Photo-curing POSS (polyhedral oligomeric silsesquioxane)/fluoroalkyl siloxane modified polyacrylate coating composition and application thereof

A technology of fluorocarbon-based siloxane and hydrocarbon-based siloxane, which is applied in the field of light-curing POSS/fluorocarbon-based siloxane modified polyacrylate coating compositions, and can solve the problems of unsatisfactory antifouling performance, low adhesion, Problems such as poor coating hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Synthesis of polymerizable reactive fluorocarbon-based siloxane-modified acrylate monomer (FS)

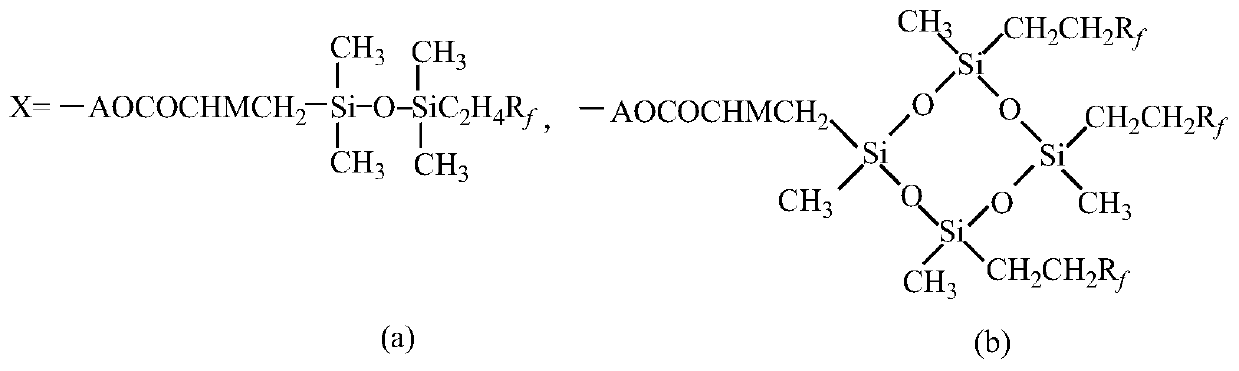

[0037] In a three-necked flask equipped with a thermometer, a reflux condenser, and a stirrer, add 0.01-0.031mol of perfluoroalkylethylene (ViR f ), 200ppm platinum catalyst KP22, stirring and heating to 80°C for coordination reaction for 60min, then adding 0.01mol hydrogen-containing siloxane oligomer DH and stirring for 20min, then adding 0.01mol double-ended diacrylate and controlling the temperature Stir continuously at 80-100°C for 8 hours. After the reaction is over, decompress and remove the low boiling point. The product obtained, that is, a polymerizable reactive fluorocarbon-based siloxane-modified acrylate monomer with the structure shown in formula (1), is denoted as FS. See Table 1 for details of the raw materials and amounts used in the synthesis of FS in each embodiment.

[0038] Table 1 Synthetic raw materials and dosage of polymerizable reactive fluoro...

Embodiment 2

[0046] (1) Synthesis of polymerizable reactive fluorocarbon-based siloxane-modified acrylate monomer FS-2

[0047] The synthesis method and raw material consumption are shown in Table 1, and the structure of the product FS-2 is shown in formula (1), where M=H, X=(1)(a), y=2, A=-(CH 2 ) 2 -, R f =C 6 f 13 .

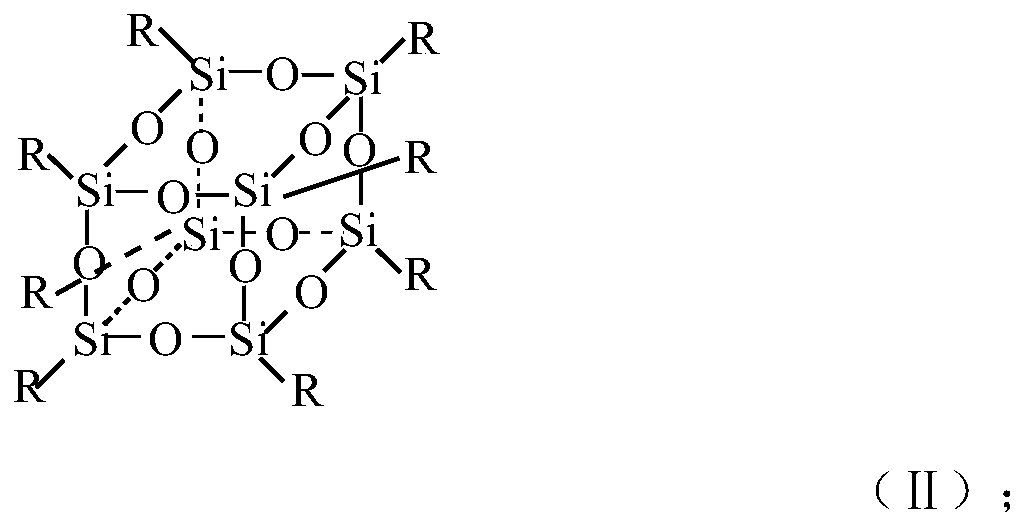

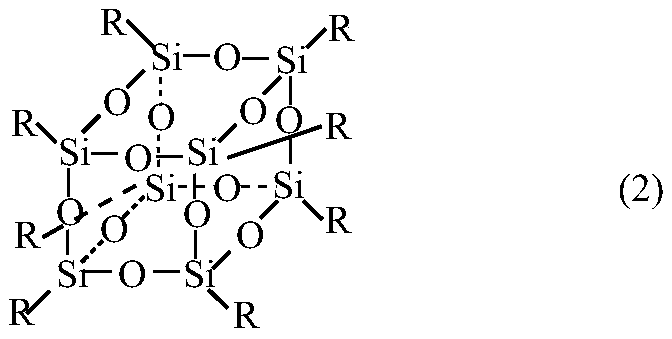

[0048] (2) Preparation of prepolymer POSS-PA-2

[0049] In a 100mL three-necked flask equipped with a reflux condenser, a thermometer, and a stirrer, successively weigh 10g of MMA, 0.5g of the structure as shown in formula (2) R=-C 3 h 6 OOCCH=CH 2 Octacryloxypropyl POSS(T 8 -POSS-2) and with MMA+T8 -POSS-2 total mass of 1%, about 0.11g free radical initiator BPO, stir and mix, then heat up to 50°C for prepolymerization for 60min, the viscosity of the system is about 130mPa.s, then cool to room temperature 30°C About 10.5g of transparent viscous liquid was obtained in total, that is, prepolymer POSS-PA-2.

[0050] (3) Light-curing POSS / fluorocarbon-based siloxane...

Embodiment 3

[0053] (1) Synthesis of polymerizable reactive fluorocarbon-based siloxane-modified acrylate monomer FS-3

[0054] The synthesis method and raw material consumption are shown in Table 1, and the structure of FS-3 is shown in formula (1), where M=CH 3 , X=(1)(b), b=7, A=-(OC 3 h 6 ) 7 -, R f =C 6 f 13 .

[0055] (2) Preparation of prepolymer POSS-PA-3

[0056] In a 100mL three-necked flask equipped with a reflux condenser, a thermometer, and a stirrer, weigh 10g of MMA and 1.5g of MMA in sequence according to the mass ratio. 2 Octavinyl POSS(T 8 -POSS-3), stirring, heating to dissolve octavinyl POSS in MMA to form a transparent solution, and then add MMA+T 8 -POSS-3 total mass of 0.5% is about 0.06g free radical initiator AIBME, stir and mix well, then heat up to 60°C to react for 40min, the viscosity of the system is about 390mPa.s, and then cool to room temperature about 30°C to obtain The total amount is about 11.5g transparent viscous liquid, that is, the prepolym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com