Preparation method for porous polyimide intelligent lubricating material

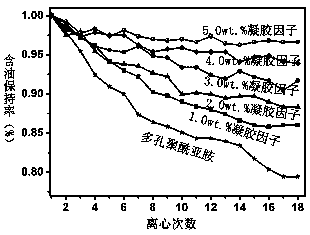

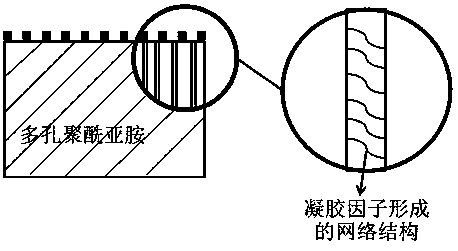

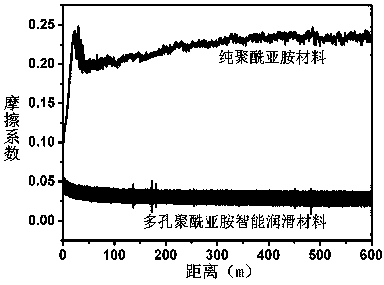

A technology of polyimide and lubricating materials, which is applied in the field of preparation of porous polyimide intelligent lubricating materials, can solve the problems of material durability decline, achieve improved stability, high oil retention rate, and increase oil retention rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 A preparation method of a porous polyimide intelligent lubricating material, comprising the following steps:

[0027] ⑴ Preparation of leucine gelling factor:

[0028] Add 6.56g of leucine, 12.12g of cetyl alcohol and 11.41g of p-toluenesulfonic acid monohydrate into 100 mL of toluene solvent, heat to 120°C and stir to form a homogeneous solution, then reflux for 24 hours for esterification. Then the toluene solvent was removed by rotary evaporation to obtain an oily substance; the oily substance was first dissolved in chloroform, and then a saturated sodium bicarbonate solution was added dropwise to adjust the pH value of the aqueous phase to be neutral, and the chloroform phase was collected and rotary evaporated to obtain leucine hexadecane Alcohol ester; leucine hexadecyl alcohol ester was dissolved in absolute ethanol, then 10.69g gluconolactone was added, stirred and refluxed at 110°C for 8h. After the reaction was completed, the ethanol solvent was ...

Embodiment 2

[0031] Embodiment 2 A preparation method of a porous polyimide intelligent lubricating material, comprising the following steps:

[0032] ⑴ Preparation of leucine gelling factor:

[0033] Add 6.56g of leucine, 13.34g of cetyl alcohol and 13.31g of p-toluenesulfonic acid monohydrate into 120 mL of toluene solvent, heat to 130°C and stir to form a homogeneous solution, then reflux for 18 hours for esterification. Then the toluene solvent was removed by rotary evaporation to obtain an oily substance; the oily substance was first dissolved in chloroform, and then a saturated sodium bicarbonate solution was added dropwise to adjust the pH value of the aqueous phase to be neutral, and the chloroform phase was collected and rotary evaporated to obtain leucine hexadecane Alcohol ester; leucine hexadecyl alcohol ester was dissolved in absolute ethanol, then 11.58g gluconolactone was added, stirred and refluxed at 100°C for 8h. After the reaction was completed, the ethanol solvent was ...

Embodiment 3

[0036] Embodiment 3 A preparation method of a porous polyimide intelligent lubricating material, comprising the following steps:

[0037] ⑴ Preparation of leucine gelling factor:

[0038] Add 6.56g of leucine, 14.54g of cetyl alcohol and 14.27g of p-toluenesulfonic acid monohydrate into 150 mL of toluene solvent, heat to 150°C, stir and mix to form a homogeneous solution, and reflux for 12 hours for esterification. Then the toluene solvent was removed by rotary evaporation to obtain an oily substance; the oily substance was first dissolved in chloroform, and then a saturated sodium bicarbonate solution was added dropwise to adjust the pH value of the aqueous phase to be neutral, and the chloroform phase was collected and rotary evaporated to obtain leucine hexadecane Alcohol ester; leucine hexadecyl alcohol ester was dissolved in absolute ethanol, then 13.36g gluconolactone was added, stirred and refluxed at 90°C for 12h. After the reaction was completed, the ethanol solvent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com