Method for preparing modified oil-absorptive resin immobilized with cyclodextrin molecules

An oil-absorbing resin and cyclodextrin technology, applied in the field of functional polymer materials, can solve the problems of volatilization of acryloyl chloride, limitation of cyclodextrin immobilization and the like, and achieve the effects of increased adsorption capacity, stable product properties and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

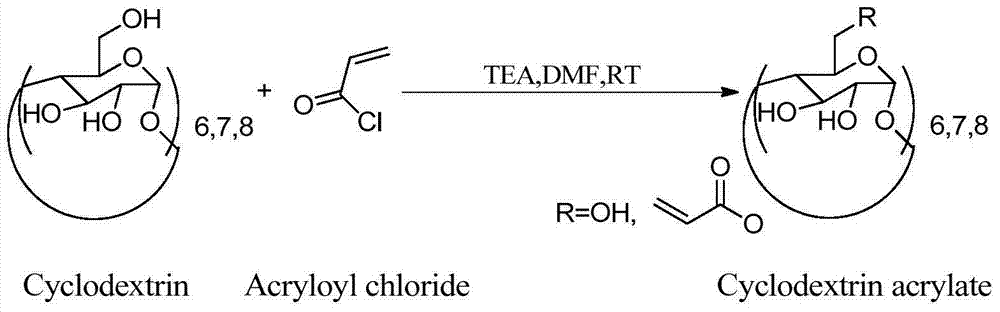

[0037] The synthesis of embodiment 1 modified cyclodextrin:

[0038] Dissolve 8.0g of β-cyclodextrin (β-CD) in 30mL of N'N-dimethylformamide (DMF) treated with anhydrous sodium sulfate, then add 4.2mL of triethylamine (TEA), stir well , add 1.15mL acryloyl chloride at 0-5°C, and react at room temperature for 5h after the dropwise addition is completed. After the reaction was completed, the precipitate was filtered off, the filtrate was precipitated with acetone, filtered with suction, and the obtained powder was dried in a fume hood to obtain the modified β-cyclodextrin product β-CD-6-A with a yield of about 80% %.

Embodiment 2

[0039] The synthesis of embodiment 2 modified cyclodextrins:

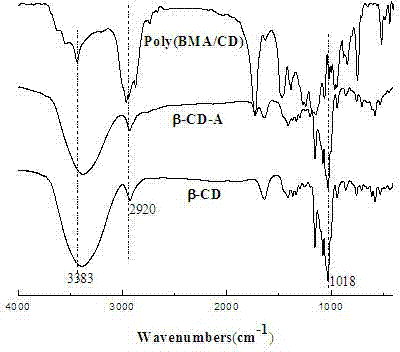

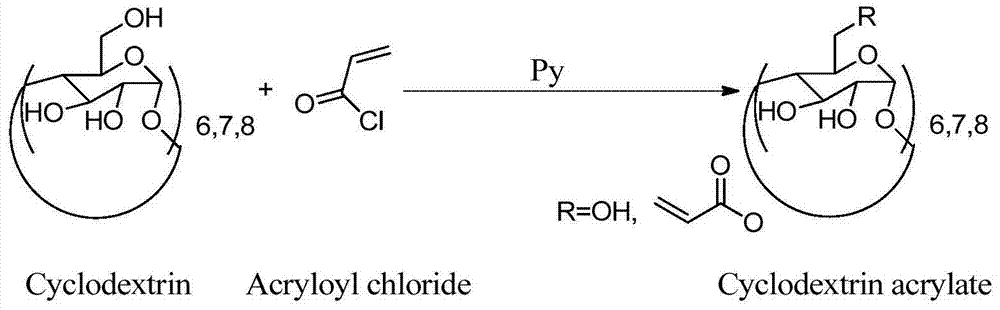

[0040] Dissolve 8.0g of β-cyclodextrin (β-CD) in 15mL of pyridine solution, after stirring, add 1.15mL of acryloyl chloride at 0-5°C, then slowly raise the temperature, and continue the reaction at room temperature for 12h. Afterwards, the reaction solvent was removed under reduced pressure until a white product was formed, and then ethanol was added to the product to wash several times to obtain the modified β-cyclodextrin β-CD-6-A with a yield of about 65%. Its infrared detection spectrogram is shown in the accompanying drawing.

Embodiment 3

[0041] The synthesis of embodiment 3 oil-absorbing resins:

[0042] Dissolve 0.75 g of polyvinyl alcohol in 200 mL of distilled water, then add 1.5 g of modified β-cyclodextrin β-CD-6-A to the solution, and ultrasonically dissolve it for 10 minutes. Then at 35-60°C, add 0.4g N'N-methylenebisacrylamide to the solution and stir quickly, then add 18.5g butyl methacrylate, 5.0g acrylic acid, 7.5g tris A mixture of methyl chloride and 0.15 g of benzoyl peroxide was reacted at 40°C for 10 min. Then the temperature was raised to 80°C, and the reaction was carried out for 8h. The obtained product was cooled, filtered, washed several times with warm water at 60-80°C, and dried in a drying oven at 60°C for 6 hours. The product was then placed in a vacuum oven at 60° C. and dried under reduced pressure for 12 hours to obtain a white granular oil-absorbing resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com