Magnesium-calcium refractory material gunning mix

A technology of refractory materials and gunning materials, applied in the field of gunning materials, can solve the problems of difficult service life to meet the requirements of steel mills, low high-temperature strength, and low calcium oxide content, and achieve improved slag resistance and high-temperature strength , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

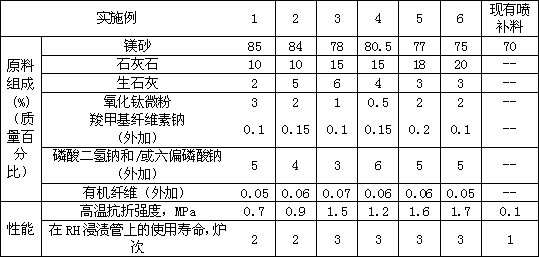

Examples

Embodiment 1

[0015] A magnesia-calcium refractory gunning material, in terms of mass percentage, including main raw materials of 75-85% of magnesia, 10-20% of limestone, 2-6% of quicklime powder and 0.5-3% of titanium oxide powder; and Add 3-6% of the binder as the main raw material and 0.1-0.2% of the thickener as the main raw material.

[0016] The main component of limestone in the gunning material is calcium carbonate CaCO 3 The theoretical calcium oxide content of calcium carbonate is 56%, and that of natural limestone is between 44-55%. Under the conditions of gunning material, the activated calcium oxide decomposed from limestone reacts with sodium phosphate to form calcium phosphate with high melting point. Secondly, natural limestone is cheap, which is beneficial to reduce the cost of gunning material.

[0017] The main component of quicklime powder in the gunning material is calcium oxide CaO. At high temperature, calcium oxide reacts with sodium phosphate to form calcium phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com