Patents

Literature

250results about How to "Improve basic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High speed processing method for realizing superfine crystal grain structure on metallic material surface

The invention relates to a method for processing the high-speed deformation on the surface of metallic material with nano structure, and particularly provides a method for realizing high-speed processing of the organization structure of ultra-fine grains. On the condition of room temperature or low temperature, by adopting a mechanical treatment method with high-speed plastic deformation, the nanoscale bulky crystalline grain structure on the surface layer of the metallic material is refined as equiaxial submicron crystalline grain or nano crystalline grain to form an ultra-fine organization structure of the crystalline grain on the surface layer of the metallic material. With the increase of the depth to the processing surface, the size of microstructure has the change of gradient, increasing from nanoscale and submicron size to micron size. Compared with the existing processing method for forming a surface ultra-fine crystalline grain structure, the high-speed processing method of the invention greatly reduces the roughness of the surface of the processed metallic material and increases the thickness of a deformation layer, and has simple processing method and high working efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

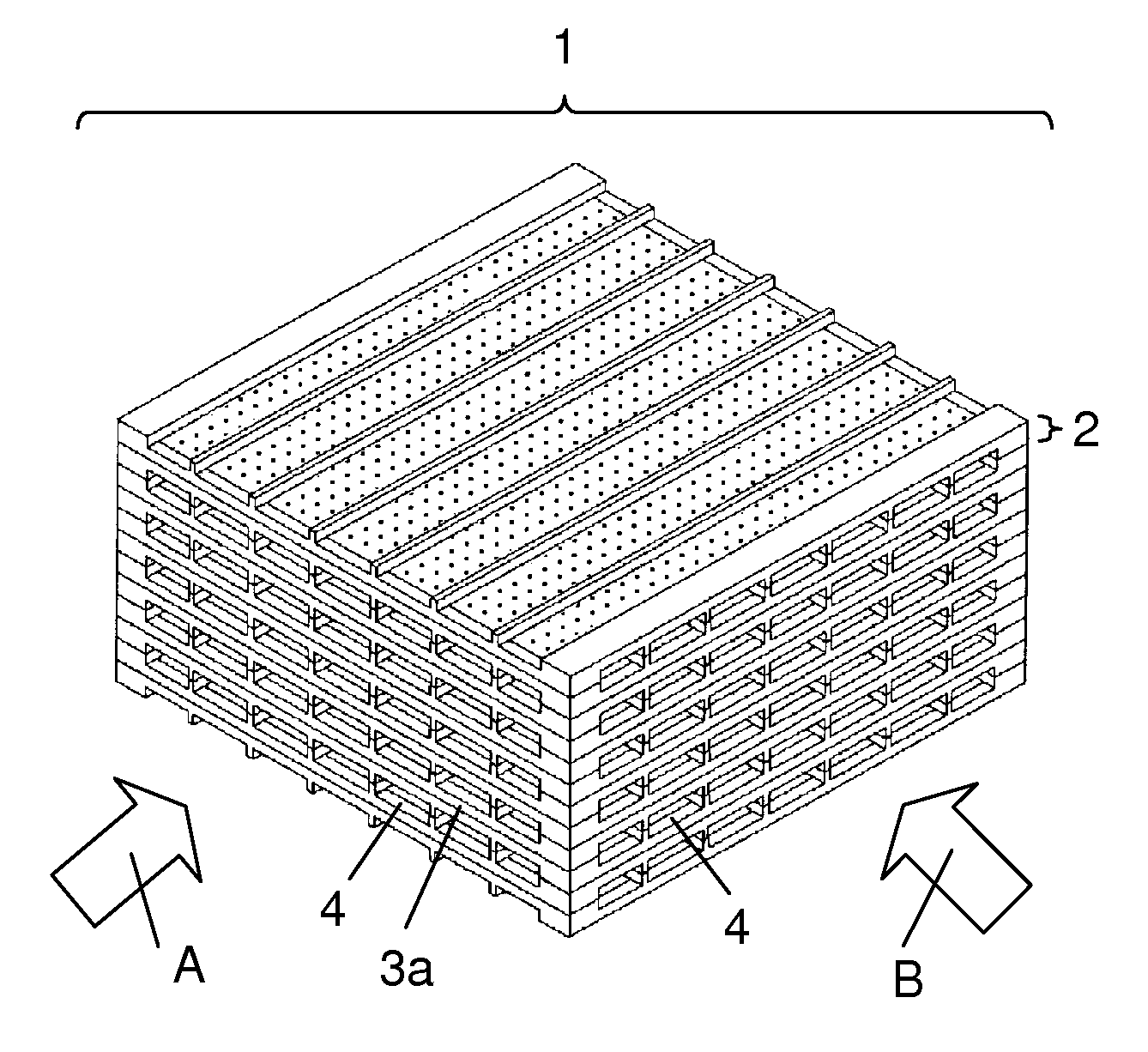

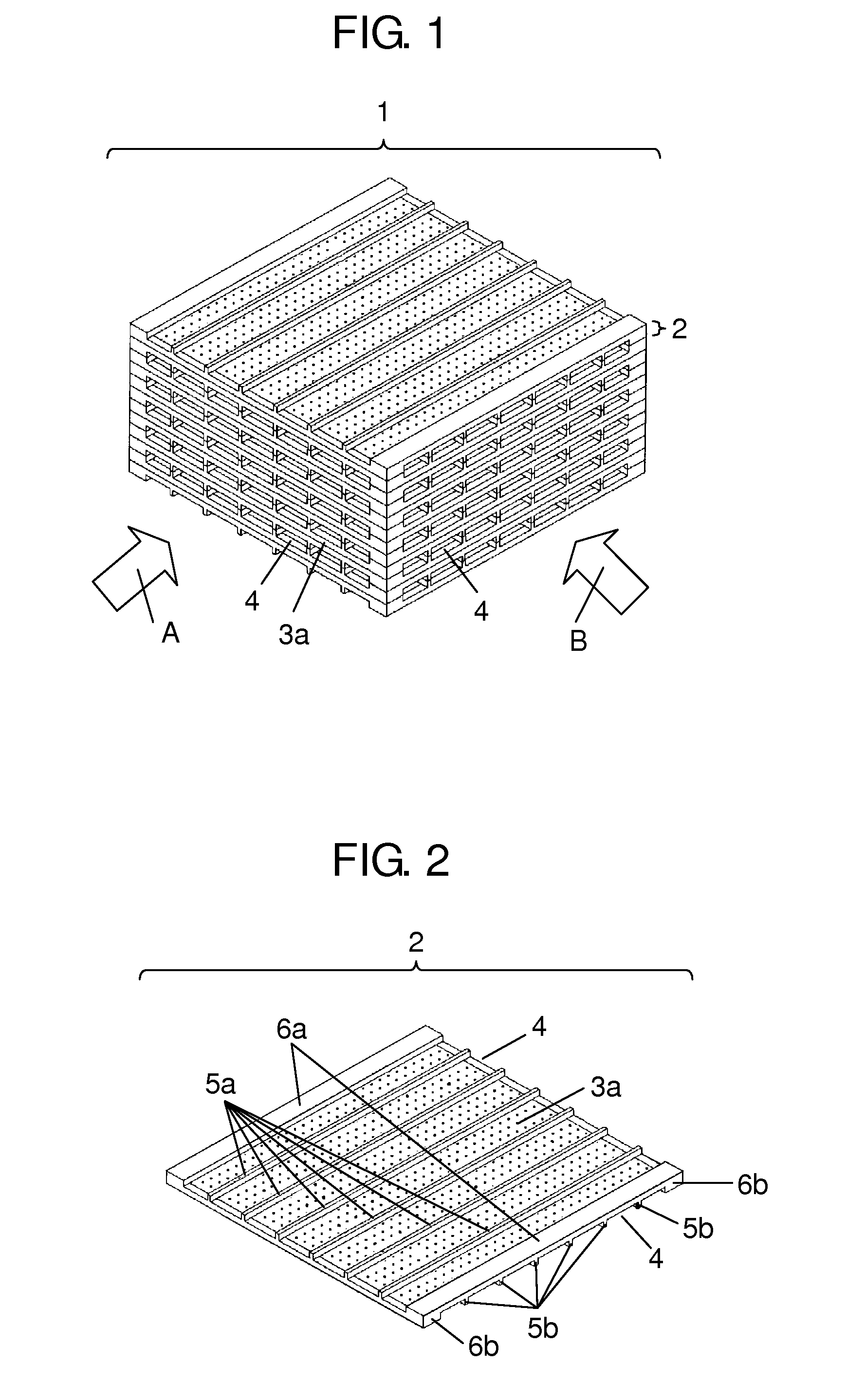

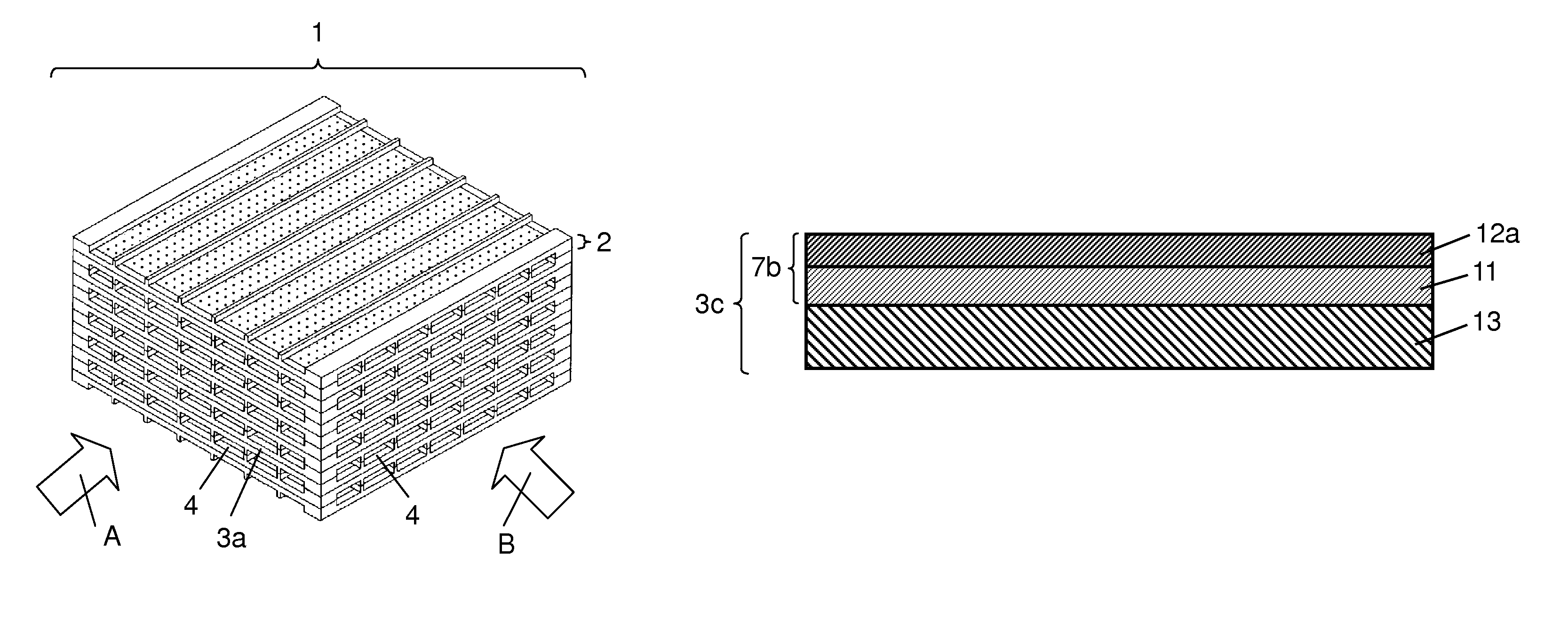

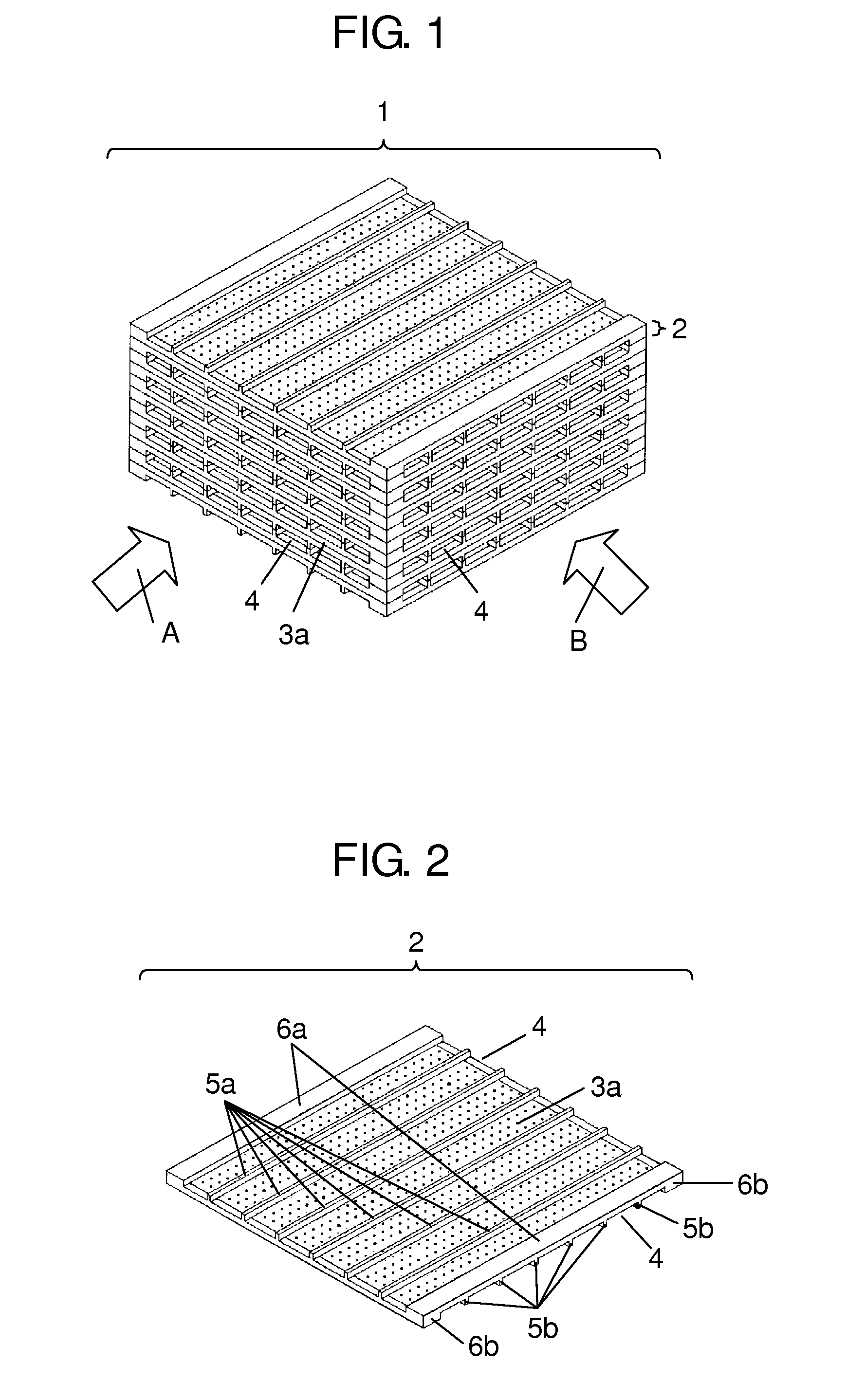

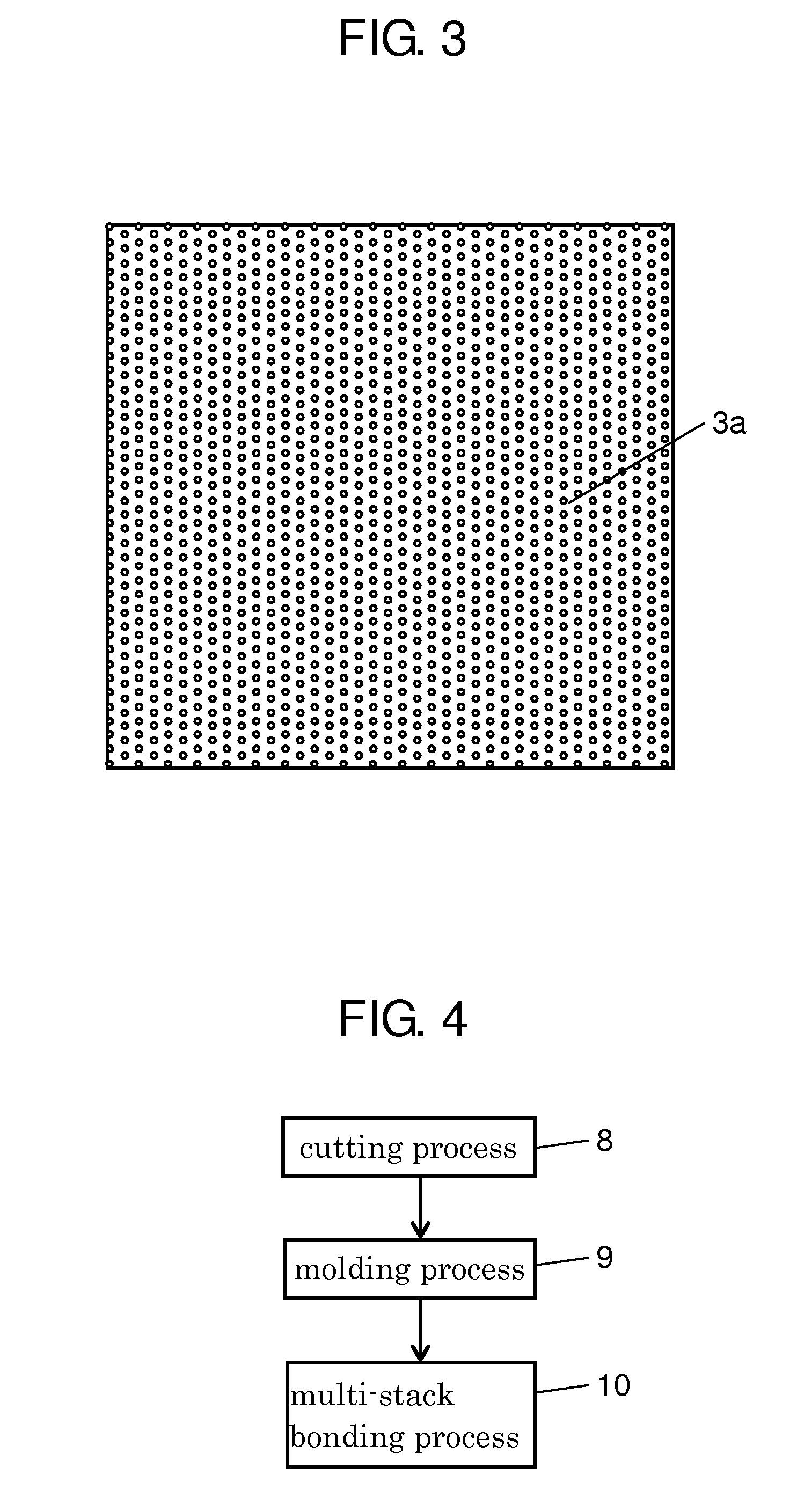

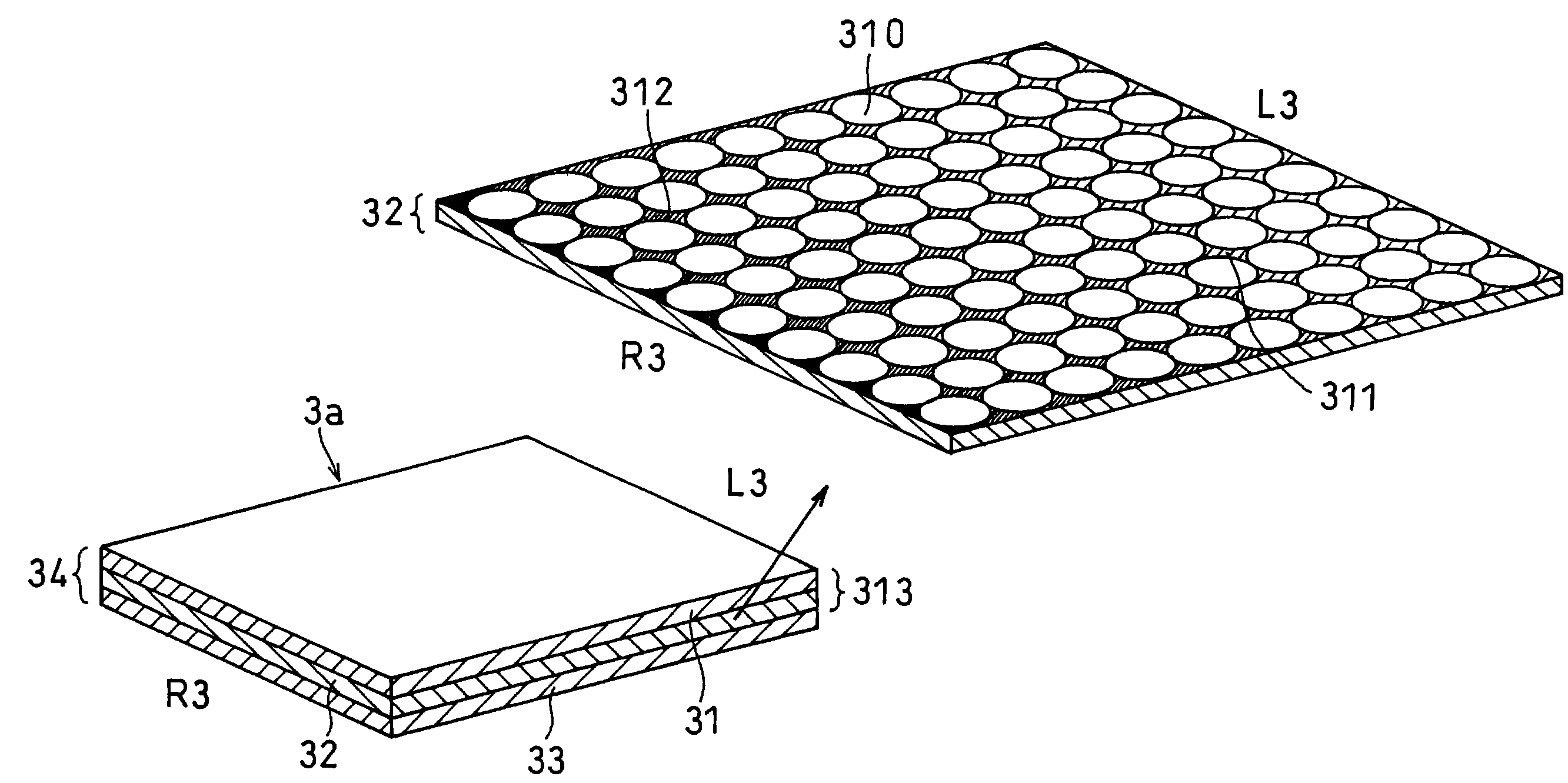

Heat exchanger

ActiveUS20090071638A1Inhibit deteriorationMaintain performanceMetal-working apparatusCorrosion preventionUnit deviceEngineering

A heat exchanger, which maintains basic performance even in an environment repeatedly subjected to dew condensation, is provided. The heat exchanger is formed of a plurality of unit devices each including a heat exchanger plate, spacer ribs, and shielding ribs. The heat exchanger plate, the spacer rib and the shielding rib are integrally molded with resin. The spacer ribs keep the spacing between the heat exchangers, and the shielding ribs shield leakage of airflow. The unit devices are stacked each other to form airflow passages between the heat exchanger plates. The airflow passages allow a first airflow and a second airflow to pass therethrough and to exchange heat through the heat exchanger plates. The heat exchanger plate is made of a moisture permeable resin film having water-insolubility and flame retardant property, and the resin has water-insolubility and flame retardant property.

Owner:PANASONIC CORP

Heat exchanger

ActiveUS8550151B2Inhibit deteriorationMaintain performanceCorrosion preventionCoatingsPlate heat exchangerUnit device

A heat exchanger, which maintains basic performance even in an environment repeatedly subjected to dew condensation, is provided. The heat exchanger is formed of a plurality of unit devices each including a heat exchanger plate, spacer ribs, and shielding ribs. The heat exchanger plate, the spacer rib and the shielding rib are integrally molded with resin. The spacer ribs keep the spacing between the heat exchangers, and the shielding ribs shield leakage of airflow. The unit devices are stacked each other to form airflow passages between the heat exchanger plates. The airflow passages allow a first airflow and a second airflow to pass therethrough and to exchange heat through the heat exchanger plates. The heat exchanger plate is made of a moisture permeable resin film having water-insolubility and flame retardant property, and the resin has water-insolubility and flame retardant property.

Owner:PANASONIC CORP

Water-curing environment-friendly type polyurethane waterproofing paint and preparation technique thereof

ActiveCN101230233AHigh molecular weightLow toxicityAntifouling/underwater paintsPaints with biocidesPolyolPlasticizer

The invention relates to a water firming environment-friendly polyurethane waterproofing paint and the preparing process, in particular to a water firming environment-friendly polyurethane waterproofing paint which can be applied to the damp interface. The invention is prepared by mixing constituent A and constituent B by a certain ratio; the constituent A includes mixed polyether polyols, the weight ratio of which is 60-70 percent; methane diphenyl diisocyanate (MDI), the weight ratio of which is 25-35 percent; plasticizer, and the weight ratio of which is 1-10 percent. The constituent B includes liquid filling, the weight ratio of which is 35-45 percent; inorganic powder filling, the weight ratio of which is 45-55 percent; chemical accessory ingredient, the weight ratio of which is 1-10 percent; and water, the weight ratio of which is 1-10 percent. The paint of the invention uses more environment-friendly material to replace the material in the prior art which is costly and unhealthy, solves the problem that the water firming waterproofing paint in the prior art is difficult to become environment-friendly, simplifies the preparing process, and lowers the production cost.

Owner:中建材苏州防水研究院有限公司

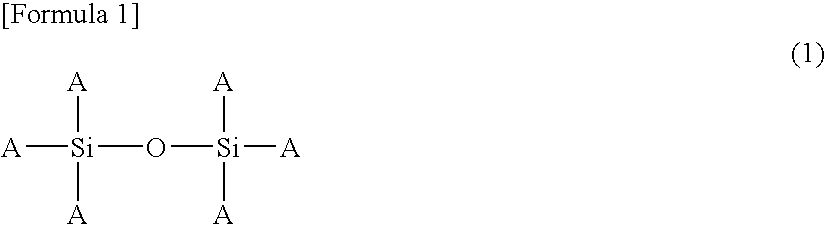

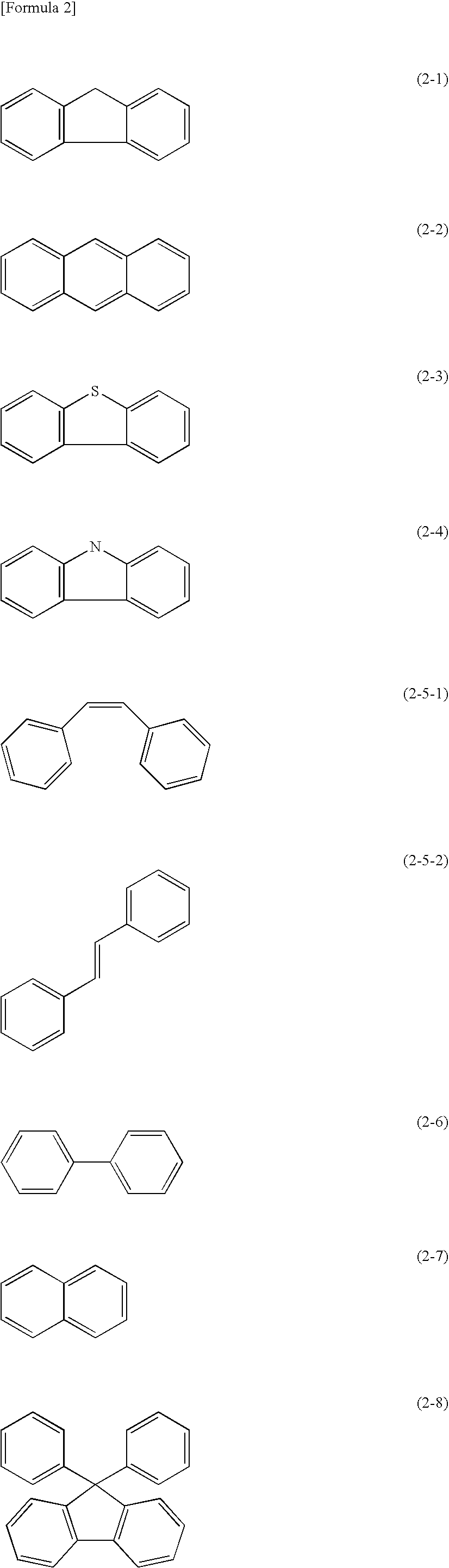

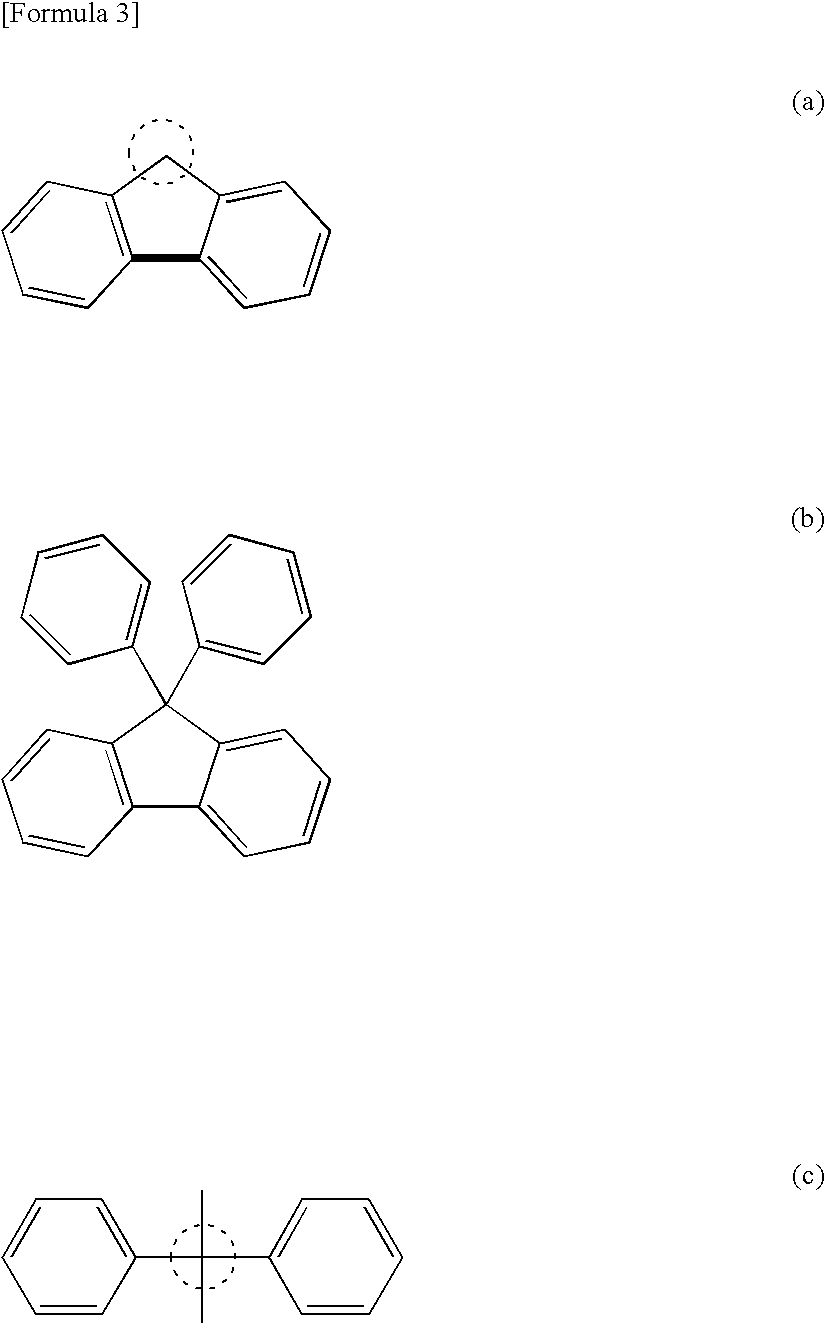

Curable resin composition for molded bodies, molded body, and production method thereof

The present invention provides a curable resin composition which exhibits the following properties : excellent basic performances such as heat resistance; sufficient optical characteristics such as transparency; and excellent demoldability when a molded body of the composition is demolded at the time of molding. The present invention further provides a molded body obtainable by molding the curable resin composition and a production method thereof. A curable resin composition for molded bodies, including a thermocurable resin, wherein the curable resin composition for molded bodies includes at least one compound selected from the group consisting a compound having a boiling point of 260° C. or less at one atmospheric pressure, a silicon compound having a polyoxyalkylene chain, a silicon compound having an aryl group, and a silicon compound having a polyoxyalkylene chain and an aryl group.

Owner:NIPPON SHOKUBAI CO LTD

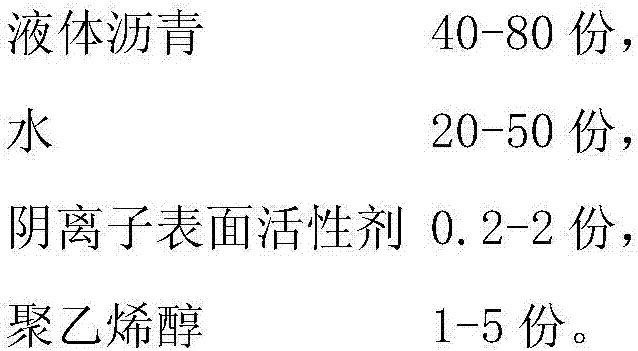

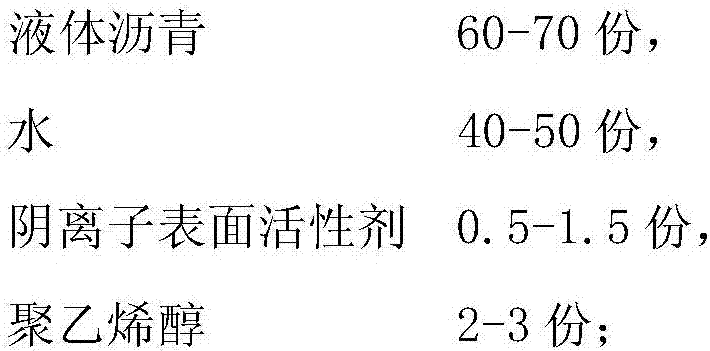

Modified asphalt waterproof coating, preparation method for modified asphalt waterproof coating and use method thereof

ActiveCN106957601AAvoid reunionTechnical effect of avoiding subsidenceBituminous coatingsBituminous waterproofingSlurry

The invention discloses a modified asphalt waterproof coating, a preparation method for the modified asphalt waterproof coating and a use method thereof and relates to the field of building materials. The problems of sound insulation and noise reduction of the waterproof coating film can be solved. The preparation method for the modified asphalt waterproof coating disclosed by the invention comprises the following steps: preparing the modified asphalt waterproof coating from a component A and a component B; mixing and uniformly stirring anion emulsified asphalt, polymer emulsion and slurry, thereby acquiring the component A; and uniformly mixing water with curing agent, thereby acquiring the component B, wherein the slurry is prepared according to the following steps: adding water, stabilizer, dispersing agent, wetting agent, de-foaming agent, fine powder and pH regulator into a dispersing device, dispersing for the first time, adding a silencing filling material soaked with a silane coupling agent solution after ending the dispersing for the first time, and then adding a thickening agent, dispersing for the second time and then ending the dispersing for the second time, thereby acquiring the slurry. The modified asphalt waterproof coating disclosed by the invention has excellent effects of sound insulation and noise reduction on the basis of excellent waterproof property.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

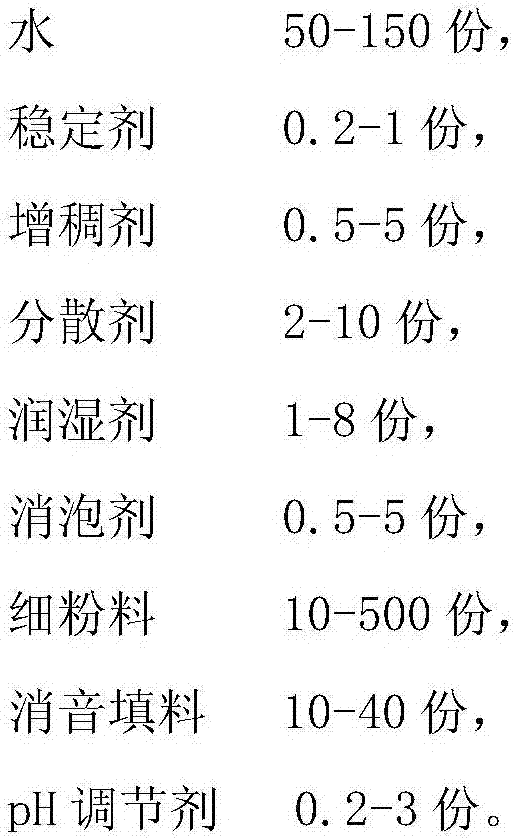

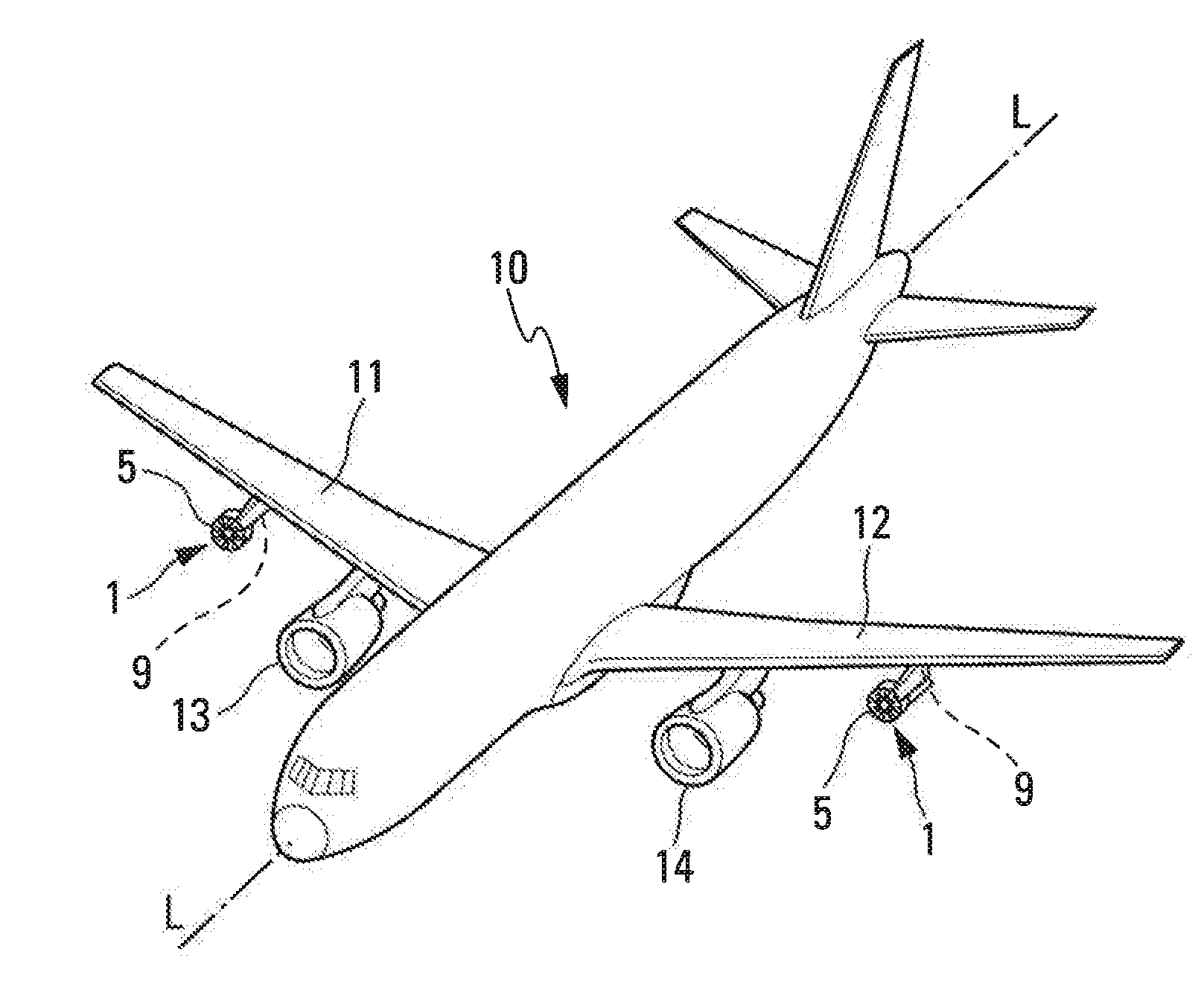

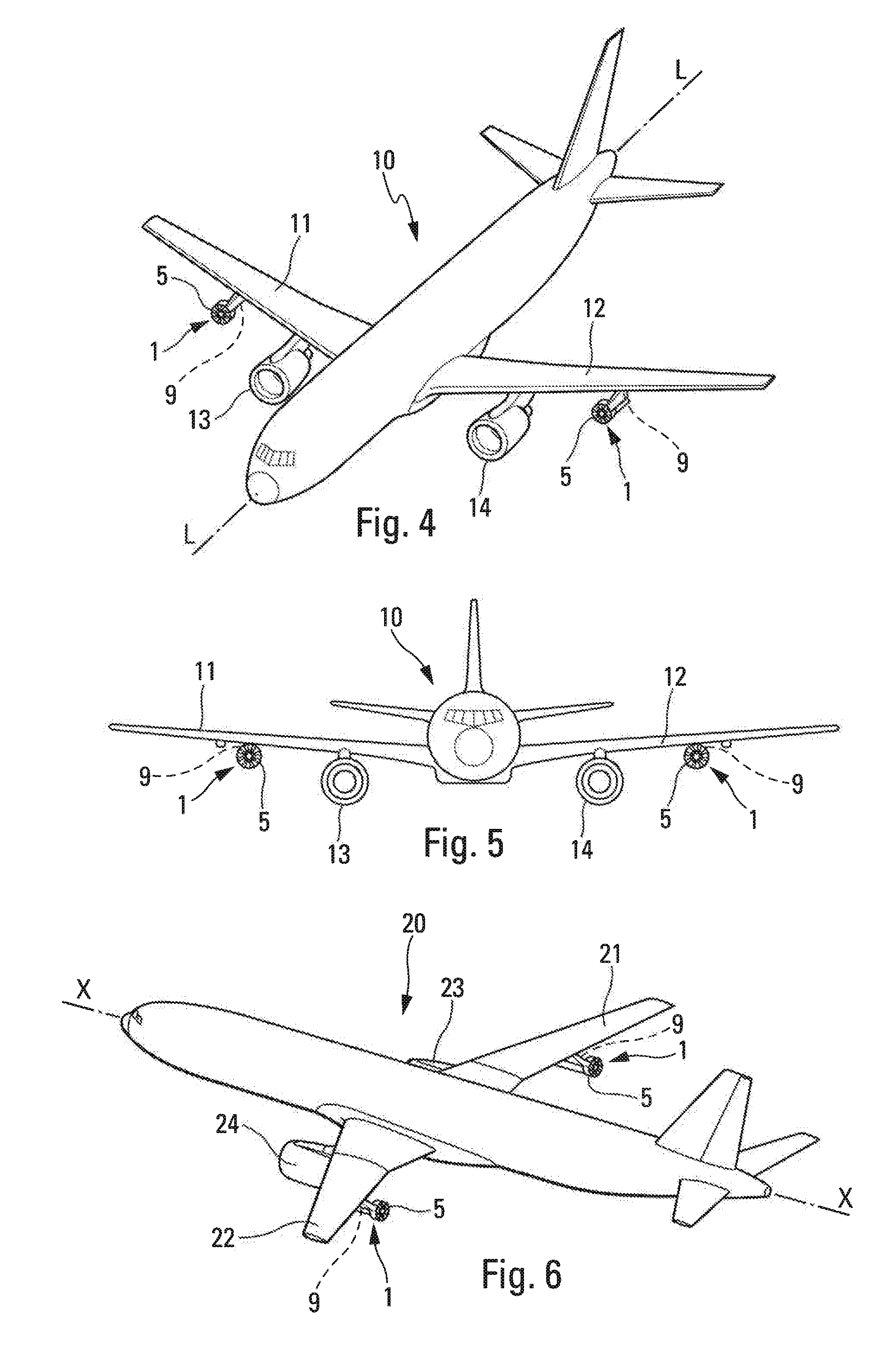

Removable auxiliary power device for aircraft and aircraft adapted to use at least one such device

InactiveUS20160176533A1Improve basic performanceHigh operating costsPropellersPower installationsPropellerEngineering

An auxiliary power device may be exteriorly removably connected to an aircraft in order to allow the increase of the performance data of the aircraft, namely at take-off and landing. The auxiliary power device includes a propeller (or fan) connected to an electric engine fed by an electric power supply.

Owner:AIRBUS OPERATIONS (SAS)

Method of preparing magnetic nano composite fibre

The present invention discloses a method for preparing magnetic nano-composite fiber. The steps are: dissolving the cellulose in NaOH / urea water solution completely and getting the cellulose solution, debubbling in vacuum and preparing fiber through spinning machine, then soaking the cellulose fiber into 0. 01 mol / L - 2mol / L ferric salt or ferrous salt solution, passing the 0. 1 mol / L - 4mol / L NaOH solution, then producing the magnetic nano-composite fiber. The method is simple to operating, raw materials are cheap, the prepared products have good mechanical and magnetic properties. The nano-magnetic fiber can be made protective clothing, health care supplies and so on, and it also has certain prospect in daily health care, military and other areas.

Owner:WUHAN UNIV

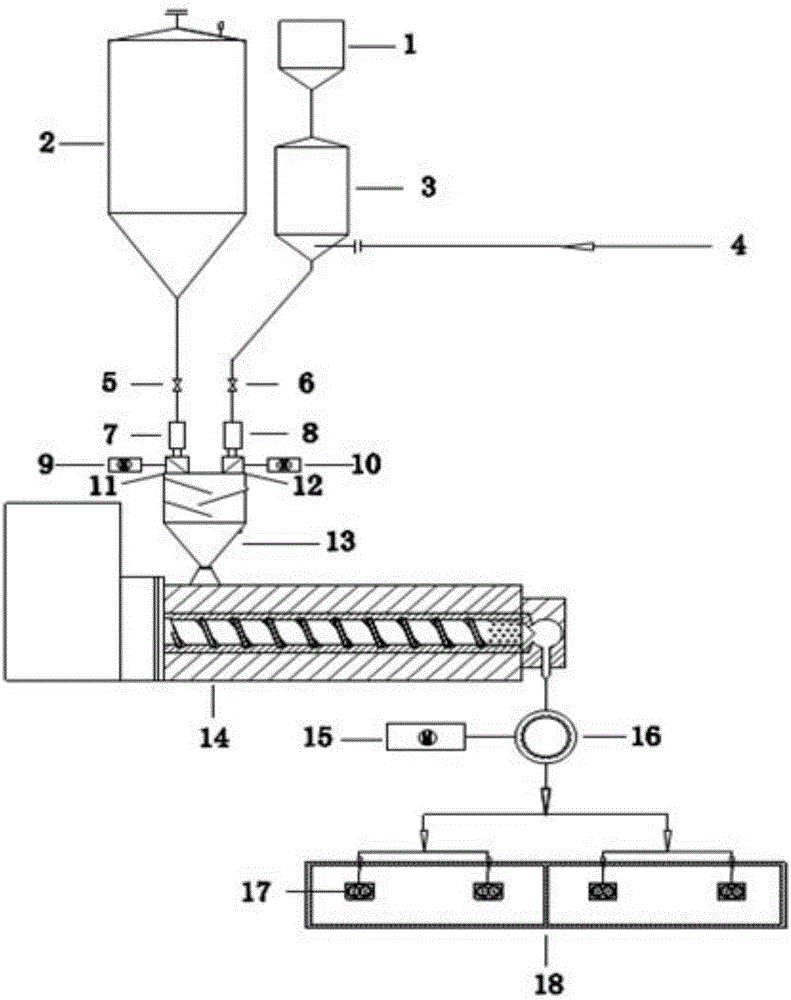

Preparation method of non-dyeing nylon six-color silk

ActiveCN106381534AGuaranteed measurement accuracyHighly uniform mixingFilament forming substance formingFibre typesMasterbatchPolyamide

The invention relates to the field of spinning and discloses a preparation method of non-dyeing nylon six-color silk. The preparation method comprises the following steps: (1) mixing, namely adding the pre-dried polyamide-6 granula and color masterbatch into a mixing device and mixing; (2) melting, namely melting the mixed polyamide-6 granula and color masterbatch in the heating shearing of a screw extruder to obtain a spinning melt; (3) carrying out dynamic mixing: namely enabling the spinning melt to flow out of the screw extruder and enter a dynamic mixing device for dynamic mixing; (4) spinning, namely feeding the spinning melt into a spinning box body for spinning, and ejecting monofilament from a spinneret plate; (5) carrying out clustering oiling, namely clustering when the monofilament reaches a clustering oiling point and oiling the tow surface; (6) carrying out hot stretching, namely guiding the oiled tow into a stretching hot roller for hot stretching; and (7) winding, namely pre-interlacing the tow after the hot stretching, and finally winding for formation. According to the method provided by the invention, the prepared non-dyeing nylon six-color silk has good controllability and causes little pollution, and the basic performance of the nylon six-color silk can be improved.

Owner:YIWU HUADING NYLON

Gaft polymer, wood-plastic material containing same and its preparing method

InactiveCN1470540AMoisture content requirements relaxedCorrosion resistancePolyolefinPlastic materials

The present invention provides a graft polymer, a wood-plastic material containing said graft polymer and their preparation method. Its preparation method includes the following steps: firstly, in the presence of organic silane grafting polyolefine to obtain a graft polymer, then using said graft polymer as total or partial base material, and in the presence of catalyst mixing it with wood powderfilling material, then making them undergo the processes of extruding, plasticizing and forming to obtain the invented wood-plastic material with double characteristics of wood and plastics. Said wood-plastic material can be made into package, tray, building material and pipe material, etc. instead of pure wood.

Owner:PETROCHINA CO LTD

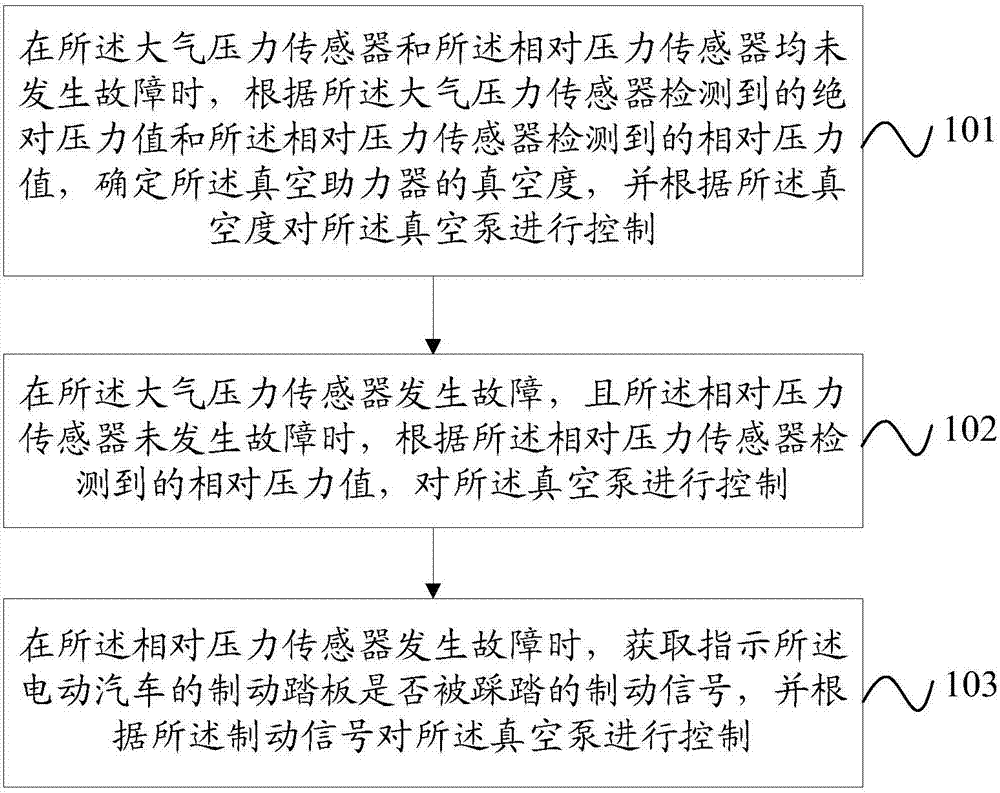

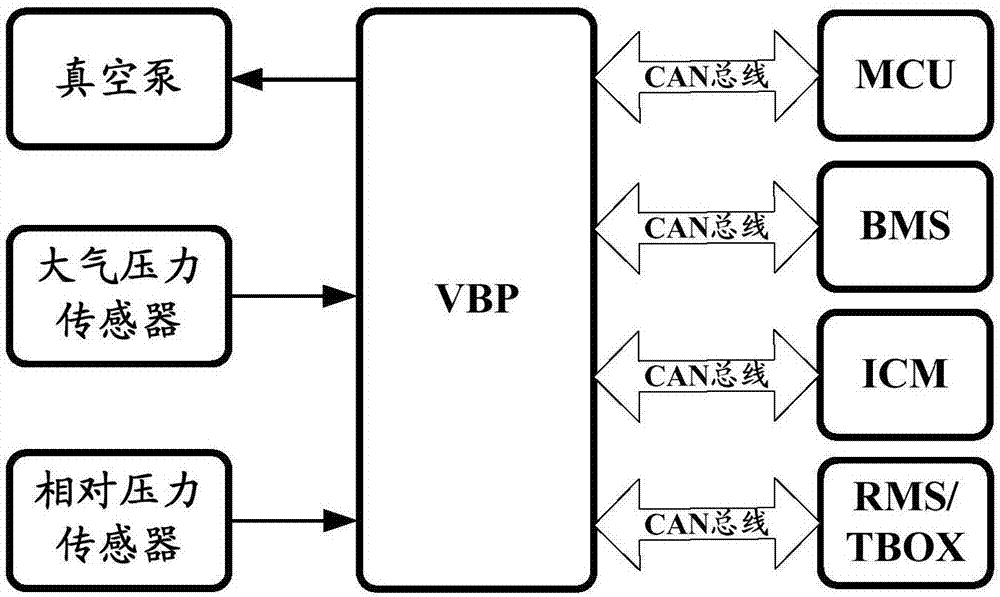

Vacuum pump control method and device and electric car

ActiveCN107097769AImprove reliabilityGuaranteed reliabilityBraking action transmissionPump/compressor arrangementsRelative pressureEngineering

The invention provides a vacuum pump control method and device and an electric car and relates to the field of electric car control. The problems that in the prior art, the property of a vacuum pump cannot be ensured, and reliability and safety are low are solved. The method is applied to a vacuum pump system which comprises an atmospheric pressure sensor and a relative pressure sensor. The method comprises the steps that when breakdowns do not occur to the two pressure sensors, the vacuum degree of a vacuum booster is determined according to an absolute pressure value detected through the atmospheric pressure sensor and a relative pressure value detected through the relative pressure sensor, and the vacuum pump is controlled according to the vacuum degree; when the breakdowns occur to the atmospheric pressure sensor and do not occur to the relative pressure sensor, the vacuum pump is controlled according to the relative pressure value; and when the breakdowns occur to the relative pressure sensor, the vacuum pump is controlled according to braking signals. According to the scheme of the vacuum pump control method and device and the electric car, effective control over the vacuum pump under different breakdown conditions is achieved, so that the property of the vacuum pump is ensured, and reliability and safety are improved.

Owner:BEIJING ELECTRIC VEHICLE

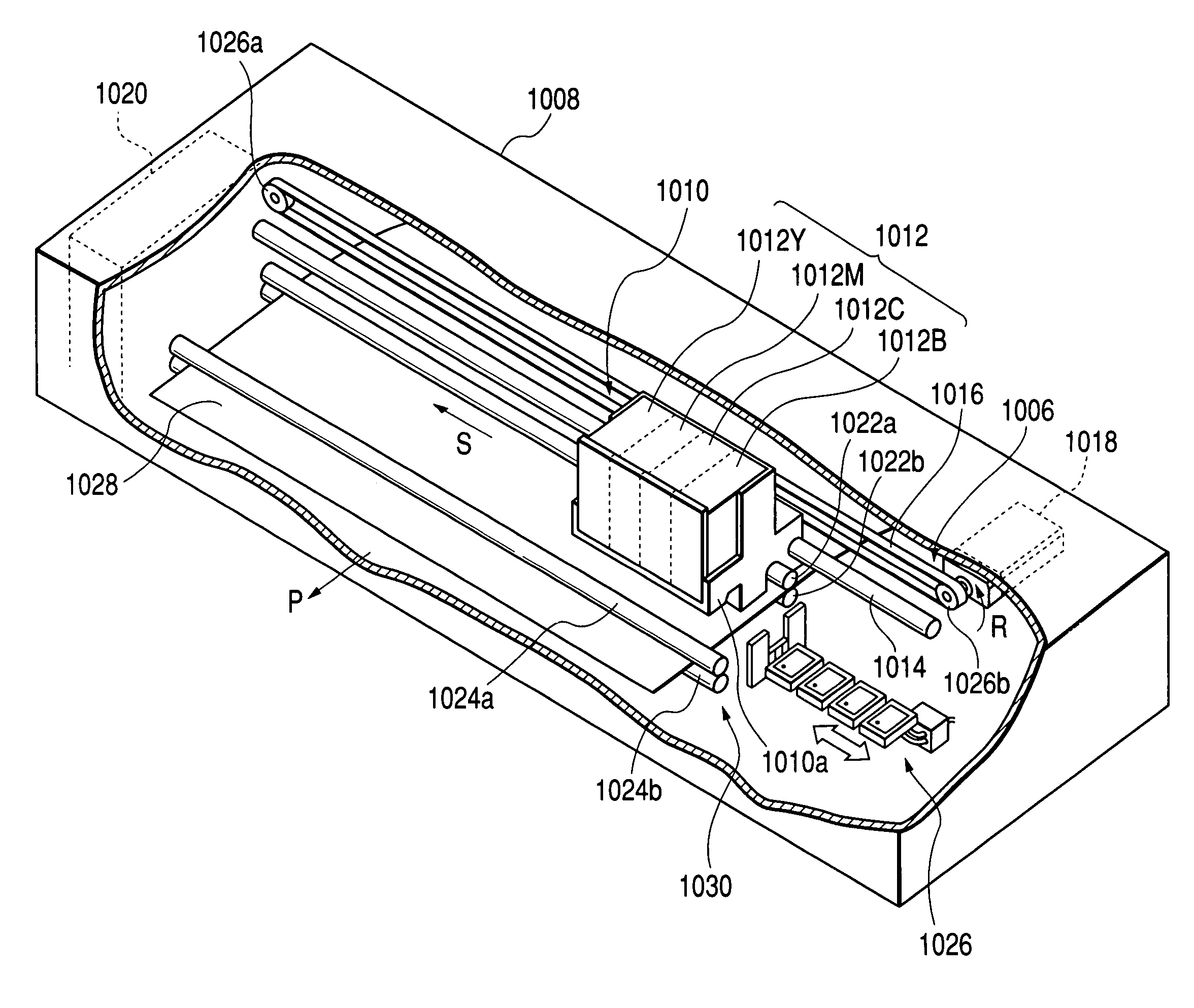

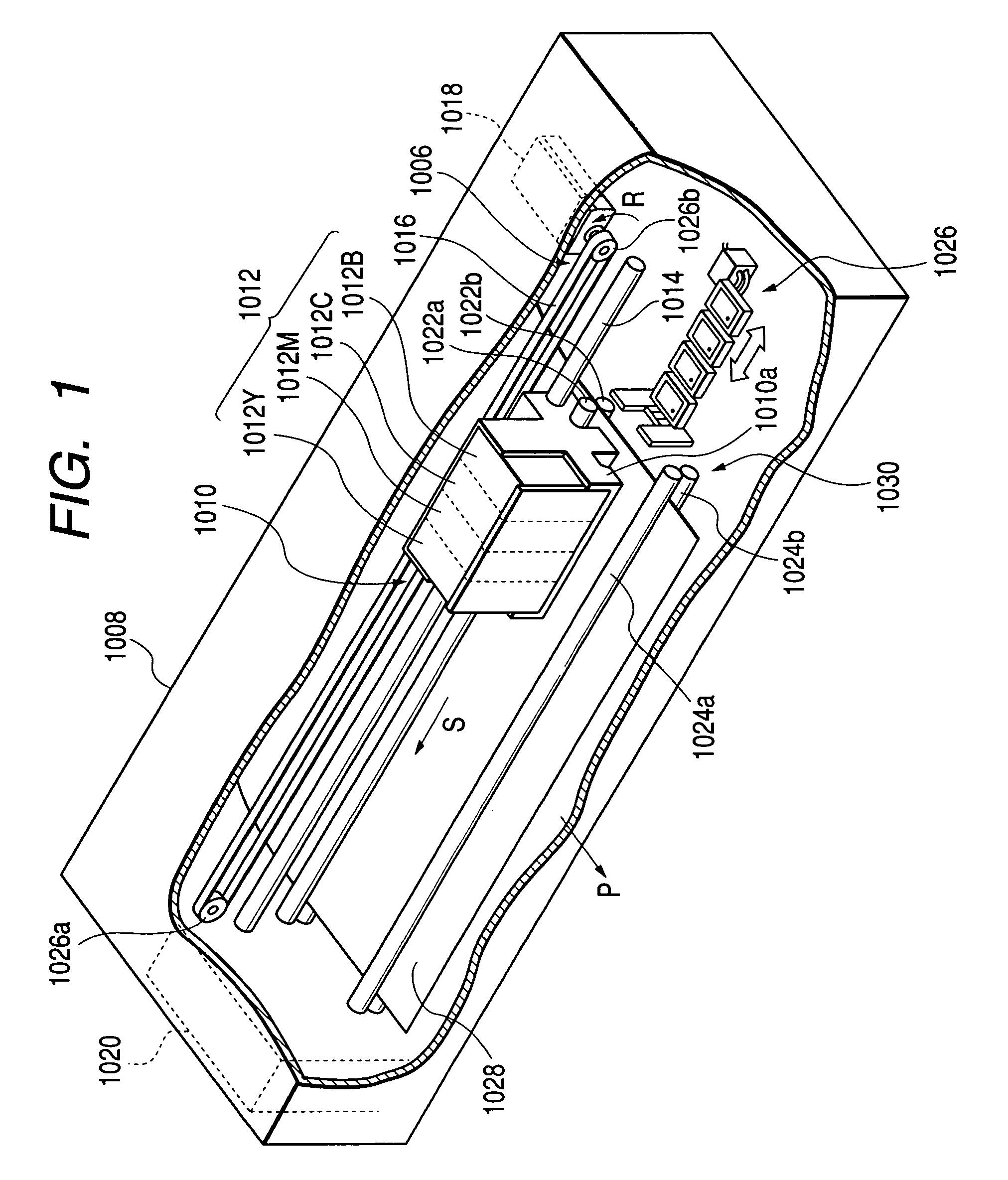

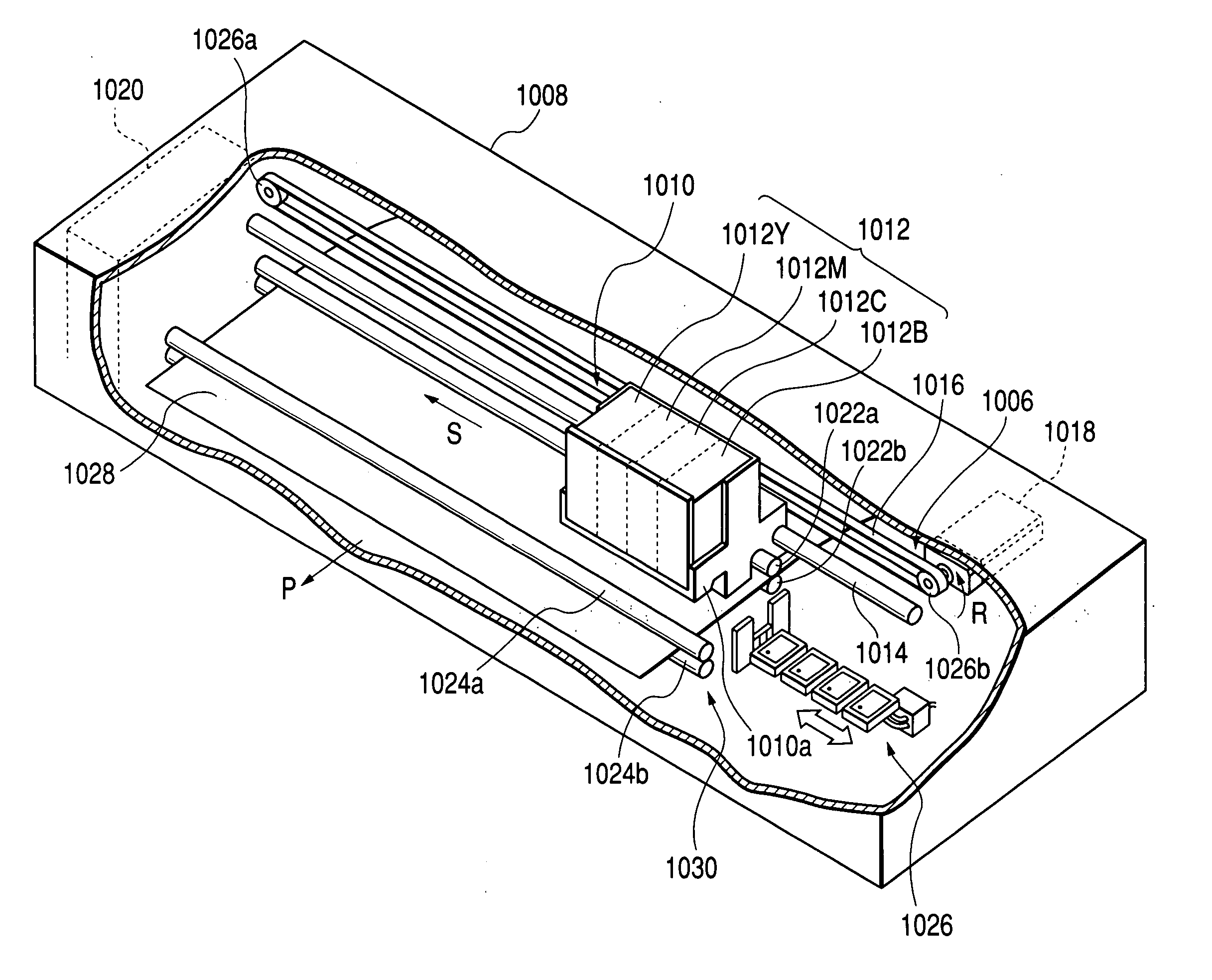

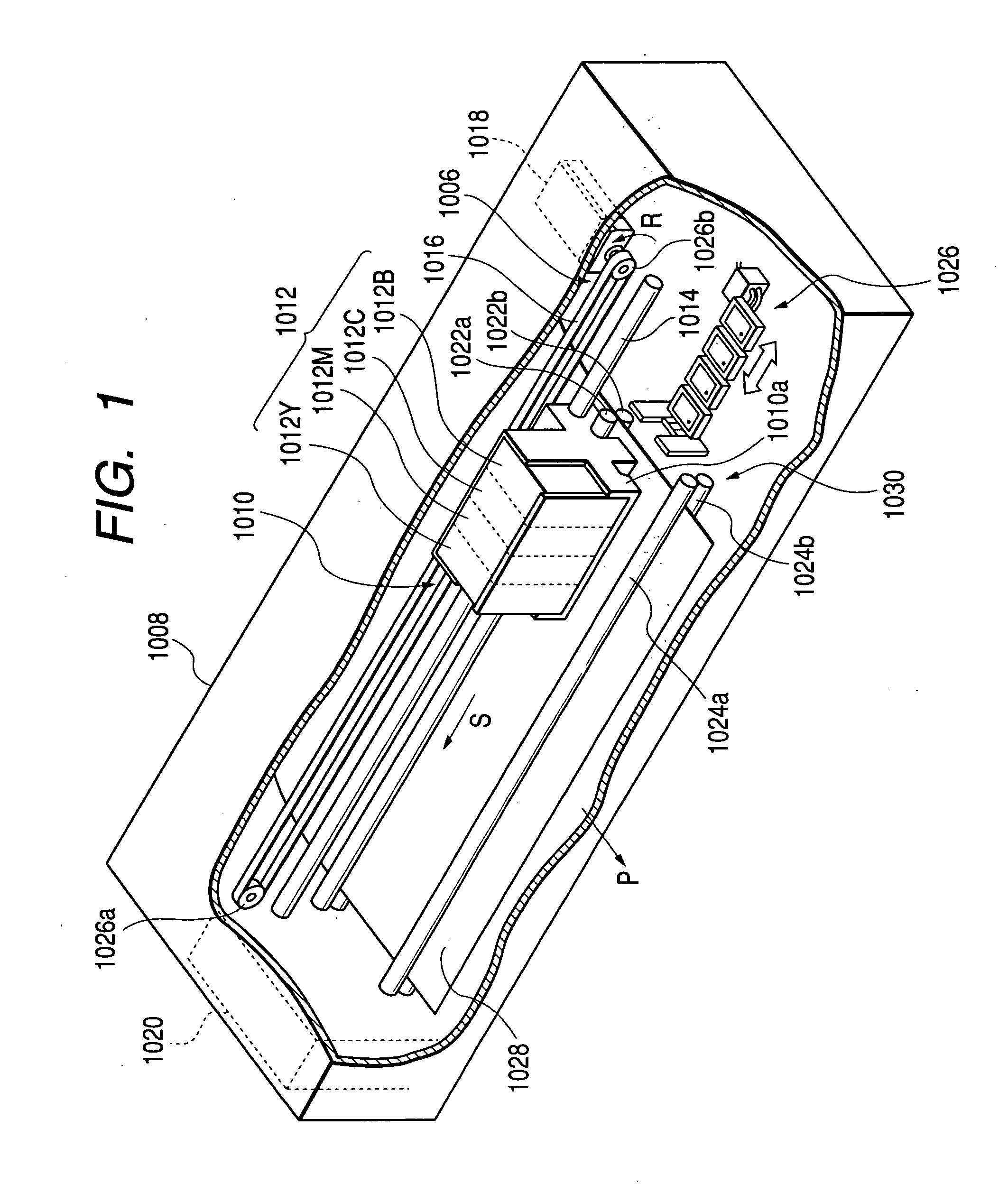

Ink-jet recording ink, ink-jet recording method, and ink-jet recording apparatus

InactiveUS7306664B2Improve basic performanceImprove responseMeasurement apparatus componentsDuplicating/marking methodsHydrogen atomPolymer chemistry

An ink jet recording ink containing water and a coloring material, wherein the ink jet recording ink further contains an ethylenediamine compound represented by Formula (I):wherein R1, R2, R3 and R4 are each selected from the group consisting of a hydrogen atom, an alkyl group and an alkylene oxide group, provided that at least one of R1 and R2 and at least one of R3 and R4 are each an alkylene oxide group, and that alkylene oxide units in one molecule are 2 to 20 in total number.

Owner:CANON KK

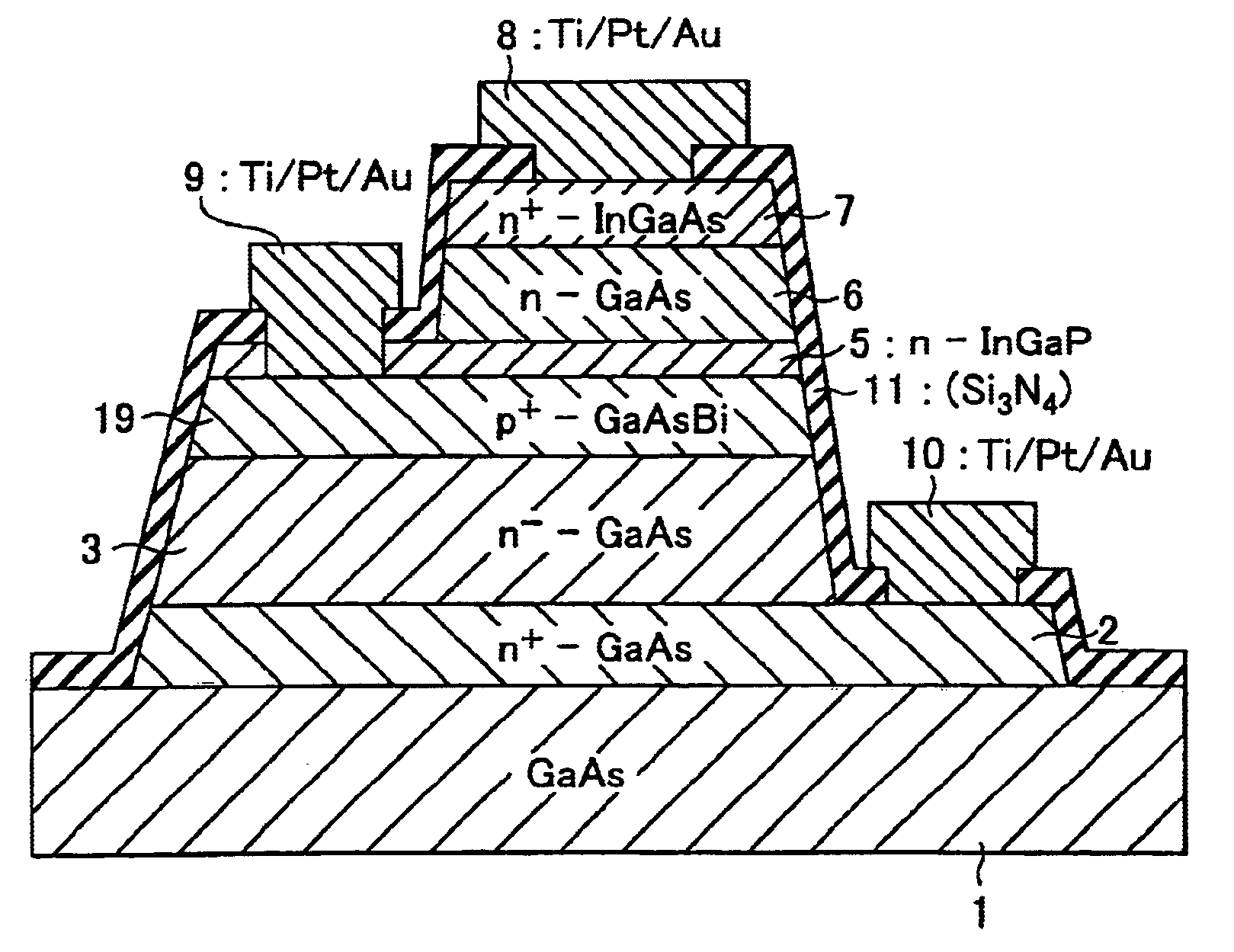

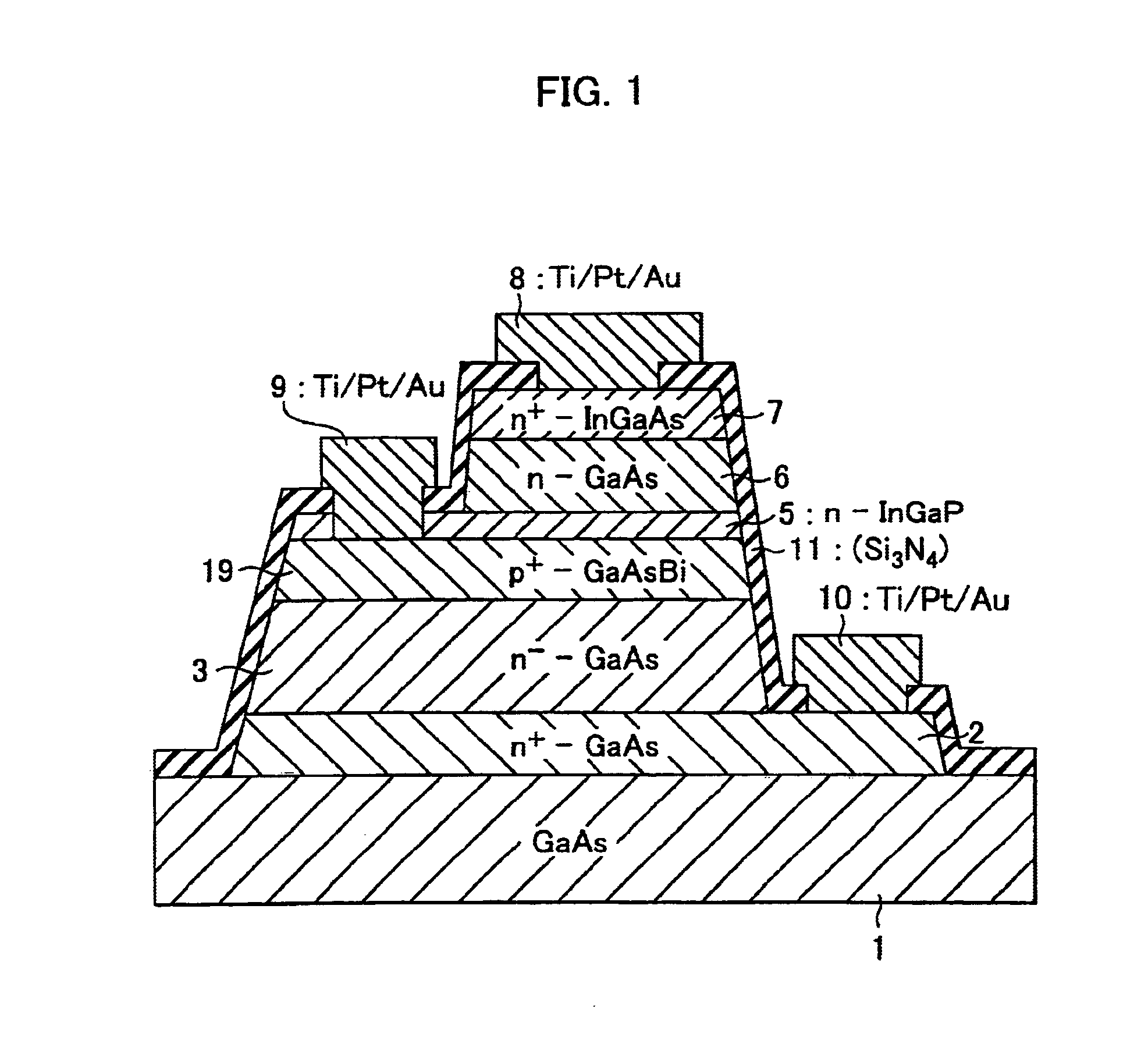

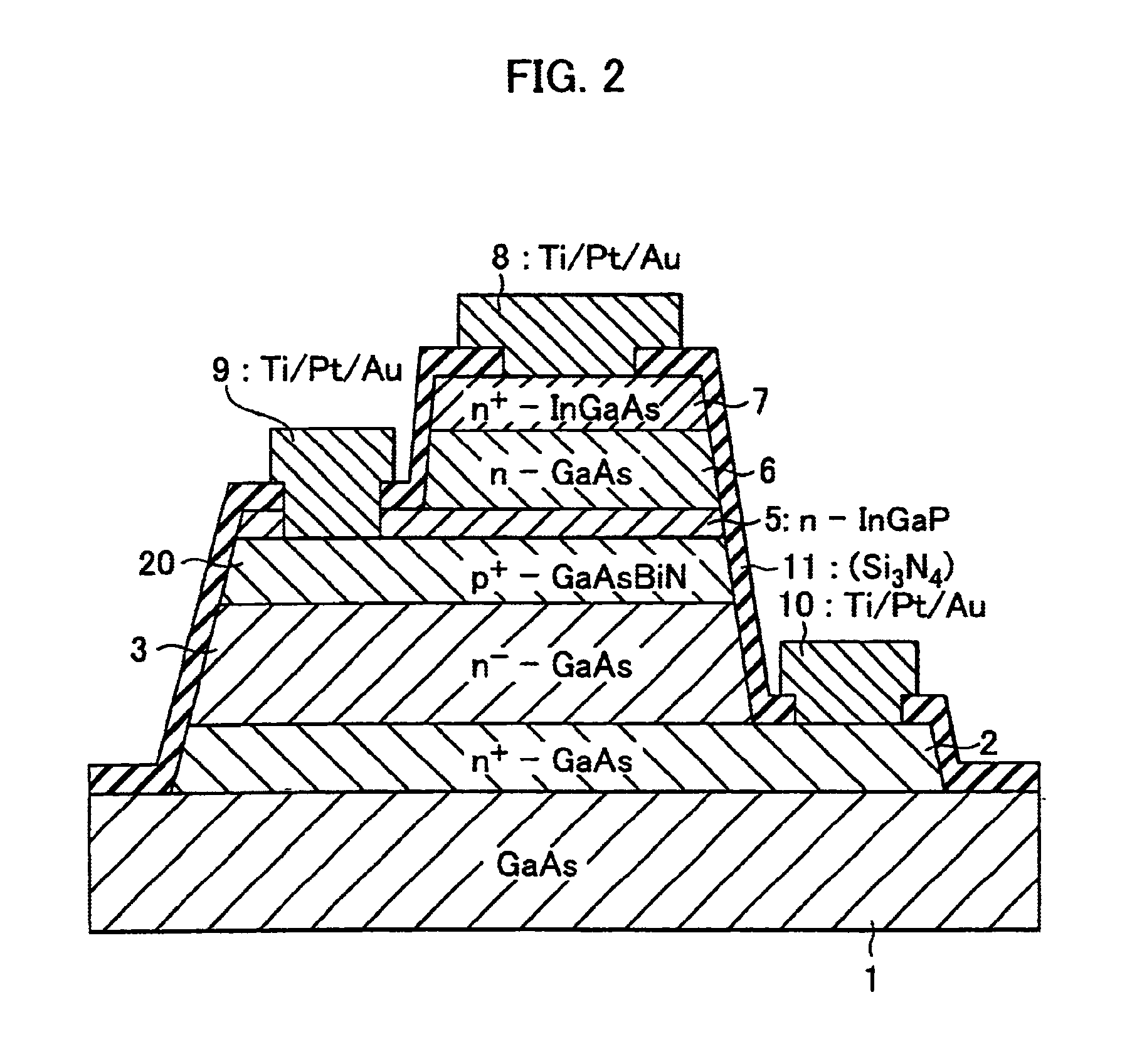

Heterojunction bipolar transistor with a base layer that contains bismuth

InactiveUS6936871B2Improve basic performanceImproved PA characteristicSemiconductor/solid-state device manufacturingSemiconductor devicesSingle crystalAtomic physics

A heterojunction bipolar transistor (HBT) with improved characteristics is provided. A III-V compound semiconductor having Bi added thereto is used for a base layer of a GaAs-based or InP-based HBT. For example, a GaAs-based HBT is formed by successively stacking a subcollector layer made of n+-GaAs, a collector layer made of n−-GaAs, a base layer made of p+-GaAsBi, an emitter layer made of n-InGaP, a first cap layer made of n-GaAs, and a second cap layer made of n+-InGaAs on a substrate 1 made of single crystal GaAs.

Owner:SONY CORP

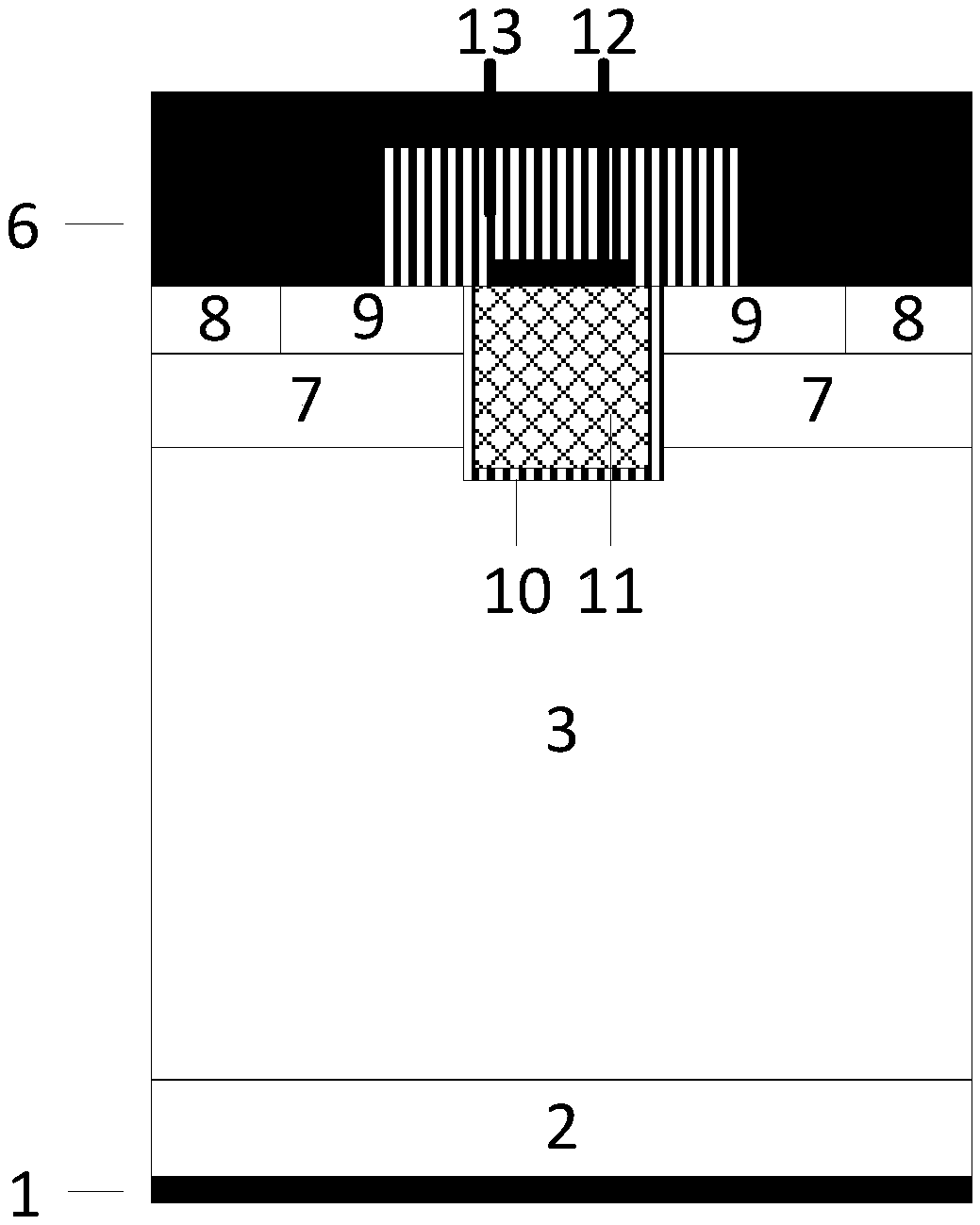

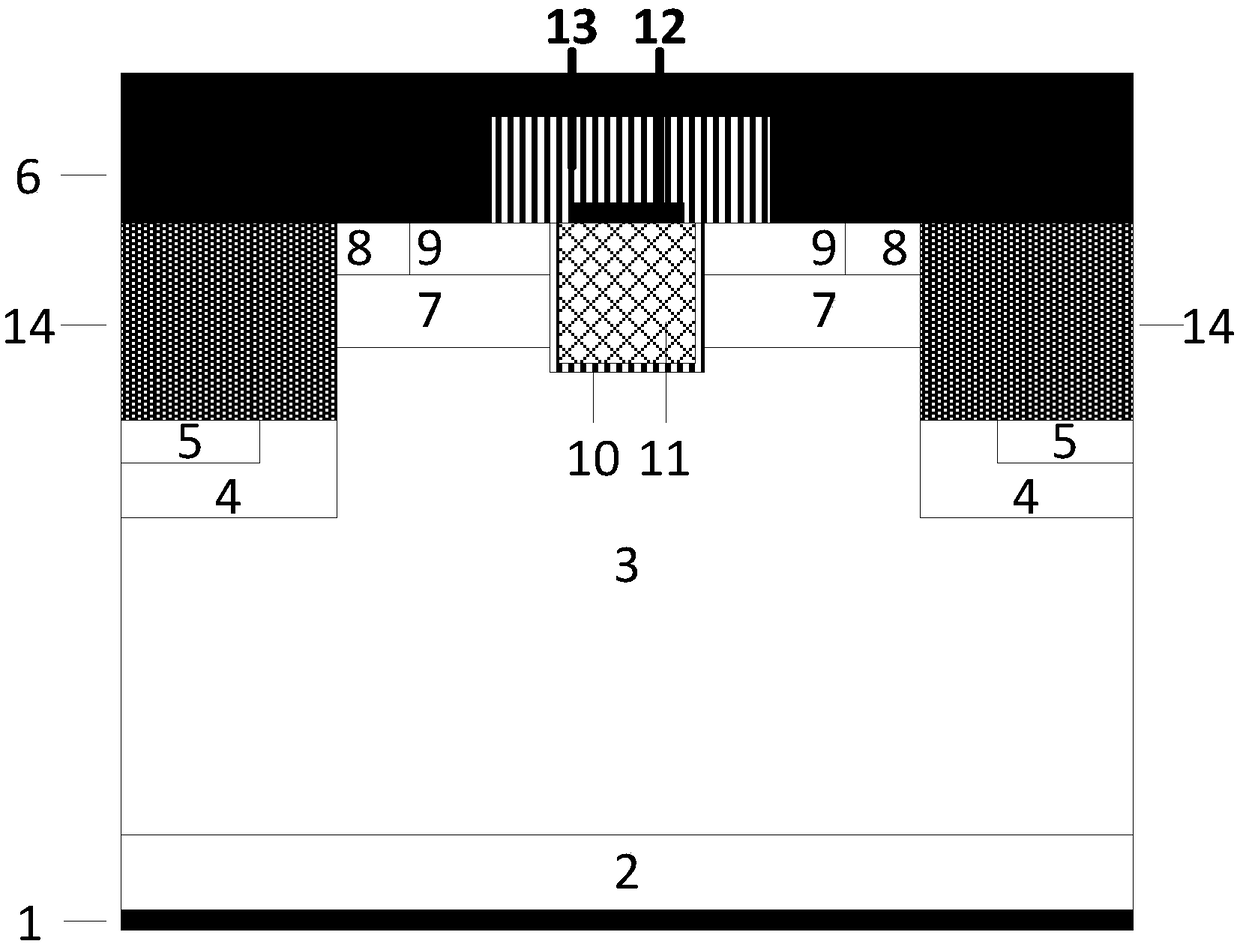

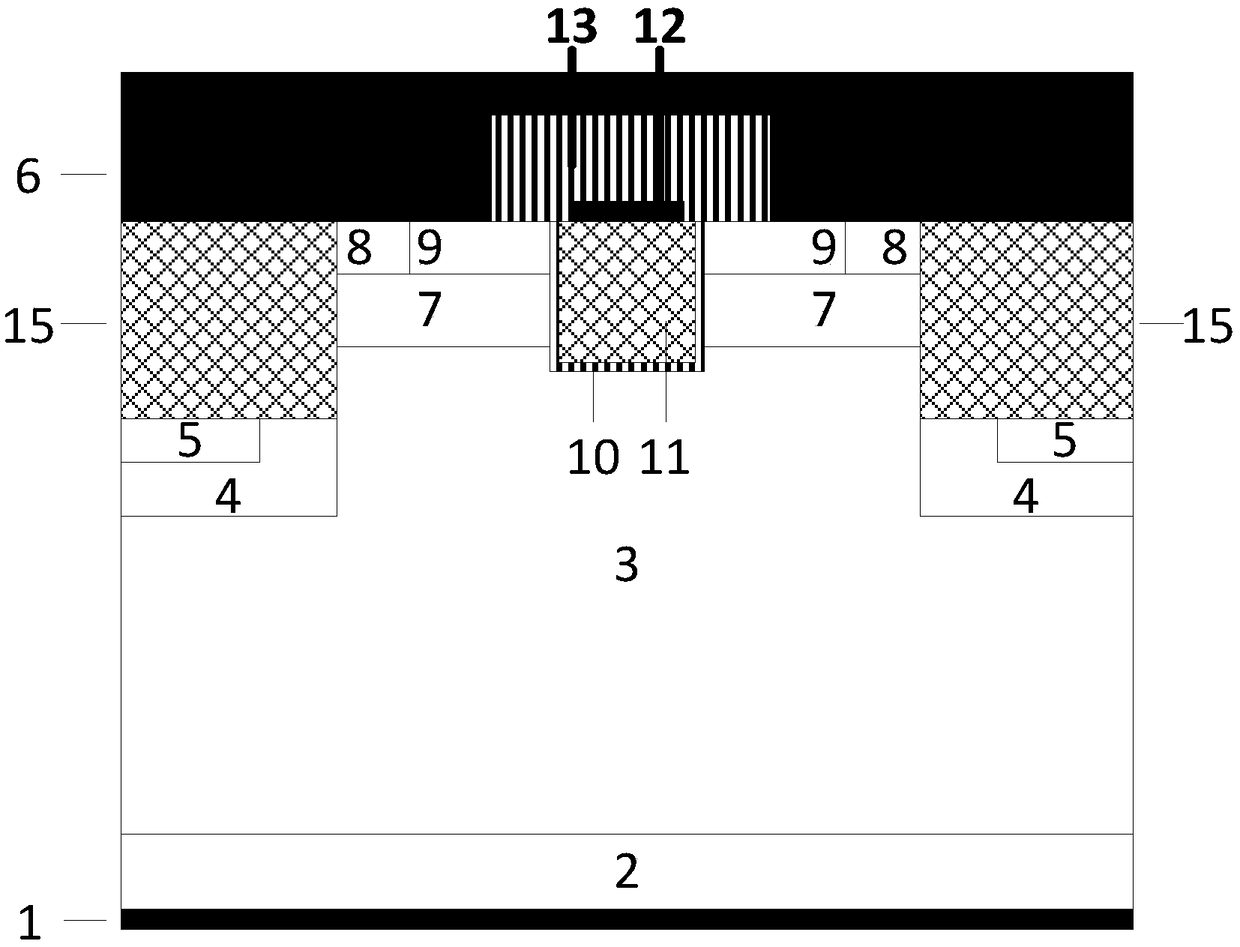

Silicon carbide MOSFET device and manufacturing method thereof

ActiveCN108807504AImprove leakageReduce leakageSemiconductor/solid-state device manufacturingSemiconductor devicesCarbide siliconMOSFET

The invention provides a silicon carbide MOSFET device and a manufacturing method thereof. Silicon carbide deep P injection is performed in a specified region, groove etching and deposition of metal or polysilicon are performed above a silicon carbide deep P doped region, and the deposited metal or polysilicon is in direct contact with the silicon carbide N-epitaxy to form a Schottky contact or aSi / SiC heterojunction contact having rectifying characteristics. Therefore, the integration of multiple sub-rectifiers is achieve while optimizing the basic performance of the conventional silicon carbide UMOSFET, the working performance of the third quadrant of the device is greatly optimized, the gate-drain capacitance of the device is reduced and the switching speed of the device is improved.

Owner:HANGZHOU SILICON-MAGIC SEMICON TECH CO LTD

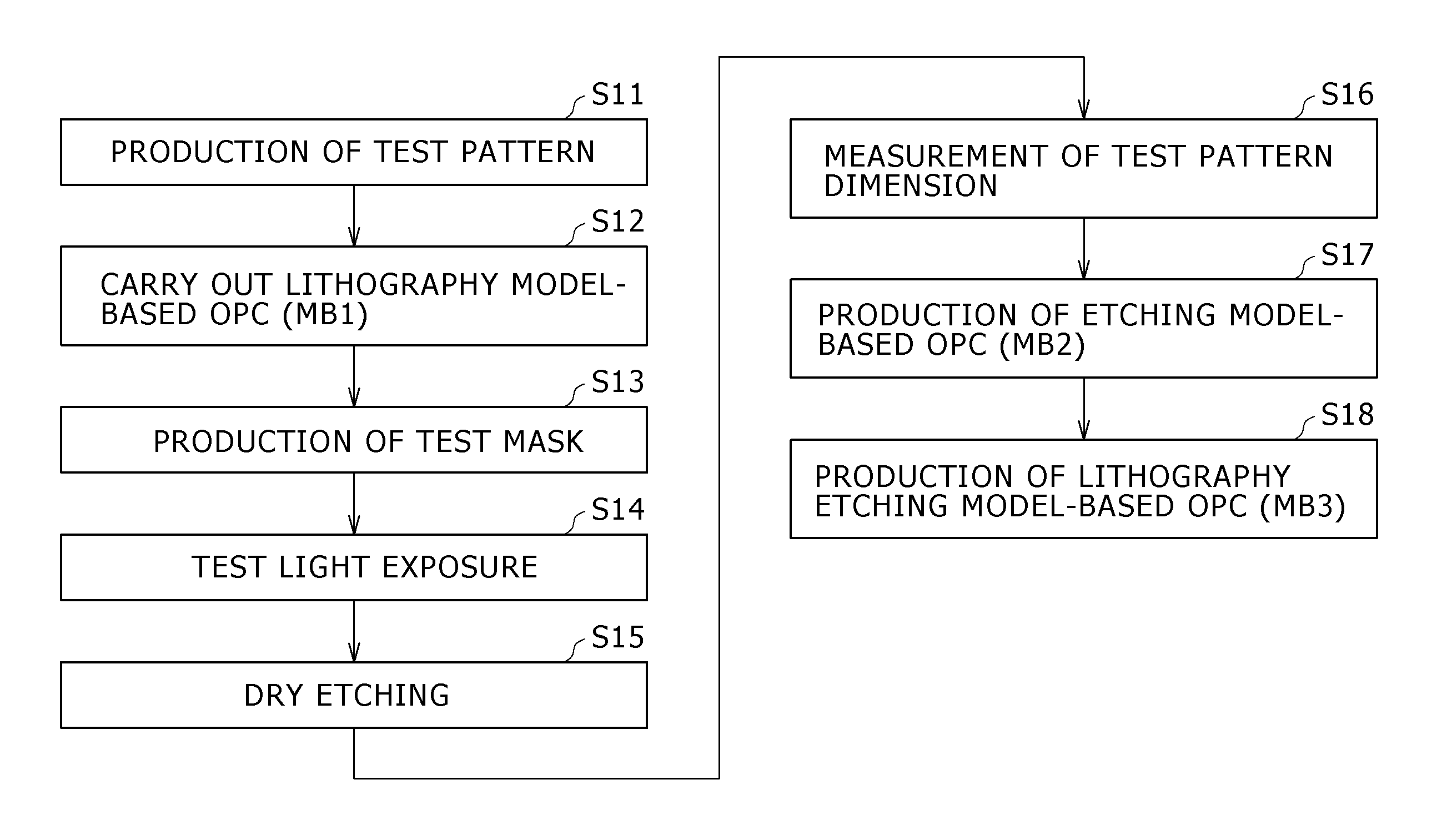

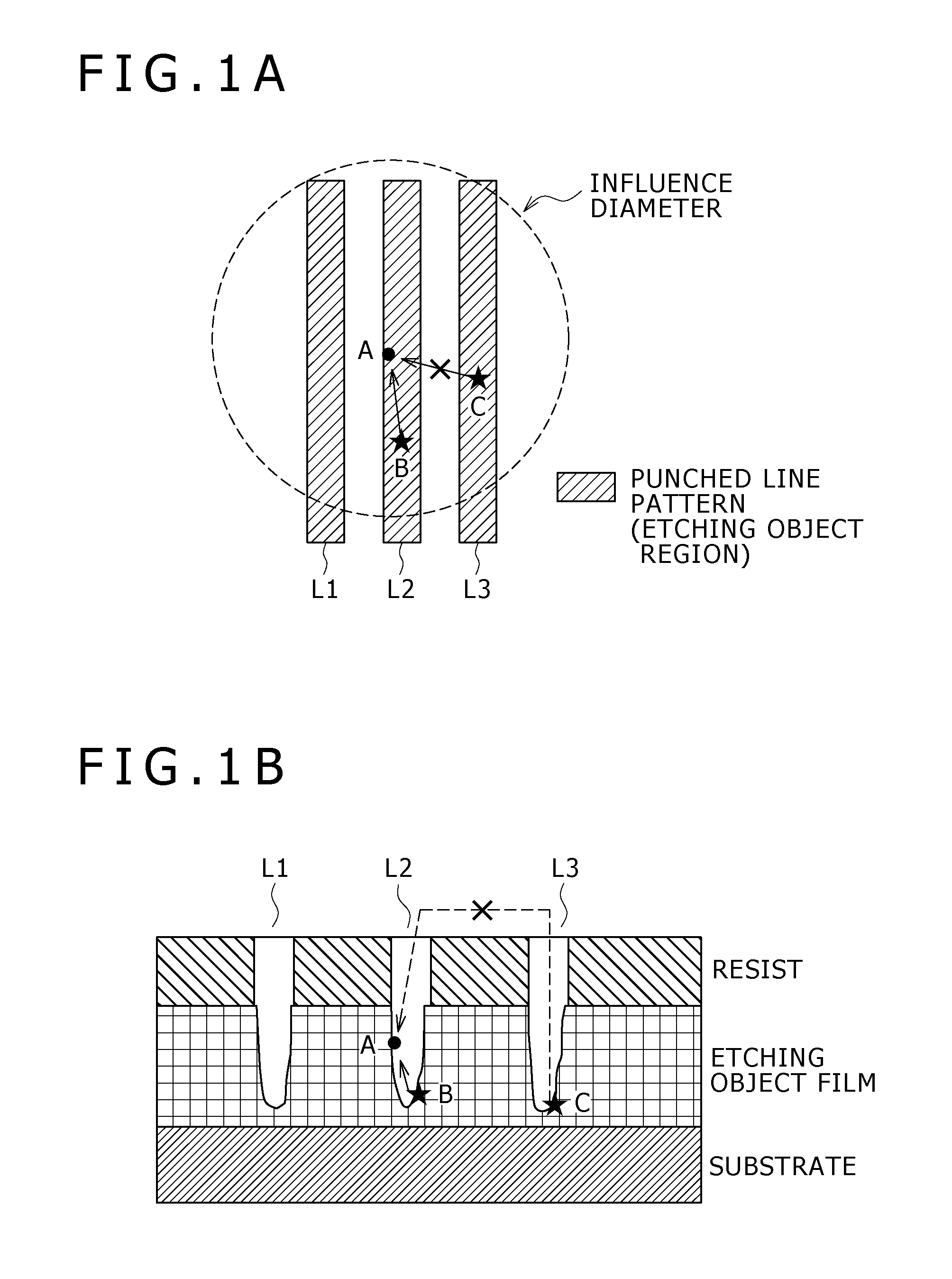

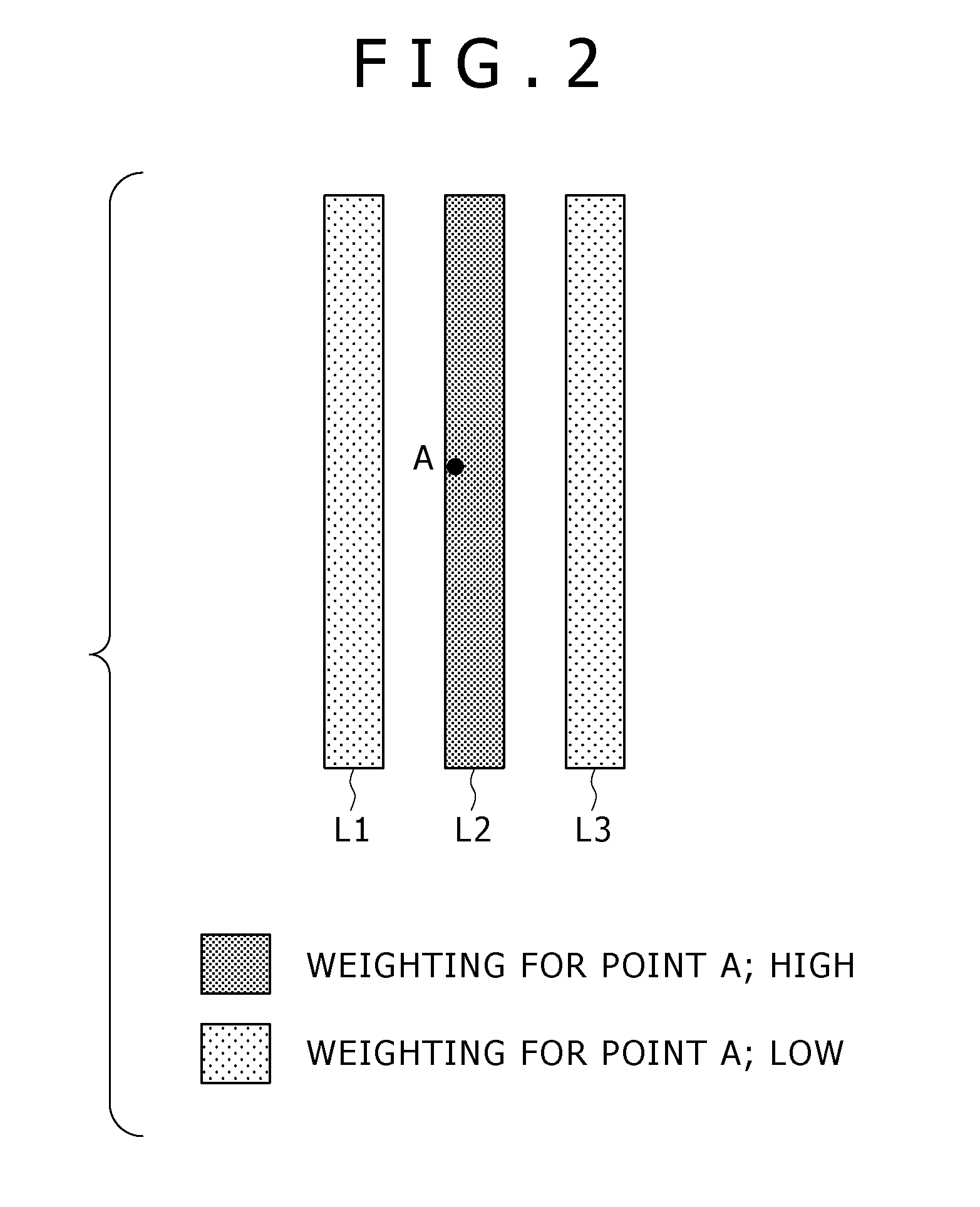

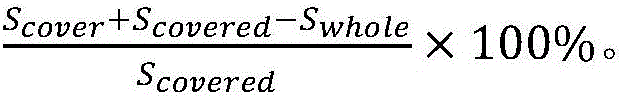

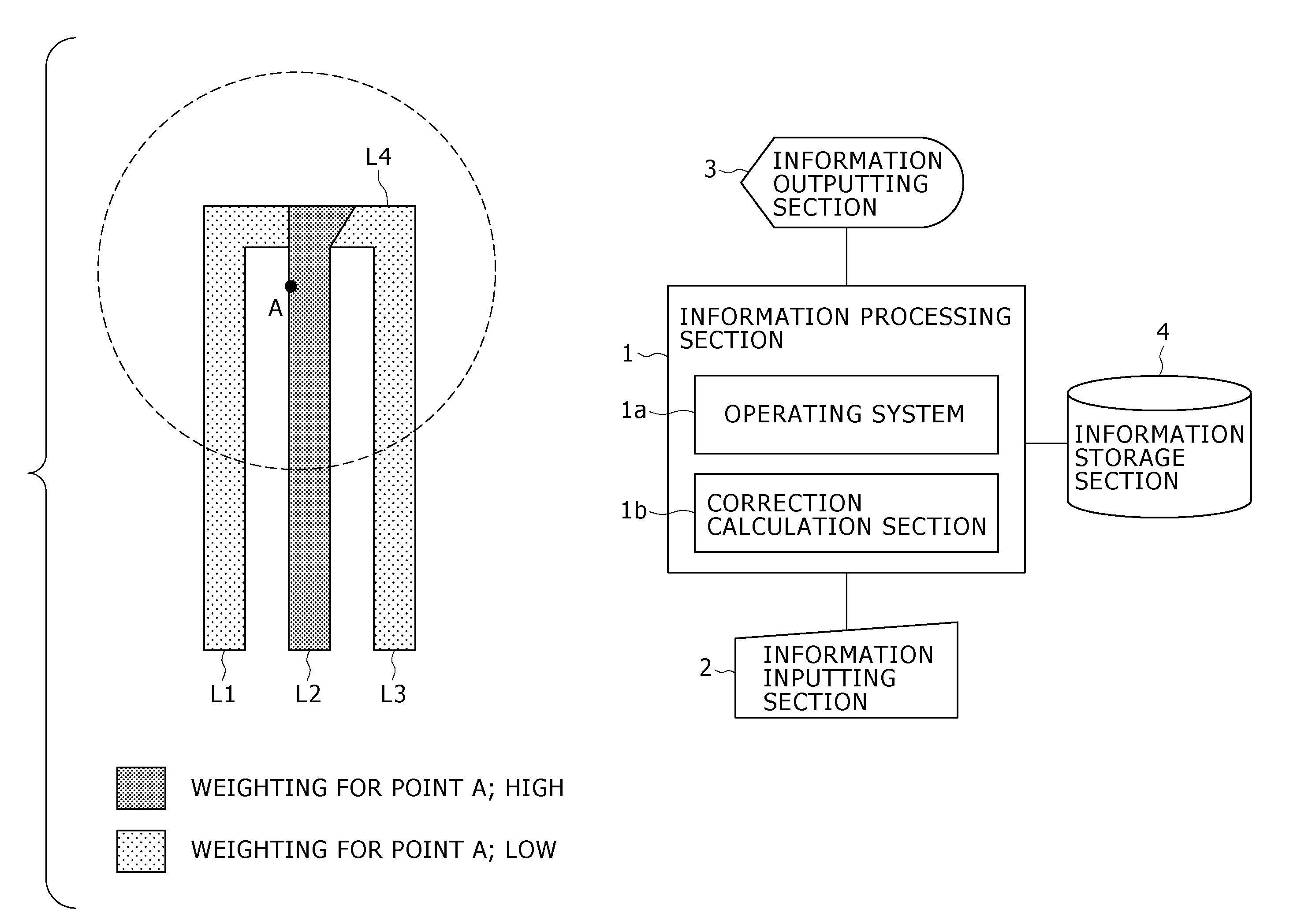

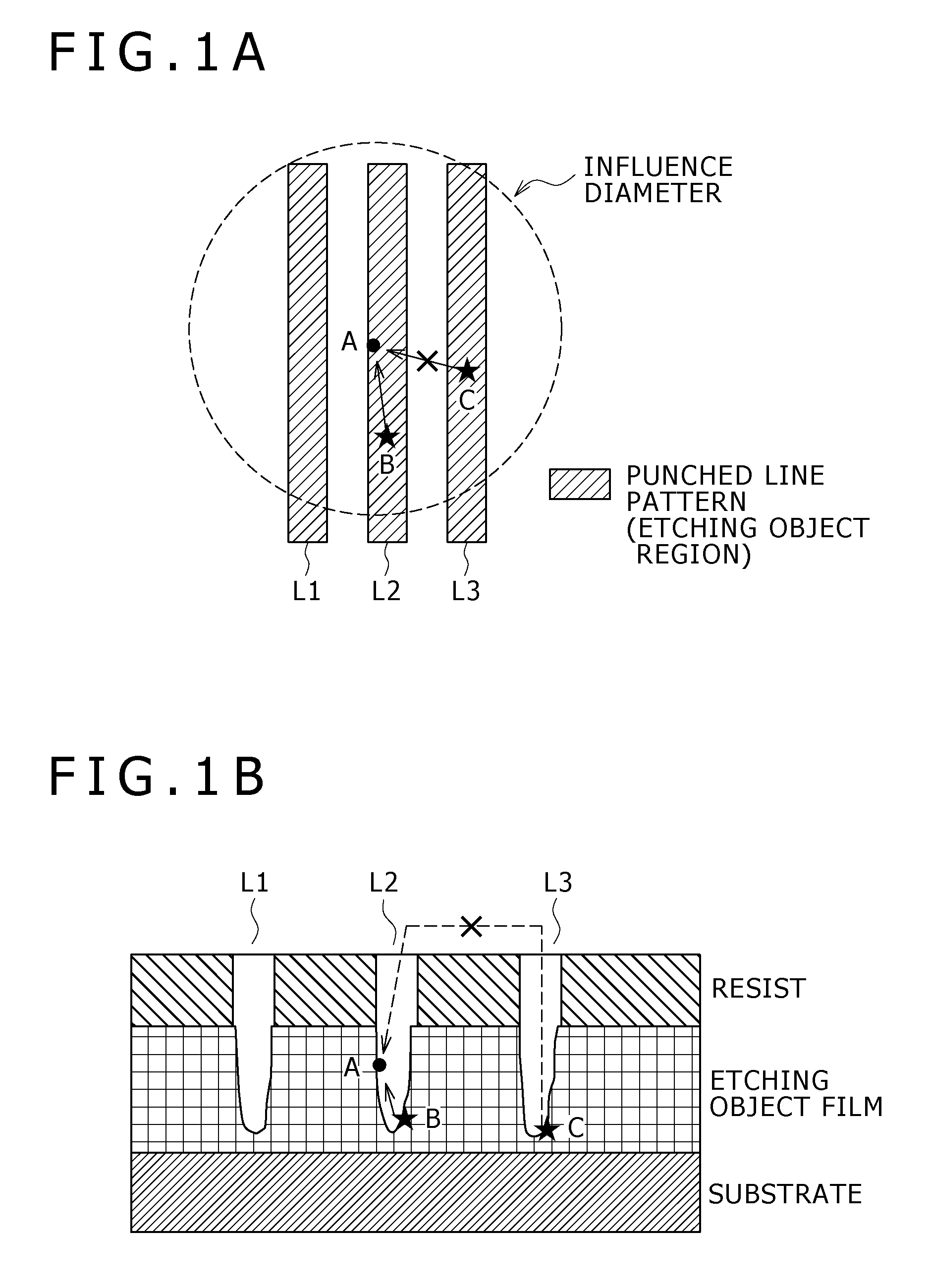

Pattern correction apparatus, pattern correction program, pattern correction method and fabrication method for semiconductor device

InactiveUS20080178141A1High degree of accuracyHigh weightSolid-state devicesSemiconductor/solid-state device manufacturingPoint setDesign pattern

A pattern correction apparatus for performing both of optical proximity effect correction and process proximity effect correction with regard to a design pattern includes: a correction calculation means configured to perform correction calculation by two-dimensional model-based optical proximity effect correction for each of sampling points set on pattern edges which form the design pattern; the correction calculation means performing the correction calculation which involves weighting with a two-dimensional distribution of the pattern edges around the sampling point taken into consideration; the weighting being performed such that a high weight is applied to a region in which reaction products which can have an influence on the sampling point are produced but a low weight is applied to any other region.

Owner:SONY CORP

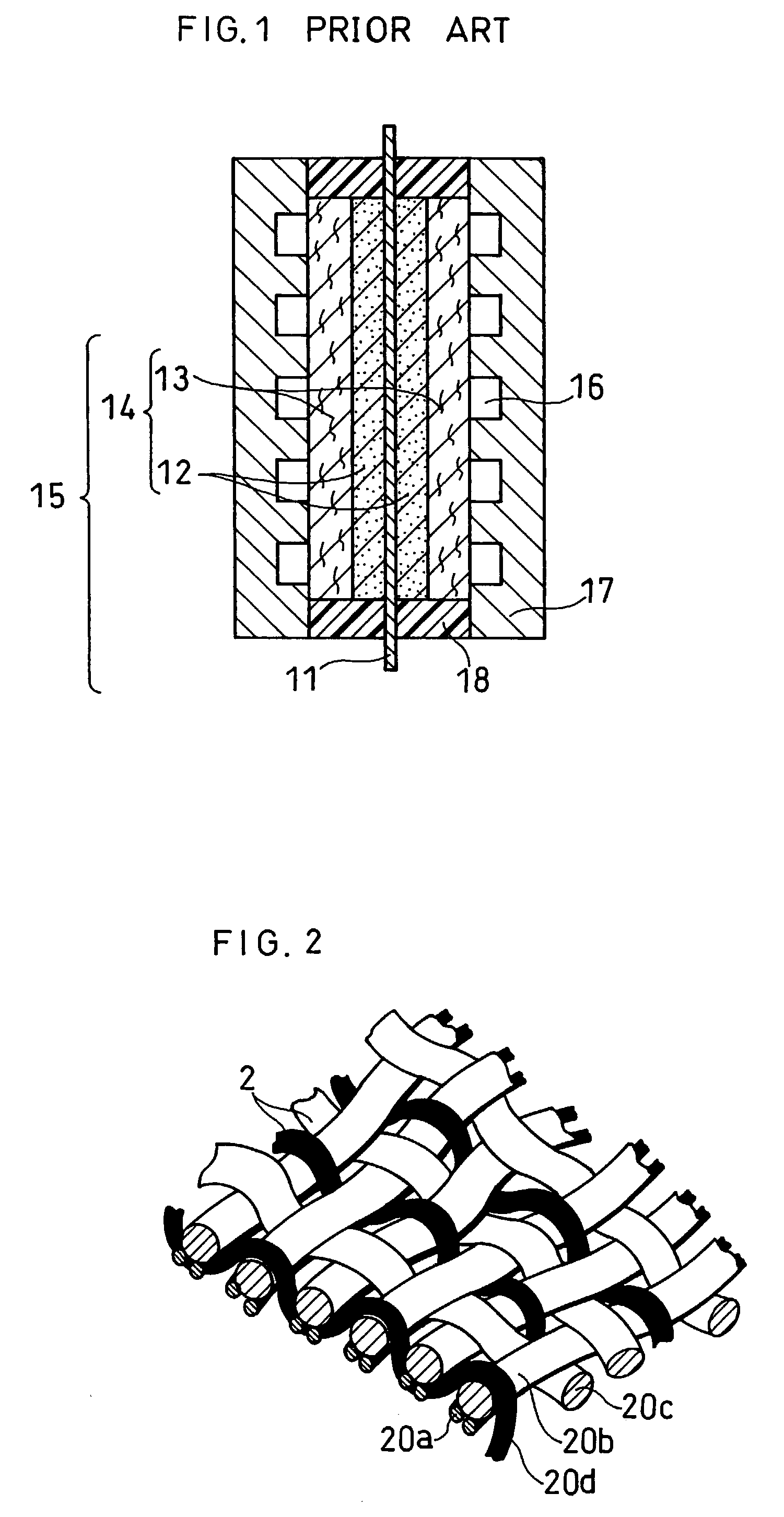

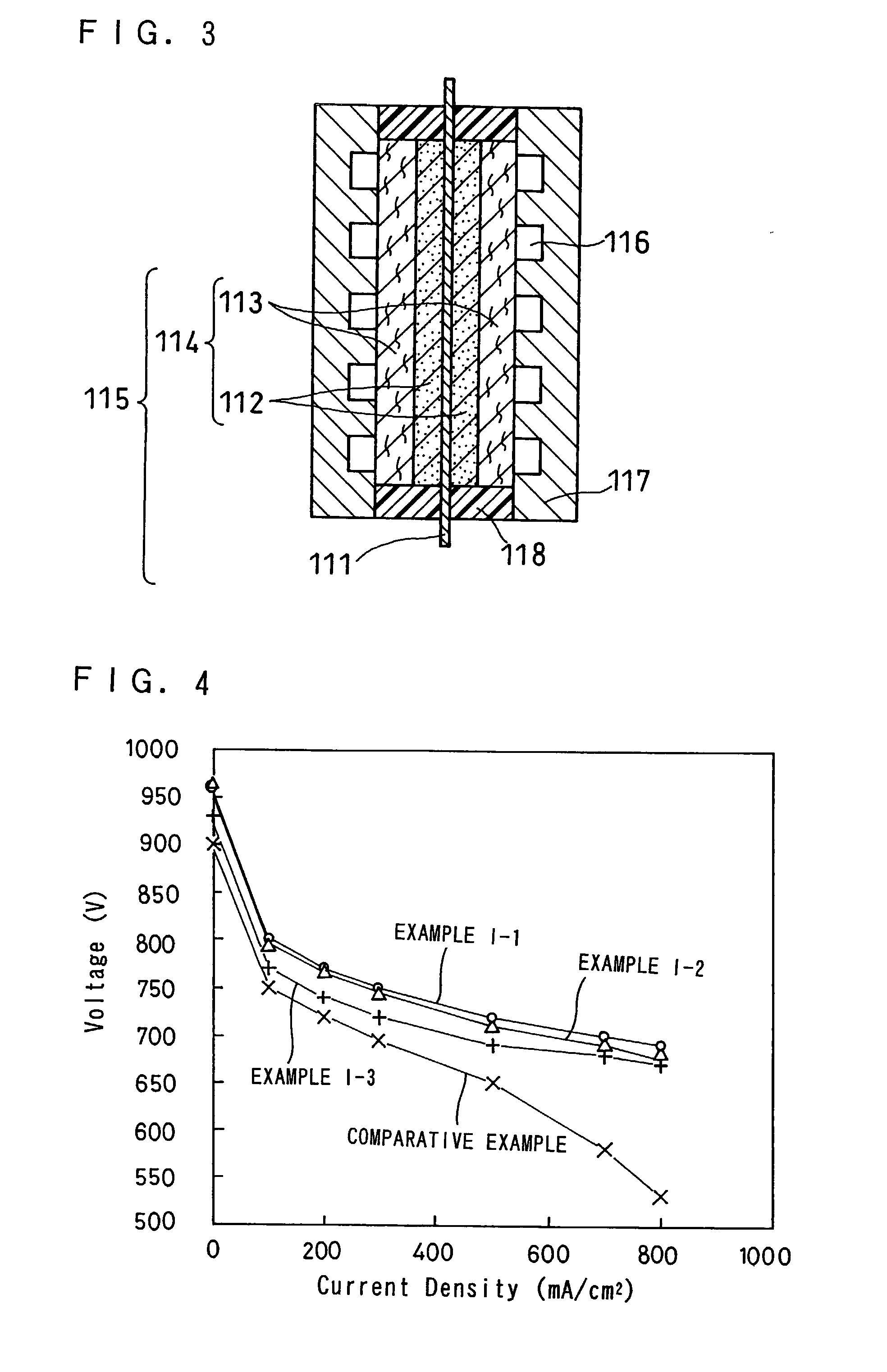

Polymer electrolyte fuel cell

InactiveUS7060384B2Improve performanceImprove basic performanceFuel cell auxillariesActive material electrodesChemistryLarge pore

A porous supporting carbon body of a gas diffusion layer is provided with a larger number of smaller pores at its catalyst layer side and a smaller number of larger pores at the other side, particularly with an appropriate distribution of finer mesh at its catalyst layer side and coarser mesh at the other side. As a result, a high performance polymer electrolyte fuel cell is obtained in which water generated at the catalyst layer is quickly sucked out to the gas diffusion layer, and is evaporated at the gas diffusion layer to be effectively exhausted to outside the fuel cell, so that excessive water can be prevented from retaining in the gas diffusion electrode, with the polymer electrolyte membrane being maintained at an appropriately wet condition.

Owner:PANASONIC CORP

Artistic coating and preparation method thereof

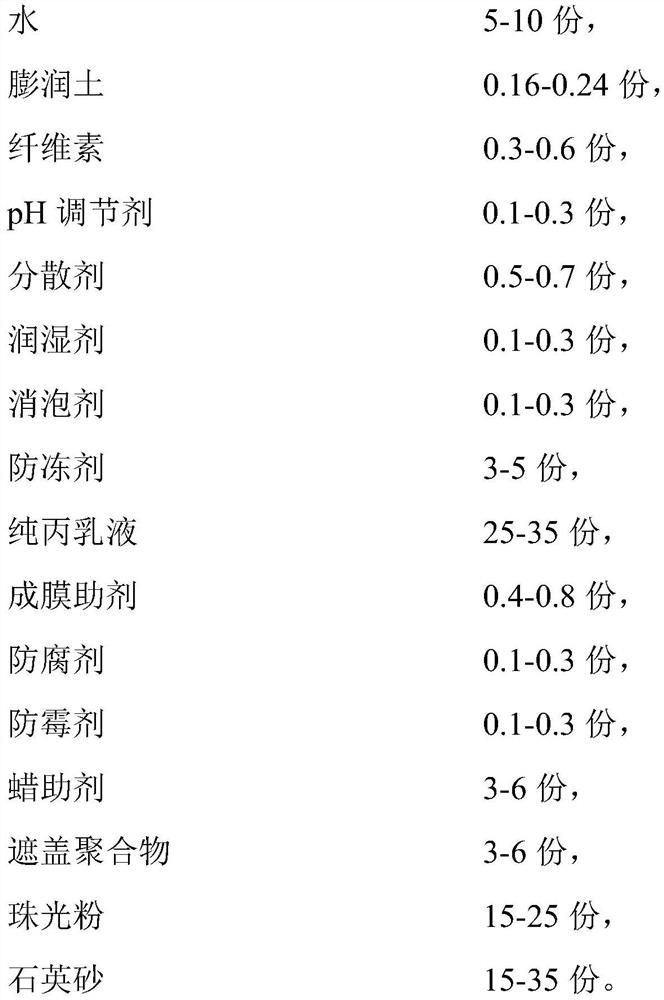

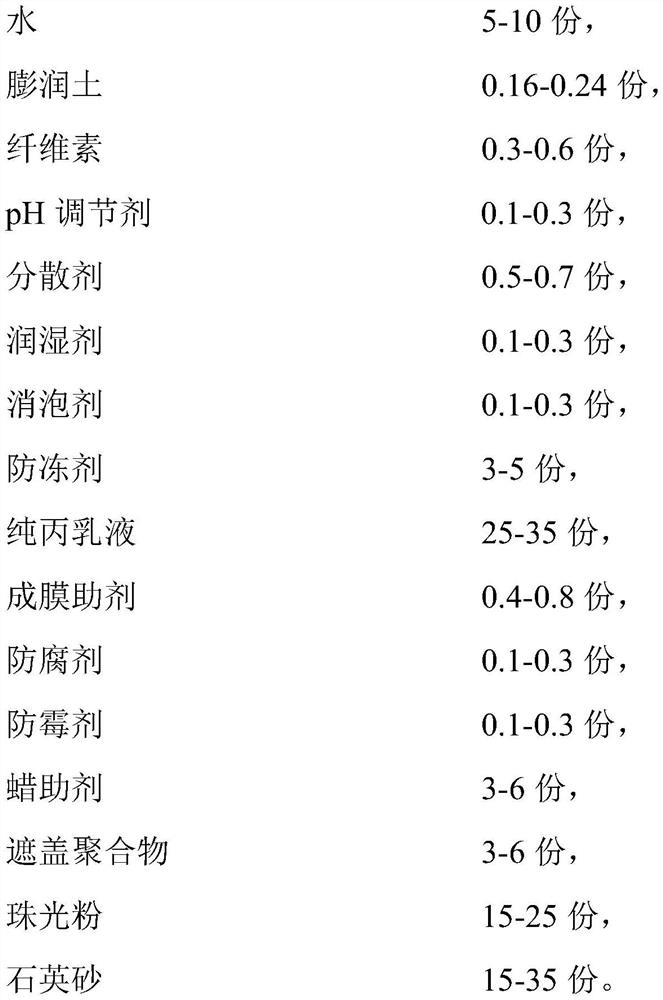

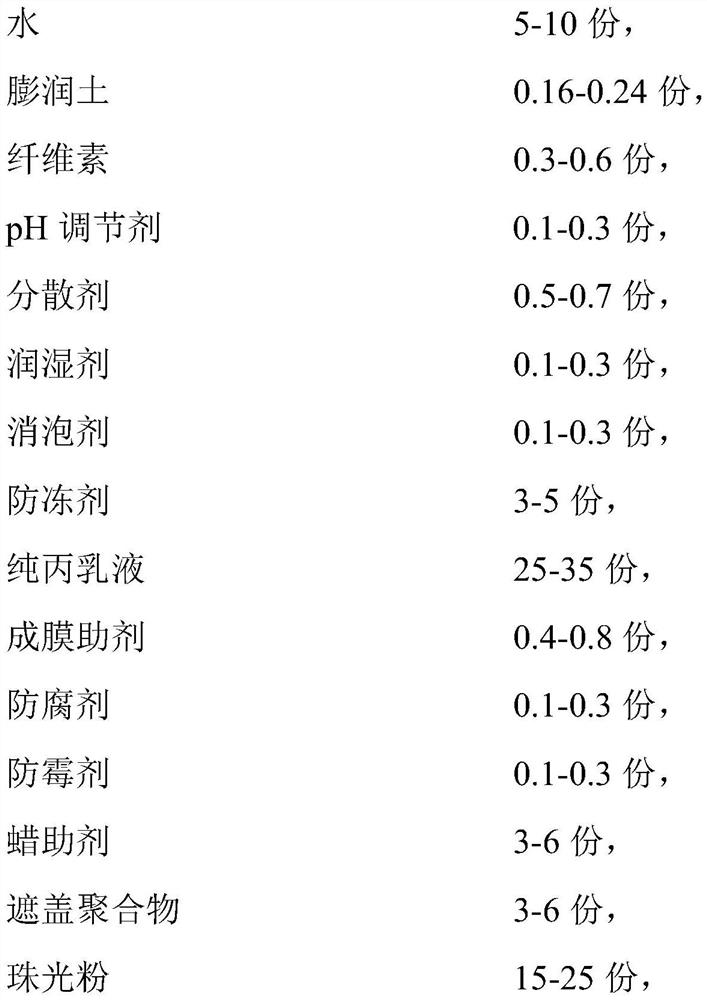

InactiveCN112063249AImprove thixotropic effectGood storage stabilityAntifouling/underwater paintsPaints with biocidesDefoaming AgentsCellulose

The invention belongs to the technical field of coatings and provides an artistic coating which comprises the following components in parts by weight: 5-10 parts of water, 0.16-0.24 parts of bentonite, 0.3-0.6 parts of cellulose, 0.1-0.3 parts of a pH regulator, 0.5-0.7 parts of a dispersing agent, 0.1-0.3 parts of a wetting agent, 0.1-0.3 parts of a defoaming agent, 3-5 parts of an anti-freezingagent, 25-35 parts of pure acrylic emulsion, 0.4-0.8 parts of a coalescing agent, 0.1-0.3 parts of a preservative, 0.1-0.3 parts of a mildew preventive, 3-6 parts of a wax aid, 3-6 parts of a coveringpolymer, 15-25 parts of pearl powder and 15-35 parts of quartz sand. Through the synergistic effect of the components, the construction difficulty of the coating is effectively reduced while the original basic performance of a paint film is maintained, and the artistic coating is endowed with good adhesive force, high stain resistance, high glossiness, decorative performance, low VOC and environmental friendliness.

Owner:珠海展辰新材料股份有限公司

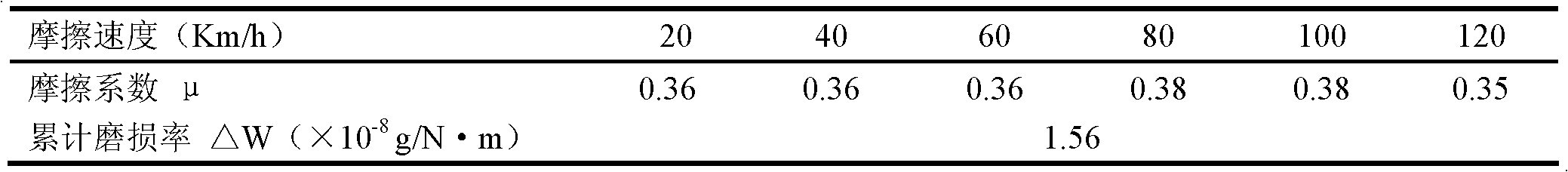

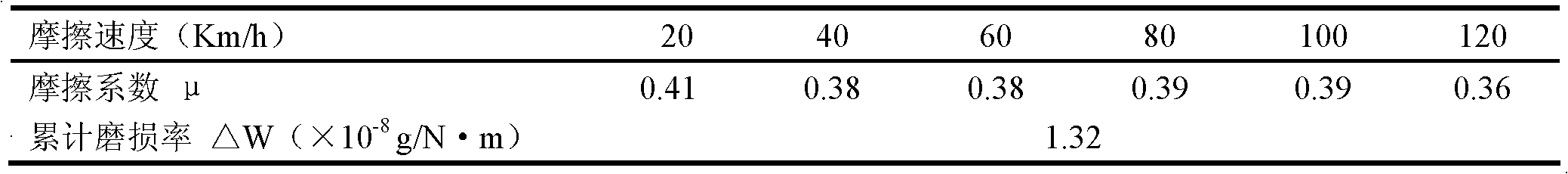

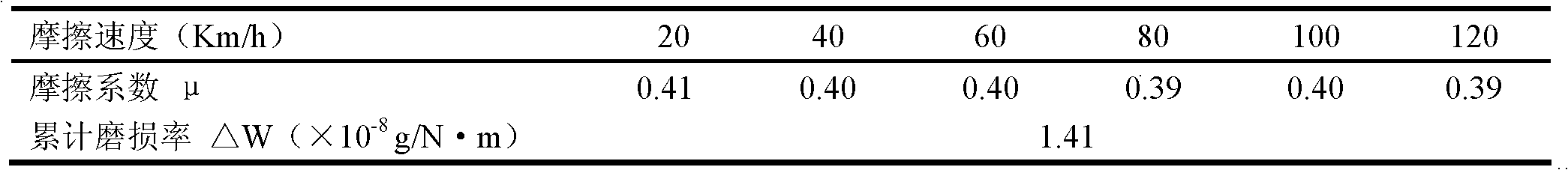

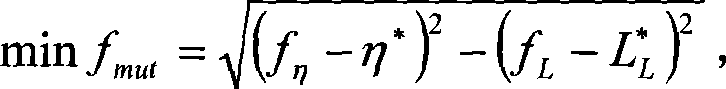

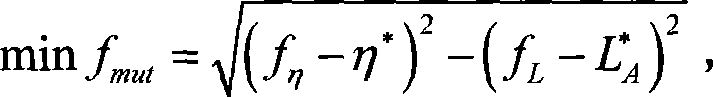

Synthetic brake shoe for urban railway vehicle and preparation method thereof

InactiveCN102134397AImprove basic performanceHigh temperature and high basic performanceFriction liningBrake arrangement with braking memberLow noiseWeather resistance

The invention discloses a synthetic brake shoe for an urban railway vehicle and a preparation method thereof. The synthetic brake shoe for an urban railway vehicle is prepared from acicular wollastonite used as a reinforcing material, polybismaleimide resin used as a base material, and a filling and frictional property regulator by a hot pressing technique. The synthetic brake shoe for an urban railway vehicle is prepared from 8-16% of polybismaleimide resin, 6-14% of nitrile-butadiene rubber, 12-24% of graphite, 4-16% of iron powder, 4-12% of wollastonite, 6-14% of friction powder, 21-39% ofbarite and 0-6% of coupling agent. The synthetic brake shoe for an urban railway vehicle has the advantages of stable friction factor, wear resistance, low abrasion, no cracking or metal inlay, favorable weather resistance and low noise, does not damage wheels, does not pollute the city, and can satisfy the operational requirements for urban railway trains.

Owner:DALIAN JIAOTONG UNIVERSITY

Preparing method of heat preservation paint with waterproof and antifouling performance

InactiveCN106147471AImprove basic performanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesEmulsionMicrosphere

The invention relates to a preparing method of heat preservation paint with waterproof and antifouling performance. The heat preservation paint comprises aggregate, a base material, auxiliary filler and an auxiliary and is characterized in that hollow glass microspheres serve as the aggregate, the base material is silicone-acrylic emulsion, and the heat preservation paint composition comprises, by weight, 16-18 parts of hollow glass microspheres and 21-27 parts of silicone-acrylic emulsion. As the silicone-acrylic emulsion is selected, while having excellent heat preservation performance, the heat preservation paint has good waterproof and antifouling performance, and particularly fluorine-containing silicone-acrylic emulsion is selected, so that the waterproof and antifouling performance of the heat preservation paint is more excellent.

Owner:泉州市合创涂料科技有限公司

Method for lowering multi-wing centrifugal fan noise

InactiveCN101021880AImprove basic performanceSpecial data processing applicationsImpellerDesign plan

This invention relates to a method for reducing noises of multi-wing centrifugal fans including the following steps: 1, carrying out number simulation and molding simulation to a model fan with the technology of computation of hydrokinetics, 2, determining the sphere of low noise fan structure parameters, 3, setting up multi-target restrained function of the fan with noise and efficiency as the target, stipulating the restraining condition in terms of the parameter sphere in step 2 to determine initial available points to carry out iteration computation utilizing an engineering complex method to get the design parameter of the fan, 4, carrying out orthogonal combination to the received optimized parameters and number simulation and determining the section influencing the fan performance the most by listing main elements method to get a final design plan, 5, carrying out number simulation to non-concentric and concentric of the impeller and spiral casing.

Owner:SHANGHAI JIAO TONG UNIV

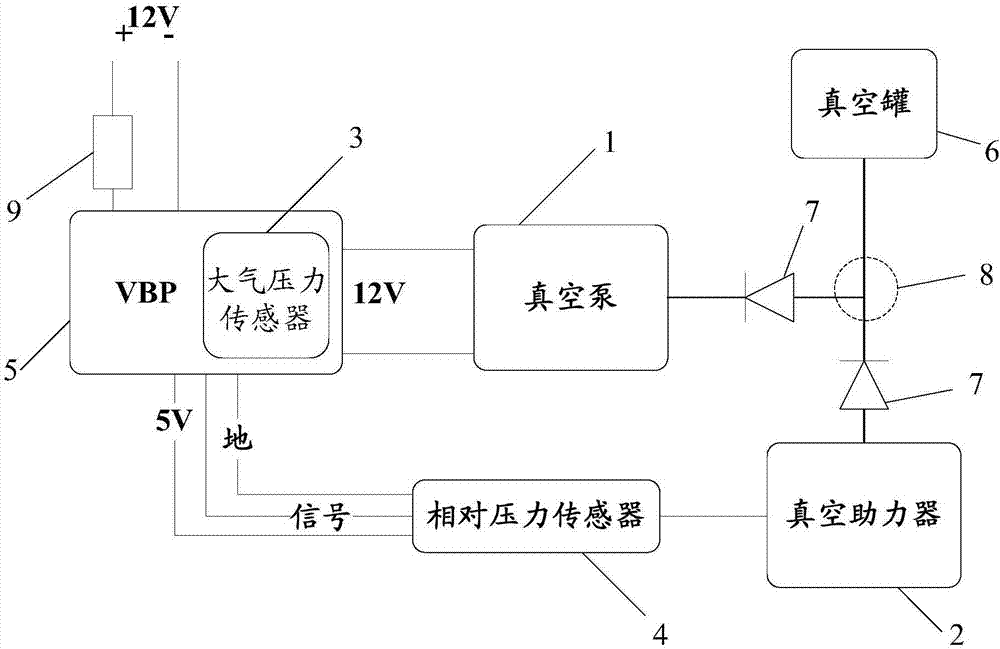

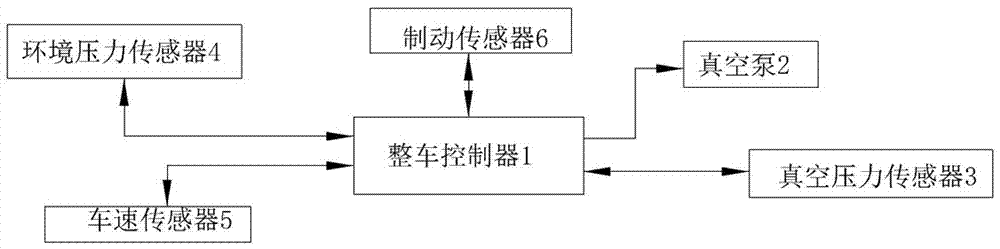

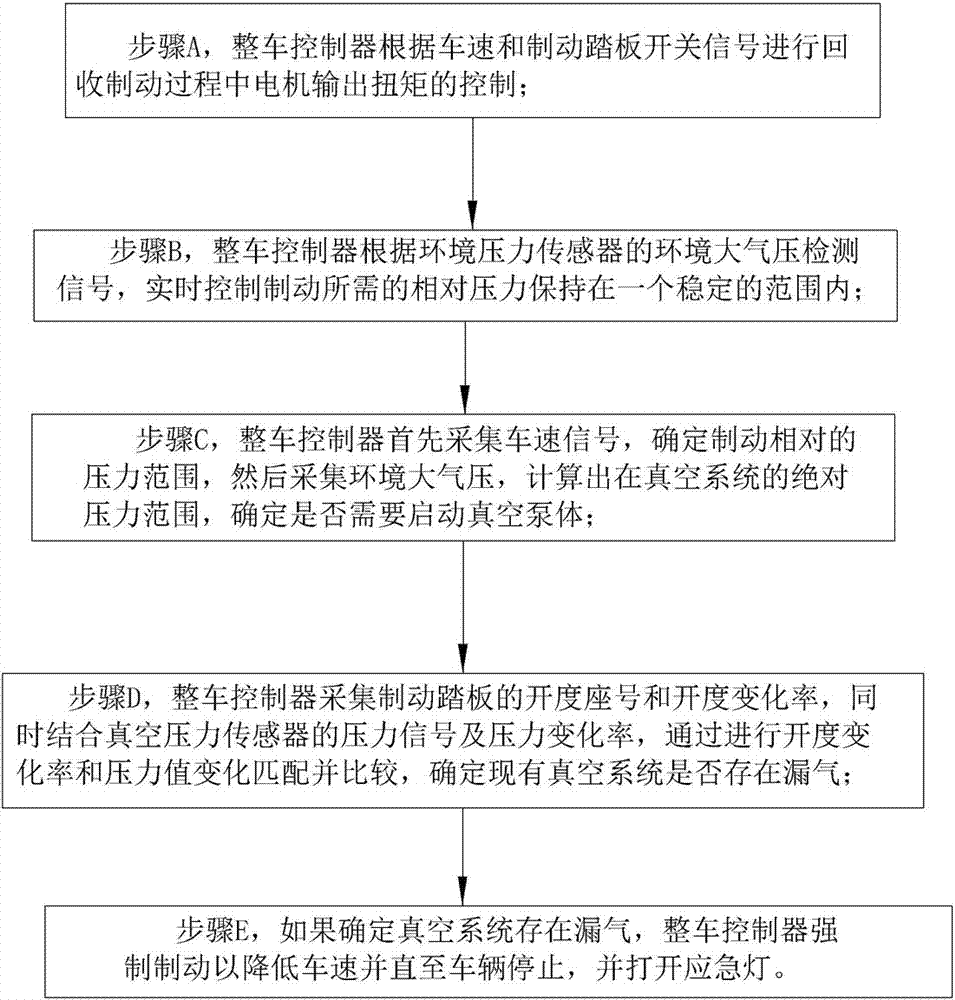

Electric vehicle with vacuum pump control system

InactiveCN107444196AImprove basic performanceImproved braking stabilitySpeed controllerBraking action transmissionAmbient pressureElectric vehicle

The invention discloses an electric vehicle with a vacuum pump control system. The electric vehicle with the vacuum pump control system comprises a vehicle controller, a vacuum pump, a vacuum pressure sensor, an ambient pressure sensor, a speed sensor and a braking sensor. A controlling method for the electric vehicle with the vacuum pump control system comprises the following steps that step A, the vehicle controller controls the motor output torque in the recycling and braking process according to speed and braking pedal switch signals; step B, signals are detected according to the ambient atmospheric pressure; step C, the relative pressure range of braking is determined, the absolute pressure range in a vacuum system is calculated, and whether starting the vacuum pump body is needed or not is determined; step D, opening degree signals and the changing rate of the opening degree of the braking pedal are collected to determine whether gas leaking is existed in the prior vacuum system or not; and step E, if gas leaking in the vacuum system is determined, the vehicle controller brakes enforcedly to reduce the speed until the vehicle is stopped, and an emergency light is turned on. According to the electric vehicle with the vacuum pump control system, the basic performance of the vacuum pump can be improved, running braking stability and reliability of the electric vehicle can be improved, running safety of the vehicle is ensured, applicability is high, and practicability is good.

Owner:中汽院智能网联科技有限公司 +1

Ink-jet recording ink, ink-jet recording method, and ink-jet recording apparatus

InactiveUS20050229811A1Improve the level ofIncrease drive frequencyMeasurement apparatus componentsDuplicating/marking methodsEthylenediaminePolymer science

An ink-jet recording ink containing water and a coloring material, wherein the ink-jet recording ink further contains an ethylenediamine compound represented by Formula (I). wherein R1, R2, R3 and R4 are each selected from the group consisting of a hydrogen atom, an alkyl group and an alkylene oxide group, provided that at least one of R1 and R2 and at least one of R3 and R4 are each an alkylene oxide group, and that alkylene oxide units in one molecule are 2 to 20 in total number.

Owner:CANON KK

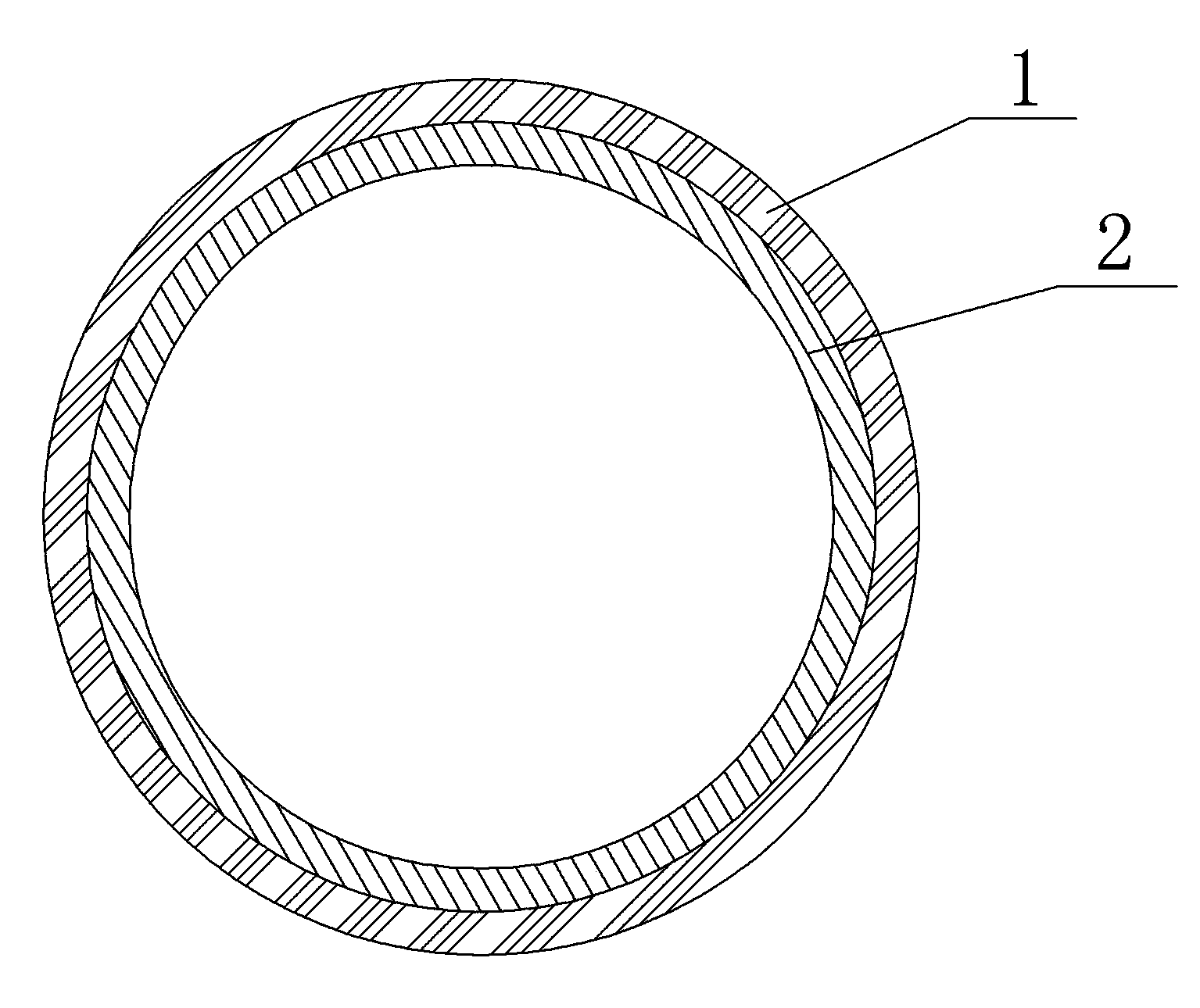

Double-layer composite tube and manufacturing method thereof

ActiveCN104019298AImprove stress resistanceFlow fastFlexible pipesLow-density polyethyleneWater quality

The invention discloses a double-layer composite tube and a manufacturing method thereof. The double-layer composite tube and the manufacturing method aim to solve the technical problems that black pigment is added into traditional HDPE tubes, accordingly inner walls are not smooth, water scale is prone to being generated, bacteria grow, and secondary pollution of water is caused. The double-layer composite tube comprises an inner layer and an outer layer, the inner layer is made of ultrahigh molecular weight polyethylene and ethylene-vinyl alcohol copolymers or low-density polyethylene, and the outer layer is made of high-density polyethylene, ethylene-vinyl alcohol copolymers and special melanin particles C of PE. The method includes the following steps of material proportioning and dehumidifying, material plastifying, material forming, vacuum sizing and spraying and cooling. The double-layer composite tube has the advantages of being good in toughness and flexibility, high in chemical stability, good in corrosion resistance, good in sealing performance, large in distribution power, long in service life, high in low temperature resistance, hygienic, free of toxin and the like. The manufacturing method is simple, easy to operate and capable of achieving integral production of the double-layer composite tube.

Owner:菏泽三垒塑业股份有限公司

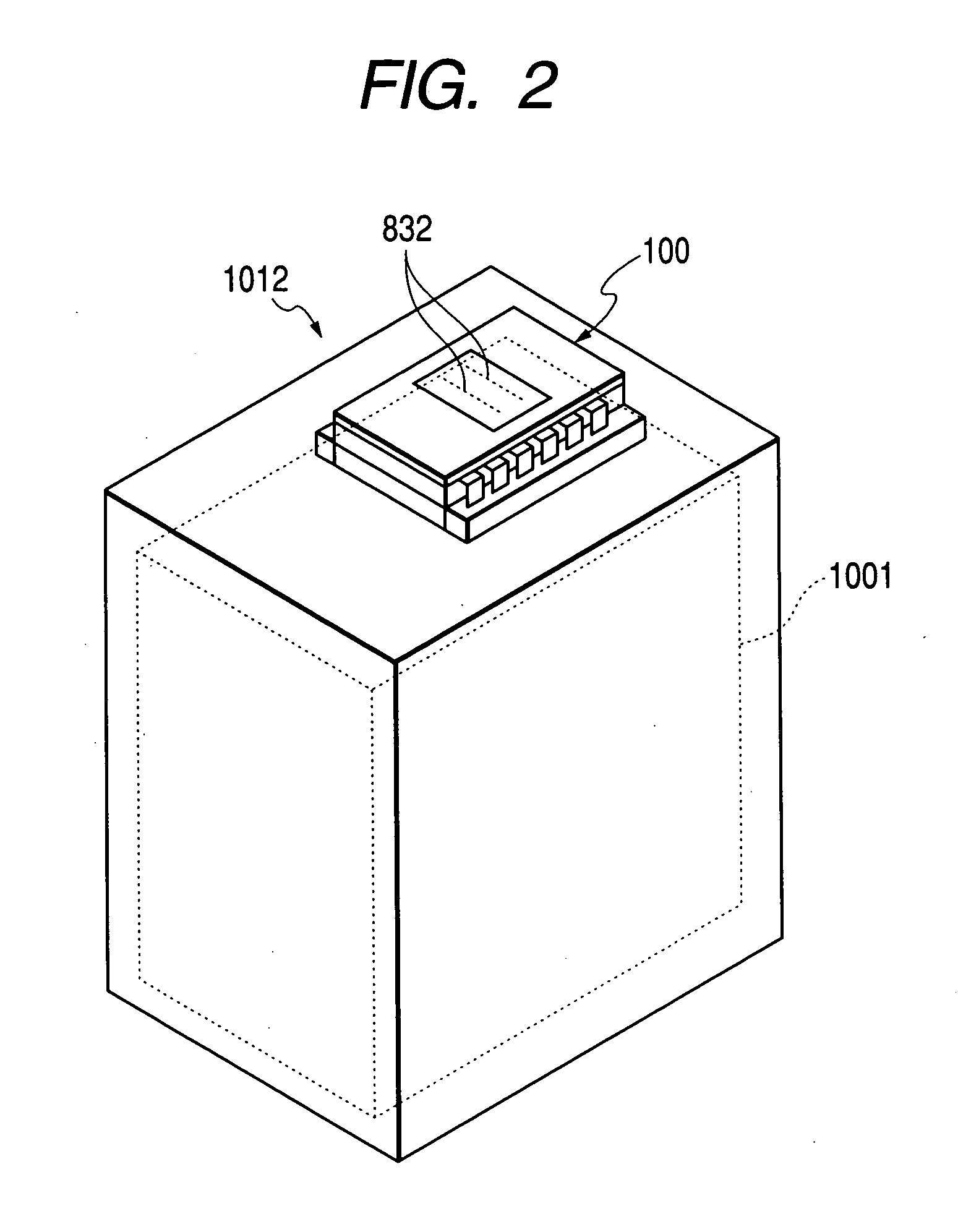

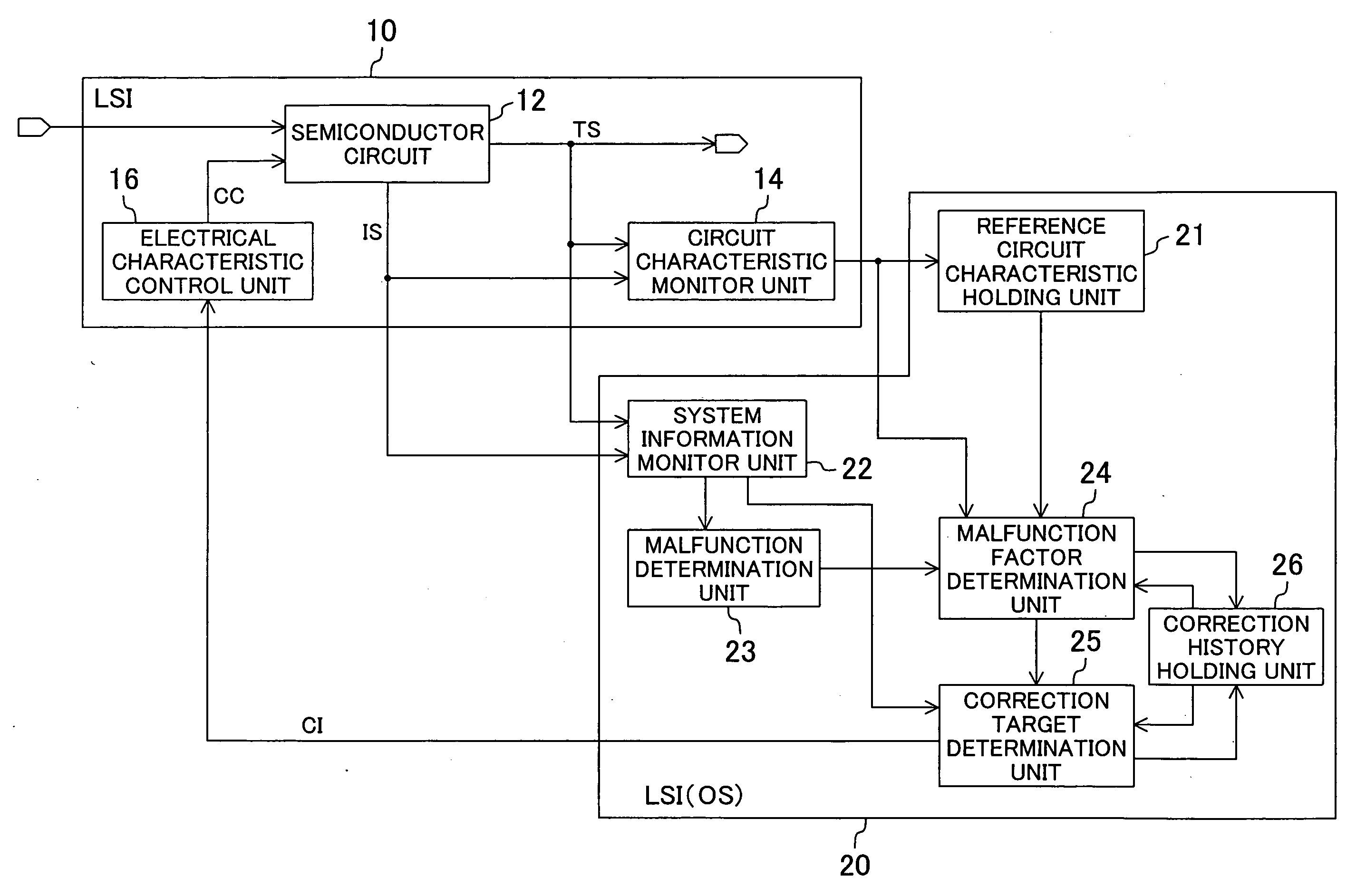

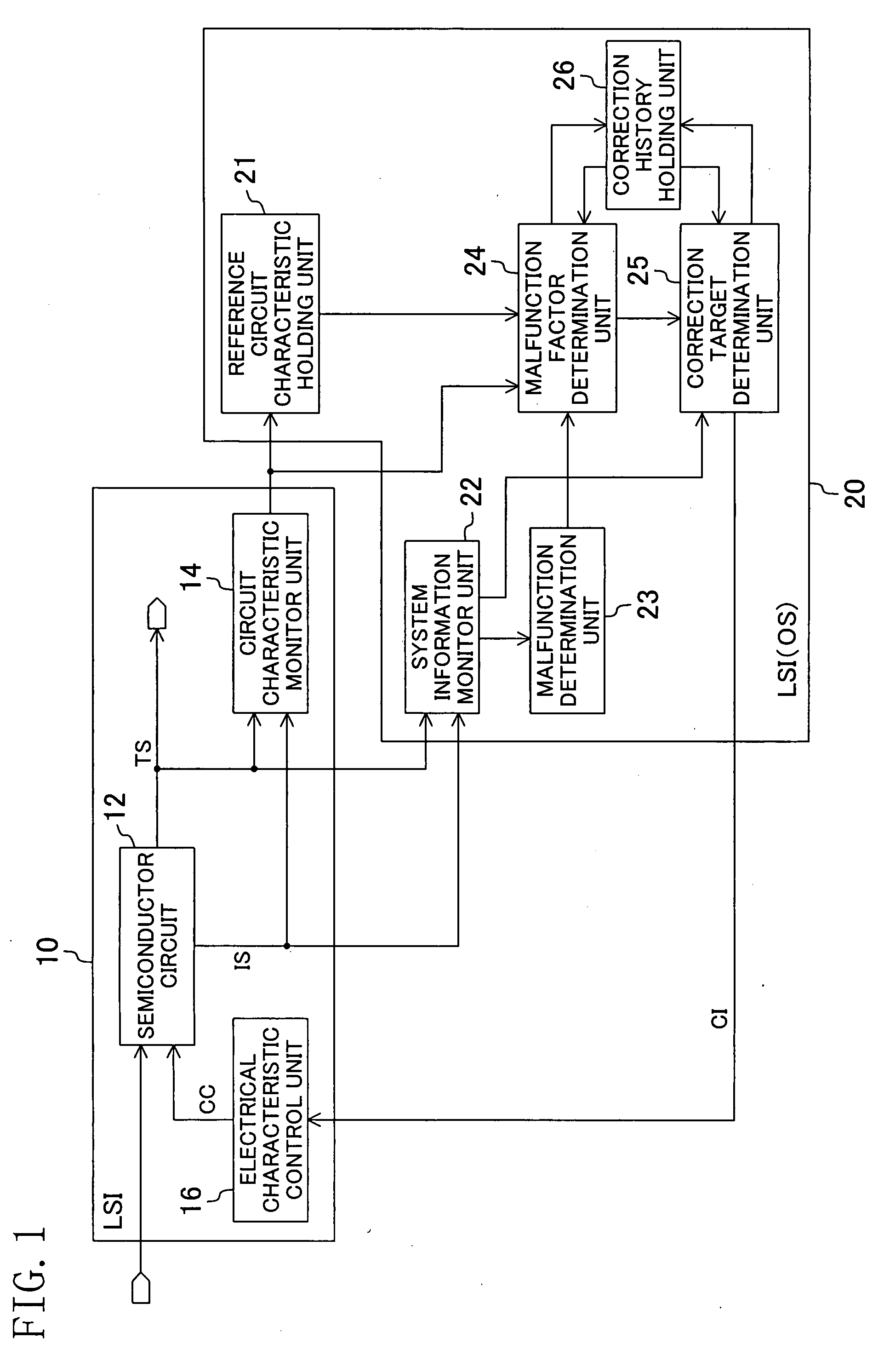

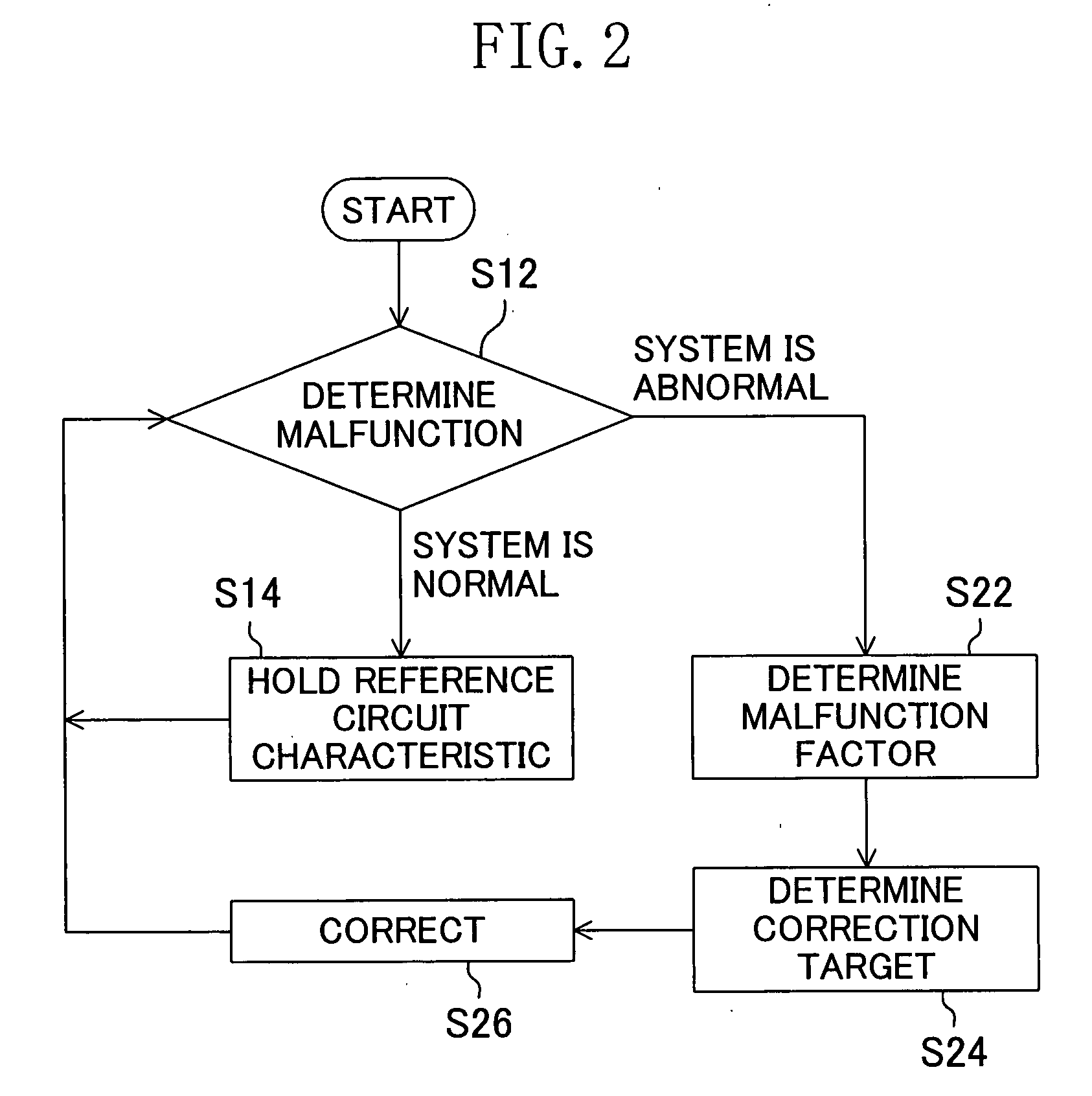

Semiconductor integrated circuit system, semiconductor integrated circuit, operating system, and control method for semiconductor integrated circuit

ActiveUS20070255992A1Good semiconductor performanceImprove performanceElectronic circuit testingError detection/correctionOperational systemEngineering

A semiconductor integrated circuit system has a control target circuit executing a program, a system information monitor unit for outputting system information indicating a state of the control target circuit, a circuit characteristic monitor unit for determining a circuit characteristic of the control target circuit and outputting the circuit characteristic as circuit characteristic information, a malfunction determination unit for determining whether or not the control target circuit is normally operating based on the system information, a reference circuit characteristic holding unit for holding the circuit characteristic information as reference circuit characteristic information when the control target circuit is normally operating, a malfunction factor determination unit for determining a malfunction factor based on the circuit characteristic information and on the reference circuit characteristic information when the control target circuit is not normally operating, and a correction target determination unit for determining a correction target in the control target circuit.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

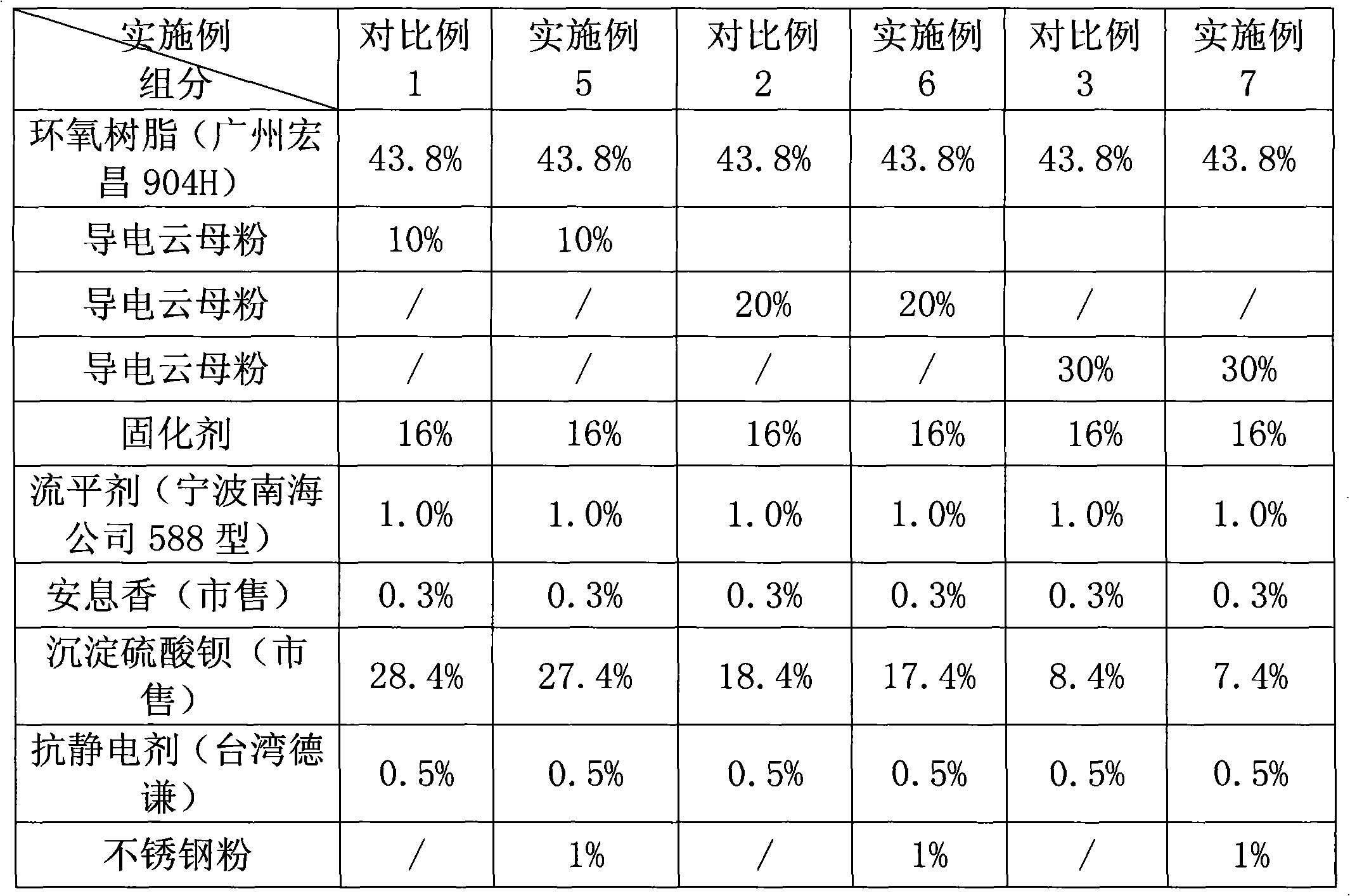

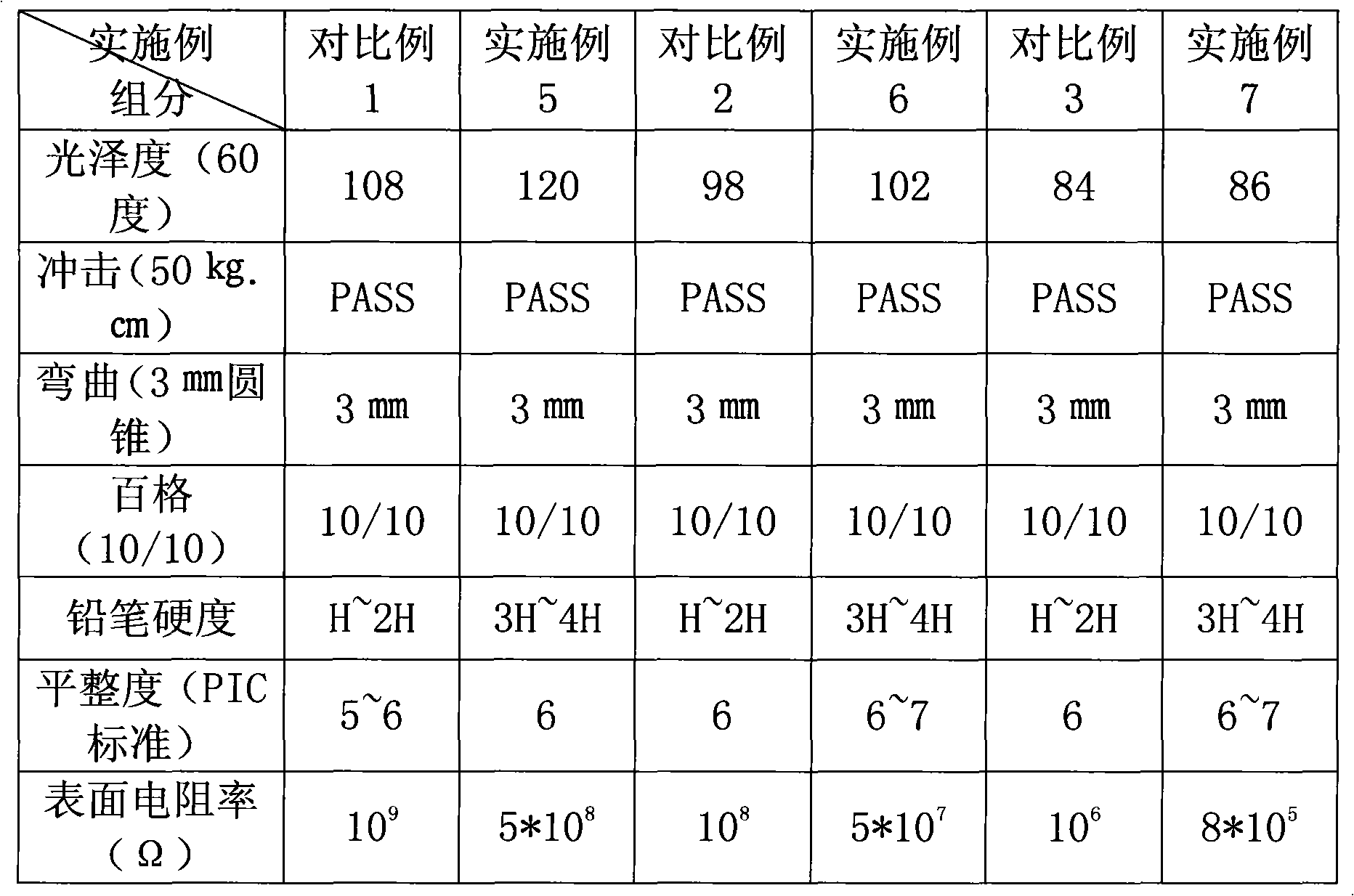

Low-resistance static conducting powder coating as well as preparation method and application thereof

InactiveCN101899255ALow costRich varietyPowdery paintsEpoxy resin coatingsEpoxyElectrical resistance and conductance

The invention relates to a low-resistance static conducting powder coating and a preparation method thereof. The low-resistance static conducting powder coating comprises the following components in percentage by weight: 35-50 percent of epoxy resin, 8-20 percent of curing agent, 10-30 percent of conducting mica powder, 0.5-3 percent of stainless steel powder, 15-30 percent of padding and 1-5 percent of auxiliary agent. The invention also discloses a preparation method and application of the powder coating. The method comprises the following steps of: adopting the high-performance epoxy resin as a film-forming substance; matching with the corresponding curing agent; and adding the conducting mica powder and the stainless steel powder. All basic performances of the project products are improved. The powder coating has lower cost, high safe performance, more category, attractive appearance and practicability, is quite suitable for being applied to industries, such as household appliance products, small household appliance products, electric power distribution cabinets, and the like and can insulate the static electricity of the household appliance products, which is accumulated on the surface of a coating in the running process in time so as to protect the physical and emotional safety and health of a human body.

Owner:ZHEJIANG HUACAI NEW MATERIAL CO LTD

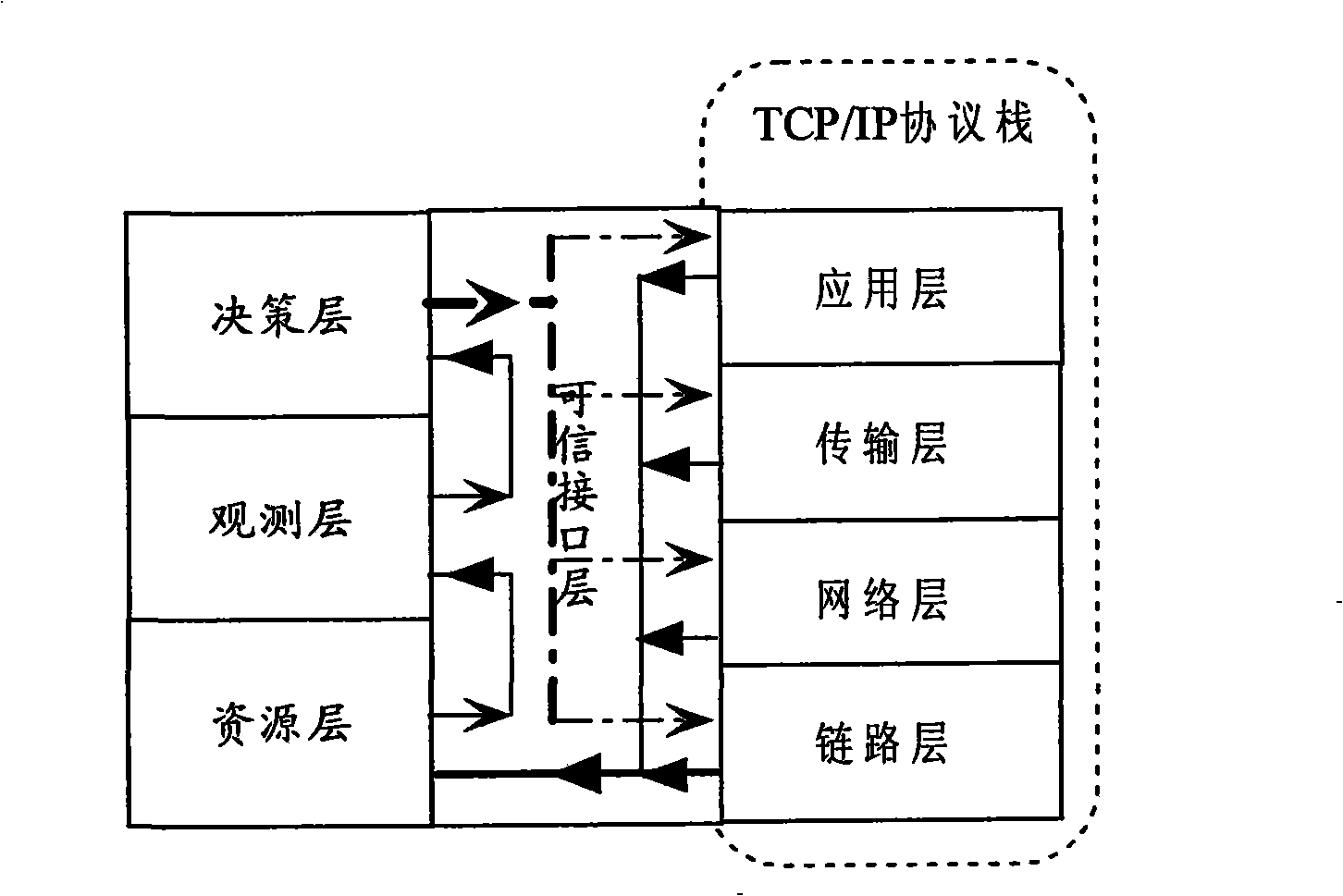

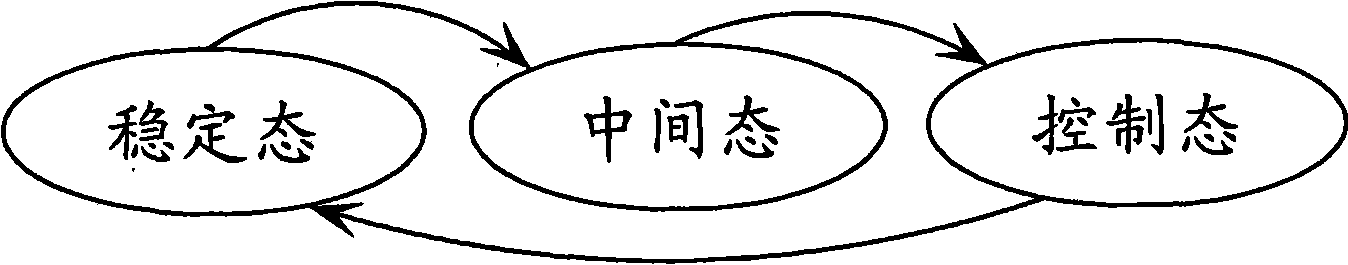

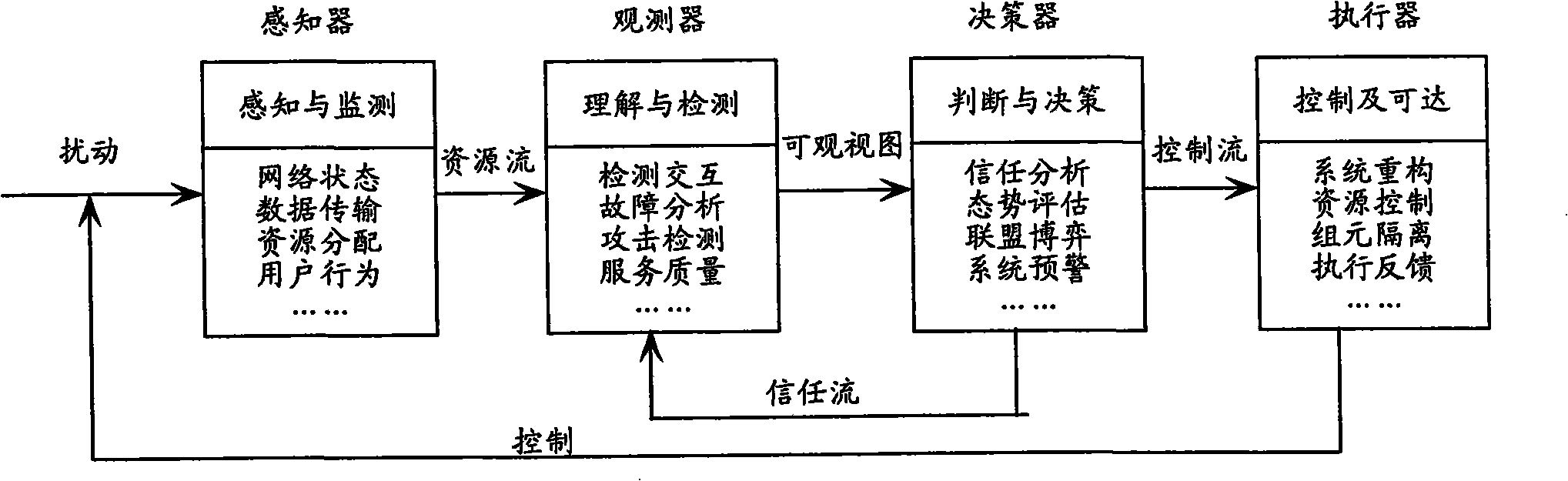

Control method for reliable controllable network architecture

InactiveCN101277303AAvoid graceful degradationSolve the centralization of network management logicData switching networksSystem structureNetwork architecture

A controllable dependable network system structure and a control method thereof are disclosed, which realizes effective control of network resources and user behavior on the basis of current network structure hierarchy, the system structure has four layers like a decision layer, an observation layer, a resource layer and a controllable interface layer, wherein the controllable interface layer achieves the interaction between the current network system and the resource layer in a manner of protocol cross-layer, the resource layer provides the observation layer with a resource stream via the protocol of the controllable interface layer, the observation layer extracts properties from a dependability stream and a logic stream to provide a view with better consistence and observability for the decision layer; the decision layer, on the ground of the observable view and in terms of current situation of the system and the overall profit maximization, sets forth a control proposal which is provided for the network through the dependable interface layer, for the purpose of control; meanwhile, dependability of each component at this moment is given out to be provided for the observation layer via the dependable interface layer in a form of dependability stream.

Owner:SOUTHEAST UNIV

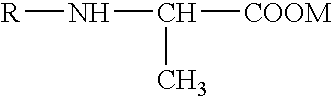

Solid N-acylalanine or a salt thereof

InactiveUS20060111258A1Foaming fastImprove basic performanceCosmetic preparationsHair cosmeticsSolubilityAlkaline earth metal

Solid N-acylalanines comprising one kind or two or more kinds of compounds, each containing an acyl group having a different number of carbon atoms, which is / are selected from the compounds represented by the formula (I): wherein R is a straight chain or branched chain, saturated or unsaturated acyl group having 8 to 22 carbon atoms, and M is a hydrogen atom, an alkali metal, an alkaline earth metal, ammonium, an organic amine or a basic amino acid, and salts thereof, are useful as ingredients for cleansing compositions. Such solid acylalanines and salts thereof are superior in solubility, and are free of moisture absorption or caking during preservation and agglomeration on dissolution in water. Powder or granular cleansing compositions containing such a solid N-acylalanine or salt thereof as a main component (main cleansing component) afford cleansing agents which exhibit extremely excellent properties, are free from caking during preservation and coagulation in practical use, are superior in the basic performance of cleansing agents (lather characteristics), are free of slimyness and friction during use, and are safe with less irritation.

Owner:AJINOMOTO CO INC

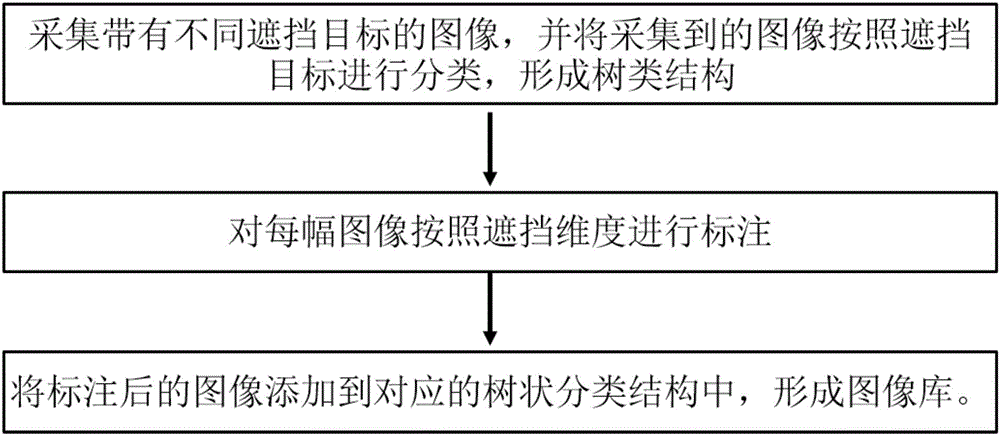

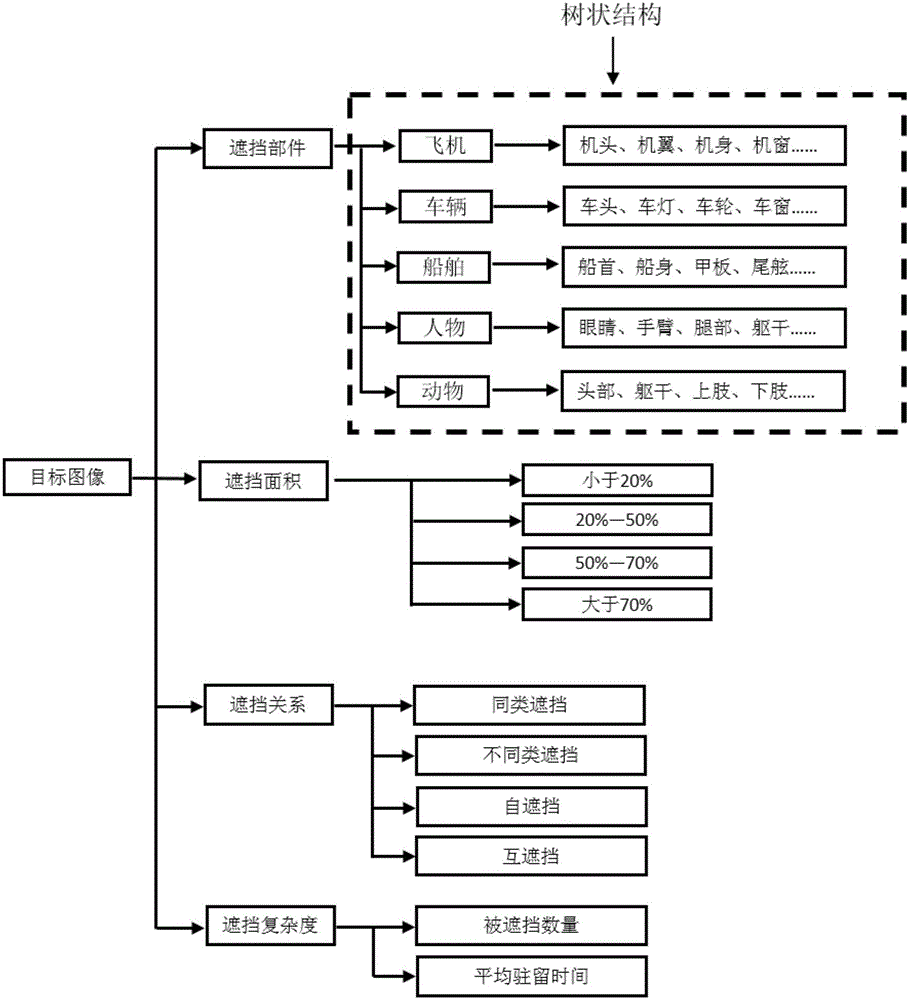

Blocking dimension based image library establishing method

ActiveCN106503170AStrong targetingImprove basic performanceCharacter and pattern recognitionSpecial data processing applicationsGraphicsPattern recognition

The invention discloses a blocking dimension based image library establishing method and belongs to the technical field of image processing. The blocking dimension based image library establishing method comprises the steps that images with different blocking targets are acquired, and the acquired images are classified according to the blocking targets to form a tree structure; each image is marked according to blocking dimensions; the marked images are added to corresponding tree-like classification structures so as to form an image library; follow-up acquired blocking images are successively added to the image library by adopting the same processing method to further update and perfect the image library. The blocking dimension based image library establishing method has the advantages of being strong in pertinence, good in fundamentality and wide in application prospect.

Owner:TSINGHUA UNIV

Proximity effect correction with regard to a semiconductor circuit design pattern

InactiveUS7689968B2Increase weightImprove accuracySolid-state devicesSemiconductor/solid-state device manufacturingComputer scienceDesign pattern

A pattern correction apparatus for performing both of optical proximity effect correction and process proximity effect correction with regard to a design pattern includes: a correction calculation means configured to perform correction calculation by two-dimensional model-based optical proximity effect correction for each of sampling points set on pattern edges which form the design pattern; the correction calculation means performing the correction calculation which involves weighting with a two-dimensional distribution of the pattern edges around the sampling point taken into consideration; the weighting being performed such that a high weight is applied to a region in which reaction products which can have an influence on the sampling point are produced but a low weight is applied to any other region.

Owner:SONY CORP

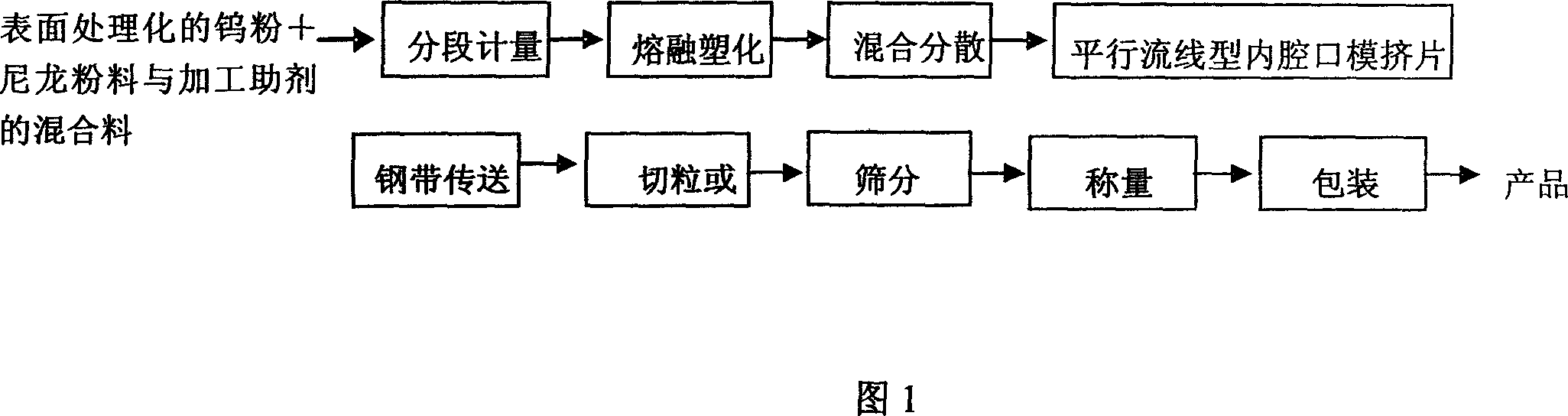

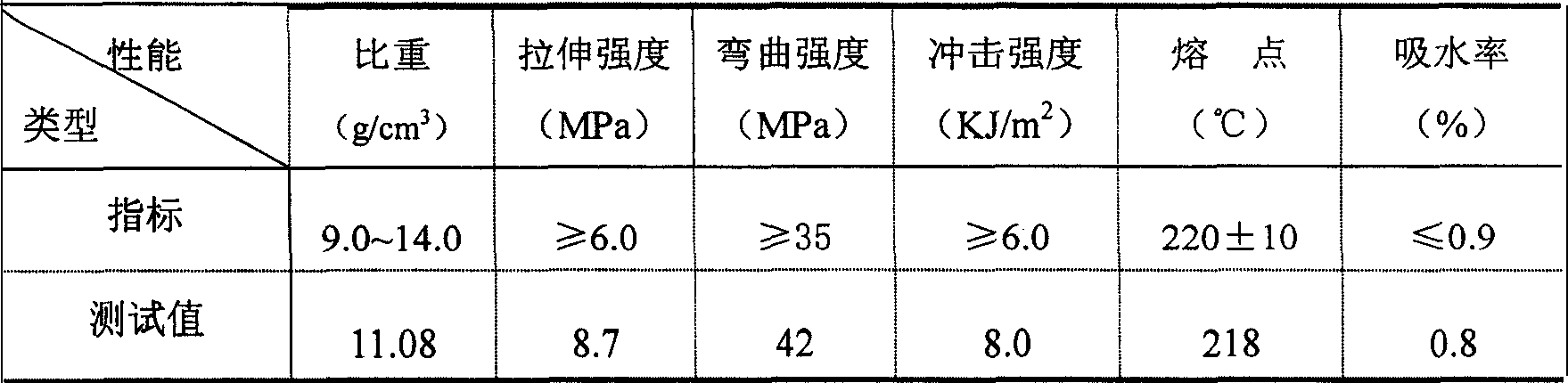

Production of high-specific weight resin

Production of high-specific weight is carried out by mixing tungsten powder with surface activator in proportion of 1000:0.8-1.5 proportion, agitating at normal temperature in ball grinder, surface activation pre-treating, mixing Nylon PA powder and coupler with plasticizer, lubricant, brightener and anti-ageing agent in proportion of 18-22:0.3-0.5:0.8-1.2:1.1-1.5:0.1-0.3:0.08-0.12 proportion, high-speed agitating in agitator at 600-900 circle / min for 6-10 mins, metering while charging for Nylon PA powder and accessory in bi-screw extruder, passing through paralleling streamline-shaped internal-cavity mouth, extruding into flake at 180-220 degree and 8-20 circle / min, and crushing to obtain final product. It's convenient and reasonable, and has excellent universal performance.

Owner:NINGBO NENGZHIGUANG NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com