Patents

Literature

148results about How to "Fast oil absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

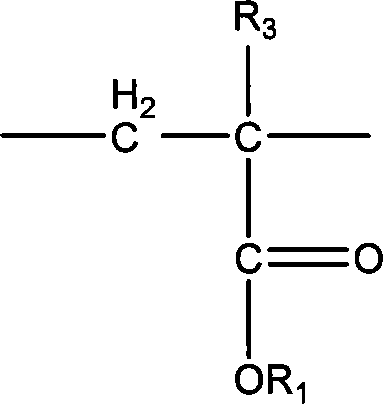

Method for preparing seaweed cellulose aerogel oil absorption material

ActiveCN103980530AEnsure thoroughnessFast oil absorptionOther chemical processesCelluloseUltimate tensile strength

The invention discloses a method for preparing a seaweed cellulose aerogel oil absorption material and relates to a method for preparing an oil absorption material. The method comprises the following steps: I, purifying seaweed cellulose; II, preparing seaweed nano cellulose microfibril in a mechanical colloid milling mode; III, preparing seaweed cellulose aerogel; and IV, performing hydrophobic modification on the seaweed cellulose aerogel. The seaweed cellulose aerogel oil absorption material prepared by using the method is natural and pollution-free and has the advantages of high oil absorption efficiency, , good strength, simple secondary treatment and the like, and is an important development direction of novel aerogel oil absorption materials.

Owner:HARBIN INST OF TECH

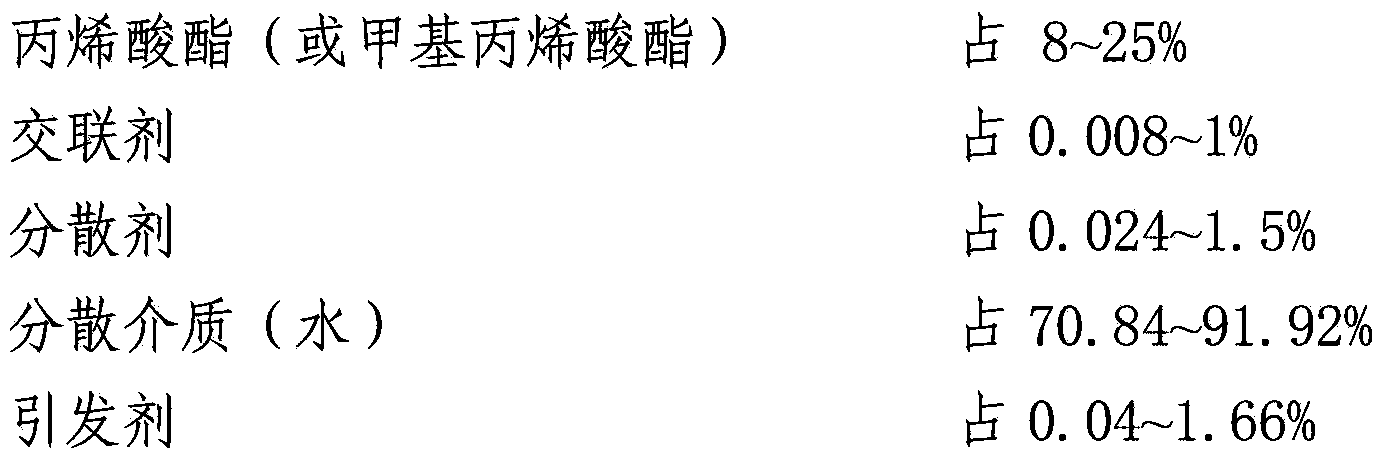

Oil absorbing fibre and perparing method thereof

InactiveCN1584148ABroaden the fieldLarger specific surface area for oil absorptionWet spinning methodsMonocomponent synthetic polymer artificial filamentFiberBenzoyl peroxide

The invention relates to a kind of oil-absorbed fiber and its producing method. Its prescription is: 100% polymer monomer, 10-40% of potential gemel agent, 0.1-0.5% solicitation, 0.5-1% dispersant. Moreover the water-like body is 3-4 times more in volume than polymer monomer. The polymer monomer is methacrylate monomer involving butyl methacrylate, the potential gemel agent is 2-hydroxyethyl methacrylate, the solicitation is benzoyl peroxide, and dispersant is poly-vinyl-alcohol. The process is (1) use water-suspending polymerization to produce butyl methacrylate under 70-80 deg.C for blending and polymerizing for 8-10 hours. (2) dissolve the polymer into proper solvent to deploy 20-25% liquid and then insert potential gemal agent and solicitation to polymerize for 3-5 hours under 75-80 deg.C to obtain the original liquid. (3) take off dunking. (4) spin using one of wet or dry method or both, (5) treat with fibre for 10-60 minutes under 120-165 deg.C to obtain the production. The solvent discussed above is one of DMF, DMAC or dimethoxysulfoxide.

Owner:TIANJIN POLYTECHNIC UNIV

High oil absorption resin and synthetic method thereof

The invention discloses a high oil absorbing resin, and a process for preparation comprises utilizing short-chain ester of (metyl group) acrylic acid, long-chain ester of acrylic acid and styrene monomer to be monomers, adding dispersing agent and surface active agent, and getting through suspension polymerization and random copolymerization under the condition of the existence of cross linker and initiating agent. The process for synthesizing has lithe time consumption, which can be industrialized, and high oil absorbing resin which is got has high oil absorbing efficiency, fast oil absorbing speed, and which can be recycled to be repeatedly used.

Owner:SUZHOU TIMELYBLUE ENVIRONMENTAL TECH

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

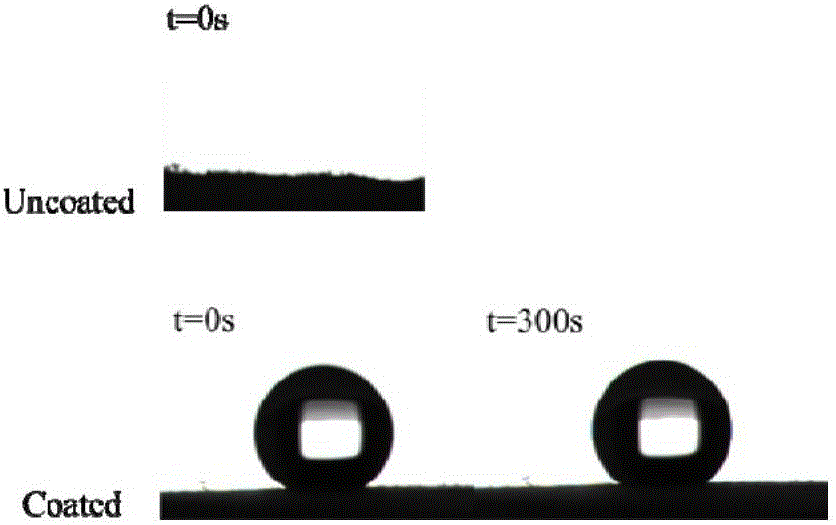

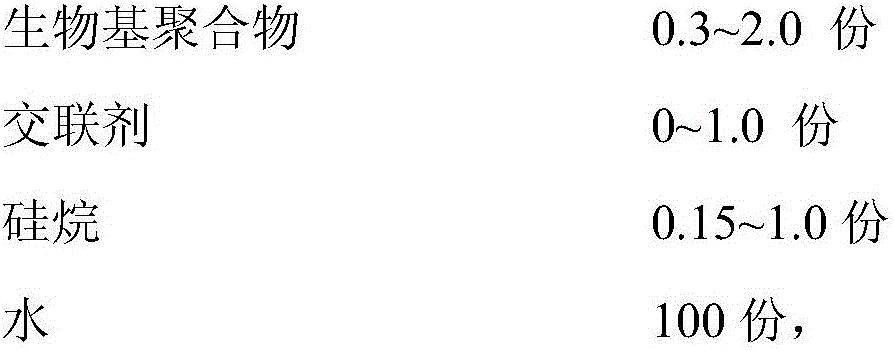

Biology base polymer aerogel oil absorption material and preparation method thereof

The invention discloses a biology base polymer aerogel oil absorption material. The oil absorption material is prepared by the following steps: at first, crosslinking biology base polymers by a crosslinking agent, to obtain a precursor liquid, then freeze-drying the precursor liquid to obtain aerogel, and finally grafting silane onto the aerogel surface to obtain the hydrophobic biology base polymer aerogel oil absorption material. The density of the oil absorption material is 3.8 to 23.1 kg / m3. The water contact angle is at least 117.8 degrees. The adsorption capacities on gasoline, paraffin oil, chloroform, and crude oil are 30.5-109.0 g / g, 33.2-131.2 g / g, 58.2-163.0 g / g, and 24.7-95.8 g / g. After 50 times of gasoline adsorption-extrusion circulation, the retention rate of adsorption capacity is 43 to 99%. The disclosed aerogel oil absorption material has the advantages of large oil absorption capacity and high oil absorption efficiency. Moreover, the oil absorption material can be repeatedly used by simply extruding the oil absorption material, while a high retention rate of adsorption capacity can be maintained. At the same time, the raw material sources are wide, the raw materials are cheap and easily available, the preparation is simple, the technology is matured, the method is environment-friendly, and the requirements of sustainable development can be met.

Owner:SICHUAN UNIV

Preparation method of super-hydrophobic, super-oleophylic and ultralight sponge

ActiveCN104324524ASmall surface areaHigh oil absorption rateLiquid separationSurface energyOrganic chemicals

The invention relates to a preparation method of super-hydrophobic, super-oleophylic and ultralight sponge. The preparation method comprises two steps of performing functionalized processing on melamine sponge by using an impregnation method and performing a curing reaction after processing. The melamine sponge used by the invention has a large quantity of active functional groups such as hydroxyl groups and amino groups on the surface, the content of the hydrophobic active functional groups on the surface of the sponge is remarkably reduced after the active groups are chemically functionalized, which causes a result that the surface energy of the material is reduced, thus the sponge is endowed with super-hydrophobic and super-oleophylic effects, and a contact angle between the sponge and water exceeds 150 degrees; and the modified melamine sponge belongs to an ultralight material due to density. The method disclosed by the invention has the advantages that raw materials are low in price and easy to available, the process is simple and easy to operate, the large-scale preparation is easily realized, and the like. The sponge prepared according to the preparation method has the advantages of low density, excellent compression resistance, high oil absorbing speed, high oil absorbing rate, high oil and water separation selectivity and the like, is a novel and efficient ultralight-density oil and water separating material, and has a wide application prospect in the fields such as organic chemical reagent treatment, oil-containing wastewater treatment, and leaking crude oil recovery.

Owner:中科瑞丽分离科技无锡有限公司

Hydrophilic oil absorption cotton

ActiveCN104383899AImprove adsorption capacityFast oil absorptionFatty/oily/floating substances removal devicesOther chemical processesFiberAdjuvant

The invention relates to hydrophilic oil absorption cotton. The oil absorption cotton consists of a hydrophilic and oleophylic adjuvant layer and a filtering layer covering the adjuvant layer, wherein the hydrophilic and oleophylic adjuvant layer is prepared from a super-amphiphilic material; the filtering layer is prepared from composite filtering cotton; the composite filtering cotton comprises a filtering cotton layer; active carbon particles are uniformly distributed in the filtering cotton layer; nonwoven cloth thin layers which are difficult to defiber are arranged on the top surface and the bottom surface of the filtering cotton; the super-amphiphilic material is a macromolecular carbon nano composite material; the composite material contains a nano-level space consisting of a hydrophilic polymer chain section and an oleophylic polymer chain section which are regularly arrayed. The hydrophilic oil absorption cotton has dual effects of oil absorption and water absorption; the filtering layer and the hydrophilic and oleophylic adjuvant layer are of multihole structures; on the premise of guaranteeing high oil absorption rate, the oil absorption rate is also increased.

Owner:浙江黎盛新材料科技有限公司

Preparation method of seaweed cellulose aerogel-carbamic acid alkyl ester type oil gelling agent composite oil spill control material

The invention discloses a preparation method of a seaweed cellulose aerogel-carbamic acid alkyl ester type oil gelling agent composite oil spill control material and relates to a preparation method of a porous network-like structural material integrating hydrophobic, lipophilic and oil gelling properties. The method specifically comprises the following steps: step 1) preparing a hydrophobic seaweed cellulose aerogel; step 2) preparing a carbamic acid alkyl ester type oil gelling agent; step 3) preparing the seaweed cellulose aerogel-carbamic acid alkyl ester type oil gelling agent composite material. According to the method, natural, renewable and seaweed cellulose harmful to the environment is adopted as raw material for preparing an oil-absorbing material, the oil-absorbing material is effectively compounded with the oil gelling agent to prepare the oil spill control material integrating the oil gelling property of anoil gelling agent and the oil-absorbing property of an oil-absorbing agent; and the oil spill control material is capable of effectively absorbing and gelling oil products, organic solvents and other pollutants which are leaked into water.

Owner:HARBIN INST OF TECH

Method for preparing high oil absorption resin

A process for preparing the resin with high oil absorptivity from styrene and long-chain olefin monomer CnH2n, where n is equal to or greater than 4, includes such steps as preparing the low-cross-linked polystryrene or styrene copolymer, immersing it in solvent or long-chain olefin monomer or their mixture, and alkylating reaction. Its advantages are high content of gel and oil absorptivity, and low cost.

Owner:NANJING UNIV OF SCI & TECH

Preparation method and application of three-element siloxane sponge

ActiveCN104194028ALow densityExcellent compression resistanceFatty/oily/floating substances removal devicesLiquid separationSilanesHydrolysis

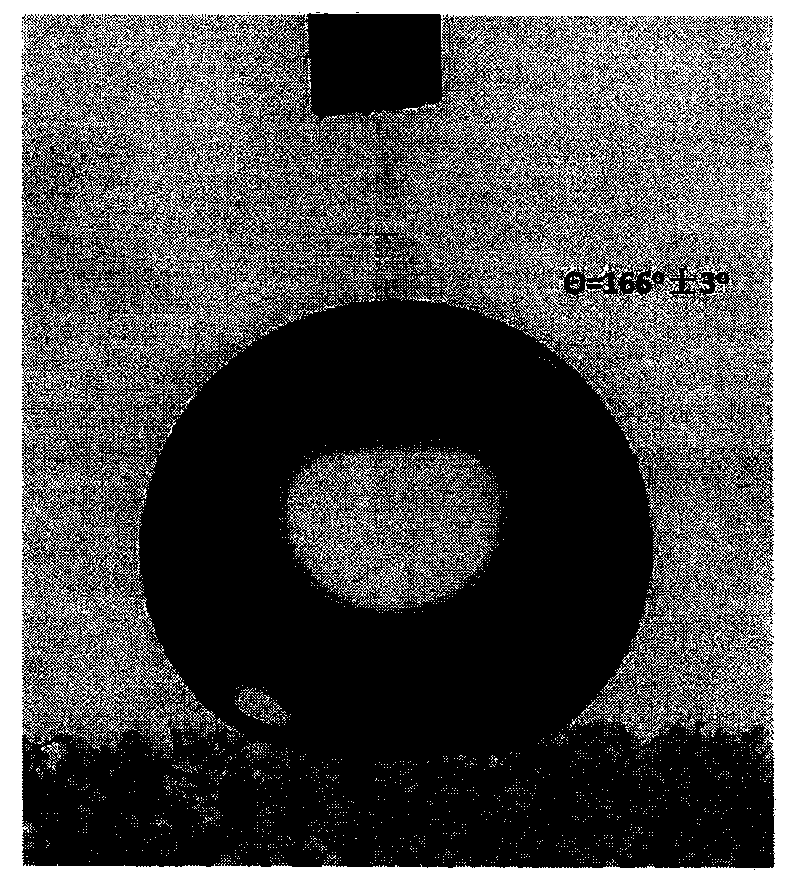

The invention relates to a preparation method and application of three-element siloxane sponge, belonging to the technical field of preparation and application of environmental functional materials. The method comprises the following steps: alkoxy silane hydrolysis, gelation, product washing and drying. Compared with the traditional two-element siloxane sponge, the three-element siloxane sponge contains abundant non-polar groups and higher roughness on the surface, and is endowed with the superhydrophobic and superoleophylic effects; the contact angle with water exceeds 160 degrees; and the material has excellent mechanical properties. The preparation method is simple to operate, has the advantages of cheap raw materials and the like, and can easily implement large-scale preparation. The three-element siloxane sponge has the advantages of low density, excellent compression resistance, high oil absorption speed, high oil absorption power and the like, has wide application prospects in the fields of organic chemical solvent treatment, oily wastewater treatment, oil spillage treatment and the like, and is a novel efficient oil-water separation material.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

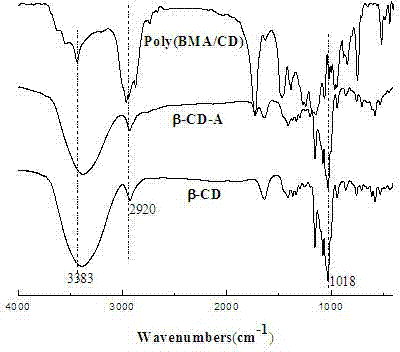

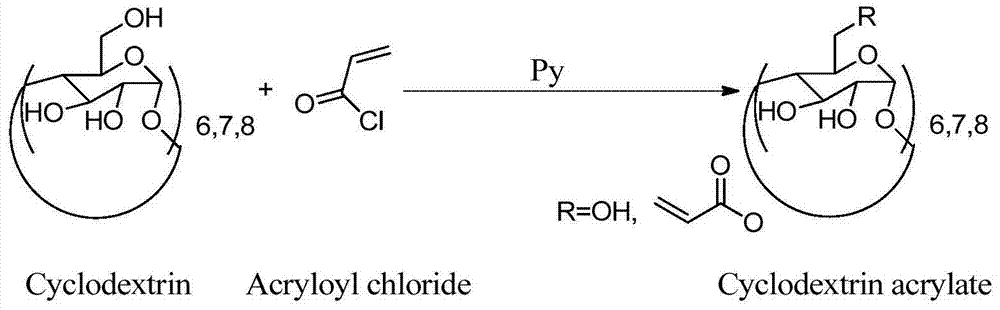

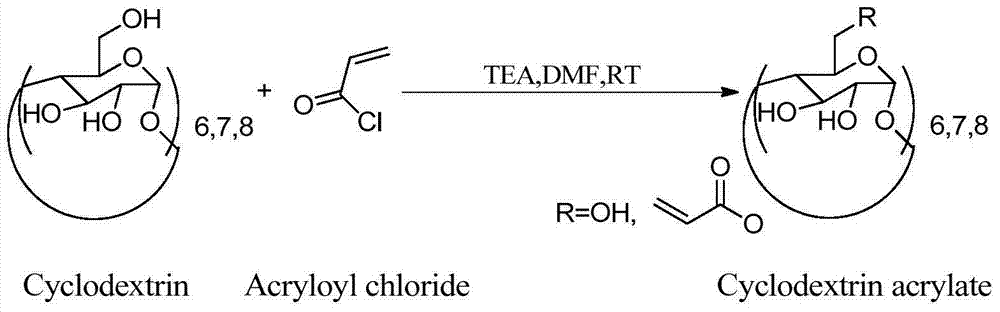

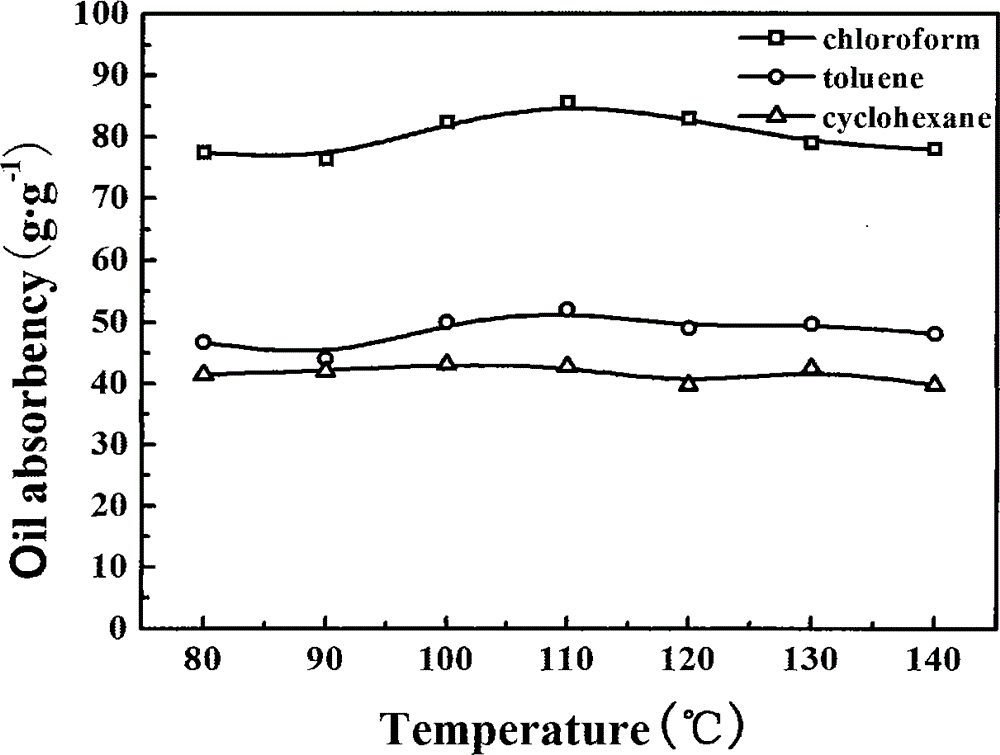

Method for preparing modified oil-absorptive resin immobilized with cyclodextrin molecules

ActiveCN104497231AAvoid reactionFast oil absorptionFatty/oily/floating substances removal devicesOther chemical processesCross-linkOrganic base

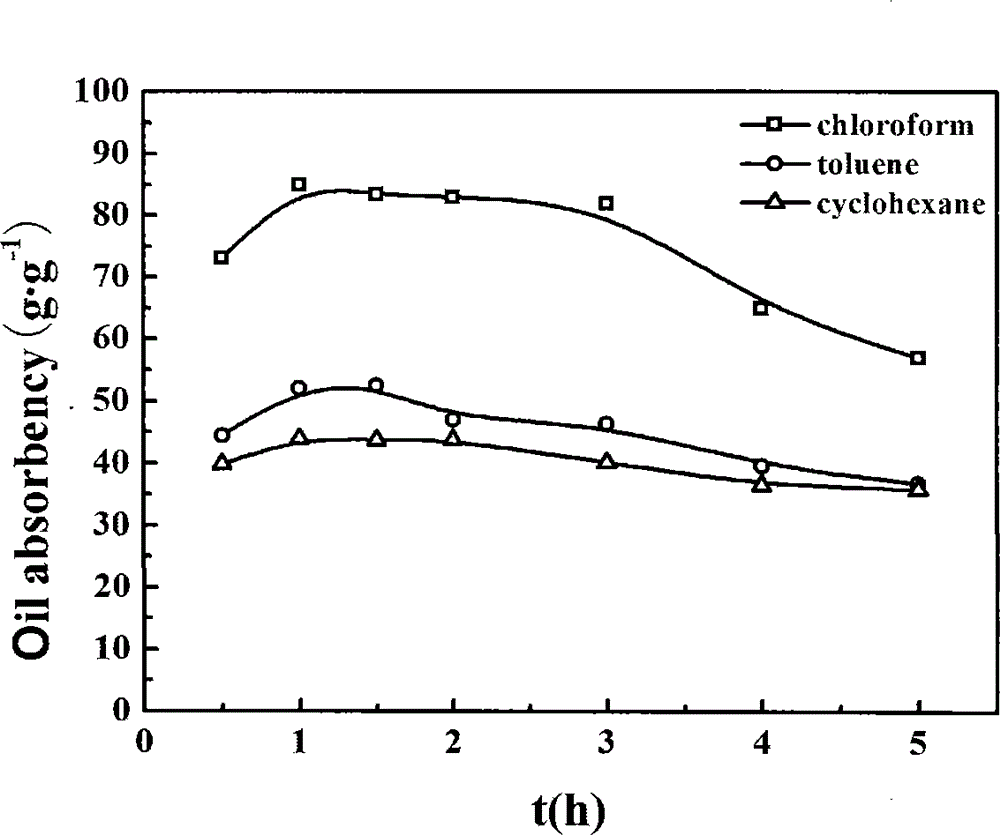

The invention discloses a method for preparing modified oil-absorptive resin immobilized with cyclodextrin molecules. The method comprises the following steps: modifying hydroxyls of cyclodextrin molecules by taking cyclodextrin molecules, and acryloyl chloride or other acylation reagents as raw mateials in the presence of an organic base and taking an organic solvent or an organic base as a reaction medium, so as to synthesize 6-acryloyl cyclodextrin; dissolving CD-6-A in an aqueous solution under the ultrasonic action, sequentially adding a monomer, an initiator, a cross-linking agent and a pore-foaming agent into the aqueous solution, carrying out a suspension polymerization reaction to obtain the modified oil-absorptive resin, and drying under reduced pressure, thereby obtaining the product. The adsorbing capacity of the modified oil-absorptive resin containing the cyclodextrin molecules on methylbenzene is close to 45g / g, the adsorbing capacity on trichloromethane reaches 80g / g, and the resin has a very obvious effect of cleaning floating oil on the water surface. The modified oil-absorptive resin disclosed by the invention has the advantages that the preparation process is simple, the production cost is low, the adsorbing capacity is large, the oil absorption efficiency is high, the rein can be repeatedly used, and the adsorption-desorption process is simple, green and environment-friendly.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Oil absorbent fibrous membranes production method

ActiveCN104264373AImprove abilitiesImprove leakageFilament/thread formingNon-woven fabricsMicro nanoFiber

The invention discloses an oil absorbent fibrous membranes production method combined by micro-nano fibers in staggered non-directional alignment in the technical field of fibrous polymer group oil absorbent material production. The production method includes that nano fibers formed by other polymers through techniques such as suspension polymerization, solution blending and electrostatic spinning are arranged into micron poly (meth) acrylate fibers, a fiber web structure combined by nano fibers is used for forming micropores, the nano fibers are used for isolating and preventing bonding among the micron poly (meth) acrylate fibers and providing high porosity, and the micron poly (meth) acrylate fibers are used for supporting and strengthening the fiber web structure combined by nano fibers. The obtained micron poly (meth) acrylate group oil absorbent fiber membrane is good in overall performance, has the advantages of quick oil absorption rate, high oil absorption amount and the like when compared with existing fibrous polymer group oil absorbent materials, can be used for the separation of an oil and water mixture, and further meets the requirements of industrial practicality.

Owner:TIANJIN POLYTECHNIC UNIV

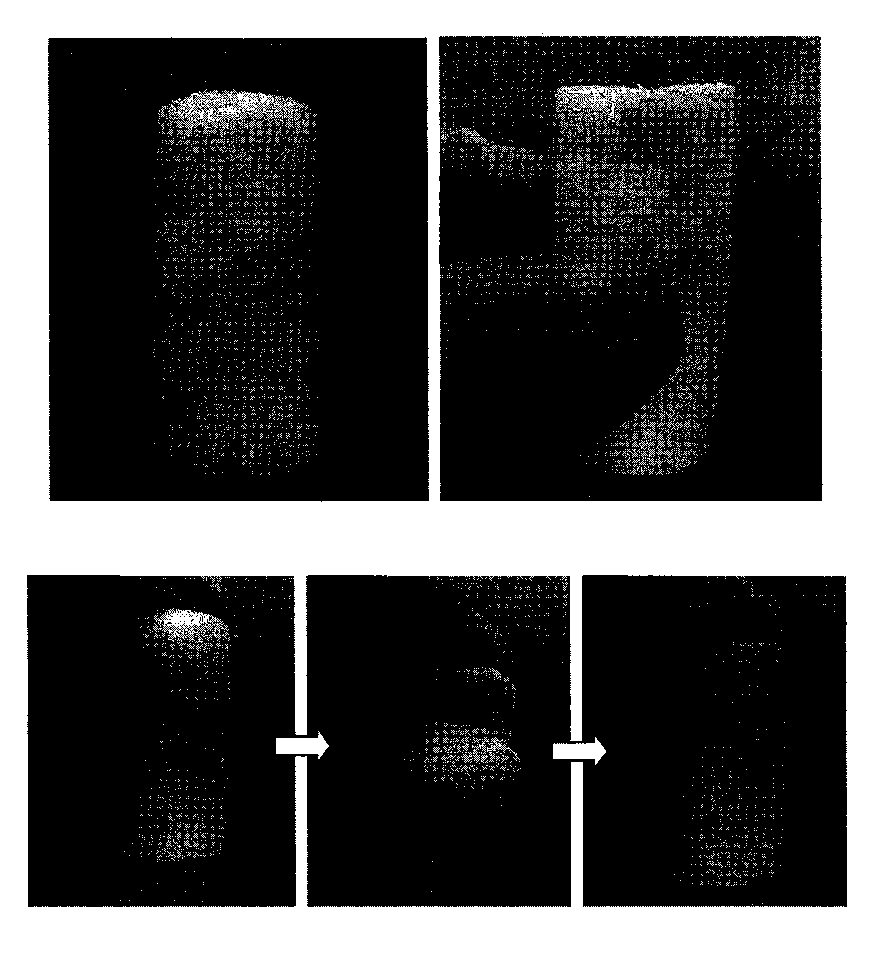

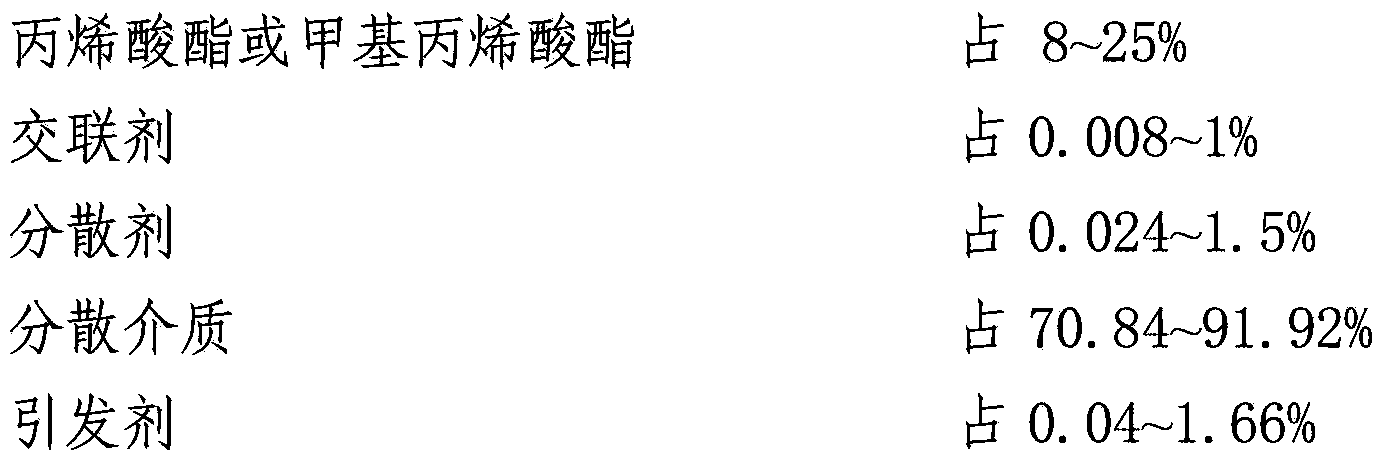

Shell-like polymer oil-absorbing microsphere preparation method

ActiveCN104341546AFast oil absorptionEasy to produceOther chemical processesMethacrylatePolymer science

The present invention relates to a shell-like polymer oil-absorbing microsphere preparation method, which adopts a suspension polymerization method, and specifically comprises: adding deionized water and a dispersing agent into a three-necked flask with a stirring device, heating to a temperature of 30-50 DEG C until the dispersing agent is dissolved, sequentially adding an acrylate or methacrylate reaction monomer, a diacrylate cross-linking agent of a diol and a free radical polymerization initiator to the three-necked flask under the protection of high purity nitrogen, slowly heating to a temperature of 60-80 DEG C, carrying out a reaction for 3-6 h to obtain polymer oil-absorbing microspheres, adding styrene and divinylbenzene, carrying out a reaction for 1-3 h so as to generate the high cross-linking degree surface layer structure on the outer surface of the microsphere, cooling the reaction system to a room temperature under the stirring condition, and carrying out filtration, water washing, suction filtration and drying on the oil-absorbing microsphere to obtain the shell-like polymer oil-absorbing microsphere, wherein a mass ratio of the deionized water to the dispersing agent is 100:0.03-4.5. The shell-like polymer oil-absorbing microsphere of the present invention has the characteristic of rapid oil absorbing.

Owner:PIPECHINA SOUTH CHINA CO

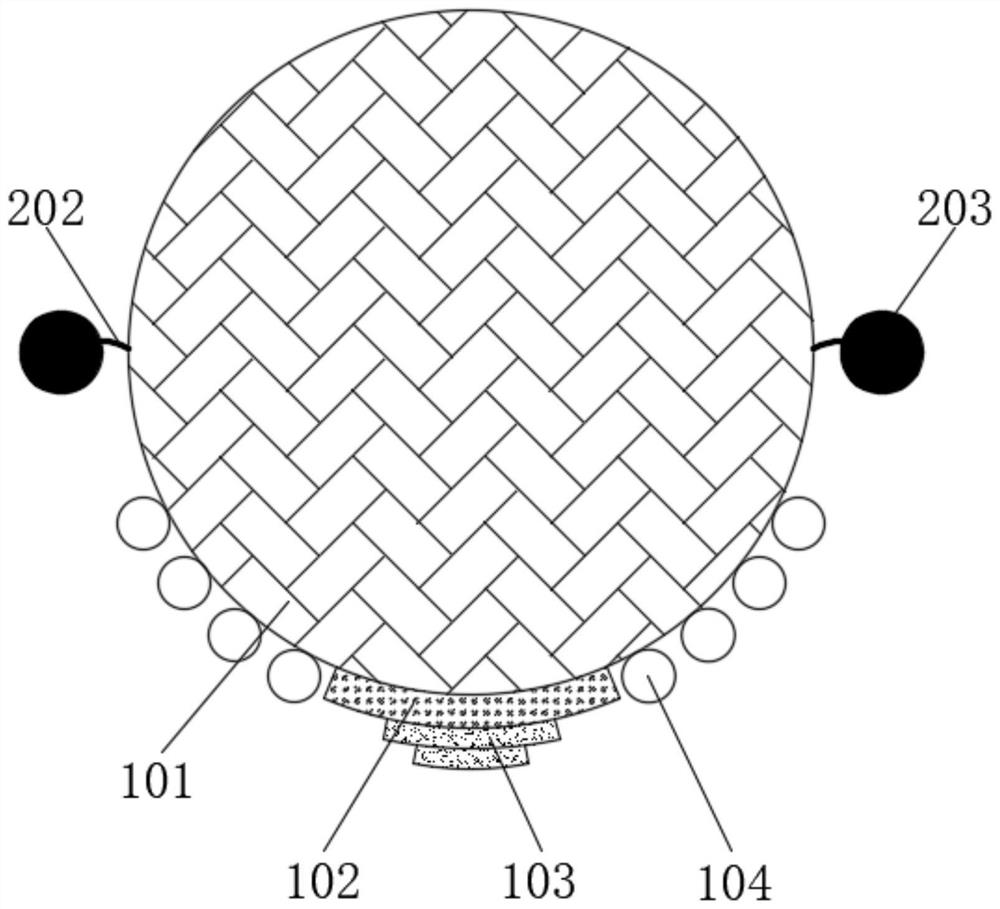

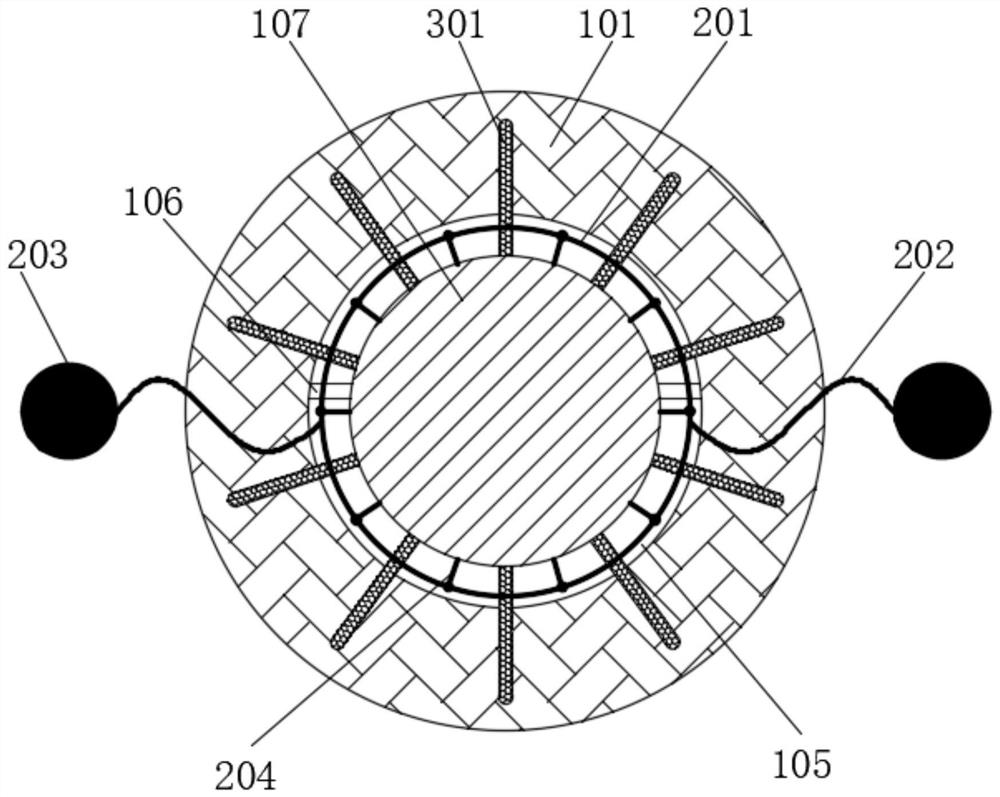

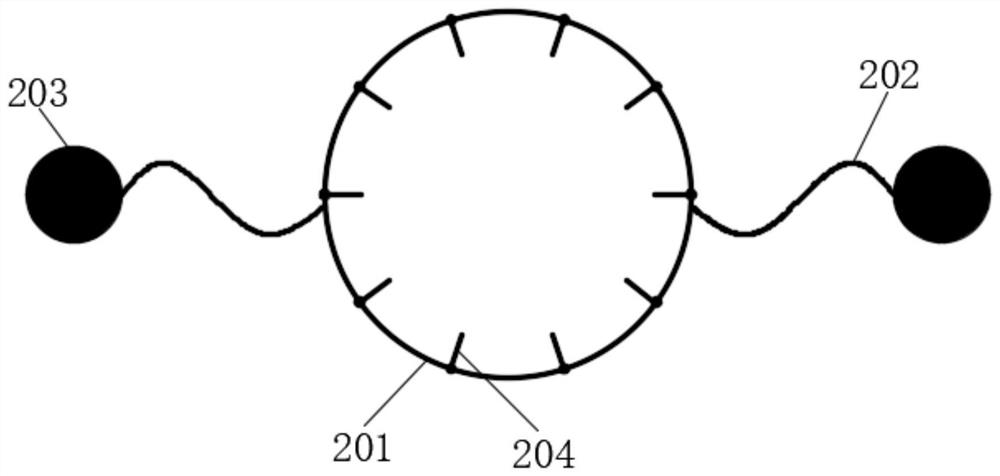

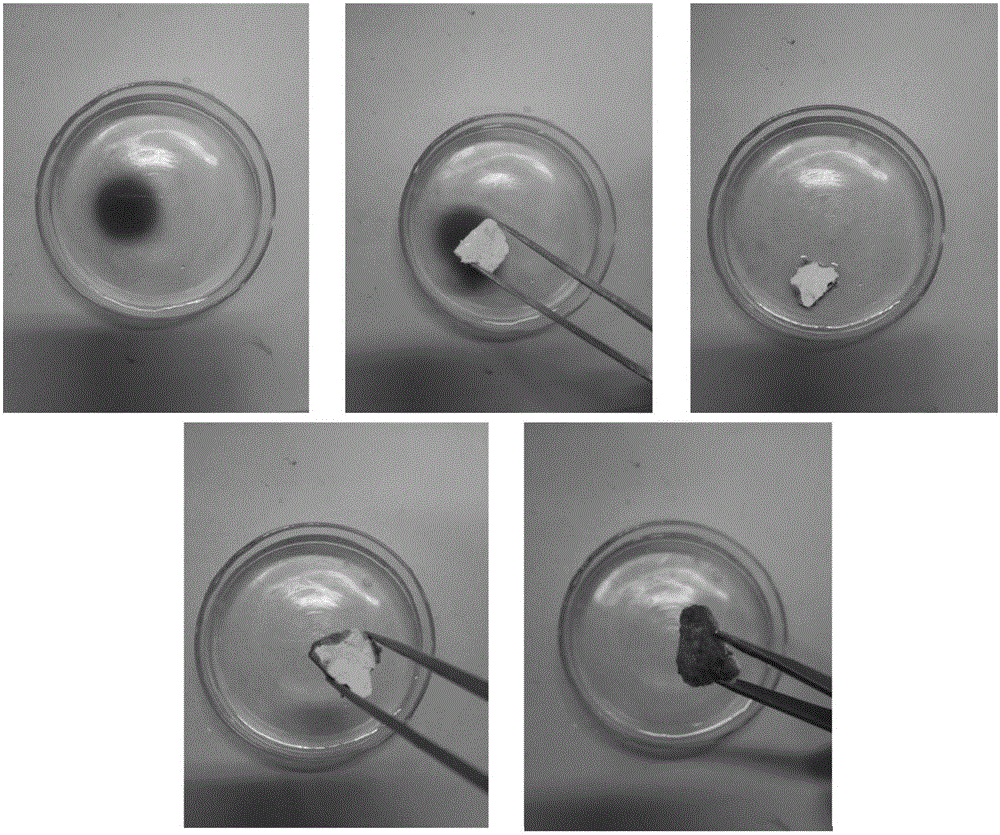

Self-deoiling type water surface oil stain adsorption ball

ActiveCN112062210AImprove practicalityHigh oil absorptionFatty/oily/floating substances removal devicesWater cleaningCotton materialOil absorption

The invention discloses a self-deoiling type water surface oil stain adsorption ball, and belongs to the technical field of water body pollution treatment. According to the invention, an adsorption ball body provided with an oil absorption cotton material can rapidly adsorb oil stains, and the oil stains adsorbed by the adsorption ball body can be diffused in an oil guide rope and an oil collection ball which are connected with the adsorption ball body and are made of the same material, so that part of the oil stain is guided to the oil collection ball; the oil collection ball is soaked in anoil stain emulsifying agent, the emulsifying agent can emulsify and decompose the oil stain in the oil collection ball and perform automatic deoiling, a specially-made expansion and shrinkage ball anda water guide net set matched with the specially-made expansion and shrinkage ball are arranged, and the water guide net set can guide water to the expansion and shrinkage ball, so that the expansionand shrinkage ball can achieve automatic repeated expansion and shrinkage; and the adjacent expansion and shrinkage balls intermittently extrude the oil collection ball between the expansion and shrinkage balls to extrude out oil stains adsorbed in the oil collection ball, so that deoiling is accelerated, the adsorption balls can adsorb and deoil at the same time, the oil adsorption capacity of the adsorption balls is greatly improved, and then the treatment efficiency is greatly improved.

Owner:HUBEI AIGUO PETROCHEM

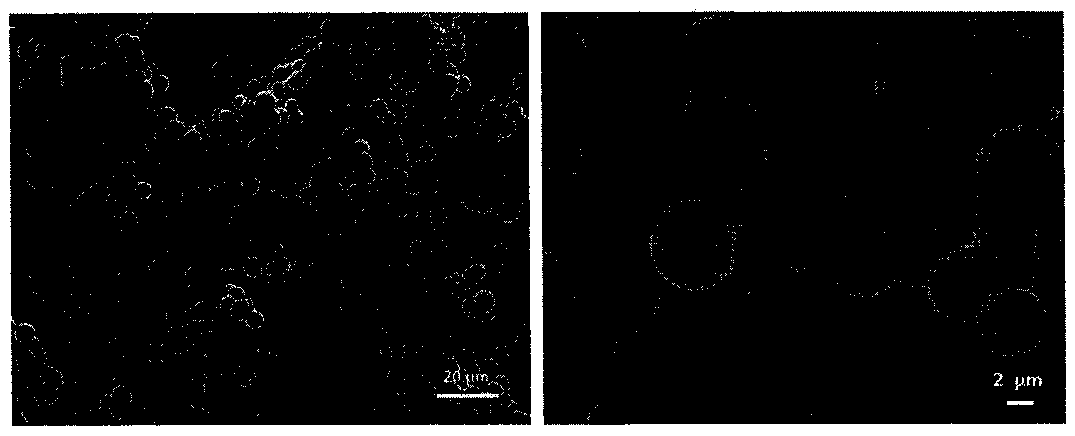

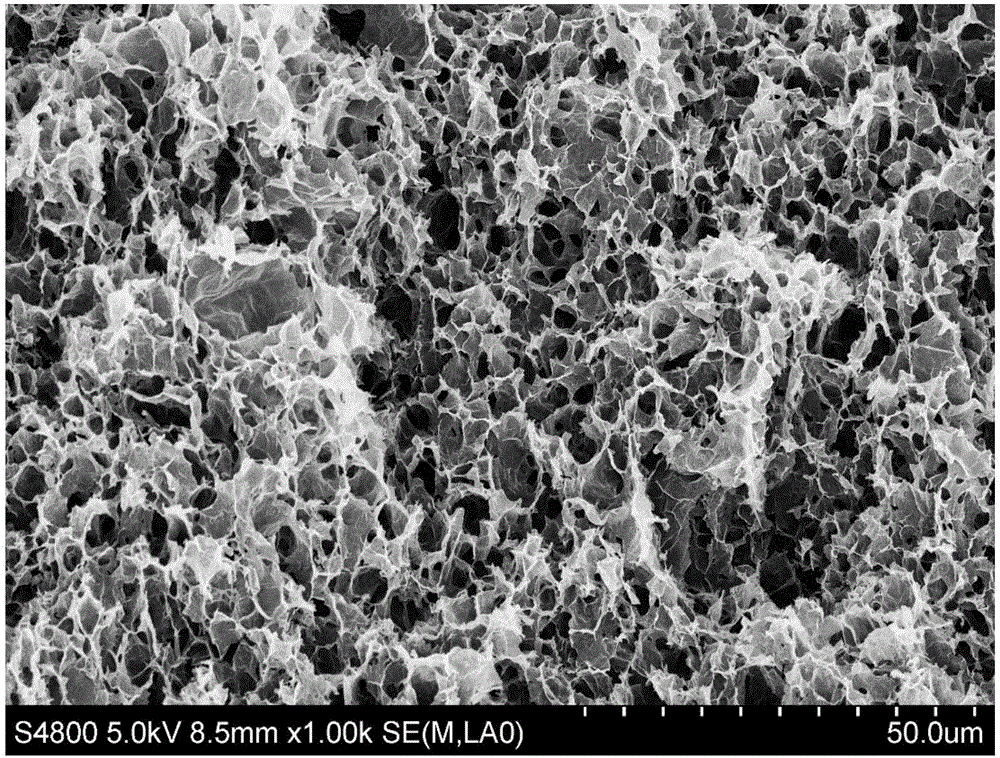

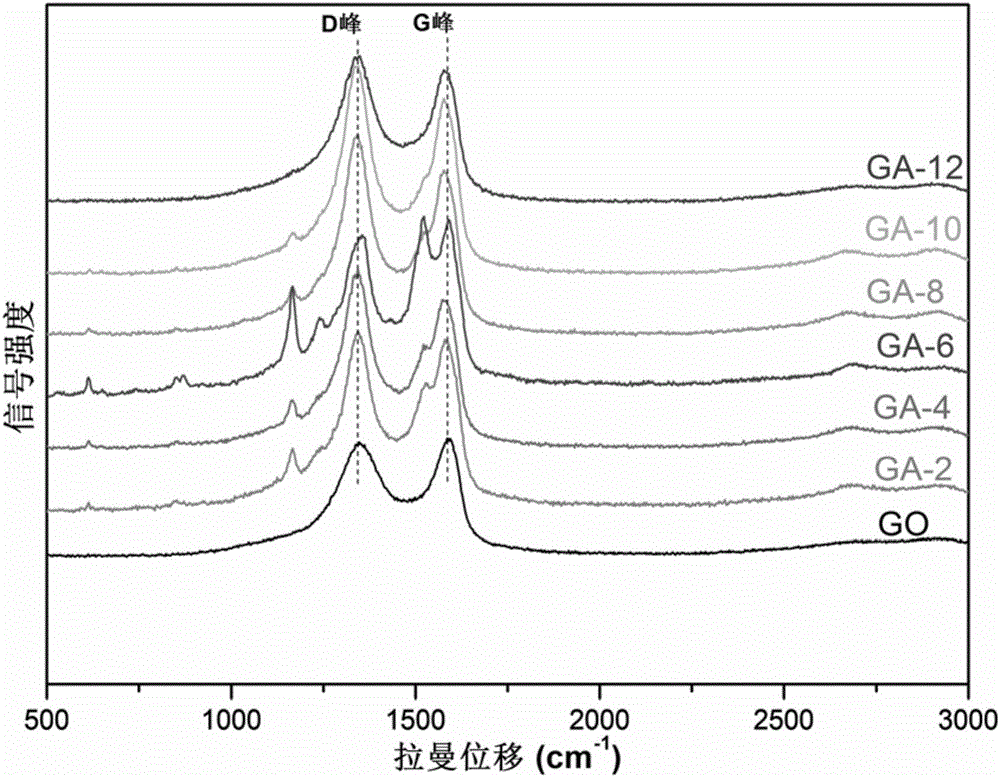

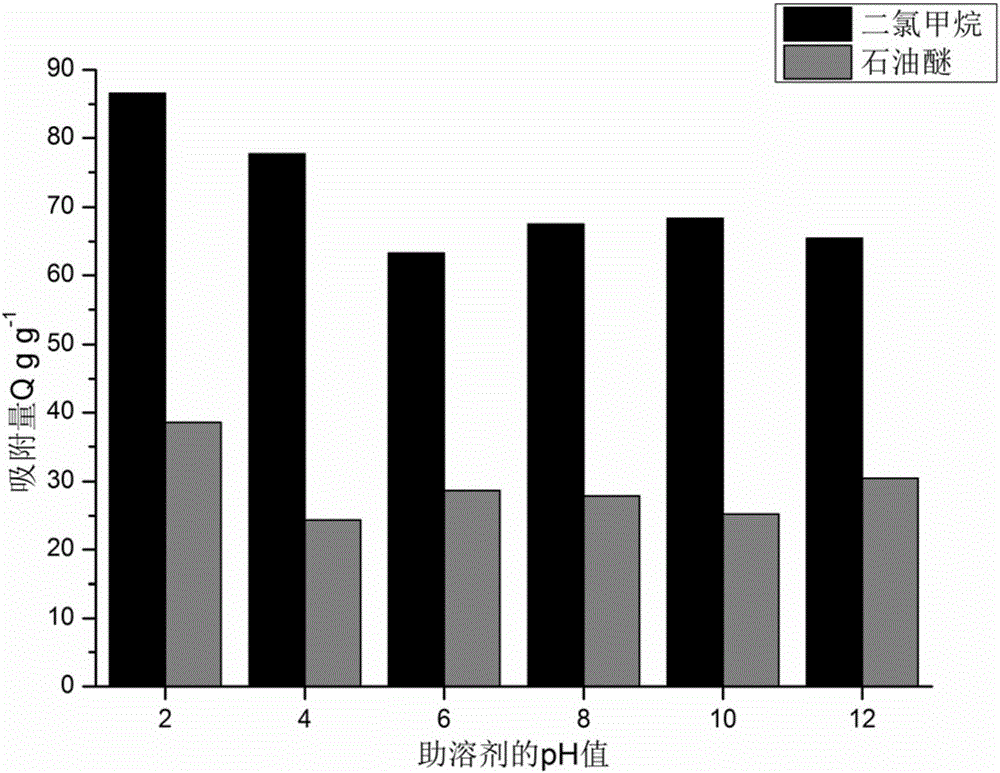

Porous reduced graphene oxide oil absorption material with controllable doping level and preparation method thereof

ActiveCN106693898AHigh oil absorptionFacilitates selective oil absorptionOther chemical processesOil waterPore diameter

The invention discloses a porous reduced graphene oxide oil absorption material with a controllable doping level and a preparation method thereof. The porous reduced graphene oxide oil absorption material with the controllable doping level is of a hierarchical porous structure stacked layer by layer; a reduced graphene oxide aerogel is adopted as a substrate; and amino acid is doped in a framework of the reduced graphene oxide aerogel. The preparation method provided by the invention comprises the steps of firstly mixing graphene oxide and an amino acid reducing agent dissolving solution; then obtaining a reduced graphene oxide hydrogel through a high pressure hydrothermal method; and finally, washing the hydrogel, freezing at low temperature for pore-forming, and obtaining the porous reduced graphene oxide oil absorption material. The oil absorption material provided by the invention has favorable hydrophobicity, has a better adsorption capacity on an oil product and an organic pollutant, and achieves the aim of oil-water separation in an oil-water composite environment; and meanwhile, pore diameter distribution and a pore structure of the material can be regulated and controlled through the control on the doping level, the selective oil absorption of the material is promoted, and the selective adsorption of the oil product is realized.

Owner:SHANGHAI INST OF TECH

Leak-proof color-changeable adsorption cotton

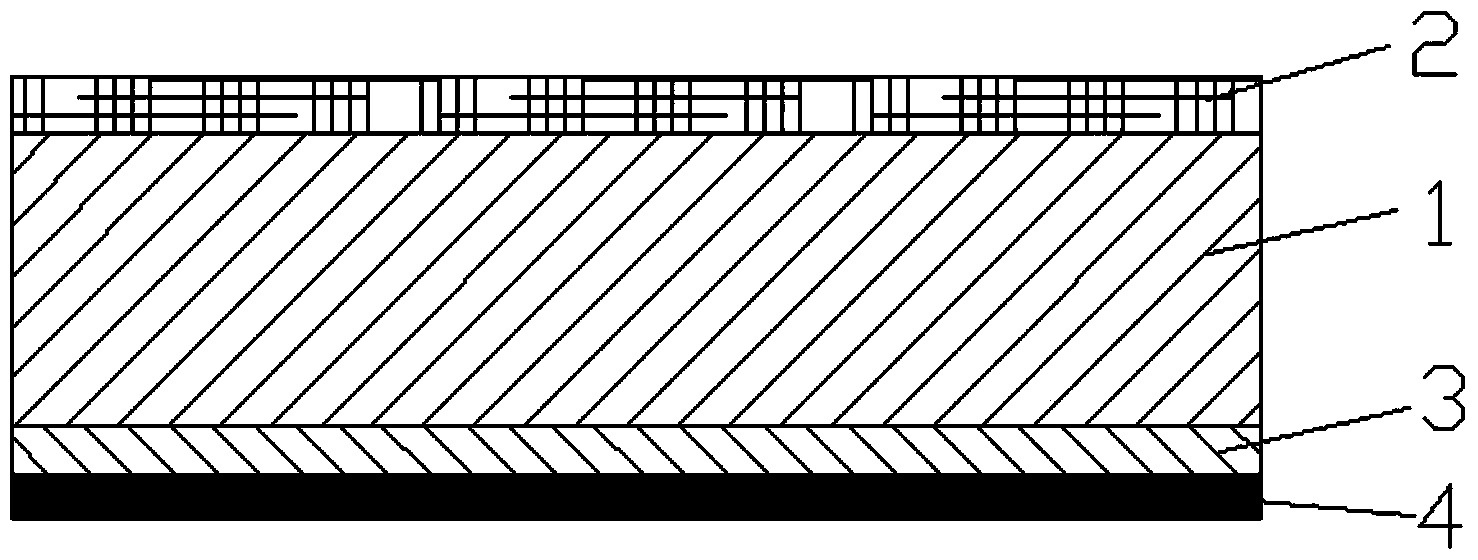

ActiveCN104383898AAvoid spillingAdjust in timeWater cleaningGeneral water supply conservationSurface layerChange color

The invention relates to the field of materials, and particularly relates to leak-proof color-changeable adsorption cotton which comprises a surface layer, a color-changeable layer and an oil holding layer, wherein the oil holding layer is positioned between the surface layer and the color-changeable layer; a leak-proof layer is arranged outside the color-changeable layer; the oil-holding layer is a coarse polypropylene fiber melt-blowing layer, the surface layer is a fine polypropylene fiber melt-blowing layer, and the color-changeable layer is a color-changeable oil absorption material layer. The leak-proof color-changeable adsorption cotton is high in oil holding rate and convenient to use, and can change color along with oil absorption amount.

Owner:FUYANG AOHONG FIBER PROD CO LTD

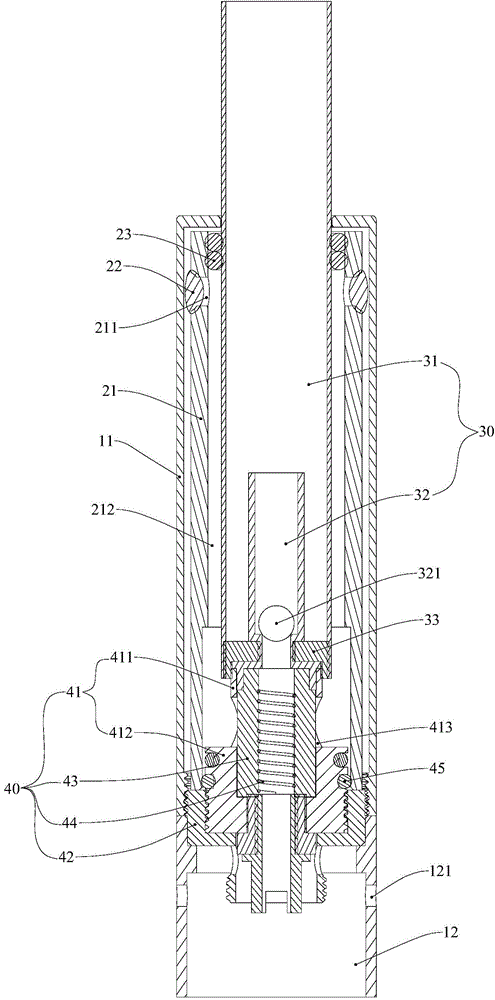

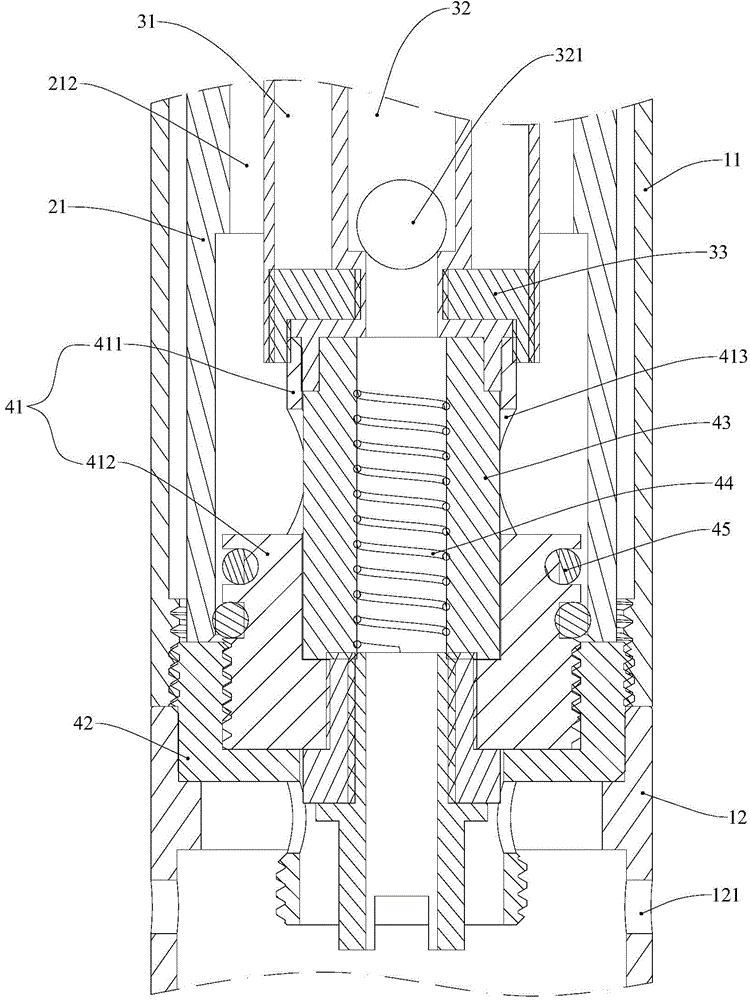

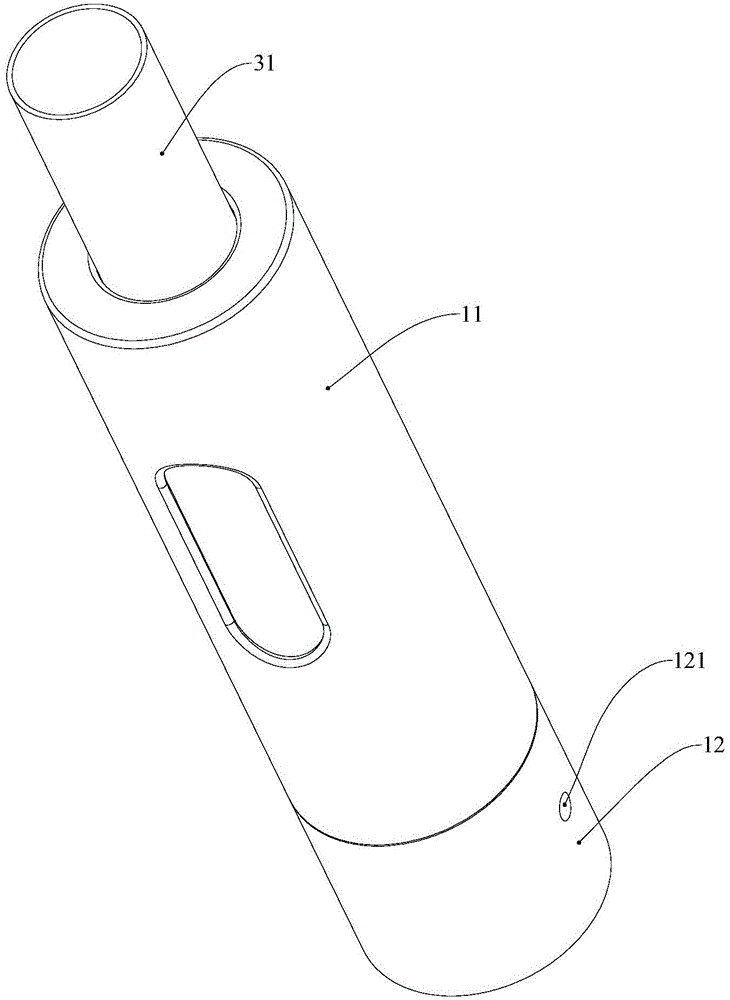

Environmentally friendly energy-saving electronic cigarette atomizer

The invention relates to an environmentally friendly energy-saving electronic cigarette atomizer. The electronic cigarette atomizer comprises a tobacco tar tube, an atomization core and an outlet duct assembly. The atomization core is inserted into the lower portion of the tobacco tar tube, the outlet duct assembly penetrates the tobacco tar tube and is in communication with the atomization core, and a liquid storage chamber used for storing tobacco tar is arranged between the outlet duct assembly and the tobacco tar oil. The atomization core comprises a cylindrical tobacco tar guide body having micropores and made from flexible ceramic, and a heating wire used for heating and atomizing the tobacco tar, the heating wire is arrange in the hole of the tobacco tar guide body and closely clings to the inner wall of the hole, the outer wall of the atomization core is provided with a tobacco tar inlet port, the tobacco tar in the liquid storage chamber permeates into the tobacco tar guide body through the inlet port. The tobacco tar guide body is made from flexible ceramic and is resistant to dry burning, the tobacco tar guide body cannot be damaged by dry burning, and no harmful and odorous gas generates during dry burning, the mouthfeel of the smoke generated by the reused atomizer after dry burning is the same as the mouthfeel of the smoke generated by the atomizer before dry burning, influence on the atomizer caused by dry burning can be effectively reduced, the durability of the atomizer can be improved.

Owner:SHENZHEN HANGSEN STAR TECH

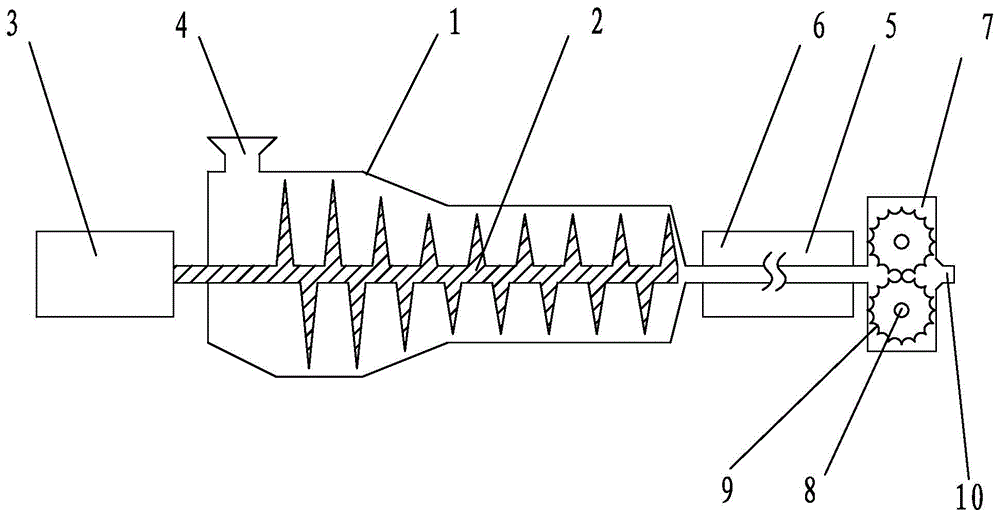

Preparation method and preparation apparatus of embedded immobilized microbial ball

InactiveCN104830826AHigh activityImprove adsorption capacityBioreactor/fermenter combinationsBiological substance pretreatmentsEmulsionHigh dimensional

The present invention relates to the field of high oil-absorbing resin preparation, and discloses a preparation method of an embedded immobilized microbial ball. The method comprises the steps of: (1) preparation of the immobilized microbial particles; (2) preparation of an acrylate copolymer emulsion; and (3) preparation of the embedded immobilized microbial ball. The present invention also discloses a preparation apparatus of the embedded immobilized microbial ball. The apparatus includes an extrusion section, an insulation transport section and a moulding section. The extrusion section comprises an extrusion sections housing, an advancing screw and a rotary motor; the insulation transport section includes a tubular type conveying channel and a heater; and the moulding section comprises a moulding section housing and a pair of reverse gears provided with hemispherical grooves. The embedded immobilized microbial ball prepared by the present invention has high oil suction rate and large oil absorption capacity, and can degrade the adsorbed oil; and microbes have good stability and long survival time. At the same time, the preparation apparatus of the present invention requires mild conditions in the preparation process, protects the survival rate of the microbes to the maximum; and the prepared product has high dimensional stability.

Owner:ZHEJIANG OCEAN UNIV

Preparation method for composite high oil-absorption resin

InactiveCN104841386AImprove stabilityImprove adsorption capacityFatty/oily/floating substances removal devicesOther chemical processesMethacrylateCellulose

Relating to the high oil-absorption resin preparation field, the invention discloses a preparation method for a composite high oil-absorption resin. The method includes: (1) preparation of immobilized microbial microspheres: mixing modified mussel shell powder with a seed bacterial liquid, adding a sodium alginate solution into a bacteria adsorbing modified mussel shell powder solution, then injecting the mixed solution into a calcium chloride solution and conducting dispersion into balls, and conducting crosslinking to obtain immobilized microbial microspheres; (2) preparation of an acrylate copolymer emulsion: adding a methylacrylate monomer, styrene, an initiator and an emulsifier into water and conducting stirring emulsification; adding a crosslinking agent and a pore making agent into the emulsion to carry out reaction so as to obtain an acrylate copolymer emulsion; and (3) preparation of composite high oil-absorption resin: adding immobilized microbial microspheres, a coupling agent and cellulose into the acrylate copolymer emulsion, conducting stirring and then performing vacuum drying, thus obtaining the composite high oil-absorption resin. The composite high oil-absorption resin prepared by the method provided by the invention has fast oil absorption speed and large oil absorption capacity, and can carry out microbial degradation on oil.

Owner:ZHEJIANG OCEAN UNIV

Porous oil absorption material and preparation and regeneration method thereof

ActiveCN105214602AModification process is simpleGuaranteed feasibilityOther chemical processesAlkali metal oxides/hydroxidesPore distributionPhysical chemistry

The invention discloses a porous oil absorption material and a preparation and regeneration method thereof. The porous oil absorption material is a porous ceramic material uniform in pore distribution and with the pore diameter distribution range of 0.1-100 micrometers and above 40% of porosity, the porous oil absorption material is prepared from Al2O3 and SiO2, surface activation treatment is conducted on the porous oil absorption material so as to improve the surface hydrophilicity of the material, and the porous oil absorption material is soaked with modified liquid to obtain super-strong oil absorption capacity. The porous oil absorption material having an oil contamination removing function has the advantages of being simple in modification process, low in modification cost, high in oil absorption speed, large in oil absorption amount, high in water body purification degree and convenient to regenerate and the like.

Owner:众达(广东)建设工程有限公司

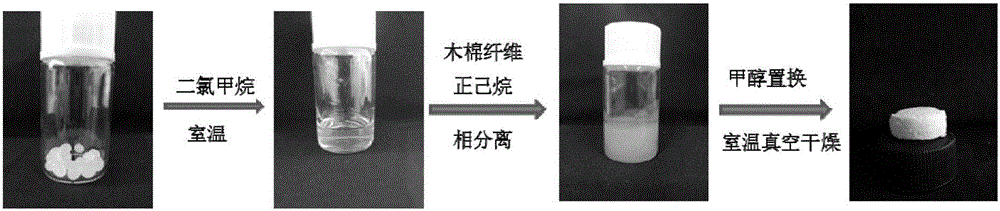

Method for preparing three-dimensional porous oil absorption material

InactiveCN106334543ASimple processHigh porosityOther chemical processesAlkali metal oxides/hydroxidesRoom temperatureSolvent

The invention relates to a method for preparing a three-dimensional porous oil absorption material. The method comprises the steps that polylactic acid is dissolved in a solvent and stirred to be dissolved, and a polylactic acid solution is obtained; under the stirring condition, a poor solvent is dropwise added into the polylactic acid solution till the solution turns turbid from clear, still standing is carried out at room temperature, replacement and vacuum drying are carried out, and the three-dimensional porous oil absorption material is obtained; or under the stirring condition, natural fibers are added into the polylactic acid solution, then the poor solvent is dropwise added till the solution phase is separated, still standing is carried out at room temperature, replacement is carried out, and the three-dimensional porous oil absorption material is obtained. The novel oil absorption material is controllable in aperture size and shape and can be suitable for different application occasions.

Owner:DONGHUA UNIV

Oil absorbing resin, preparation method and application thereof

InactiveCN105153342AFast oil absorptionIncrease elasticityOther chemical processesCross-linkFoaming agent

The invention relates to an oil absorbing resin, which comprises, by mass part, 40-60 of a water phase and 5.25-7.5 of an oil phase. The water phase is composed of, by volume, 30-45 of water and 10-25 of a dispersing agent. The oil phase is composed of, by mass, 3-8 parts of a polymer monomer, 0.045-0.095 part of an initiator, 0.03-0.2 part of a cross-linking agent, and 0.5-2 parts of a pore-foaming agent. The invention also discloses a preparation method of the oil absorbing resin, and the method includes: adding the oil phase into the water phase, performing heating to 78-82DEG C and conducting mixing, maintaining the temperature at 78-82DEG C for 1-6h till liquid drops shape; raising the temperature to 88-90DEG C, carrying out heat preservation for 0.5-2h and performing cooling, thus obtaining the resin. The invention discloses application of the oil absorbing resin in edible oil, gasoline, kerosene or diesel oil adsorption. And the oil absorbing resin has the advantages of high elasticity, high swelling speed, high strength, and fast oil absorption rate.

Owner:HEILONGJIANG UNIV

Oil absorbent prepared from low grade diatomite and preparation method thereof

InactiveCN103252209AGood compatibilityGood dispersionFatty/oily/floating substances removal devicesOther chemical processesVolumetric Mass DensityPollution

The invention relates to a preparation method of an oil absorbent, in particular to a method for preparing the oil absorbent from low grade diatomite. The preparation method comprises the following 9 steps of: low grade diatomite raw material selection, crushing, acidification treatment, washing, drying, adding of the assistant (3%-5%) Na2Cl (industrial salt) and mixing, roasting at 750-850DEG C, breaking winnowing, and adding of the silane coupling agent KH-550 (gamma-aminopropyl triethoxysilane, Nanjing Union silicon Chemical Co., LTD. 5%-7%) to conduct modification treatment, thus obtaining the particle and powder diatomite oil absorbent. The oil absorbent has simple and easy preparation method, wide raw material sources and low cost, solves the current solid waste pollution problem of low grade diatomite, opens up a new way for low grade diatomite application, and realizes recycling of waste materials. The oil absorbent has good selectivity, strong absorptivity up to 500% of its own weight, rapid oil absorption speed, small oil absorbent stacking density, a melting point of 1450DEG C, and a high use temperature, and can float on the water surface before and after oil absorption, thus being convenient for recovery and post-treatment.

Owner:任象玉

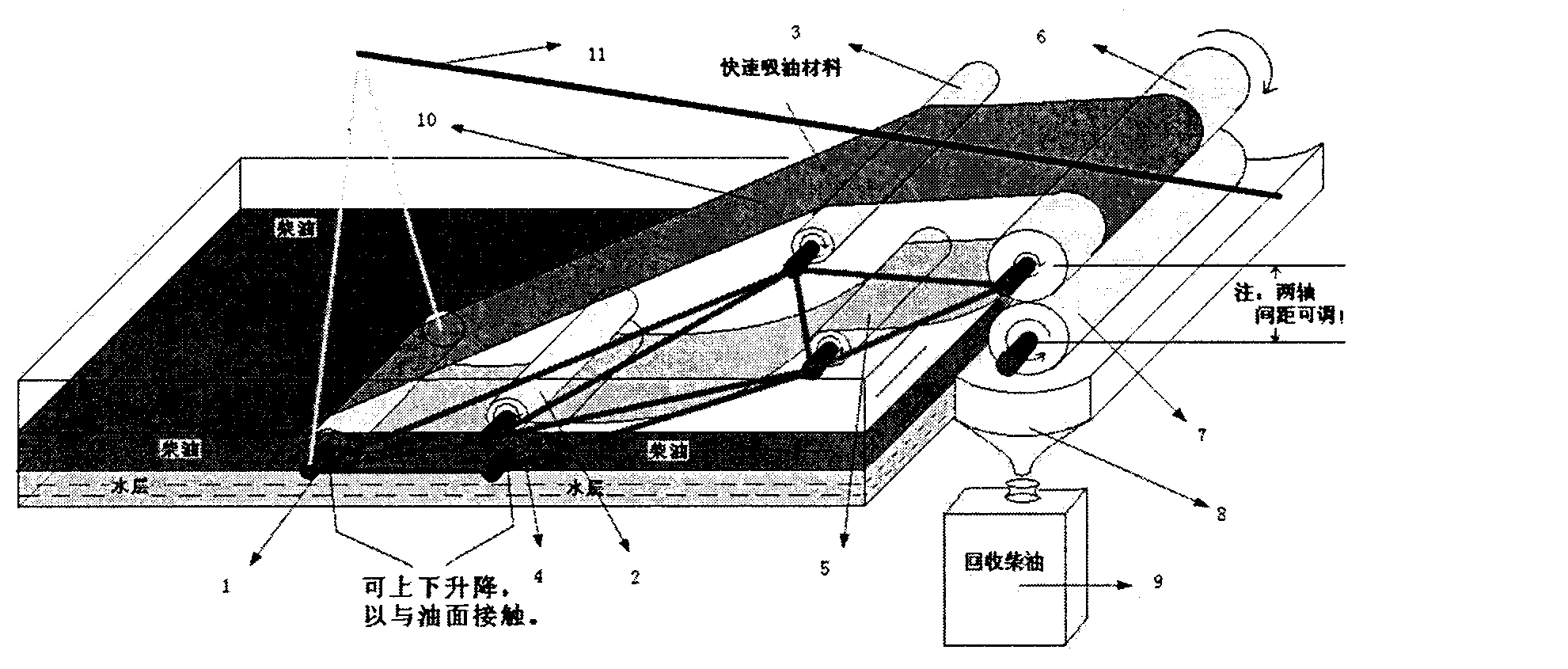

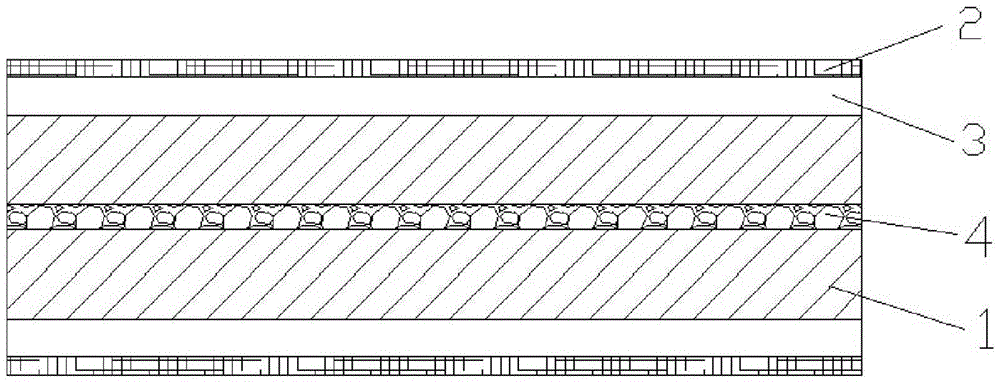

Continuously liftable caterpillar-band-type water surface oil absorption device comprising rapid oil absorption material

InactiveCN103254873AFast oil absorptionFlexible useWater cleaningOther chemical processesPetroleum engineeringWater pool

The invention discloses a continuously liftable caterpillar-band-type water surface oil absorption device comprising a rapid oil absorption material. The oil absorption device comprises the rapid oil absorption material, a continuous-circulating-type oil absorption recovery device and a brake lever system. Based on the principle, the height of the rapid oil absorption material is adjusted according to the height of an oil surface by utilizing a brake lever, so that the oil absorption material can be used for easily contacting and adsorbing the floating oil on the water surface; then driving rollers and driven rollers are driven to rotate together under the action of a driving device, so that the caterpillar-band-type rotation of the oil absorption material is realized; and by the rotation of the upper and the lower driving rollers, the oil in the oil absorption material is squeezed out, and the squeezed oil is transferred into a groove so as to enter a recovery box. Therefore, the floating oil layer is continuously absorbed and treated. The oil absorption device disclosed by the invention is suitable for the oil-containing water surfaces with various height requirements, for example: the oil absorption device can be placed outside the edge of a water tank, at the shore of a water pool, on a ship and the like.

Owner:NANJING UNIV OF TECH

Preparing method of super oil absorbing polypropylene spray-fusing non-woven fabric

InactiveCN108342837AHigh porosityImprove hydrophobicityConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolymer scienceFiltration

The invention belongs to the field of textiles in the industry of filtration and separation, and aims at providing a preparing method of super oil absorbing polypropylene spray-fusing non-woven fabric. By means of the non-woven fabric prepared according to the method, a lot of porous structures are arranged in spray-fusing polypropylene fiber, thus the roughness is improved, the hydrophobic natureis superior, and the oil absorbing performance is obviously improved. According to the technical scheme, the preparing method of the super oil absorbing polypropylene spray-fusing non-woven fabric sequentially comprises the following steps of 1, uniformly mixing polypropylene with pore-forming agent to obtain a mixture in which the mass concentration of the pore-forming agent accounts for 20-80%;2, producing the mixture through spray-fusing equipment to obtain initial non-woven fabric formed by the spray-fusing polypropylene fiber; 3, using cleaning agent to remove the pore-forming agent inthe initial non-woven fabric obtained in step 2, and thus making the spray-fusing polypropylene fiber form the porous structures, so that after drying, the super oil absorbing polypropylene spray-fusing non-woven fabric is obtained; 4, recycling mixed waste liquid of the cleaning agent and the pore-forming agent.

Owner:浙江省轻工业品质量检验研究院

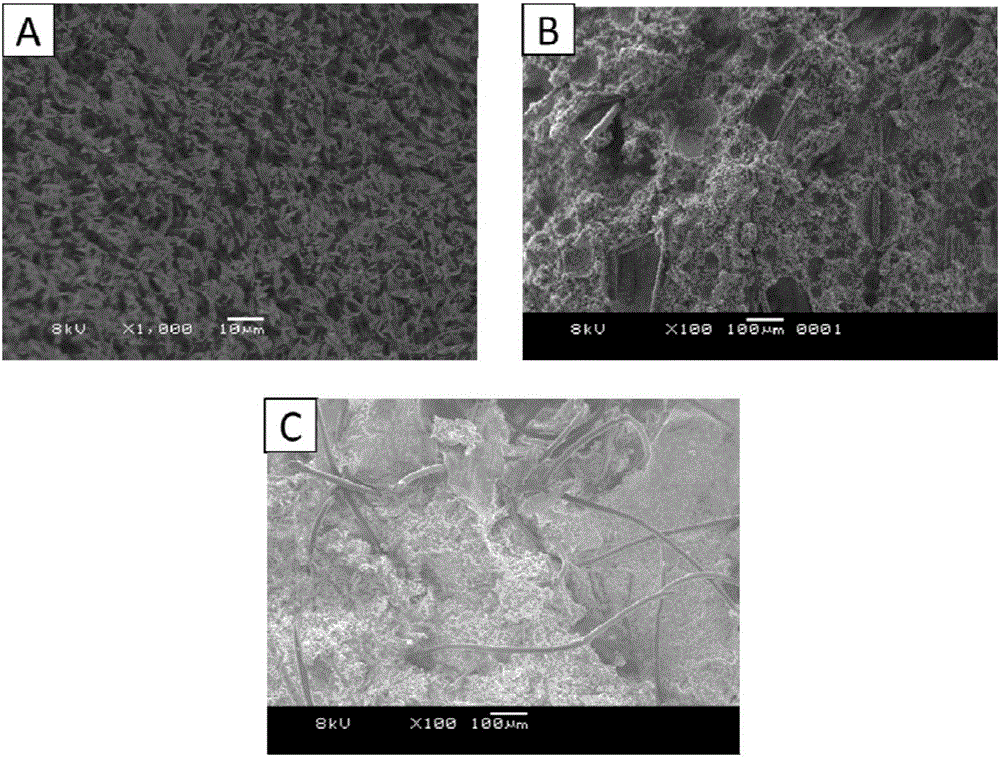

Kapok fiber oil absorption material

InactiveCN103061117ALow densityLight in massOther chemical processesVegetal fibresKapok fiberOil absorption

The invention discloses a kapok fiber oil absorption material. The kapok fiber oil absorption material is obtained by performinh acylation treatment on the kapok fiber, filtering, washing and drying the treated kapok fiber. The kapok fiber has wide source and low cost. The oil absorption material prepared by the kapok fiber has an oil absorption capacity reaching 40-80 times, and can reach oil absorption balance in 30 minutes. The kapok fiber oil absorption material can still float on water surface after oil absorption, so that the kapok fiber oil absorption material can be used for large-scale treatment of oil pollutions in sea surfaces and water surfaces of rivers and lakes.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

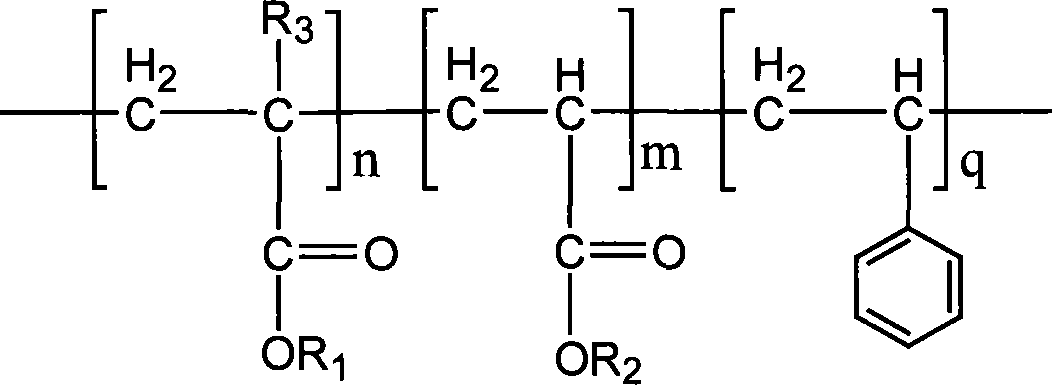

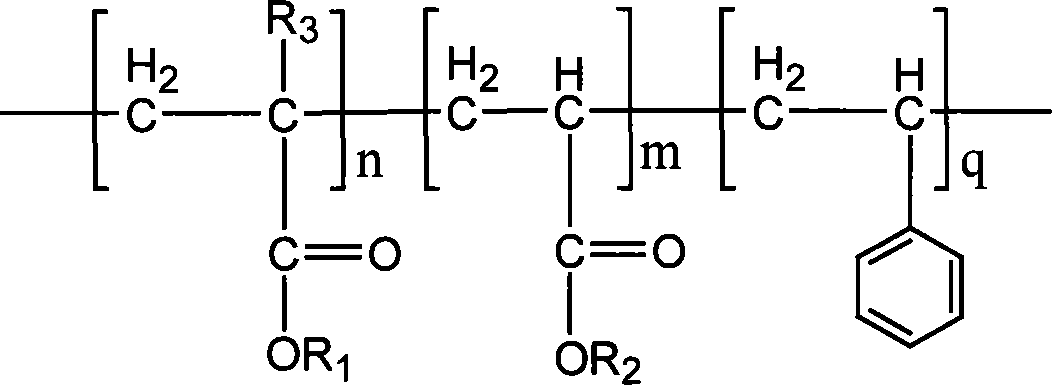

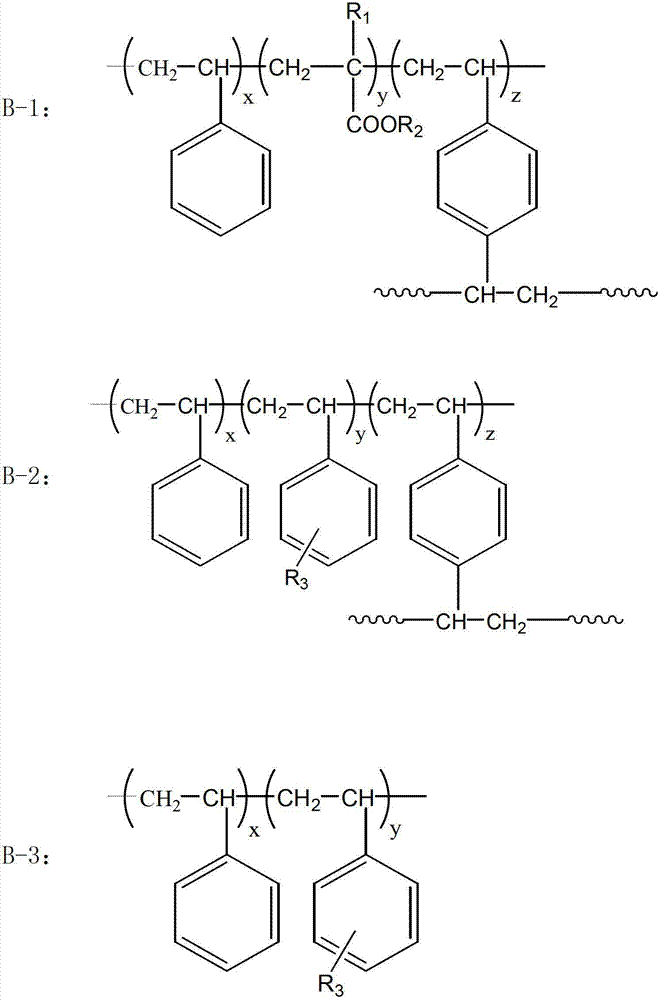

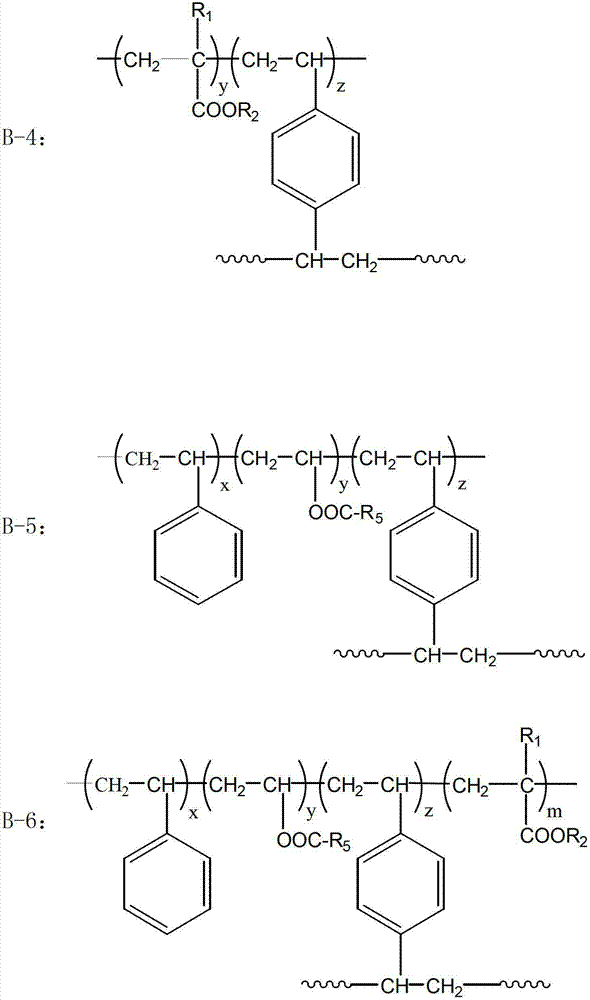

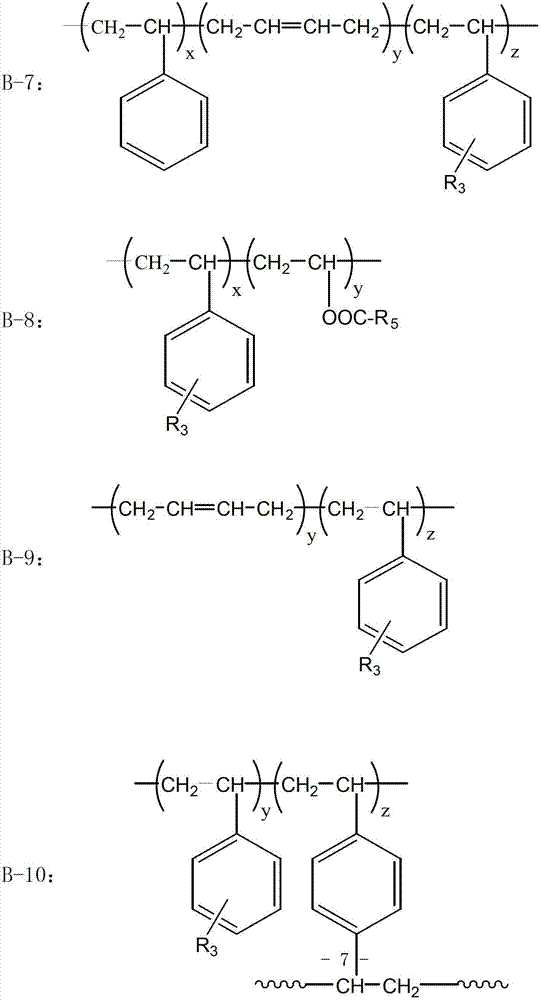

Manufacturing method of composite oil-absorbing material

ActiveCN104211854AGood compatibilityEnhanced interactionOther chemical processesManufacturing technologyIn situ polymerization

The invention discloses a manufacturing method of composite oil-absorbing resin which takes poly(meth)acrylate as a matrix polymer and other substances as reinforcing components, belongs to the technical field of composite oil-absorbing material manufacturing, and particularly relates to a manufacturing method for composite resin which takes poly(meth)acrylate as the matrix and other organic high polymer compounds as the reinforcing components, or composite resin which takes poly(meth)acrylate as the matrix and inorganic substances as the reinforcing components or composite resin which takes poly(meth)acrylate as the matrix, and other organic high polymer compounds and the inorganic substances as the reinforcing components. The manufacturing method utilizes the technologies such as suspension polymerization, cryogenic high-speed crushing, local high-temperature instantaneous modification, in-situ polymerization and reactive extrusion. Compared with the existing poly(meth)acrylate-based high oil absorption resin, the composite oil-absorbing resin has slightly declined oil absorption amount, high oil absorption velocity and high strength, is not formed into a muddy shape after absorbing oil, and is convenient to recycle and capable of meeting the practical industrial needs.

Owner:TIANJIN POLYTECHNIC UNIV

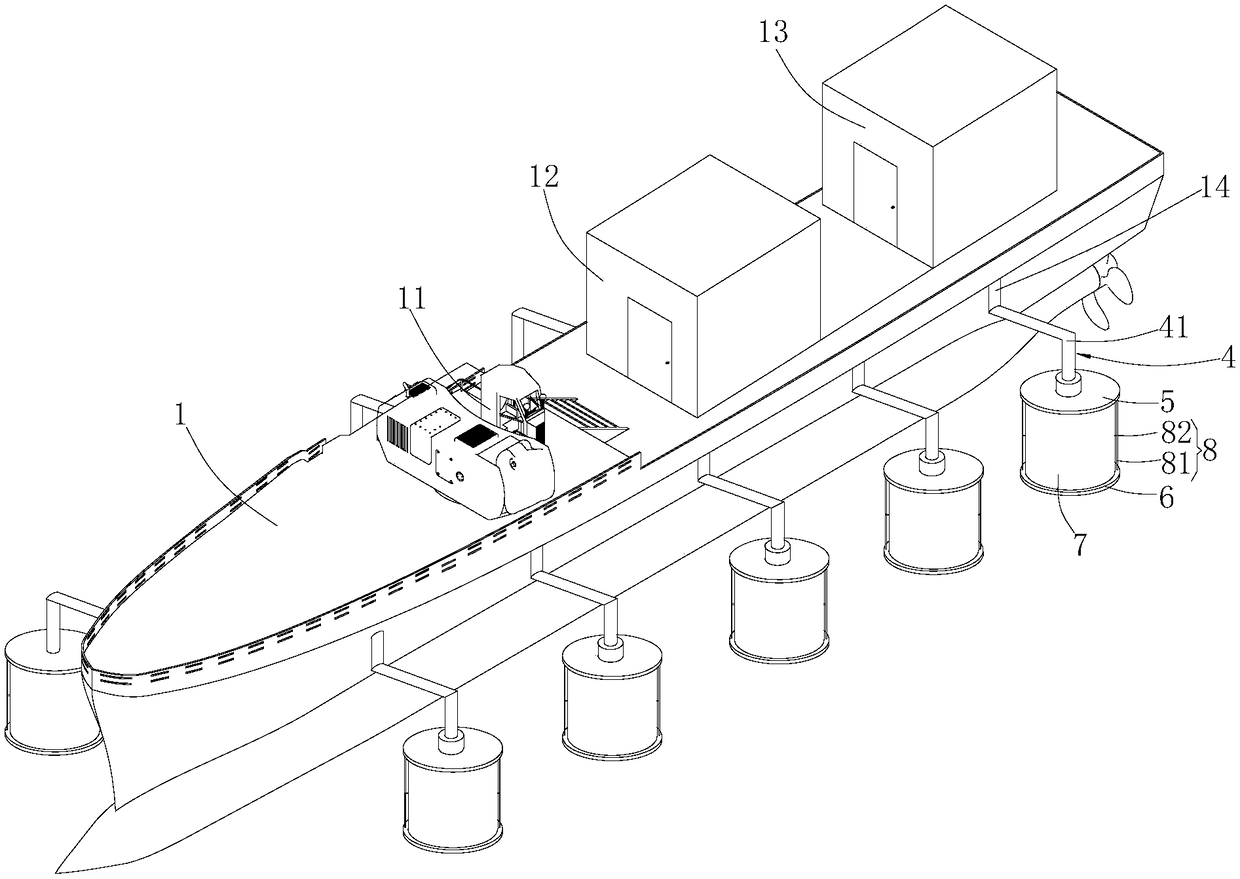

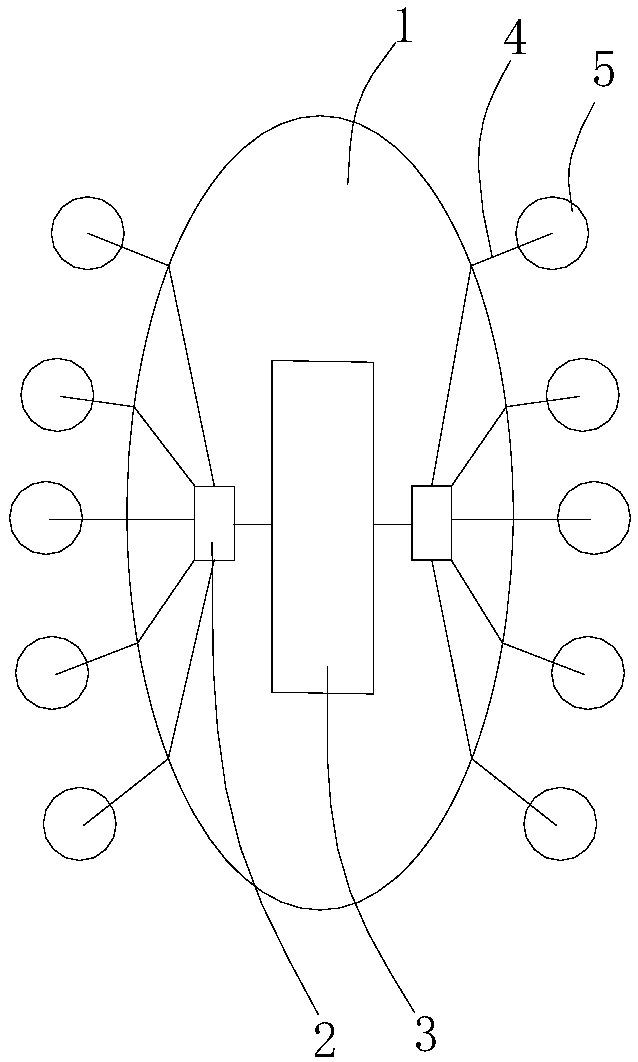

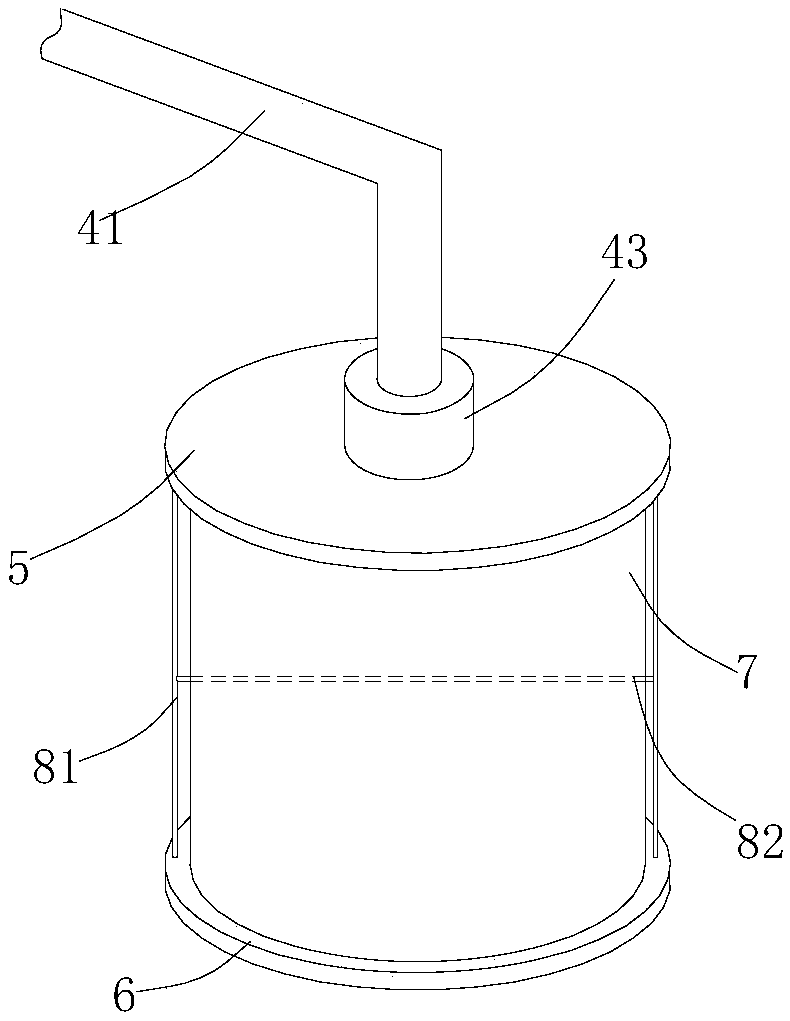

Boat for cleaning floating oil on water surface

ActiveCN109322290AOptimum immersion heightFast oil absorptionWater cleaningWaterborne vesselsFixed frameOil well

The invention discloses a boat for cleaning floating oil on the water surface. The boat for cleaning the floating oil on the water surface comprises a boat body, oil well pumps, an oil compartment andmultiple oil suction mechanisms, wherein the oil compartment is arranged in the boat body; the multiple oil suction mechanisms are uniformly distributed on two sides outside the boat body and are connected with the oil well pumps in the boat body through oil suction pipes; the two oil well pumps are connected to two sides of the oil compartment through oil outlet pipes; each oil suction mechanismcomprises a top plate, a bottom plate, a filter element and a fixed frame; each fixed frame comprises vertical rods and a cross rod; the vertical rods and each filter element are connected between the corresponding top plate and the corresponding bottom plate; the two vertical rods are arranged on two sides of each filter element; each cross rod penetrates through the corresponding filter elementand is connected with the vertical rods; each oil suction pipe comprises an oil conveying pipe part, a connecting pipe part and a fixed cover; one end of each oil conveying pipe part penetrates through the boat body and is connected with the corresponding oil well pump; the other end of each oil conveying pipe part communicates with the corresponding connecting pipe part; the lower end of each connecting pipe part penetrates through the corresponding top plate and is connected with the corresponding filter element; and the filter elements are made of oleophilic lyophobic materials. Accordingto the boat for cleaning the floating oil, through arranging the oil well pumps, the oil compartment and the oil suction mechanisms, the floating oil on the water surface is cleaned high-efficiently.

Owner:CHINA PETROLEUM & CHEM CORP +1

Color-changing adsorption material

InactiveCN104437429ALarge specific surface areaPrevent water and oil from spittingOther chemical processesAlkali metal oxides/hydroxidesSurface layerEngineering

The invention relates to the field of a material, and particularly relates to a color-changing adsorption material. The adsorption material consists of an oil holding layer and surface layers which are arranged at two sides of the oil holding layer, wherein a color-changing layer is arranged in the middle of the oil holding layer, and the oil holding layer is a coarse polypropylene fiber melt-blowing layer; each surface layer is formed by pressing an inner layer and an outer layer, the inner layer is a fine polypropylene fiber melt-blowing layer, the outer layer is a thin nonwoven fabric layer with the surface density of 8 to 30g / m<2> and with fibers being unlikely to drop, the outer layer is also provided with pressed patterns, and the outer layer and the inner layer are composited together by a plurality of press points. The polypropylene fiber melt-blowing nonwoven oil absorption material which is of a sandwich structure and has two dense surfaces, sparse middle part and the variable density is produced by adopting the melt-blowing forming technology in conjunction with an ultrasonic pressing technology, the color-changing layer made from color-changing silicone is additionally arranged in the middle of the oil holding layer, the adsorption material can absorb oil and also can absorb water in the oil absorption process by utilizing the characteristic that the color is changed when the silicone encounters the water; moreover, the color of the material can be changed according to the absorption quantity, so that whether the adsorption material needs to be replaced or not can be judged by a user.

Owner:柳州市金旭节能科技有限公司

Preparation method of oil-absorbing material

The invention discloses a preparation method of an oil-absorbing material. According to the invention, a monomer A, water and a cross-linking agent are subjected to a suspension polymerization reaction under the effect of an initiator and a dispersant, and produced polymer particles are separated by screening. The monomer A is composed by one or more components selected from acrylic ester, vinyl ester, and styrene monomer organics. The cross-linking agent is composed of olefin ester or olefin containing two or more unsaturated carbon-carbon double bonds. The oil-absorbing material prepared from the method and the raw materials is advantaged in high oil absorption speed, and good oil retaining performance. Oil absorbed into the oil-absorbing material is prevented from being released into the environment during transportation and storage processes, such that secondary pollution is prevented. The oil-absorbing material with the absorbed oil can be used as furnace or boiler fuel for combustion. The preparation method is simple, and the operation is simple.

Owner:ANHUI CHENGFANG NEW MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com