Method for preparing three-dimensional porous oil absorption material

An oil-absorbing material, three-dimensional porous technology, applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal oxides/hydroxides, etc., can solve problems such as high cost, complicated process, and only 40% porosity. Achieve the effects of large oil absorption, simple process and fast oil absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

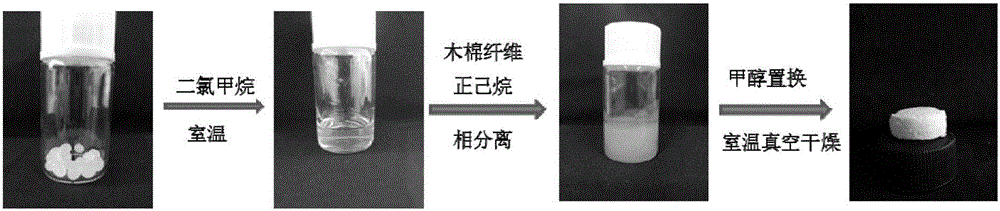

[0030] (1) Take by weighing 0.395g polylactic acid particles respectively with ME104E Mettler-Tolly electronic balance, be dissolved in 2ml dichloromethane, under room temperature, make it fully stir until completely dissolving, obtain the polylactic acid particle that concentration is 13%. Lactic acid solution.

[0031] (2) With the prepared polylactic acid solution, under the stirring of a magnetic stirrer, add 3ml of poor solvent drop by drop until the solution turns from clear to cloudy, leave it at room temperature for 24h, take it out, immerse it in anhydrous methanol, and place Shake it on a shaker, change it several times, and dry it under vacuum at room temperature to obtain a three-dimensional porous material.

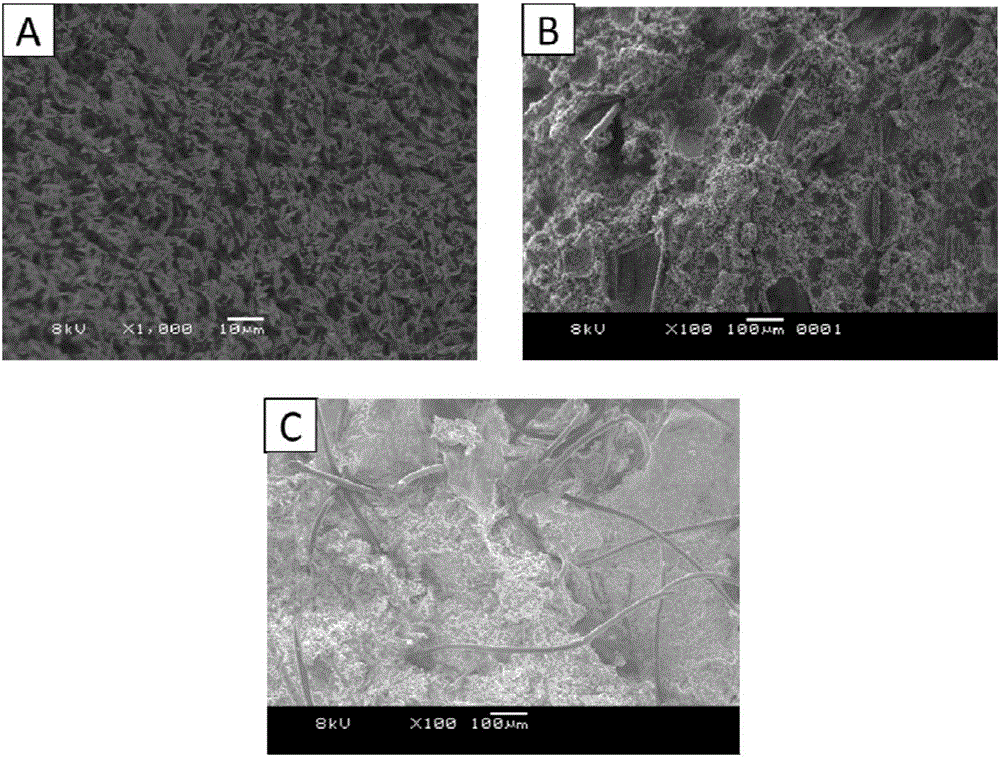

[0032] (3) The oil absorption performance of the three-dimensional porous material was tested. The porosity of the porous material was 90%, the water contact angle was 141.7°, and the oil absorption was 13 g / g.

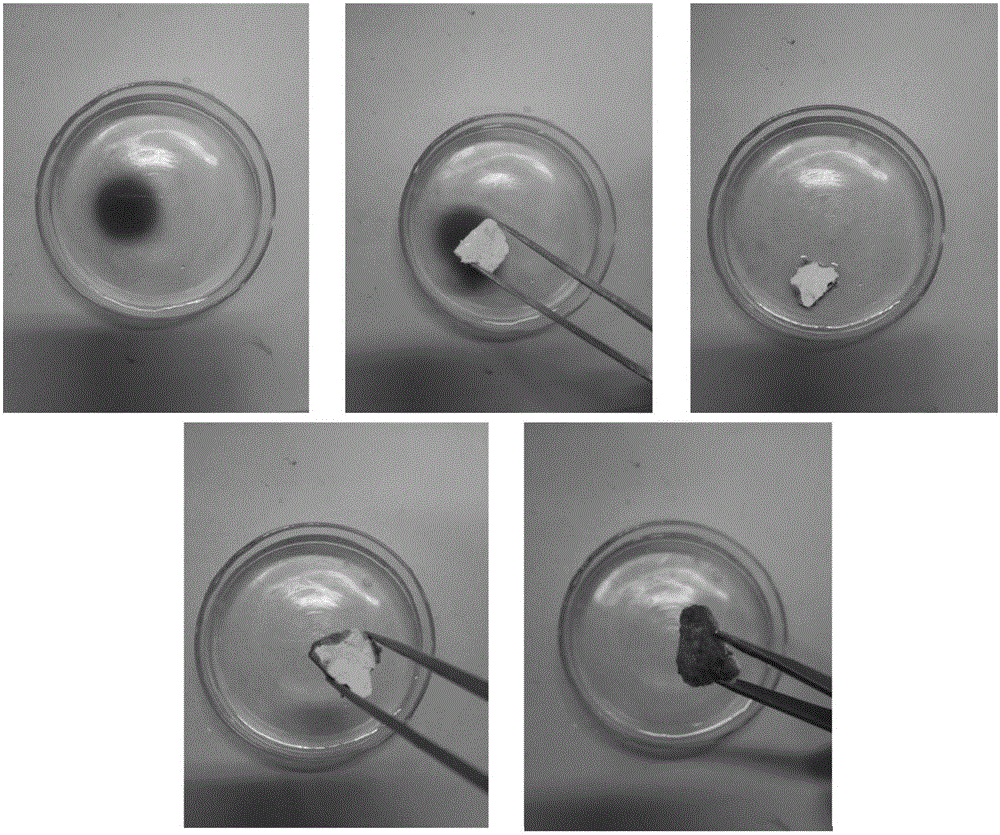

[0033] (4) Submerge the porous material after...

Embodiment 2

[0035] (1) Take by weighing 0.395g polylactic acid particles respectively with ME104E Mettler-Tolly electronic balance, be dissolved in 2ml dichloromethane, under room temperature, make it fully stir until completely dissolving, obtain the polylactic acid particle that concentration is 13%. Lactic acid solution.

[0036] (2) Add 0.07g of kapok fibers with a length of 0.2mm to the prepared polylactic acid solution under the stirring of a magnetic stirrer, stir evenly, add 3ml of poor solvent drop by drop until the solution is separated, and stand at room temperature for 24h , taken out, immersed in anhydrous methanol, and placed on a shaker to vibrate, after being replaced several times, vacuum-dried at room temperature to obtain a polylactic acid / kapok short fiber composite porous material.

[0037] (3) The oil absorption performance of the composite porous material was tested. The porosity of the porous material was 84.7%, the water contact angle was 141.4°, and the oil absor...

Embodiment 3

[0039] (1) Take by weighing 0.395g polylactic acid particles respectively with ME104E Mettler-Tolly electronic balance, be dissolved in 2ml dichloromethane, under room temperature, make it fully stir until completely dissolving, obtain the polylactic acid particle that concentration is 13%. Lactic acid solution.

[0040] (2) Add 0.07 g of kapok fibers with a length of 5 mm to the prepared polylactic acid solution under the stirring of a magnetic stirrer, stir evenly, add 3 ml of poor solvent drop by drop until the solution is separated into phases, and stand at room temperature for 24 hours. Take it out, immerse it in anhydrous methanol, and place it on a shaker to vibrate. After changing it several times, it is vacuum-dried at room temperature to obtain a polylactic acid / kapok long fiber composite porous material.

[0041] (3) The oil absorption performance of the composite porous material was tested. The porosity of the porous material was 87.3%, the water contact angle was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com