Patents

Literature

166results about How to "Foaming fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

Foam scrubbing agent as well as preparation method and application thereof

ActiveCN105154053ALow flow resistanceIncrease productionFluid removalDrilling compositionGlycineActive agent

The invention provides a foam scrubbing agent as well as a preparation method and application thereof. The foam scrubbing agent comprises components in weight of 25%-50% of glycine betaine, 6%-28% of alpha-sodium-olefinsulfonate, 3%-14% of cocoanut fatty acid diethanolamide, 10%-22% of a fluorocarbon surfactant and the balance of water. The invention further provides a preparation method and application of the foam scrubbing agent in processing a natural gas well. The foam scrubbing agent has the advantages of high temperature resistance, high salinity resistance and gas condensate resistance, and the use concentration of the foam scrubbing agent in mineralized water is 0.2%-1.2%. Besides, the foam scrubbing agent has the characteristics that raw materials are easy to obtain, the toxicity is low, and the agent is easy to degrade, doesn't react with gas and liquid components and is favorable for large-scale application of a site gas well.

Owner:PETROCHINA CO LTD

Foamer and foam gas flooding method

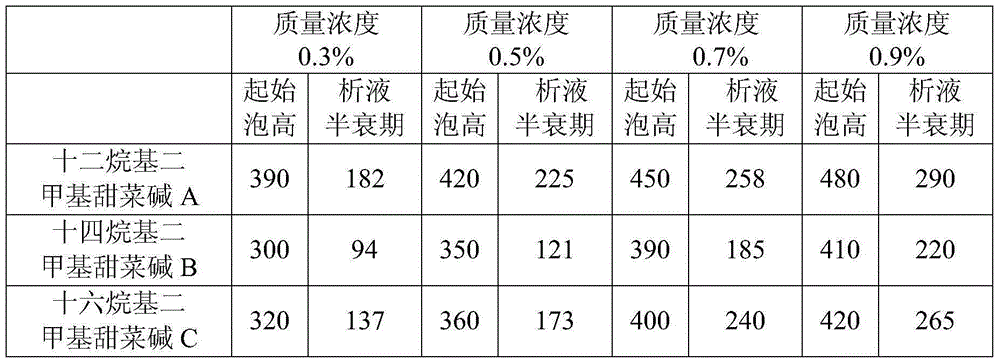

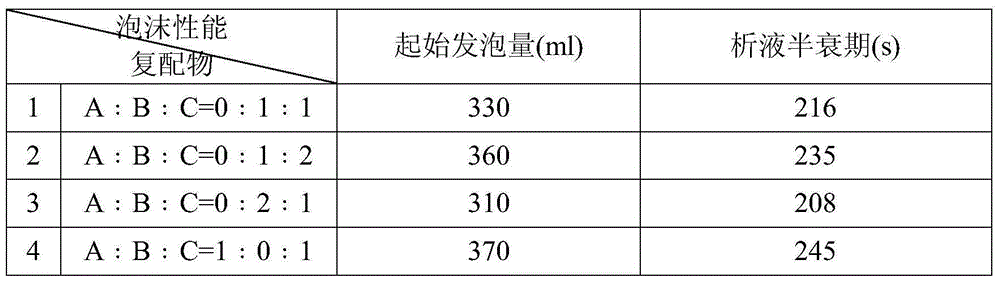

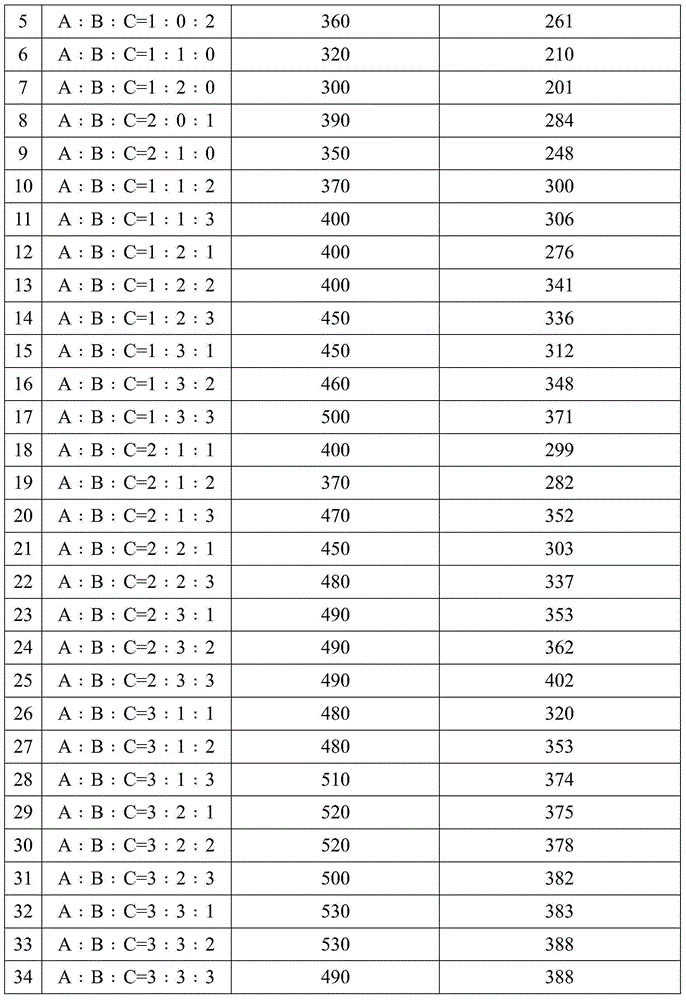

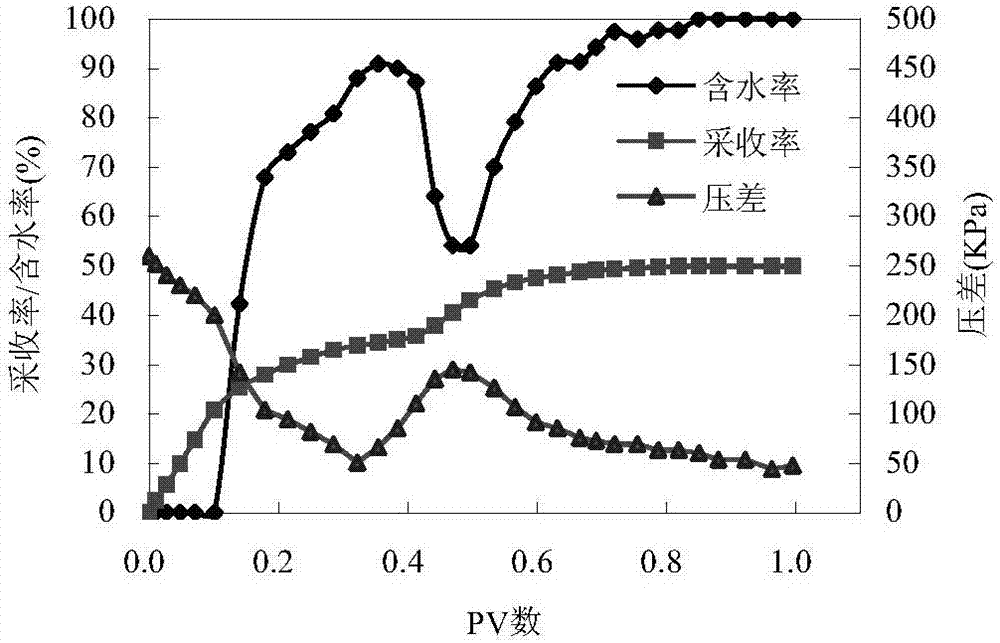

ActiveCN107227147APlugged channelingFoaming fastFluid removalDrilling compositionAlcoholInjection equipment

The invention relates to the field of foam flooding and discloses a foamer and a foam gas flooding method. The foamer comprises a weak-cationic amphoteric surfactant, water and at least one of cationic surfactant, amphoteric surfactant and alcohol. The foam gas flooding method comprises the steps of injecting the weak-cationic amphoteric surfactant containing foamer and gas into an oil reservoir, and carrying out foam profile control and oil displacement. According to the foamer and the method, disclosed by the invention, the foamer has high foamability, stability and profile control and oil displacement capability, so that the corrosion action on injection equipment and an oilfield injection-production system caused by air foam in an air foam flooding profile control and oil displacement process can be obviously lowered; and the foamer not only can be applied to a foam profile control and oil displacement process of ordinary strata, but also can be applicable to the foam profile control and oil displacement process under the condition that stratum water is high in degree of mineralization and high in calcium and magnesium ion content.

Owner:CHINA PETROLEUM & CHEM CORP +1

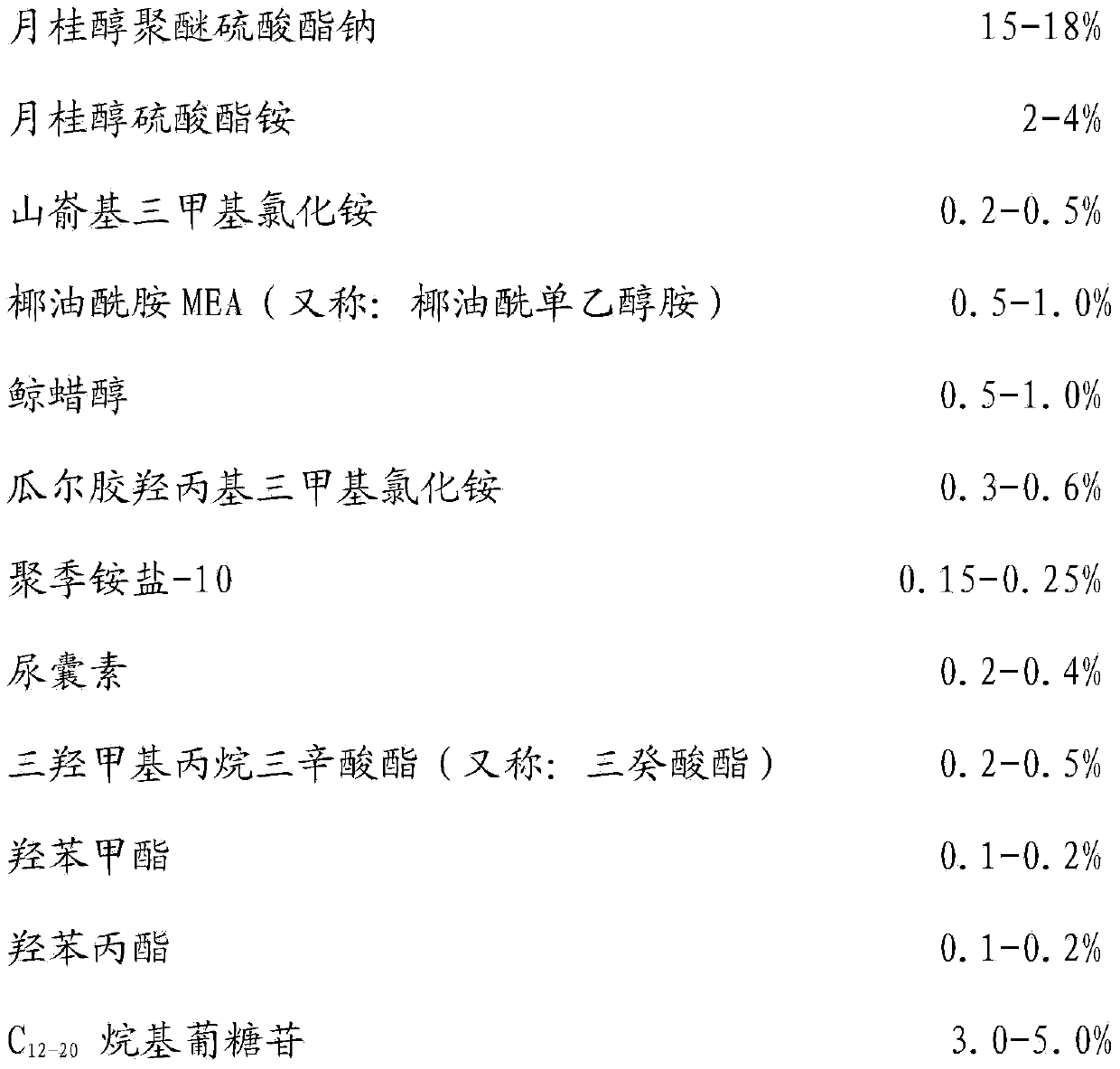

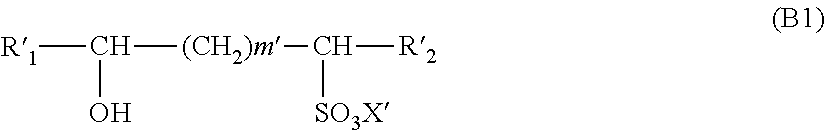

Three-in-one liquid shampoo and preparation method thereof

ActiveCN103735430AReduce stimulationImprove foaming speedCosmetic preparationsHair cosmeticsGuar hydroxypropyltrimonium chlorideCross-link

The invention discloses a three-in-one liquid shampoo and a preparation method thereof. The three-in-one liquid shampoo is prepared from the following raw materials: sodium laureth sulfate, ammonium lauryl sulfate, behentrimonium chloride, cocamidopropyl MEA, cetanol, guar hydroxypropyltrimonium chloride, polyquaternium-10, allantoin, trimethylol propane octanoate ester, methylparaben, propyl hydroxybenzoate, C12-20 alkyl polyglycoside, cocamidopropyl betaine, cocamidopropyl dimethylamine oxide, dimethiconol or dodecylbenzene sulfonic acid TEA salt, zinc pyrithione, hydrolyzed keratin, hydrolyzed silk protein, methyl-isothiazol-ketamine, polyquaternium-7, essence, crylic acid (ester) / C10-30 alkanol acrylic ester cross-linked polymer and deionized water. By adopting the three-in-one liquid shampoo, the stability of the product and the use effects of the raw materials can be improved, the three-in-one liquid shampoo achieves good cleaning and nursing effects, does not generate aggregation and stimulation problems after being used for a long period of time, and achieves the three-in-one effect of cleaning, nursing and conditioning.

Owner:广州市白云区大荣精细化工有限公司

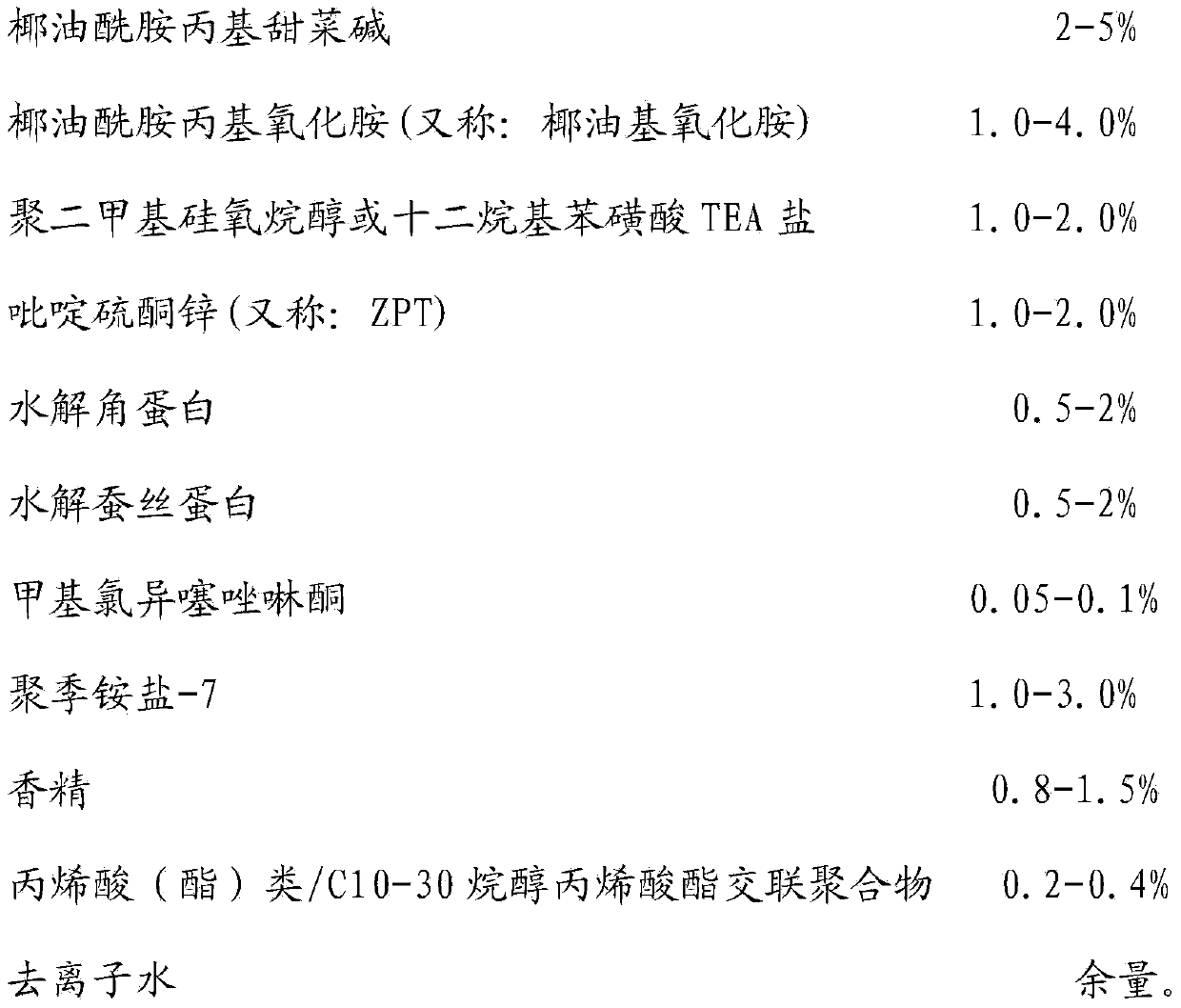

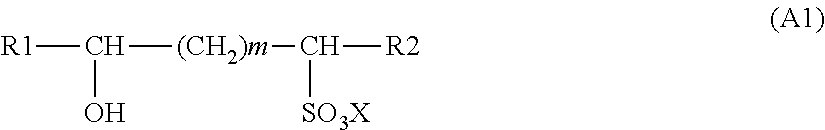

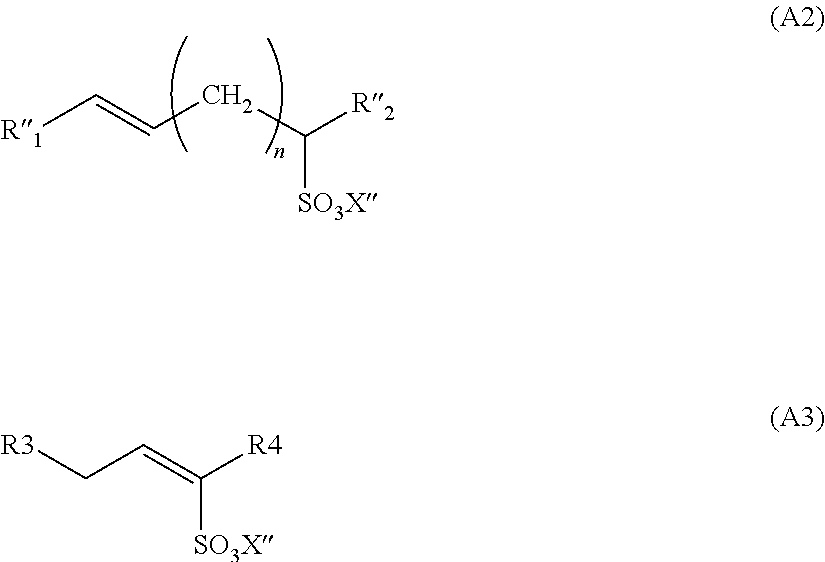

Foaming composition containing internal olefin sulfonates and one polymeric suspension agent

InactiveUS20170079899A1Improve performanceGood skin feelCosmetic preparationsHair cosmeticsSulfonateAqueous medium

The present invention relates to a composition containing in an aqueous medium, at least: 1) an internal olefin sulfonate composition comprising: (A) an internal olefin sulfonate having 16 carbon atoms and (B) an internal olefin sulfonate having 18 carbon atoms, wherein a mass content ratio (A / B) of the component (A) to the component (B) contained in the sulfonate composition ton is from 75 / 25 to 90 / 10, and wherein a mass ratio (hydroxy form / olefin form) of a content of a hydroxy form in the internal olefin sulfonate of the component (A) and the component (B) to a content of an olefin form in the internal olefin sulfonate of the component (A) and the component (B) is from 75 / 25 to 100 / 0; and 2) at least one polymeric suspension agent. The present invention relates also to a process for cleansing keratin materials, which consists of applying to the said keratin materials a composition according to the invention, in working the said composition into a foam and then rinsing off the said composition, especially with water. The present invention relates also to the cosmetic use of the composition as defined above, for removing makeup and / or cleansing the skin, the hair and / or mucous membranes, or for skincare.

Owner:LOREAL SA

Skin cleansing compositions

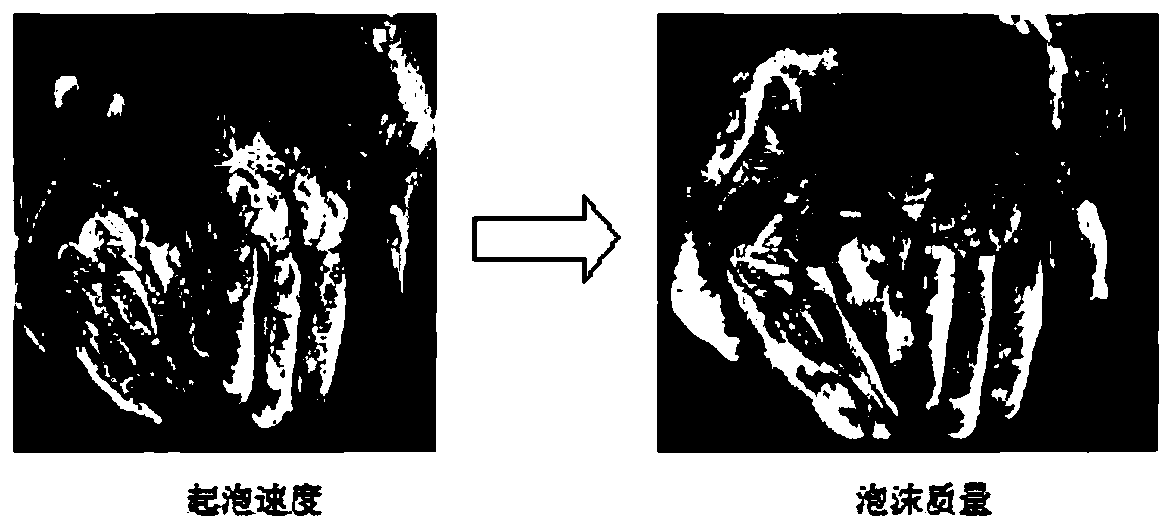

ActiveUS20080261845A1Fast in latherImprove appearanceCosmetic preparationsMake-upCarboxylateSkin cleansing

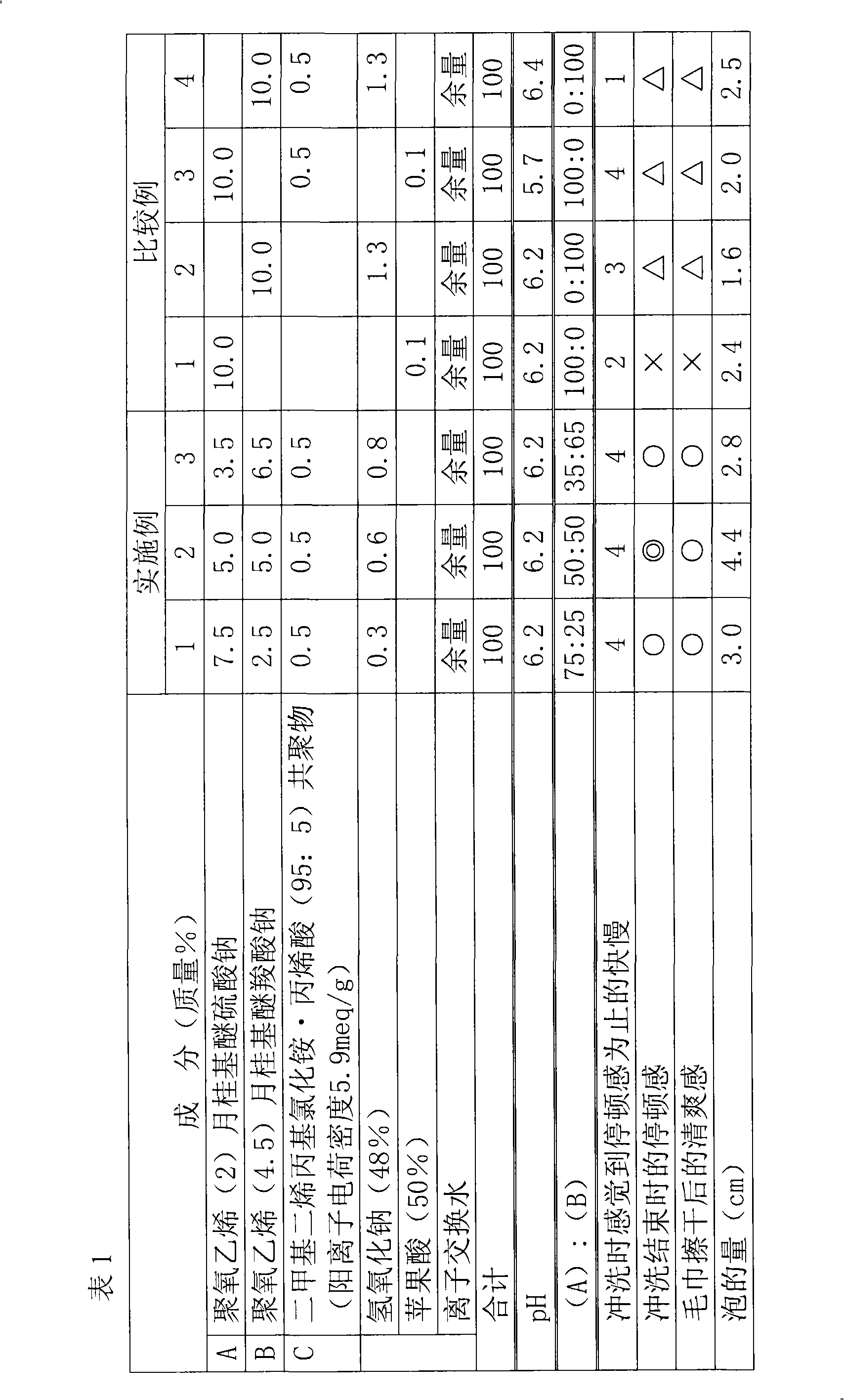

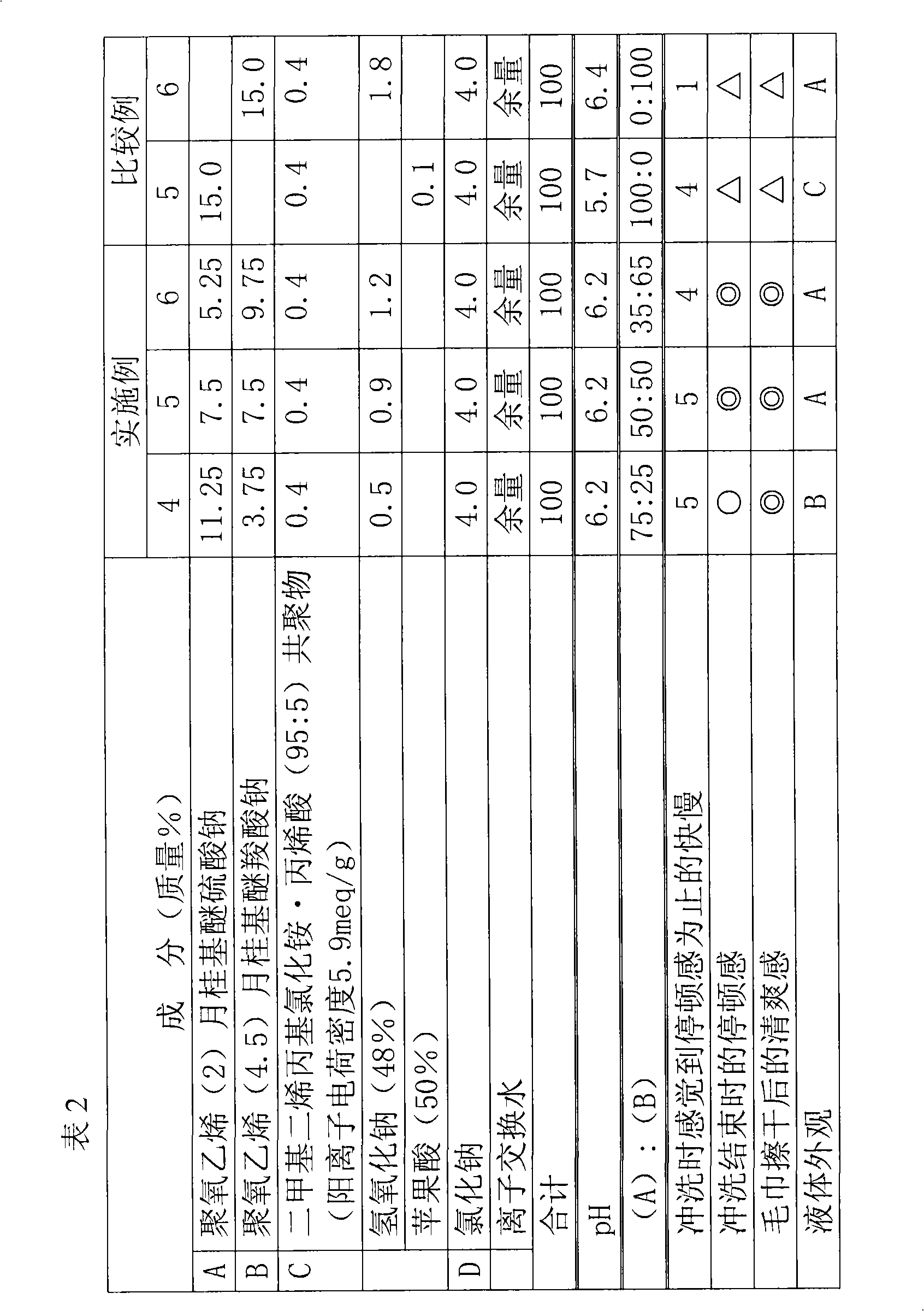

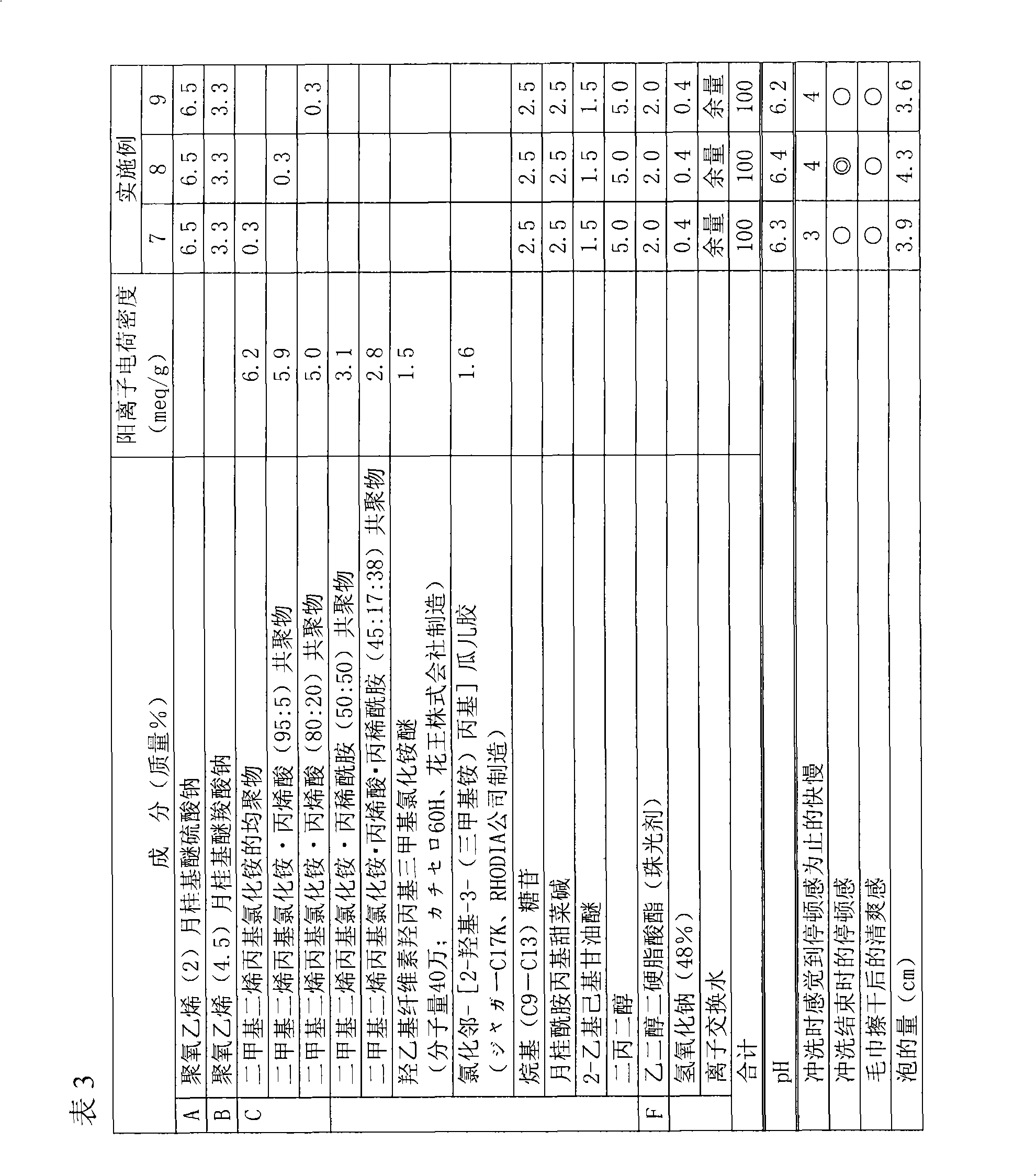

A skin cleansing composition contains the following ingredients (A), (B) and (C):(A) a polyoxyethylene alkylether sulfate,(B) a polyoxyethylene alkylether carboxylate, and(C) a cationic group-containing polymer having a cationic charge density of not less than 4.5 meq / g, and / or polyvinylpyrrolidone. A weight ratio (A):(B) of the ingredient (A) to the ingredient (B) is from 85:15 to 25:75. A total content of the ingredients (A) and (B) based on the whole composition ranges from 5 to 25 wt %. A content of the ingredient (C) ranges from 0.05 to 1 wt %. The skin cleansing composition is excellent in foamability and foam quality, and provides a good stop feeling during rinsing and a refreshed touch feeling after towel blotting.

Owner:KAO CORP

Skin cleaning agent composite

ActiveCN101288631AFoaming fastExcellent foam volumeCosmetic preparationsToilet preparationsSulfateAdditive ingredient

A skin cleansing composition contains the following ingredients (A), (B) and (C): (A) a polyoxyethylene alkylether sulfate, (B) a polyoxyethylene alkylether carboxylate, and (C) a cationic group-containing polymer having a cationic charge density of not less than 4.5 meq / g, and / or polyvinylpyrrolidone. A weight ratio (A):(B) of the ingredient (A) to the ingredient (B) is from 85:15 to 25:75. A total content of the ingredients (A) and (B) based on the whole composition ranges from 5 to 25 wt %. A content of the ingredient (C) ranges from 0.05 to 1 wt %. The skin cleansing composition is excellent in foamability and foam quality, and provides a good stop feeling during rinsing and a refreshed touch feeling after towel blotting.

Owner:KAO CORP

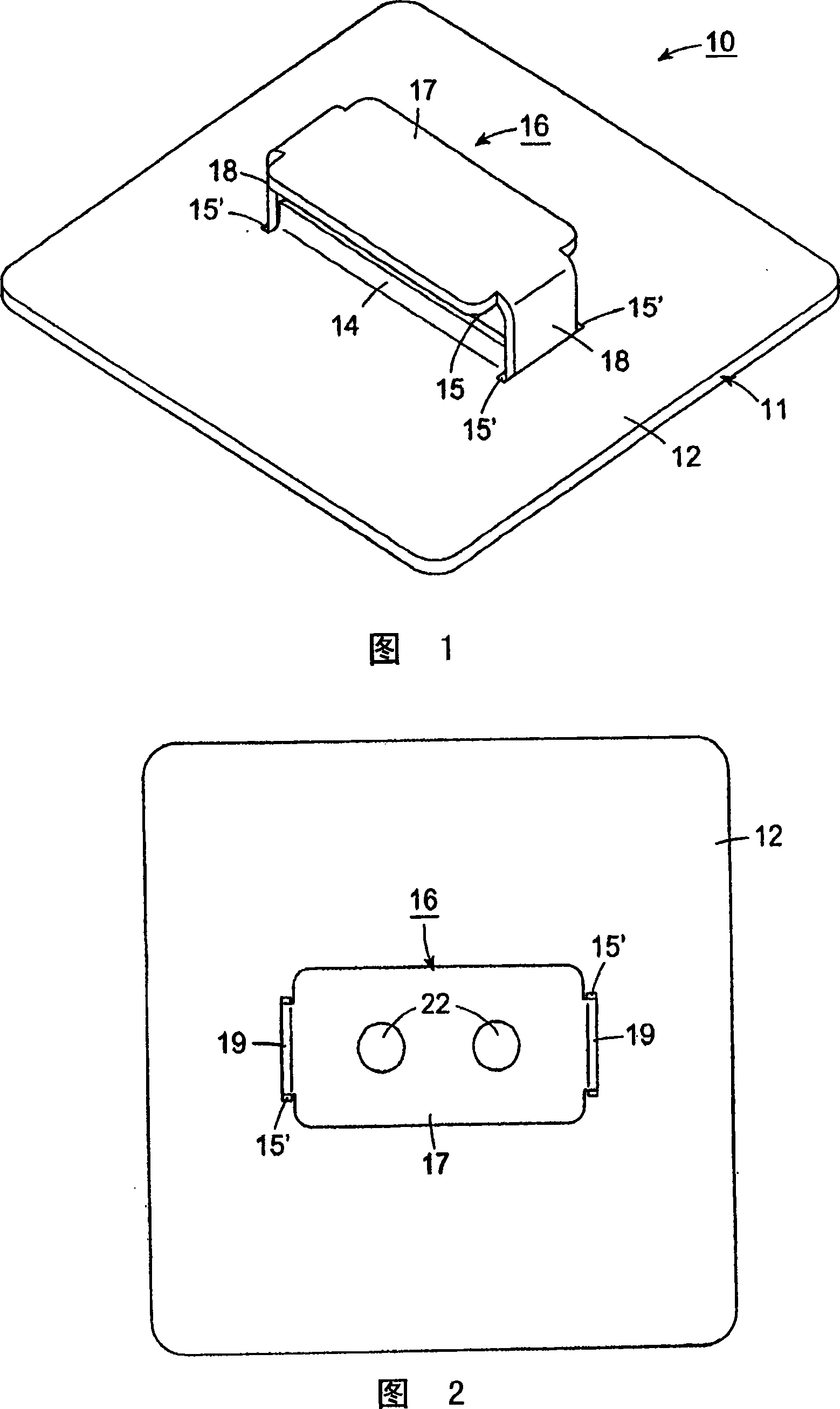

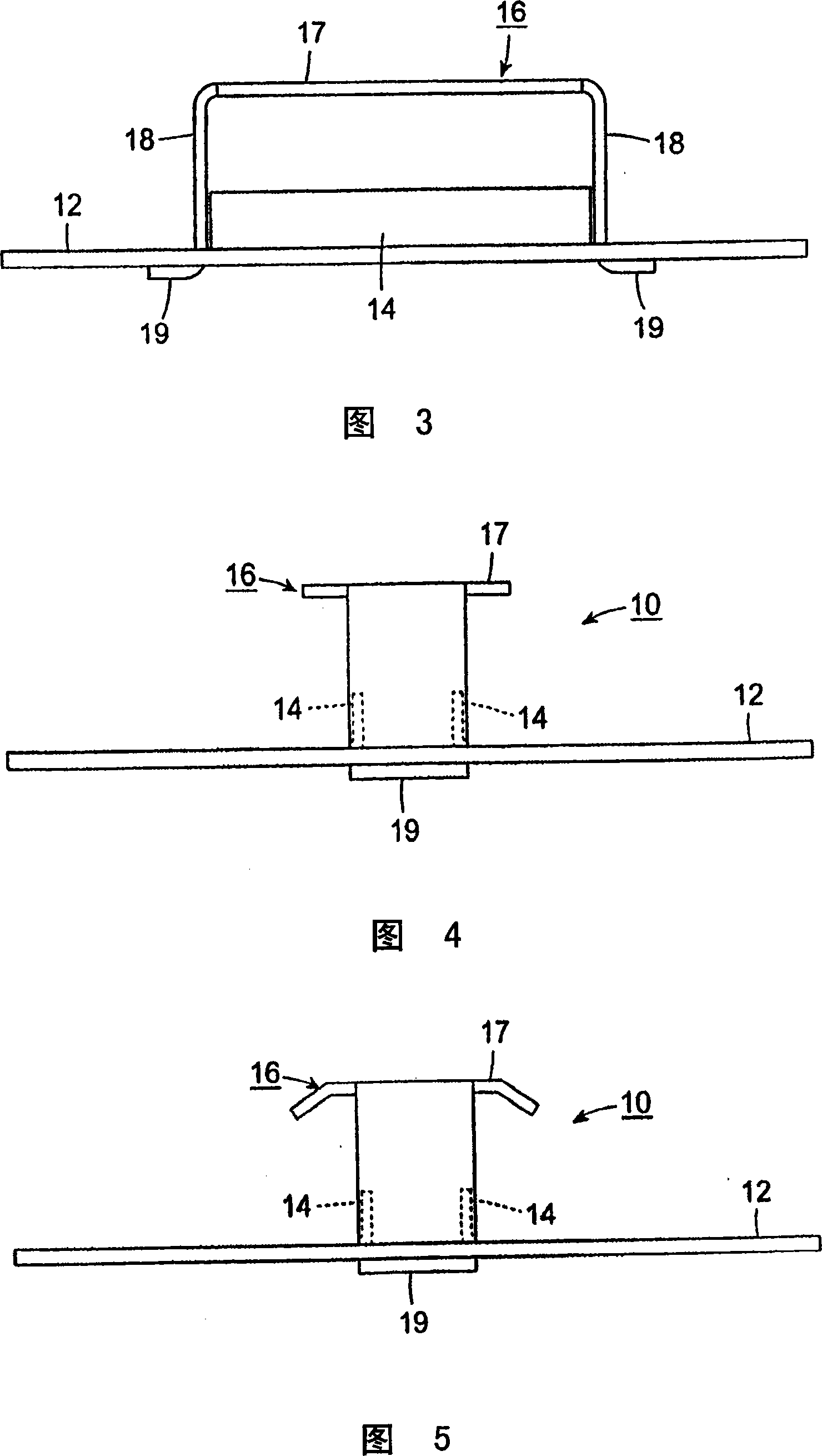

Valve for a contact tray

InactiveCN101138685AReduce loadIncrease capacityDistillation separationEngineeringMechanical engineering

The valve for a contract tray employs an aperture in a deck that is of rectangular or trapezoidal shape with upstanding walls at the sides of the aperture. The valve body is disposed in the aperture with a cover above the aperture and legs that extend downwardly to interfit with at least the upstream end of the walls to block the liquid flow. The valve body may be fixed or movable. In the movableembodiment, the valve body is seated on the walls about the aperture to close the aperture. The ascending vapor lifts the valve to allow bubbling of the vapor in the liquid on the deck.

Owner:SULZER CHEMTECH AG

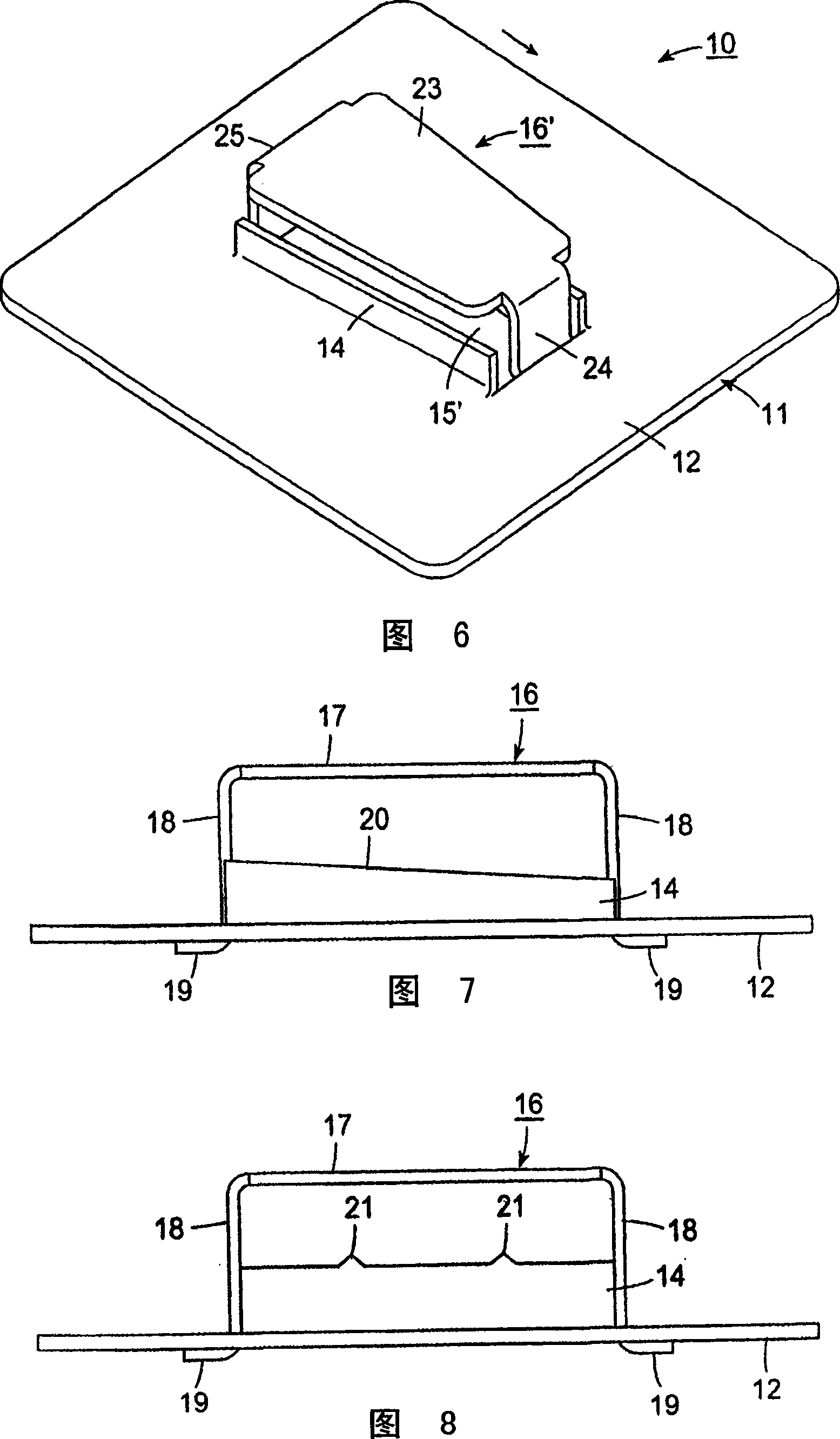

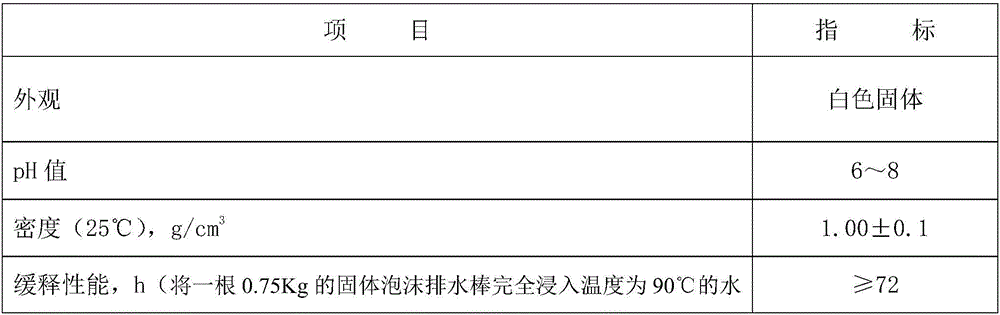

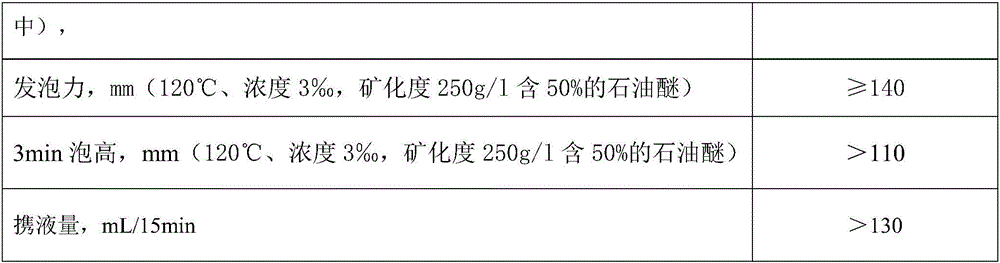

Oil-proof sustained-release solid foaming drainage agent used for gas wells, and preparation method and applications thereof

The invention discloses an oil-proof sustained-release solid foaming drainage agent used for gas wells, and a preparation method and applications thereof. The oil-proof sustained-release solid foaming drainage agent is mainly used for solving problems of conventional solid foaming drainage agents that high local concentration and waste are caused because of high dissolving speed, and preferable application is different to realize when gas well output water is high in gas condensate content, high in mineralization degree, and high in temperature. The dissolving time of the oil-proof sustained-release solid foaming drainage agent at 90 DEG C formation water condition is longer than 72h, and agent effect lasting time is long; the oil-proof sustained-release solid foaming drainage agent is capable of resisting gas condensate of 50% or higher, temperature of 120 DEG C or higher, and mineralization degree of 250000ppm; the foaming power is equal to or larger than 140mm; foam stabilizing time is long; and compatibility with agents such as methyl alcohol, corrosion inhibitors, and scale inhibitors is high. The preparation method is simple; no environment pollution is caused; no chemical reaction of products with gas and liquid ingredients is caused; equipment or pipeline corrosion is not caused; the prominent problems of gas wells are solved; and the oil-proof sustained-release solid foaming drainage agent is suitable for a plurality of water-producing gas wells.

Owner:四川锦盛油田技术服务有限公司

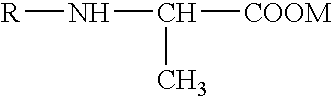

Solid N-acylalanine or a salt thereof

InactiveUS20060111258A1Foaming fastImprove basic performanceCosmetic preparationsHair cosmeticsSolubilityAlkaline earth metal

Solid N-acylalanines comprising one kind or two or more kinds of compounds, each containing an acyl group having a different number of carbon atoms, which is / are selected from the compounds represented by the formula (I): wherein R is a straight chain or branched chain, saturated or unsaturated acyl group having 8 to 22 carbon atoms, and M is a hydrogen atom, an alkali metal, an alkaline earth metal, ammonium, an organic amine or a basic amino acid, and salts thereof, are useful as ingredients for cleansing compositions. Such solid acylalanines and salts thereof are superior in solubility, and are free of moisture absorption or caking during preservation and agglomeration on dissolution in water. Powder or granular cleansing compositions containing such a solid N-acylalanine or salt thereof as a main component (main cleansing component) afford cleansing agents which exhibit extremely excellent properties, are free from caking during preservation and coagulation in practical use, are superior in the basic performance of cleansing agents (lather characteristics), are free of slimyness and friction during use, and are safe with less irritation.

Owner:AJINOMOTO CO INC

Oral composition and preparation method thereof

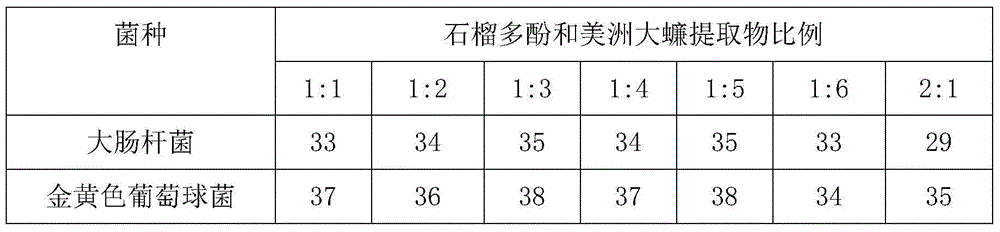

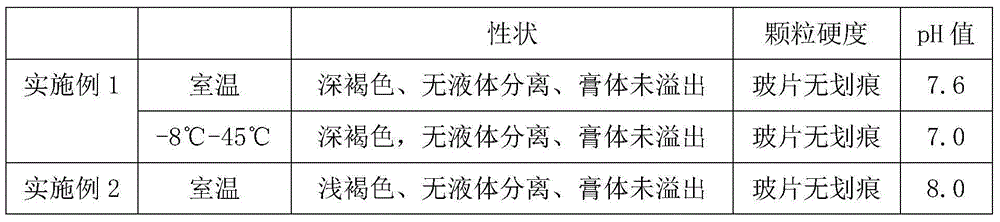

ActiveCN104688648AImprove antioxidant capacityHigh activityCosmetic preparationsToilet preparationsAdditive ingredientToothpaste

The invention provides an oral composition which is an oral preparation prepared by taking Periplaneta americana extract and Punicosides as active ingredients, wherein the weight ratio of the Periplaneta americana extract to Punicosides is 1:1-1:5. The invention also provides a preparation method and application of the oral composition. According to the oral composition disclosed by the invention, toothpaste can perform synchronous nursing on the oral cavity, teeth and gingiva and can effectively solve dental ulcer, the Punicosides have high in-vivo anti-oxidation and free radical cleaning activities, and the oral composition has a broad-spectrum antibacterial effect, has obvious effects of inhibiting staphylococcus aureus, hemolytic streptococcus, comma bacillus and shigella dysenteriae and has the effects of astringing, stopping bleeding, improving eyesight and the like.

Owner:耿福能

Inorganic foaming filling and reinforcing composition for coal mine as well as using method and application thereof

ActiveCN104446624AResolution timeSolve the non-plasticUnderground chambersMaterial fill-upCoalMaterials science

The invention provides an inorganic foaming filling and reinforcing composition for a coal mine as well as a using method and application thereof. The inorganic foaming filling and reinforcing composition for the coal mine can be used as a novel safe plugging and reinforcing material, is especially suitable for plugging and reinforcing of the coal mine, and is the best water-proof, fire-proof, gas-proof, collapse-proof and accident-proof material.

Owner:廊坊坐城矿用材料有限公司

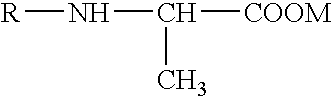

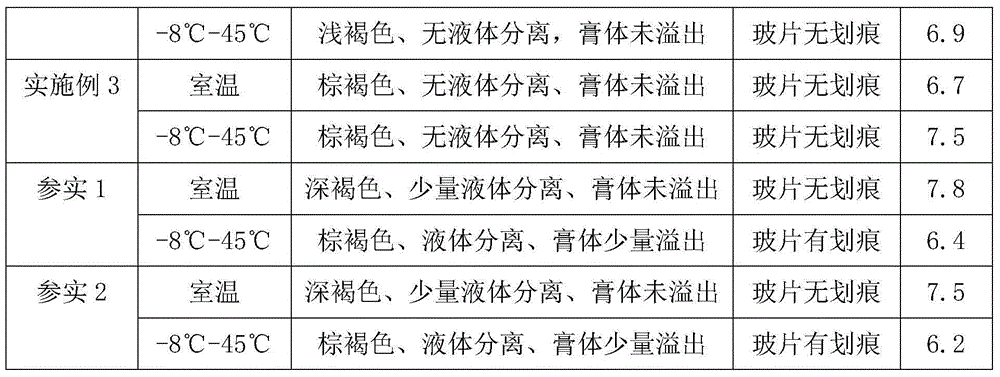

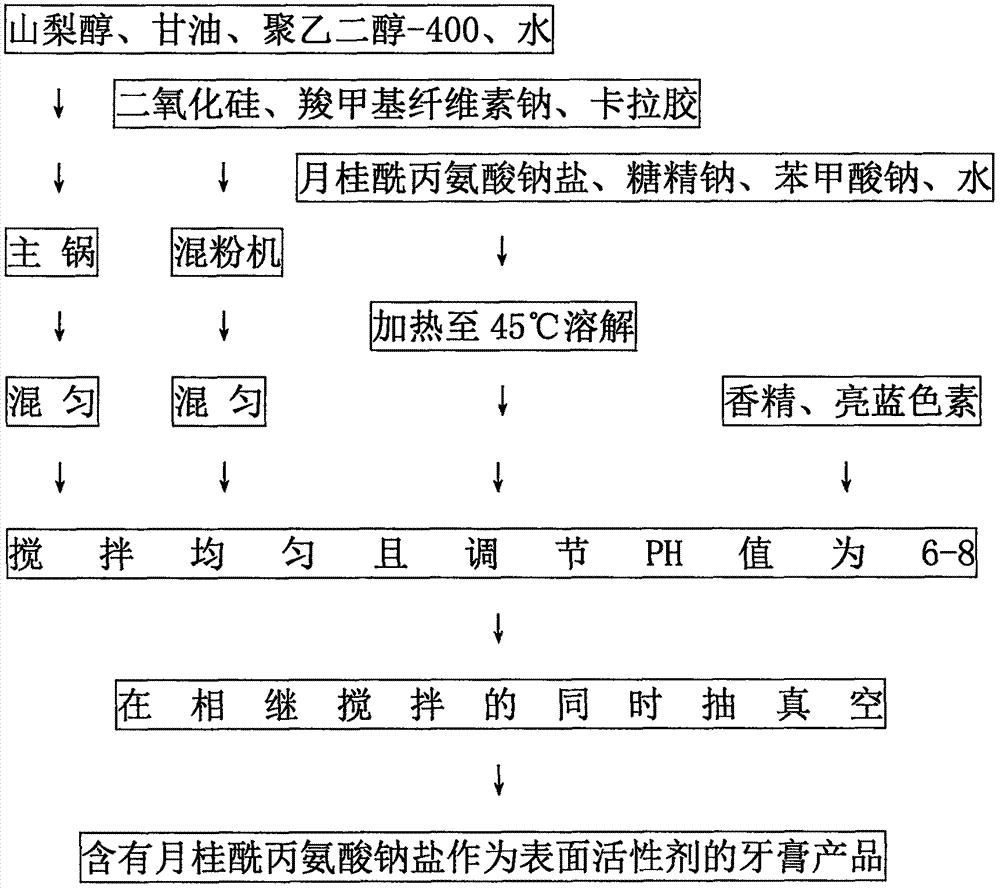

Toothpaste containing sodium N-dodecanoyl-L-alaninate as surfacant

InactiveCN107260563AGood antibacterial effectGood biocompatibilityCosmetic preparationsToilet preparationsChemistrySodium carboxymethylcellulose

The invention discloses a toothpaste containing sodium N-dodecanoyl-L-alaninate as a surfacant, and relates to the field of daily chemical products. By adopting a sodium N-dodecanoyl-L-alaninate or potassium N-dodecanoyl-L-alaninate containing key technology, 30 to 50 parts by weight of sorbitol, 5 to 15 parts by weight of glycerol, 2 parts by weight of polyethylene glycol-400 and 10 parts by weight of water are put into a main boiler and are evenly mixed; 15 to 20 parts by weight of powder phase silicon dioxide, 0.1 to 1 part by weight of sodium carboxymethyl cellulose, and 0.1 to 0.3 part by weight of carrageenan are put into a powder mixing machine for being evenly mixed, and then are put into the main boiler to be evenly stirred; 1 to 3 parts by weight of sodium N-dodecanoyl-L-alaninate or potassium N-dodecanoyl-L-alaninate, 0.1 to 0.3 part by weight of saccharin sodium, 0.2 to 0.6 part by weight of sodium benzoate and 2.8 to 41.5 parts by weight of water are heated to 45 DEG C and then are dissolved and put into the main boiler; 0.2 to 1 part by weight of essence and 0.0001 to 0.1 part by weight of brilliant blue fluorescent are put into the main boiler; all materials in the main boiler are stirred and PH is regulated to 6 to 8, and the materials are vacuumized while the materials are stirred so as to prepare the toothpaste containing sodium N-dodecanoyl-L-alaninate or the potassium N-dodecanoyl-L-alaninate as the surfacant. The preparation of the toothpaste has a stable and reliable effect.

Owner:苏州三君日化科技有限公司

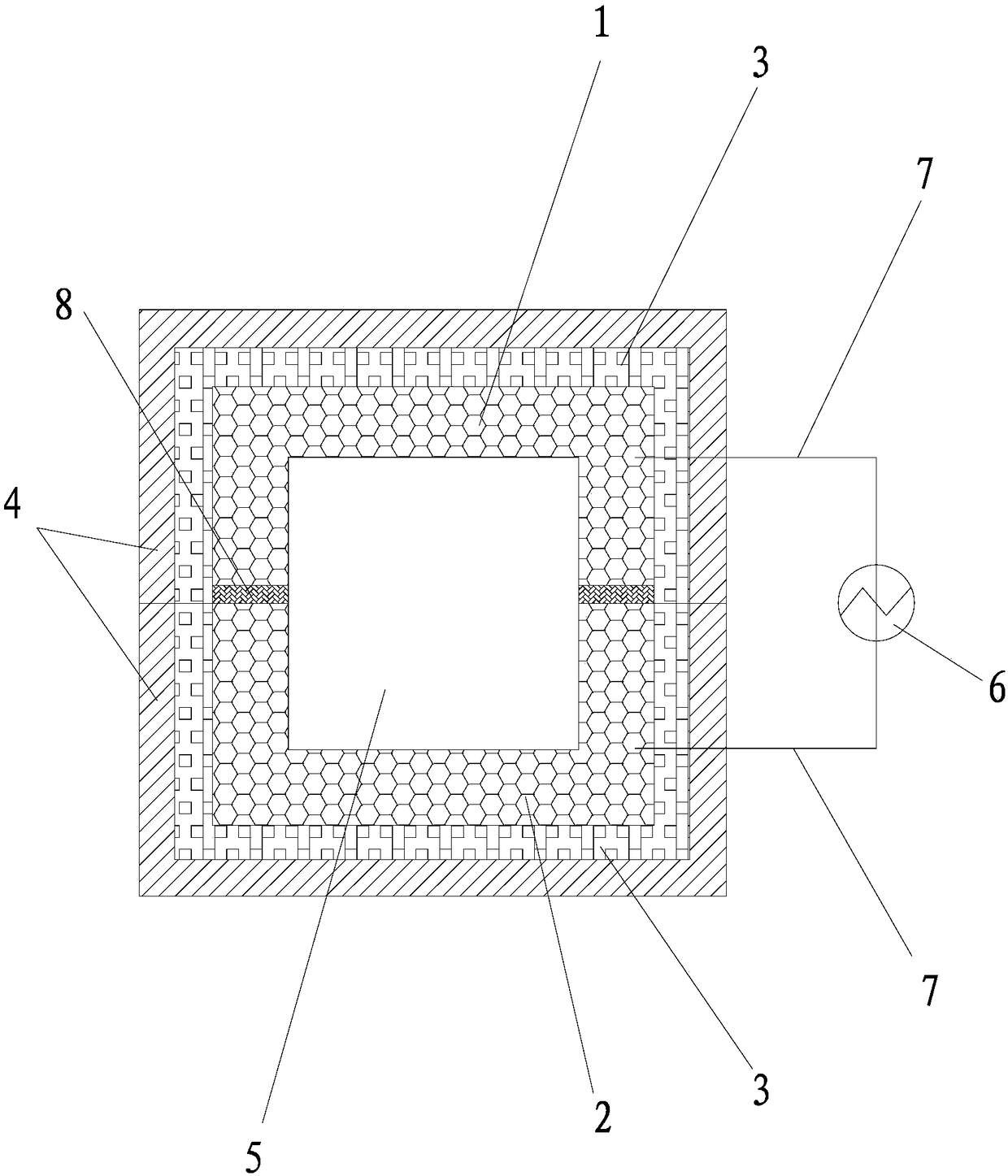

High-molecular material foaming device and application method thereof

The invention discloses a high-molecular material foaming device. The high-molecular material foaming device mainly comprises a foaming mold and a high-frequency electric source, wherein the foaming mold comprises an upper mold and a lower mold, insulated spacers are arranged between the upper mold and the lower mold at intervals, after the high-frequency electric source is powered on, a high-frequency oscillation electric field is generated between the upper mold and the lower mold, in the high-frequency oscillation electric field, polar molecules and / or functional groups inside a to-be-foamed base metal can incessantly switch directions along with the high-frequency oscillation electric field to collide with each other, mutual friction generates heat so as to enable the temperature of the to-be-foamed base metal in a mold chamber to rise, a foaming agent can be heated and decomposed to generate gas, the foaming material expands to fill the whole mold chamber so as to realize foamingof the foaming material. By adopting the foaming device, the rapid, efficient and uniform foaming of a high-molecular material can be realized. The high-molecular material foaming device has a broad application prospect in the material foaming field.

Owner:QUANZHOU NORMAL UNIV

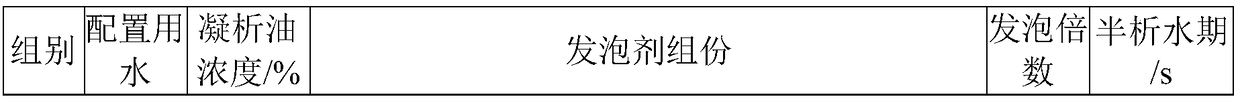

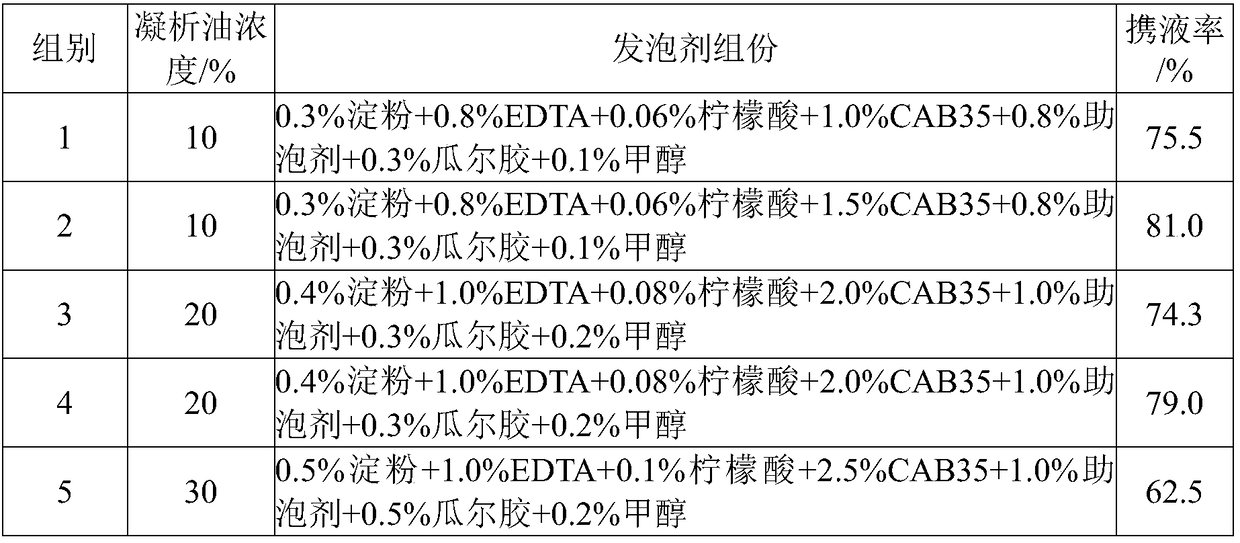

High salt-resistant foaming agent and preparation method thereof

InactiveCN108929668AGood resistance to high mineralizationGood hardness resistanceDrilling compositionAcetic acidEthylenediamine

The invention provides a high salt-resistant foaming agent and a preparation method thereof. The high salt-resistant foaming agent comprises 0.2-0.5% of starch, 0.3-1.0% of ethylenediaminetetraaceticacid, 1.0-2.5% of cocamidopropyl betaine, 0.5-1.0% of a foam booster, 0.05-0.5% of a foam stabilizer, 0.05-0.2% of a pH adjuster, 0.1-0.2% of methanol, and the balance of highly mineralized water. Theinvention also provides the preparation method of the foaming agent. The foaming agent has the advantages of high mineralization resistance and good gas condensate resistance.

Owner:PETROCHINA CO LTD

Method for preparing emulsion explosive by high-temperature sensitization

InactiveCN104262067AModerate size distributionUniform foamingExplosive working-up apparatusNon-explosive/non-thermic compositionsExplosive AgentsPhosphate

The invention relates to a method for preparing an emulsion explosive by high-temperature sensitization. The method comprises the following steps: preparing a water phase, preparing an oil phase, emulsifying, sensitizing, charging and cooling. The emulsion explosive comprises the following raw materials: ammonium nitrate, sodium nitrate, urea, water, a composite oil phase, an emulsifier, a foamer and an accelerant, wherein the accelerant is a potassium biphthalate buffer solution with the pH value of 5.5, a potassium dihydrogen phosphate buffer solution with the pH value of 4.5, a potassium tartrate buffer solution with the pH value of 3.5 or a potassium tetroxalate buffer solution with the pH value of 1.0; the sensitizing process comprises the following sub-steps: uniformly mixing the accelerant with the foamer to obtain a mixture, adding the mixture into a latex matrix with the temperature of 85-110 DEG C, uniformly mixing, and sensitizing for 0.5-10 minutes. According to the method, the raw material-accelerant is wide in source, low in cost and nontoxic, and the pH value of the explosive is increased, and the explosive performance can be improved; the sensitizing process is simple, quick and free of aftereffect, the production process is simplified, the cost is reduced, and the energy consumption is reduced.

Owner:XUZHOU LEIMING CIVILIAN BLASTING EQUIP CO LTD

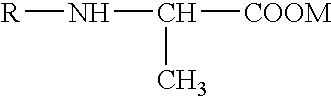

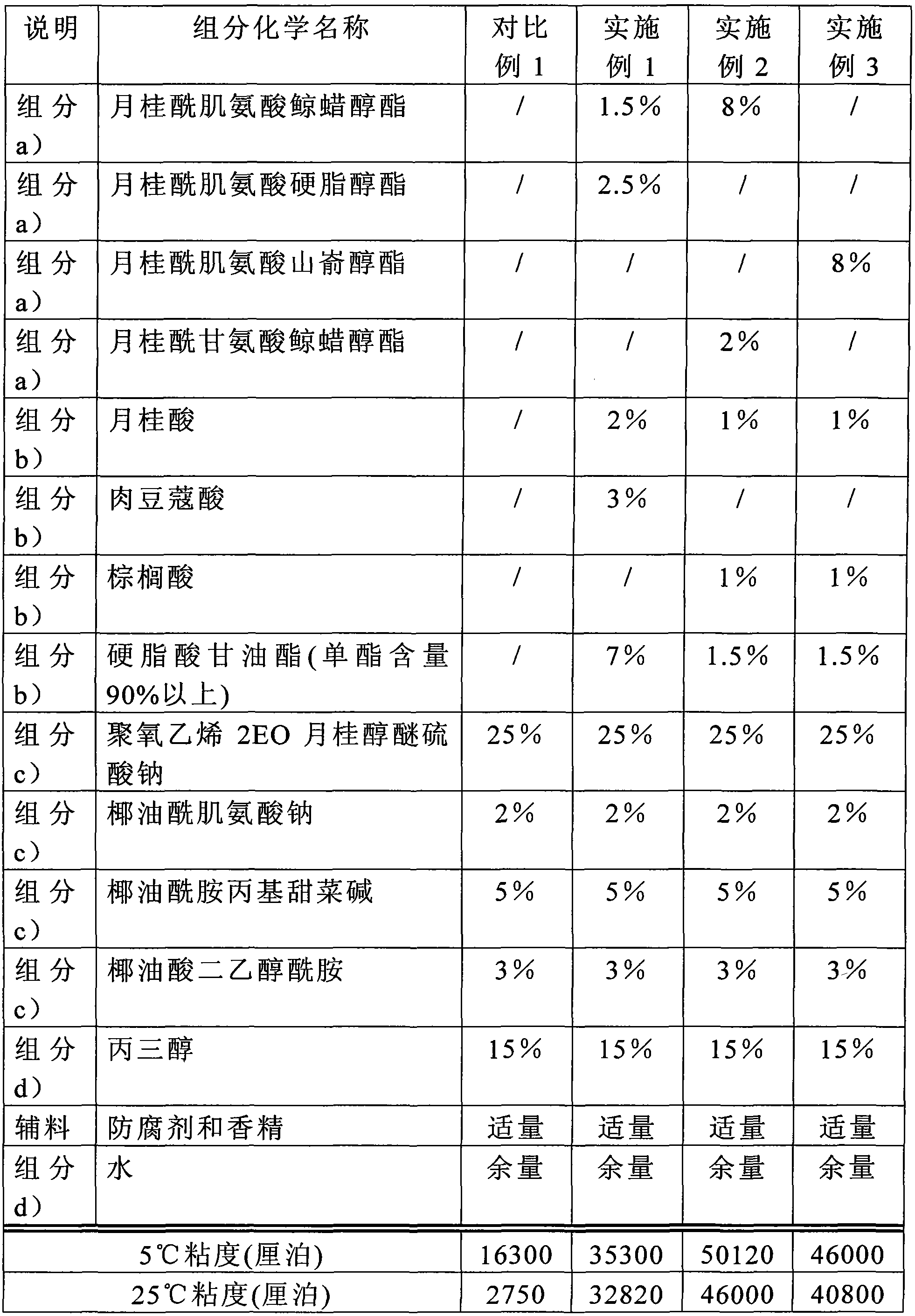

Stiff cleaning composite

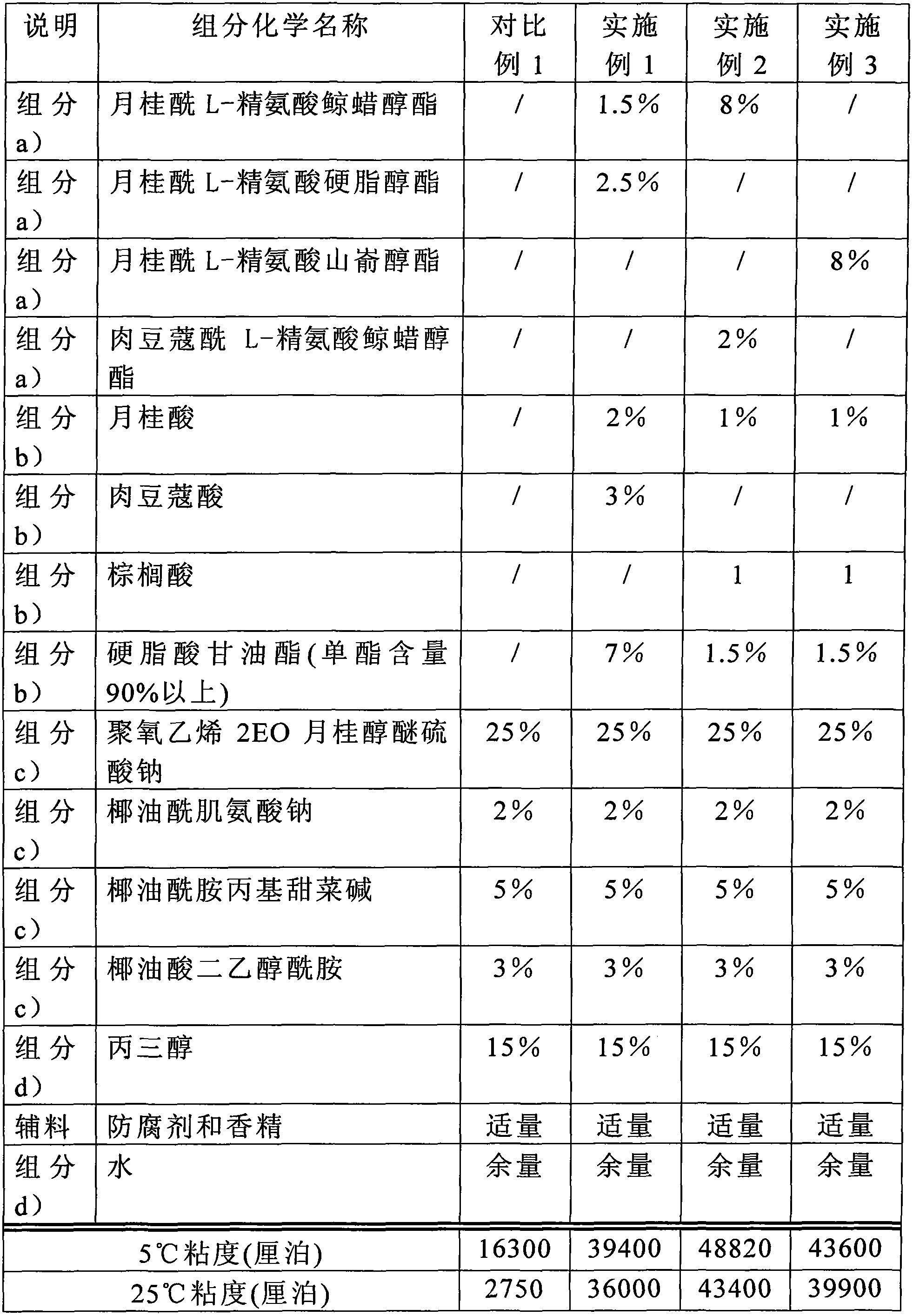

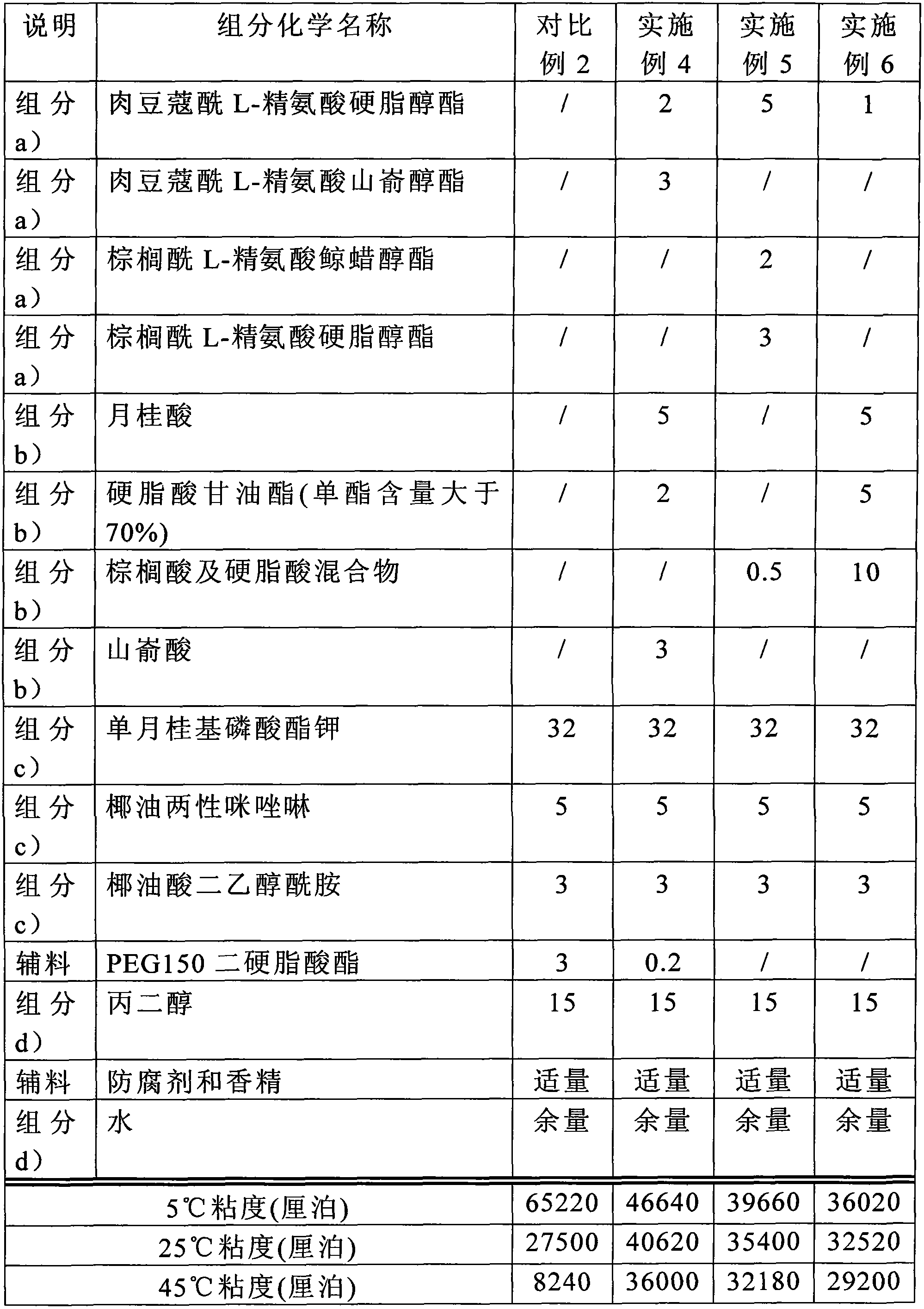

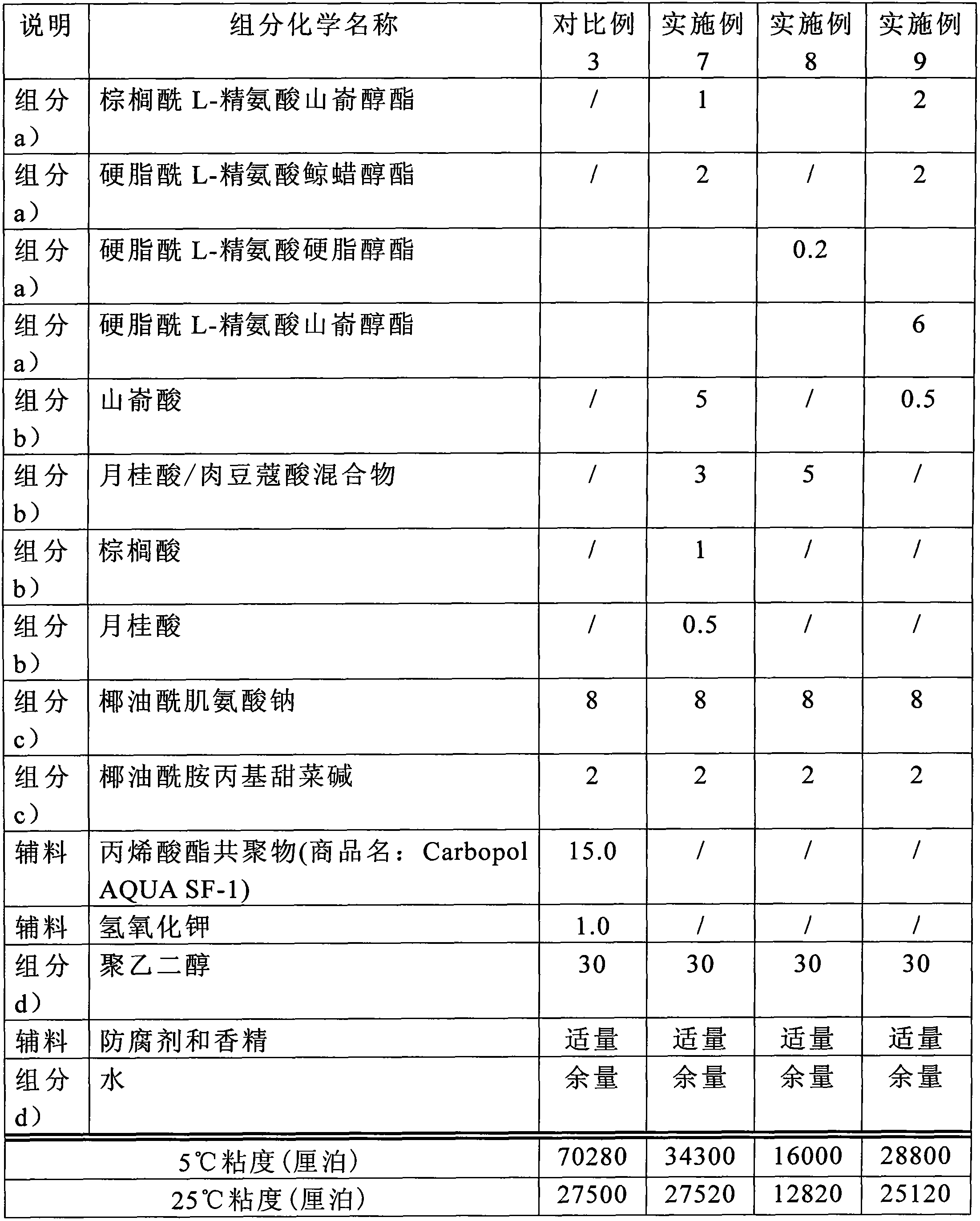

ActiveCN102058489AHigh viscosityFoaming fastCosmetic preparationsHair cosmeticsNeutral Amino AcidsAlcohol

The invention discloses a stiff cleaning composite, relating to a stiff cleaning composition used for cleaning skin, eyes, teeth and hair in the field of personal care products. The cleaning composite comprises long-chain fatty acyl neutral amino-acid ester, a fatty compound, surfactant, solvent and beautifying and cleaning assistant solvent, wherein the fatty compound is one of fatty acid, fatty alcohol, fatty alcohol ether or polyol fatty acid ester; the solvent is composed of water, lower alcohol, polyalcohol and polyalcohol ether; and the beautifying and cleaning assistant solvent is used for skin, eyes, teeth and hair. The cleaning composite can obtain satisfactory stiff appearance when being used for cleaning skin and hair, can maintain stable viscosity at different temperatures, is easy to smear and quick to foam and has good foaming quality when being used by consumers.

Owner:SUZHOU ELECO CHEM IND

High-oil-content facial cleanser and preparation method thereof

PendingCN109966161AFoaming fastEasy to rinseCosmetic preparationsToilet preparationsGlycerolPotassium hydroxide

The invention discloses a high-oil-content facial cleanser which is prepared from, by weight, 10-20 parts of fatty acid, 10-30 parts of soothing oil, 5-12 parts of glycerin, 8-12 parts of acrylic ester / beheneth-25 metacrylic acid ester copolymers, 1-3 parts of glyceryl stearate, 4-6 parts of potassium hydroxide, 0.5-2 parts of accessories and 10-30 parts of water. The accessories comprise preservative, chelating agents and film-forming agents, the fatty acid is C12-C18 acid, and the soothing oil is mineral oil or plant oil. The facial cleanser has better skin feeling, stability and foamabilityand is easy to clean, and a moistening protective layer is retained on the surface of the skins after the skins are cleaned by the facial cleanser. The invention further provides a preparation methodof the high-oil-content facial cleanser.

Owner:MENTHOLATUM (CHINA) PHARM CO LTD

Fast sensitizer for emulsion explosive

ActiveCN101870626AGood explosive performanceHigh intensityNon-explosive/non-thermic compositionsThioureaEmulsion explosive

The invention relates to a fast sensitizer for emulsion explosive, which comprises components A and B in weight percent: component A: 15-42% of sodium nitrite, 15-42% of ammonium nitrate and 14-68% of water; component B: 40-60% of oxalic acid and 40-60% of thiourea; and the mixed ratio of component A to component B is 30-50:1. The fast sensitizer of the invention has fast foaming speed, simple process, convenient operation, low production cost and no aftereffect reaction; and the emulsion explosive prepared by the fast sensitizer has good explosive property, high brisance and strong work capacity.

Owner:广东华威化工股份有限公司

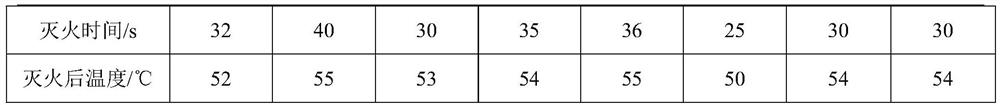

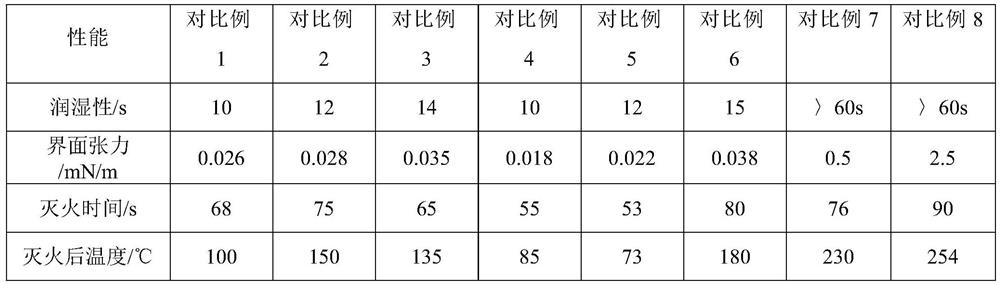

Environment-friendly water-based fire extinguishing agent for fire protection

PendingCN112675469AReduce interfacial tensionImprove interfacial tensionFire extinguisherPhosphoric Acid EstersPhosphate

The invention belongs to the technical field of fire-fighting foam, and discloses a fire-fighting environment-friendly water-based fire extinguishing agent. The fire extinguishing agent is prepared from the following raw materials in percentage by weight: 15 to 40 percent of fatty acid amide, 5 to 10 percent of phosphate, 5 to 10 percent of foaming agent, 3 to 5 percent of fatty alcohol, 1 to 3 percent of pH regulator, 0.5 to 0.8 percent of preservative, 0.2 to 0.5 percent of stabilizer, 10 to 15 percent of organic solvent and the balance of water. According to the invention, fatty acid amide is used as a main surfactant and cooperates with other assistants, so the prepared fire extinguishing agent has the advantages of low interfacial tension, high wettability and high foaming and fire extinguishing speed; phosphate is added into the fire extinguishing agent, so that the flame retardance can be improved, the wettability of the system is improved, and the foaming property and the fire extinguishing property of the system are promoted to a certain extent; the addition of the fatty alcohol can increase the emulsifying property of the system, reduce the interfacial tension of oil and water and reduce the height of an emulsifying layer of mixed oil and water; the emulsifying effect is promoted by controlling the addition amount of the fatty alcohol, but the height of an oil-water mixing layer is not increased, and fire extinguishment and field treatment after fire extinguishment are facilitated.

Owner:四川科宏达集团有限责任公司

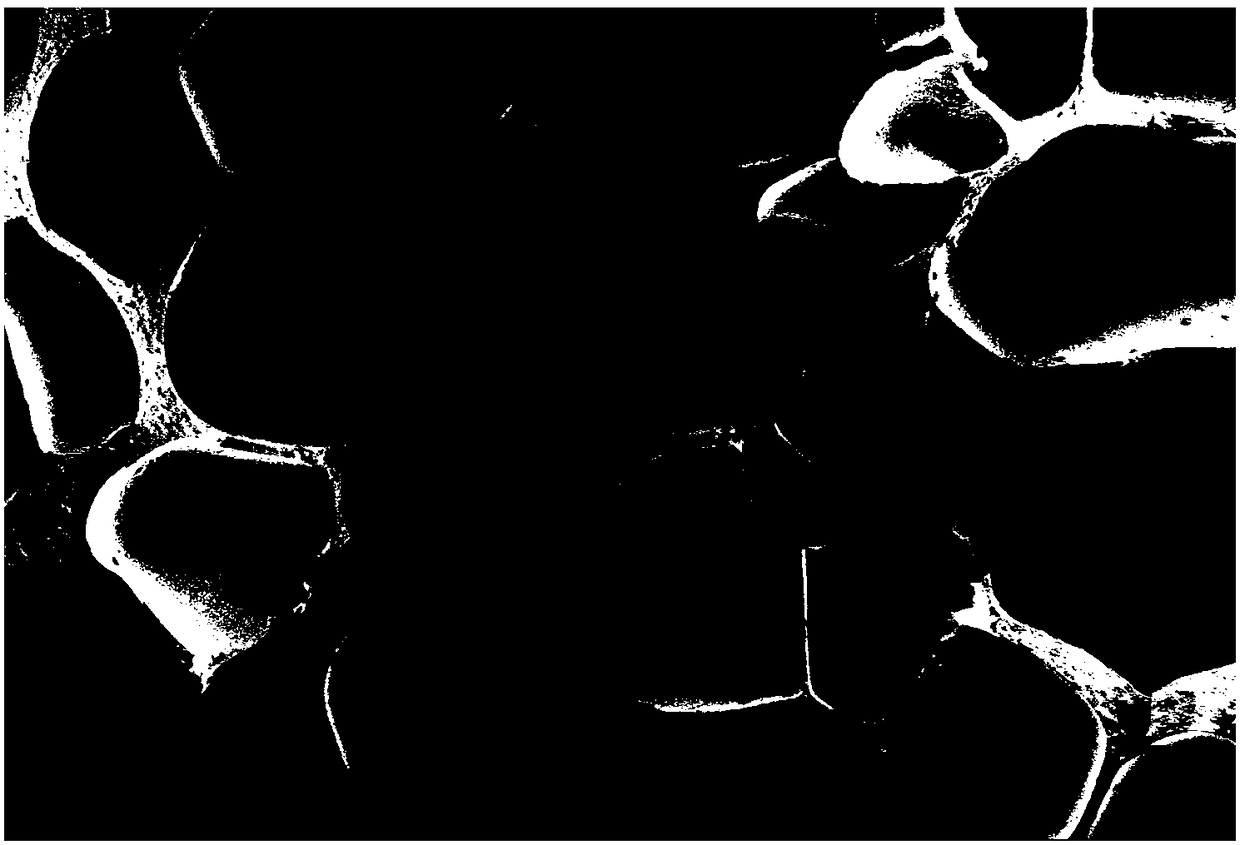

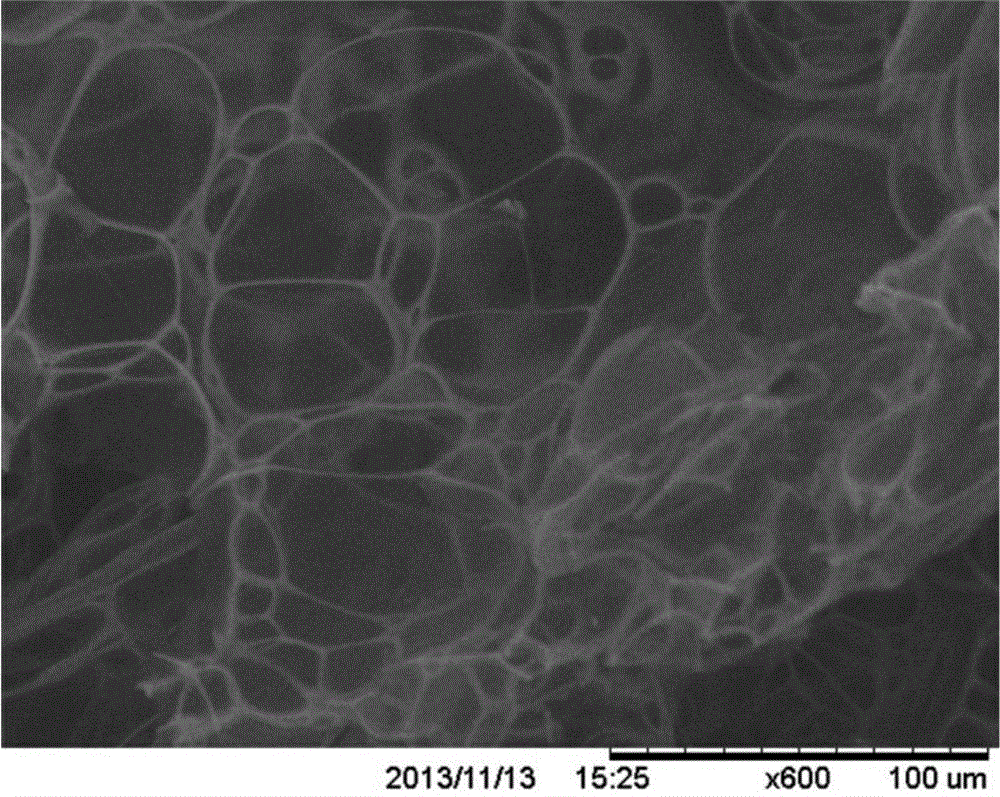

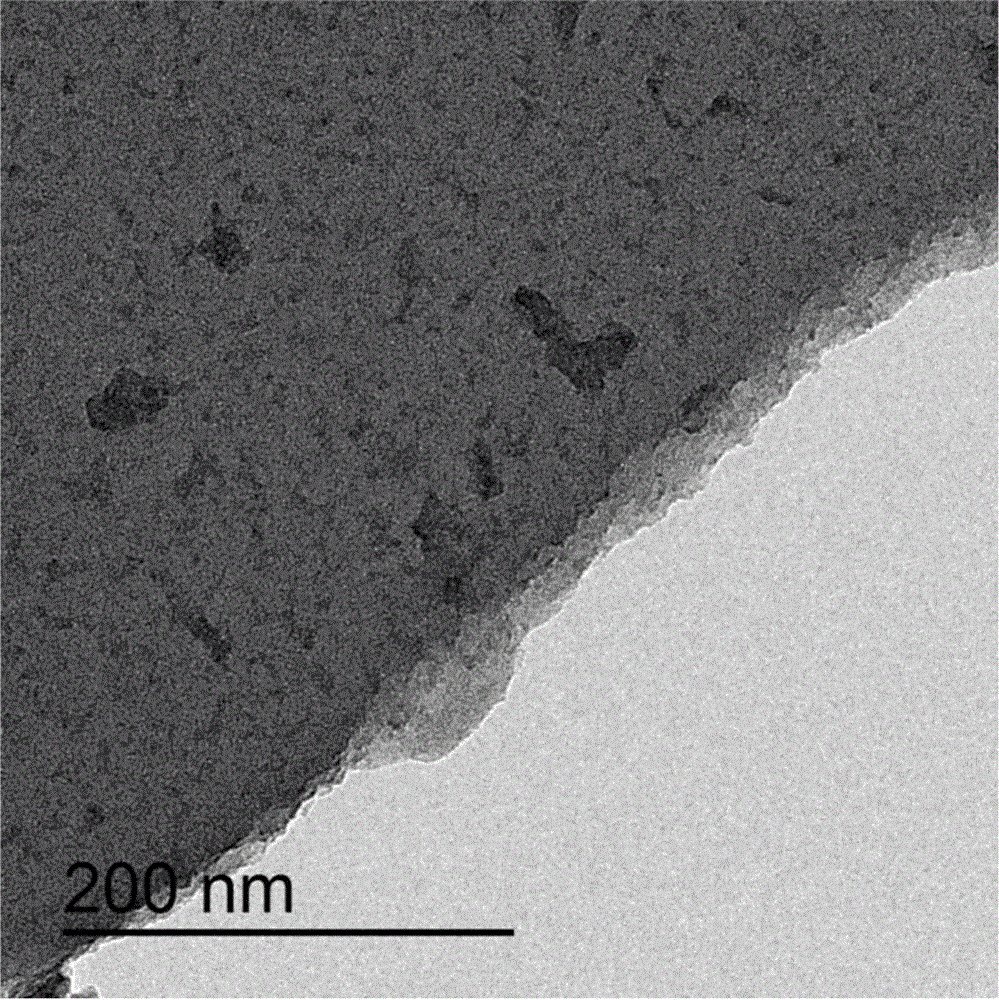

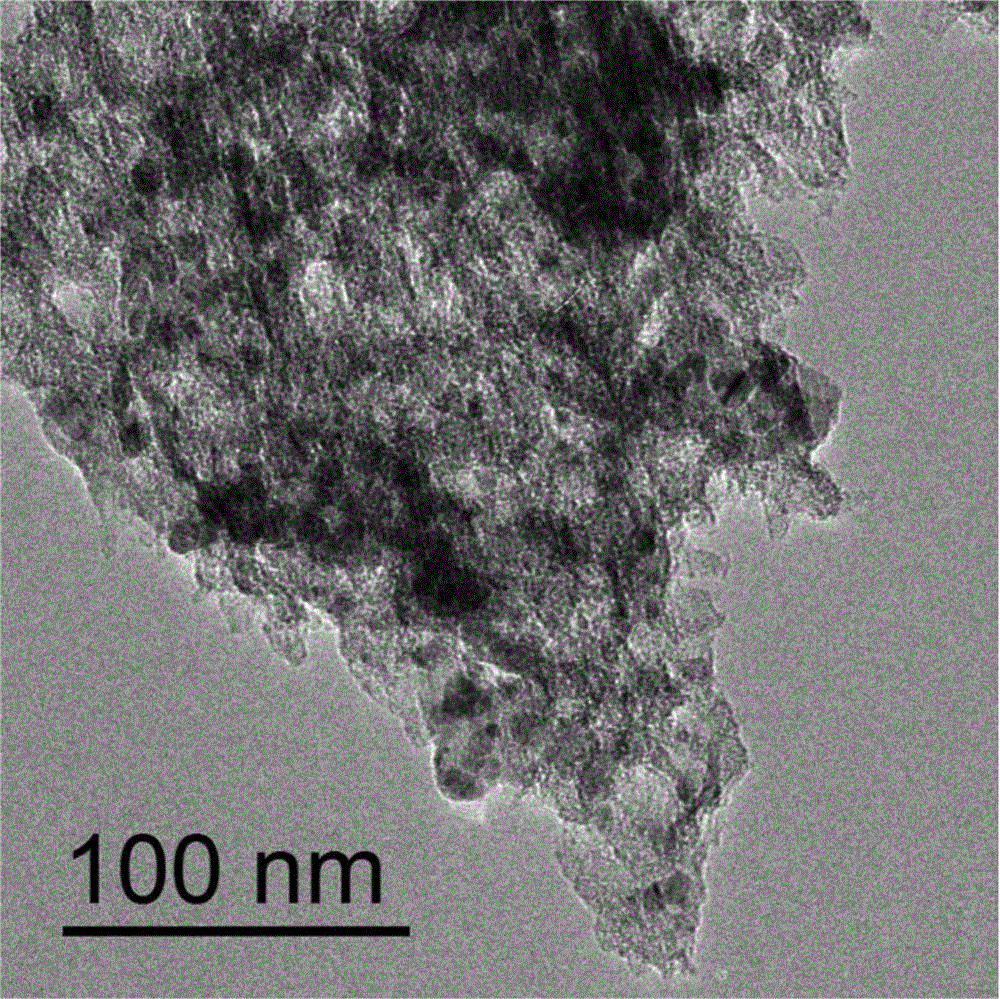

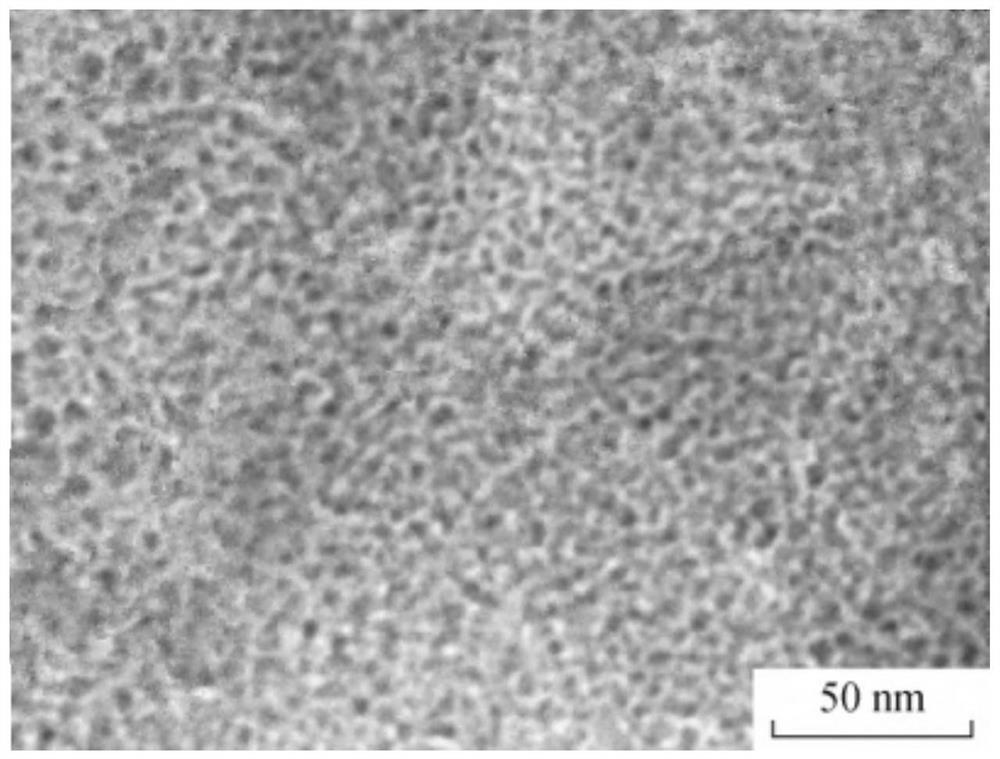

Thin-wall foam carbon material with nanoscale wall thickness and preparation method thereof

The invention relates to a foam carbon material and a preparation technology thereof, and particularly relates to a thin-wall foam carbon material with nanoscale wall thickness and a rapid preparation method thereof. Through adoption of corrosive pitting hydrolysis and dehydration of acid liquor on corn starch, the starch is rapidly foamed and carbonized due to microwave, so that the thin-wall foam carbon material with nanoscale wall thickness is formed. The carbon yield can reach 25-35%. The thin-wall foam carbon material has a three-dimensional net structure, the meshes are connected through thin-wall carbon layers, the carbon wall area of one mesh is 10-50mu m, the carbon wall is 25nm thick, and the carbon wall comprises hydroxy, carbonyl and epoxy active groups. The material contains micropores and mesopores. The mesopores are mainly in narrow distribution in 2-9nm, and the carbon wall of the activated thin-wall foam carbon material is overlapped by porous carbon plates. The thin-wall foam carbon material is beneficial for fully exposing and effectively using a carbon skeleton, and can be used as an electrode material or a catalyst carrier.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Preparation method of fracture acidizing foaming cleanup additive

InactiveCN109135718AAvoid breakingIncrease electropositivityDrilling compositionElectricityFoaming agent

The invention relates to a preparation method of a fracture acidizing foaming cleanup additive, and belongs to the technical field of cleanup additives. A prepared foam-stabilizing surfactant mainly comprises a zwitterionic surfactant and has large relative molecular weight and larger superficial area, a denser and firmer interfacial film can be formed on the solid-liquid two-phase surface after part of foaming power is sacrificed, and bubbles are not prone to breaking accordingly; dodecyl sulfobetaine molecules show higher positive electricity and are easily associated with electronegative lauryl sodium sulfate molecules, and by means of combined action of hydrophobic force and electrostatic force of the two kinds of molecules, compounding can be enhanced and the deficiency of the foamingpower of the foam-stabilizing surfactant can be made up. The fracture acidizing foaming cleanup additive prepared with the method is dual-purpose, avoids troubles caused by compounding of a foaming agent and a cleanup additive during construction, realizes fast foaming and is high in bubble strength and simpler to use, and the cost is reduced.

Owner:黄旭东

Polyurethane raw material special for cosmetic powder puff

InactiveCN108715629AOvercome unfriendlinessRebound fastPackaging toiletriesPackaging cosmeticsFirming agentUltimate tensile strength

The invention discloses a polyurethane raw material special for a cosmetic powder puff. The polyurethane raw material special for the cosmetic powder puff comprises a polyurethane prepolymer and a curing agent. Meanwhile, the invention further provides a special production process for producing the cosmetic powder puff by using the polyurethane raw material. According to the polyurethane raw material special for the cosmetic powder puff, the traditional foaming mode of directly using isocyanate is adjusted into the mode of using prepolymer foaming, a mode of using water as a main component ofthe curing agent, and foaming is conducted in a mode of adding fillers, so that no friendliness of latex serving as a raw material is overcome, a mode for producing hydrophilic makeup cotton by takingthe polyurethane as the raw material is created, and the makeup cotton is hydrophilic and skin-friendly in hand feeling; furthermore, a brand new foaming process is used for the special raw material,the common foaming machine can be used for rapidly foaming, and the demolding time can be shortened to 2 to 3 minutes, so that the foam hole structure is more exquisite, and the product has skin-friendly hand feeling, is flexible and rebounded rapidly and meets the requirements of female consumers. The polyurethane raw material special for the cosmetic powder puff has the following characteristics: the product has high water-absorbing rate; the strength and the resilience maintaining rate are high after the product is wetted.

Owner:滁州市赢聚高分子材料有限公司

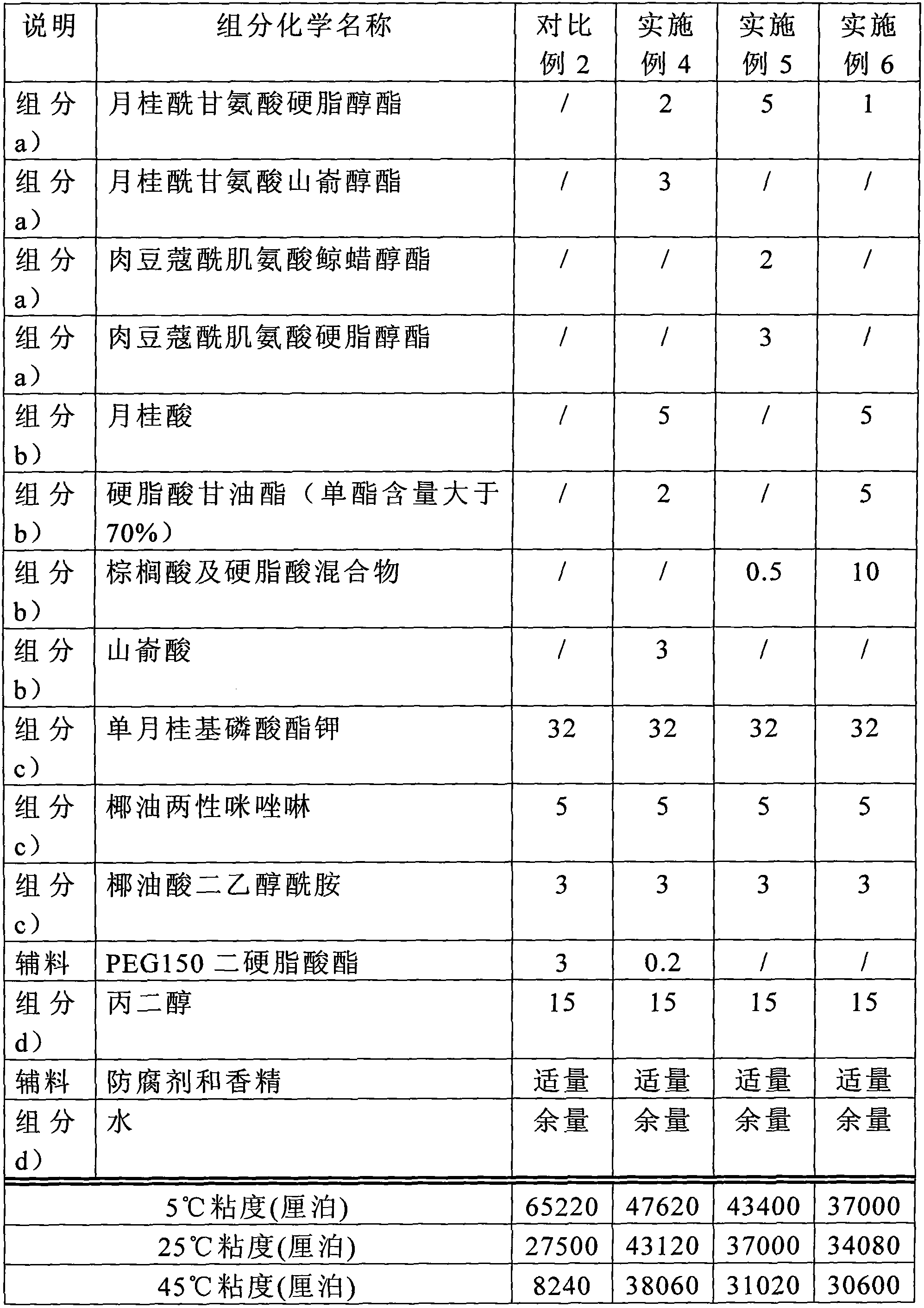

Thick cleaning composite

The invention relates to a thick cleaning composite, in particular to a thick cleaning composite used for cleaning skin, eyes, teeth and hair in the field of personal care products. The cleaning composite comprises long-chain fatty acyl basic amino acid ester, fatty compound of fatty acid, fatty alcohol, fatty alcohol ether or polyalcohol fatty acid ester, surfactant, solvent composed of water, lower alcohol, polyalcohol and polyalcohol ether as well as auxiliary reagent used for beautifying and cleaning skin, eyes, teeth and hair. The cleaning composite is used for cleaning skin and hair, can obtain satisfactory thick appearance and ensures viscosity to be stable at different temperatures, thus being easy for a consumer to smear when in use and realizing rapid foaming and good foam quality.

Owner:SUZHOU ELECO CHEM IND

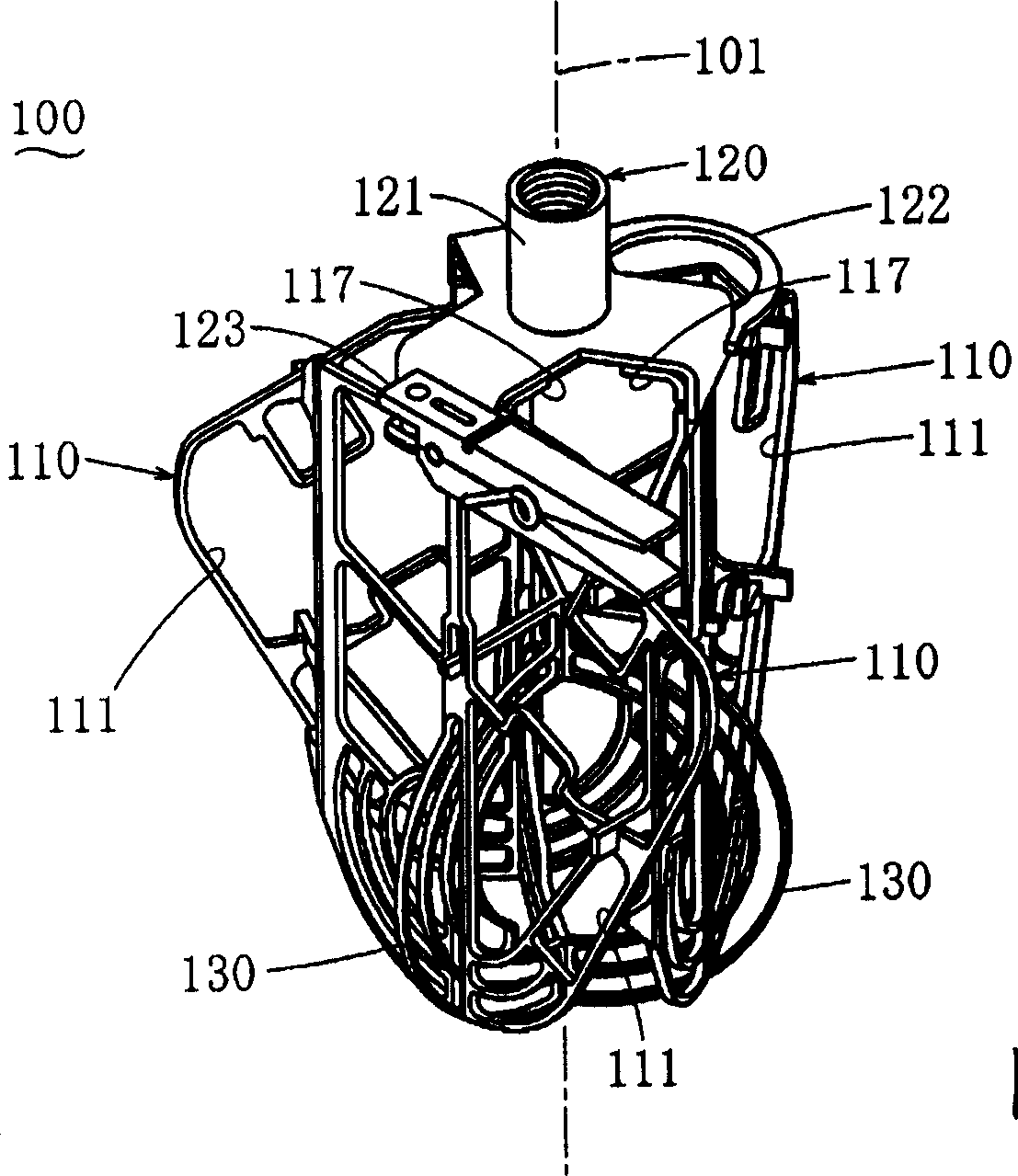

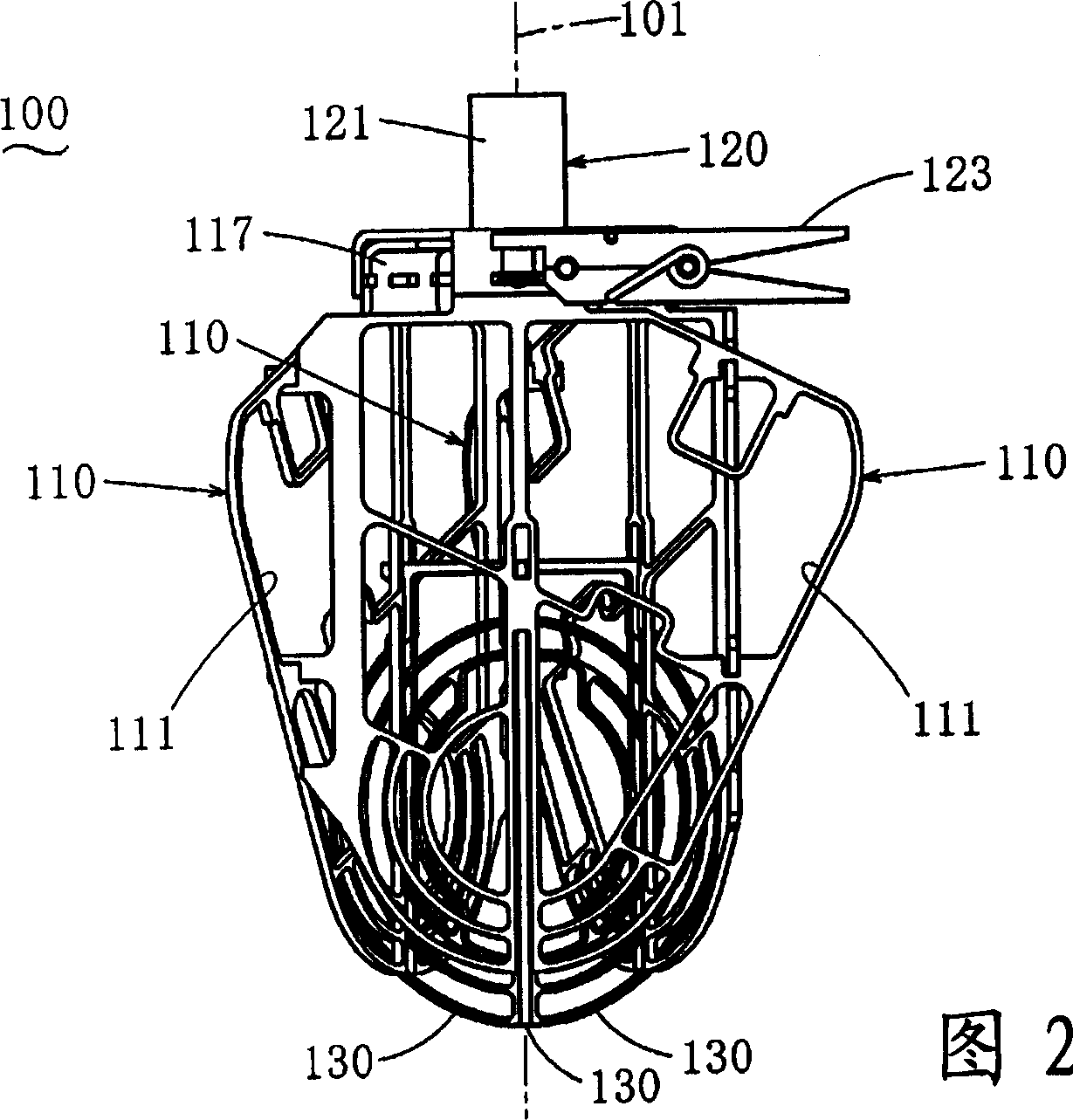

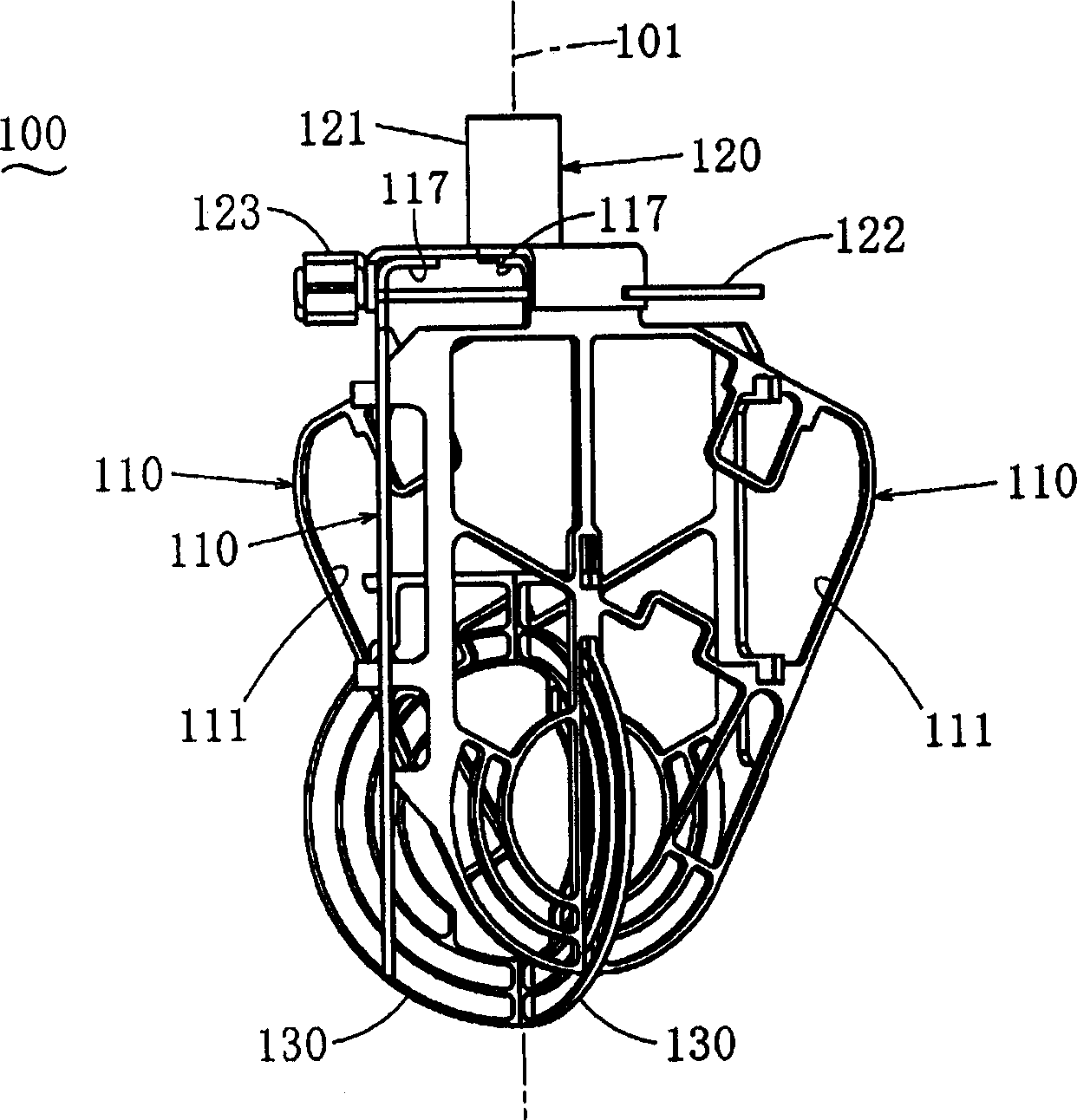

Agitator and agitating device with agitator

InactiveCN1856351APrevent concomitant rotationStir wellRotary stirring mixersTransportation and packagingMechanical engineeringStructural component

An agitator capable of being easily disassembled and assembled, being cleaned on a structural component basis, and capable of securing safety of food under excellent workability, achieving stability etc. of quality of chemicals, and effectively preventing co-turning of a material to improve an agitation effect. At least three deflection agitation blades are arranged so as to be in contact with an imaginary sphere having the center on a vertically extending imaginary axis and to surround the axis. Each of the deflection agitation blades has a window penetrating through the blade. Each blade is provided such that blade's end section on one side in the circumferential direction of the axis butts against the inner surface, facing the axis, of an adjacent blade on the one side in the circumferential direction of the axis, blade's end section on the other side in the circumferential direction of the axis projects in the direction further away from the axis than an adjacent blade on the other side in the circumferential direction of the axis, and adjacent blades are connected so that they can be disassembled.

Owner:AICOHSHA MFG

Environment-friendly refractory material for buildings and preparation method thereof

InactiveCN111647251ATo achieve the purpose of environmental protectionFoaming fastPolyvinyl alcoholAdipic acid

The invention provides an environment-friendly refractory material for buildings. The composite material is prepared from the following raw materials: modified phenolic resin, MgO-Al2O3-ZnO nano powder, graphene oxide modified fly ash floating beads, glass wool, expanded graphite, an excitant, a foaming agent, a foam stabilizer, a water reducing agent, perlite, ethylenediamine, adipic acid, polycaprolactone glycol, glycerol triglycerides and polyvinyl alcohol. The refractory material for buildings has the advantages of small heat conductivity coefficient, light weight, high strength, favorablethermal shock resistance, high refractoriness (higher than 1800 DEG C) and the like, thereby having wide application prospects.

Owner:杭州佧斯家居设计有限公司

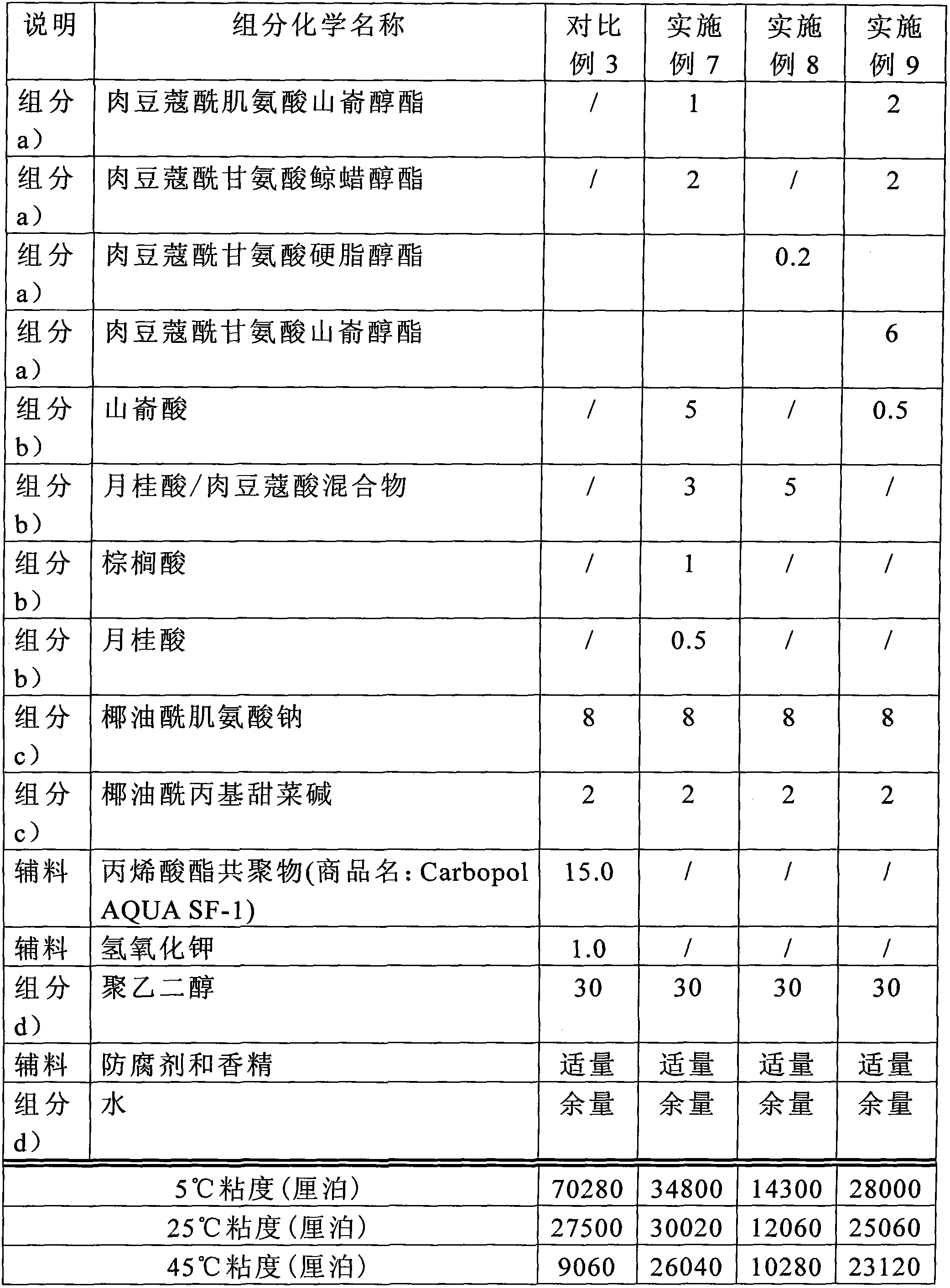

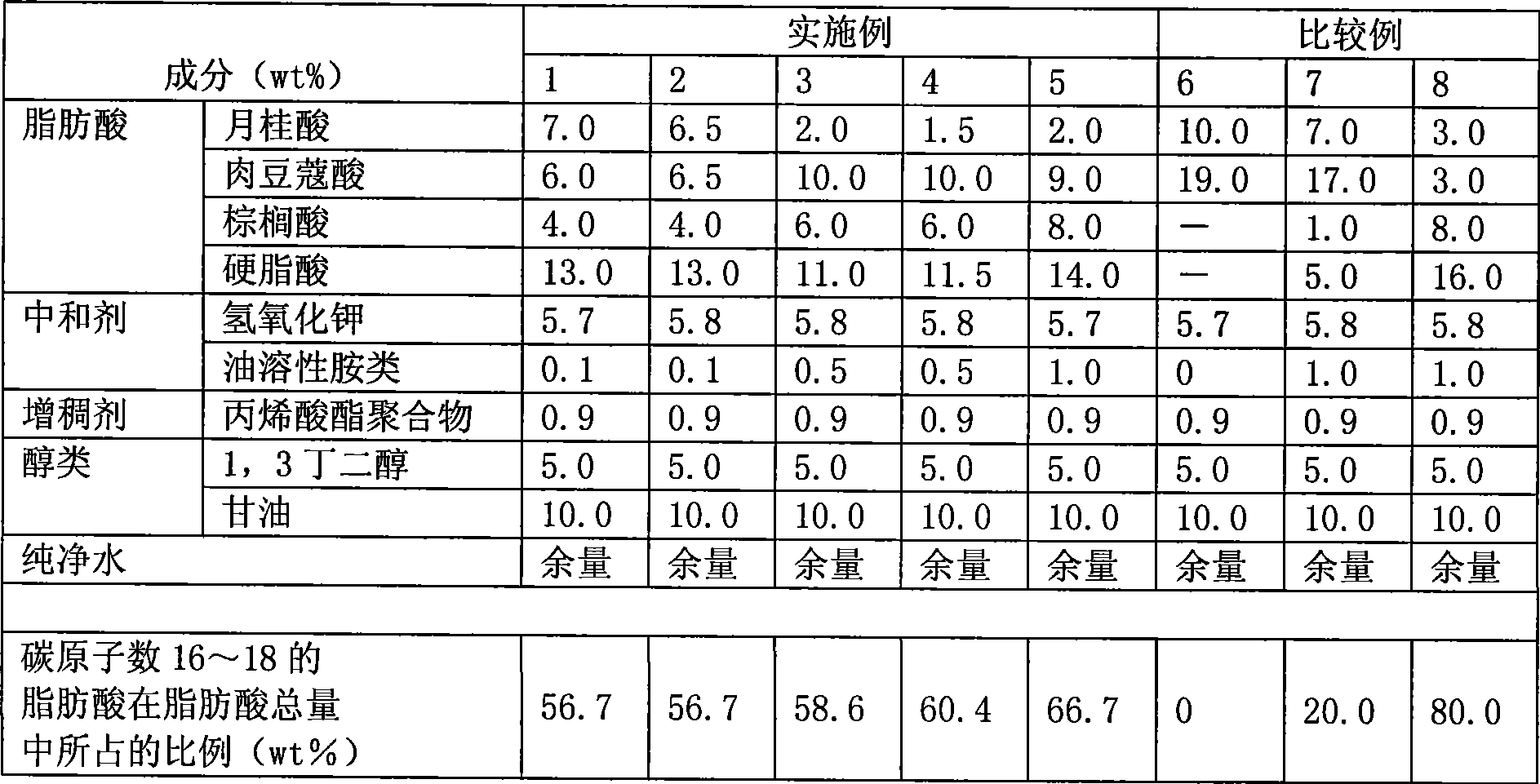

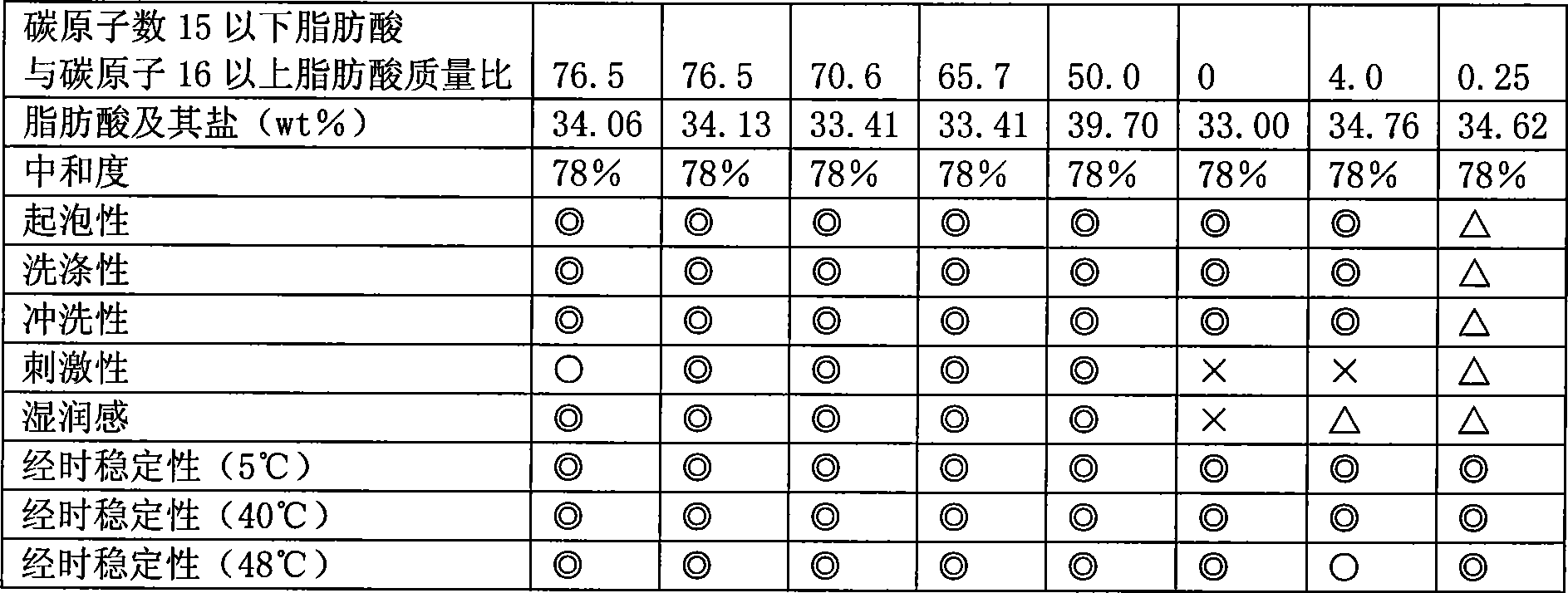

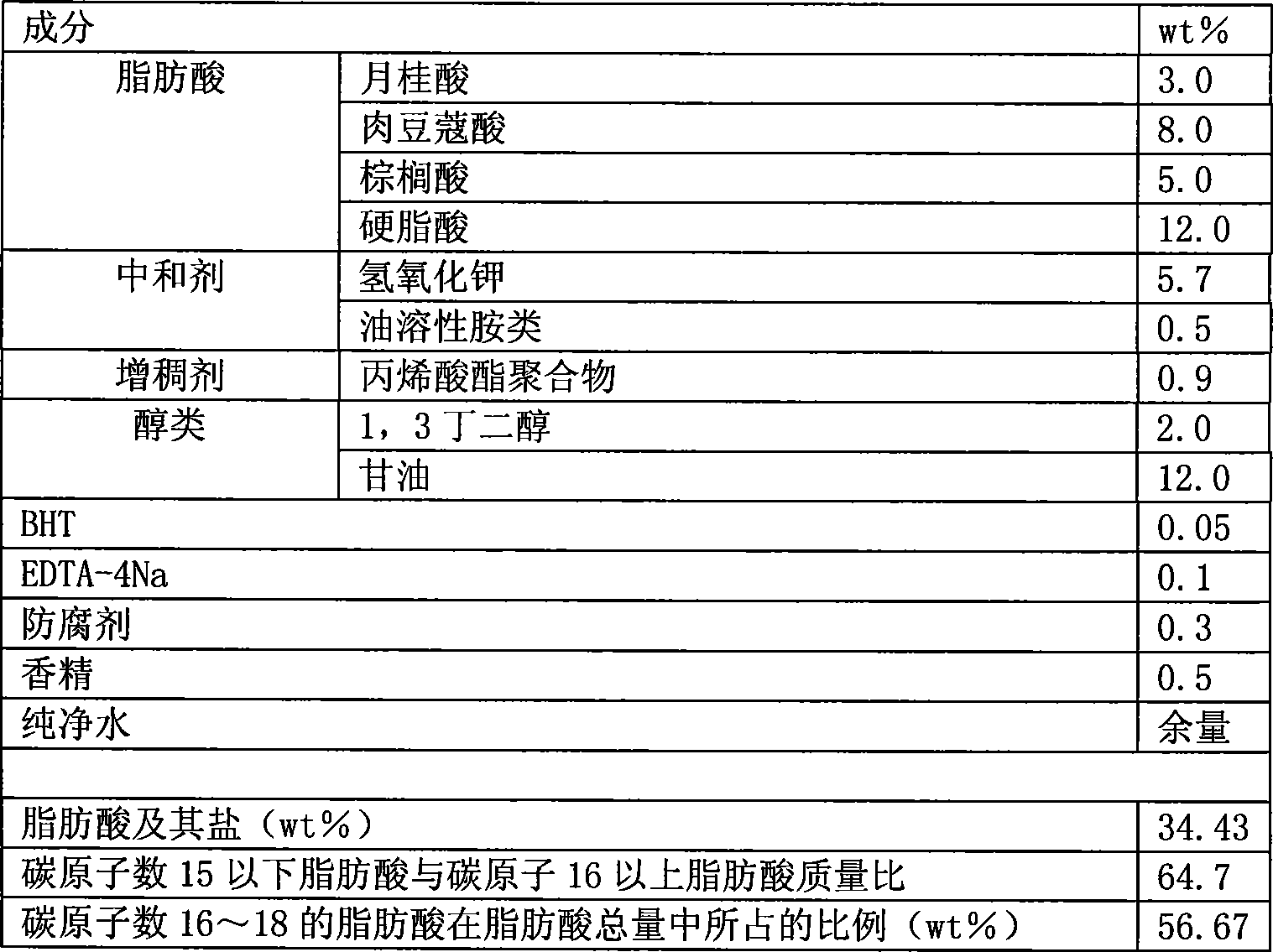

Skin cleaning type composition

ActiveCN101427984AImprove overall lifespanFoaming fastCosmetic preparationsToilet preparationsAlcoholMass ratio

The invention discloses skin cleaning composition. The prescription of the composition comprises the following components by mass percent: 15% to 50% of fatty acid and the soap thereof, wherein, fatty acid comprises the following components: 20% to 75% of fatty acid with the number of carbon atoms of 16 to 18, fatty acid with the number of carbon atoms being below 15 and above 16, (the mass ratio of the two fatty acids are 15:90 to 42:50); 0.1% to 5% of polymer viscosifier; 0.01% to 15% of neutralizer; 2% to 35% of alcohol; and water in balancing amount. The product of the skin cleaning composition has the advantages that the product foams quickly, the foam is fine and rich and can be rushed out by water quickly, and the product is temperate to the skin; the skin after cleaning is endowed with feeling of smoothness and moisture, the stability is good within a wide temperature range (minus 15 to 48 DEG C), the product does not flow at a high temperature of 40 DEG C, does not delaminate at a high temperature of 48 DEG C and does not harden at a low temperature of 0 DEG C; moreover, the product is superior in the storage life and the shelf life.

Owner:广东名臣日化有限公司

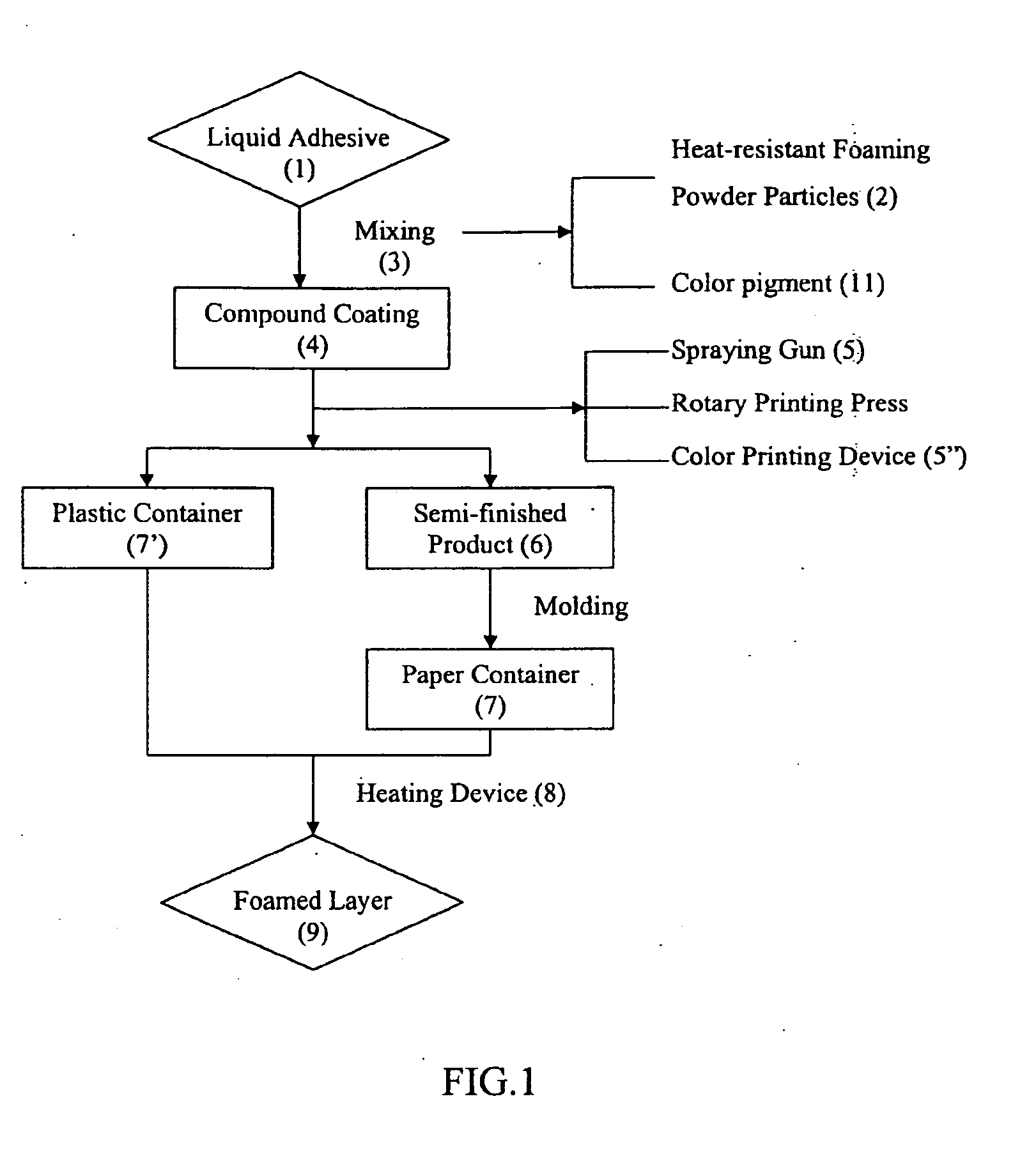

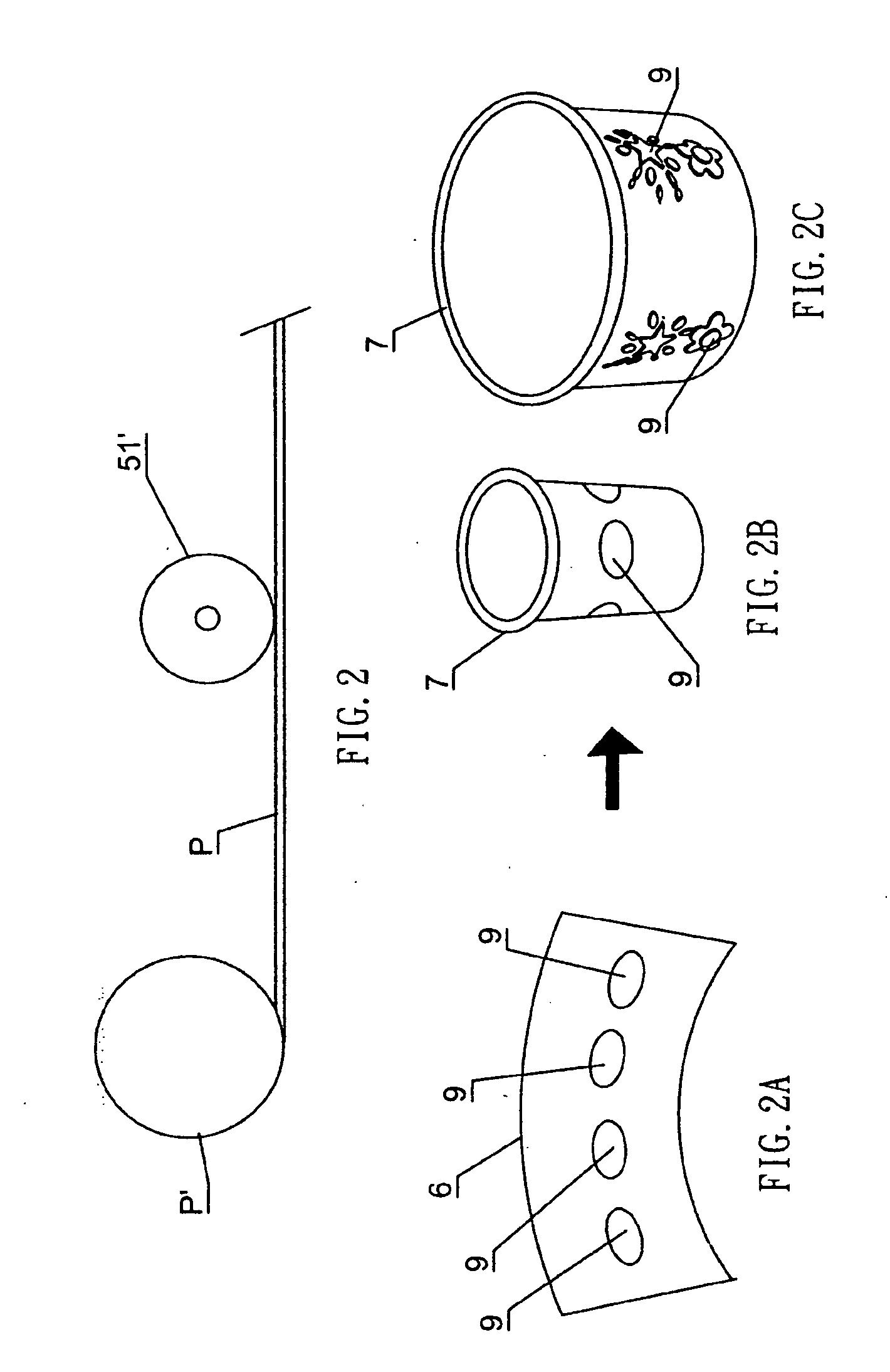

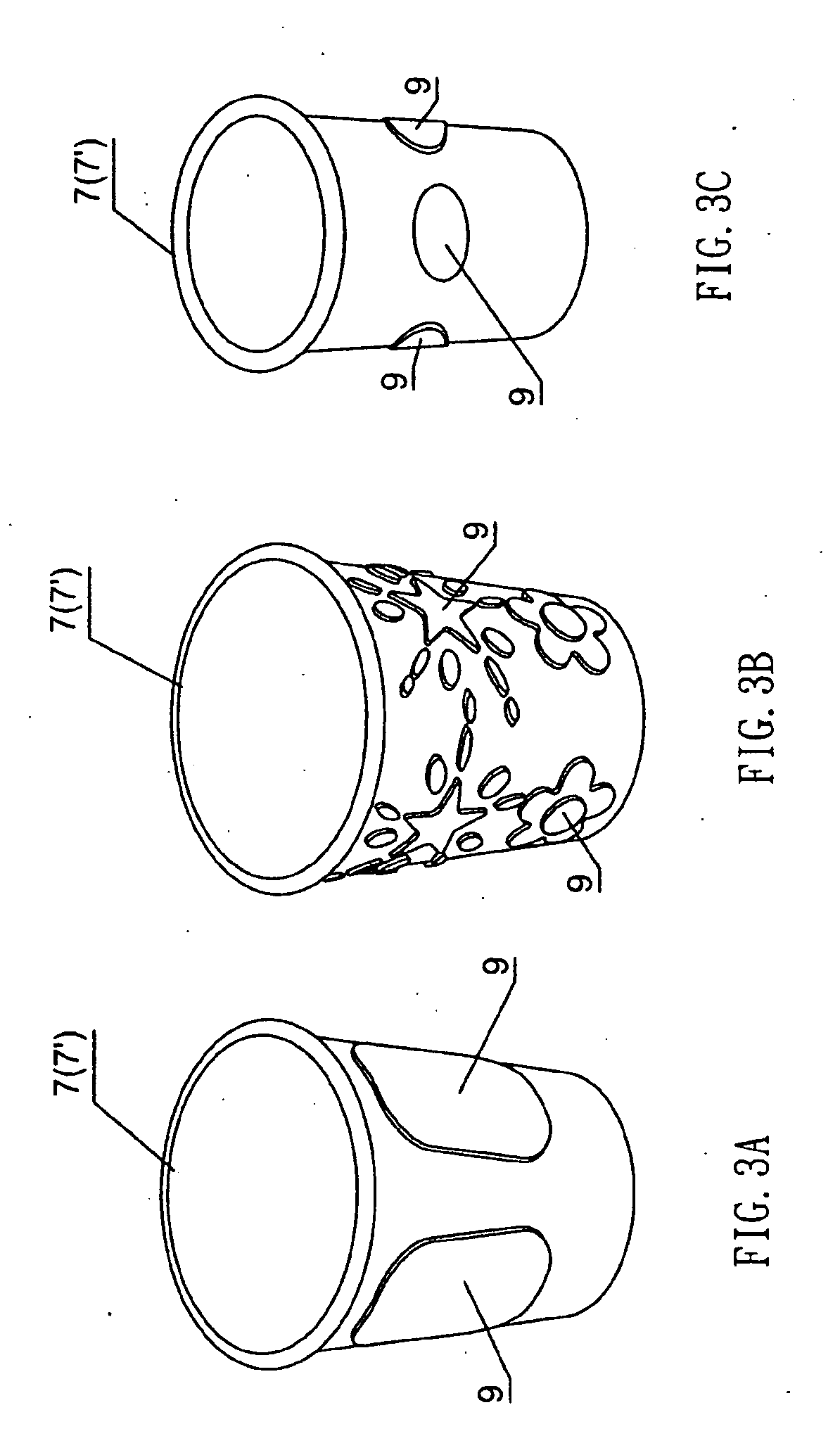

Method for Producing Paper or Plastic Container of Heat Insulation, Heat Preservation and Scald Prevention and the Same Container Obtained Thereby

InactiveUS20100227088A1Foaming fastNo damagePaper-makingBox making operationsEngineeringShipping container

A method for producing paper or plastic container of heat insulation, heat preservation and scald prevention and the same container obtained thereby are disclosed. The method includes the following steps: agitating and mixing (3) a liquid binder with a heat-resistant foamed particle powder (2) to prepare a composite coating (4); applying the composite coating (4) onto a given area of a continuous paper strip (p), a plastics or a plastic container (7,7′), and heating it and then making the heated continuous paper strip (p) or the plastics into a required shaped container according to the prior art. The properties of the inventive container include heat insulation, heat preservation and scald prevention and so on, so when the container contains a substance of higher temperature, a user's hand would not be scalded even if the user holds the container. The inventive method is applicable to prepare various paper or plastic containers, such as cups, bowls, dishes, fast food boxes and various packing containers. The obtained containers are of heat insulation, heat preservation and scald prevention.

Owner:RICH CUP BIO CHEM TECH

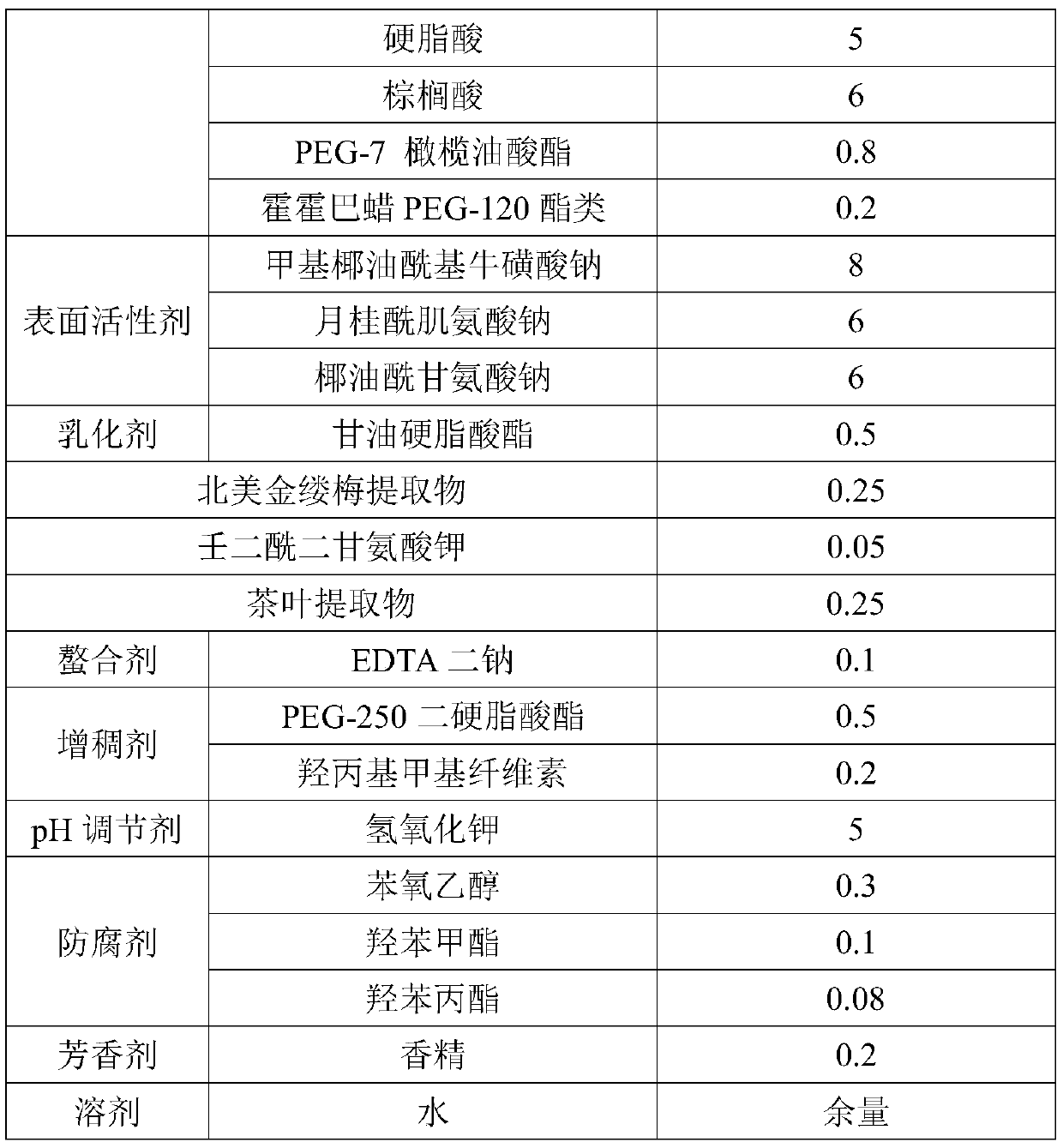

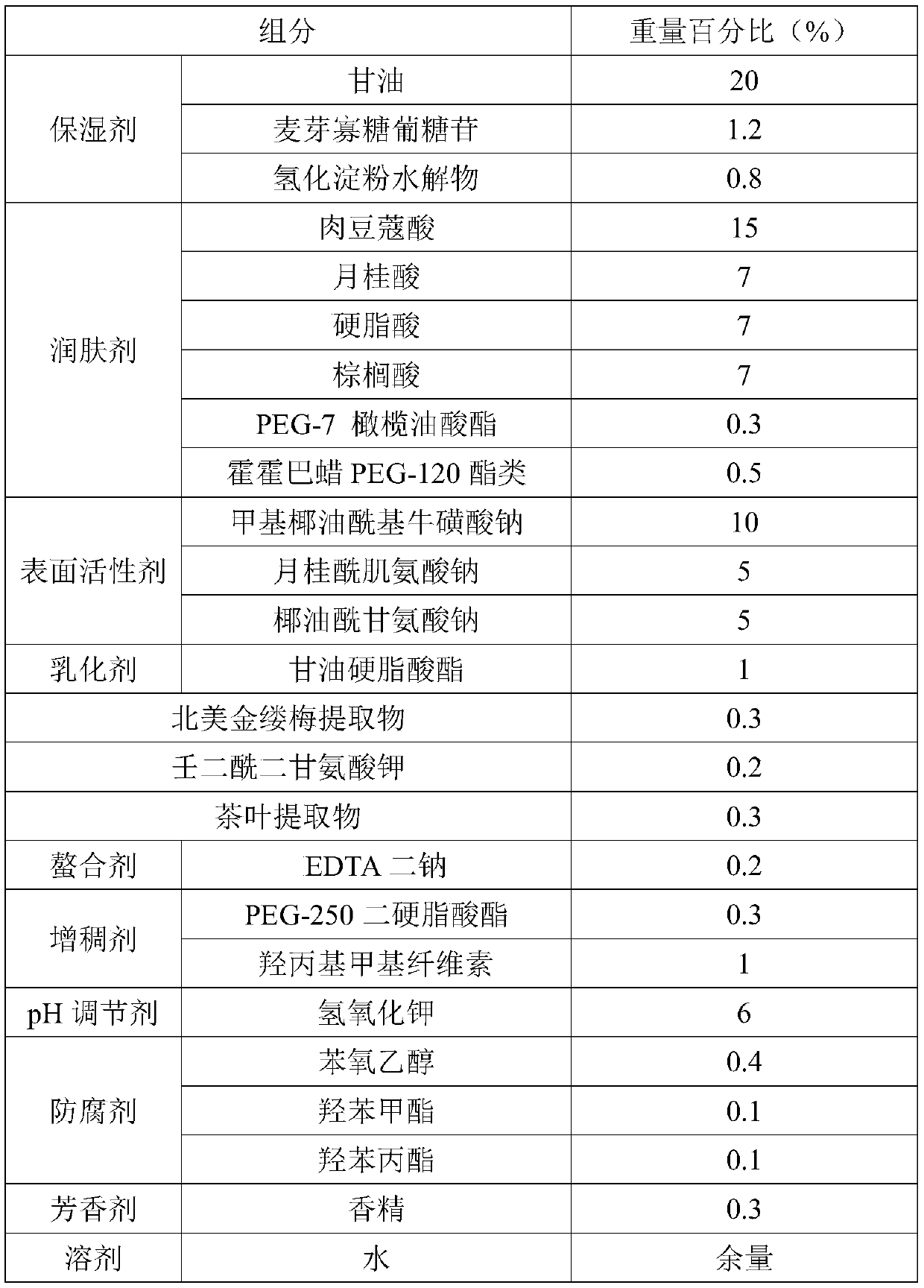

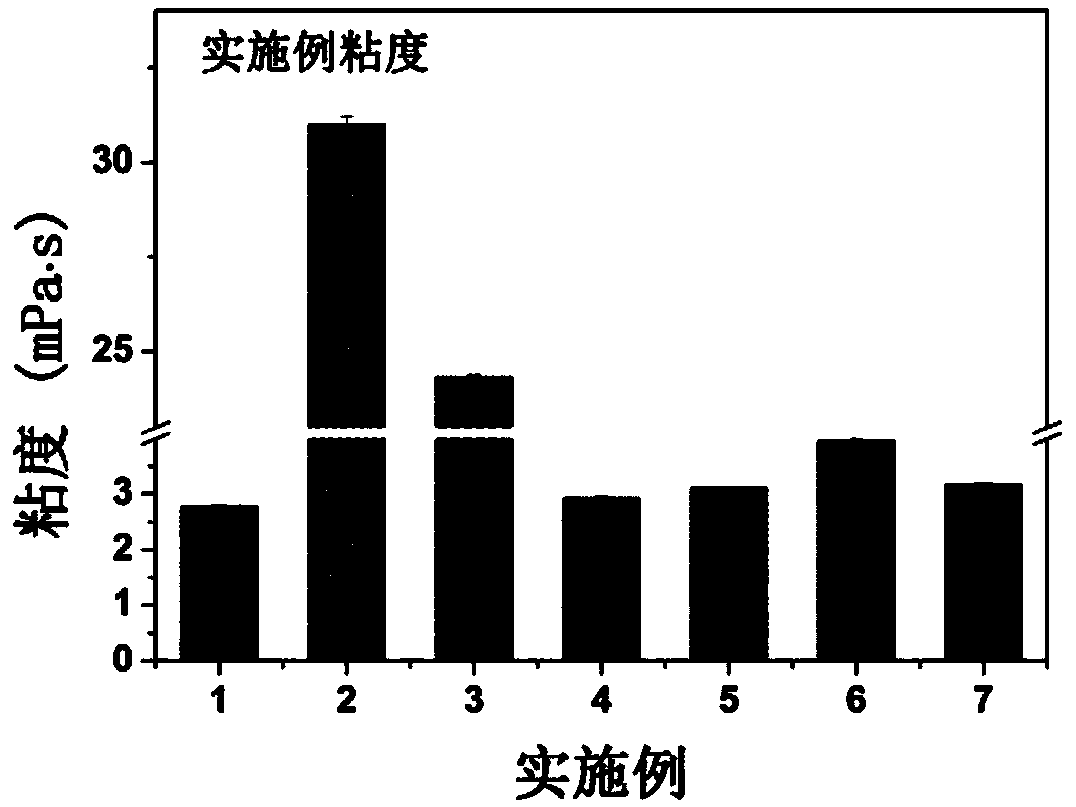

Man cleansing foam and preparation method thereof

ActiveCN110638715AReduce accumulationSoothing oil secretionCosmetic preparationsToilet preparationsPotassium azeloyl diglycinateActive agent

The invention provides man cleansing foam and a preparation method thereof. The man cleansing foam is prepared from the components in percentage by weight: 5-30% of a humectants, 20-50% of an emollient, 1-30% of a surfactant, 0.3-1% of an emulgator, 0.01-0.1% of a witchhazel extractive, 0.01-0.5% of potassium azeloyl diglycinate, 0.01-0.5% of a tea extractive and 4-7% of a pH regulator, and the balance of water. The components of the man cleansing foam are mutually matched and synergized to improve efficiency, deep cleaning can be achieved, pores are dredged, the accumulation of black and white heads is reduced, and according to the characteristics of strong oil secretion of the skin of men, the oil secretion of the skin is fundamentally relieved and improved.

Owner:广州一一生物技术有限公司

Composite foaming agent for cast-in-place foam concrete

ActiveCN109574543AStrong hydrophilic abilityIncreased water carrying capacityFoam concreteFatty alcohol

The invention discloses a composite foaming agent for cast-in-place foam concrete. The foaming agent is prepared from, by mass, 2.0%-8.0% of fatty alcohol polyoxyethylene lauryl ether sodium sulfate,1.5%-8.0% of alkyl glycoside, 0.5%-3.0% of a foam stabilizer, 0%-1.5% of a tackifier and the balance water, wherein the total mass percentage is 100%, a mass ratio of fatty alcohol polyoxyethylene lauryl ether sodium sulfate to alkyl glycoside is 1:4-4:1, the foam stabilizer refers to modified silicon resin polyether emulsion and / or polyvinylpyrrolidone, and the tackifier refers to hydroxypropyl methyl cellulose and / or polyacrylamide. The foaming agent is fast in foaming, high in foaming quantity, great in foam stability, excellent in performance, great utilization effects can be achieved without adding of other auxiliary agents, and the foaming agent can be diluted by 30-60 times to be used for preparation of cast-in-place foam concrete. Raw materials of the foaming agent are excellent inbiodegradability, safe and environmentally friendly, and the prepared foaming agent is green and environmentally friendly. In addition, a preparation process of the foaming agent is simple, mild in condition and applicable to industrial production.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com