Waterproof thermal insulation coating composition and preparation method thereof

A technology for thermal insulation coatings and compositions, applied in antifouling/underwater coatings, reflection/signal coatings, coatings, etc., can solve the problem of poor anti-fouling and waterproof effects of thermal insulation coatings, attenuation of heat insulation effects, and loss of heat insulation effects To achieve the effect of reducing the attenuation of heat insulation temperature difference, improving the performance of heat insulation and improving the basic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

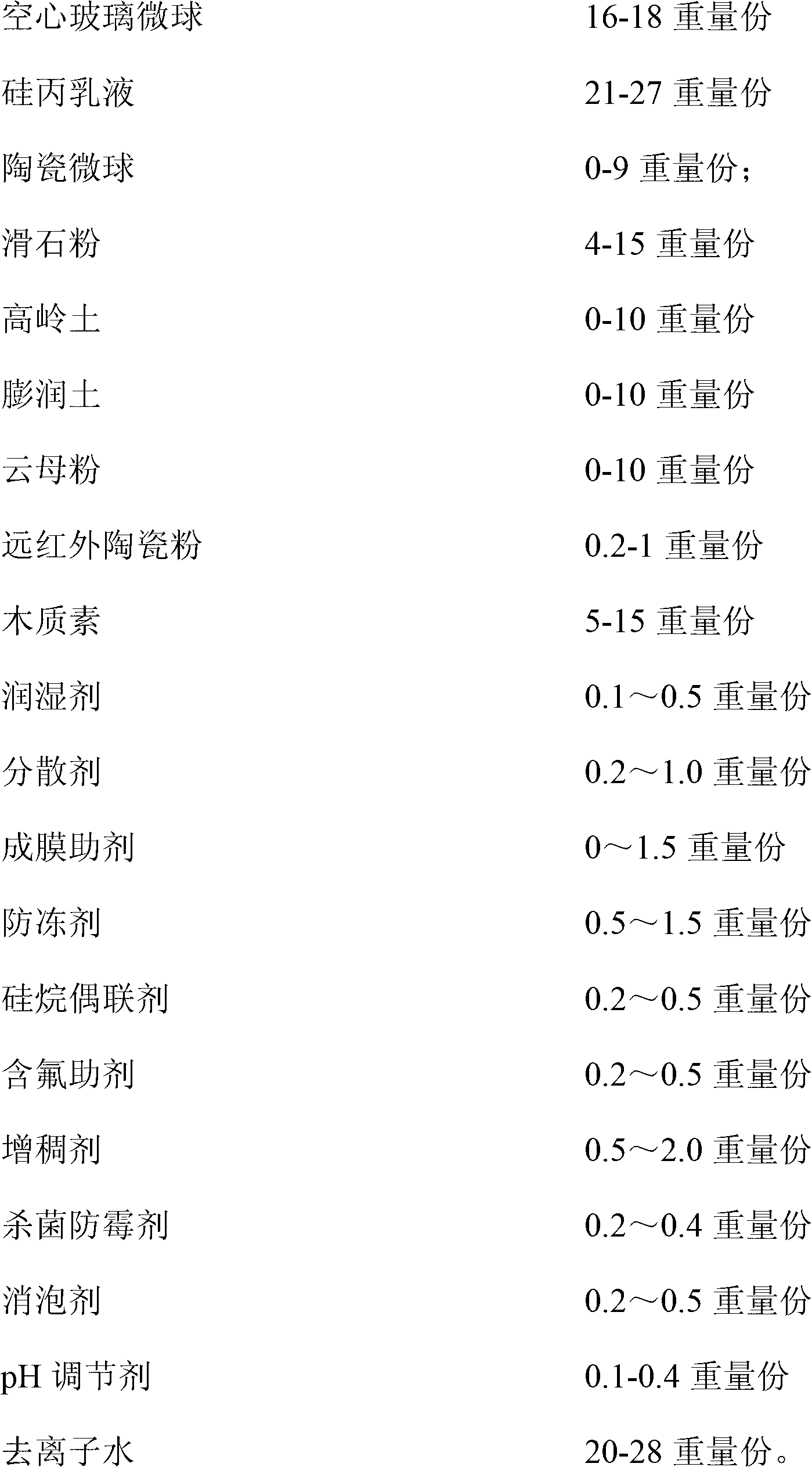

[0054] A kind of waterproof and thermal insulation coating comprises the following components in parts by weight:

[0055]

[0056]

[0057] The preparation steps of the waterproof thermal insulation coating are as follows:

[0058] (1) Add film-forming aids, antifreeze agents, wetting agents, dispersants, defoamers, silane coupling agents and thickeners to 13 parts of deionized water according to the formula, and stir at a speed of 500r / min 3min obtains mixture;

[0059] (2) Add the formulated amount of titanium dioxide, far-infrared ceramic powder, ceramic microspheres, wood fiber, talcum powder and kaolin to the mixture obtained in step (1), and disperse at a speed of 2000r / min for 15min to obtain a fineness of 60μm mixed system;

[0060] (3) At a speed of 300r / min, add the formula amount of bactericide and antifungal agent, silicon acrylic emulsion, hollow glass microspheres, defoamer, remaining deionized water, and pH adjustment to the mixed system obtained in ste...

Embodiment 2

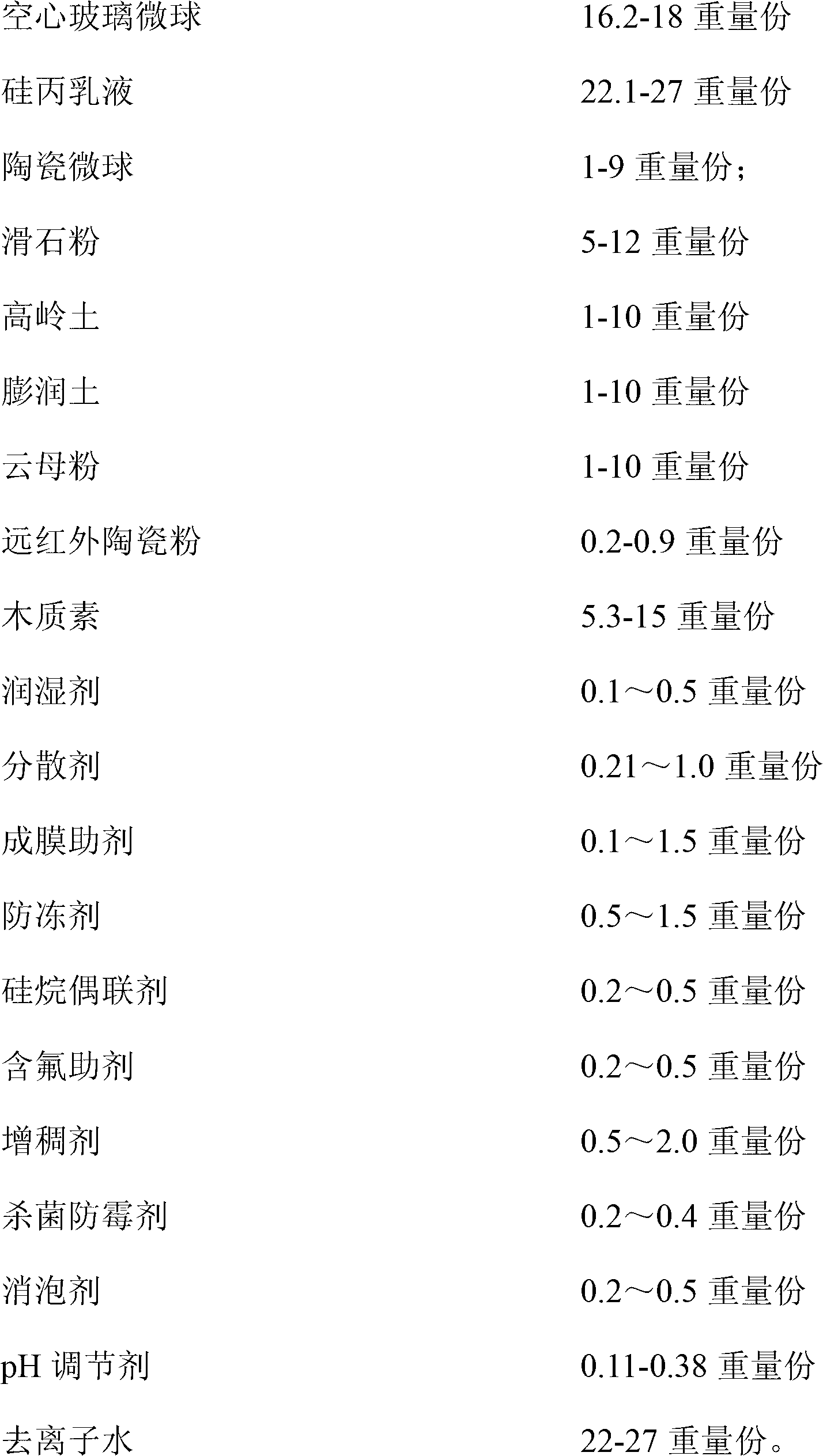

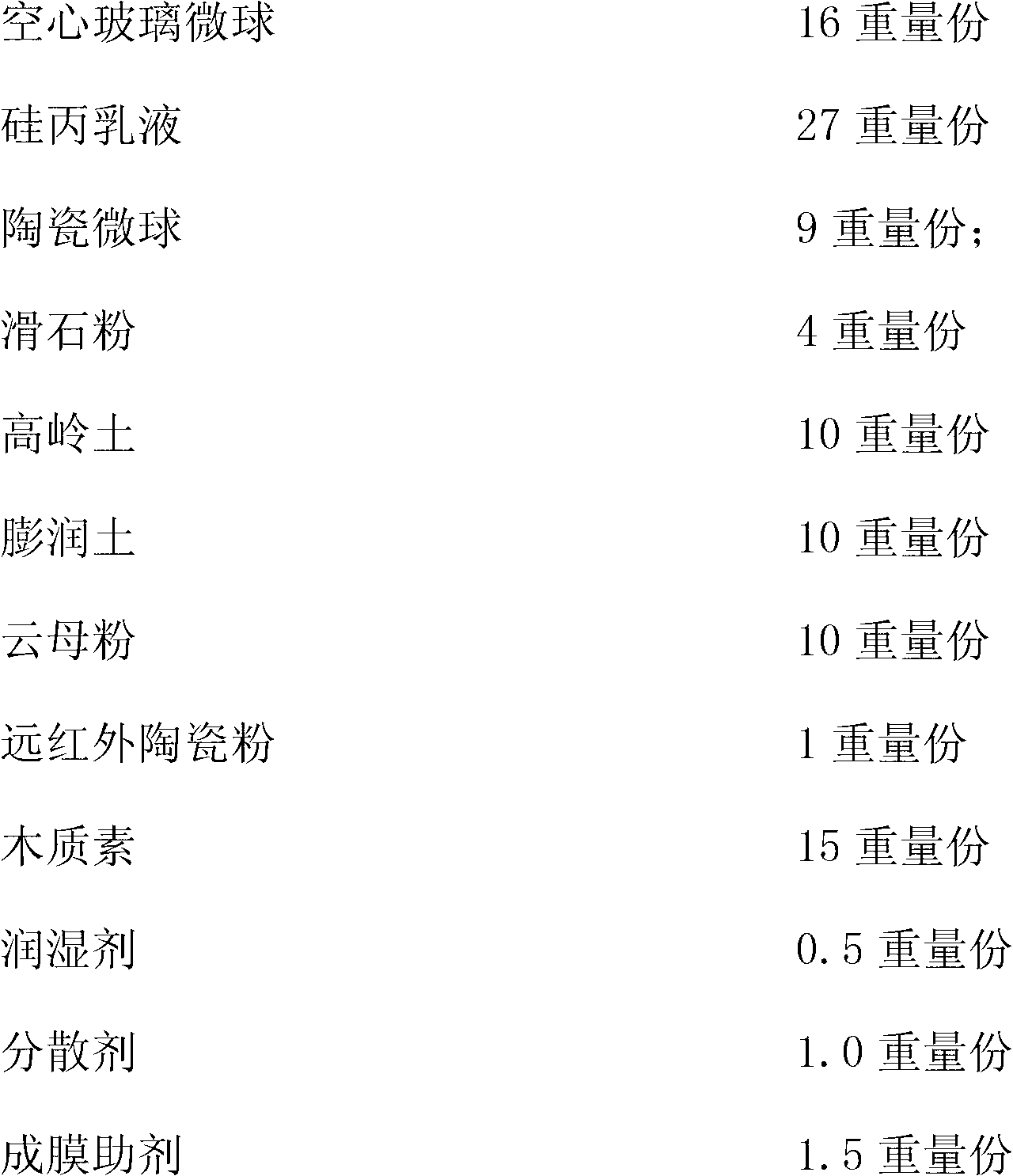

[0062] A kind of waterproof and thermal insulation coating comprises the following components in parts by weight:

[0063]

[0064]

[0065] The preparation steps of the waterproof thermal insulation coating are as follows:

[0066] (1) Add film-forming aids, antifreeze agents, wetting agents, dispersants, defoamers, silane coupling agents and thickeners to 18 parts of deionized water according to the formula, and stir at a speed of 300r / min 10min obtains mixture;

[0067] (2) Add the formulated amount of titanium dioxide, far-infrared ceramic powder, ceramic microspheres, wood fiber, talcum powder and kaolin to the mixture obtained in step (1), and disperse at a speed of 1000r / min for 60min to obtain a fineness of 40μm mixed system;

[0068] (3) At a speed of 600r / min, add the formula amount of bactericidal and antifungal agent, silicon acrylic emulsion, hollow glass microspheres, defoamer, remaining deionized water, and pH adjustment to the mixed system obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com