Patents

Literature

257results about How to "Good oil retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microencapsulated Oil Product and Method of Making Same

ActiveUS20090004333A1Increase loadAvoid excessive shear and damageDough treatmentConfectionerySolid shellProtein free

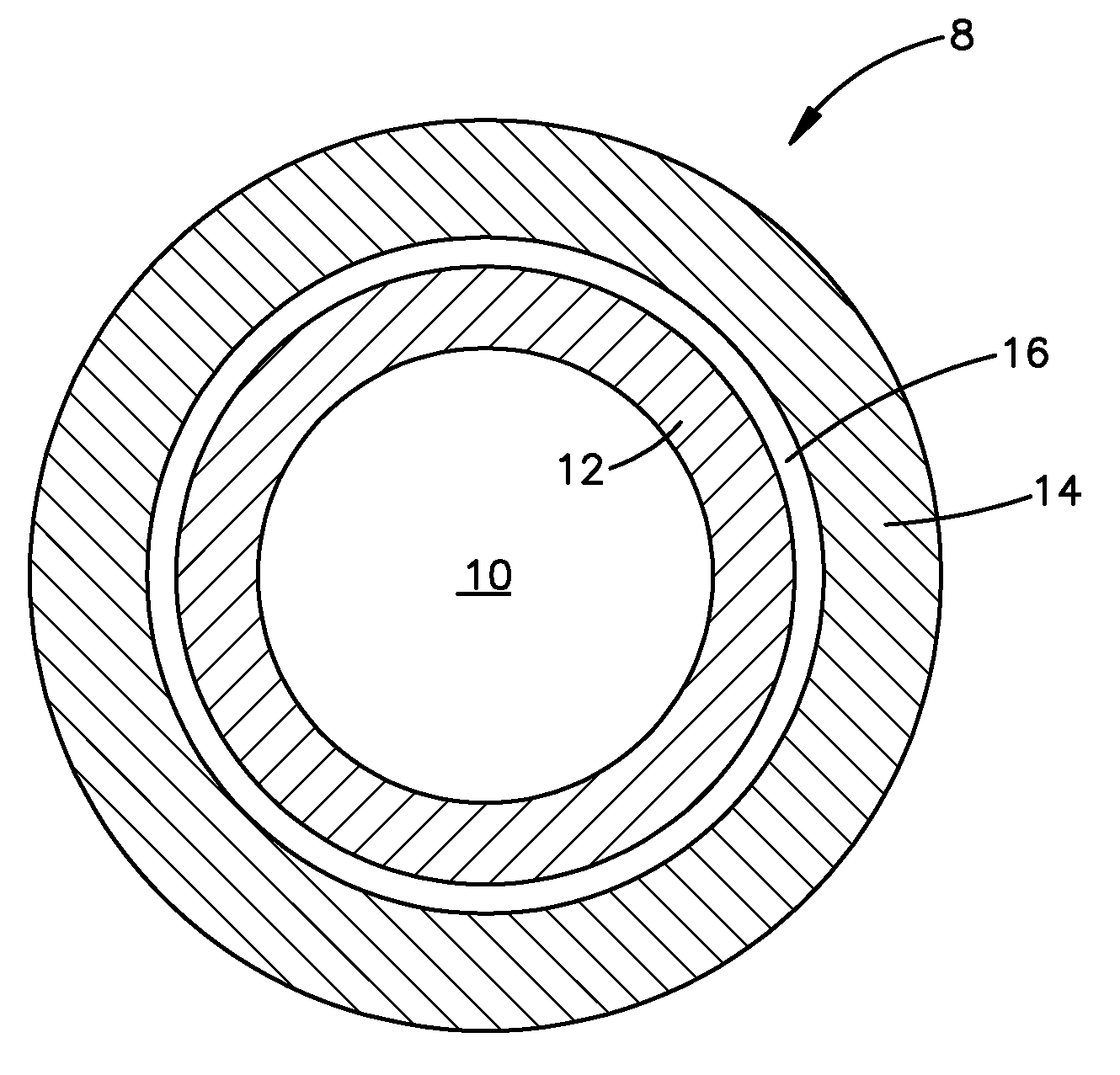

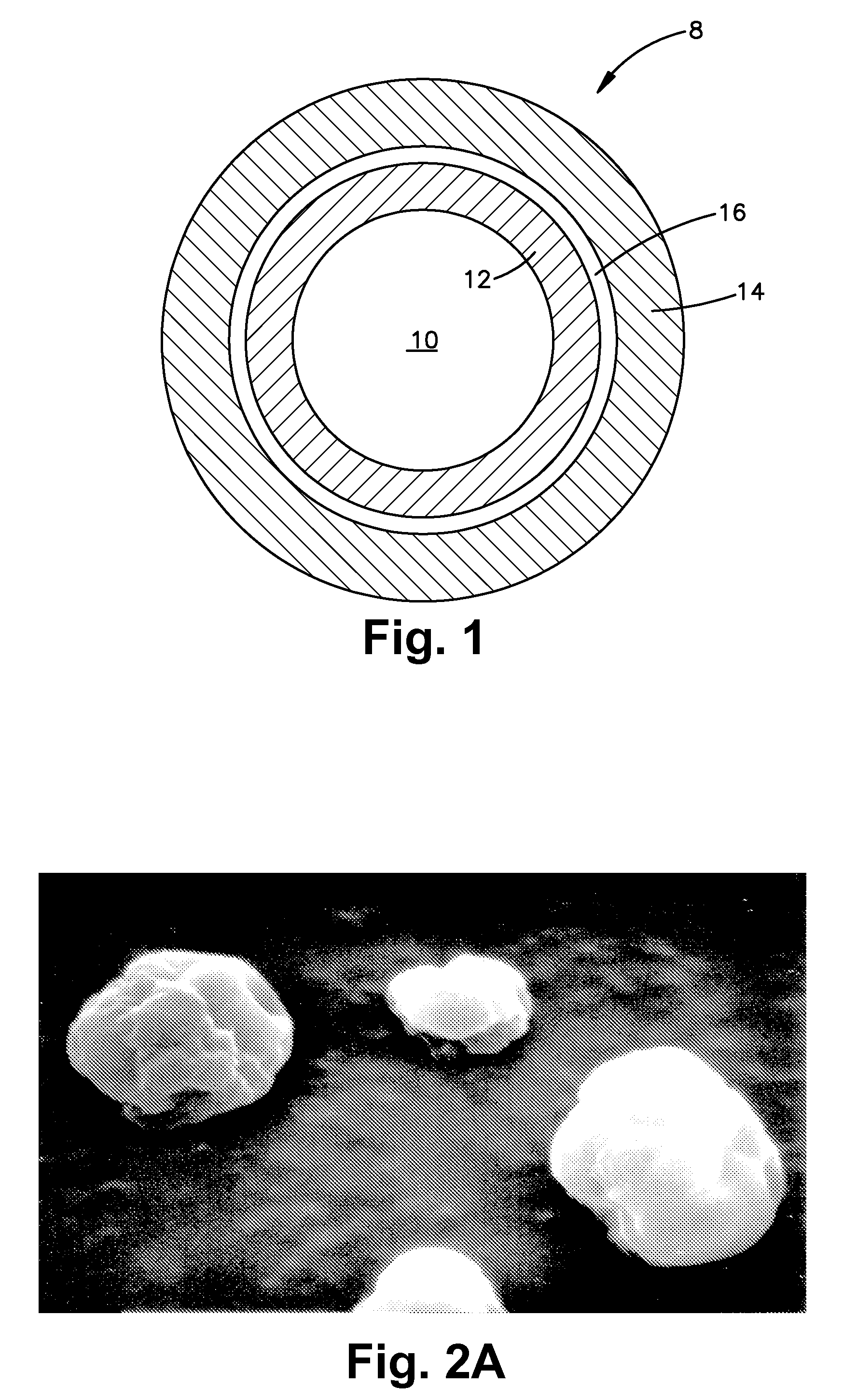

A microencapsulated product comprises a core, a first shell comprising a protein and being substantially carbohydrate-free, and a second shell comprising a carbohydrate and being substantially protein-free. The double shell structure provides a strong shell that makes the microcapsule suitable for use in food products. The core can be a lipid, and in particular a structured lipid with nutritional benefits, such that the nutritional benefits can be passed on to the consumer. The microcapsules of the present invention can be used in making foods products, beverage products, and mixes for making such food and beverage products.

Owner:BUNGE OILS INC

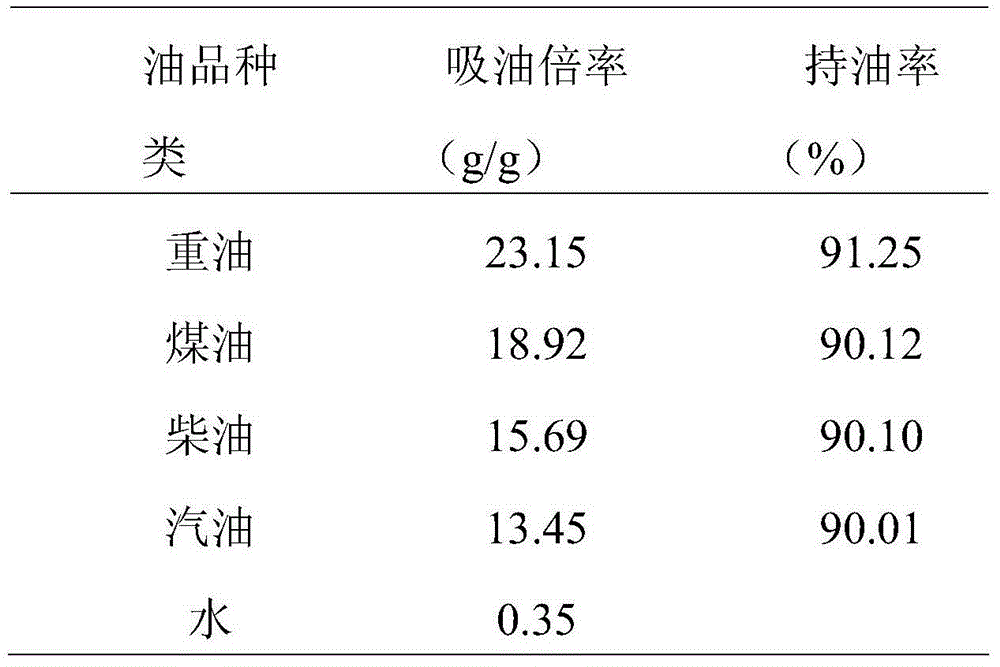

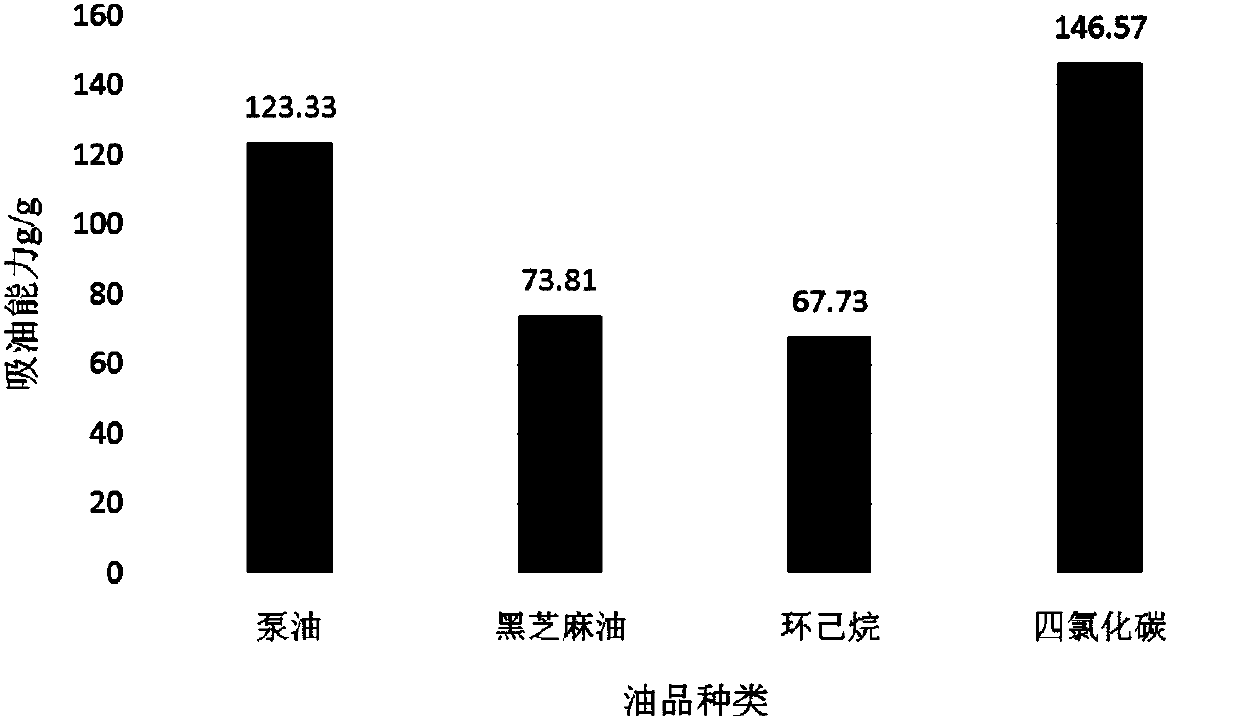

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

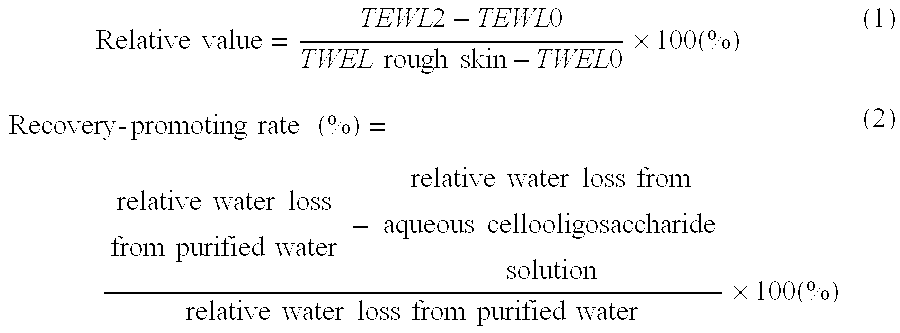

Cellooligosaccharide-Containing Composition

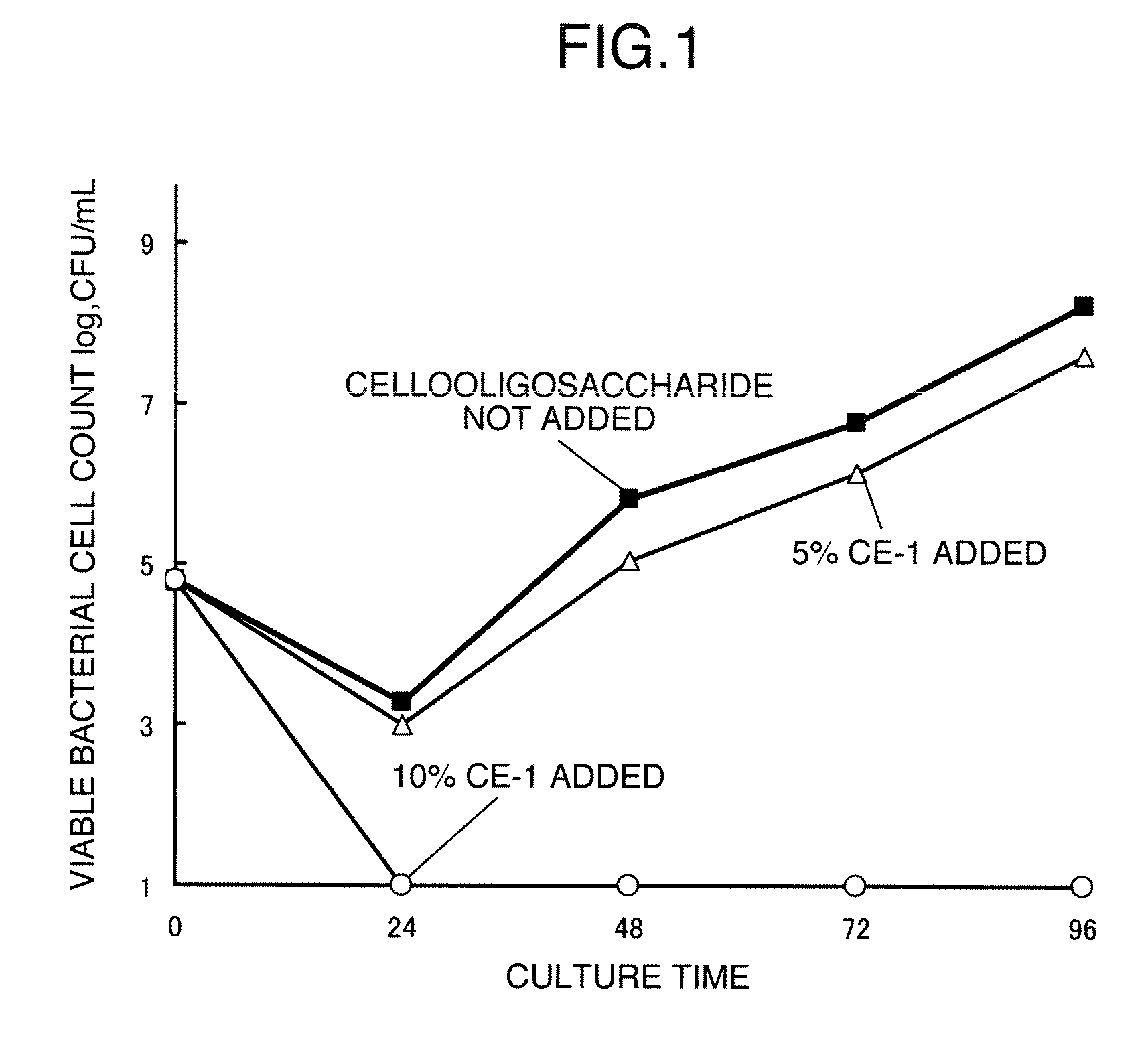

InactiveUS20090232892A1To promote metabolismEnhance skin barrier functionAntibacterial agentsPowder deliveryAdditive ingredientMedicine

Disclosed is a cellooligosaccharide composition comprising, as the main ingredient, at least one cellooligosaccharide selected from the group consisting of cellobiose, cellotriose, cellotetraose, cellopentaose and cellohexaose, which is in the powdery form having an average L / D value of 3.0 or lower, a bulk density of 0.80 g / mL or lower and an angle of repose of 60° or lower.

Owner:ASAHI KASEI CHEM CORP

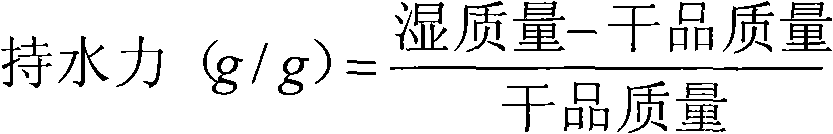

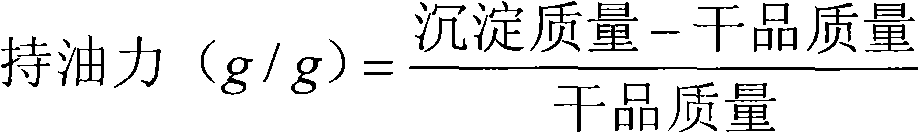

Preparation of dietary fiber from rice bran particles and application of the same in sausage

InactiveCN101558844AImprove water holding capacityImprove tasteFood preparationDietary fibreFood processing

The invention provides preparation of dietary fiber from rice bran particles and application of the same in sausage, and belongs to the technical field of food processing. The preparation method comprises the following steps: taking defatted rice bran as a raw material, pulverizing, sieving, soaking in alkali liquor, allowing proteinase hydrolysis and amylase zymolysis, centrifuging, taking residues, dissolving the residues in 95% ethanol according to weight-volume ratio of 1:4, allow precipitating of dietary fiber, drying the precipitate after suction filtration to obtain the dietary fiber; and allowing superfine pulverization of the extracted dietary fiber to obtain the dietary fiber from rice bran particles. The superfine pulverization technology can help greatly improve physical and chemical properties of the dietary fiber from rice bran particles such as water retention, oil retention and expansive force, and improve taste and can be applied to the sausage by selecting the best particle size range and addition level. The dietary fiber made from rice bran particles has the advantages of richness in nutrition, low cost, innocuity and safety, and simple and convenient preparation method. The dietary fiber made from rice bran particles expands use scope of the defatted rice bran, provides the foundation for further research on properties of the dietary fiber from defatted rice bran, and promotes research and development of functional sausage.

Owner:JIANGNAN UNIV

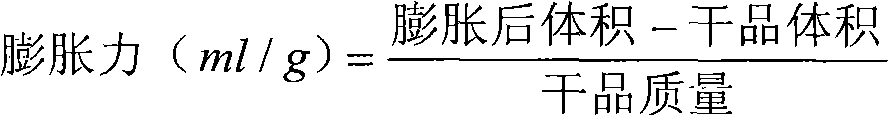

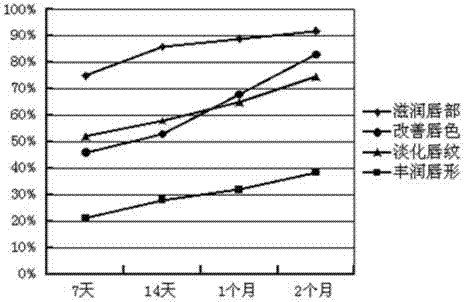

Plant essence type rouge allure lipstick

InactiveCN103494739AGood whitening effectImprove permeabilityCosmetic preparationsMake-upCaprylyl GlycolAdditive ingredient

The invention discloses a plant essence type rouge allure lipstick which comprises an emollient, a sun protection agent, a thickening agent and an aromatic, wherein the emollient comprises macadimia nut seed oil, simmondsia chinensis seed oil, butyrspermum parkii, tocopheryl acetate, coconut oil, grape seed oil, prunus amygdalus dulcis oil, caprylyl glycol and ethylhexylglycerin; the sun protection agent comprises benzophenone-3, 2-ethylhexyl4-methoxycinnamate, zinc oxide and titanium dioxide; the thickening agent comprises beewax, candelilla wax and copernicia cerifera wax; the aromatic comprises Tujue rose flower oil. According to the plant essence rouge allure lipstick, natural plant ingredients are prepared into natural cosmetics, and effective sun protection ingredients are added, the SPF (Sun Protection Factor) value reaches 15 and PA++, and the tender and lovely skin of the lip is protected from being hurt by ultraviolet rays.

Owner:JOTM DAILY CHEM HANGZHOU CO LTD

Preparation method of oil absorbing material by taking palm fiber as basic material

ActiveCN104624162ARich pore structureOptimized areaFatty/oily/floating substances removal devicesOther chemical processesParaffin waxChemical synthesis

The invention relates to a preparation method of an oil absorbing material, and the oil absorbing material is prepared by subjecting a basic material namely palm fibers to hydrophobic modification. The preparation method comprises the following steps: washing palm fibers, drying palm fibers, cutting the palm fibers into sections with a length of 0.5 to 5 cm; putting the palm fibers into a hydrophobic agent solution, soaking for 10 to 120 minutes at a temperature of 25 to 100 DEG C, taking out the palm fiber containing a hydrophobic agent, and quickly drying so as to obtain the modified oil absorbing material; wherein the hydrophobic agent is composed of paraffin, palm wax, or a mixture of paraffin and palm wax, the addition amount of the hydrophobic agent is 0.01 to 0.2 times of the weight of the palm fibers, the solvent is one or more of carbon tetrachloride, vinyl acetate, ethanol, and benzene, and the addition amount of the solvent is 20 to 800 times of the weight of the hydrophobic agent. Cheap and easily-available natural plant palm is taken as the raw material, the oil absorbing material is prepared by carrying out hydrophobic modification on the palm fibers, and compared with the oil absorbing materials prepared through chemical synthesis, the provided oil absorbing material has the advantages of low cost, biodegradability, and excellent oil absorbing performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

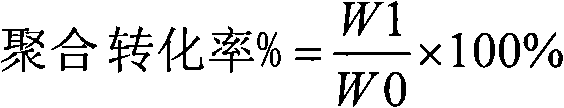

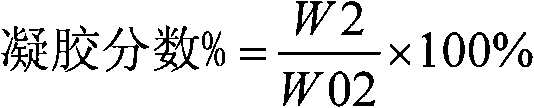

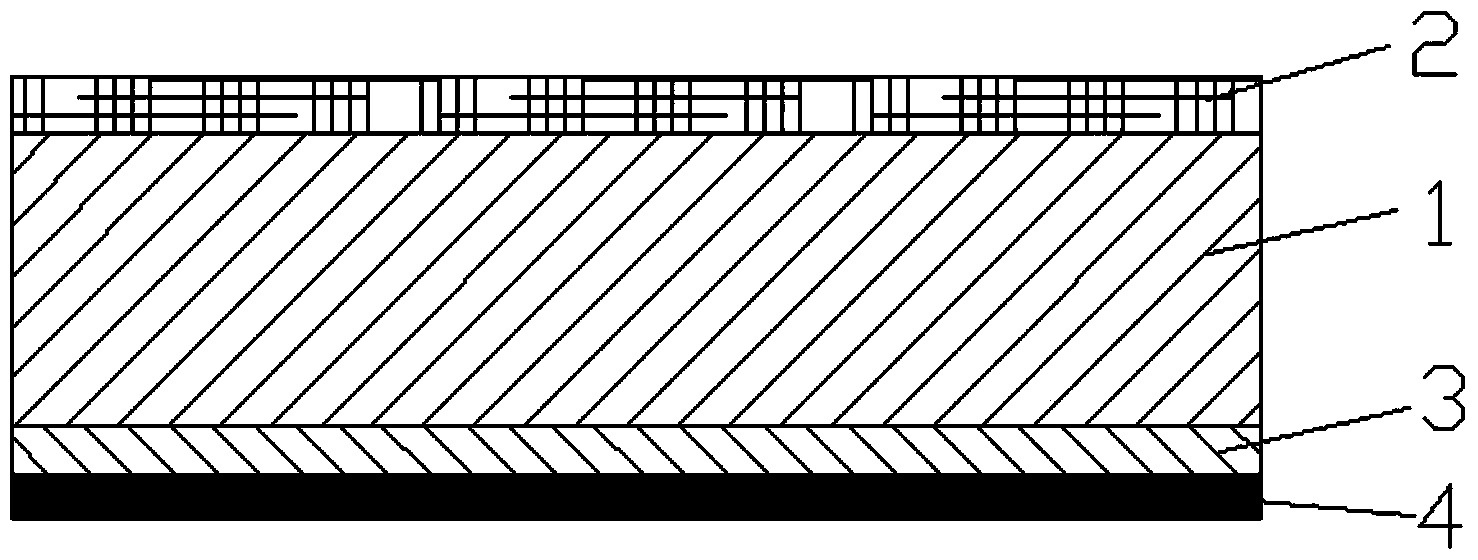

Preparation method for copolymethacrylate/polypropylene composite oil-absorbing material

InactiveCN104693592AHigh oil absorption rateGood oil retentionMelt spinning methodsConjugated synthetic polymer artificial filamentsBenzoyl peroxideDibenzoyl Peroxide

The invention relates to a preparation method for a copolymethacrylate / polypropylene composite oil-absorbing material. The method comprises the following steps: adding a dispersant and deionized water into a polymerization kettle, adding a mixed solution and carrying out polymerization so as to obtain copolymethacrylate, wherein the dispersant is polyvinyl alcohol, and the mixed solution comprises 85 to 90% of alkyl methacrylate substances and styrene, 0.5% of benzoyl peroxide and 10 to 15% of beta-hydroxylethyl methacrylate; mixing copolymethacrylate with polypropylene master batch so as to obtain modified polypropylene master batch; and applying the modified polypropylene master batch to manufacturing of a melt-blown non-woven fabric so as to obtain the composite oil-absorbing material. To diesel oil No. 0, the oil absorption rate of the composite oil-absorbing material prepared in the invention is increased to 12.2 g / g from 11.2 g / g before compositing, the oil holdup rate is increased to 96.8% from 83.1% before compositing, and the water absorption rate is decreased to 6.6% from 18.2% before compositing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

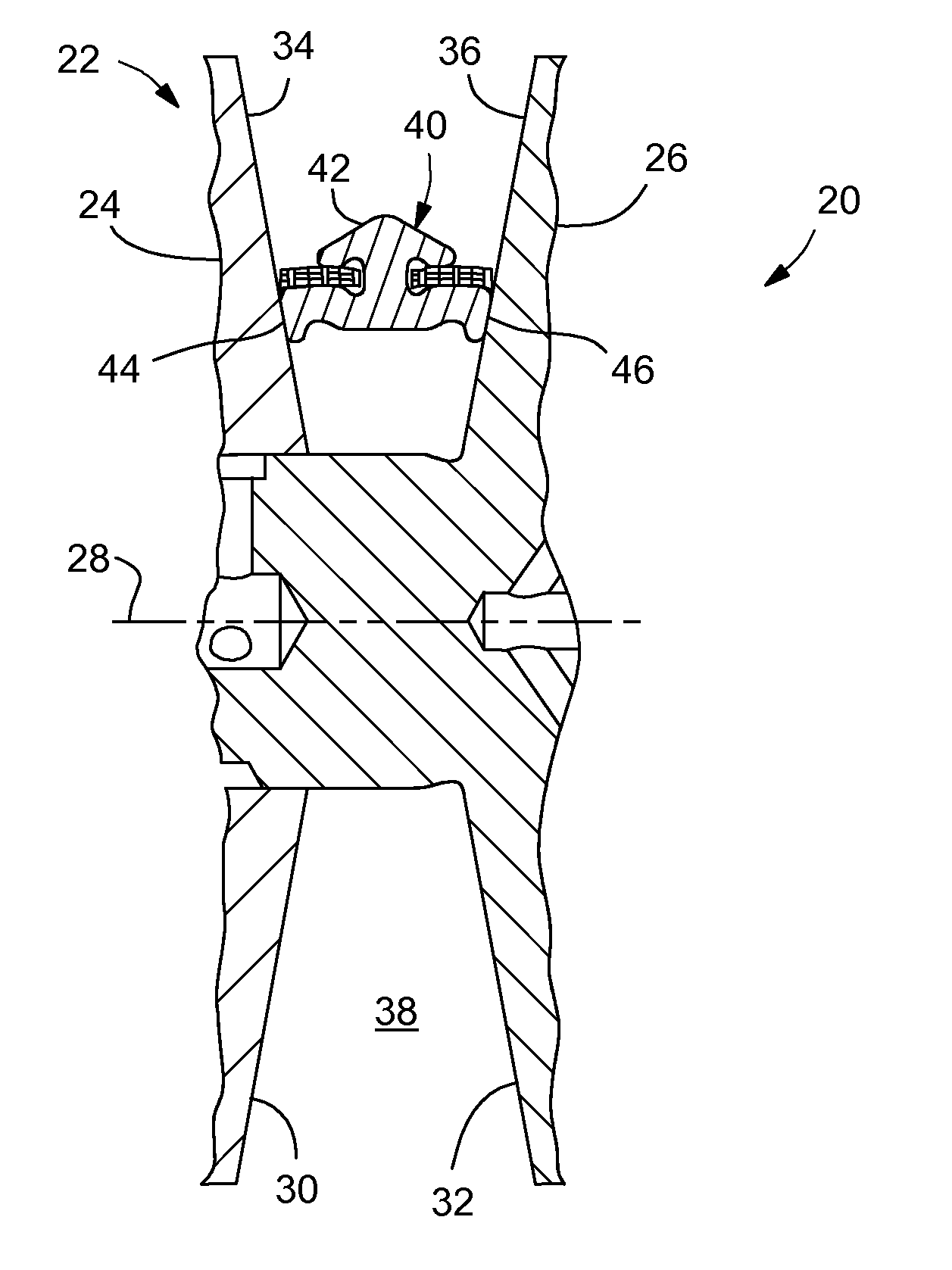

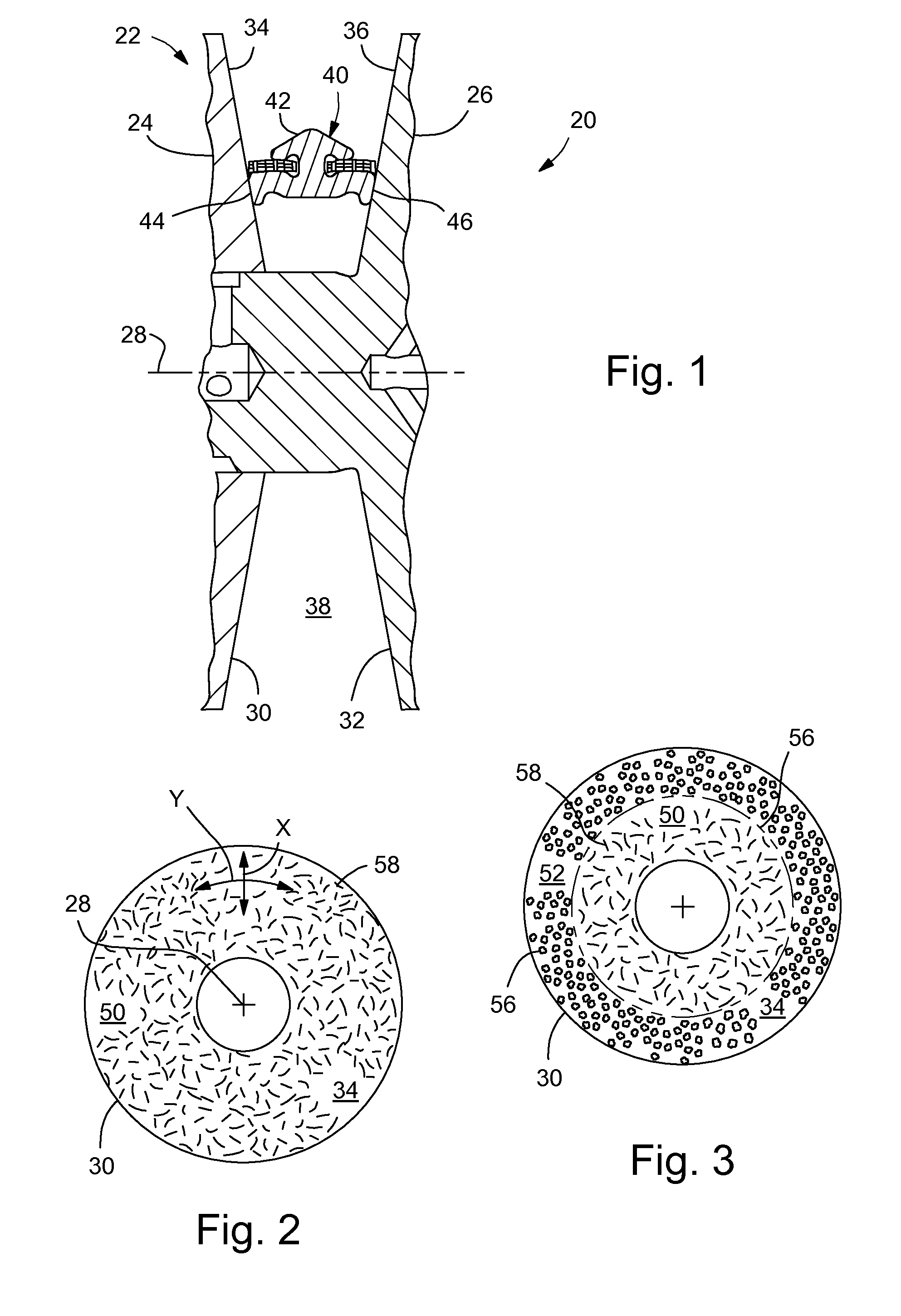

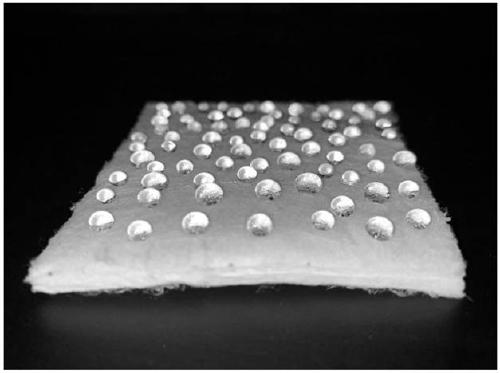

CVT Pulley With Engineered Surface

ActiveUS20120088615A1Reduce wearGood oil retentionVacuum evaporation coatingPortable liftingEngineeringFriction force

A pulley for a continuously variable transmission and a method of creating an engineered surface on an outer surface of a pulley of a continuously variable transmission, with the engineered surface engaging with a belt or chain of the continuously variable transmission. The method comprising the steps of: determining an actual engineered roughness (Rpk) on the outer surface needed to obtain a predetermined friction between the engineered surface and the belt or chain; and etching microgrooves in at least a portion of the outer surface to create the engineered surface by employing a laser to etch the microgrooves, the microgrooves being formed to a depth that produces the actual engineered roughness (Rpk).

Owner:GM GLOBAL TECH OPERATIONS LLC

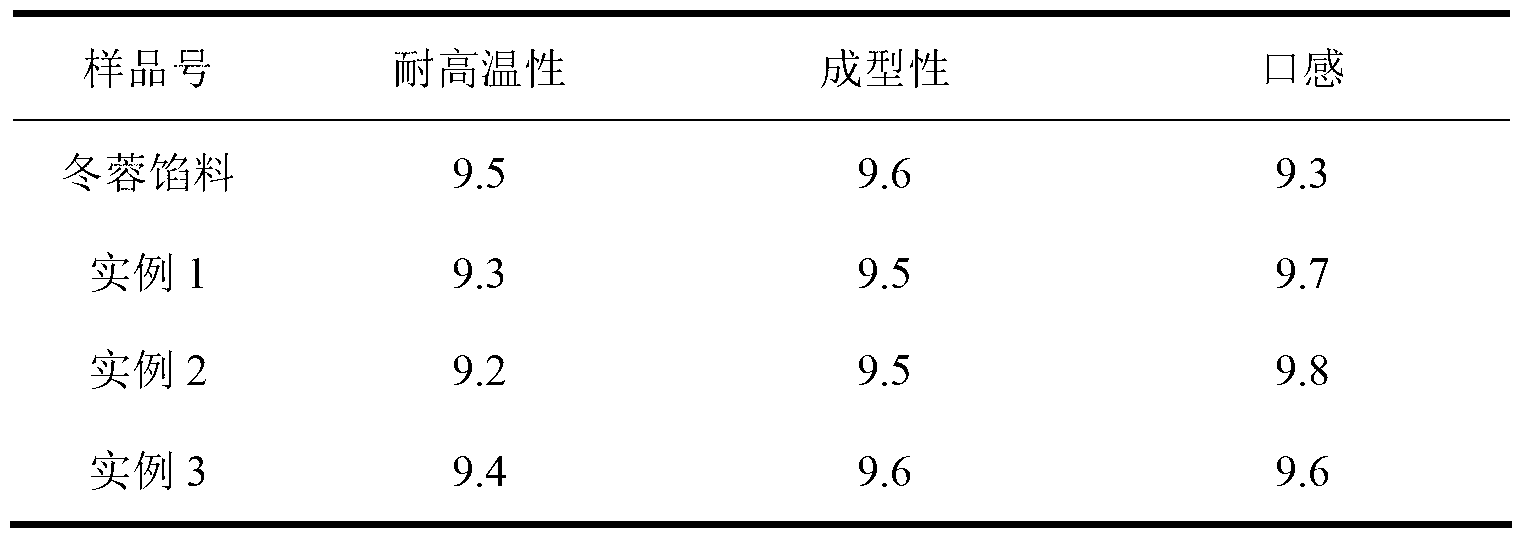

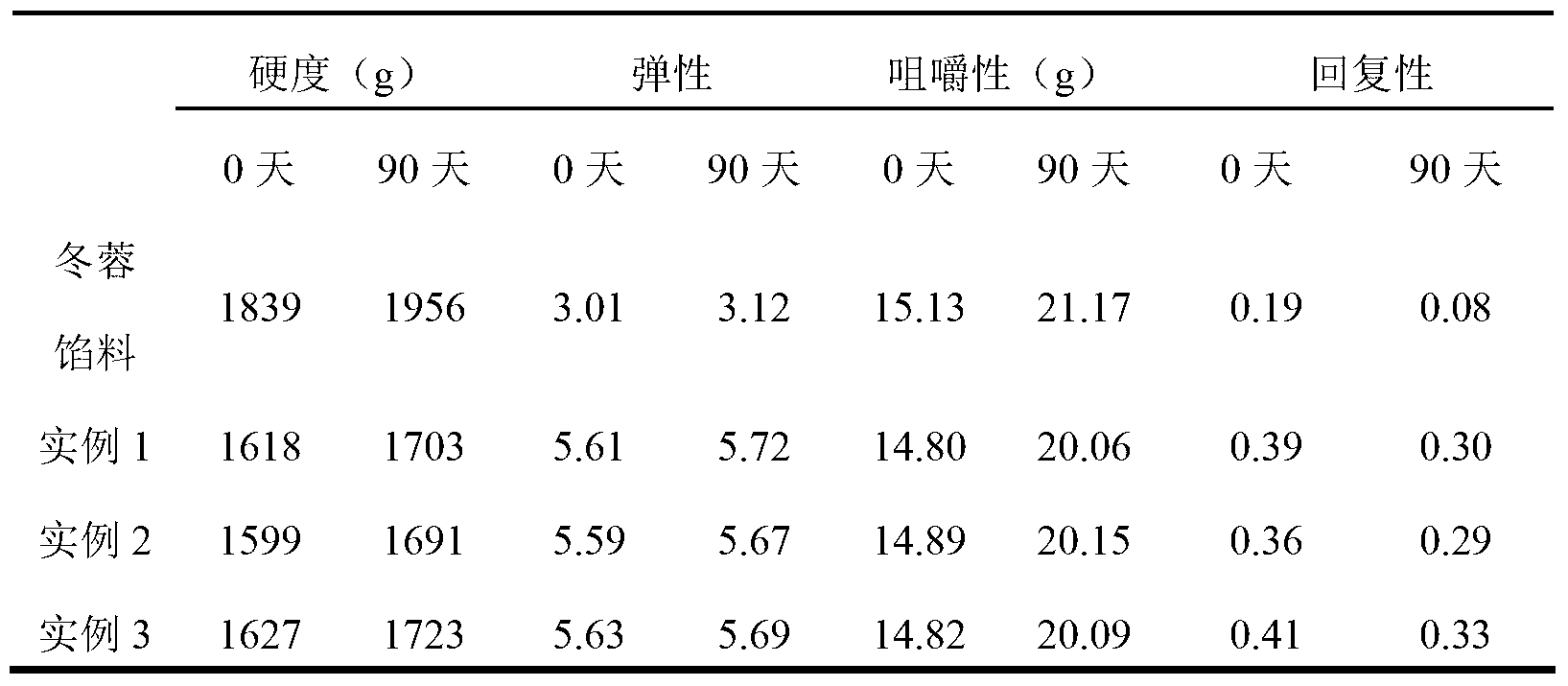

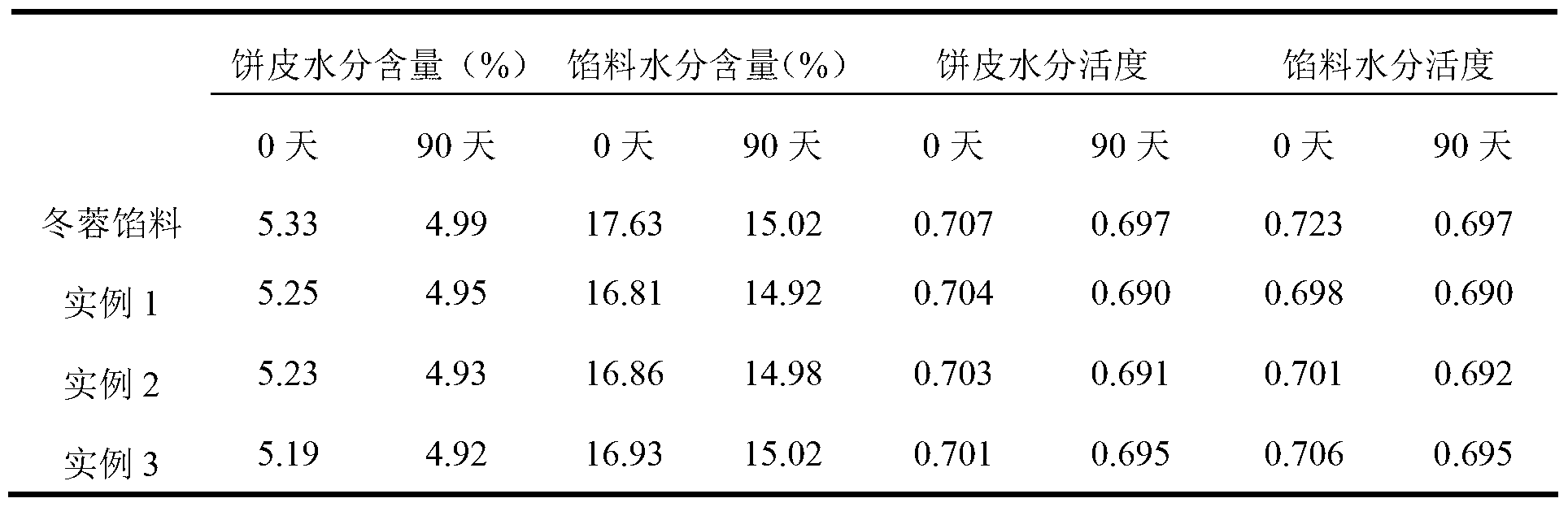

Baked-resistant mooncake stuffing pre-mixed powder and mooncake fruit jam stuffing and preparation methods thereof

ActiveCN103283789ASimple processLow costDough treatmentBakery productsSodium polyacrylateSodium carboxymethylcellulose

The invention discloses a baked-resistant mooncake stuffing pre-mixed powder and mooncake fruit jam stuffing and preparation methods thereof. The baked-resistant mooncake stuffing pre-mixed powder comprises, by mass percentage, 34.7-36.5% of oxidized hydroxypropyl starches, 26.9-28% of hydroxy propyl distarch phosphate, 32.6-33% of distarch phosphate, 0.7-1% of sodium polyacrylate, 1.1-1.2% of sodium carboxymethyl cellulose, 1.1% of sucrose fatty acid ester and 0.8-1% of molecular distillation monoglyceride. Stuffing prepared by the baked-resistant mooncake stuffing pre-mixed powder is good in taste, low in oil content, good in shape preserving and resistant to high-temperature baking, and overcomes the defect of high oil content of conventional mooncake stuffing. Besides, the baked-resistant mooncake stuffing pre-mixed powder is good in ageing resistance, can be stored in six months at room temperature, is simple in manufacturing process and low in cost and has wide market prospect.

Owner:广州合诚实业有限公司

Preparation method for oil absorption material made of polypropylene non-woven cloth

The invention discloses a preparation method for an oil absorption material made of polypropylene non-woven cloth. The preparation method comprises the steps of treatment of the polypropylene non-woven cloth, preliminary grafting reaction, grafting reaction and final treatment so as to obtain the oil absorption material made of the polypropylene non-woven cloth. In the preliminary grafting reaction and the grafting reaction, a monomer drop addition method or a monomer infusion method is adopted. The process of the drop addition method is as follows: adding an oleophylic monomer dropwise in preliminary grafting reaction solution, and conducting the grafting reaction for 30 minutes to 120 minutes under constant-temperature agitation so as to obtain a graft polymerization product, wherein the oleophylic monomer belongs to methacrylic acid alkyl esters, and the adding amount of the oleophylic monomer is 3%-6% of the total mass of the preliminary grafting reaction solution. The process of the infusion method is as follows: taking out a product of the grafting reaction, putting the product into the oleophylic monomer, conducting constant-temperature agitation, and conducting the grafting reaction for 30 minutes to 120 minutes so as to obtain the graft polymerization product, wherein the oleophylic monomer belongs to methacrylic acid alkyl esters, and the adding amount of the oleophylic monomer is 3%-6% of the total mass of the preliminary grafting reaction solution.

Owner:河北维嘉无纺布有限公司

Edible products with low content of saturated and trans unsaturated fats

ActiveUS8182857B2Good oil retentionIncrease resistanceFatty acid chemical modificationConfectioneryTriglycerideUnsaturated fat

Owner:FUJI OIL CO LTD

Preparation method of seaweed cellulose aerogel-carbamic acid alkyl ester type oil gelling agent composite oil spill control material

The invention discloses a preparation method of a seaweed cellulose aerogel-carbamic acid alkyl ester type oil gelling agent composite oil spill control material and relates to a preparation method of a porous network-like structural material integrating hydrophobic, lipophilic and oil gelling properties. The method specifically comprises the following steps: step 1) preparing a hydrophobic seaweed cellulose aerogel; step 2) preparing a carbamic acid alkyl ester type oil gelling agent; step 3) preparing the seaweed cellulose aerogel-carbamic acid alkyl ester type oil gelling agent composite material. According to the method, natural, renewable and seaweed cellulose harmful to the environment is adopted as raw material for preparing an oil-absorbing material, the oil-absorbing material is effectively compounded with the oil gelling agent to prepare the oil spill control material integrating the oil gelling property of anoil gelling agent and the oil-absorbing property of an oil-absorbing agent; and the oil spill control material is capable of effectively absorbing and gelling oil products, organic solvents and other pollutants which are leaked into water.

Owner:HARBIN INST OF TECH

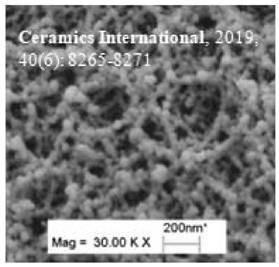

SiO2 aerogel modified polypropylene melt-blown nonwoven material and preparation method thereof

InactiveCN111041587AGood mechanical propertiesReduce manufacturing costFilament forming substance formingSpinning head liquid feederPolypropylene compositesMasterbatch

The invention provides a preparation method of an SiO2 (Silicon Dioxide) aerogel modified polypropylene melt-blown nonwoven material. The preparation method comprises the following steps of (1) usingtetraethyl orthosilicate as a silicon source, preparing SiO2 aerogel by a sol-gel method, and performing crushing after the SiO2 aerogel is subjected to hydrophobic modification to obtain hydrophobicSiO2 aerogel powder; (2) mixing the hydrophobic SiO2 aerogel powder with polypropylene slices, and performing melting granulation to obtain an SiO2 aerogel / polypropylene composite masterbatch; and (3) performing melt-blowing after the SiO2 aerogel / polypropylene composite masterbatch and pure polypropylene are mixed to prepare the SiO2 aerogel modified polypropylene melt-blown nonwoven material.Compared with a polypropylene melt-blown nonwoven material before modification, the modified material has higher oil absorption performance and a higher oil holding rate. The SiO2 aerogel modified polypropylene melt-blown nonwoven material provided by the invention has good mechanical properties, low production cost and a simple process, is hopeful to realize scaled production, and can be used foremergency treatment of oil stain and oil spilling leakage.

Owner:宿迁市美达净化科技有限公司

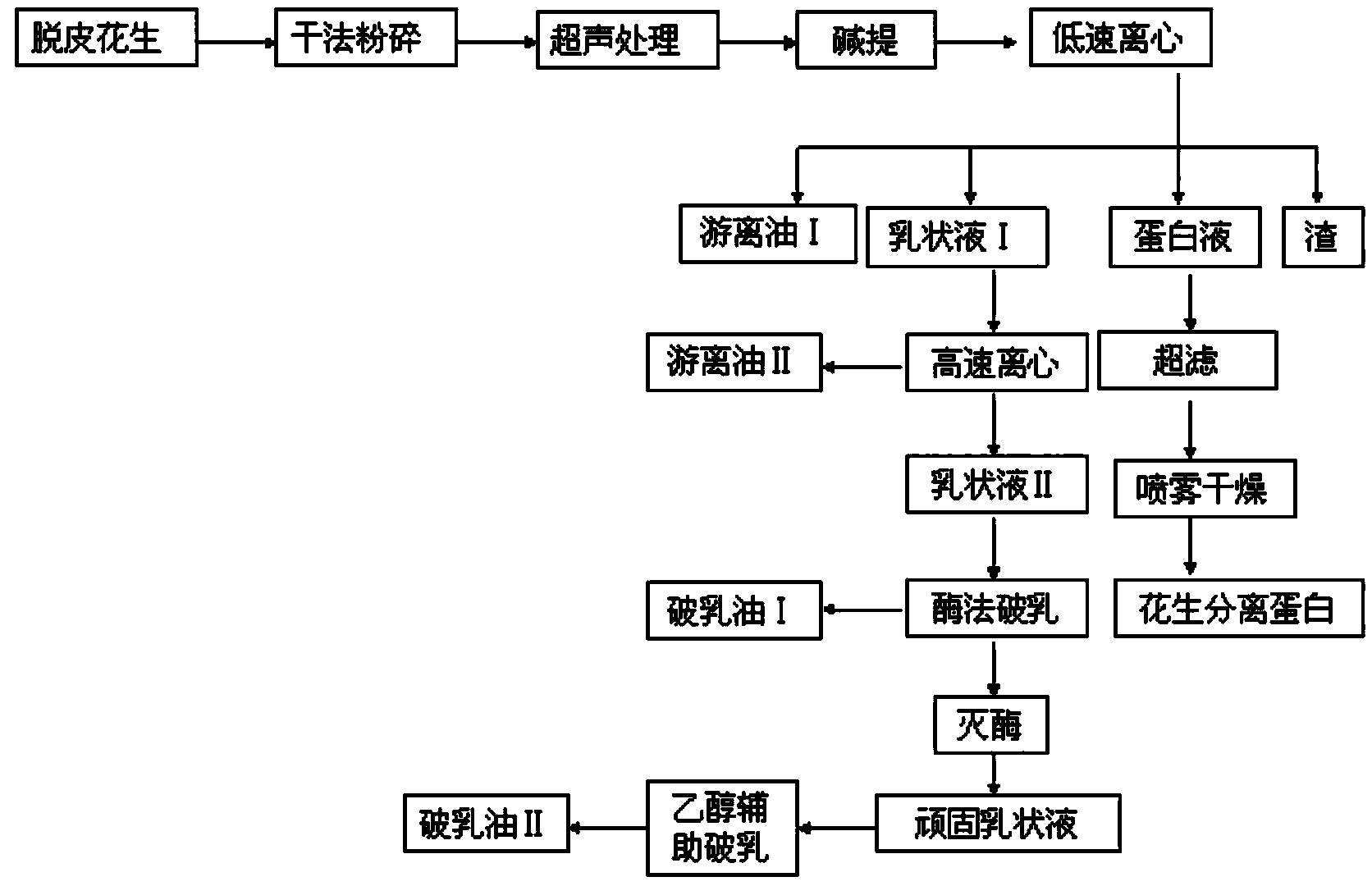

Method for extracting peanut oil and fat and protein with ultrasonic assisted aqueous enzymatic method

ActiveCN103588856ASimple equipment and processReduce energy and resource consumptionPeptide preparation methodsFatty-oils/fats productionUltrafiltrationChemistry

The invention discloses a method for extracting peanut oil and fat and protein with an ultrasonic assisted aqueous enzymatic method, belonging to the technical field of fine processing of agricultural products and comprehensive utilization of by-products. The method comprises the following steps: after grinding blanched peanuts with a dry method, adding water to adjust alkali for ultrasonic-assisted extraction, and digesting after adjusting alkali at the second time; low-speed centrifuging to obtain free oil I and emulsion I, and high-speed centrifuging the emulsion I to obtain free oil II and emulsion II; causing the emulsion II to carry out complex enzyme breaking to obtain demulsification oil I, and causing stubborn emulsion to carry out ethanol-assisted breaking to obtain demulsification oil II; ultra-filtering and desalting protein fluid, and then spray drying to obtain peanut isolate protein powder. Finally, the extraction ratio of free oil is 83 percent, the extraction ratio of total oil is 92 percent, the protein recovery ratio is 91.6 percent, the peanut protein purity is 89 percent, and the breaking ratio of emulsion can achieve 97-98 percent. Compared with the traditional aqueous enzymatic method, the method has the advantages that the extraction ratio of free oil is increased, the dosage of enzyme is greatly reduced, the residual oil ratio of emulsion is significantly reduced, and meanwhile, the peanut protein powder with high purity and good functionality is obtained.

Owner:JIANGSU JOILK GRAIN & OIL

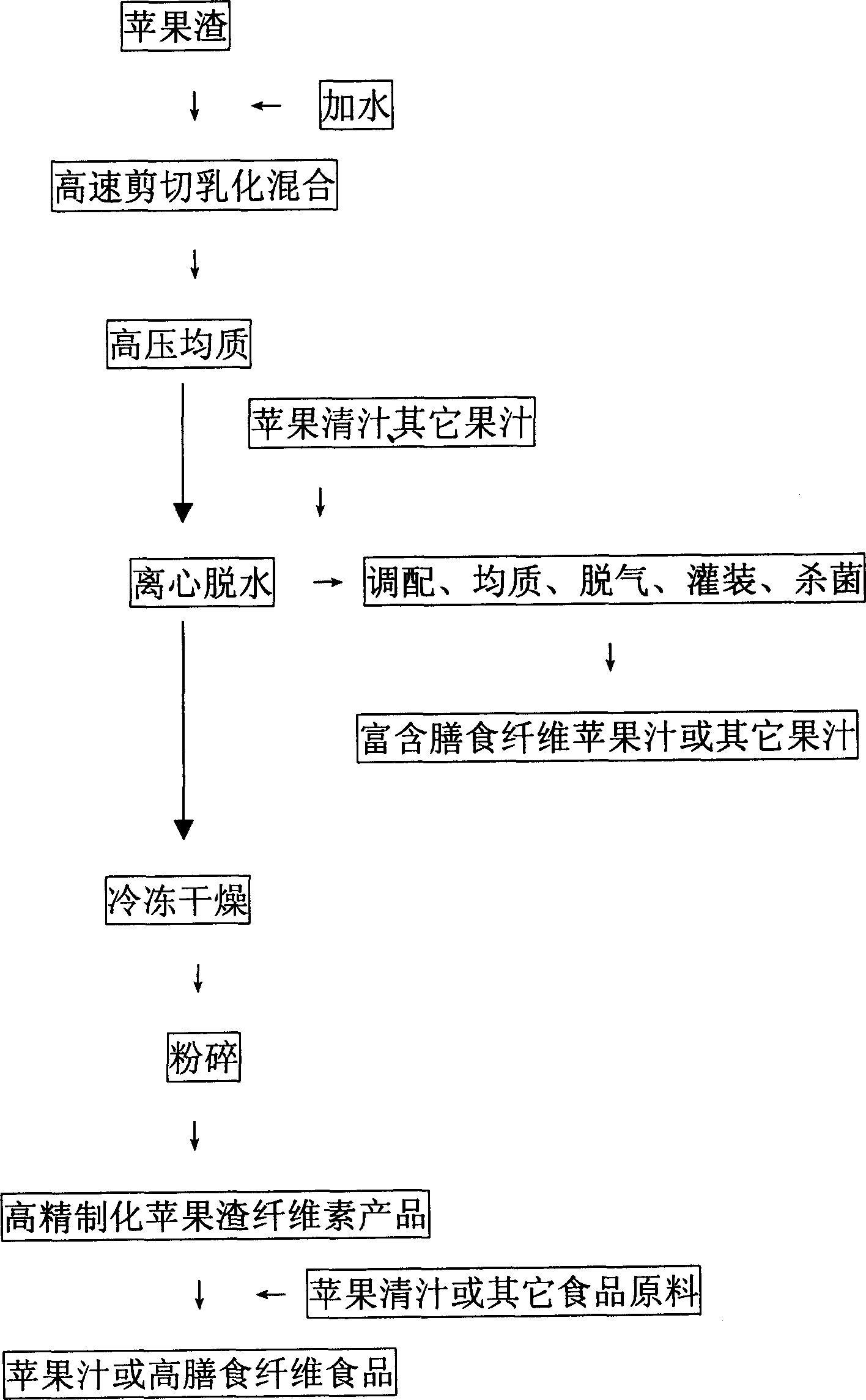

Method for preparing high grade edible fiber using apple slag as raw material and fruit juice enriched with said edible cellulose

The method of preparing high grade diet fiber with apple dregs as material includes high speed shearing, mixing and emulsifying, high pressure homogenizing, dewatering, freeze drying and other technological steps. The produced diet fiber is added into apple juice in certain ratio to obtain apple juice with refined diet fiber. The pure physical process obtains pure natural product containing no any chemical. The process has no environmental pollution and the diet fiber is easy to be absorbed by human body. The diet fiber powder may be used as the additive for other fruit juice and food.

Owner:张晓宾

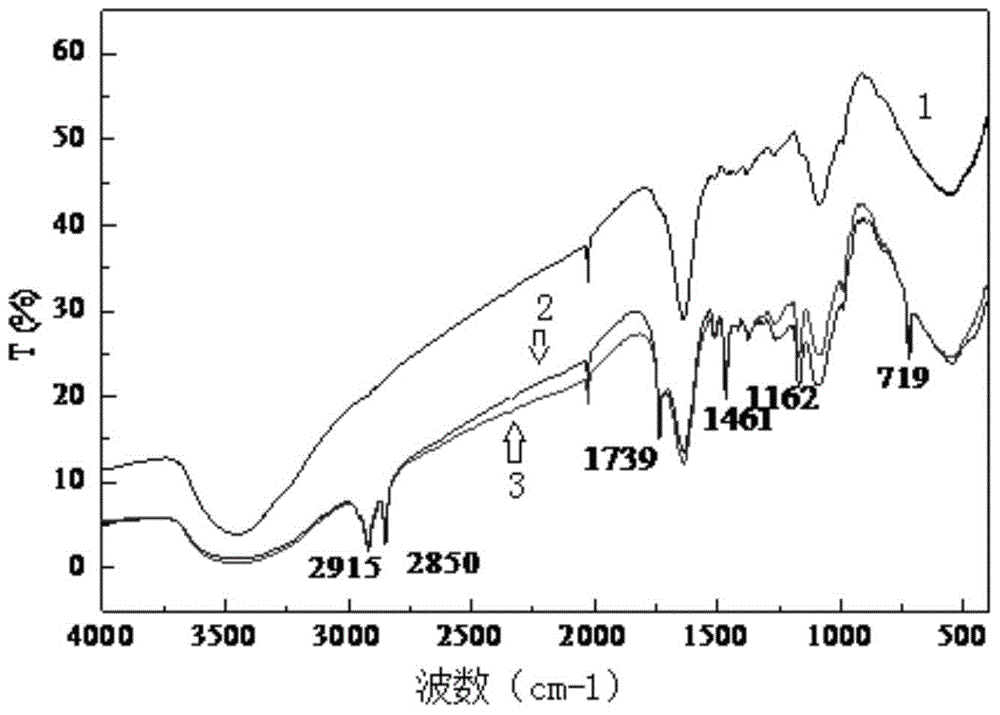

Acrylate polymer high oil absorption resin and preparation method and application thereof

ActiveCN101967212AHigh purityHigh oil absorption rateOther chemical processesWater/sewage treatment by sorptionCross-linkOil retention

The invention relates to acrylate polymer high oil absorption resin and a preparation method and application thereof. The oil absorption resin comprises the following components in part by weight: 50 to 95 parts of flexible chain segment monomer, 5 to 50 parts of rigid chain segment monomer, a cross-linking agent in an amount which is 0.2 to 5 percent of the total weight of the monomers, and a solvent in an amount which is 1.5 to 4 times the total weight of the monomers. The high oil absorption resin is prepared by free radical solution polymerization at room temperature under the initiation of gamma rays. The preparation process is simple, the reaction condition is easy to control, energy consumption is saved, and the method is safe and environmental-friendly and is more suitable for industrial production. The prepared high oil absorption resin has the advantages of high purity, complete hydrophobicity, wide application range, capacity of absorbing multiple types of oil, high oil absorption multiplying power, high oil retention performance, recyclability and the like, and can be widely applied to the absorption of floating oil on the sea surface, scattered oil, cooled emulsified oil on lathes of factories, and oil and organic substances in industrial production and domestic sewage.

Owner:SHANGHAI FINETAC PRECISION TECH CO LTD

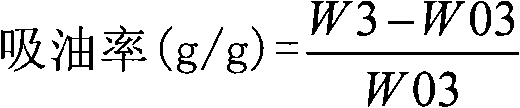

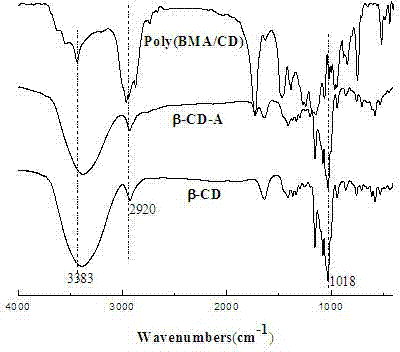

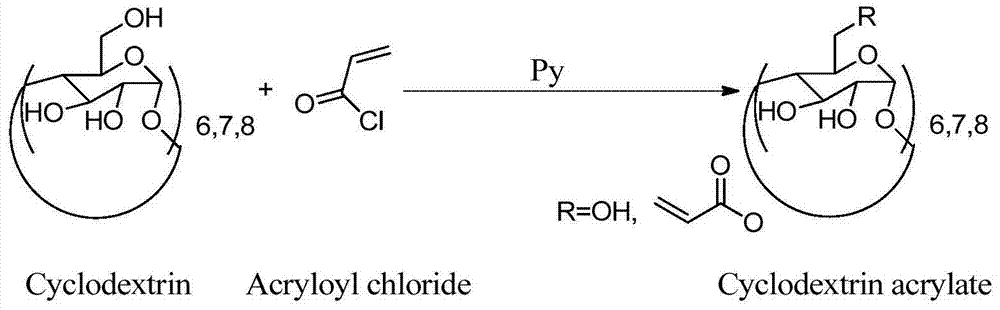

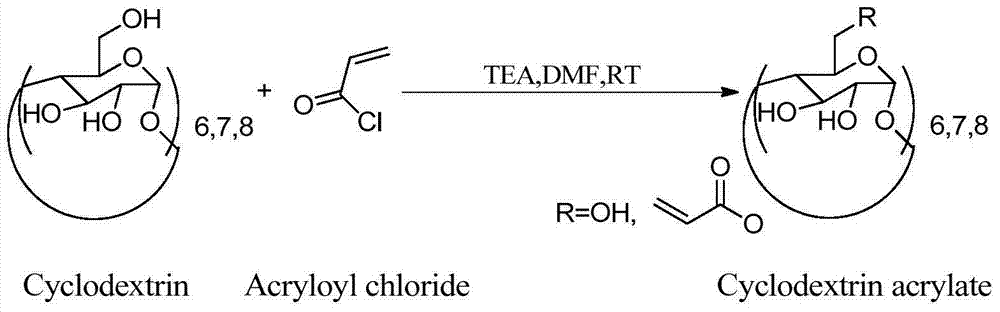

Method for preparing modified oil-absorptive resin immobilized with cyclodextrin molecules

ActiveCN104497231AAvoid reactionFast oil absorptionFatty/oily/floating substances removal devicesOther chemical processesCross-linkOrganic base

The invention discloses a method for preparing modified oil-absorptive resin immobilized with cyclodextrin molecules. The method comprises the following steps: modifying hydroxyls of cyclodextrin molecules by taking cyclodextrin molecules, and acryloyl chloride or other acylation reagents as raw mateials in the presence of an organic base and taking an organic solvent or an organic base as a reaction medium, so as to synthesize 6-acryloyl cyclodextrin; dissolving CD-6-A in an aqueous solution under the ultrasonic action, sequentially adding a monomer, an initiator, a cross-linking agent and a pore-foaming agent into the aqueous solution, carrying out a suspension polymerization reaction to obtain the modified oil-absorptive resin, and drying under reduced pressure, thereby obtaining the product. The adsorbing capacity of the modified oil-absorptive resin containing the cyclodextrin molecules on methylbenzene is close to 45g / g, the adsorbing capacity on trichloromethane reaches 80g / g, and the resin has a very obvious effect of cleaning floating oil on the water surface. The modified oil-absorptive resin disclosed by the invention has the advantages that the preparation process is simple, the production cost is low, the adsorbing capacity is large, the oil absorption efficiency is high, the rein can be repeatedly used, and the adsorption-desorption process is simple, green and environment-friendly.

Owner:HUIZHOU RES INST OF SUN YAT SEN UNIV

Preparation method of superhydrophobic melamine sponge modified by utilizing dopamine and carbon nanotubes

ActiveCN107722343AImprove hydrophobicityNo significant change in oil absorption capacityOther chemical processesAlkali metal oxides/hydroxidesOil waterDopamine

The invention discloses a preparation method of superhydrophobic melamine sponge modified by utilizing dopamine and carbon nanotubes. The preparation method is characterized in that the carbon nanotubes are combined with melamine sponge through oxidative autopolymerization of dopamine, so that oil-water selectivity of the melamine sponge is improved. The preparation method comprises the followingconcrete steps: firstly, combining the carbon nanotubes with dopamine by utilizing adhesion of dopamine, then coating a melamine sponge skeleton with the carbon nanotubes through the oxidative autopolymerization under alkaline conditions, and drying sponge to be constant weight, thus obtaining modified sponge with hydrophobic and lipophilic properties. The preparation method disclosed by the invention has the advantages that the carbon nanotubes are connected with the melamine sponge by virtue of chemical bonds, so that connection is tight and content is high; meanwhile, the structures of thecarbon nanotubes are not destroyed, so that sponge has stronger hydrophobic property and oil retaining capability, the obtained melamine sponge is light in weight and can be conveniently recycled, andefficient purification on floating oil on water surface can be realized.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Processing method of catfish luncheon meat

The invention relates to a processing method of catfish luncheon meat, belonging to the technical field of foods. The processing method of the catfish luncheon meat is characterized by comprising thefollowing steps: preprocessing: removing the abodominal organs, the skin and the head of a catfish, cleaning and cutting the catfish into blocks; rinsing: using a 0.1-1.0 percent of NaCl solution or a0.1-1.0 percent of NaHCO3 solution to rinse the catfish at 2-12 DEG C; dewatering: dewatering the catfish by using a centrifuger or using gauze to extrude; pickling: using a curing agent to pickle the catfish at 1-10 DEG C for 3-20 hours; mixing and kneading: adding spices to the pickled catfish and mixing and kneading the catfish at 2-10 DEG C for 2-10 minutes; heating: canning mixed and kneadedminced fillet into a die and cooking at 60-95 DEG C for 1-6 hours; and cooling: cooling the die to a room temperature. The invention has the advantages of simple process, economy, practicability, high production efficiency, good water and oil retention, emulsifying property, excellent strength, tastes, texture and shape of gel and the like, and the luncheon meat has tender fiber and fresh tastes,stimulates the appetite, is digestible and particularly suitable for eating by old people and children.

Owner:天津市宽达水产食品有限公司

Kenaf core/resin composite oil-absorption material and preparation method thereof

The invention relates to a kenaf core / resin composite oil-absorption material and a preparation method thereof. The preparation method is characterized in that kenaf core waste in a textile industry is taken as a raw material to carry out graft copolymerization on oil-absorption resin and cellulose on the surfaces of kenaf core particles, so as to obtain a degradable kenaf core / resin composite high-oil-absorption resin. Compared with traditional inorganic oil-absorption materials and resin oil-absorption materials, the kenaf core / resin composite oil-absorption material and the preparation method have the advantages that the production cost can be substantially lowered, the waste of the textile industry is effectively utilized, and by utilizing a unique porous structure of a kenaf core, the oil absorption and keeping properties of the oil-absorption material are greatly improved; besides, after the kenaf core is subjected to graft copolymerization with the resin, the water absorbing capacity of the kenaf core is reduced, and the ratio of the oil absorbing capacity to the water absorbing capacity of the kenaf core is increased; the kenaf core simultaneously has the biodegradability of a straw and high water absorbing performance of the resin.

Owner:QINGDAO UNIV

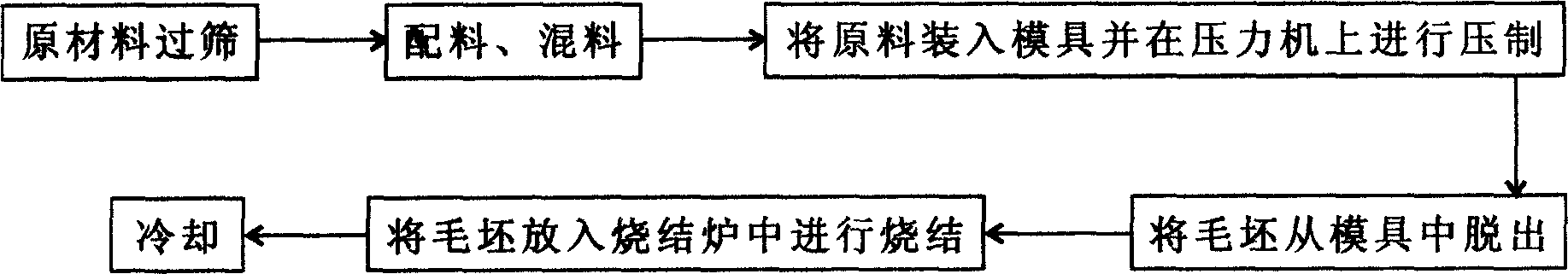

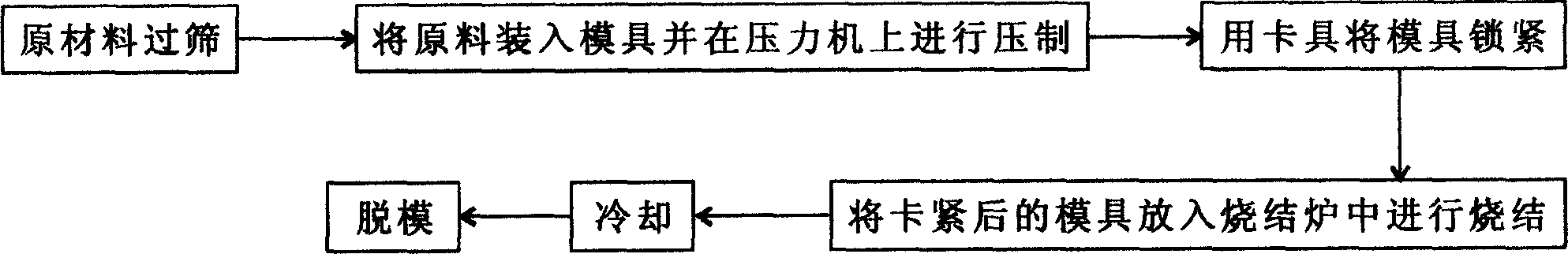

Caron micron tube filling polymer oil-containing friction material for ultrasonic motor and preparation method thereof

ActiveCN105968662AEasy accessHigh hardnessOther chemical processesMaterials preparationPolymer substrate

The invention discloses a carbon micron tube filling polymer oil-containing friction material for an ultrasonic motor and a preparation method thereof and particularly relates to an oil-containing friction material taking a carbon micron tube as an oil-containing carrier and applied to a traveling wave ultrasonic motor so as to solve the problems that stable operation of an ultrasonic motor is hard to guarantee by existing dry friction materials, the porous-structure friction material has bad elasticity and the oil content, elasticity modulus, hardness and contact deflection of the oil-containing friction material taking polyimide as a substrate are hard to adjust in a large range and the application of the ultrasonic motor is limited. The oil-containing friction material comprises the following components in percentage by mass: 45-80% of polymer substrate, 10-30% of friction regulator and 1-30% of carbon micron tube; and the preparation method comprises the following steps: 1) preparing a final mixture; 2) performing compression moulding to obtain a moulded object; 3) sintering the moulded object; 4) preparing a platy friction material; and 5) preparing the carbon micron tube filling polymer oil-containing friction material for the ultrasonic motor. The invention belongs to the field of oil-containing material preparation.

Owner:NINGBO UNIV

Leak-proof color-changeable adsorption cotton

ActiveCN104383898AAvoid spillingAdjust in timeWater cleaningGeneral water supply conservationSurface layerChange color

The invention relates to the field of materials, and particularly relates to leak-proof color-changeable adsorption cotton which comprises a surface layer, a color-changeable layer and an oil holding layer, wherein the oil holding layer is positioned between the surface layer and the color-changeable layer; a leak-proof layer is arranged outside the color-changeable layer; the oil-holding layer is a coarse polypropylene fiber melt-blowing layer, the surface layer is a fine polypropylene fiber melt-blowing layer, and the color-changeable layer is a color-changeable oil absorption material layer. The leak-proof color-changeable adsorption cotton is high in oil holding rate and convenient to use, and can change color along with oil absorption amount.

Owner:FUYANG AOHONG FIBER PROD CO LTD

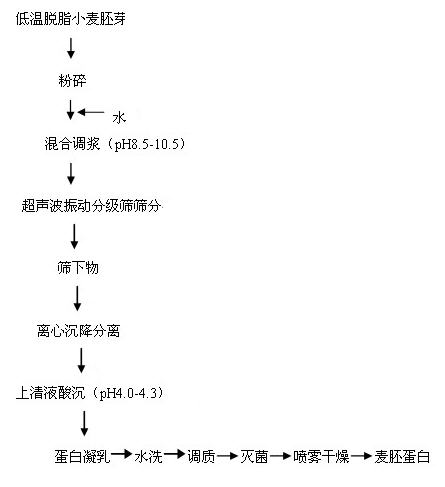

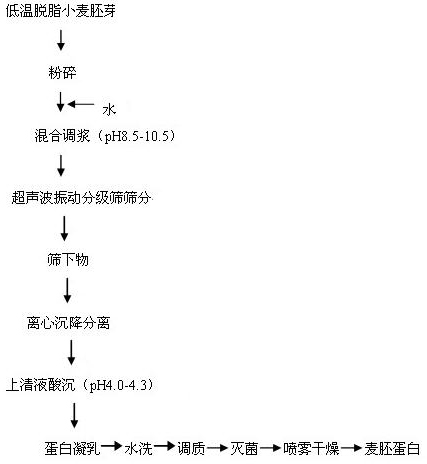

Extraction method of defatted wheat germ protein

ActiveCN102669404AImprove screening efficiencyNot easy to blockFood preparationProtein proteinChemistry

The invention discloses an extraction method of defatted wheat germ protein. The extraction method includes crushing low-temperature defatted wheat germs to make even wheat germ slurry, using an ultrasonic vibration classifying screen for wet screening, subjecting screening product to centrifugal settling separation and acid precipitation to obtain protein precipitate, and subjecting the protein precipitate to washing, modifying, sterilizing and drying to obtain the finished wheat germ protein. Compared with the prior art, the extraction method has the advantages that screening efficiency is high, meshes are less easy to block, power consumption is low and the like. By the extraction method, protein dissolution quantity can be increased, protein purity and yield can be increased, the protein is fine in dispersiblity, emulsibility, foamability, water retention and oil retention, the primary concentration of the protein can be achieved, and wheat germ dietary fiber, high-added-value product, can further be obtained from oversize product, and accordingly comprehensive utilization rate of the wheat germs is increased. In addition, the extraction method has low requirement for production equipment, is simple in process sequence and is convenient for industrial popularization.

Owner:JIANGNAN UNIV

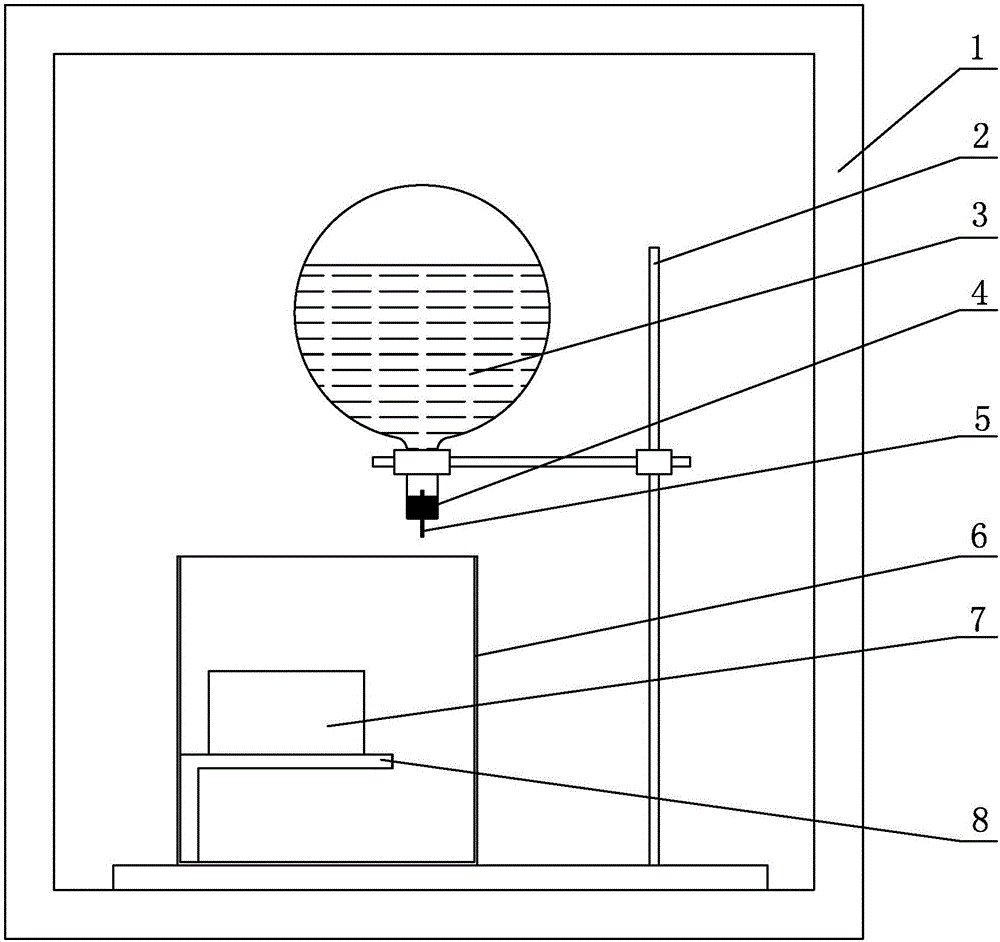

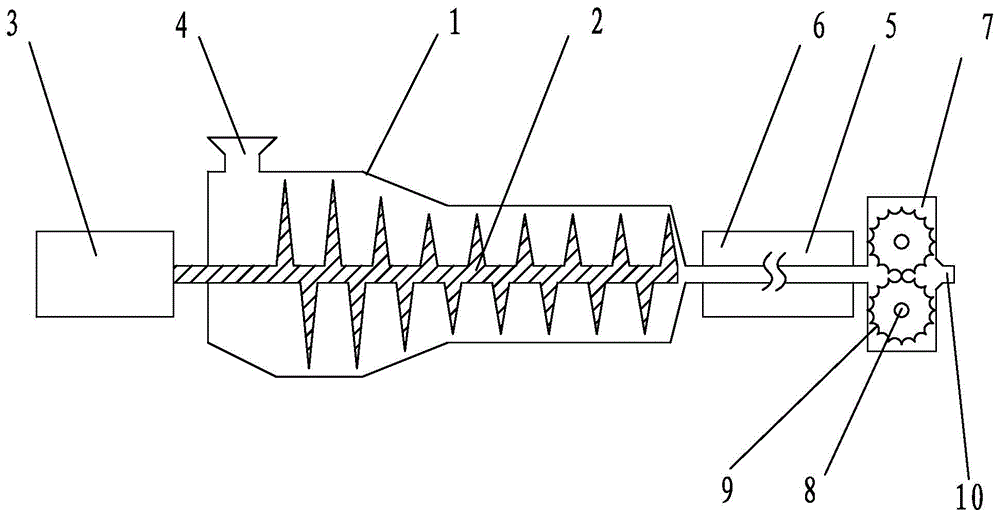

Preparation method and preparation apparatus of embedded immobilized microbial ball

InactiveCN104830826AHigh activityImprove adsorption capacityBioreactor/fermenter combinationsBiological substance pretreatmentsEmulsionHigh dimensional

The present invention relates to the field of high oil-absorbing resin preparation, and discloses a preparation method of an embedded immobilized microbial ball. The method comprises the steps of: (1) preparation of the immobilized microbial particles; (2) preparation of an acrylate copolymer emulsion; and (3) preparation of the embedded immobilized microbial ball. The present invention also discloses a preparation apparatus of the embedded immobilized microbial ball. The apparatus includes an extrusion section, an insulation transport section and a moulding section. The extrusion section comprises an extrusion sections housing, an advancing screw and a rotary motor; the insulation transport section includes a tubular type conveying channel and a heater; and the moulding section comprises a moulding section housing and a pair of reverse gears provided with hemispherical grooves. The embedded immobilized microbial ball prepared by the present invention has high oil suction rate and large oil absorption capacity, and can degrade the adsorbed oil; and microbes have good stability and long survival time. At the same time, the preparation apparatus of the present invention requires mild conditions in the preparation process, protects the survival rate of the microbes to the maximum; and the prepared product has high dimensional stability.

Owner:ZHEJIANG OCEAN UNIV

No-egg low-fat salad sauce and preparation method thereof

InactiveCN104509837AImprove textureImprove structural stabilityFood preparationFood ingredient as replacerOCTENYLSUCCINIC ACIDXanthan gum

The invention provides no-egg low-fat salad sauce, which consists of the following components in percentage by weight: 3.0 to 4.7 percent of octenyl succinic anhydride modified waxy rice starch, 3.0 to 3.7 percent of hydroxypropyl crosslinked glutinous rice starch, 21 to 27 percent of water, 25 to 33 percent of salad oil, 22 to 28 percent of maltodextrin, 9.2 to 9.4 percent of soft sugar, 1.62 to 1.72 percent of salt, 3.2 to 4.2 percent of table vinegar, 0.007 to 0.015 percent of potassium sorbate and 0.01 to 0.04 percent of xanthan gum. According to the no-egg low-fat salad sauce, collaborative emulsification and thickening effects of edible gum and the glutinous rice starch are utilized, so that the use of fresh eggs is avoided, and low-cholesterol and low-fat salad sauce are provided for people; not only be cold-mixed no-egg low-fat salad sauce provided, but also high-temperature-resistant no-egg low-fat salad sauce is provided, so that the application fields of the no-egg low-fat salad sauce can be greatly expanded.

Owner:HENAN HENGRUI STARCH TECH CO LTD

Preparation method for composite high oil-absorption resin

InactiveCN104841386AImprove stabilityImprove adsorption capacityFatty/oily/floating substances removal devicesOther chemical processesMethacrylateCellulose

Relating to the high oil-absorption resin preparation field, the invention discloses a preparation method for a composite high oil-absorption resin. The method includes: (1) preparation of immobilized microbial microspheres: mixing modified mussel shell powder with a seed bacterial liquid, adding a sodium alginate solution into a bacteria adsorbing modified mussel shell powder solution, then injecting the mixed solution into a calcium chloride solution and conducting dispersion into balls, and conducting crosslinking to obtain immobilized microbial microspheres; (2) preparation of an acrylate copolymer emulsion: adding a methylacrylate monomer, styrene, an initiator and an emulsifier into water and conducting stirring emulsification; adding a crosslinking agent and a pore making agent into the emulsion to carry out reaction so as to obtain an acrylate copolymer emulsion; and (3) preparation of composite high oil-absorption resin: adding immobilized microbial microspheres, a coupling agent and cellulose into the acrylate copolymer emulsion, conducting stirring and then performing vacuum drying, thus obtaining the composite high oil-absorption resin. The composite high oil-absorption resin prepared by the method provided by the invention has fast oil absorption speed and large oil absorption capacity, and can carry out microbial degradation on oil.

Owner:ZHEJIANG OCEAN UNIV

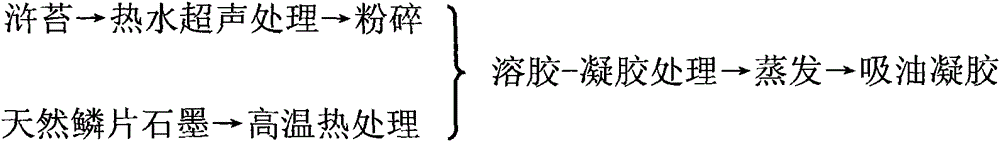

Enteromorpha gel oil suction material and preparation method thereof

The invention relates to an enteromorpha gel oil suction material and a preparation method thereof, the gel oil suction material comprises the following components: 60-70% of enteromorpha extract product, 10-15% of expandable graphite, 2-4% of ferric nitrate, 5-8% of cobalt nitrate, 8-12% of citric acid and 2-4% of ammoniacal liquor. According to the invention, enteromorpha with abundant output in sea is taken as a raw material, sugar alcohol, aliphatic acid and crude fiber extracted in enteromorpha are taken as base, and are mixed with expandable graphite by using a sol-gel method, the gel oil suction material can be recovered and used with high efficiency and environmental protection, the molecular structure of three-dimensional fiber mesh can greatly absorb oil molecule. The oil suction material has good oil adsorption performance, oil suction can reach saturation in 60-80 minutes under dynamic state, the saturation adsorption multiple is 40-60 which is higher than that of the current resin oil suction material and biomass oil suction material, and the enteromorpha gel oil suction material has the advantages of fast oil suction speed, good oil binding capacity and low cost.

Owner:QINGDAO UNIV

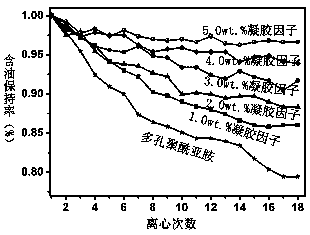

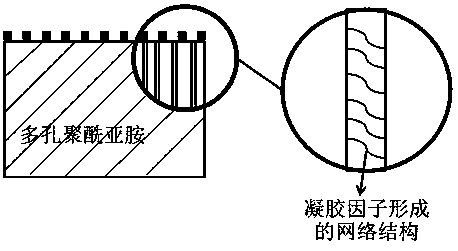

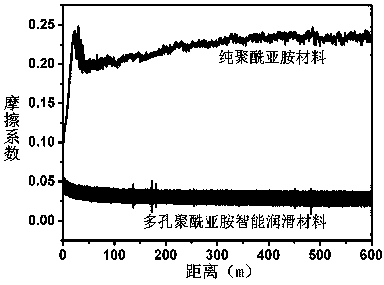

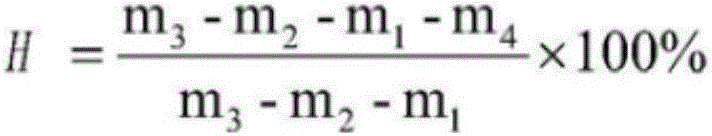

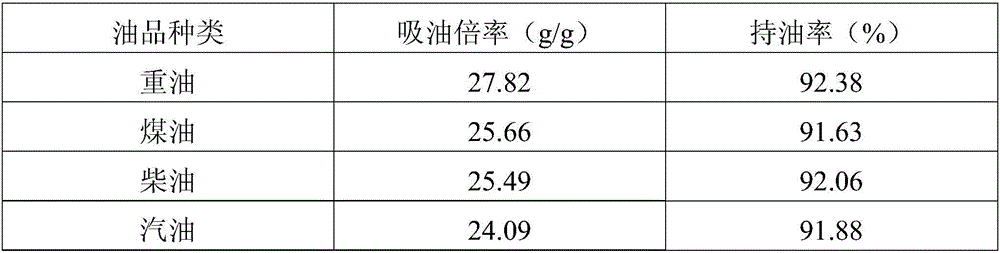

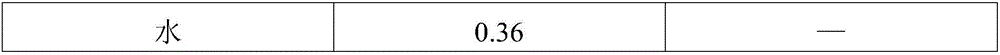

Preparation method for porous polyimide intelligent lubricating material

The invention relates to a preparation method for a porous polyimide intelligent lubricating material. The method comprises the following steps: (1) preparing a leucine gelator: adding leucine, hexadecanol and a p-toluene sulfonic acid monohydrate to a methylbenzene solvent, after performing an esterification reaction, to obtain an oily substance; firstly dissolving the oily substance, and adjusting a pH value, to obtain leucine hexadecyl ester; after enabling the leucine hexadecyl ester to be dissolved in absolute ethyl alcohol, adding glucolactone, after performing a reflux reaction, enabling a residue to be dissolved in hot 1,4-dioxane, filtering while hot, and recrystallizing, to obtain the leucine gelator; and (2) preparing the porous polyimide intelligent lubricating material: aftersieving polyimide powder, cold-pressing, covering die in a normal pressure, sintering, and slicing, preparing a massive porous polyimide material; adding the leucine gelator to lubricating oil, afterheating and adequately dissolving, enabling the massive porous polyimide material to be immerged, cooling in a room temperature, to obtain the porous polyimide intelligent lubricating material. The porous polyimide intelligent lubricating material is capable of effectively improving an oiliness retention rate.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for obtaining oil absorption material by adopting melamine resin foam as matrix

InactiveCN106215904APorousLarge specific surface areaOther chemical processesWater/sewage treatment by sorptionOil retentionPolymer science

The invention discloses a method for obtaining an oil absorption material by adopting melamine resin foam as a matrix, and belongs to the technical field of oil pollution treatment. The method comprises the following steps that the melamine resin foam is placed in a hydrophobing agent solution, and vacuum impregnation is carried out for 20-60 minutes at the temperature of 25 DEG C to 100 DEGC; the melamine resin foam containing a hydrophobing agent is taken out and dried fast, a hydrophobing agent infusion with the melamine resin foam as the matrix is obtained, and the oil absorption material is obtained. According to the oil absorption material prepared by adopting the melamine resin foam as the matrix, the modifying method that the hydrophobing agent is loaded in a dipping mode is adopted, the method is a simple physical modifying method, the process is simple, cost is low, and the advantages of being porous, large in specific surface area, low in density, high in oil absorption performance and good in oil retention effect are achieved.

Owner:郑州峰泰纳米材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com