Patents

Literature

62results about How to "Improve waterproof and antifouling performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterproof thermal insulation coating composition and preparation method thereof

InactiveCN102702904AStir wellHigh solar reflectanceAntifouling/underwater paintsPaints with biocidesEmulsionThermal insulation

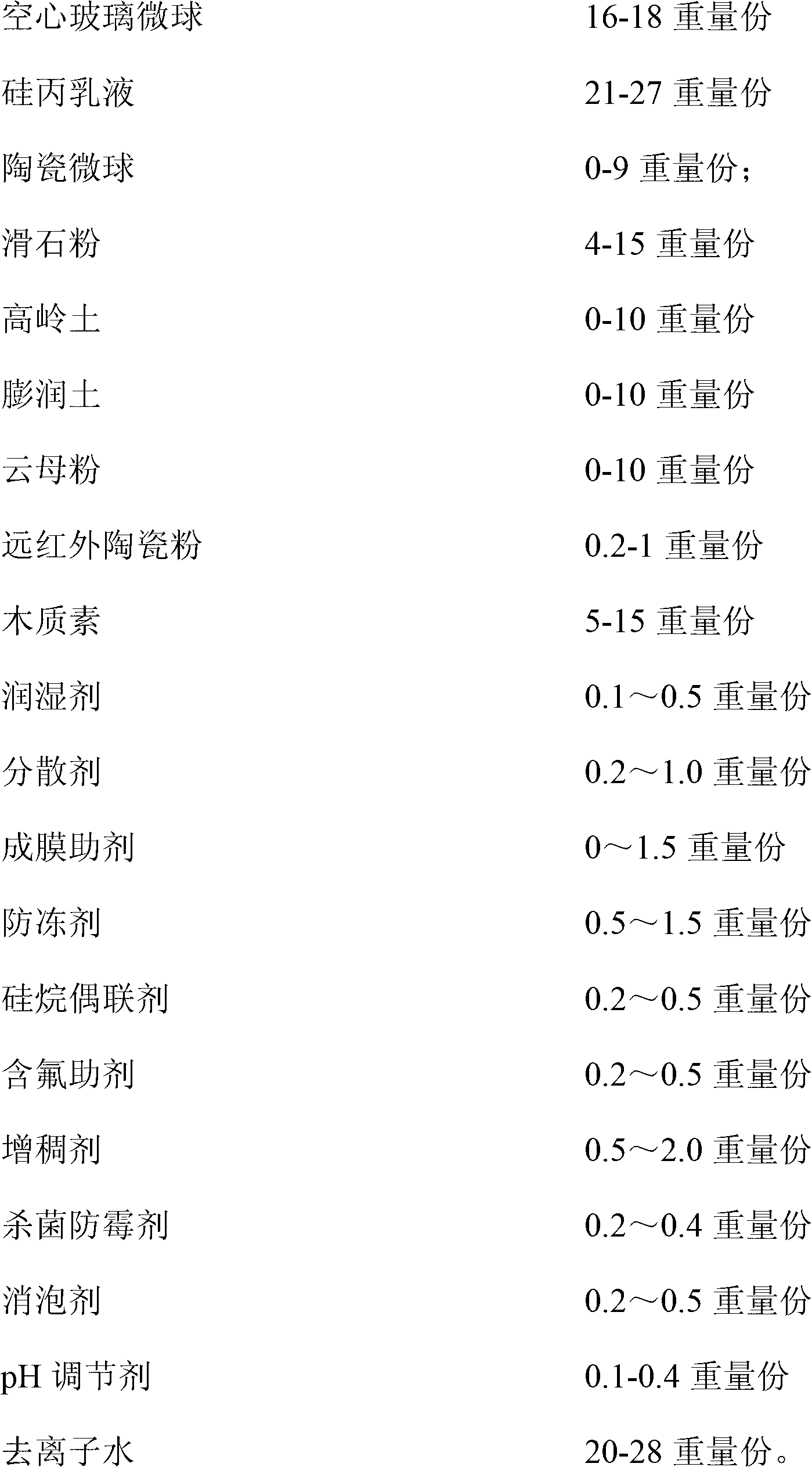

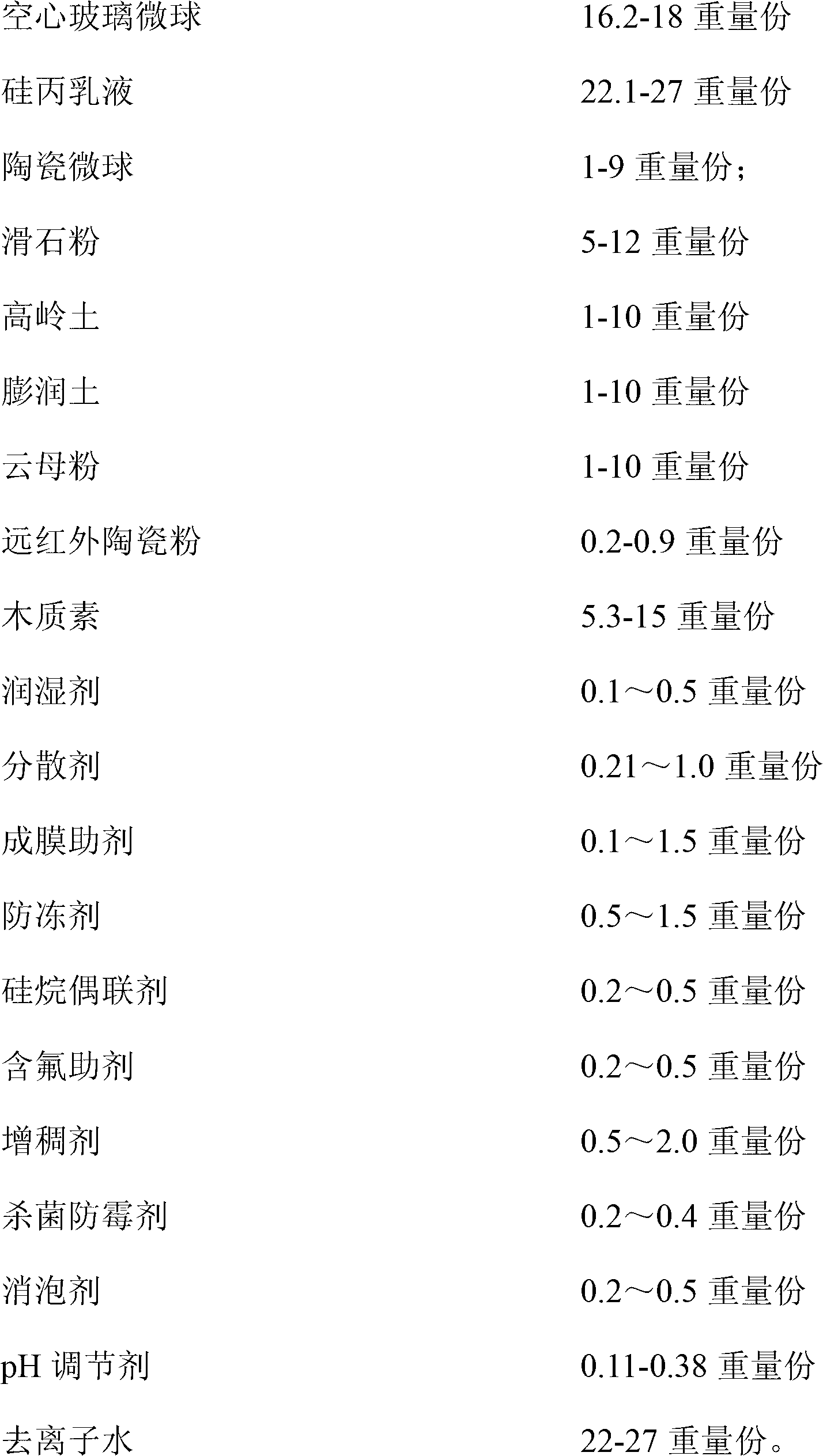

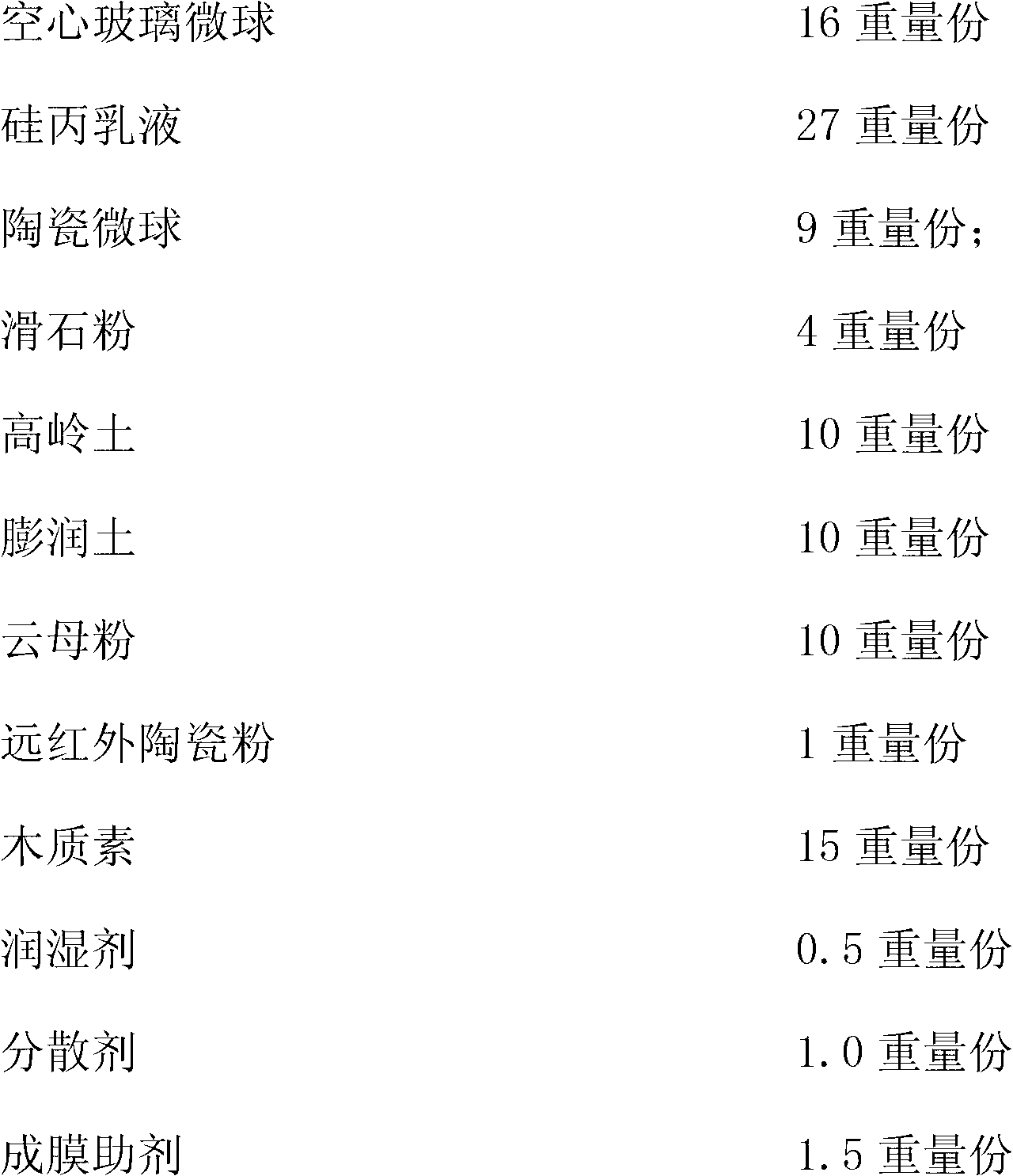

The invention relates to a waterproof thermal insulation coating composition, which comprises an aggregates, a substrate, an auxiliary filling and an assistant, and is characterized in that the aggregates are hollow glass microspheres, and the substrate is silicone acrylic emulsion; in the thermal insulation coating composition, 6-18 parts by mass of hollow glass microspheres and 21-27 parts by mass of silicone acrylic emulsion are provided. According to the invention, the silicon acrylic emulsion is selected, so that the thermal insulation coating has excellent thermal insulation property, and good waterproof and antifouling performance, and the waterproof and antifouling performance is more excellent for fluorine-containing silicone acrylic emulsion.

Owner:TIANCHANG JULONG TRAVEL PAINT

Preparing method of heat preservation paint with waterproof and antifouling performance

InactiveCN106147471AImprove basic performanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesEmulsionMicrosphere

The invention relates to a preparing method of heat preservation paint with waterproof and antifouling performance. The heat preservation paint comprises aggregate, a base material, auxiliary filler and an auxiliary and is characterized in that hollow glass microspheres serve as the aggregate, the base material is silicone-acrylic emulsion, and the heat preservation paint composition comprises, by weight, 16-18 parts of hollow glass microspheres and 21-27 parts of silicone-acrylic emulsion. As the silicone-acrylic emulsion is selected, while having excellent heat preservation performance, the heat preservation paint has good waterproof and antifouling performance, and particularly fluorine-containing silicone-acrylic emulsion is selected, so that the waterproof and antifouling performance of the heat preservation paint is more excellent.

Owner:泉州市合创涂料科技有限公司

Polishing method for irregular marble surface

ActiveCN102765013AAchieve mechanized polishingImprove polishing efficiencyPolishing machinesPolishingGrinding mill

The invention discloses a polishing method for an irregular marble surface. The method is as follows: placing marble blank and abrasive in a vibration grinding machine, followed by coarse grinding and fine grinding so as to obtain stones with a better polishing effect. The polishing method has excellent polishing effect. Due to the adoption of the method, the marble polishing surface has various art visual effects rather than single mirror smoothing effect in the prior art; the mechanical polishing of the marble, particularly, the irregular marble, is realized; the polishing efficiency of the irregular marble is greatly improved, and the polishing cost of irregular marble material can be greatly reduced, and is only tens of times less than the polishing cost of the traditional method; and the irregular polishing stone products can possibly become popular building material products, and expression forms of the irregular marble products and building decoration marble are enriched.

Owner:GAOYAO CITY DONGYING STONEMASONRY

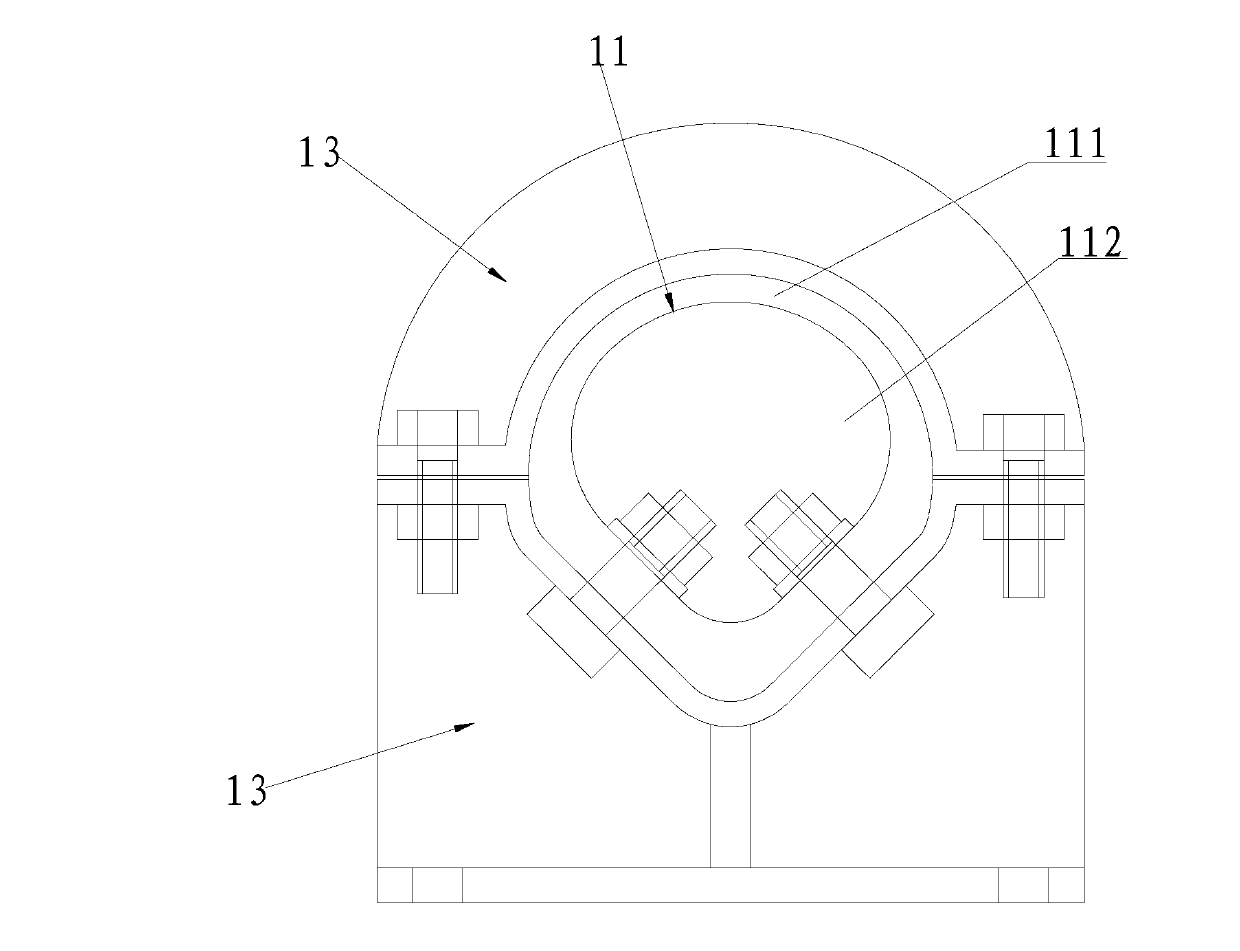

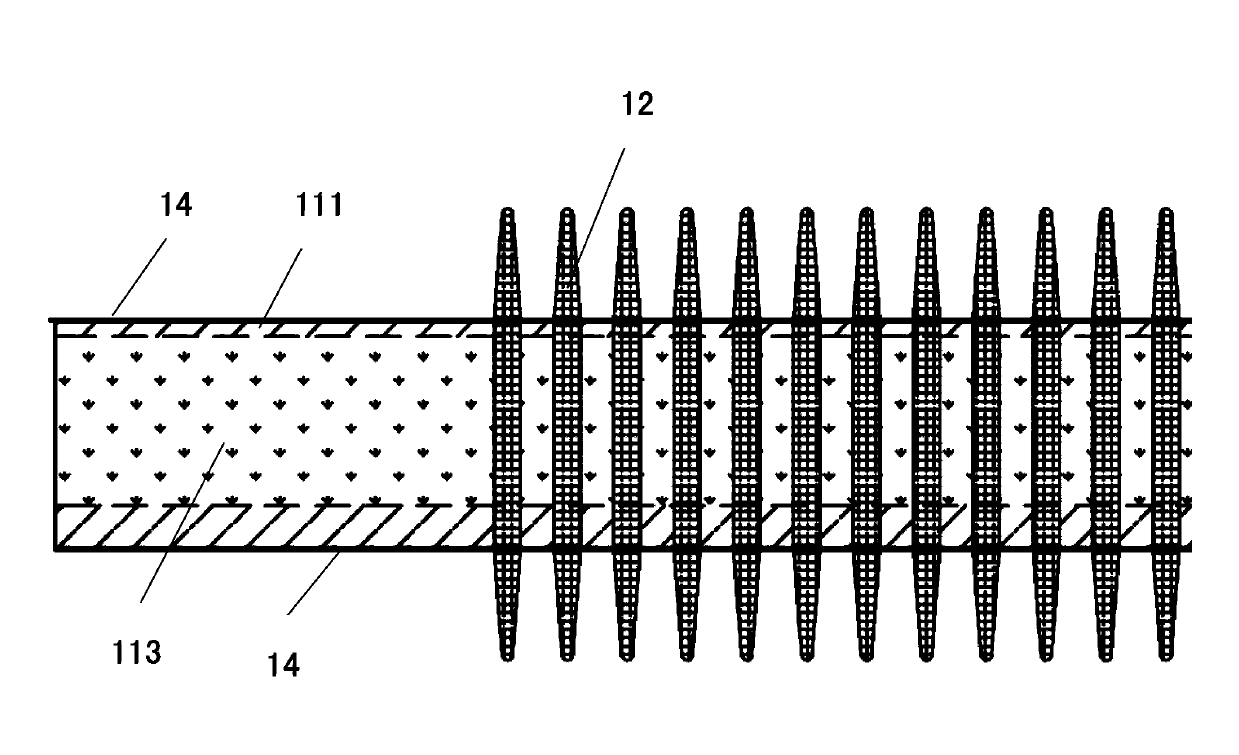

Composite cross arm and manufacturing process thereof

The invention discloses a composite cross arm and a manufacturing process thereof. The composite cross arm comprises an insulating core rod, an umbrella skirt and connectors, wherein the umbrella skirt is fixedly arranged on the insulating core rod; the connectors are fixedly connected to the two ends of the insulating core rod; the insulating core rod has a D-shaped cross section and comprises a resin fiber composite layer which is manufactured by a pultrusion winding process; the umbrella skirt is fixedly poured on the composite layer; and surface coatings are coated on the outer surfaces of the composite layer and the umbrella skirt respectively. Since the core rod which is made of the resin fiber composite material is adopted by the cross arm, the cross arm has light weight and better insulation performance and mechanical performance; and the cross section of the insulating core rod is D-shaped, so that the cross arm has the advantages of capability of preventing ash deposition, convenience in mounting and the like. The fixedly poured umbrella skirt is made of an outdoor resin material; and since the outdoor resin material has superior weather resistance and good mechanical performance, corrosion resistance and water-proof and anti-fouling performance, a person can step on the umbrella skirt to operate during construction, and meanwhile, the damage caused by worms and birds is avoided.

Owner:STATE GRID CORP OF CHINA +3

Organic fluorine modified polyurethane stain and water resisting coating

InactiveCN105086806AImprove water resistanceImprove stain resistanceFireproof paintsAntifouling/underwater paintsAntioxidantAlpha-methylstyrol

The invention discloses an organic fluorine modified polyurethane stain and water resisting coating. The coating comprises, by weight, 80-120 parts of organic fluorine modified polyurethane, 30-50 parts of alpha methyl styrene linear trimer, 10-30 parts of melamine polyphosphates, 2-8 parts of ammonium polyphosphate, 3-5 parts of nanometer zinc borate, 3-9 parts of magnesium hydrate, 2-6 parts of ultrafine ceramic powder, 4-8 parts of montmorillonoid, 6-12 parts of white fused alumina powder, 3-5 parts of carbon fluoride, 2-4 parts of sodium persulfate, 3-5 parts of aluminum oxide, 1-3 parts of silica powder, 1-5 parts of sodium molybdate, 1-5 parts of aluminum triphosphate, 1-3 parts of titanium dioxide, 2-6 parts of nano-barium sulfate, 3-8 parts of calcium stearate, 1-3 parts of pentaerythritol, 2-4 parts of dispersing agents, 3-5 parts of silane coupling agents, 2-5 parts of antioxidants, and 16-23 parts of water. The coating has excellent stain and water resistance and high wearing and corrosion resistance.

Owner:ANHUI JINYANG FLUORINE CHEM

Ultraviolet-proof fiber coating material

InactiveCN104893465AGood waterproof and antifouling performanceImprove waterproof and antifouling performanceRubber derivative coatingsCellulose coatingsPolyacrylamidePVA - Polyvinyl alcohol

The invention relates to an ultraviolet-proof fiber coating material. The ultraviolet-proof fiber coating material is prepared from the raw materials in parts by weight: 70-90 parts of acrylic resin, 20-30 parts of cellulose polymer, 10-15 parts of short fibers, 20-35 parts of chlorinated rubber, 25-40 parts of aluminum silicate fibers, 20-30 parts of polyester fibers, 10-30 parts of acidified graphite, 20-25 parts of polyvinyl alcohol, 30-50 parts of polyacrylamide and the balance of ultraviolet-resistant organic silicone oil. The ultraviolet-proof fiber coating material disclosed by the invention has the characteristics of good water resistance, fouling resistance and ultraviolet resistance.

Owner:康圣科

Antistatic textile fabric and preparing method thereof

ActiveCN110528141ASuitable for large-scale productionWide variety of sourcesElectroconductive/antistatic filament manufactureConjugated cellulose/protein artificial filamentsMethoxyacetic acidFiber

The invention discloses an antistatic textile fabric. The antistatic textile fabric is characterized by being prepared from, by weight, 40-60 parts of antistatic functional fiber, 20-30 parts of otherfiber and 7-15 parts of alginic acid fiber, The antistatic functional fiber is prepared by mixing a methyl 2-methoxy-2-(prop-2-enoylamino)acetate / 1-allyl-3-methylimidazolium chloride / vinyl-functionalized Zr-MOFs / 1-[3-(triethoxysilyl)propyl]-1H-pyrrole-2,5-dione / acrylonitrile / monovinyl-terminated polydimethylsiloxane copolymer with carboxymethyl cellulose sodium. The invention further discloses apreparing method of the antistatic textile fabric. The antistatic textile fabric has the advantages of remarkable antistatic effect, excellent sweat absorbing property, high conductivity, good thermal insulation effect, high wearing comfort level and high water absorption and decontamination capacity.

Owner:无锡兴之盛针织有限公司

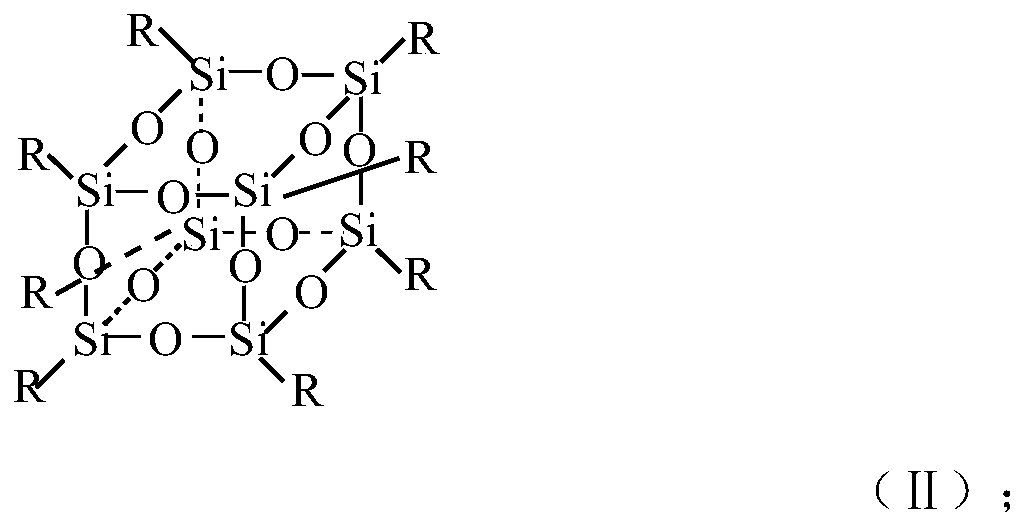

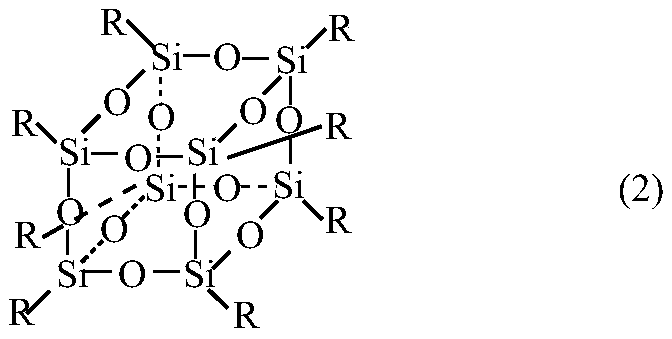

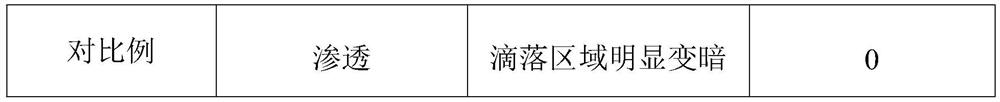

Photo-curing POSS (polyhedral oligomeric silsesquioxane)/fluoroalkyl siloxane modified polyacrylate coating composition and application thereof

ActiveCN109735144AHigh hardnessImprove heat stabilityAntifouling/underwater paintsPaints with biocidesPolyamideRoom temperature

The invention provides a photo-curing POSS (polyhedral oligomeric silsesquioxane) / fluoroalkyl siloxane modified polyacrylate coating composition which comprises a material A and a material B. The material A comprises 40-70wt% of POSS-PA (polyamide) prepolymers, 15-58.9wt% of photo-curing acrylate monomers UVAA, 1-10wt% of polymerizable reactive fluoroalkyl siloxane modified acrylate monomers FS and 0.1-5wt% of adhesive force intensifiers. The material B comprises photoinitiators accounting for 1-6wt% of the total weight of the material A. The material A and the material B are uniformly mixed,leveled at room temperature, preliminarily dried at the temperature of 50-60 DEG C and then cured under the action of UV (ultraviolet) light to prepare a POSS / fluoroalkyl siloxane modified polyacrylate coating, and an application indicates that the coating prepared by the method has good water and dirt repellent performances and good scratch resistance.

Owner:SHAANXI UNIV OF SCI & TECH

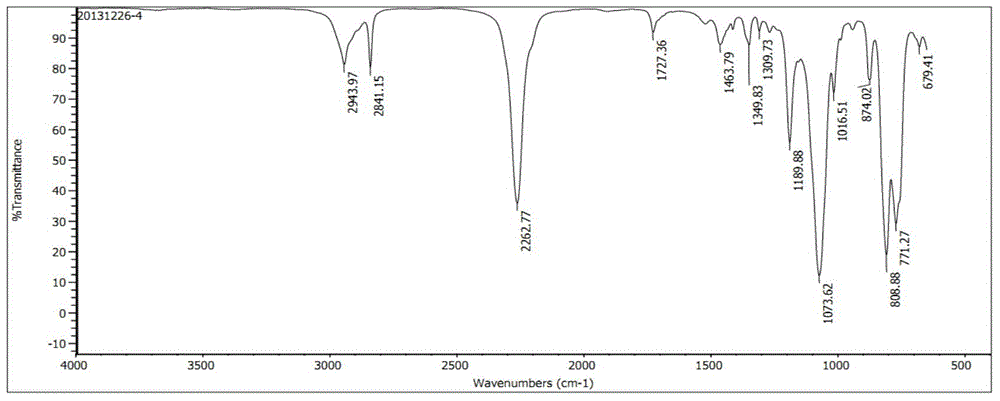

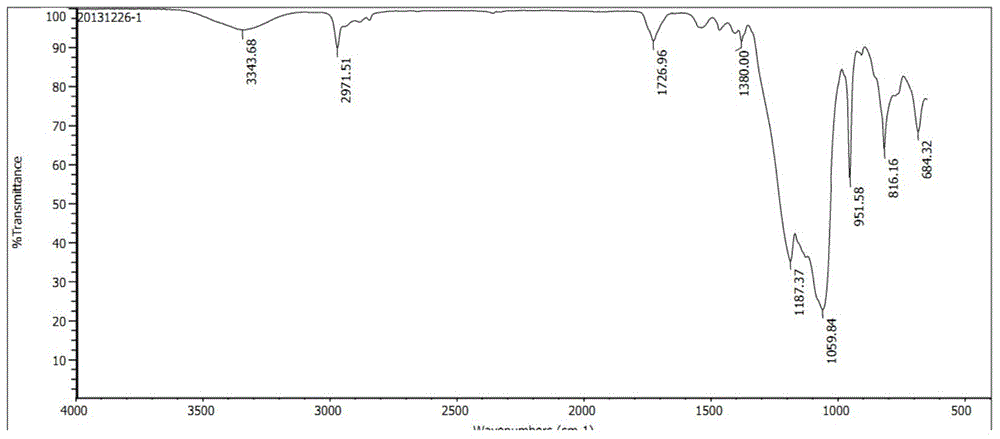

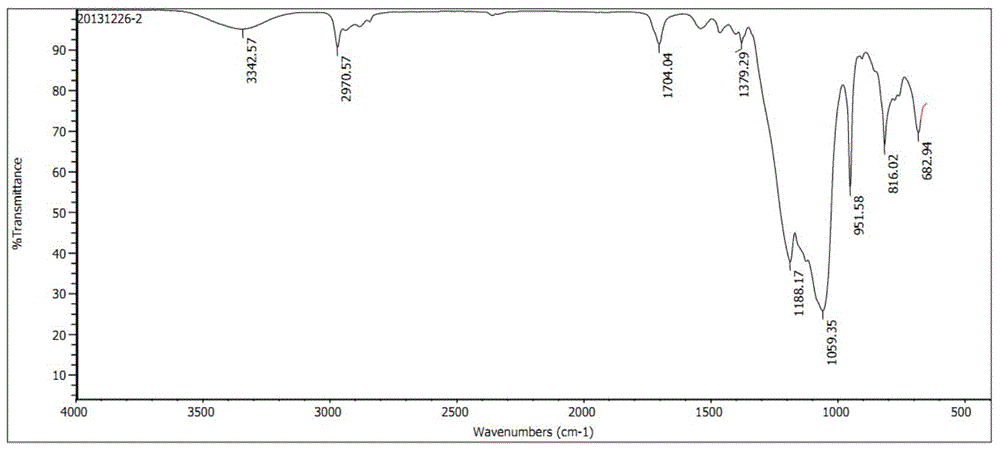

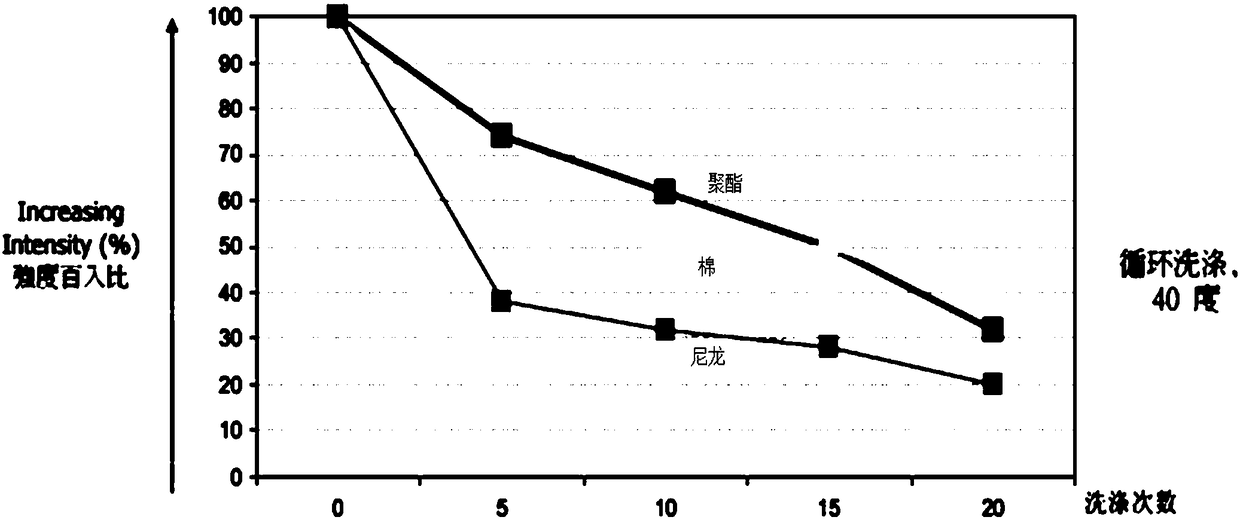

Preparation method of fluorine/silicone co-modified waterborne polyurethane

InactiveCN110128616AImprove waterproof and antifouling performanceImprove stabilityTextiles and paperCross-linkPolymer science

A preparation method of the fluorine / silicone co-modified waterborne polyurethane comprises the following steps: (1) adding diisocyanate, polymer dihydric alcohol, dihydroxy silicone oil, a hydrophilic chain extender and a catalyst dibutyltin dilaurate into a reaction kettle, and stirring all the components at 50-70 DEG C for 90-120 minutes to obtain a prepolymer; (2) adding acetone into the obtained prepolymer to dilute the prepolymer, then adding micromolecular fluorine substituted alcohol, micromolecular dihydric alcohol and a cross-linking agent, and continuously performing the reaction at50-70 DEG C for 90-120 minutes; (3) reducing the temperature of the reactant to 30-40 DEG C, adding a neutralizer triethylamine, and uniformly stirring the reactant; and (4) adding a diamine chain extender and water, carrying out high-speed emulsification, and finally carrying out reduced pressure suction filtration to remove acetone so as to obtain the product. Due to the adoption of a fluorine / silicone co-modification process, the waterproof and antifouling properties of the obtained waterborne polyurethane can be improved by more than 30%, and the waterborne polyurethane has good stabilityand lower production cost.

Owner:嘉兴禾大科技有限公司

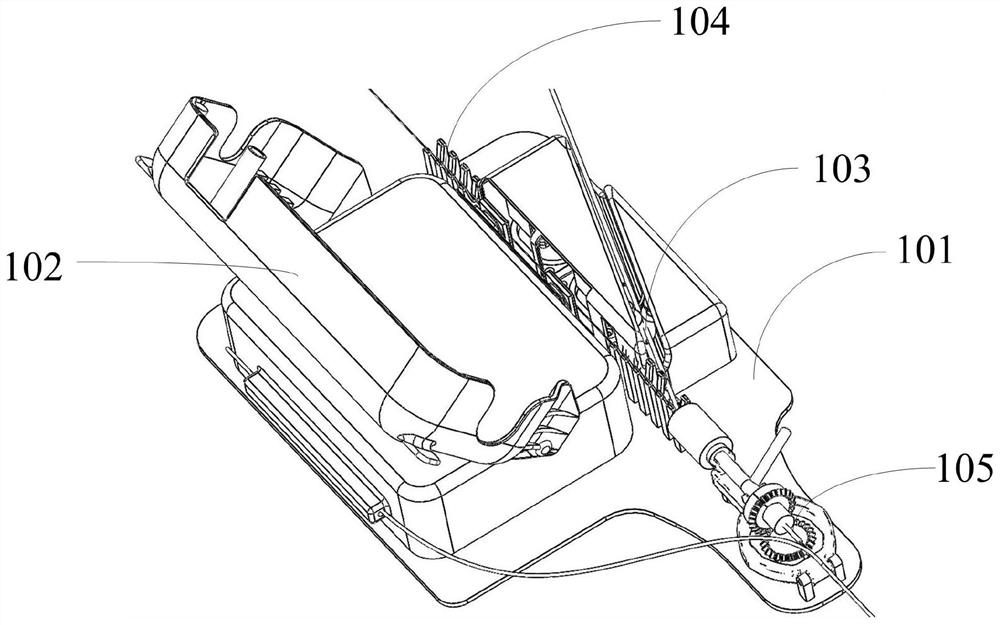

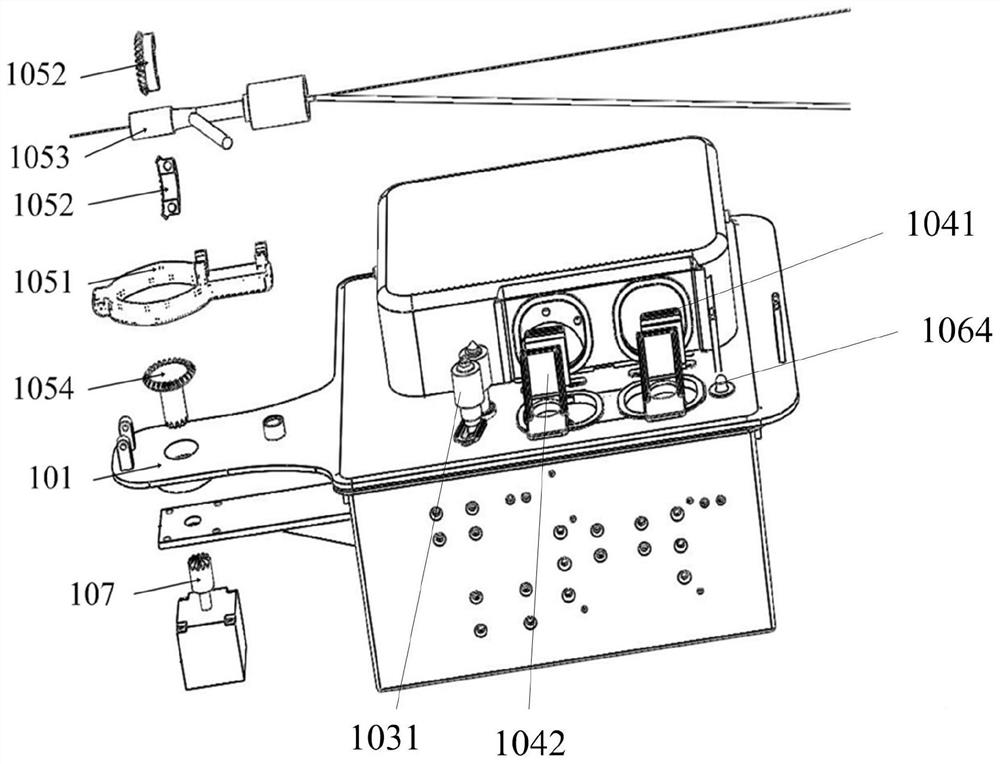

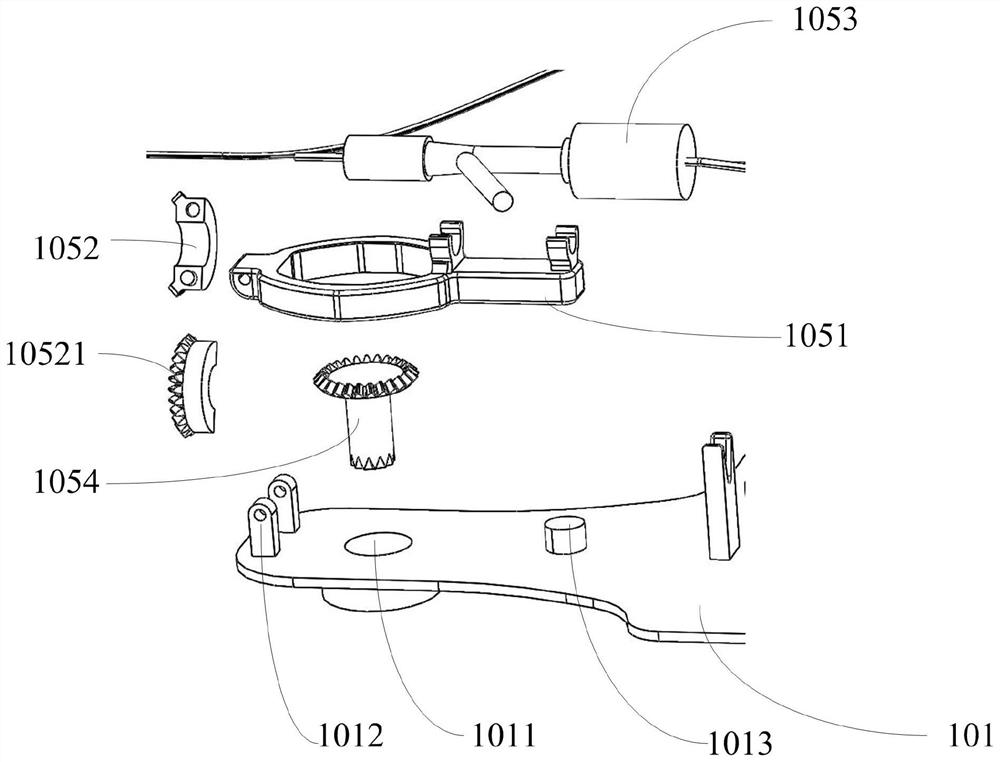

Universal waterproof disinfection box for interventional robot

PendingCN112107369AEasy to replaceAchieve universalGuide wiresMedical devicesCatheterReoperative surgery

The invention relates to a universal waterproof disinfection box for an interventional robot. The universal waterproof disinfection box comprises a sterile box body, a sterile box cover, a catheter driving assembly and a guide wire driving assembly, wherein a Y-shaped valve assembly is arranged at one end of the sterile box body, one end of a Y-shaped valve fixing piece rotates at one end of the sterile box body, and the other end of the Y-shaped valve fixing piece is magnetically connected with the sterile box body; a meshing through hole is formed in the middle of the Y-shaped valve fixing piece, a wheel shaft at the bottom of a Y-shaped valve driving gear rotates in a shaft hole, a wheel shaft gear matched with a motor output gear in a propelling mechanism is arranged at the bottom of the wheel shaft, the Y-shaped valve driving gear is located a meshing through hole, and two or more groups of Y-shaped valve clamping pieces can be connected to form an arc-shaped piece of a ring; a gear ring meshed with the Y-shaped valve driving gear is arranged on the ring; and one end of a Y-shaped valve body is fixed in the Y-shaped valve clamping pieces through an elastic filler, and the other end of the Y-valve body is fixed to the Y-shaped valve fixing piece. Therefore, Y-valve bodies of different specifications can be used, catheters of different specifications can be mounted, the catheters can rotate, and the universal use of an interventional radiography and treatment operation disinfection box is achieved.

Owner:BEIJING WEIMAI MEDICAL EQUIP CO LTD

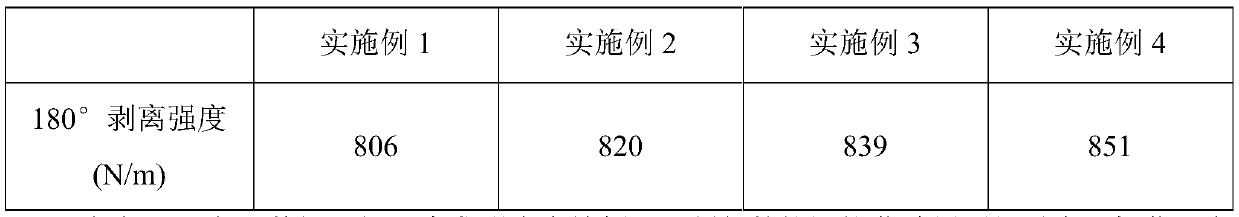

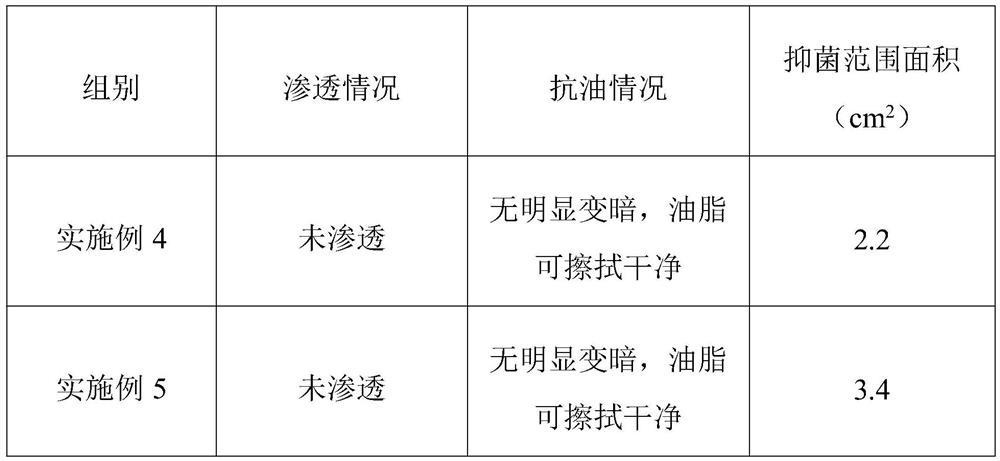

Sticker with anti-fouling and antibacterial properties and preparation method thereof

ActiveCN111423825AImprove waterproof and antifouling performanceHas anti-fouling and anti-bacterial propertiesStain/soil resistant fibresCovering/liningsPlant fibreNonwoven fabric

The invention provides a sticker with anti-fouling and antibacterial properties, the sticker is composed of three layers, including a waterproof, oil-proof and anti-fouling layer, a functional composite fiber non-woven fabric layer and a release layer, and the functional composite fiber non-woven fabric layer is prepared by grafting esterified plant fibers and modified chemical fibers and adsorbing nano-silver ions. The invention further provides a preparation method of the anti-fouling and antibacterial sticker. The preparation method comprises the steps of esterification of the plant fibers,modification of the chemical fibers, preparation of the composite modified fibers, preparation of the composite fiber non-woven fabric, adsorption of the nano-silver particles and preparation of thesticker. The sticker with the anti-fouling and antibacterial properties is better in waterproof and anti-fouling properties, free of warping, not prone to crack, good in antibacterial property and antistatic property, excellent in high-temperature resistance and weather resistance and capable of keeping the natural hand feeling and appearance of the non-woven fabric sticker.

Owner:江苏正康新材料科技股份有限公司

Waterproof foam brick and preparation method thereof

InactiveCN104402497AImprove waterproof and antifouling performanceEasy to cleanCeramicwareParaffin waxCalcium bicarbonate

A disclosed waterproof foam brick is characterized by being prepared from the following raw materials in parts by weight: 40-50 parts of waste glass, 10-15 parts of potash feldspar powder, 5-10 parts of quartz sand, 5-10 parts of dolomite powder, 10-15 parts of calcium bicarbonate, 1-2 parts of polyethylene wax, 2-4 parts of liquid paraffin, 2-4 parts of castor oil, 1-2 parts of tung oil, 1-2 parts of polydimethylsiloxane, 3-5 parts of dodecyl polyglucoside, 1-2 parts of hydroxypropyl methyl cellulose ether, 10-15 parts of a composite filling material, and 50-70 parts of water. The foam brick has good waterproof antifouling performances, is easy to clean and is suitable for occasions with relatively high waterproof requirement.

Owner:HEFEI KANGLING HEALTH TECH

Preparation method of polishing cloth for polishing and grinding lens of high-precision camera

The invention relates to the technical field of preparation of damping clothes, specifically to a preparation method of a polishing cloth for polishing and grinding a lens of a high-precision camera.The method comprises the following steps: preparing mixed polyurethane slurry; dipping in water; ironing; covering; solidifying; fully washing with water; drying and sizing; coiling; polishing; separating, and the like. According to the method, the raw material components of the mixed polyurethane slurry are reasonable; the added additive is prepared by mixing glycerinum, ethidene diamine and liquid paraffin; glycerinum and ethidene diamine are both chain extenders and can react with a functional group on a polymer chain to extend a molecule chain and increase the molecular weight, thus the polyurethane is promoted to size, and the stress at definite elongation and the wear resistance of the damping cloth can be greatly improved; glycerinum has melting prompting effect and coordinates withthe liquid paraffin to act to reduce the surface tension of the mixed polyurethane sizing, so that the leveling property and the uniformity can be improved, and the surface of the prepared damping cloth is flat, smooth and uniform; the waterproofing and dirt preventing performances of the damping cloth are improved by the liquid paraffin.

Owner:ANHUI HECHEN NEW MATERIAL CO LTD

Rapid leveling ultra-thin grid adhesive tape and preparation method thereof

ActiveCN113969115AIncrease stickinessImprove fitMacromolecular adhesive additivesPressure sensitive film/foil adhesivesAdhesiveSide chain

The invention provides a quick-leveling ultra-thin grid adhesive tape and a preparation method thereof. Acrylic pressure-sensitive adhesive and the tackifying resin are utilized and matched with a unique grid release film, so that the prepared grid adhesive tape can be rapidly leveled and has excellent adhesive property and temperature resistance. Phenyl is introduced into linear polysiloxane with a fluorine-containing group on a side chain to prepare modified fluorosilicone oil, then tackifying resin is modified and then added into the grid adhesive tape, and the temperature resistance and aging resistance of the adhesive tape are greatly improved. The modified tackifying resin is added into the adhesive tape, the molar weight of the added fluorine group and phenyl group is limited, and the wear-resistant protection stability of the adhesive tape is improved, so that the mechanical property and temperature resistance of the prepared adhesive tape are greatly improved because of the unique process design.

Owner:SUZHOU SHIHUA NEW MATERIAL TECH

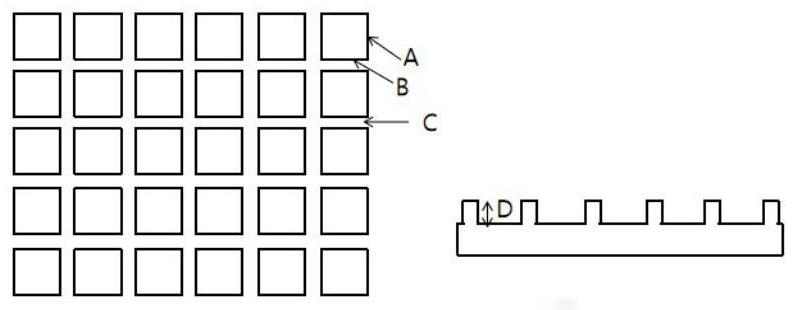

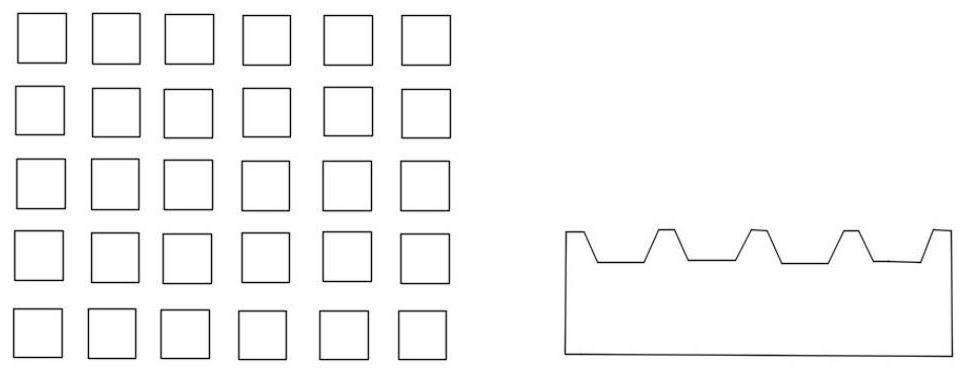

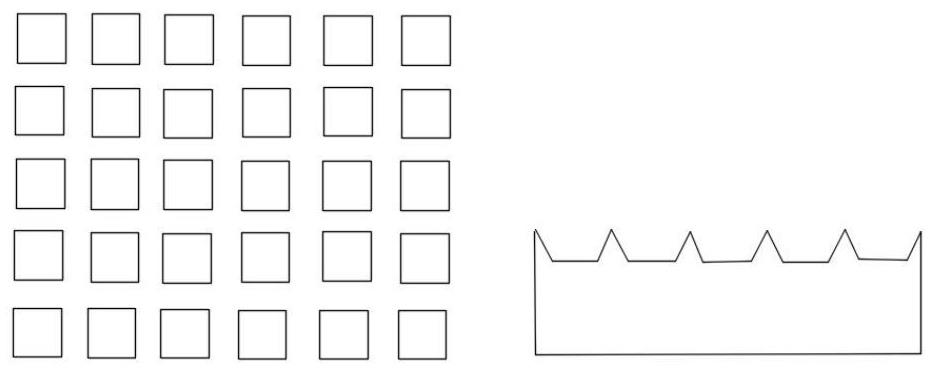

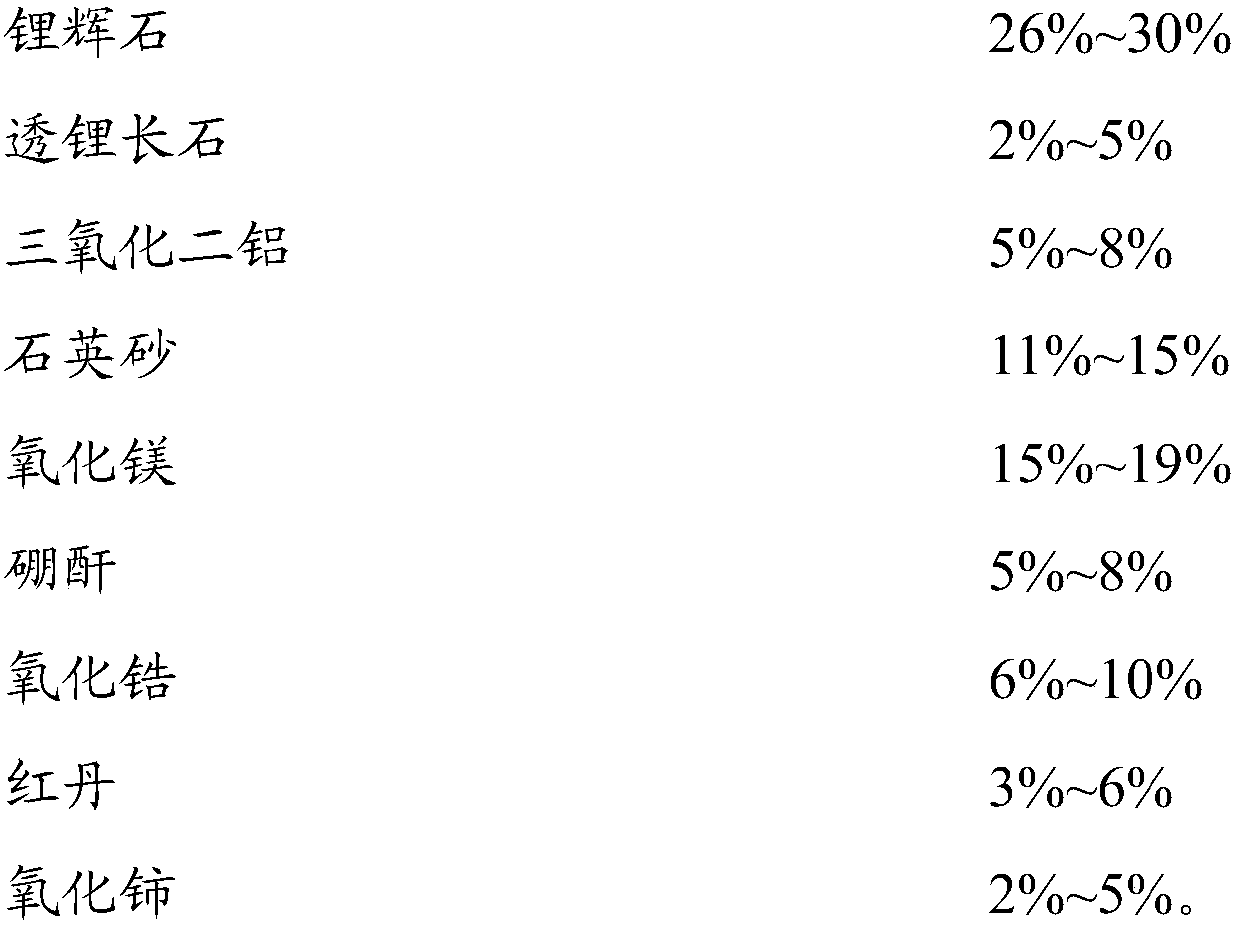

Low-melting-point glass glaze for sealing bottom of low-expansion ceramic liner and preparation method and application of low-melting-point glass glaze

ActiveCN107892482ALow softening temperatureHigh softening temperatureEnvironmental resistanceMaterials science

The invention relates to a low-melting-point glass glaze for sealing the bottom of a low-expansion ceramic liner and a preparation method and application of the low-melting-point glass glaze. The low-melting-point glass glaze is mainly prepared from the following raw materials in percent by mass: 26-30% of spodumene, 2-5% of petalite, 5-8% of aluminum oxide, 11-15% of quartz sand, 15-19% of magnesium oxide, 5-8% of boron anhydride, 6-10% of zirconia, 3-6% of minium and 2-5% of cerium oxide. The glass glaze has the advantages of low softening and solidifying temperatures and a low expansion coefficient which is matched with the expansion requirement of the low-expansion ceramic liner at the same time, so that the requirements of bottom sealing of the low-expansion ceramic liner are met, andthe glass glaze is durable and resistant to ablation, aging, detaching, melting and the like which are caused by high temperatures brought by various heating methods; in addition, no dissolved matteris generated during the application of the glass glaze, and the glass glaze has high applicability, brighter appearance and good waterproof and antifouling performance, and is healthier and more environmentally friendly, so that the problems that during the application of an organic coating and a water repellent agent, peeling off or generating of dissolved toxic matter occurs, and the organic coating and the water repellent agent cannot be cured simultaneously with decals and stuck water level lines are solved, and the production efficiency is improved.

Owner:湖南嘉盛电陶新材料股份有限公司

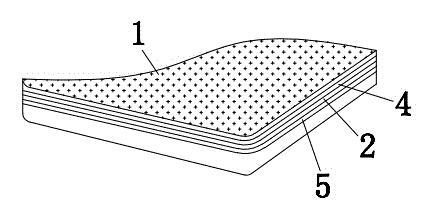

Vibration absorption material, mattress and preparation method of mattress

InactiveCN104610559ASuitable for anti-vibrationSuitable for cushioningStuffed mattressesSpring mattressesPolymer sciencePtru catalyst

The invention relates to a vibration absorptive material. The vibration absorptive material comprises a basic layer, wherein a coating is formed on the surface of the basic layer, and the coating material is an organic silicon coating or a polyurethane coating. The organic silicon coating comprises the following components in parts by mass: 65-130 parts of organic silicon, 0-7 parts of a solvent, 0-16 parts of a curing agent, 0-12 parts of a catalyst, and 0-12 parts of a film forming agent. The polyurethane coating comprises the following components in parts by weight: 65-130 parts of polyurethane, 0-7 parts of a solvent, 0-16 parts of a curing agent, 0-12 parts of a catalyst, and 0-12 parts of a film forming agent.

Owner:TAICANG ALL MATS PLASTIC IND

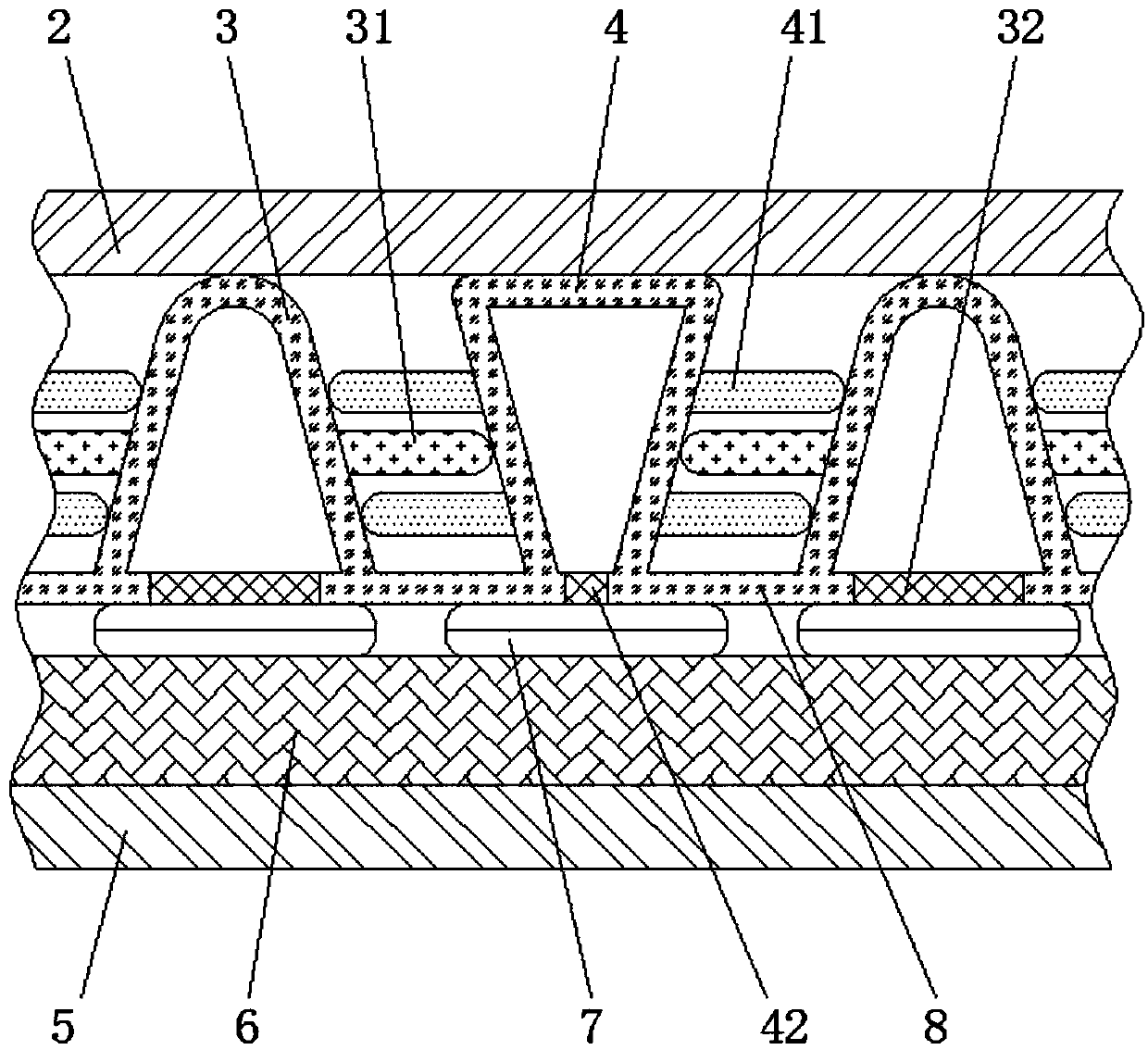

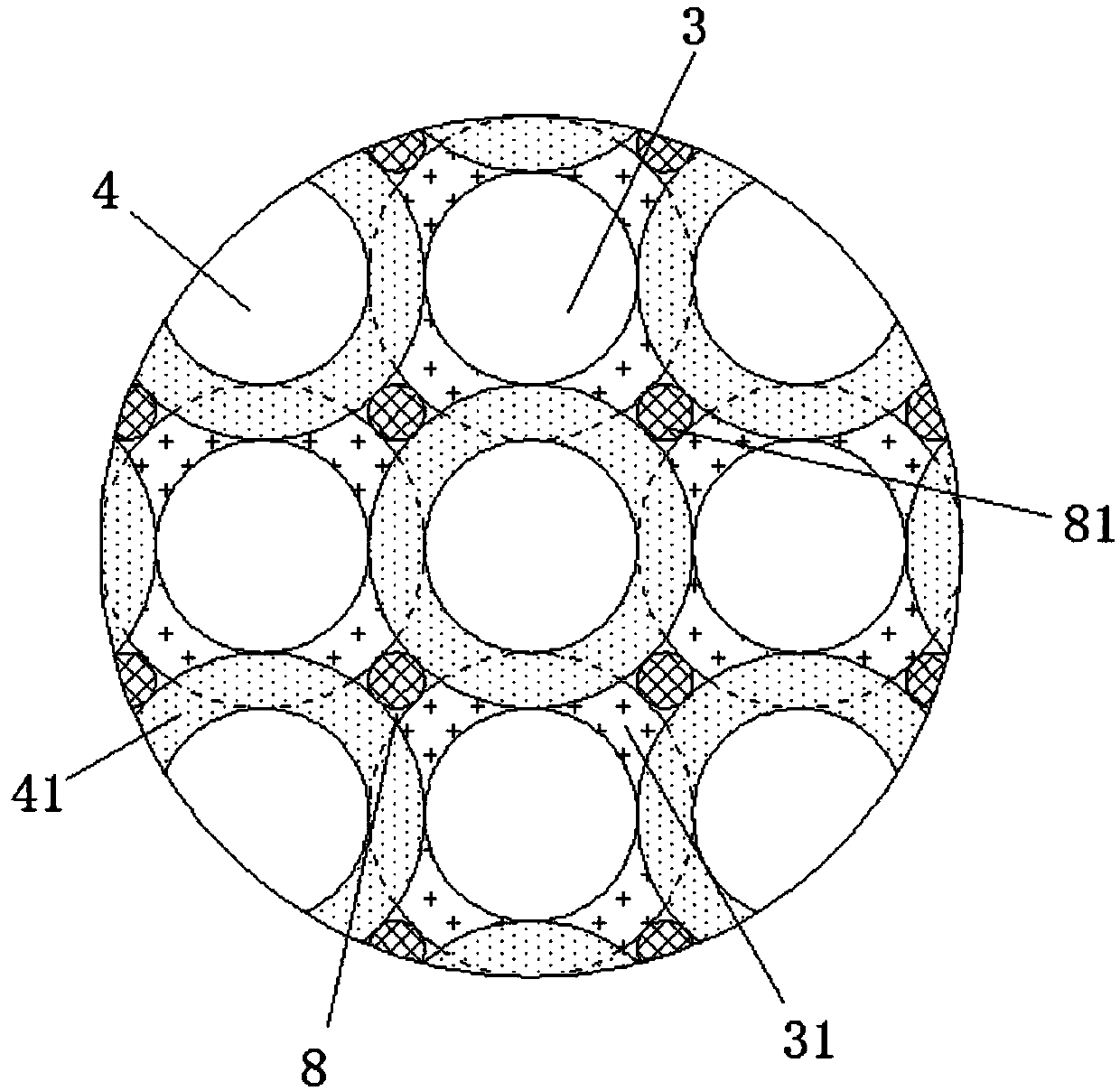

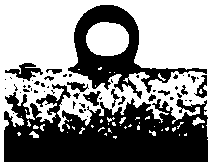

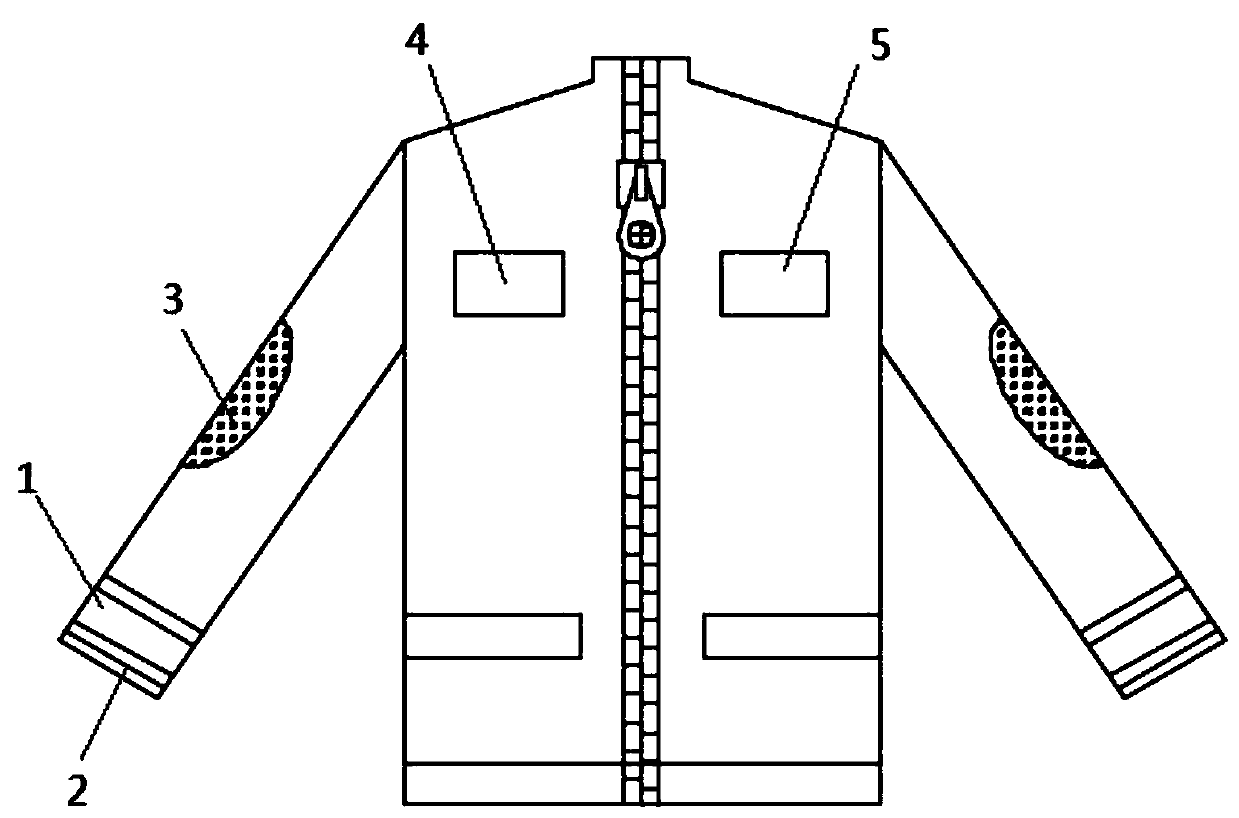

Garment comprising protective element and manufacturing method thereof

ActiveCN109662358AHigh strengthIncrease elasticityGarment special featuresSynthetic resin layered productsProtection mechanismEngineering

The invention discloses a garment comprising a protective element and a manufacturing method thereof, and belongs to the field of garments. The garment comprises a garment body, wherein the garment body comprises outer cloth, a protective mechanism, inner cloth and polypropylene plastic foaming elastic foam cotton, one side of the inner layer cloth is sewn with the polypropylene plastic foaming elastic foam cotton, the edge position of the outer layer cloth and polypropylene plastic foaming elastic foam cotton is sewn and fixed, and a protection mechanism is fixed between the outer layer clothand the polypropylene plastic foaming elastic foam cotton. The garment can effectively prevent water and dirt, ventilates and keeps warm, has certain wear resistance and elasticity, protects a humanbody at the moment of being impacted by external force, effectively slows down the action of impact forces at different angles on a single part, reduces the damage to the human body of a user during outdoor exercise and increases the protection property of the garment body.

Owner:ANHUI POLYTECHNIC UNIV

Synthesizing method for acrylate copolymers with hydrophobicity

ActiveCN109134741AEfficient removalAvoid the disadvantage of low polymerization conversion rateEmulsionSeparation technology

The invention discloses a synthesizing method for acrylate copolymers with hydrophobicity. A small amount of compound emulgator and co-stabilizer is used for making acrylate monomers form uniform andstable miniemulsion. A miniemulsion polymerization method is adopted for obtaining acrylate copolymer emulsion, and after polymerization is finished, through a separation technology of demulsificationcohesion and many-time dissolution-sediment circulating operation, the acrylate copolymer with hydrophobicity is obtained. No obvious emulgator residues are contained in the obtained copolymer, the purity and hydrophobicity performance of the acrylate copolymers with hydrophobicity are improved, the using amount of fluorine-containing monomers is reduced, and the cost is reduced; a polymerizationsite of miniemulsion polymerization is oily monomer drops, it is avoided that in the conventional emulsion polymerization process, acrylate monomers need to be diffused to solubilizing micelles through an aqueous phase, the polymerization conversion rate of the fluorine-containing acrylate monomers with hydrophobicity is effectively improved, the discharging amount of fluorine-containing monomersis reduced, and environmental pollution is reduced. The synthesizing method has a good application prospect in the field of water-proof antifouling paint.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Anti-ultraviolet coating

InactiveCN107141993AImprove waterproof and antifouling performanceFireproof paintsAntifouling/underwater paintsAcrylic resinUltraviolet

The invention relates to an anti-ultraviolet coating. The coating comprises anti-hollow glass microspheres, water glass, polyurethane copolymers, acrylic resins, butyl acetate, graphene, ethyl cellulose and sodium tetraborate; the coating is prepared from, by weight, 10-20 parts of anti-hollow glass microspheres, 20-30 parts of water glass, 20-30 parts of polyurethane copolymer, 10-15 parts of acrylic resin, 15-20 parts of butyl acetate, 5-8 parts of graphene, 15-20 parts of ethyl cellulose and 10-18 parts of sodium tetraborate. The anti-ultraviolet coating has the advantages of being good in water-proof and fouling-proof properties and ultraviolet-proof.

Owner:周淑华

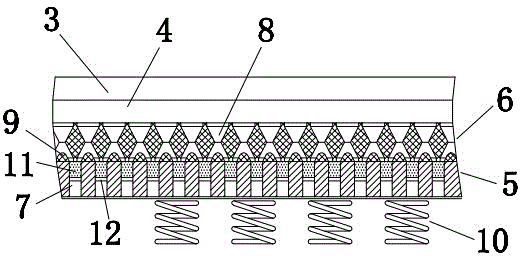

Mattress with purification function

ActiveCN104856501AImprove waterproof and antifouling performanceEffective filteringStuffed mattressesSpring mattressesEngineeringCotton cloth

The invention discloses a mattress with a purification function. The mattress comprises a waterproof layer and a cushion core, and is characterized by further comprising a board arranged below the cushion core; the waterproof layer comprises cotton cloth and a PTFE film attached to the cotton cloth; the cushion core is made of a whole piece of silicone or latex; hourglass-shaped exhaust holes are intensively distributed in the surface of the silicone mat; hemispherical sealing bulges are arranged in lower holes of the exhaust holes; the spherical radius (SR) of each sealing bulge is larger than the size of a neck of each exhaust hole; the board is arranged below the silicone mat; a plurality of air holes are formed in the surface of the board, are communicated with the exhaust holes, and aliged to the lower holes of the exhaust holes in a crossed manner; a plurality of groups of springs are arranged below the board. Poisonous substances in the mattress can be easily discharged through the exhaust holes under the pressure of a human body or appropriate external force, and can be prevented from storage for a long time, so that damage of the poisonous substances to the human health is effectively reduced.

Owner:罗继兵

Ultraviolet-proof fiber coating

InactiveCN105331283AGood waterproof and antifouling performanceImprove waterproof and antifouling performanceRubber derivative coatingsAntifouling/underwater paintsFiber coatingPolyvinyl alcohol

The invention relates to an ultraviolet-proof fiber coating. The ultraviolet-proof fiber coating comprises raw materials by weight as follows: 70-90 parts of organic silicon resin, 20-30 parts of a cellulose polymer, 10-15 parts of short fibers, 20-35 parts of chlorinated rubber, 25-40 parts of aluminum silicate fiber, 10-30 parts of acidized graphite, 20-25 parts of polyvinyl alcohol and 30-70 parts of ultraviolet-proof dimethylsilicone fluid. The ultraviolet-proof fiber coating has the characteristics of good waterproof and antifouling properties and ultraviolet proofing.

Owner:YIZHENG YILI GEOSYNTHETICS

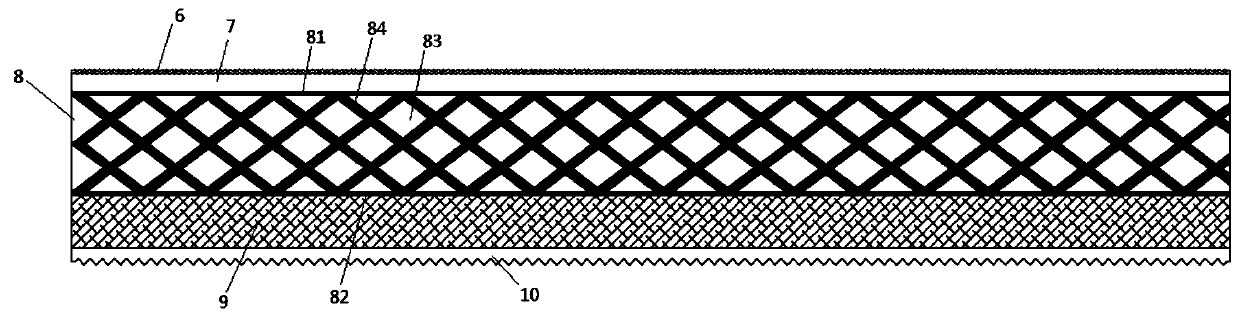

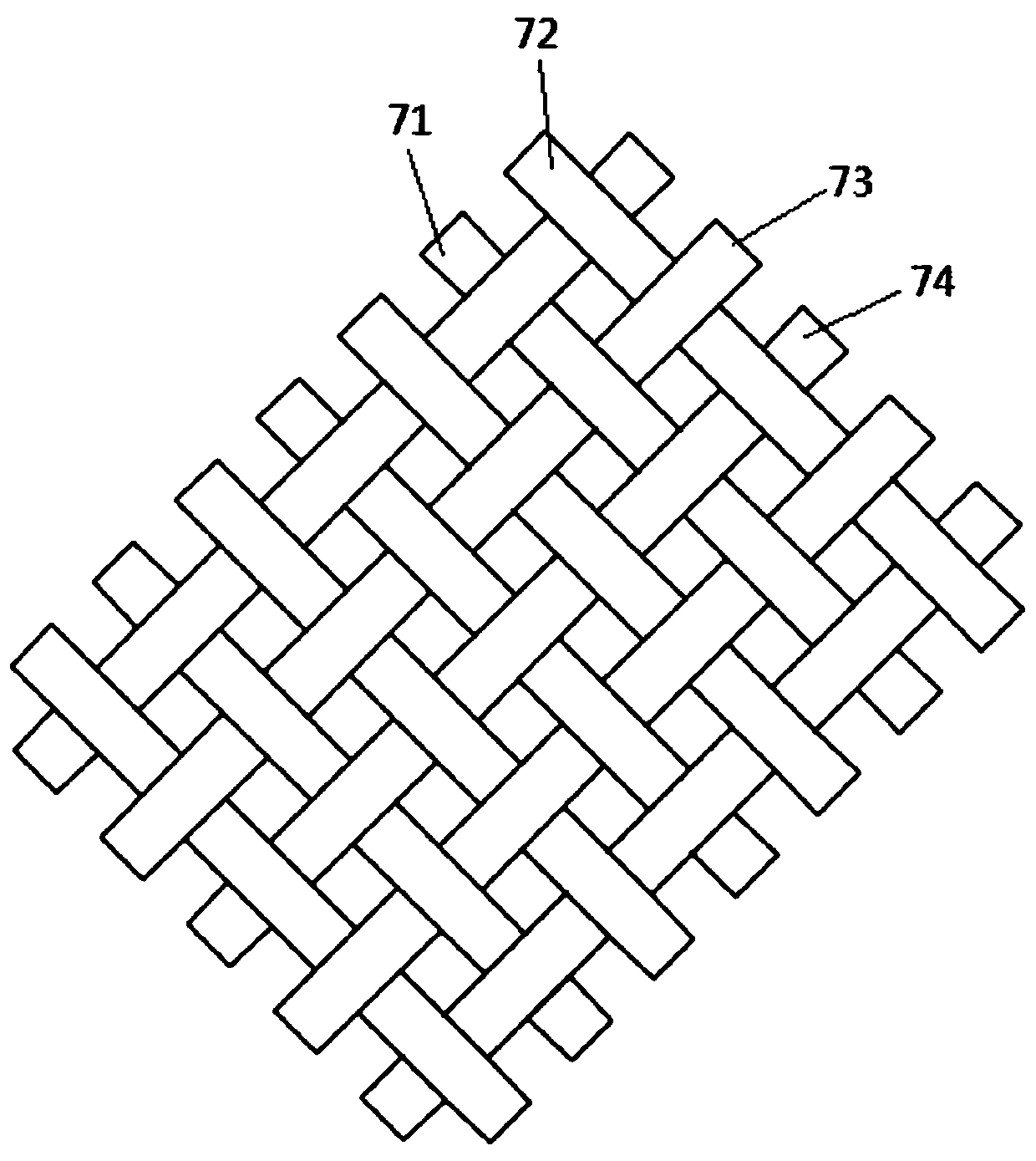

Wear-resistant and cold-proof school uniform

InactiveCN110859340AStrong tensile ductilityImprove insulation effectLayered productsClothingsPhysical chemistryEngineering

The invention discloses a wear-resistant and cold-proof school uniform. The wear-resistant and cold-proof school uniform comprises reflective strips, wear-resistant edges, elbow and knee wear-resistant blocks, a student information card, a school badge, a waterproof layer, a woven mesh layer, a heat preservation air cushion layer, a cotton cloth layer, a flannelette layer and wear-resistant pads.Wherein the elbow and knee wear-resistant blocks are arranged at the elbow joint parts of sleeves of the school uniform; a school uniform fabric is composed of the waterproof layer, the woven mesh layer, the heat preservation air cushion layer, the cotton cloth layer and the flannelette layer, and the wear-resistant pads are arranged on the surface of the fabric at the elbow and knee wear-resistant blocks; the heat preservation air cushion layer is located in a middle layer of the school uniform fabric; and the heat preservation air cushion layer is composed of a top rubber layer, a bottom rubber layer, an isolation rubber net and heat preservation air bags, the isolation rubber net is arranged between the top rubber layer and the bottom rubber layer, and the isolation rubber net divides aspace between the top rubber layer and the bottom rubber layer into the multiple heat preservation air bags. The wear-resistant and cold-proof school uniform has the characteristics that the tensileductility is strong, the heat preservation effect is good, the light reflection angle is increased, the travel safety of students is ensured, easily-consumable parts are wear-resistant and durable, and the waterproof and anti-fouling effects are good.

Owner:凤台县画锦服装有限公司

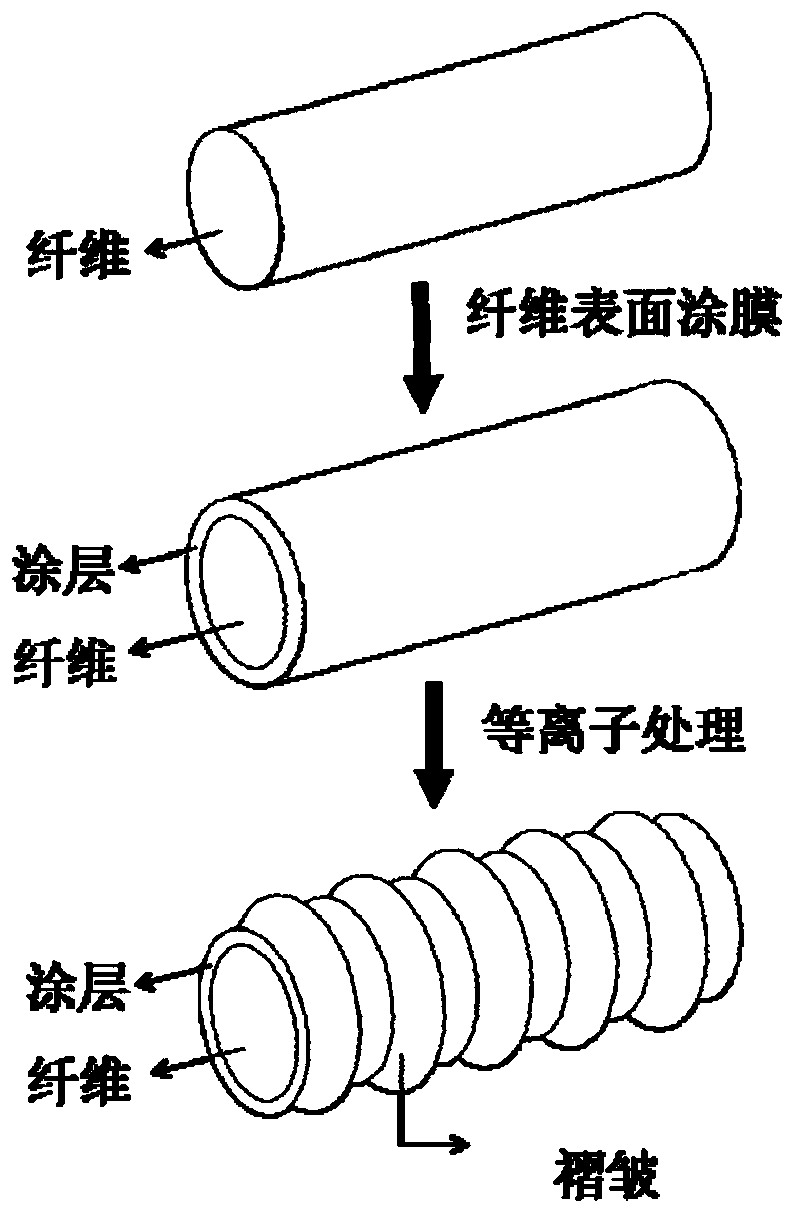

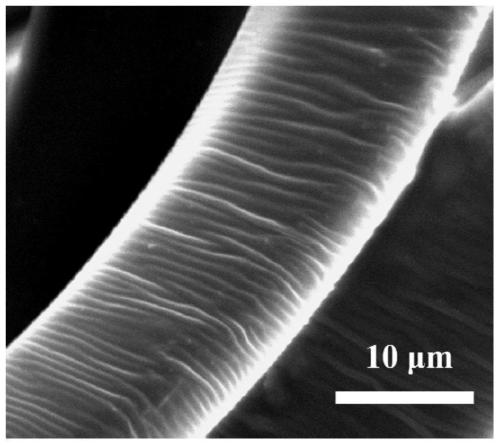

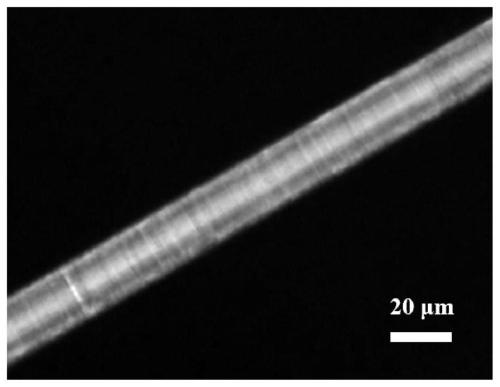

Surface wrinkled fiber type material and preparing method thereof

ActiveCN111501325AImprove performanceImprove waterproof and antifouling performanceStain/soil resistant fibresPhysical treatmentPolymer scienceFiber type

The invention relates to a surface wrinkled fiber type material and a preparing method thereof. The method comprises the steps that firstly, coating liquid made of resin and a diluent is prepared; secondly, a material is soaked in the coating liquid and then is taken out to be dried; and a material with the surface coated with a coating is obtained; and thirdly, the material with the surface coated with the coating is subjected to plasma treatment to obtain a surface wrinkled material. A fiber with the wrinkled surface is composed of a fiber base body and the resin coating liquid coating whichcoats the surface of the fiber base body, a wrinkled structure is annularly mounted on the fiber surface in the length direction of the fiber, the contact angle between the surface wrinkled fiber fabric made of the fiber and the water is larger than 150 degrees, the rolling angle is smaller than 10 degrees, the surface wrinkled fiber fabric has super-hydrophobicity, according to the method, the material waterproof and antifouling property can be improved, and the surface wrinkled fiber type material has the wide application prospect in the fields of functional garments, outdoor supplies, military protection garments, photoelectricity and the like.

Owner:DONGHUA UNIV

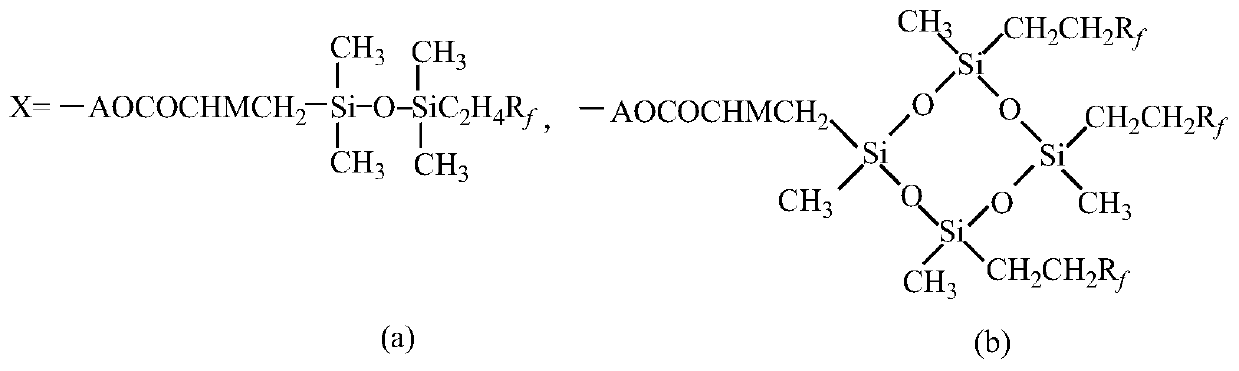

A kind of fluorinated polyether siloxane compound, its preparation method and coating composition

ActiveCN103739814BImprove wear resistanceImprove waterproof and antifouling performanceAntifouling/underwater paintsPaints with biocidesPolymer scienceReagent

The invention relates to a fluorinated polyether siloxane compound, a preparation method and a coating composition thereof. The fluorinated polyether siloxane compound can be represented by the following formula shown as the specification, and can be used for forming transparent materials including glass, lenses, electronic product displays and the like, and an antifouling, waterproof, chemical-reagent-resisting and abrasion-resisting transparent protective coating on a textile material.

Owner:塔威新材料科技(上海)有限公司

Packaging paper as well as preparation method and use method thereof

The invention belongs to the technical field of packaging paper, and discloses packaging paper as well as a preparation method and a use method thereof, the packaging paper comprises a base material layer, an aromatic insect expelling layer, a waterproof breathable layer and a water-soluble sealing layer which are sequentially distributed from inside to outside; wherein the aromatic insect-repelling layer is prepared from the following components in parts by mass: 40 to 80 parts of water-based film-forming resin emulsion, 10 to 15 parts of aromatic insect-repelling powder, 15 to 20 parts of water and 5 to 20 parts of auxiliaries; the aromatic insect expelling powder comprises wormwood, camphor tree foam, alfalfa and lavender in a mass part ratio of (2-8): (1-4): 1: (1-2); the waterproof breathable layer is formed by stacking and pressing nanofibers; the water-soluble sealing layer is formed by coating and curing a hydrogel solution; in conclusion, on the basis of the arrangement of the aromatic insect repelling layer, the prepared packaging paper can volatilize to form a smell with fragrance and an insect repelling effect, so that the packaging paper has a good fragrance effect and an insect repelling effect.

Owner:何国庆

Clothes aroma-enhancing antibacterial agent as well as preparation method and application thereof

InactiveCN108402054AEasy to makeStrong adhesionBiocideStain/soil resistant fibresStearic acidAntibacterial agent

The invention relates to the field of clothes care agents, in particular to a clothes aromatizing antibacterial agent as well as a preparation method and application thereof. The clothes aromatizing antibacterial agent comprises a waterproof microcapsule and a functional medicine agent, wherein the functional medicine agent is adsorbed to the surface or interior of the waterproof microcapsule; thefunctional medicine agent is prepared from a bacteria inhibiting agent and essence; the waterproof microcapsule is mainly prepared from the following components in parts by weight: 6 to 14 parts of methyl sodium silicate, 5 to 11 parts of paraffin, 2 to 8 parts of rosin, 3 to 7 parts of stearic acid, 1 to 5 parts of aluminum sulfate, 0.5 to 3.5 parts of acetic acid, 0.5 to 3.5 parts of calcium oxide, 0.5 to 3.5 parts of sodium hydroxide, and 0.5 to 3.5 parts of 4-chloro-3-methylphenol. The clothes aromatizing antibacterial agent has the advantages that the preparation is simple, and the preparation technology can be completed at normal temperature; the washing-resistant ability is realized, the adhesion force of the microcapsule is strong, and the aroma can be maintained for a longer time.

Owner:佛山市顺德区智域服装设计有限公司

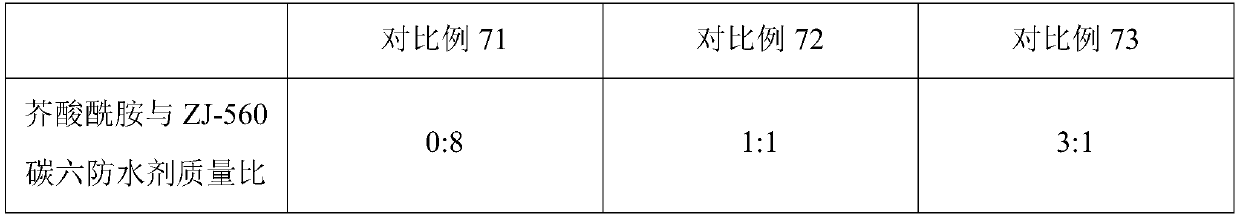

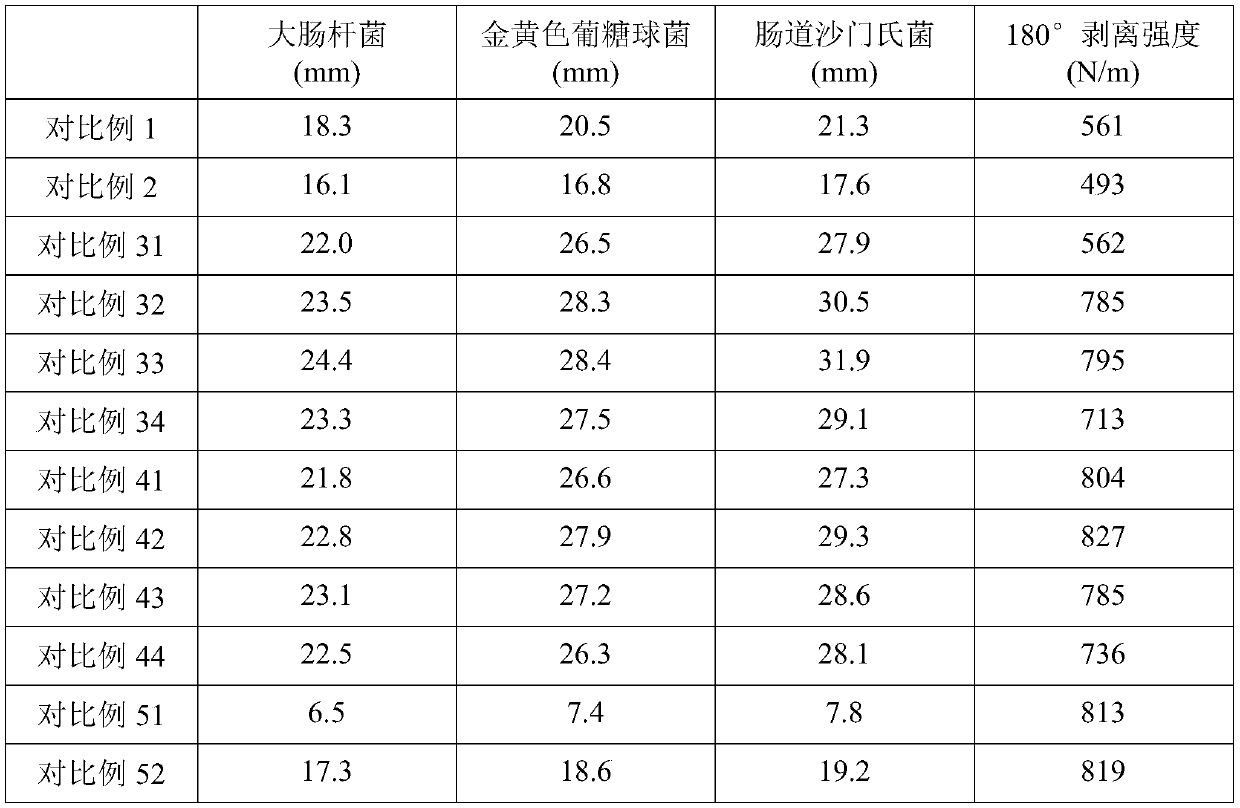

Environment-friendly coating, preparation method and application

InactiveCN114108368AIncrease stickinessReduced strippabilityWater-repelling agents additionPaper coatingEnvironmentally friendlyEnvironmental geology

The invention provides an environment-friendly coating as well as a preparation method and application thereof, and relates to the technical field of coatings. The coating comprises the following raw materials in parts by weight: 8-10 parts of potato starch, 5-7 parts of polyurethane, 2-4 parts of acrylic acid and 1-3 parts of chitosan. The polyurethane is used as a framework, so that the coating has better chemical resistance, aging resistance and toughness; potato starch is used as a composite raw material to improve the viscosity of the coating; chitosan is used for chain extension, so that the toughness of the coating is further improved, and meanwhile, the antibacterial and mildew-proof properties of the coating are enhanced; and acrylic acid is used as a linking substance to enhance the interaction among the raw materials. According to the preparation method of the coating, toxic and harmful substances are not generated in the preparation process, and the environment friendliness is high. When the coating is applied to corrugated packaging paper, the waterproof and antifouling performance can be improved, and the coating is ecological, environmentally friendly and convenient to recycle.

Owner:詹美

Hydrophobic coating for power transformation equipment and preparation method thereof

ActiveCN106519852AImprove hydrophobicityLower surface energyAntifouling/underwater paintsPaints with biocidesPhosphatePower equipment

The invention provides a hydrophobic coating for power transformation equipment and a preparation method thereof and belongs to the technical field of hydrophobic materials and a preparation method thereof. The hydrophobic coating for power transformation equipment is prepared from 50 to 70 parts by weight of methyltriethoxysilane, 20 to 40 parts by weight of a phosphate-modified acrylic emulsion, 10 to 18 parts by weight of a solvent, 5 to 12 parts by weight of a filler, 3 to 9 parts by weight of a dispersant and 5 to 12 parts by weight of a film-forming agent. The methyltriethoxysilane and the phosphate-modified acrylic emulsion as main raw materials are processed to form the hydrophobic coating with good hydrophobic performances by a sol-gel method. The surface energy of the hydrophobic coating is low, a static contact angle of a water droplet on the surface of the hydrophobic coating is 160 degrees or more, water resistance is good, the layering, shedding or blistering phenomenon after long-term use is avoided, and acid and alkali resistance is good. The hydrophobic coating is suitable as hydrophobic paint of electrical equipment and improves the waterproof and antifouling performances of the electrical equipment.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

Method for producing structure body having super-hydrophobic surface

InactiveCN111218153AIncrease roughnessImprove wear resistanceFireproof paintsAntifouling/underwater paintsNano sio2Prepolymer

The invention provides a method for producing a structure body having a super-hydrophobic surface, and belongs to the technical field of materials. The preparation method comprises the following steps: preparing modified nano SiO2 particles and SiO2 alcosol by taking nano SiO2 particles as a raw material; and preparing a prepolymer solution from the modified nano SiO2 particles and the SiO2 alcosol, coating a clean matrix structure with the prepolymer solution, and curing the prepolymer solution on the matrix structure to form a structure body with a stable super-hydrophobic surface, wherein the super-hydrophobic surface exhibits a contact angle of not less than 158 degrees and a rolling angle of less than 5 degrees. According to the preparation method provided by the invention, the roughstructure and the roughness of the super-hydrophobic surface can be increased, the water contact angle is increased, the rolling angle and the viscous force to water are reduced, the wear resistance,the durability and the high-temperature stability are improved, and the ultraviolet aging resistance is enhanced, so that the contact angle loss rate under ultraviolet weathering is reduced, the service life is prolonged, and the waterproof and antifouling effects are enhanced.

Owner:李岩康

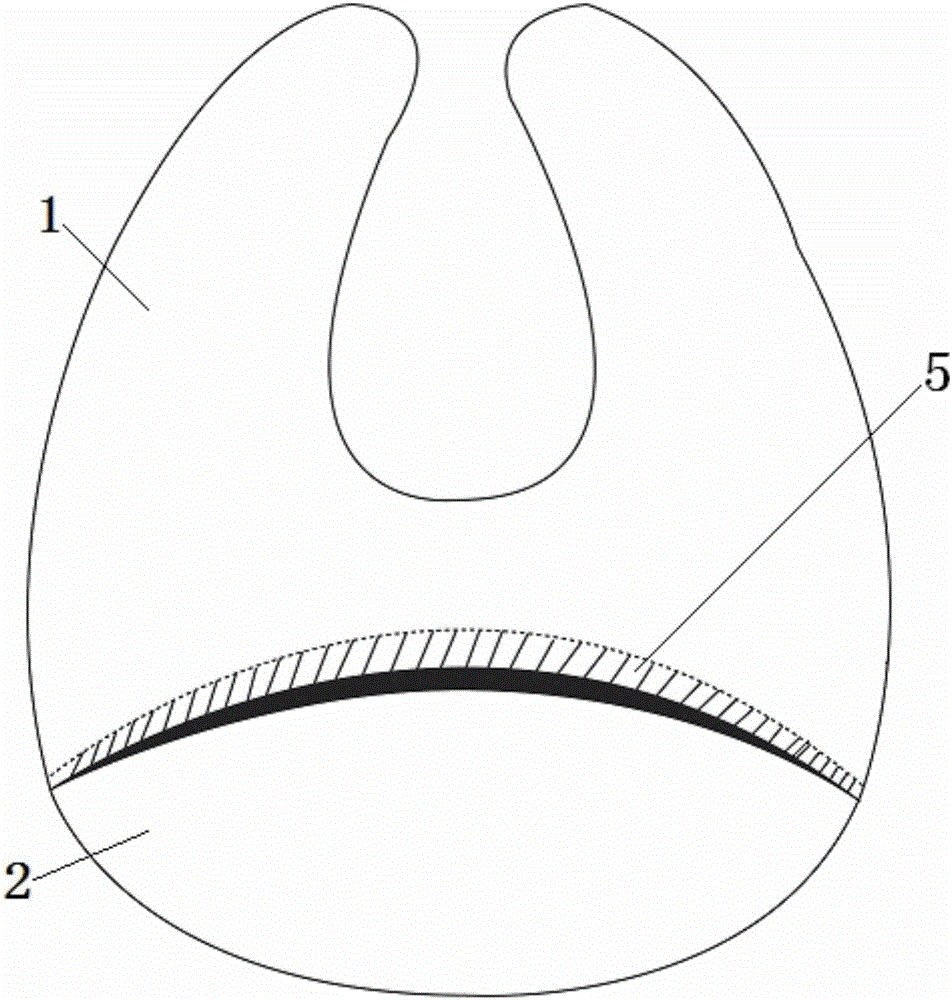

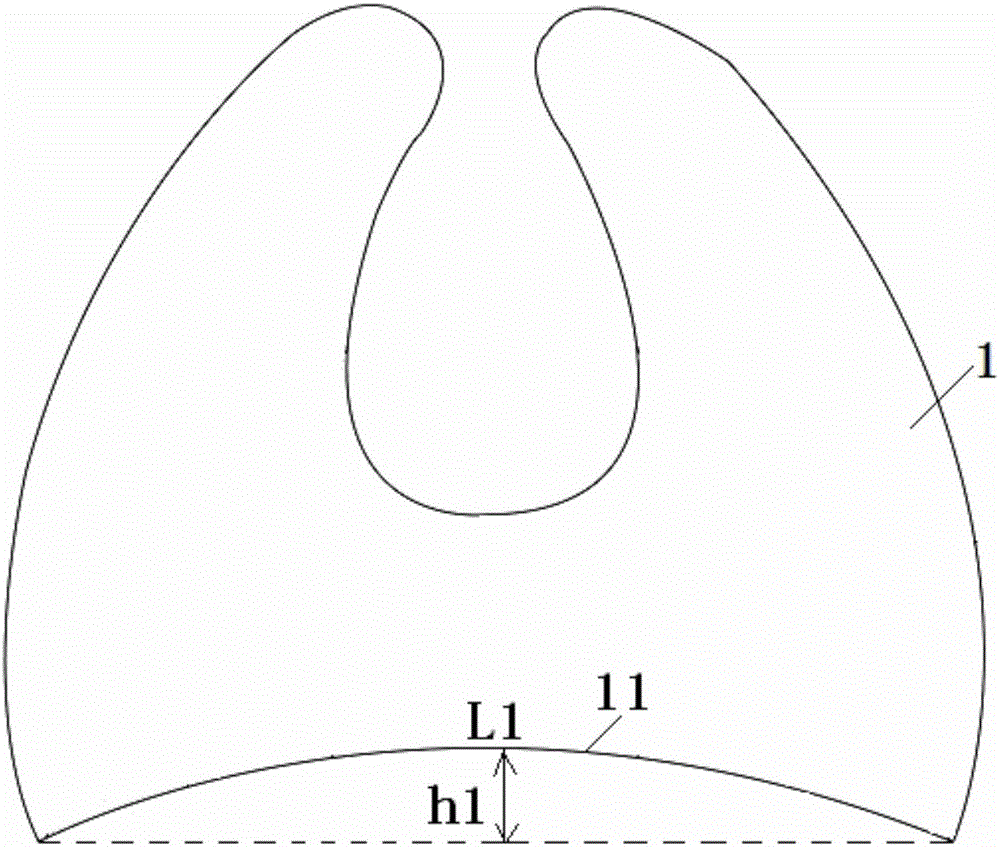

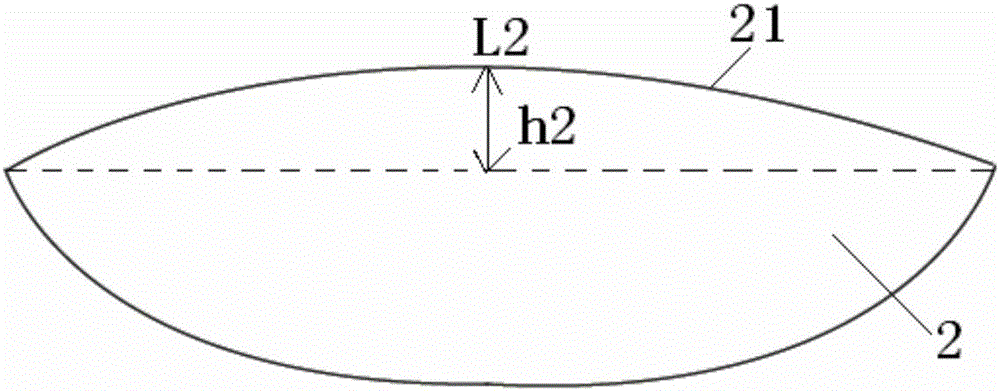

Bib with three-dimensional outwards-convex face and making technology thereof

ActiveCN105901786AAvoid Airtight DefectsGuaranteed cleanlinessHandkerchiefsBaby linensMaterials scienceContour line

Owner:SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com