Patents

Literature

452results about How to "Congeal fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of composite high-expansion cementing material by using industrial slag and preparation technique thereof

The invention relates to a preparation process of using industrial slag to prepare composite cementing materials with high expansibility. The cementing materials consist of four components. The first component includes three parts: one or a plurality of combinations of fly ashes, slag, etc., which contain aluminosilicate; one or a plurality of combinations of phosphogysum, fluorine gypsum, etc., which contain calcium sulfate; one or a plurality of combinations of carbide, alkaline residue, quick lime or slaked lime. The second component includes: one or a plurality of combinations of alkaline composition, such as the quick lime or slaked lime, the carbide slag, etc.. The third component includes one or a plurality of combinations of the phosphogypsum, fluorine gypsum, etc., which contain the calcium sulfate. The preparation method is: firstly, to evenly mix the raw materials of the first component which are grinded to be with the surface area of 200-500m<2> / kg through the steam curing of four hours to ten days at 50-100 DEG C and the calcining of 0.5-24h at the high temperature of 400-1000 DEG C to obtain the first component; secondly, to dry and grind the raw materials of the second and the third component to be with the surface area of 200-500m<2> / kg to obtain the second and the third component; thirdly, to evenly mix the first, the second and the third component.

Owner:BEIHANG UNIV

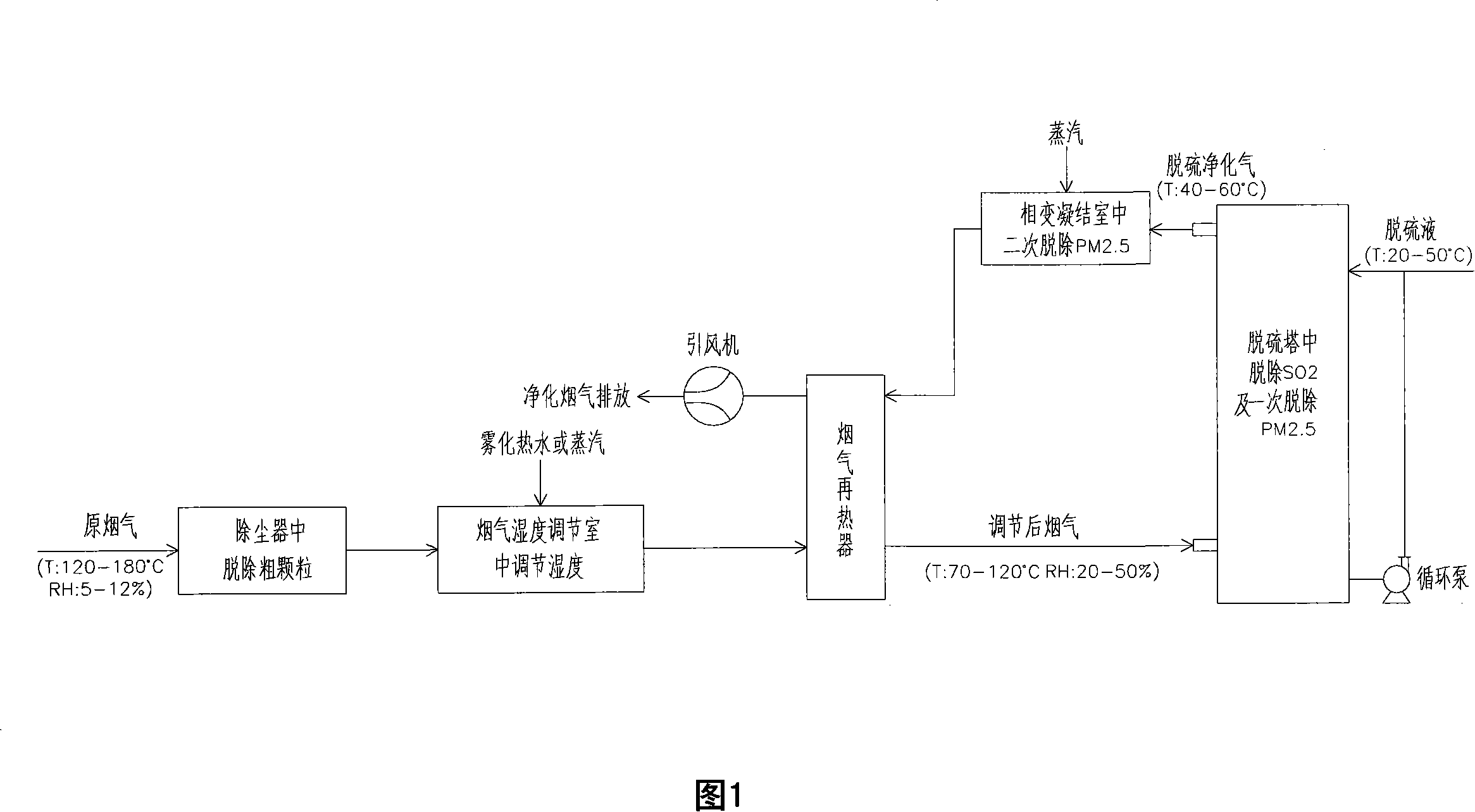

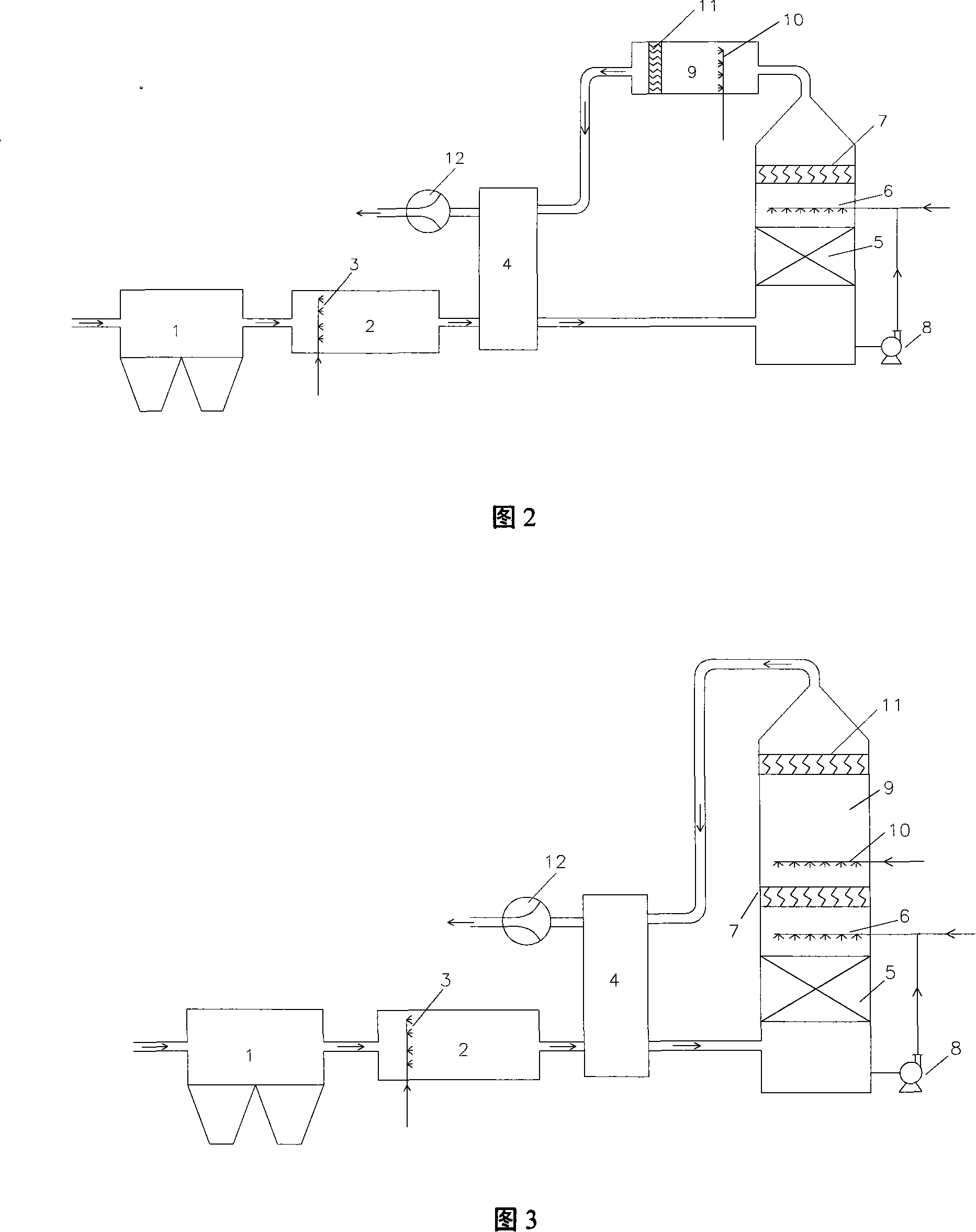

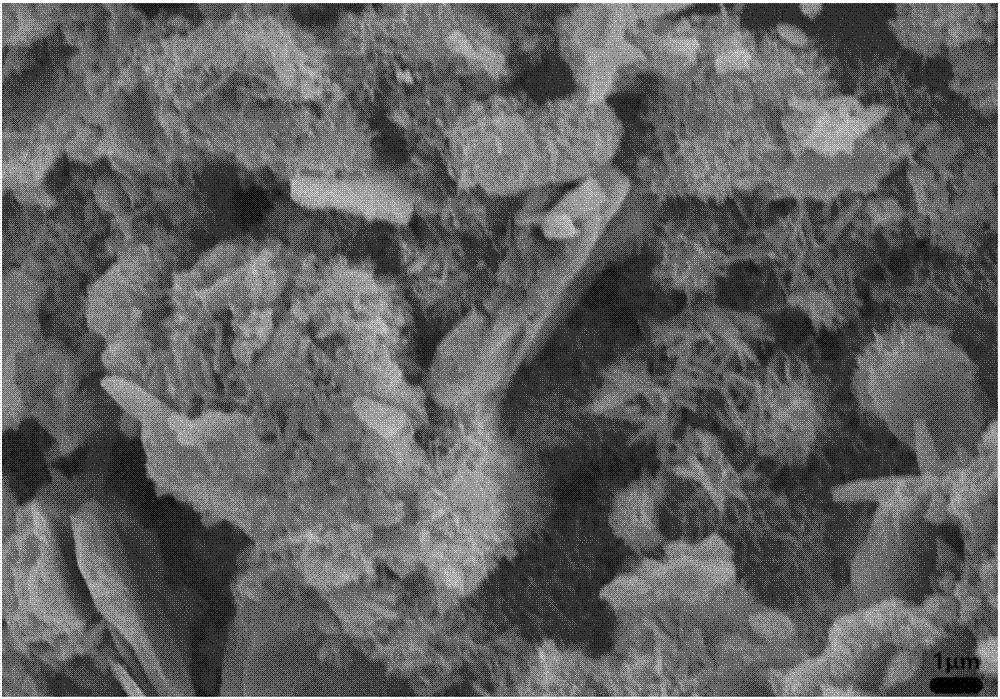

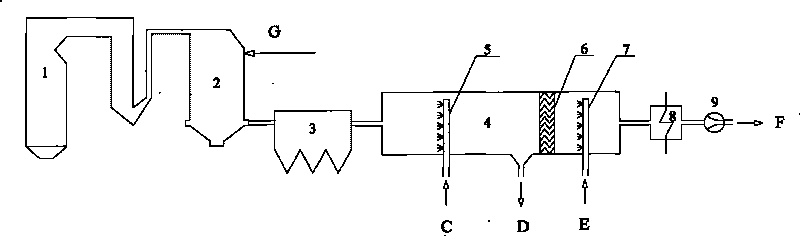

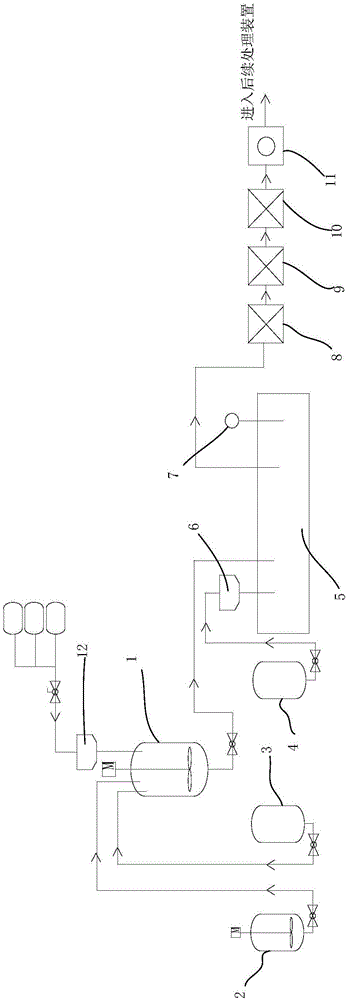

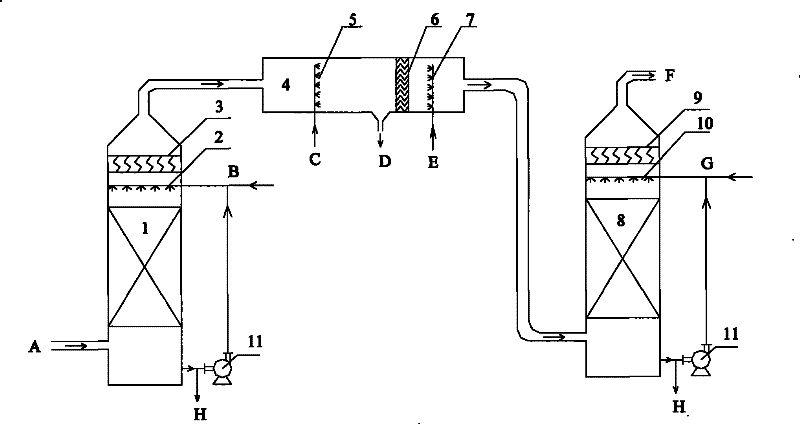

Method and device for cooperation-removal of PM2,5 in flue gas wet desulphurization

InactiveCN101219333AReduce the nucleation critical supersaturationReduce surface tensionDispersed particle separationHigh humidityFlue gas

The invention provides a method that fully utilizes the characteristics of relatively high humidity content of flue gas in the existing wet desulfurization technology and employs vapor phase change theory to effectively remove SO2 through WFGD so as to cause PM2.5 to be condensed and enlarged as well as be removed effectively and a device thereof. The invention has simple technique, and arranging a moisture regulation chamber for the flue gas and a phase change condensing chamber in the existing flue gas wet desulfurization devices can cause the wet desulfurization device to have the effect of enlarging and removing PM2.5 granules. The invention is widely used in the existing wet desulfurization devices for the flue gas generated by power plants.

Owner:SOUTHEAST UNIV

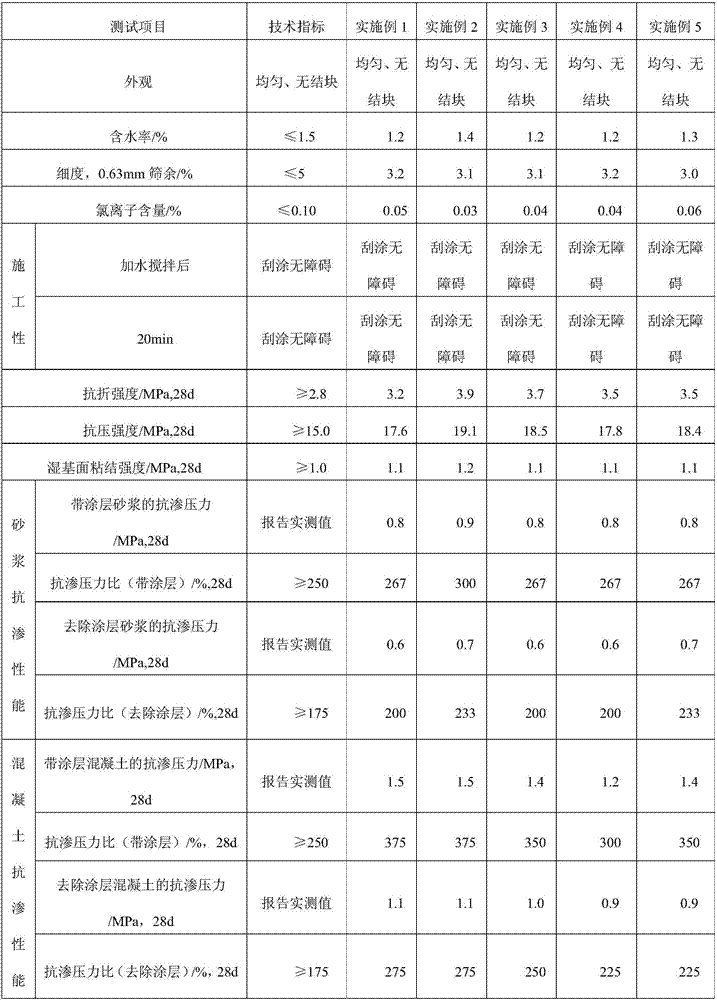

Quick-setting cement-based capillary crystalline self-repairing waterproofing material and preparation method therefor

ActiveCN106946518AAchieve waterproof effectImprove flexural and compressive capacityIon contentBULK ACTIVE INGREDIENT

The invention discloses a quick-setting cement-based capillary crystalline self-repairing waterproofing material and a preparation method therefor. The quick-setting cement-based capillary crystalline self-repairing waterproofing material is prepared from the following ingredients in parts by weight: 55-75 parts of silicate cement, 25-45 parts of quartz sand, 3-10 parts of buffering agent, 4-12 parts of active ingredient A, 4-15 parts of active ingredient B, 2-6 parts of expanding agent, 1-12 parts of calcium ion supplement and 1-4 parts of water reducing agent. The waterproofing material disclosed by the invention is prepared by a simple physical mixing method, is short in initial setting time and low in chloride ion content and can infiltrate into the interior of a cement-based material to form crystals so as to block up microcracks, thus, the folding and compressing resistance and secondary infiltrating resistance are improved, and meanwhile, the cement-based material is endowed with long-lasting self-repairing performance and good waterproof and durable performance. In addition, the preparation method for the quick-setting cement-based capillary crystalline self-repairing waterproofing material is simple, has low requirements on equipment and processes and has very high application power.

Owner:SOUTH CHINA UNIV OF TECH +1

Super early strength accelerator for portland cement concrete

InactiveCN104710128AReduce lossesMeet the requirements for patching open trafficSuperplasticizerSodium aluminate

The invention discloses a super early strength accelerator for portland cement concrete. The super early strength accelerator is prepared from the following constituents in percent by weight: 20-50% of an early strength constituent, 10-40% of quick setting constituent, and 20-45% of a water reducing constituent, wherein the early strength constituent is obtained by compounding at least two of hydramine, an organic salt and an inorganic salt; the quick setting constituent is one of sodium aluminate, aluminum sulfate and sodium silicate; the water reducing constituent is one of a polycarboxylate type high performance water reducer, a high-performance naphthalene-based superplasticizer, and a high-performance aliphatic superplasticizer. The super early strength accelerator disclosed by the invention is free of chlorine and alkali; the 16 h compressive strength of the portland cement concrete prepared by using the super early strength accelerator in a low temperature environment in winter is up to 20 MPa above, so that the portland cement concrete can meet the requirement on quick road repair, and achieves the excellent construction performance.

Owner:SOUTHEAST UNIV

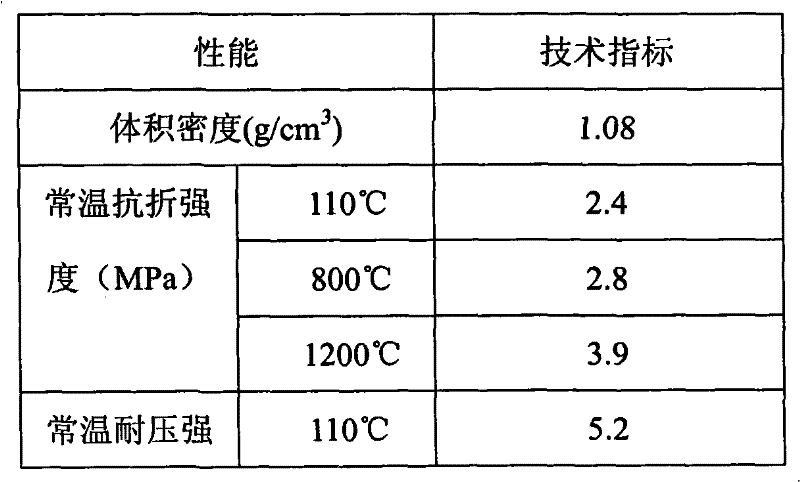

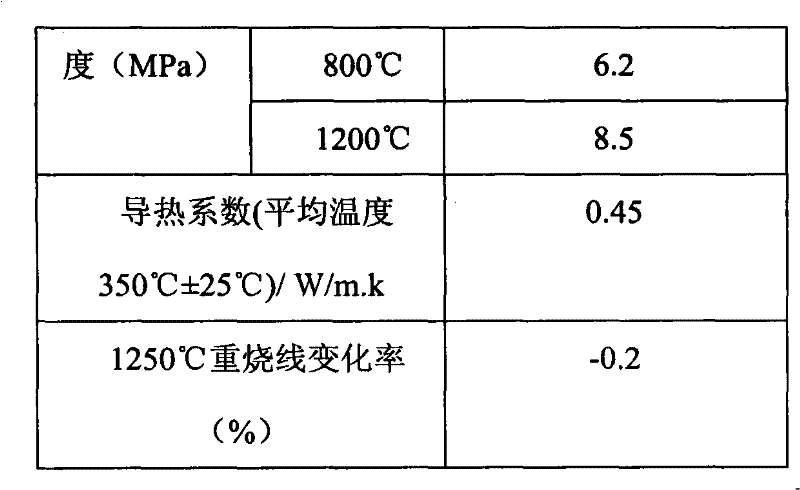

Lightweight energy-saving paint and its preparation method

The invention discloses a lightweight energy-saving paint and its preparation method. The paint provided by the invention comprises the following components of: by weight, 45-55 parts of corundum hollow spheres, 20-30 parts of a lightweight filling material, 5-10 parts of fiber, 15-20 parts of a binder and 0-5 parts of an additive. The lightweight energy-saving paint prepared in the invention has characteristics of good fluidity, high strength, low thermal conductivity, strong adhesive force, high refractoriness, good chemical stability, strong corrosion resistance and the like, can be used for the surface coating of high temperature pipelines, thermal equipment and hearth inside and outside parts to effectively inhibit heat radiation and calorific loss, and can be used for spraying and coating the internal and external surfaces of various concrete structures and steel structure buildings so as to save energy, insulate sound and prevent fire.

Owner:王立旺

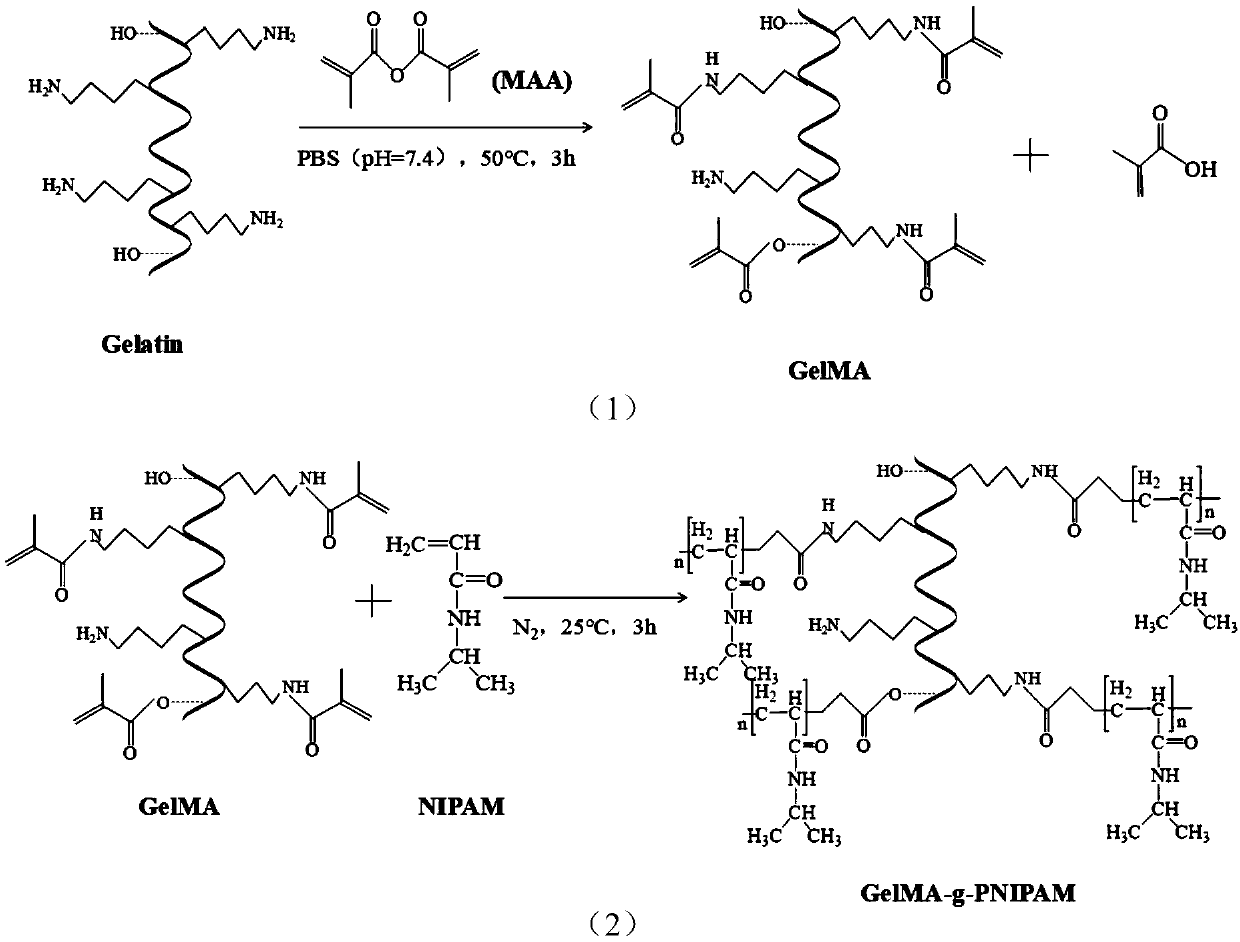

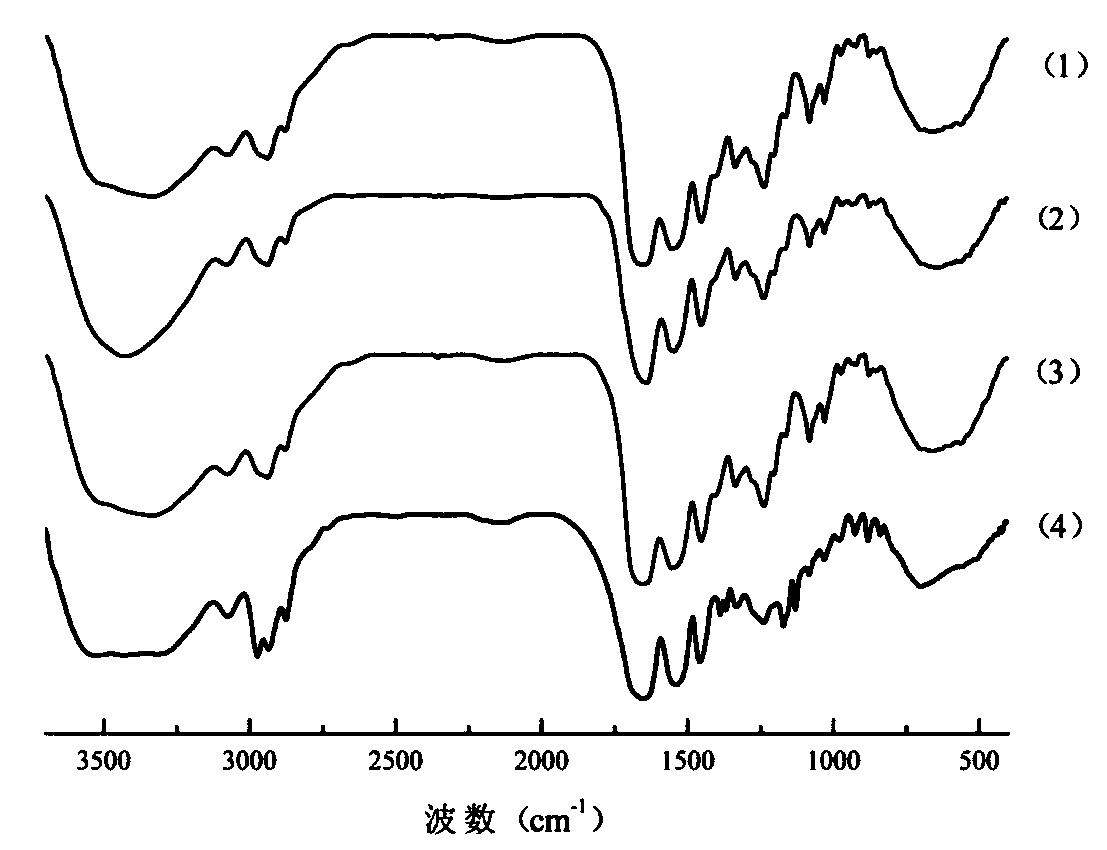

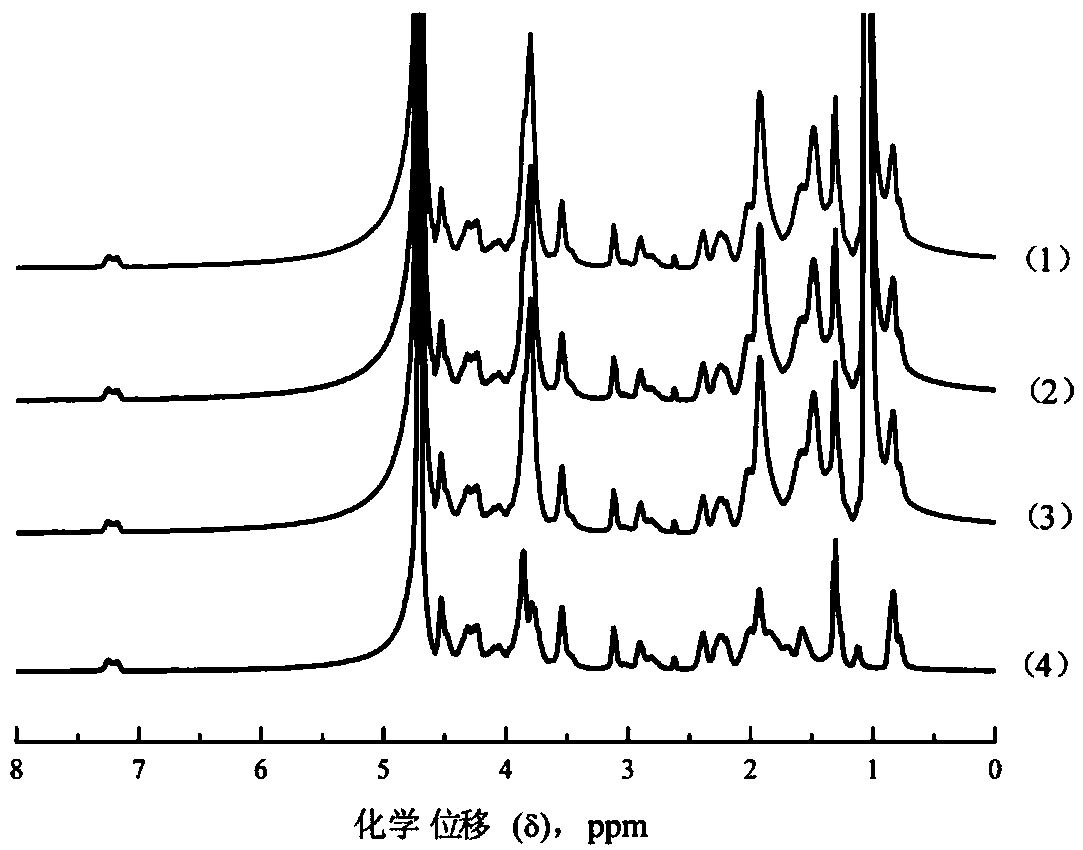

Thermosensitive hydrogel loaded with copper metal organic skeleton nanoparticles and preparation method of thermosensitive hydrogel

InactiveCN109513038AAggregation is simpleStable in naturePharmaceutical delivery mechanismBandagesMetal-organic frameworkDouble bond

The invention discloses thermosensitive hydrogel loaded with copper metal organic skeleton nanoparticles and a preparation method of the thermosensitive hydrogel. The preparation method comprises thesteps that an amino group on gelatin and methacrylic anhydride are subjected to acylation reaction to synthesize methylacrylic esterified gelatin with a branch containing a carbon-carbon double bond,the carbon-carbon double bond on the branch and N-isopropyl acrylamide are subjected to free radical polymerization, and methylacrylic esterified gelatin-g-poly N-isopropyl acrylamide is prepared; 1,3,5-benzene tricarbonic acid and copper acetate monohydrate are used for preparing copper-based MOF nanoparticles; the copper-based MOF nanoparticles are added to a methylacrylic esterified gelatin-g-poly N-isopropyl acrylamide solution, and a product is prepared. Copper ions are embedded in the biodegradable thermosensitive hydrogel in the form of HKUST-1 NPs, controlled slow release of the copperions is achieved, cytotoxicity is effectively reduced, migration of in-vitro dermal cells is promoted, angiogenesis is induced, and wound healing is promoted.

Owner:SOUTH CHINA UNIV OF TECH

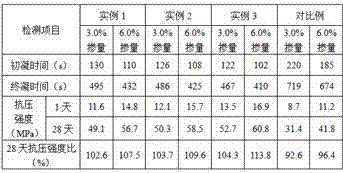

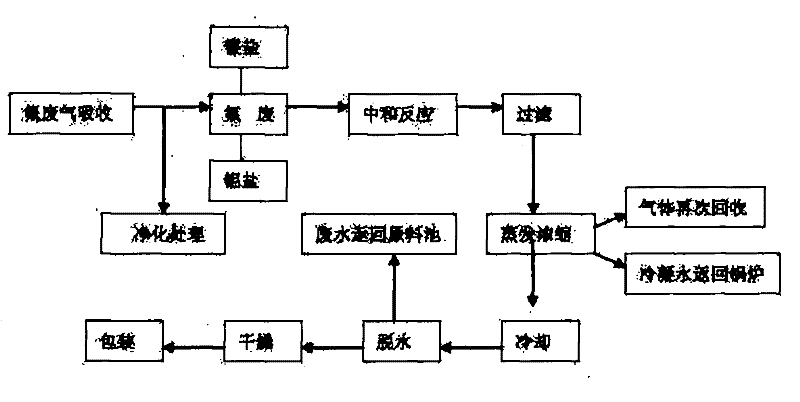

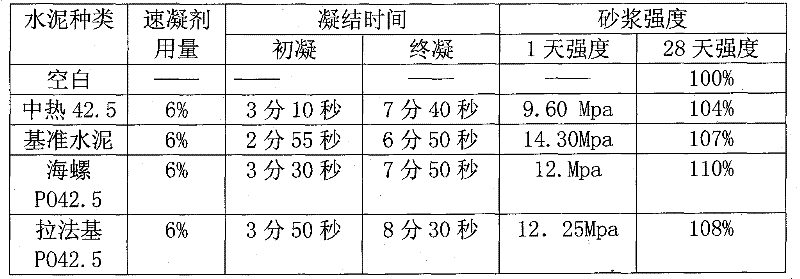

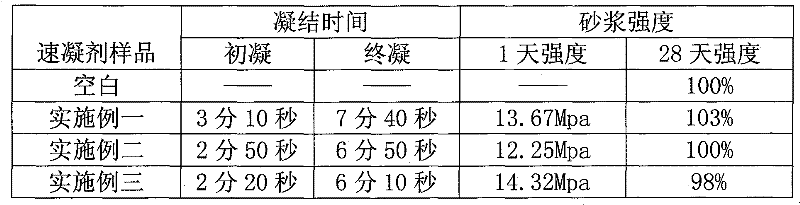

Chlorine-free and alkali-free liquid setting accelerator and preparation method thereof

The invention belongs to the technical field of preparation of additives, and in particular relates to a chlorine-free and alkali-free liquid setting accelerator and a preparation method thereof. The preparation method comprises the steps of adding aluminum sulfate and aluminum hydroxide into deionized water, and heating to obtain mother liquor of aluminate; then, adding magnesium fluosilicate and disodium ethylenediamine tetraacetate into the deionized water, and heating to obtain a magnesium fluosilicate solution; mixing the magnesium fluosilicate solution with the mother liquor of aluminate, then adding organic amine, organic acid and a stabilizer, and stirring to obtain the chlorine-free and alkali-free liquid setting accelerator. The setting accelerator prepared by the method has the characteristics of being small in mixing amount and good in setting acceleration effect; furthermore, after the setting accelerator is used, the mechanical properties of the concrete are improved, and the compressive strength of the concrete is increased; therefore, the chlorine-free and alkali-free liquid setting accelerator is an ideal concrete additive.

Owner:常州文诺纺织品有限公司

Low-shrinkage early-strength mine filling gel material for superfine iron tailings

The invention provides a low-shrinkage early-strength mine filling gel material for superfine iron tailings and belongs to the technical field of metal mine underground filling. The low-shrinkage early-strength mine filling gel material comprises, by weight, 50-90% of mineral residue powder, 5-25% of cement clinker, 1-30% of slag powder, 0-15% of gypsum, 0.5-10% of an alkaline activator, 0-10% ofan early strength agent, 0.1-10% of an anti-cracking material, and 0.5-10% of a suspending agent. Low-shrinkage early-strength mine filling slurry with effectively reduced usage of additives, good mobility and high early strength is finally acquired by: studying the functionality of mine filling gel materials, selecting mineral residue powder, cement clinker, slag powder, gypsum, the alkaline activator, the early strength agent, the anti-cracking material and the suspending agent as the mine filling gel materials, and adaptively studying their ratio. The low-shrinkage early-strength mine filling slurry has the advantages of good strength, good size stability and the like, and all the properties exceed those of a cement material.

Owner:HEBEI JINTAICHENG BUILDING MATERIAL

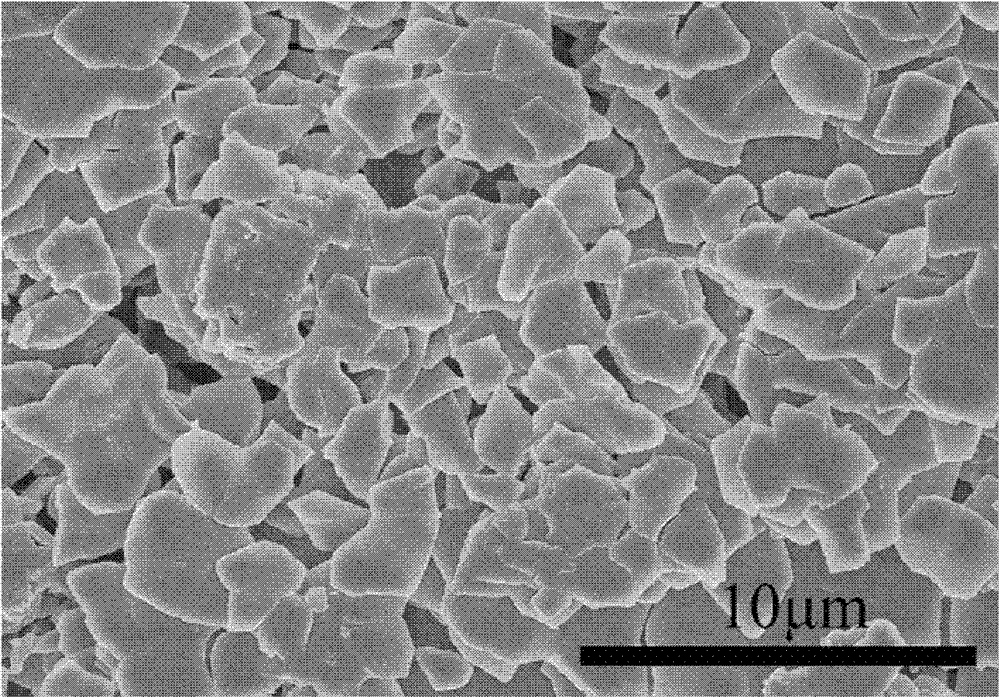

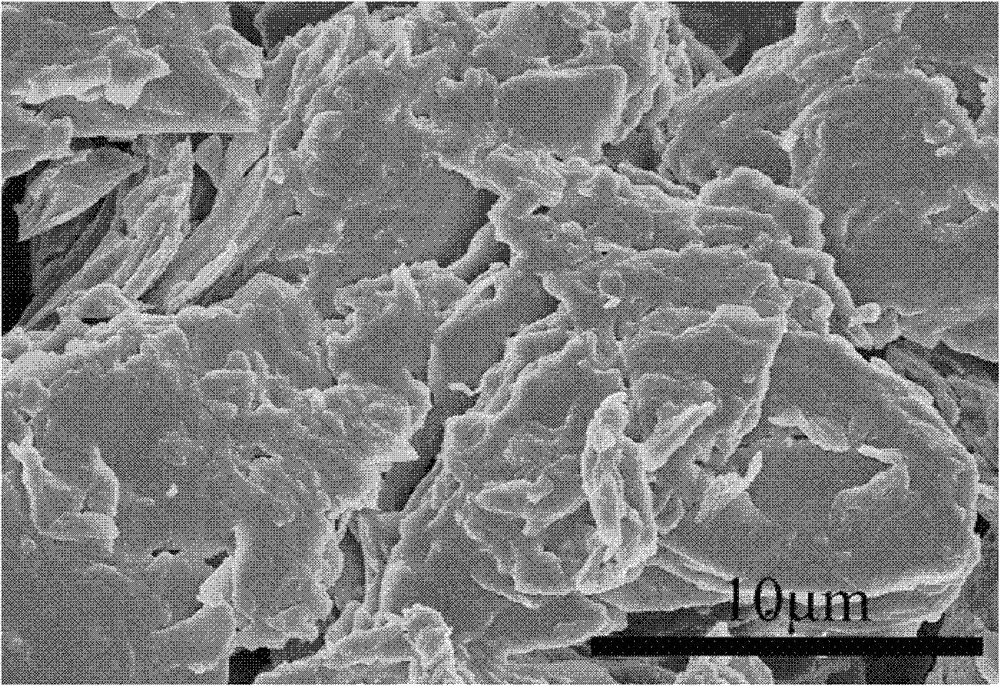

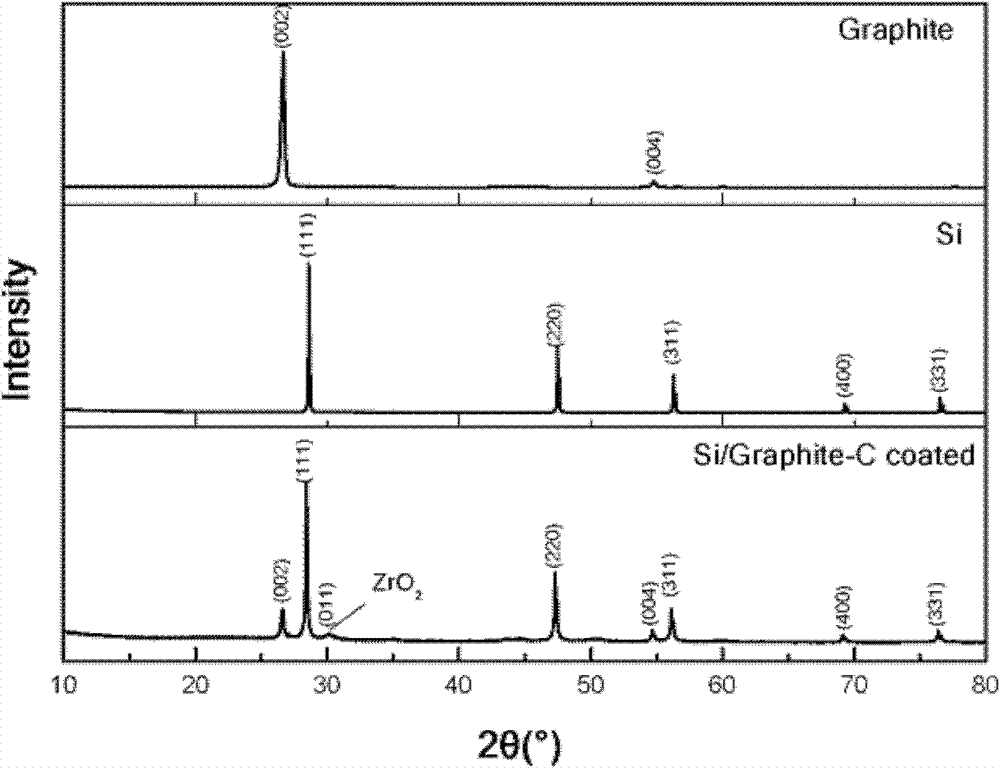

Preparation method of silicon carbon lithium ion battery cathode material

ActiveCN102790204AImprove cycle performanceIncrease capacityCell electrodesSurface oxidationFreeze-drying

The invention provides a preparation method of a silicon carbon lithium ion battery cathode material, which comprises the following steps: a) mixing a polymer solution, silicon powder and graphite to obtain a mixed solution; b) performing freeze drying of the mixed solution to obtain a solid mixture; c) sintering the solid mixture to obtain the silicon carbon lithium ion battery cathode material. The invention adopts freeze drying instead of a common drying method; the freeze drying means freezing the material, allowing the solvent component to rapidly become a solid state and to directly sublime under a vacuum condition so as to reach the drying purpose. With the process, the composite material and a carbon source can rapid coagulate within a short period, which avoids the problems of surface oxidation of the silicon material caused by normal temperature drying or high temperature drying, and non-uniform coating caused by settlement of the composite material powder. The obtained carbon-coated material has improved recycle performance and capacity when compared with materials obtained by common drying.

Owner:宁波富理电池材料科技有限公司

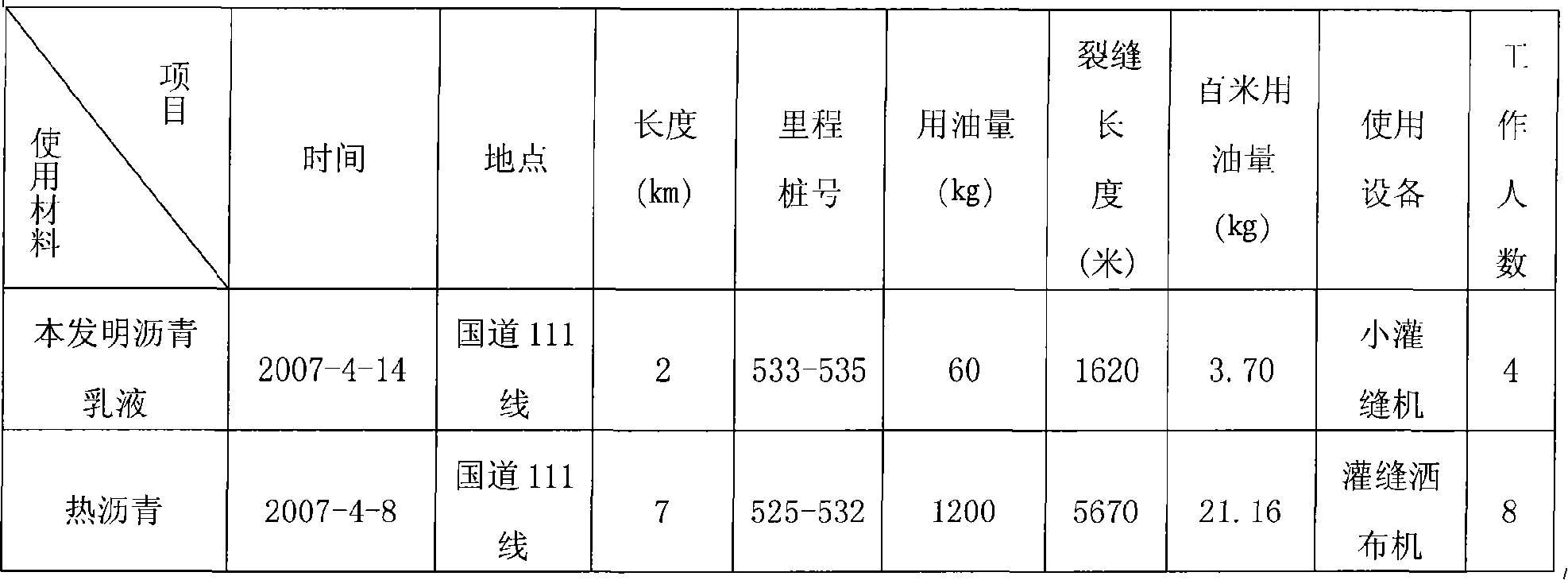

Cold crack pouring asphalt emulsion and preparation method thereof

InactiveCN101148544AGood potting effectReduce dosagePaving detailsBuilding insulationsSolventHighway maintenance

The present invention discloses one kind of cold crack pouring asphalt emulsion and its preparation process. The cold crack pouring asphalt emulsion is prepared with asphalt 50-60 weight portions, solvent oil 3-5 weight portions, vegetable oil 3-5 weight portions, anionic or cationic asphalt emulsifier 1-2 weight portions, ethylene glycol or glycerin 8-10 weight portions, and water 20-30 weight portions. The preparation process includes the following steps: 1. heating asphalt to 110-120 deg.c; 2. mixing vegetable oil and solvent oil, and adding the mixture oil into the hot asphalt through stirring; 3. adding ethylene glycol or glycerin into water through stirring and heating to 55-60 deg.c; 4. adding the asphalt emulsifier into water at 55-60 deg.c through stirring to form emulsion; and 5. mixing the emulsion and asphalt mixture. The asphalt emulsion is poured to crack in highway, and has lowered highway maintenance cost.

Owner:李文义

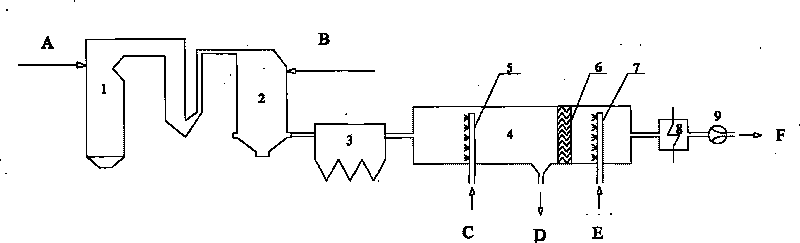

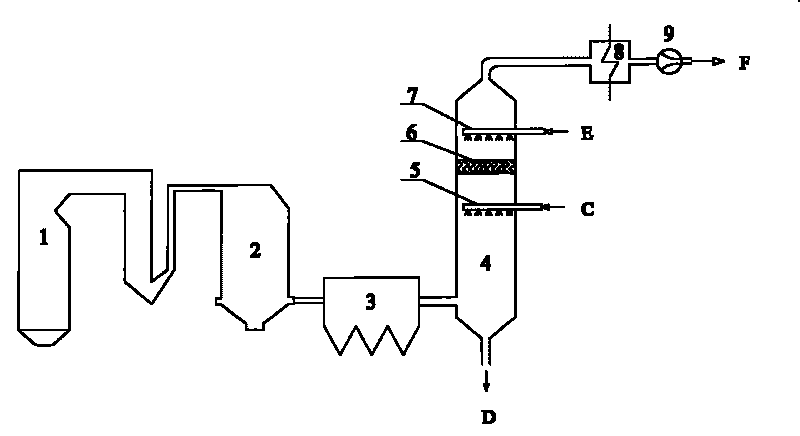

Device and method for enhancing removal of fine particle substances in flue gas desulfurization process of fire coal

InactiveCN101732977AImprove desulfurization effectIncrease relative humidityCombination devicesSurface energyCorrosion

The invention aims at the characteristic of higher relative humidity of the flue gas of fire coal after spray drying, calcium spraying in a furnace, tail humidification, activation and desulfurization are carried out on the flue gas of the fire coal and provides a device and a method which apply a vapour phase change principle to realize the effective removal of SO2, also induce the coagulation and the growth of fine particle substances and remove the fine particle substances with high efficiency. The device for enhancing the removal of the fine particle substances in a flue gas desulfurization process of the fire coal comprises a desulfurizing tower or a humidification activator, an electrostatic dust collector, a flue gas reheater and a draught fan, wherein the electrostatic dust collector, the flue gas reheater and the draught fan are sequentially connected with the desulfurizing tower or the humidification activator by pipelines, a vapour phase change chamber is provided with a rinsing waste liquid outlet, a flue gas inlet and a flue gas outlet, the flue gas inlet is connected with a flue gas outlet of the electrostatic dust collector, the flue gas outlet is connected with the flue gas reheater, a vapour nozzle, a defogger and a rinsing water nozzle are sequentially arranged between the flue gas inlet and the flue gas outlet of the vapour phase change chamber, an inside lining of the vapour phase change chamber is provided with an anticorrosion material with low surface energy, and the anticorrosion material with low surface energy has double effects of increasing the phase change effect and preventing corrosion.

Owner:SOUTHEAST UNIV

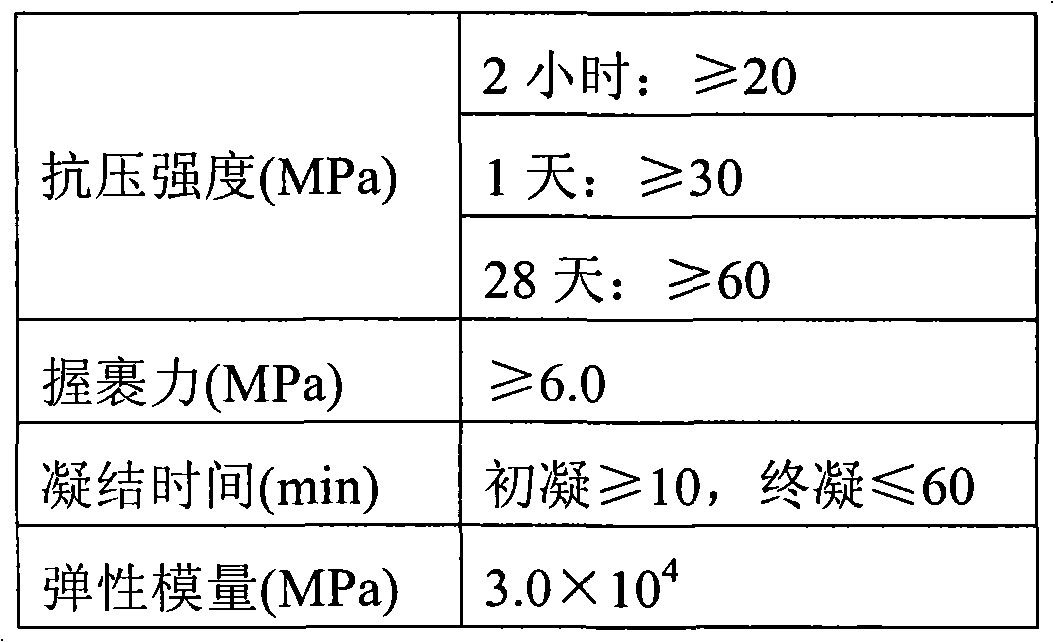

Self-flow hard grouting material and using method thereof

The invention relates to the field of silicate cement, in particular to a self-flow hard grouting material and a using method thereof. The self-flow hard grouting material consists of cement, an expanding agent, a thickening time control agent, a retarder, a water reducer, sand, an antifoaming agent and macadam, and is characterized by comprising the following components in part by mass: 0.5 to 1.5 parts of cement, 0.05 to 0.20 part of expanding agent, 0.2 to 0.3 part of thickening time control agent, 0.004 to 0.006 part of retarder, 0.01 to 0.02 part of water reducer, 0.6 to 0.7 part of sand, 0.001 to 0.002 part of antifoaming agent and 0.7 to 1 part of macadam. The self-flow hard grouting material has the advantages of high mechanical strength and high coagulation speed.

Owner:MCC5 GROUP CORP SHANGHAI

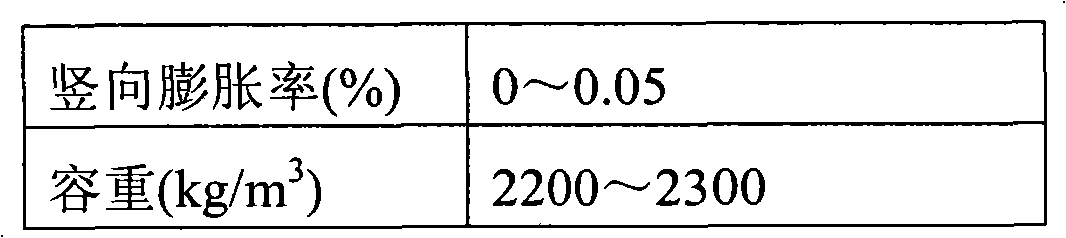

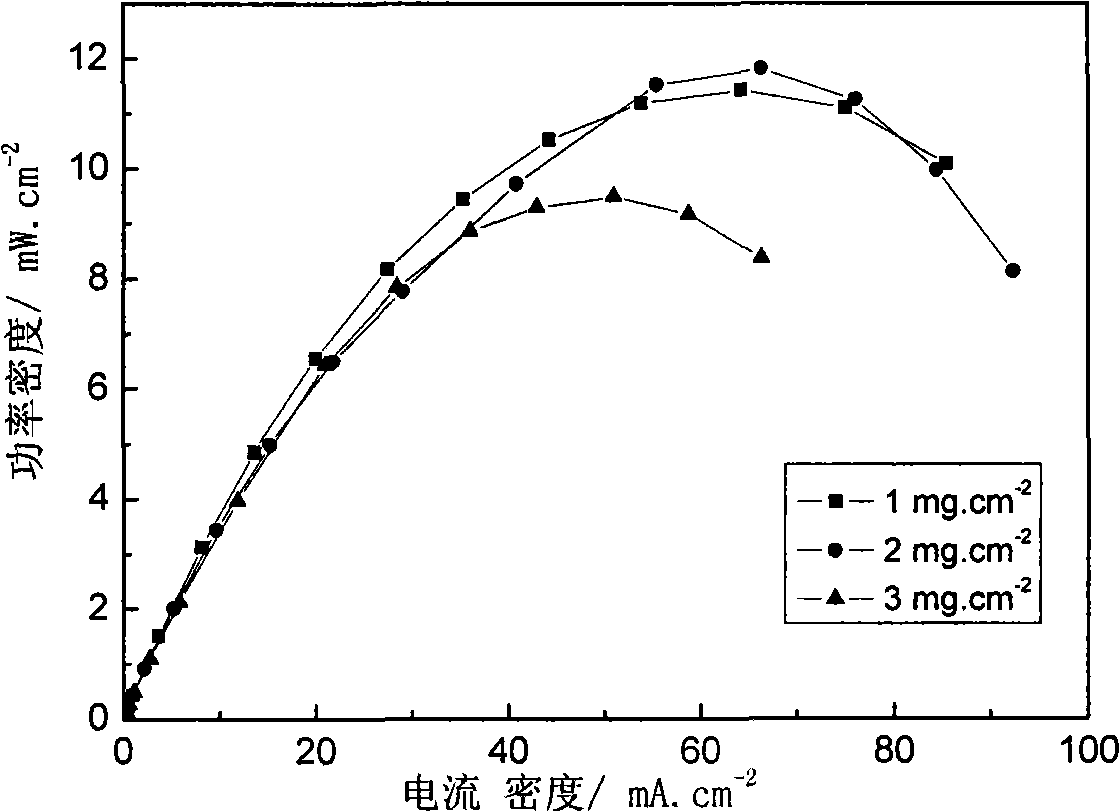

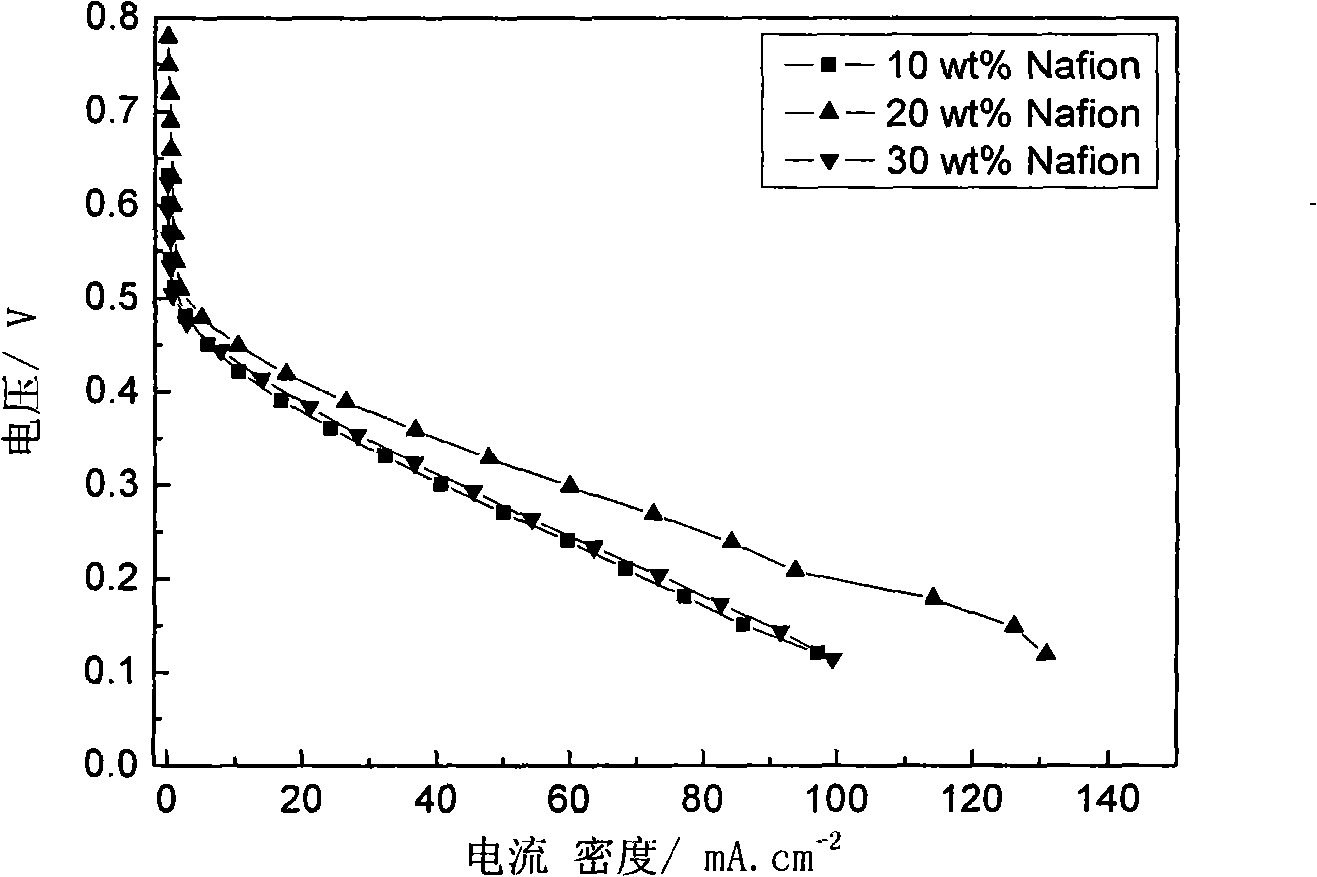

Method for preparing direct methanol fuel cell membrane electrode

InactiveCN101281971APerformance advantagesIncrease profitCell electrodesFinal product manufacturePorosityElectrolyte

The invention discloses a preparation method for a direct methanol fuel cell film electrode, which belongs to field of direct methanol fuel cell. The film electrode employs a proton exchange film as an electrolyte film, a platinum-ruthenium-carbon catalyst as an anode and a platinum-carbon catalyst as a cathode, and is composed of a supporting layer, a micro-pore layer, a catalytic layer, a proton exchange film which are arranged at the anode side and a supporting layer, a micro-pore layer, a catalytic layer which are arranged at the cathode side. The preparation method for the film electrode includes: preparation and pretreatment of the film, preparation of a catalyst paste, preparation of the catalytic layer, preparation of a micro-pore layer paste, preparation of the micro-pore layer and hot pressing process. Advantages of the preparation method are that: the micro-pore layer and the supporting layer prepared by the method have higher porosity, reduce mass transfer resistance of the film electrode, improve interface between the micro-pore layer or the catalytic layer and the supporting layer, thereby increasing three-phase contact area of catalyst and reactant and increasing output power density of the cell.

Owner:UNIV OF SCI & TECH BEIJING

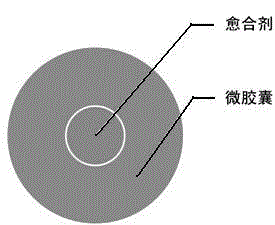

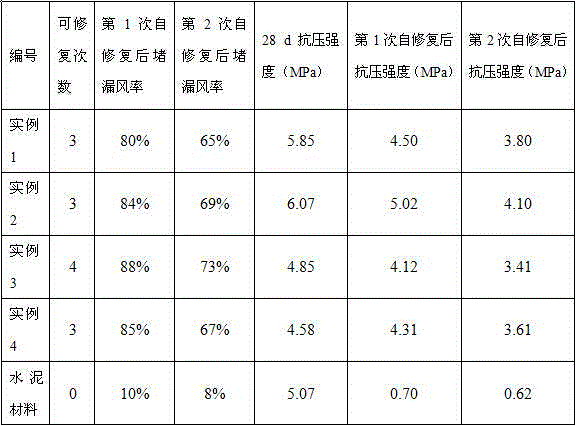

Bionic self-healing material for air leakage stoppage in coal mine

The invention relates to a bionic self-healing material for air leakage stoppage in a coal mine. The bionic self-healing material comprises a fast-setting expanding material, microcapsules containing a healing agent, and a catalyst, wherein the fast-setting expanding material comprises several of a cement clinker, coal ash, steel slag, mountain flour, salty mud, carbide slag, an expanding agent, a water reducing agent and sand, and each microcapsule is composed of a wall material (polymer resin) and a core material (the healing agent); the wall material of each microcapsule is at least one of urea resin, melamino-formaldehyde resin, melamine urea-formaldehyde resin and polyurethane, the healing agent is at least one of olefins containing double bonds, such as polyurethane prepolymer, isocyanate, phenolic resin, epoxy resin, styrene, acrylics and dicyclopentadiene (DCPD), and the catalyst is at least one of Grubbs catalyst, dibutyltin dilaurate and amines. The bionic self-healing material for air leakage stoppage in the coal mine disclosed by the invention has the advantages of being automatic in detection and healing, moderate in expansion, fast to set, good in conveying performance, strong in setting performance, green and environmentally friendly, and low in price.

Owner:胡相明

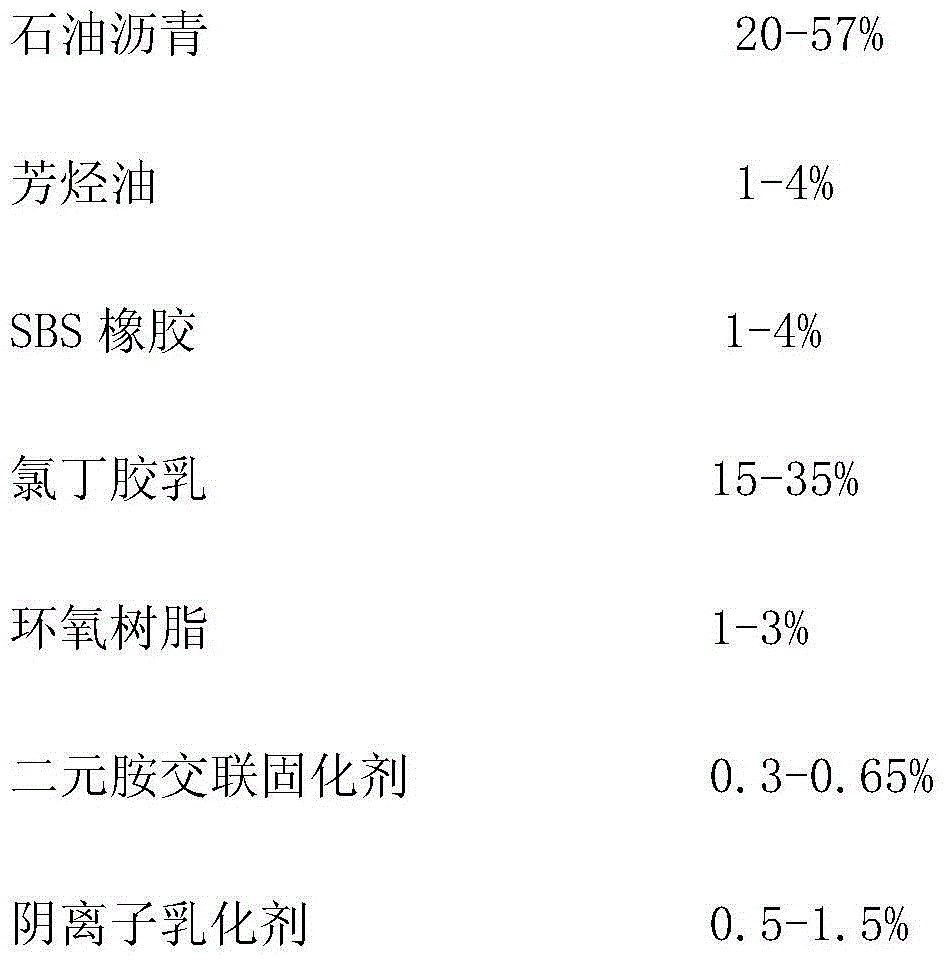

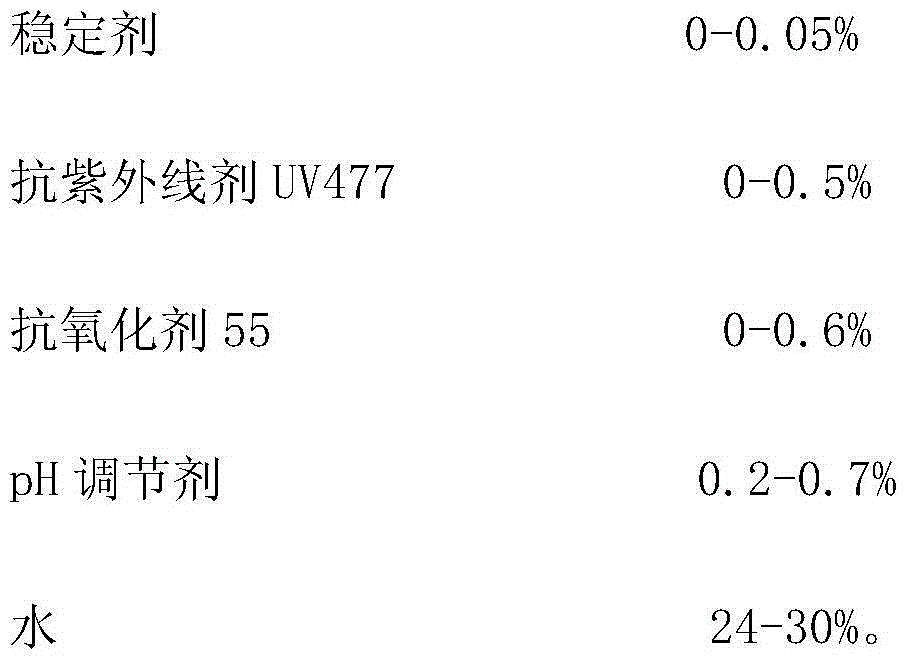

High-polymer modified water-emulsion asphalt-based waterproof paint and preparation method thereof

ActiveCN103555203ACongeal fastEasy constructionChloropene polymer coatingsEpoxy resin coatingsHigh concentrationEpoxy

The invention discloses a high-polymer modified water-emulsion asphalt-based waterproof paint and a preparation method thereof. The paint is prepared by taking high-concentration ultrafine suspension microemulsion anion modified emulsified asphalt, multiple synthetic high-molecular polymers such as cis-1,4-polybutadiene rubber, SBS rubber, epoxy resin and the like, and multiple functional agents as raw materials and mixing by employing a special production technology. When applied, the paint is subjected to mechanical spraying by employing a two-component spray gun, the demulsification coagulation is fast, and after a film is formed, the low-temperature work temperature reaches -30 DEG C and the high-temperature work temperature reaches 100 DEG C, and the elasticity recovery rate reaches 90% or more.

Owner:ZHEJIANG YUXI CORROSION CONTROL CORP

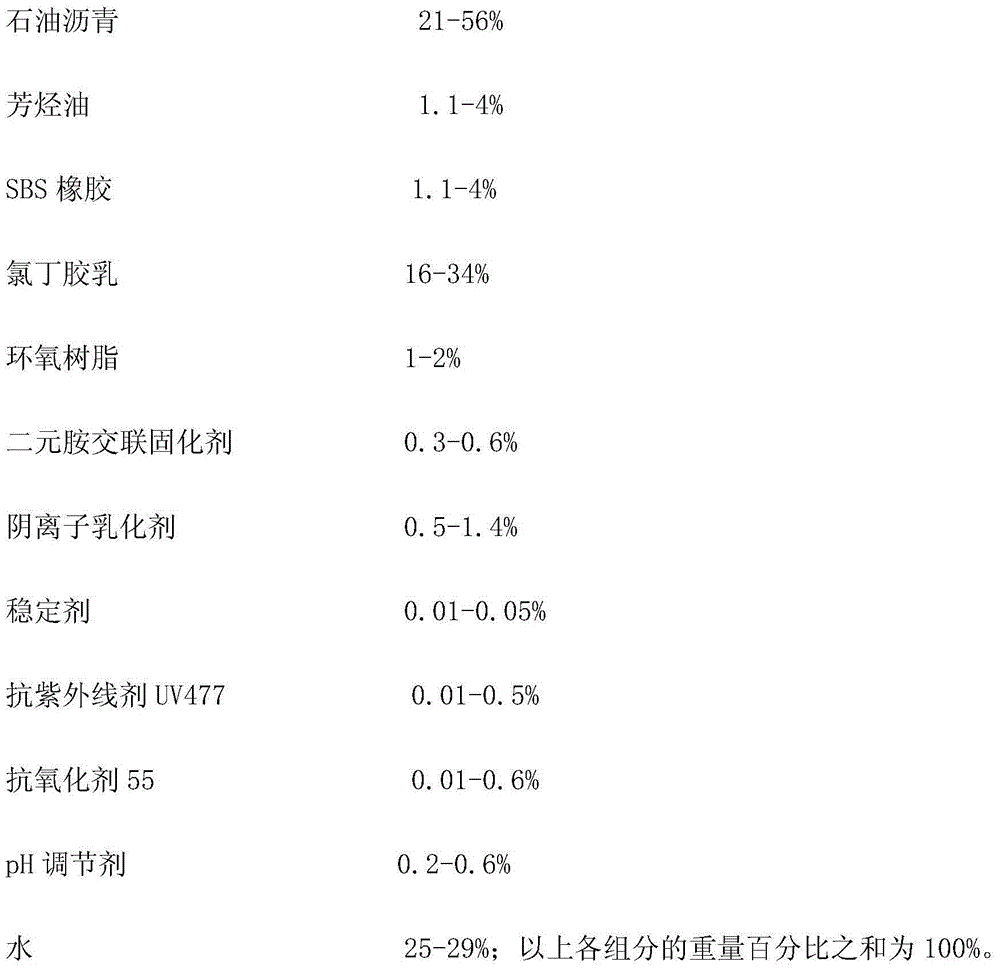

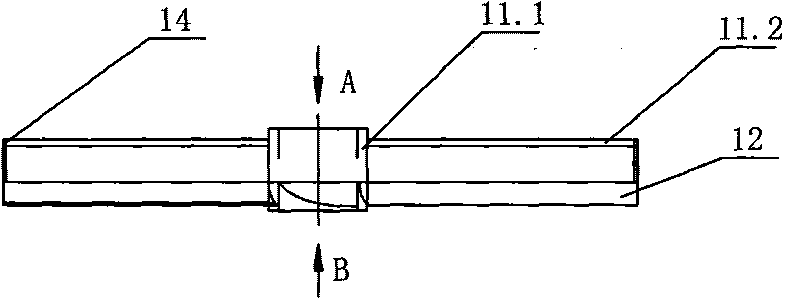

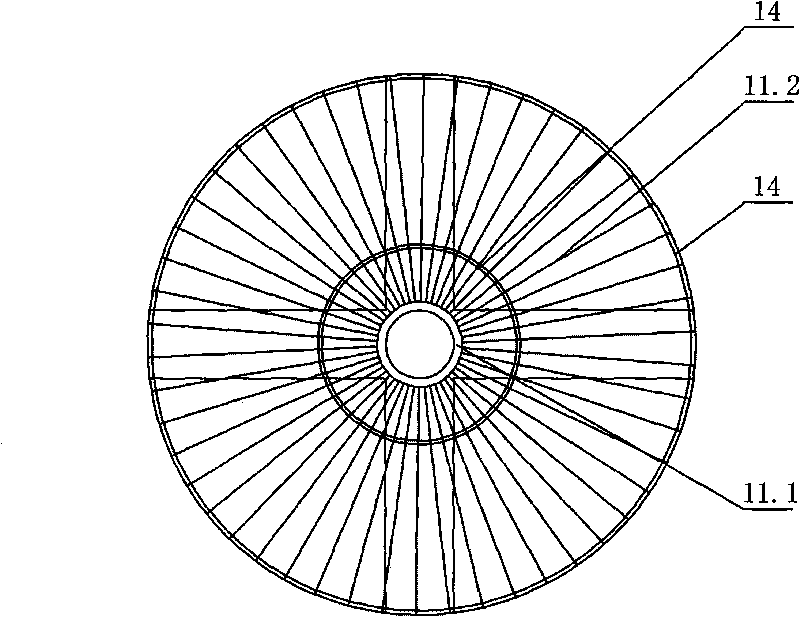

Wind speed-reducing water mist removing device

InactiveCN101693157ACongeal fastSlow down the flowDispersed particle separationIndustrial wasteAirflow

The invention relates to a wind speed-reducing water mist removing device which comprises a toggle joint and a purifying cylinder, wherein the toggle joint is connected with an air inlet pipeline, and the purifying cylinder is connected with an air outlet of the toggle joint; the purifying cylinder comprises an outer cylinder body with an air outlet, a middle cylinder body and an inner cylinder body, wherein the outer cylinder body is installed above the air outlet of the toggle joint and the middle cylinder body and the inner cylinder body are installed in the outer cylinder; multiple layers of damping disks are arranged in both an annular passage between the outer cylinder body and the middle cylinder body and an annular passage between the middle cylinder body and the inner cylinder body; multiple layers of damping disks are formed by mutually spacing at least two small damping disks and at least two big damping disks; and a drain pipe is installed at the bottom of the outer cylinder body. The invention is used for the purification processing of industrial waste gases, and the water mist and the waste gases after being mixed are rapidly discharged into the toggle joint by the air inlet pipeline through an induced draft fan; after carrying out centrifugal shunting, the water mist mixed with smoke and poisonous substances is condensed in the purifying cylinder and separated from an airflow, thus purified air is discharged; and the invention has the advantages of low cost and obvious purifying effect.

Owner:张宏生

High-performance chlorine-free alkali-free liquid accelerating agent

The invention discloses a high-performance chlorine-free alkali-free liquid accelerating agent which is prepared from the following materials by weight percent: 6 to 15 percent of magnesium aluminum fluoride, 20 to 50 percent of aluminum sulfate, 2 to 6 percent of organic amines, 0 to 2 percent of stabilizer, and the balance of water. The production process comprises the following steps of: adding water at the given weight percent to a stirring drum, adding magnesium aluminum fluoride and stirring to dissolve, adding organic amines and stirring to dissolve, adding aluminum sulfate and stirring to dissolve, and making the final product. The high-performance chlorine-free alkali-free liquid accelerating agent is free of chlorine and alkali and non-corrosive to human beings and steel-bar-made machines, and has the advantages of long holding period, low addition amount, quick setting action, low rebound rate, high one-day strength, substantially no loss of long-term strength and good material compatibility. The production process is simple, pollution-free and noise-free, does not produce gas discharge or waste water, and is safe and environment-friendly. The materials are abundant, the production cost is low, and the social and economic benefits are extremely good.

Owner:昆明合起工贸有限公司

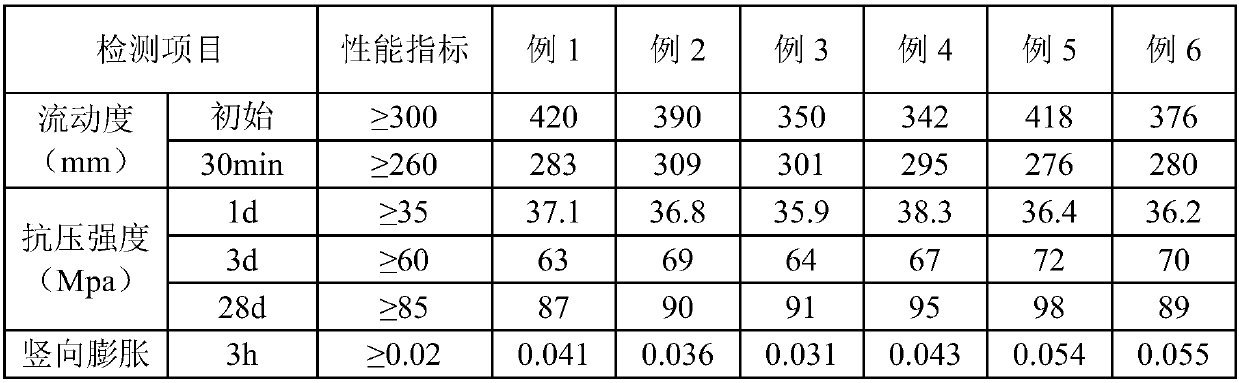

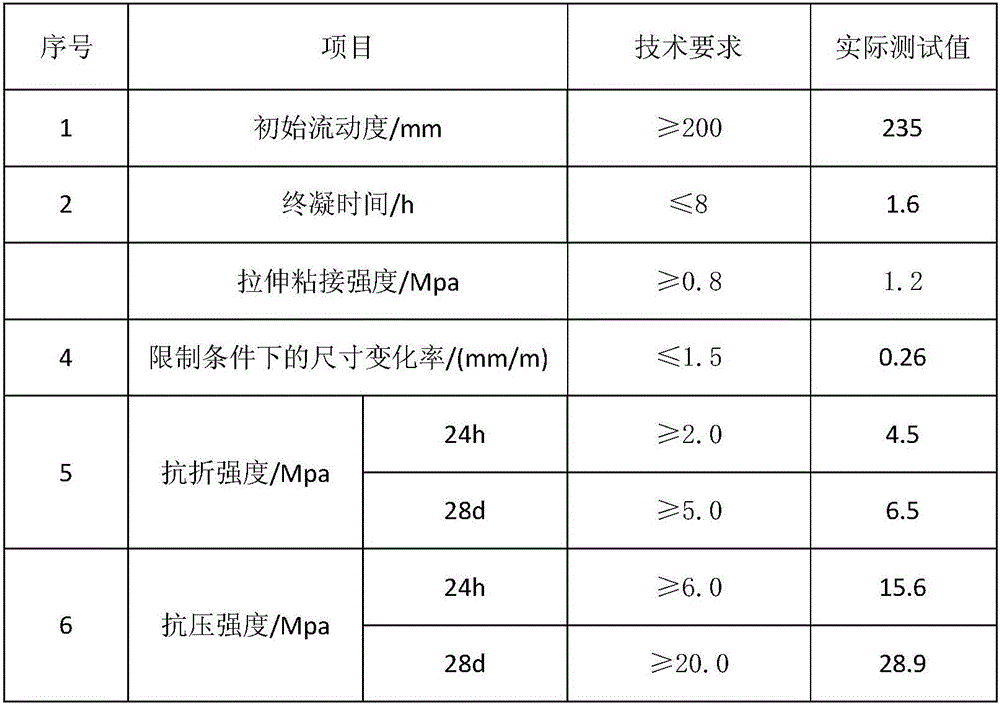

Construction connector grouting material prepared by wet grinding

The invention discloses a construction connector grouting material prepared by wet grinding. The preparation method comprises following steps: adding water into mineral slag and steel slag in a wet grinding machine, carrying out wet grinding to obtain a mixed slurry material; grinding calcium carbide residues, desulfurized gypsum, and silica fume in a dry grinding machine to obtain a mixed powderymaterial; mixing the mixed slurry material and the mixed powdery material to obtain a mixture; adding SAP, tailing sand, cement, a water reducer, an early strength agent, and water into the mixture,stirring the mixture for 2 minutes in a blending machine at a low speed at first, then stopping the blending machine for 15 seconds, and stirring the mixture for 2 minutes at a high speed then to obtain the grouting material. A large amount of wastes such as mineral slag, steel slag, calcium carbide residues, desulfurized gypsum, silica fume, and the like, is added, and the wastes are converted into valuable resources. A wet grinding technology is adopted, solid wastes namely mineral slag and steel slag are fully wet-grinded and completely activated; the grouting material is used to connect steel bar sleeves; and the water absorbing material (SAP) can fully absorb water that enters the sleeves and fix the heavy metal ions to prevent the steel bars from being corroded.

Owner:HUBEI UNIV OF TECH

Sludge consolidating agent

InactiveCN1363531AWell mixedCongeal fastSolid waste managementSolid waste disposalSpecific gravityGypsum

A sludge consolidating agent for well field and road bed, which uses waste and used sludge as basic raw material, is prepared from thioaluminate as cernent clinker, gypsum powder, slags, lime powder,powdered coal ash, calcium carbide powder and fluorspar powder through proportional mixing to obtain low-specific-weight (less than 1.65) prdouct, and proportional mixing it with efficient water-reducing agent, Na2CO3 and Na2SO4 to obtain high-specific-weight product (higher than 1.65).

Owner:大庆油田建设设计研究院

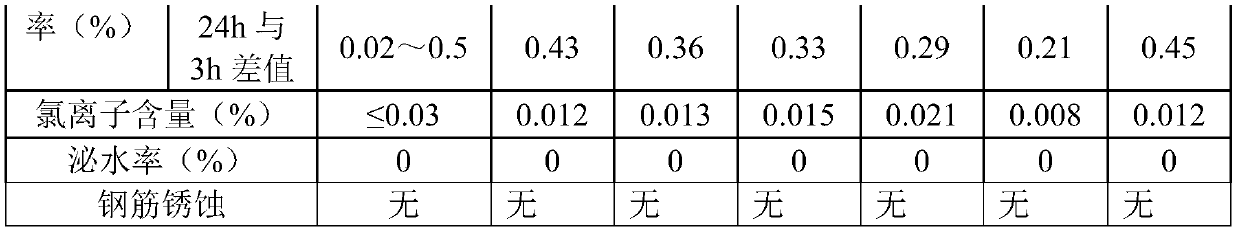

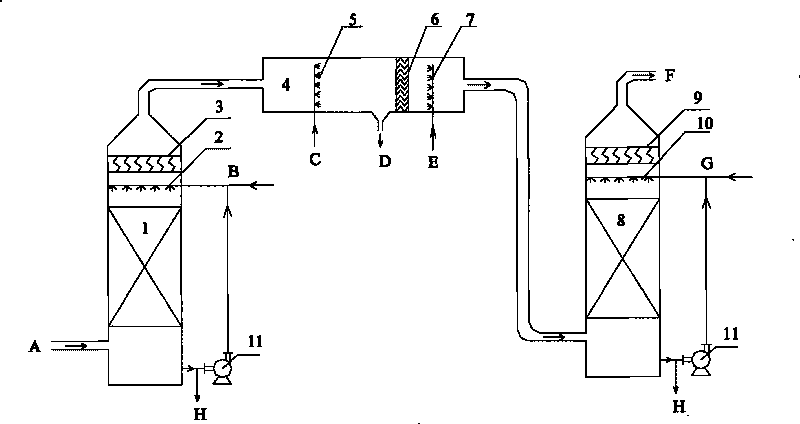

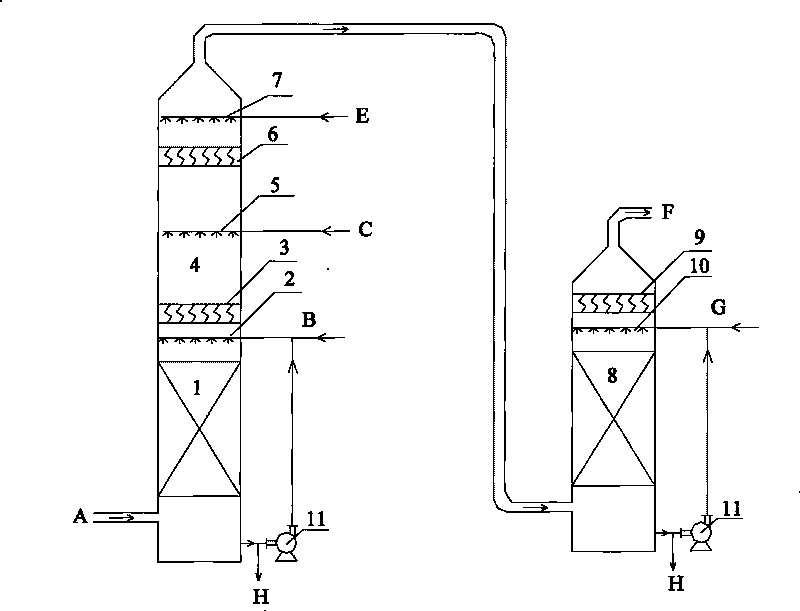

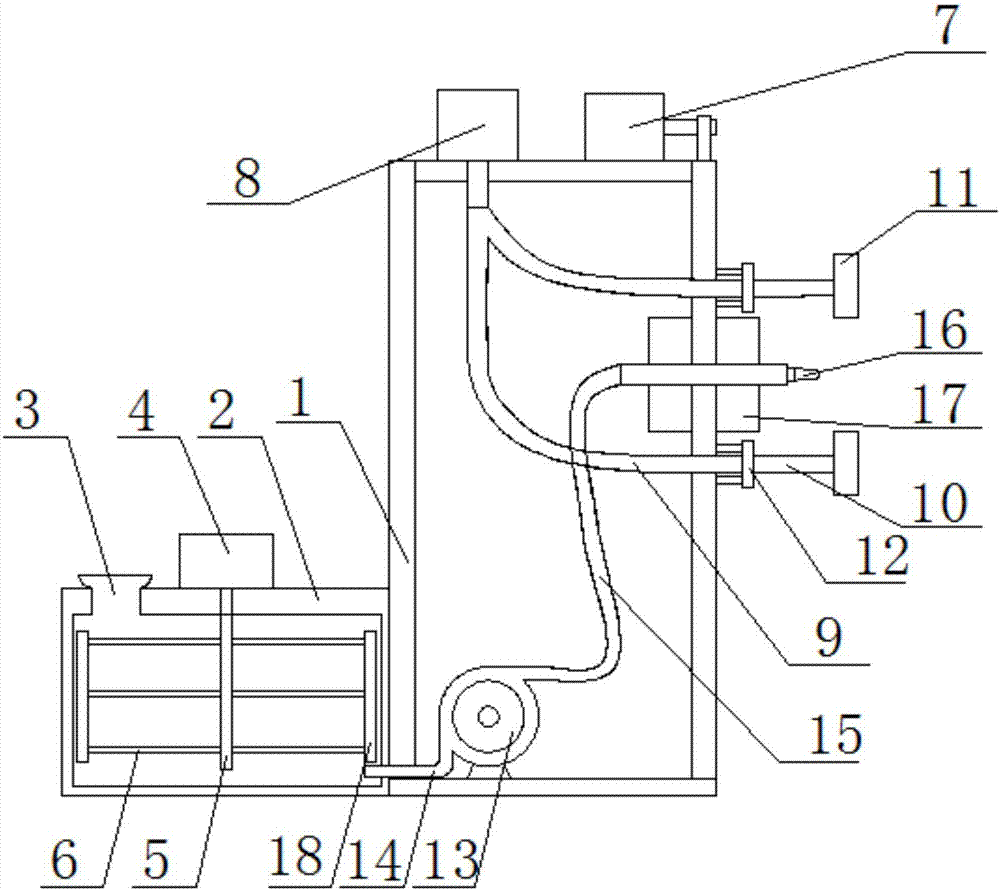

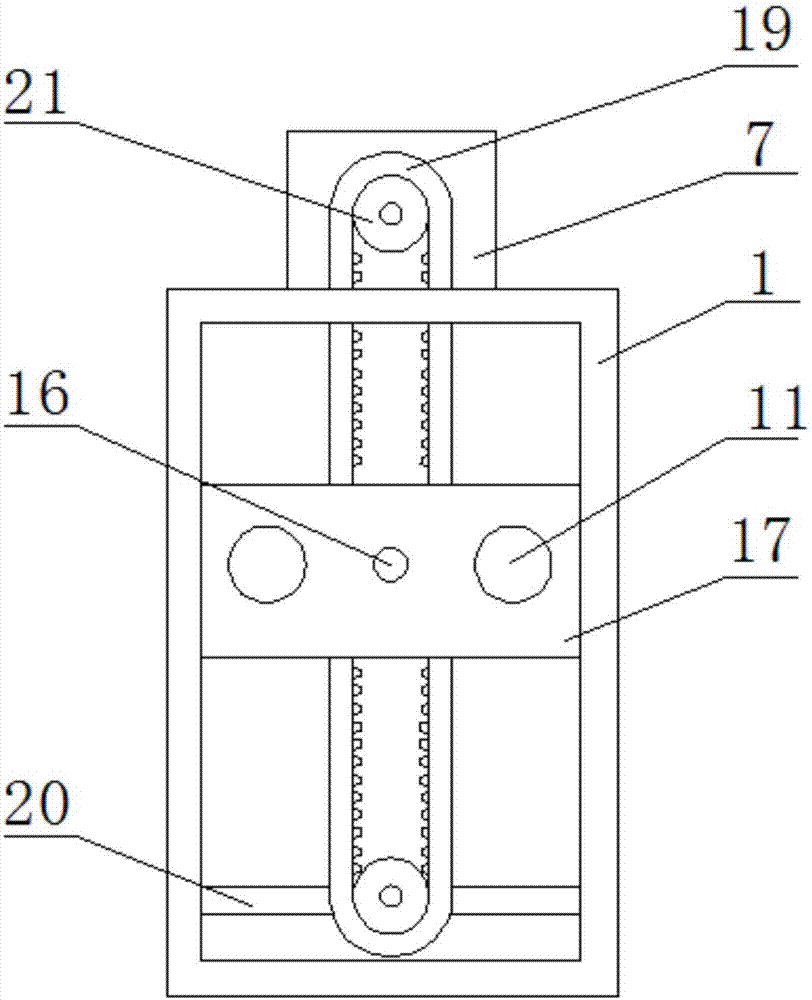

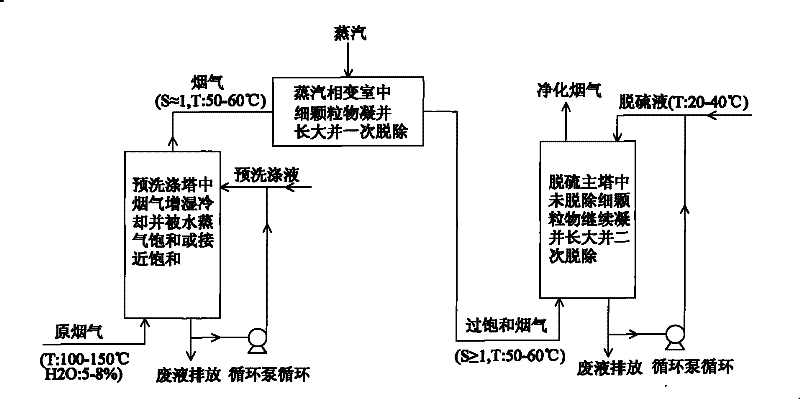

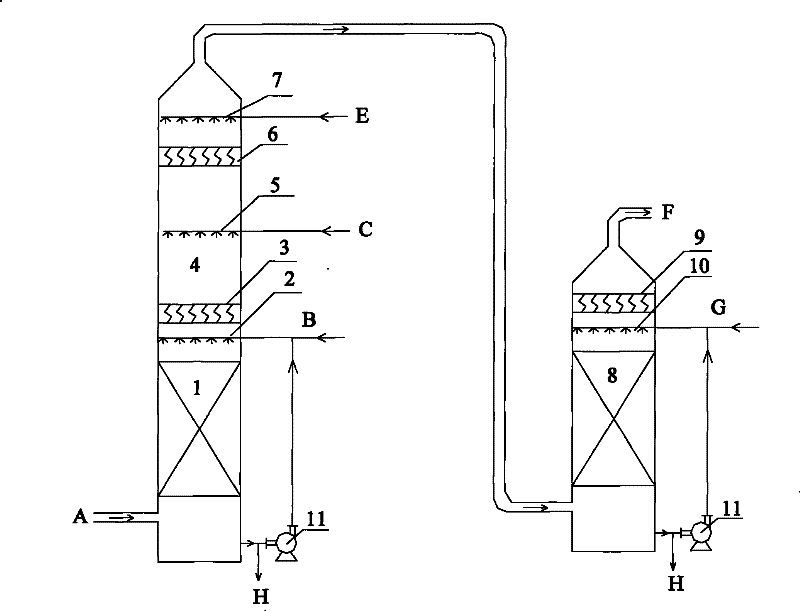

Device and method for promoting fine particle matters to be removed in coal-burning wet flue gas desulfuration process

InactiveCN101732970AReduce consumptionEfficient removalUsing liquid separation agentLiquid wasteWater vapor

The invention provides a device and a method for promoting fine particle matters to be removed by applying a steam phase-change principle, aiming at the character of high flue gas and water vapor content in a coal-burning WFGD process with a pre-washing tower. The device for promoting the fine particle matters to be removed in the coal-burning wet flue gas desulfuration process comprises the pre-washing tower, a steam phase-change chamber and a main desulfurizing tower; the steam phase-change chamber is provided with a waste liquor washing outlet, a flue gas inlet and a flue gas outlet; the flue gas inlet is connected with a flue gas outlet of the pre-washing tower; the flue gas outlet is connected with a flue gas inlet of the main desulfurizing tower; and a steam nozzle, a demister and a washing water nozzle are sequentially arranged between the flue gas inlet and the flue gas outlet of the steam phase-change chamber.

Owner:SOUTHEAST UNIV

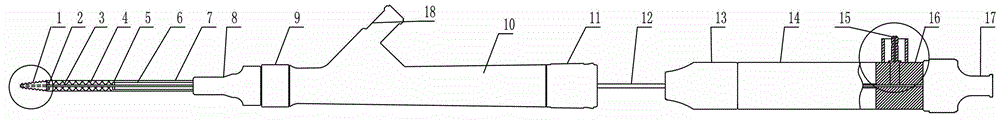

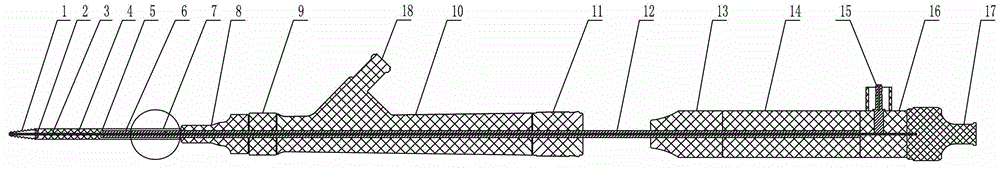

Integrated bracket embedder

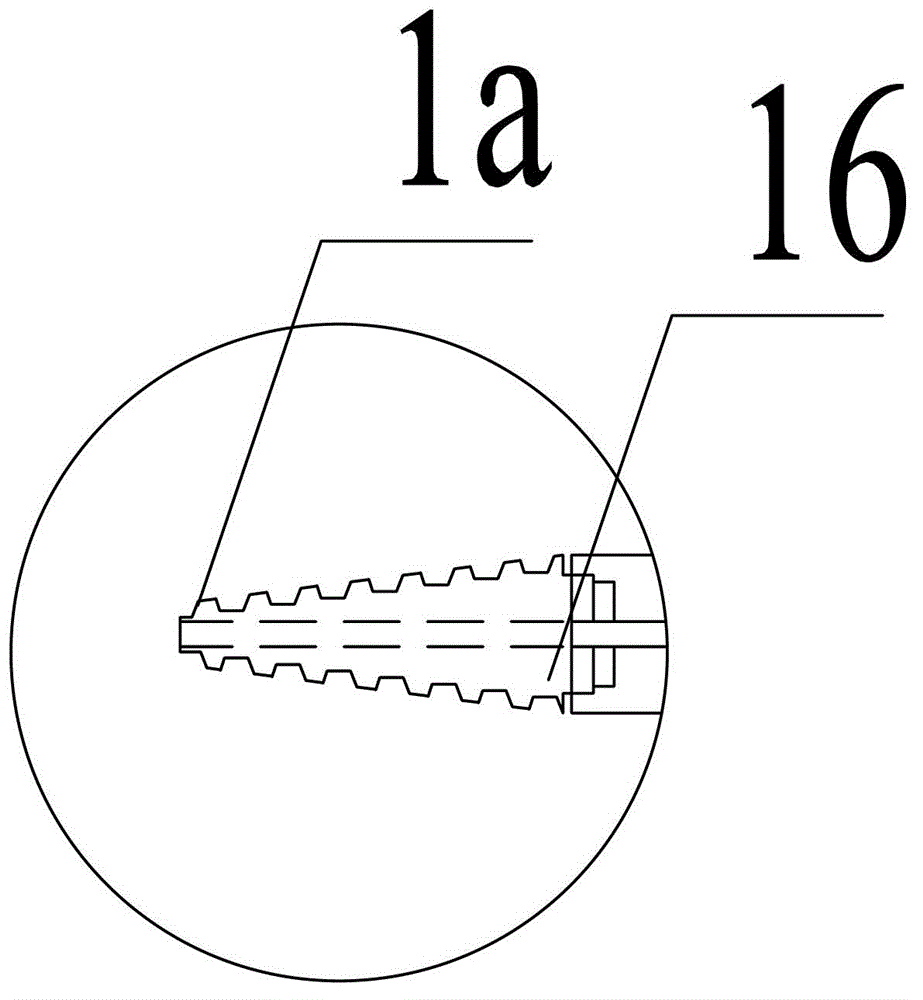

ActiveCN103142336AEasy to cutEasy to insertStentsSurgical needlesSurgical operationArchitectural engineering

The invention discloses an integrated bracket embedder, which comprises a front handle and a rear handle, wherein the front end of the front handle is provided with an outer pipe; the top end of the outer pipe is movably connected with a cutting head; a middle pipe and a bracket are arranged in the outer pipe; the rear handle comprises a stainless steel pipe for supporting and an inner pipe which is positioned in the stainless steel pipe; the top end of the inner pipe is fixedly connected with the cutting head; one end of the middle pipe is butted against one end of the bracket, and the other end of the middle pipe is mutually connected with the stainless steel pipe; one end of the bracket is close to the cutting head, and a certain gap is reserved; and when the front handle is withdrawn along the stainless steel pipe, the outer pipe is withdrawn simultaneously and is separated from the cutting head, the positions of the middle pipe and the rear handle are kept unchanged, and the bracket is automatically released. According to the integrated bracket embedder, after a focal organ is cut open, the bracket can be directly embedded, a passage for the focal organ and the exterior is established, other surgical operations such as infected matter or necrotic tissue removal can be continuously performed by using other instruments, the comprehensiveness of the surgery is increased, and a patient can be prevented from suffering from the pain of multiple surgeries.

Owner:MICRO TECH (NANJING) CO LTD +1

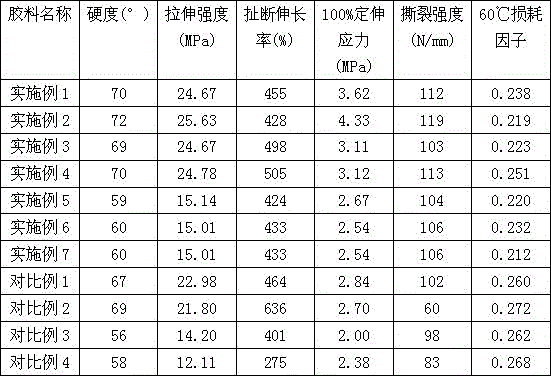

Method and production device for preparing graphene micro-plate pre-dispersion master batch

The invention relates to the technical field of technologies for processing rubber, in particular to a method and a production device for preparing graphene micro-plate pre-dispersion master batch. The method includes stirring and mixing graphene micro-plate dispersion liquid and latex with each other by the aid of a high-speed stirring machine to obtain mixed materials, adding flocculating agents into the mixed materials and coagulating the mixed materials to obtain pulp; dehydrating and drying the pulp to obtain the master batch. The method and the production device have the advantages that technologies are simple, the method and the production device are safe in operation, the graphene micro-plate pre-dispersion master batch can be continuously produced on a large scale, and the production efficiency can be improved as compared with original preparation technologies by the aid of batch processes; graphene micro-plates in the master batch prepared by the aid of the method can be highly dispersed as compared with melt processing methods; quick mixing and condensation can be implemented as compared with previous methods, drying and dehydrating phases are combined with squeezing drying and oven-drying modes, accordingly, the drying time can be shortened, rubber materials can be prevented from being aged, and the graphene micro-plate pre-dispersion master batch with excellent performance can be prepared by the aid of the method and the production device.

Owner:青岛蓝湾烯碳材料科技有限责任公司

Rapid ground leveling mortar

The invention discloses rapid ground leveling mortar. The rapid ground leveling mortar is prepared from the following raw materials in parts by weight: 200 to 350 parts of cementing material, 500 to 600 parts of aggregate, 100 to 200 parts of filler, 0.5 to 1.0 part of water reducing agent, 0.3 to 1.0 part of water retaining agent, 0 to 20 parts of latex powder, 0 to 1 part of retarder, 0 to 1 part of early strength agent and 0 to 1 part of anti-foaming agent. The rapid ground leveling mortar has a high levelling property and a high self-healing property, is free from sedimentation and bleeding, has high bonding strength with a base layer, is easy and convenient for ground construction, and can be used for realizing mechanical large-scale rapid construction; meanwhile, accurate ground leveling of 10 to 60mm in thickness can be realized, the single construction thickness is larger than 10mm, and fracturing and hollowing are avoided while the maximum single construction thickness is up to 60mm; people can tread on the ground 2 to 4 hours after construction, the strength can be up to the final strength of ordinary M15 ground mortar after 24 hours, a construction flow is realized, high construction efficiency and low labor strength are achieved, and the ground leveling construction period can be greatly shortened.

Owner:VASA MORTAR CO LTD

Isolated fireproof filling material for roof falling area of underground coal mine

The invention relates to an isolated fireproof filling material for a roof falling area of an underground coal mine. The isolated fireproof filling material is formed by uniformly mixing the following materials, by weight, 15-25% of hydrophobic expanded and vitrified small balls, 20-30% of ordinary Portland cement 42.5, 40-50% of water, 0.1-0.2% of a JW-I naphthalene retarded high range water reducing agent, 2.0-3.0% of a foaming agent aluminium powder, 3.0-4.0% of an accelerator sulphate aluminium cement, 0.3-0.6% of dispersible latex powder, 0.10-0.30% of hydroxypropyl methyl cellulose and 4-6% of red mud. The sum of weight percentage of the above ingredients is 100%. By the use of the filling material, weight of a filling body is reduced well, and the filling body has high temperature resistance and good plasticity. In addition, transport of a dry material is realized successfully, tube plugging is avoided, and the falling problem due to large weight is avoided. Meanwhile, disasters such as gas accumulation and gas spontaneous combustion and the like that easily happen in a high roof falling area can effectively be solved, and the problem that a high roof falling area is still in an unstable state and a new wider range of roof falling phenomenon might appear can be better solved.

Owner:HENAN POLYTECHNIC UNIV

Fluorgypsum-based self-leveling floor material and preparation method thereof

Disclosed is a fluorgypsum-based self-leveling floor material. The fluorgypsum-based self-leveling floor material is prepared from the following components in parts by weight: 100 parts of fluorgypsum, 15-30 parts of excitents, 5-35 parts of low-temperature phase-change energy storage and heat accumulation materials, 0.25-1 part of water reducer, 0-4 parts of latex powder, 0.02-0.12 part of stabilizer and 35-65 parts of fillers. The invention further discloses a preparation method of the fluorgypsum-based self-leveling floor material and fluorgypsum-based self-leveling floor mortar prepared from the fluorgypsum-based self-leveling floor material.

Owner:BEIJING NEW BUILDING MATERIAL

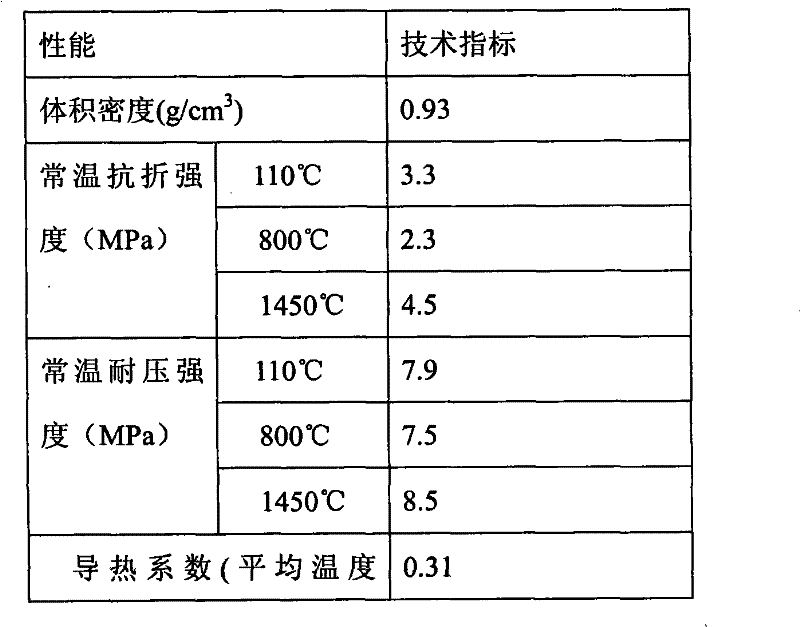

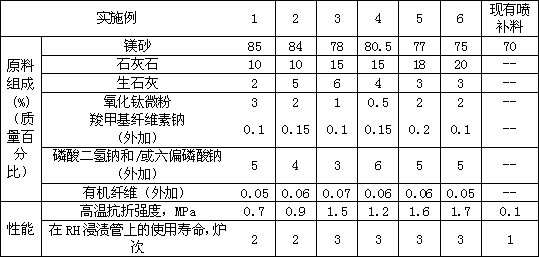

Magnesium-calcium refractory material gunning mix

The invention relates to the field of refractory materials, in particular to a gunning mix. A magnesium-calcium refractory material gunning mix comprises, by weight, the following raw materials: 75-85% of magnesia, 10-20% of limestone, 2-6% of quicklime powder and 0.5-3% of titanium oxide powder; the gunning mix also comprises binding agent, the addition amount of which is 3-6% of the main raw materials, and thickening agent, the addition amount of which is 0.1-0.2% of the main raw materials. According to the invention, calcium oxide raw materials such as calcium carbonate powder and lime powder are introduced in a large amount to react with sodium phosphate to generate Na2O. 2CaO. P2O5 (Na2Ca2P2O8) and 3CaO. P2O5 with high melting points, titanium oxide micro power is used for promoting sintering of the gunning mix under high temperature, the density and penetration resistance of the gunning mix is improved, the gunning mix has high high-temperature strength and fast coagulation performance, and the gunning mix is used in the parts easy-to-flush of a converter, an electric furnace and a RH refining furnace, has long service life, reduces the consumption of gunning mixes, can be widely used in the lining and the repair of the damaged part of the lining of the converter, the electric furnace, the RH refining furnace and other high-temperature industrial furnaces of steel-makingindustry.

Owner:BAOSHAN IRON & STEEL CO LTD

Thin-layer pavement patching mortar

The invention discloses thin-layer pavement patching mortar which is composed of a basic material and an accessory material, wherein the basic material comprises cement and quartz sand, and the accessory material comprises a water retention agent, rubber powder, a water reducing agent, a defoamer, fibers, a flocculant, coarse whiting powder and water. The thin-layer pavement patching mortar disclosed by the invention has the beneficial effects that the thin-layer pavement patching mortar provided by the invention can meet the strength needed for pavement traffic, and can be combined with pavement materials well, especially in harsh environments such as expansion caused by wet and contraction caused by dry, expansion caused by heat and contraction caused by cold, freezing and thawing cycle, and the like, and the mortar can overcome a tensile stress between the mortar and concrete due to unsynchronized construction, thereby meeting the requirements on the long-term protection of concrete pavements; the patching mortar provided by the invention has the characteristics of high early strength and stable long-term strength development, and is good in flexibility, impact resistance and abrasion resistance; in addition, the mortar has good liquidity and water retention, and can satisfy the demands of different engineering constructions, therefore, the mortar can be widely applied to the patching of concrete pavements in the fields of municipal engineering, pavements, airports, and the like.

Owner:北京宝辰联合科技股份有限公司

Wall paint spraying machine

InactiveCN107386604ACongeal fastSpray evenly and conveniently and efficientlyBuilding constructionsElectric machinerySpray nozzle

The invention discloses a wall paint spraying machine, which comprises a support frame and a mixing bucket. A stirring motor is arranged coaxially on the top surface of the mixing bucket. The output shaft of the stirring motor passes through the mixing barrel and is fixedly connected to the stirring rod, the stirring rod is fixedly connected to the stirring paddle, the top of the support frame is provided with a lifting motor, and the top of the support frame is located at the top of the lifting One side of the motor is fixed with a hot air blower. The invention sets a support frame on one side of the mixing tank and a transmission mechanism on the support frame so that the atomizing nozzle of the spraying machine can move up and down for spraying, which achieves uniform and convenient spraying. For the purpose of high efficiency, in addition, a hot air blower is installed on the support frame to dry the freshly sprayed wall surface with hot air, so that the wet paint on the wall surface will condense quickly, and the dust on the instant noodles will condense with the paint on the wall surface, making the wall surface dry. The surface is beautiful and the spraying quality is effectively improved.

Owner:WUXI SPECIAL EDUCATION SCHOOL

Inorganic early-strength and quick-setting material

The invention discloses an inorganic early-strength and quick-setting material, which is characterized in that the inorganic early-strength and quick-setting material is mainly prepared from magnesium oxide, sodium hydroxide, magnesium dihydrogen phosphate, aluminum dihydrogen phosphate, retarder, short fiber, filling material and water according to a certain weight proportion; and the inorganic early-strength and quick-setting material can be formed by direct casting or mould casting, or be prepared into various products by extrusion forming. The material disclosed by the invention is simple and convenient to operate, excellent in physical performance, good in density, leakage-resistant, acid and alkali corrosion-resistance, low in manufacturing cost, and environment-friendly in material and preparation process, wide in application range, wide in application prospect and the like. The material is simple and convenient in preparationand forming process and low in cost, and is not only suitable for the small-scale manual manufacturing but applicable to the large-scale industrial production. The material is suitable for preparing the artist decoration, the section bar, the tank body, the framework, the board and the civil construction engineering, and is capable of replacing the silicate cement, the glass fiber-reinforced plastic, the ceramic, the plastic, the metal, the wood material and other materials on many aspects.

Owner:郭静萍 +1

Device and method for promoting fine particle matters to be removed in coal-burning wet flue gas desulfuration process

InactiveCN101732970BReduce consumptionEfficient removalUsing liquid separation agentLiquid wasteFlue gas

The invention provides a device and a method for promoting fine particle matters to be removed by applying a steam phase-change principle, aiming at the character of high flue gas and water vapor content in a coal-burning WFGD process with a pre-washing tower. The device for promoting the fine particle matters to be removed in the coal-burning wet flue gas desulfuration process comprises the pre-washing tower, a steam phase-change chamber and a main desulfurizing tower; the steam phase-change chamber is provided with a waste liquor washing outlet, a flue gas inlet and a flue gas outlet; the flue gas inlet is connected with a flue gas outlet of the pre-washing tower; the flue gas outlet is connected with a flue gas inlet of the main desulfurizing tower; and a steam nozzle, a demister and awashing water nozzle are sequentially arranged between the flue gas inlet and the flue gas outlet of the steam phase-change chamber.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com