Low-resistance static conducting powder coating as well as preparation method and application thereof

A powder coating, electrostatic conduction technology, applied in powder coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems affecting printing speed and printing quality, reducing product quality, secondary accidents, etc., to achieve a variety of beautiful and practical, improve Basic performance and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

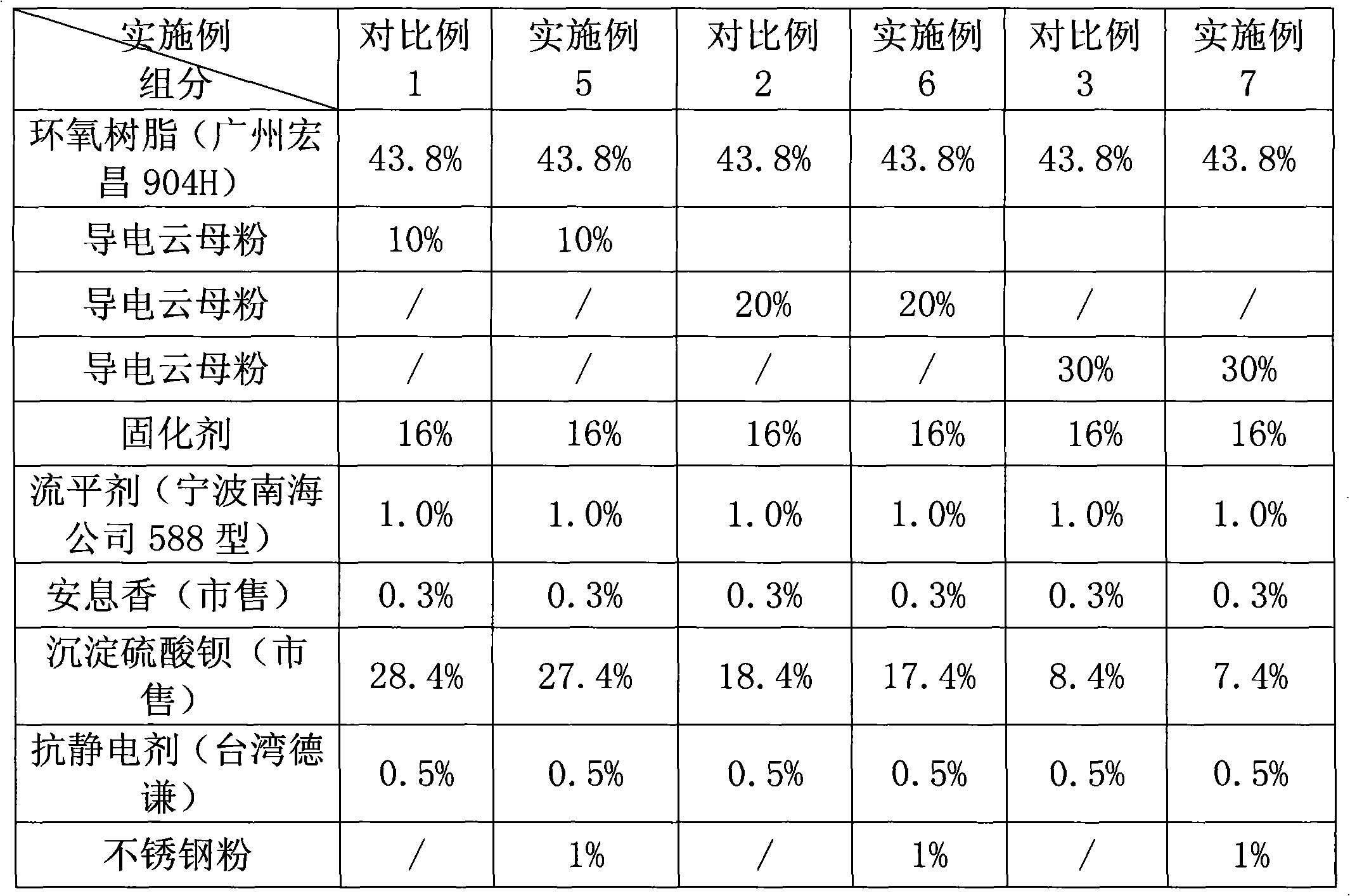

[0039] A low-resistance electrostatic conductive powder coating, the powder coating comprises the following components by weight percentage:

[0040] Epoxy resin 40%, curing agent 12%,

[0041] Conductive mica powder 15%, stainless steel powder 1.0%,

[0042] Precipitated barium sulfate 30%, leveling agent 1%,

[0043] Benzoin 0.5%, antistatic agent 0.5%.

[0044] The formula consists of accurately weighing the materials and mixing them in a high-speed mixer for 6-8 minutes; after mixing, the materials are extruded by an extruder at a temperature of 90-100 °C; the extruded materials are cooled and crushed and crushed into an average particle size by a pulverizer It is powder particles of 38-42 microns; sieved with a 160-mesh sieve, and finally packaged into a finished product.

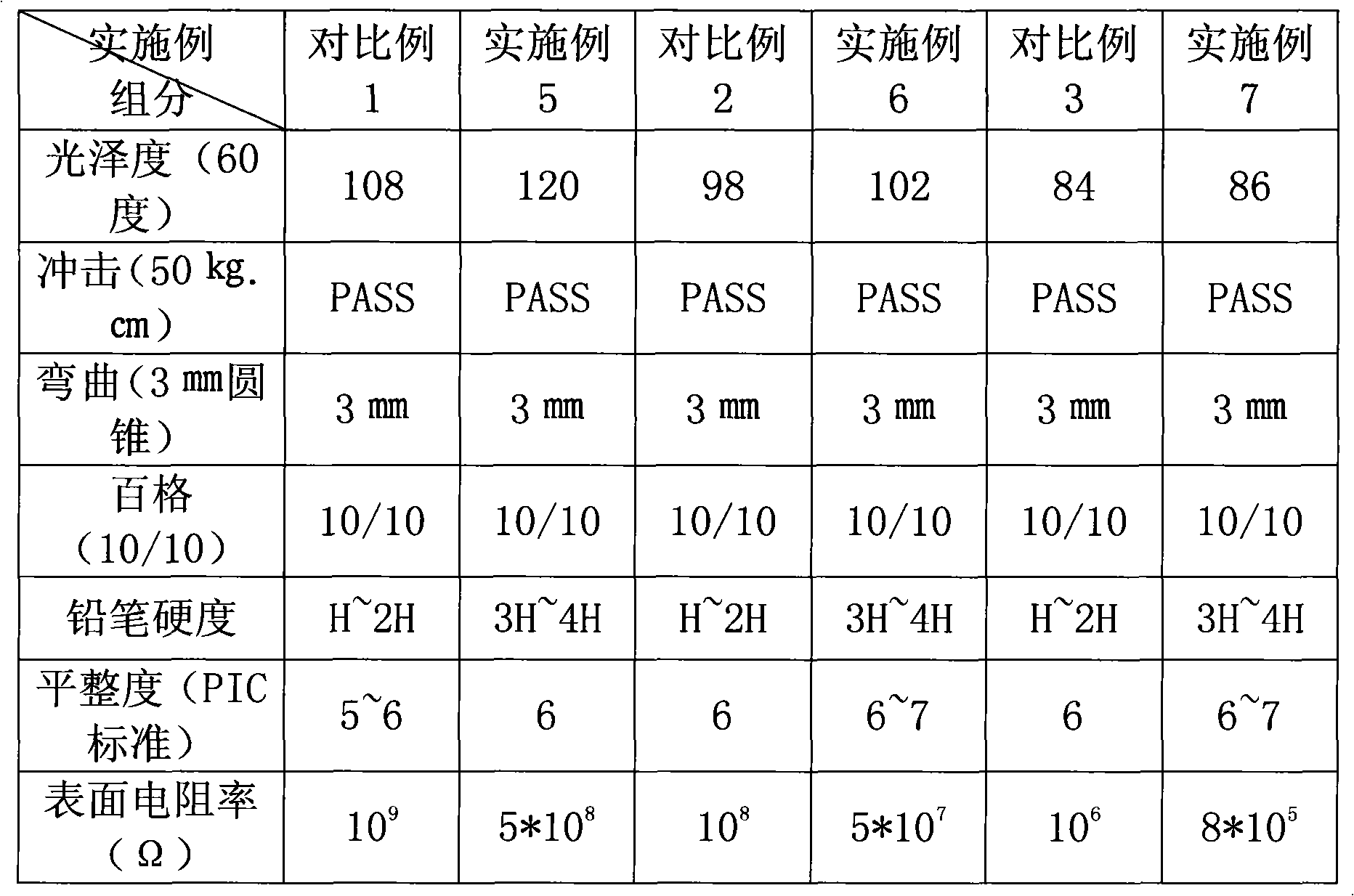

[0045] After testing, the product of this embodiment can reach the following technical indicators after film formation:

[0046] Hardness ≥2H; Gloss 50-100%;

[0047] Adhesion ≤ grade 1; impact re...

Embodiment 2

[0050] A low-resistance electrostatic conductive powder coating, the powder coating comprises the following components by weight percentage:

[0051] Epoxy resin 45%, curing agent 18%,

[0052] Conductive mica powder 24%, stainless steel powder 1.0%,

[0053] Superfine calcium carbonate 20%, leveling agent 1%,

[0054] Benzoin 0.5%, antistatic agent 0.5%.

[0055] The formula consists of accurately weighing the materials and mixing them in a high-speed mixer for 6-8 minutes; after mixing, the materials are extruded by an extruder at a temperature of 90-100 °C; the extruded materials are cooled and crushed and crushed into an average particle size by a pulverizer It is powder particles of 38-42 microns; sieved with a 160-mesh sieve, and finally packaged into a finished product.

[0056] After testing, the product of this embodiment can reach the following technical indicators after film formation:

[0057] Hardness ≥2H; Gloss 50-100%;

[0058] Adhesion ≤ grade 1; impact re...

Embodiment 3

[0061] A low-resistance electrostatic conductive powder coating, the powder coating comprises the following components by weight percentage:

[0062] Epoxy resin 43.8%, curing agent 10%,

[0063] Conductive mica powder 10%, stainless steel powder 1.5%,

[0064] Precipitated barium sulfate 33%, leveling agent 1%,

[0065] Benzoin 0.2%, antistatic agent 0.5%.

[0066] The formula consists of accurately weighing the materials and mixing them in a high-speed mixer for 6 to 8 minutes; after mixing, the materials are extruded by an extruder at a temperature of 90 to 100 °C; the extruded materials are cooled and crushed and crushed into an average particle size by a pulverizer It is powder particles of 38-42 microns; sieved with a 160-mesh sieve, and finally packaged into a finished product.

[0067] After testing, the product of this embodiment can reach the following technical indicators after film formation:

[0068] Hardness ≥2H; Gloss 50-100%

[0069] Adhesion ≤ grade 1; im...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com