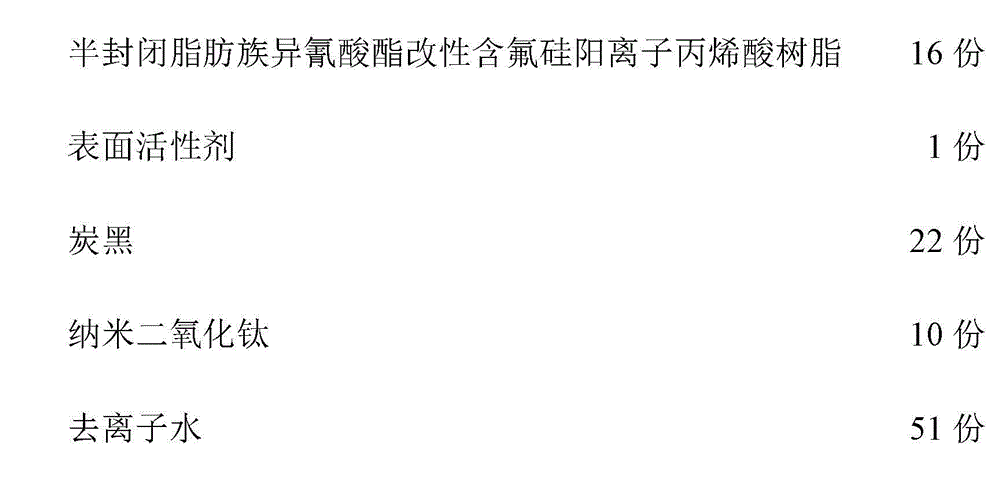

[0040] 2) The formula of the semi-blocked aliphatic isocyanate modified fluorine-containing silicon cationic acrylic resin:

[0041]

[0042]

[0043] Add methyl ethyl ketone and hexamethylene diisocyanate into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen gas, raise the temperature to 75°C, add ethylene glycol monoethyl ether dropwise, and drop it in 1 hour. After 2 hours of heat preservation, the temperature was lowered to below 45°C and the material was discharged to obtain a semi-blocked aliphatic isocyanate, which was put into a desiccator for later use. Dimethylaminoethyl methacrylate, hydroxyethyl methacrylate, methyl methacrylate, styrene, n-butyl acrylate, γ-methacryloxypropyltrimethoxysilane, methyl Tridefluorooctyl acrylate and benzoyl peroxide are mixed evenly for use, which is called mixed solution 1; azobisisobutyronitrile and 1 part of cyclohexanone are mixed evenly for use, called mixed solution 2 . Add ...

Embodiment 3

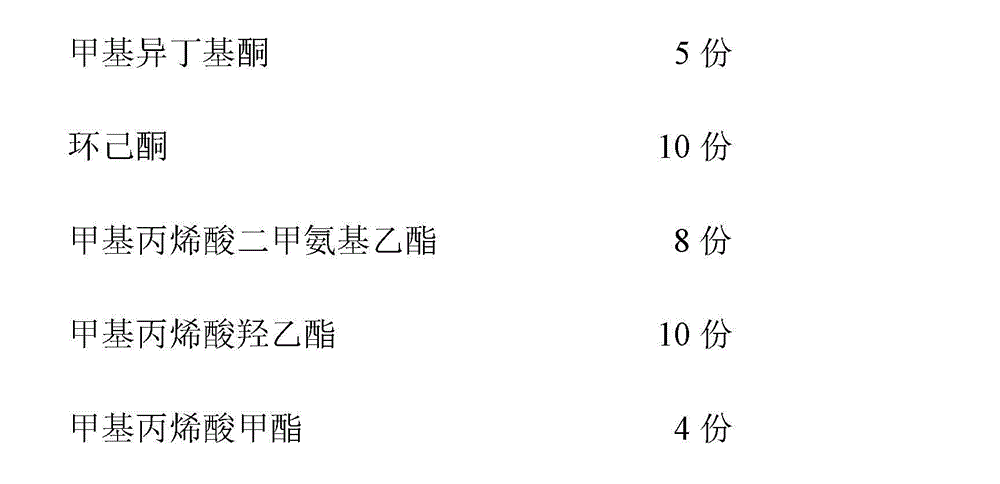

[0053] 3) The formula of the semi-blocked aliphatic isocyanate modified fluorine-containing silicon cationic acrylic resin:

[0054]

[0055]

[0056] Add methyl ethyl ketone and hexamethylene diisocyanate into a reaction vessel with a stirrer and a condenser according to the formula amount, blow nitrogen gas, raise the temperature to 75°C, add ethylene glycol monoethyl ether dropwise, and drop it in 1 hour. After 2 hours of heat preservation, the temperature was lowered to below 45°C and the material was discharged to obtain a semi-blocked aliphatic isocyanate, which was put into a desiccator for later use. Dimethylaminoethyl methacrylate, hydroxyethyl methacrylate, methyl methacrylate, styrene, n-butyl acrylate, γ-methacryloxypropyltrimethoxysilane, methyl Tridefluorooctyl acrylate and benzoyl peroxide are mixed evenly for use, which is called mixed solution 1; azobisisobutyronitrile and 1 part of cyclohexanone are mixed evenly for use, called mixed solution 2 . Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com