Device and method for enhancing removal of fine particle substances in flue gas desulfurization process of fire coal

A technology of fine particles and desulfurization process, which is applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve the problems of fine particles discharged into the atmosphere and low capture efficiency, and achieve enhanced phase change effect, simple process, The effect of increasing relative humidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

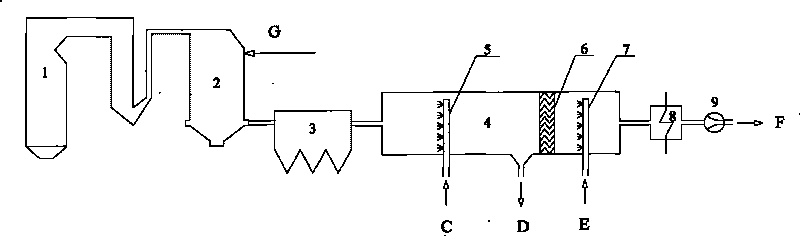

[0017] In the coal-fired spray drying flue gas desulfurization process of the present invention, the method of using steam phase change to improve the removal of fine particles is as follows: figure 1 Shown: the dust-laden flue gas produced by the coal-fired boiler 1 first enters the desulfurization reaction tower 2, and is sprayed with lime slurry. After the atomized lime slurry contacts the high-temperature flue gas, the water in the slurry begins to evaporate, and the flue gas cools down and humidifies. The smoke temperature drops from 140-160°C to 50-65°C, the relative humidity increases from 5-8% to over 50-60%, and the near-adiabatic saturation temperature is 5-15°C. After the desulfurization and purification flue gas is removed from the coarse particles by the electrostatic precipitator 3, it enters the steam phase change chamber 4, and an appropriate amount of saturated steam at normal pressure is injected through the steam nozzle 5 to make the flue gas reach a supersat...

Embodiment 2

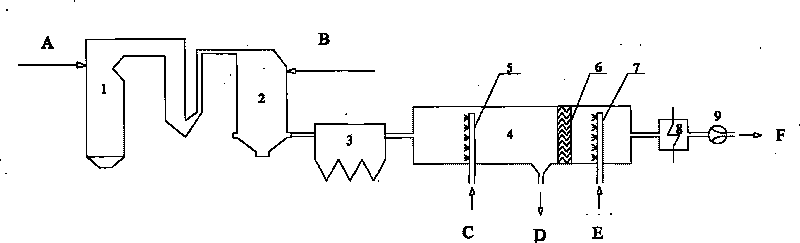

[0020]The method of applying steam phase change to improve the removal of fine particles in the tail humidification activation flue gas desulfurization process of the coal-fired furnace of the present invention is as follows: figure 2 As shown, the difference from Example 1 is that limestone powder is sprayed into the coal-fired boiler furnace 1, and the flue gas enters the humidification activator 2 after the first step of desulfurization, and is sprayed with atomized water, which evaporates rapidly and the smoke The temperature of the gas decreases and the humidity increases. The flue gas temperature at the outlet of the activator is 55-60° C., and the relative humidity increases from 5-8% to more than 50-60%; the rest are the same as in Example 1.

Embodiment 3

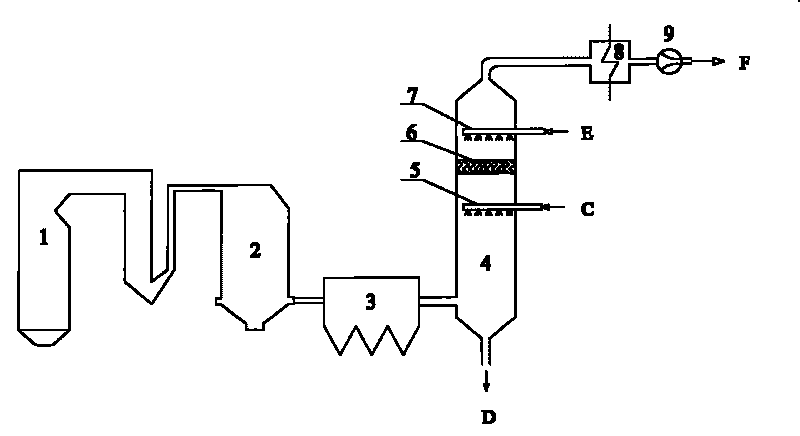

[0022] Such as image 3 As shown, the difference from Examples 1 and 2 is that the steam phase change chamber is arranged vertically, the flue gas from the electrostatic precipitator 3 enters from the lower part of the steam phase change chamber 4, and steam is injected from the upper part of the phase change chamber through the steam nozzle 5 , contact with the flue gas in countercurrent, and the fine particles trapped by the mist eliminator 6 are discharged through the flushing waste liquid outlet located at the bottom of the steam phase change chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com