Patents

Literature

371results about How to "Improve desulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fluorinated and phosphor-contained hydrogenation catalyst with silicon oxide-alumina as carrier and its production

ActiveCN1853780AHigh activityImprove desulfurizationPhysical/chemical process catalystsRefining to eliminate hetero atomsNickel oxidesChemistry

An F and P contained hydrocatalyst with silicon oxide-aluminum oxide as its carrier contains nickel oxide (1-10 Wt%), molybdenum oxide and tungsten oxide (10-50), F (1-10) , phosphorus oxide (0.5-8) and carrier (rest). It has high hydrorefining performance. It is prepared by introducing F, P, Mo, Ni and W to carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation modifying catalyst for poor ignition quality fuel and its preparing process

ActiveCN101463271AIncrease cetane numberImprove desulfurizationHydrocarbon oils refiningMolecular sieveSilicon oxide

The invention discloses a hydro-upgrading catalyst for inferior diesel and a preparation method thereof. The preparation method comprises the steps of: mixing, forming and roasting silicon oxide-alumina, alumina and / or a precursor of the alumina and Y-shaped molecular sieve, then introducing an effective dose of metallic components selected from at least one Group VII and at least one Group VI into the roasted forming composition; the preparation method is characterized in that the silicon oxide-alumina is selected from at least two the silicon oxide-alumina having different N values, the difference between the N values of the silicon oxide-alumina is 0.02-0.2. Compared with the prior art, the catalyst provided by the invention method has better upgrading performance for the inferior diesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ultrafine lead oxide prepared by using waste lead plaster and preparation method thereof

InactiveCN103374657AReduce energy consumptionSimple ingredientsReclaiming serviceable partsLead oxidesFiltrationTwo step

The invention discloses an ultrafine lead oxide prepared by using a waste lead plaster and a preparation method thereof. The preparation method comprises the following steps of: carrying out desulphurization process by mixing the waste lead plaster with an aqueous solution containing a composite desulfurizer for reaction; carrying out filtration to remove the desulphurization filtering solution to obtain the desulfurated lead plaster (filter residue); carrying out a leaching and crystal transformation process by adding a citric acid solution and a reducing agent into the desulfurated lead plaster obtained in the process, and carrying out filtration, washing, and drying to obtain the lead citrate after the desulfurated lead plaster reacts with the citric acid solution; carrying out a roasting process by roasting the lead citrate to obtain the ultrafine lead oxide. According to the preparation method disclosed by the invention, the ultrafine lead oxide is prepared from the waste lead storage lead plaster; a two-step leaching process is adopted; the filtering solution is simple in ingredient and can be recycled; a side product is recycled from the desulphurization solution. The preparation method disclosed by the invention is low in energy consumption, simple in equipment, high in lead recycling rate, and high in ultrafine lead product quality, and has the characteristics of good resource recycling effect, environmentally-friendly and pollution-free production process, and capability of clean production.

Owner:湖北金洋冶金股份有限公司 +1

Hydrogenation catalyst with silicon oxide-alumina as carrier and its preparation

ActiveCN1840618AHigh activityImprove hydrogenation activityRefining to eliminate hetero atomsSilicon oxideHydrocarbon

Owner:CHINA PETROLEUM & CHEM CORP +1

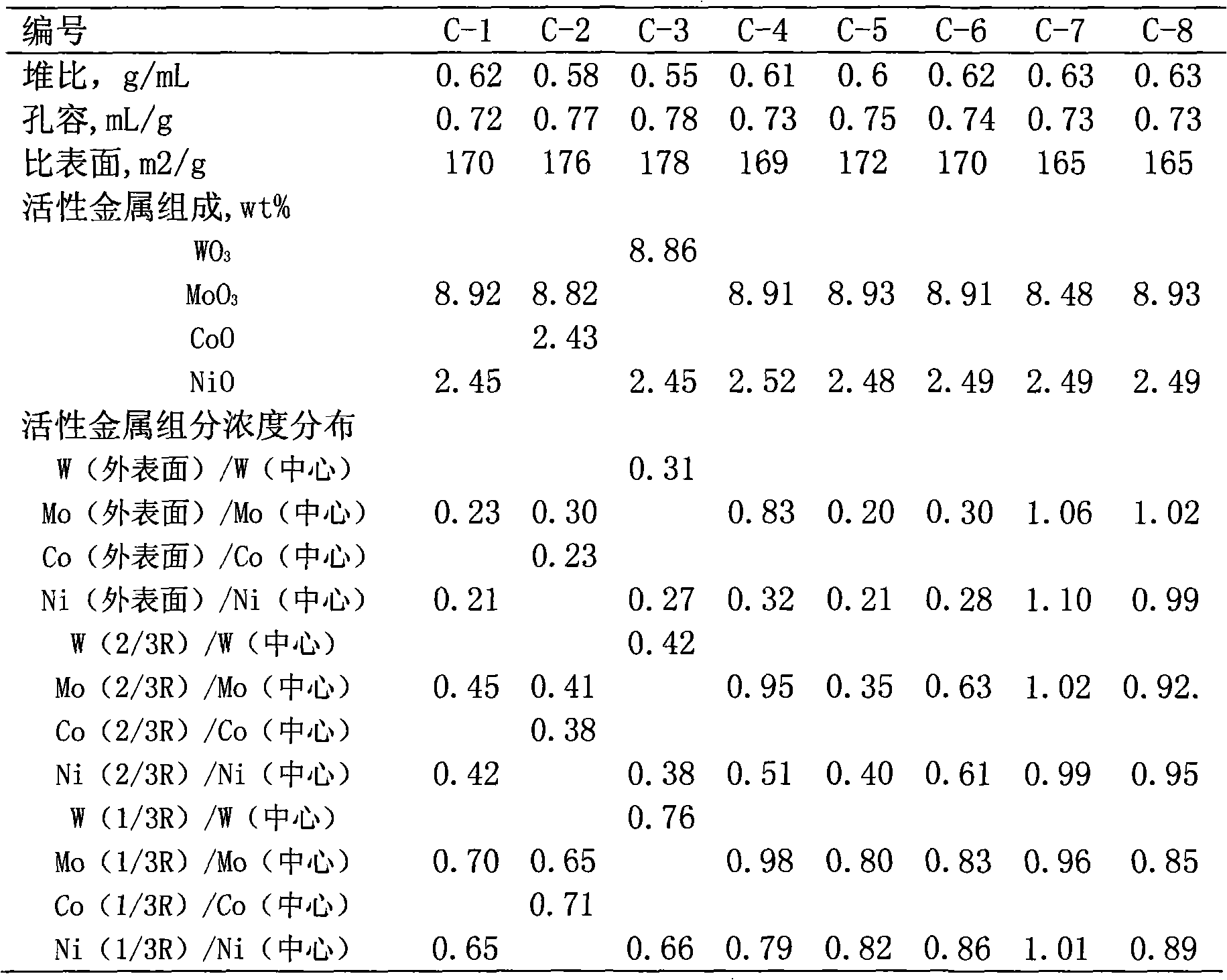

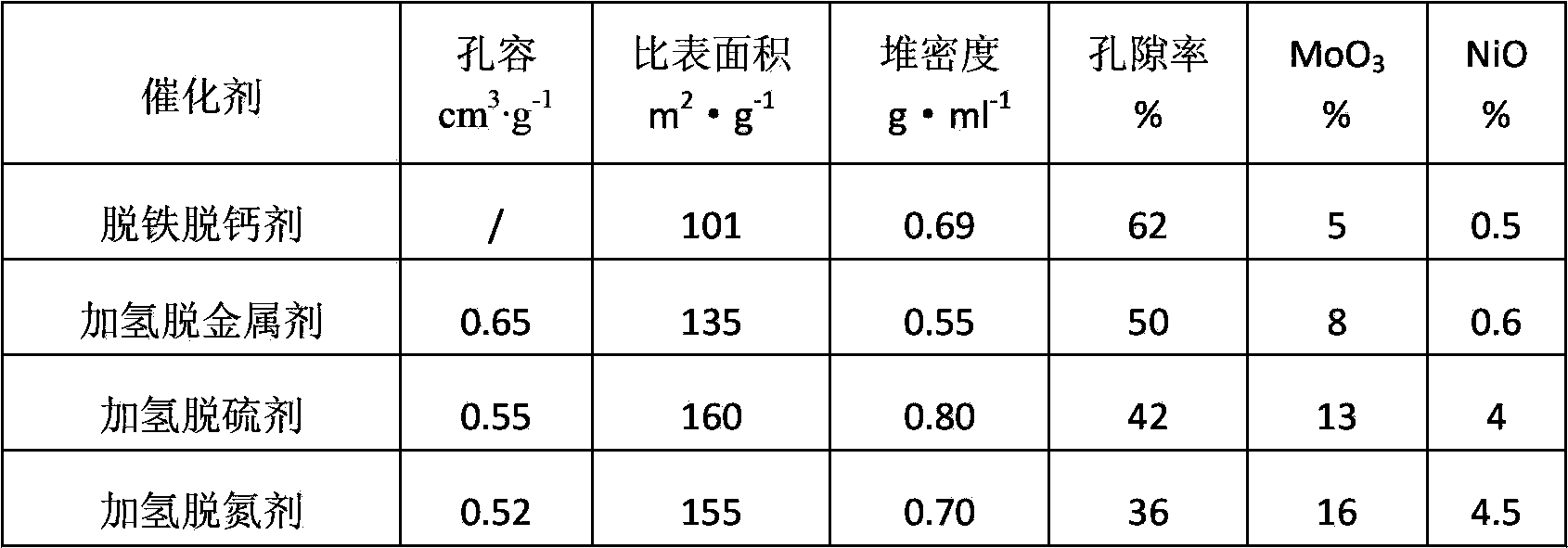

Graded composition of heavy oil hydrogenation catalysts

ActiveCN101928593ASlow down inactivationExtended operating cycleRefining to eliminate hetero atomsPorosityGranularity

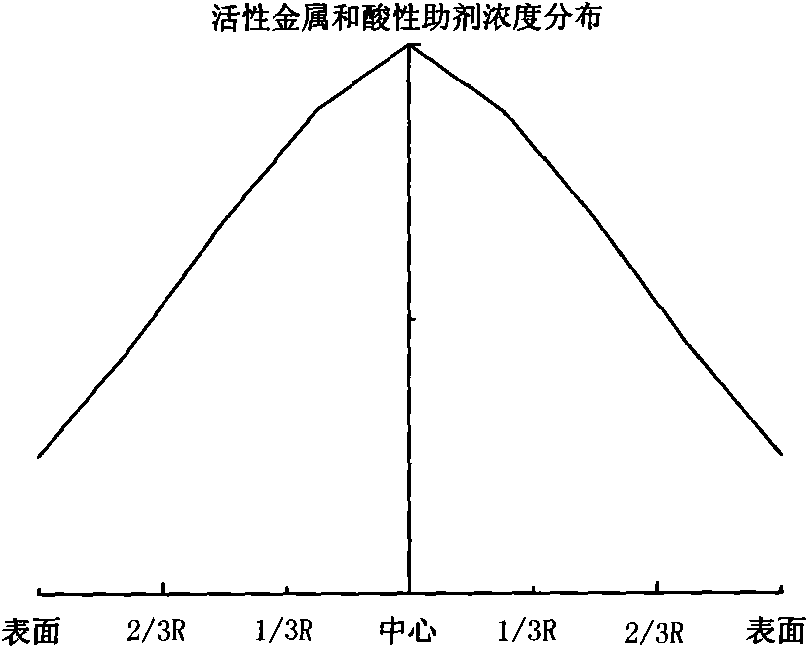

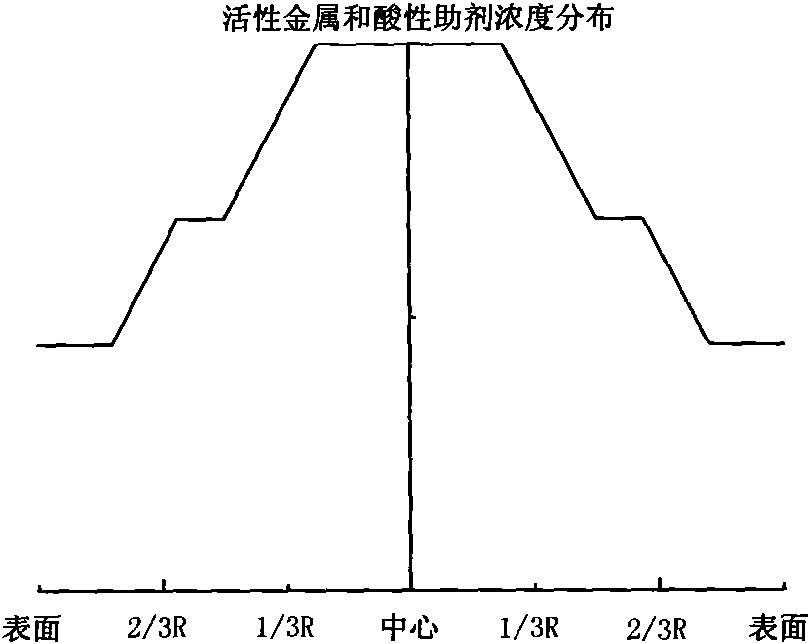

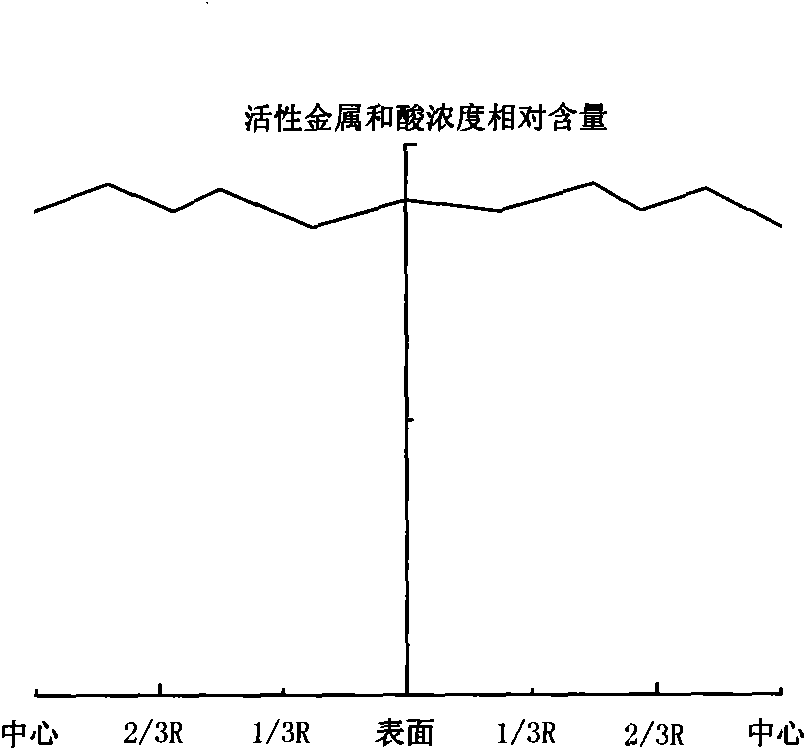

The invention relates to a graded composition of heavy oil hydrogenation catalysts. 5 to 55 percent of hydrodemetallization catalyst, 5 to 55 percent of hydrodesulfurization catalyst and 5 to 55 percent of hydrodenitrogenation catalyst are filled into a reactor from the top to the bottom respectively; along the flow direction, the activity of the catalysts is gradually increased, the aperture is gradually reduced, the granularity is gradually reduced and the porosity is gradually reduced; the active metal ingredients and the acid aid concentrations of the demetallization catalyst and the desulfurization catalyst are in non-uniform distribution, the active metal ingredient and the acid aid concentration of the demetallization catalyst are in gradient reduction, and the active metal ingredient and the acid aid concentration of the denitrogenation catalyst are in gradient increment; the active metal ingredient and the acid aid concentration of the desulfurization catalyst are in uniform distribution; the demetallization catalyst, the desulfurization catalyst and the denitrogenation catalyst consist of one or more catalysts respectively; and the demetallization, carbon residue removal, desulfurization and denitrogenation activities and stability of the catalyst graded composition system are high, and the service life is long.

Owner:PETROCHINA CO LTD

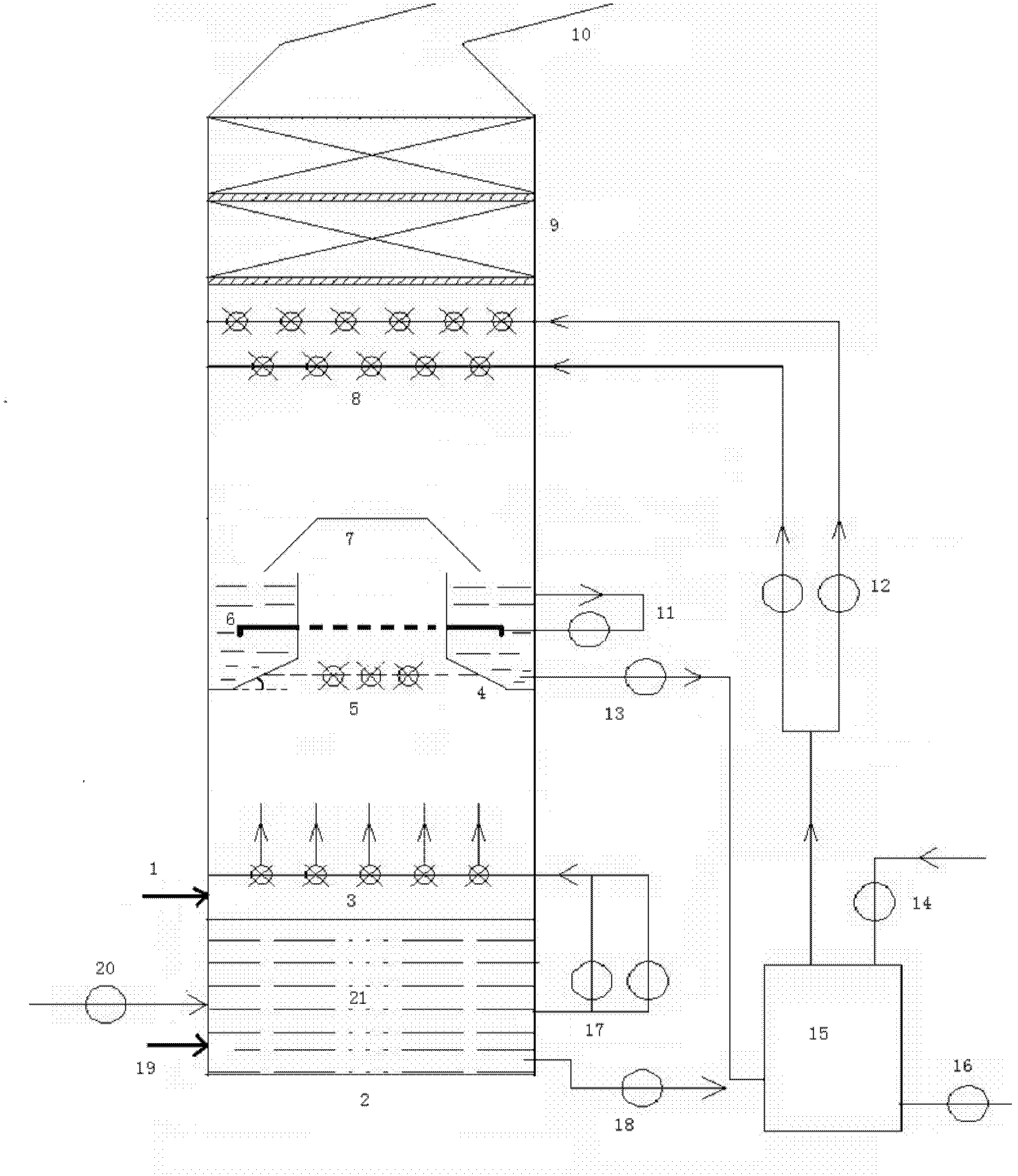

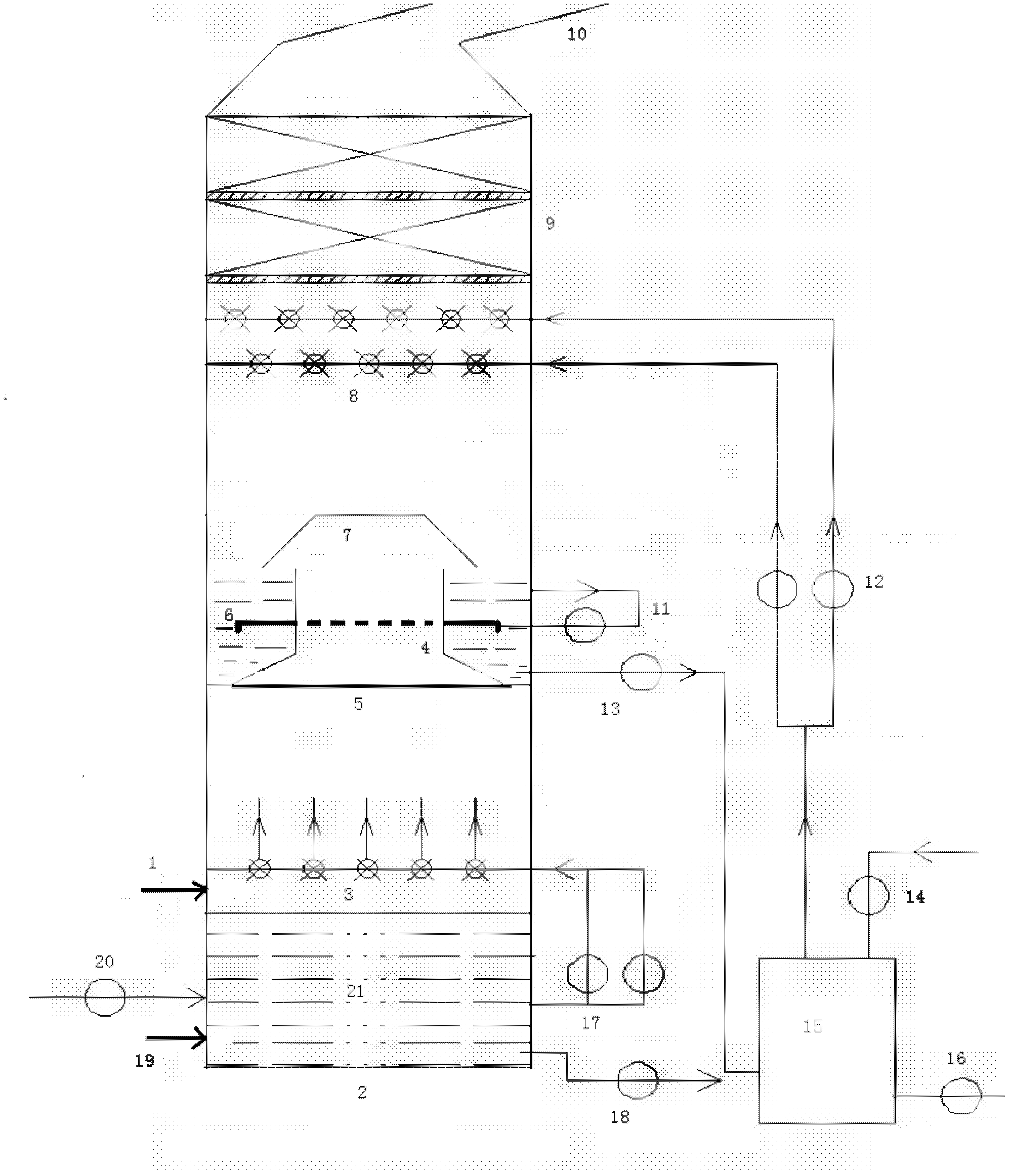

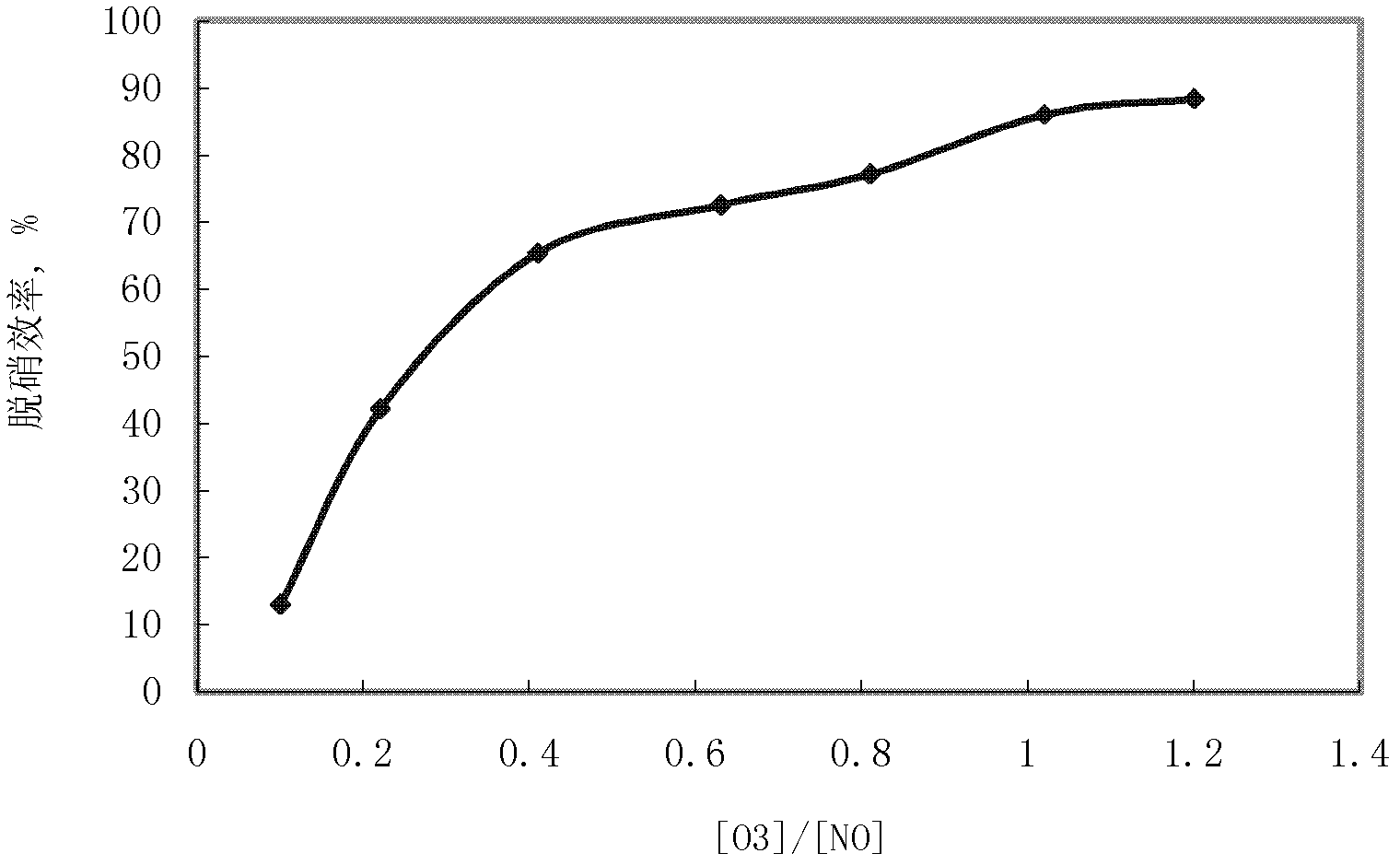

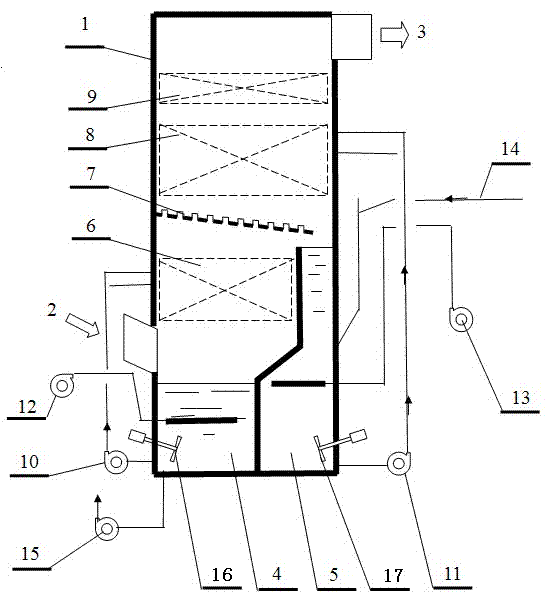

Absorption tower for desulfurization and denitrification combined with oxidant in forward-flow and back-flow spraying and method

InactiveCN102553428AAchieve removalUnique structureDispersed particle separationAir quality improvementOxidation zoneSlurry

The invention discloses an absorption tower for desulfurization and denitrification combined with an oxidant in forward-flow and back-flow spraying mode and a method. The absorption tower includes two washing sections: a first section is a desulfurization loop and arranged on the lower portion of the absorption tower, and sulfur dioxide and hydrogen chloride are removed through slurry forward-flow and back-flow and smoke contact cleaning; a second section cleans oxidized smoke pollutants in slurry back-flow and smoke contact mode mainly for removing oxynitride and heavy metal mercury. A slurry divider is arranged between the two cleaning sections, the bottom of the slurry divider is an oxidization area, and strong oxidant is sprayed in the area. For reducing consumption of the oxidant, a catalyst is added in second-loop slurry for achieving auxiliary oxidization. Sulfur dioxide, oxynitride, heavy metal mercury and the like can be removed simultaneously in a washing tower by the technology, and the absorption tower has the advantages of being high in efficient and simple and suitable for various combustion devices including fuel coal power stations, refuse incineration plants, organic and inorganic production enterprises and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

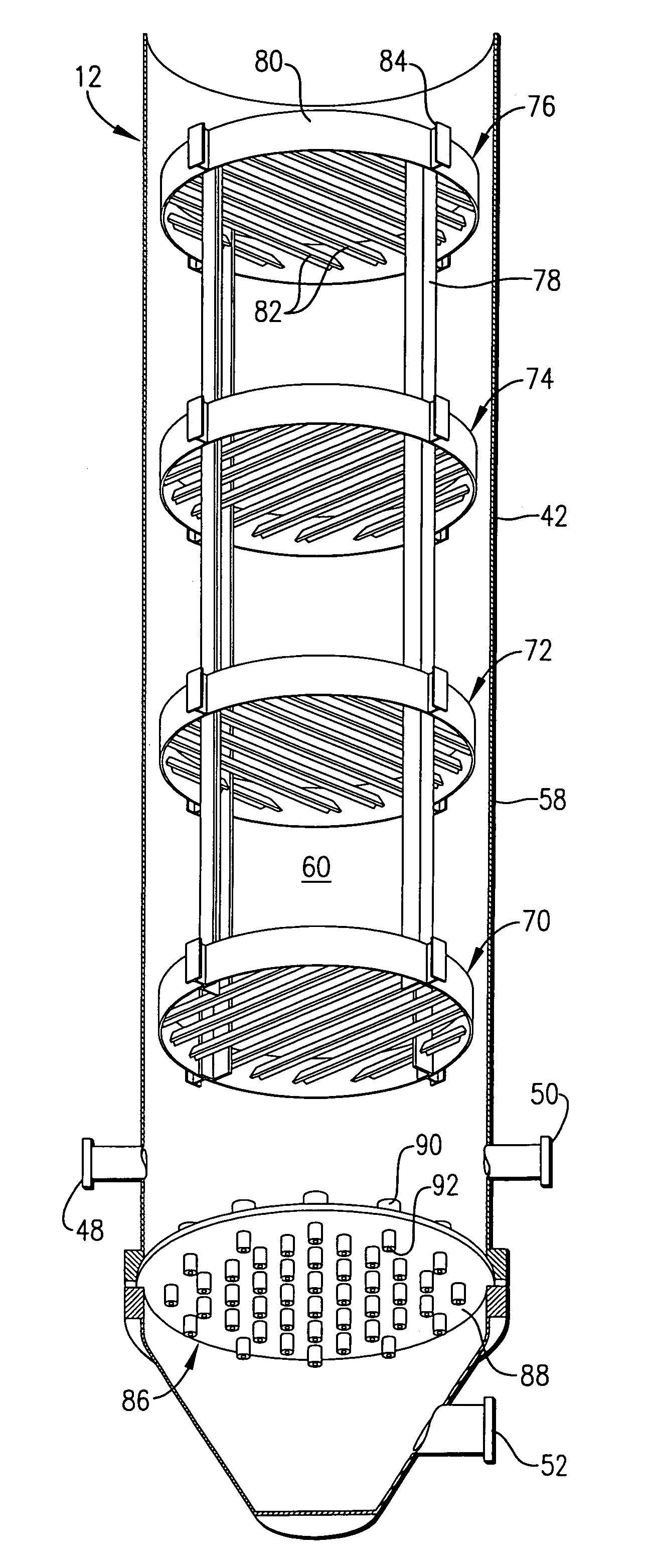

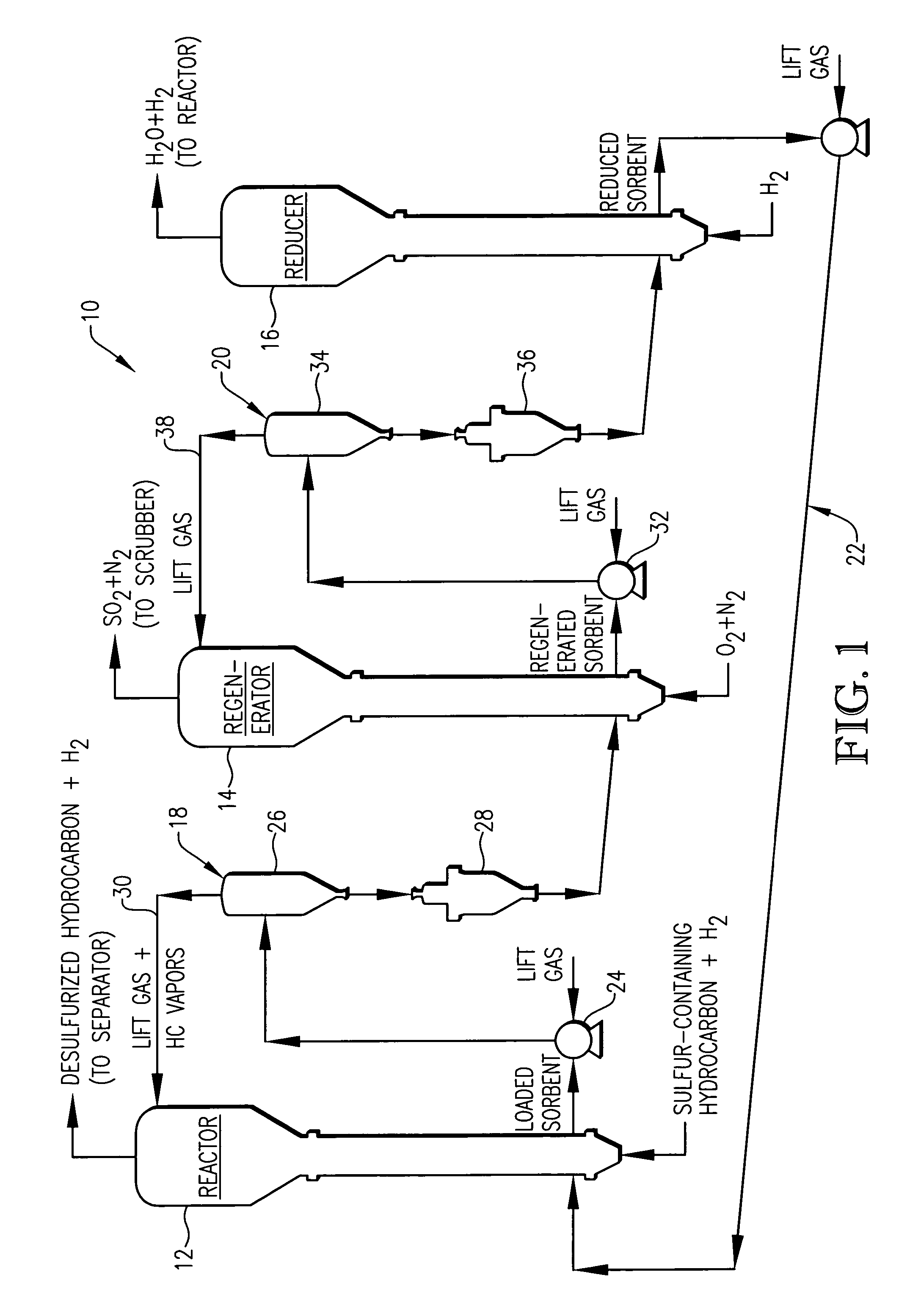

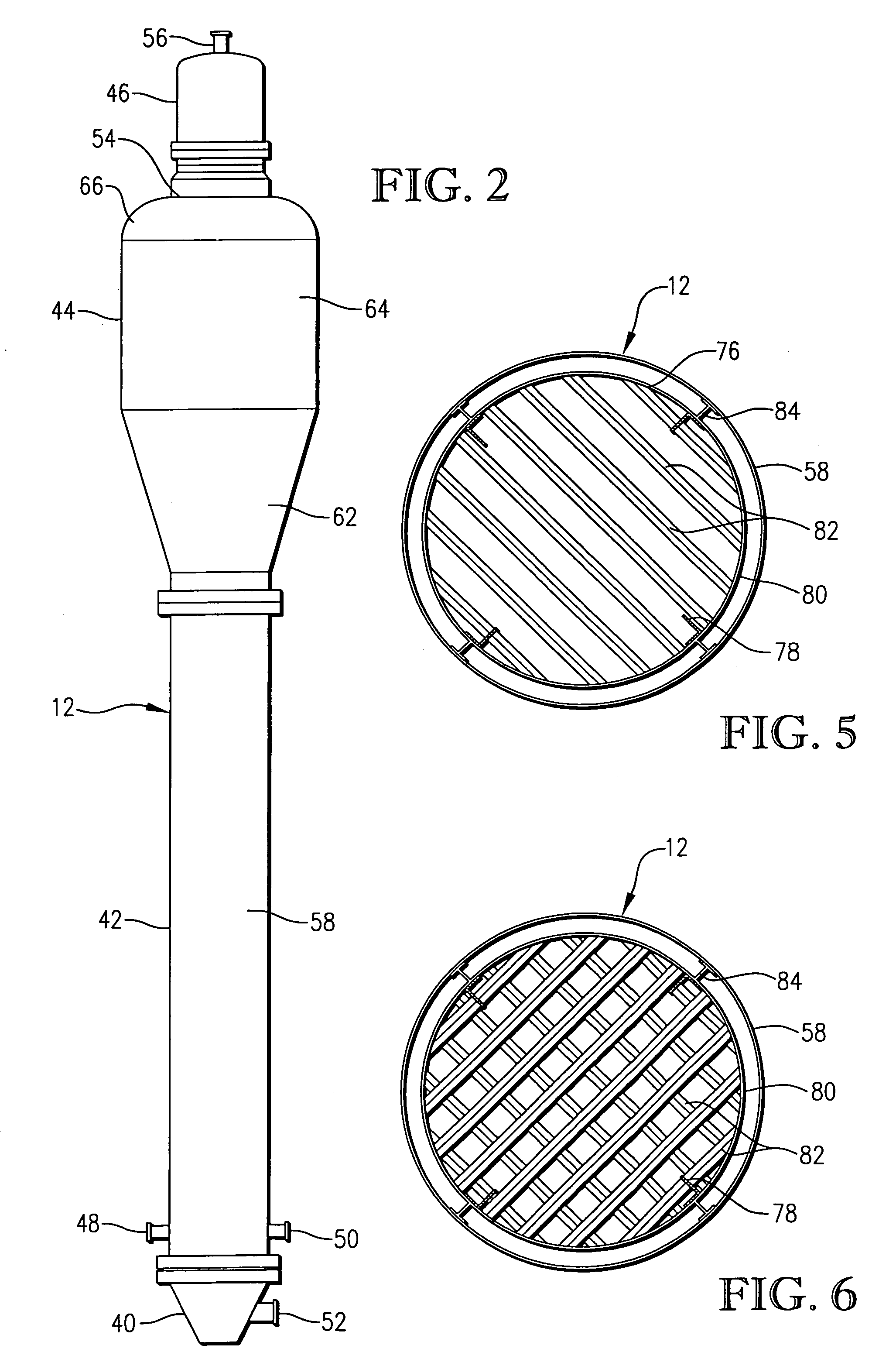

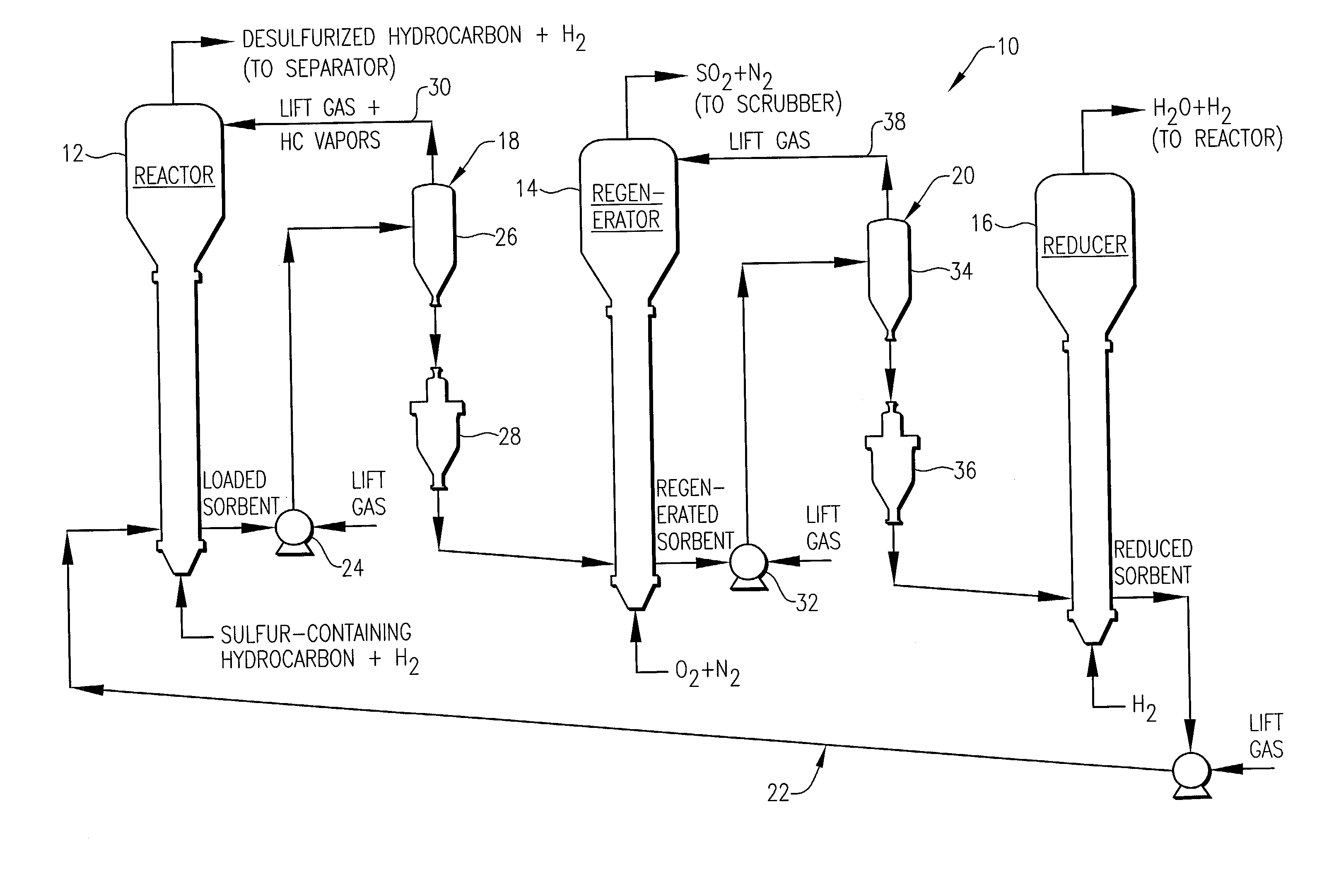

Desulfurization in turbulent fluid bed reactor

ActiveUS7491317B2Improve desulfurizationSmooth connectionChemical/physical/physico-chemical stationary reactorsFluidised-bed furnacesParticulatesSulfur

A method and apparatus for removing sulfur from a hydrocarbon-containing fluid stream wherein desulfurization is enhanced by improving the contacting of the hydrocarbon-containing fluid stream and sulfur-sorbing solid particulates in a fluidized bed reactor.

Owner:CHINA PETROCHEMICAL CORP

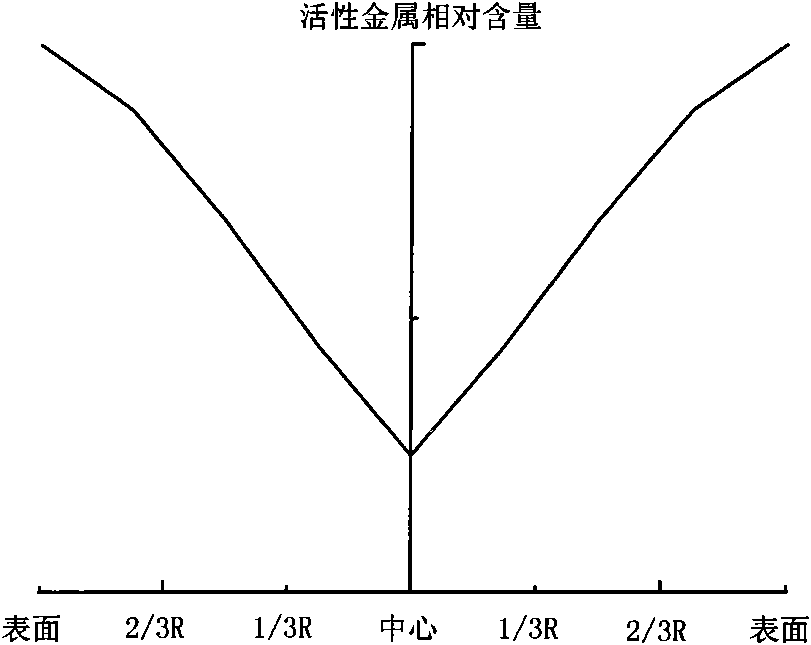

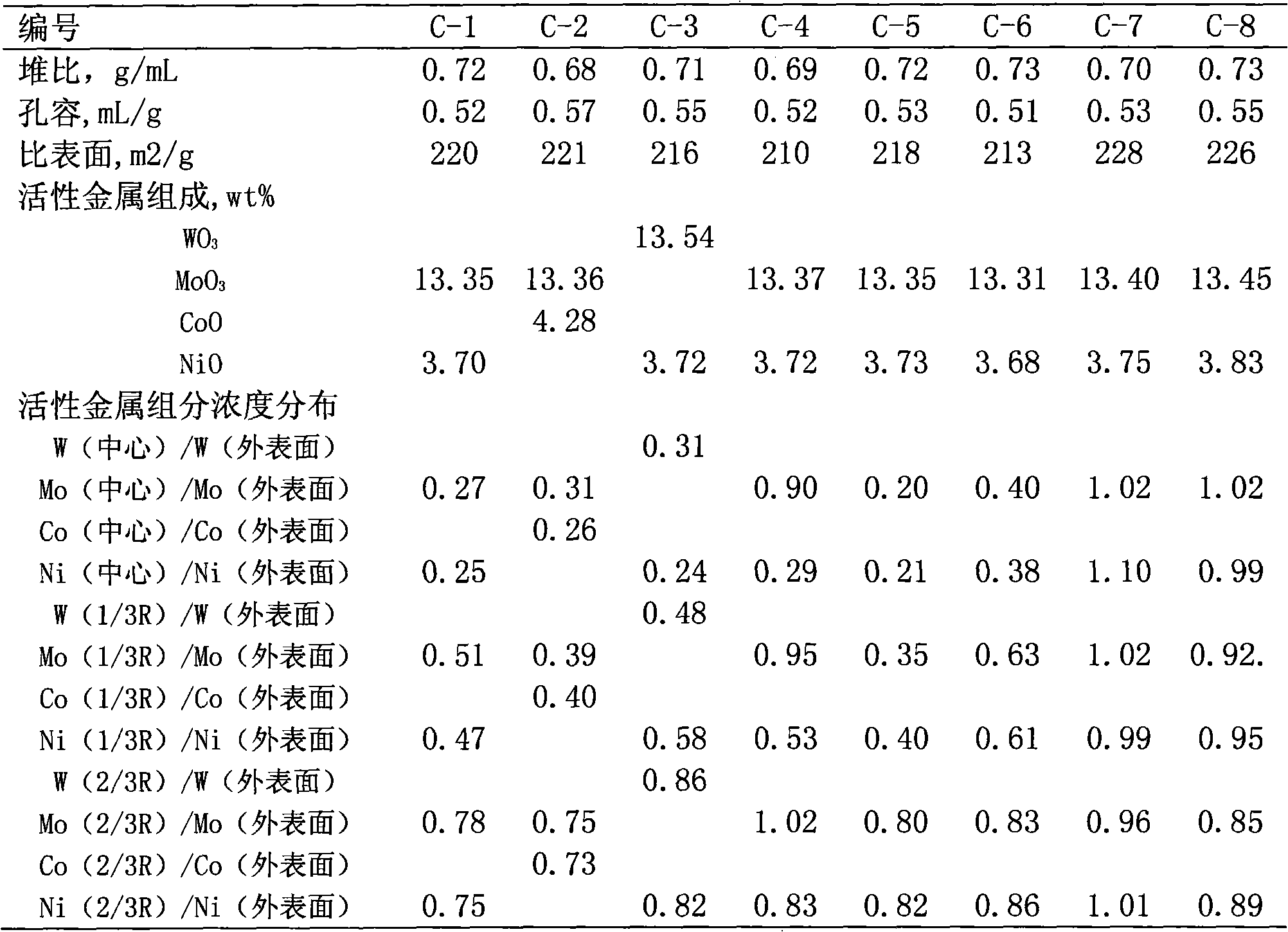

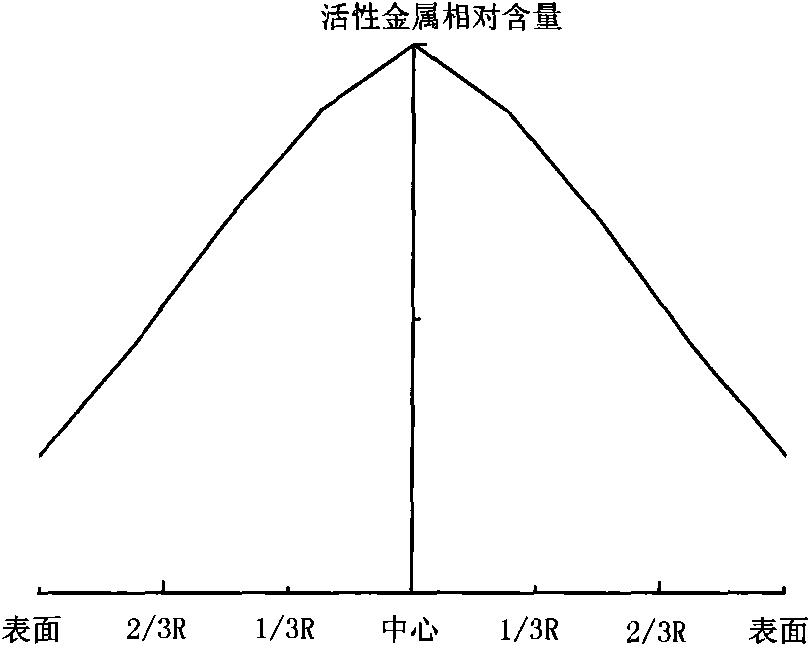

Hydrogenation catalyst with active metal component concentration in gradient increase and distribution and preparation method thereof

ActiveCN101927169AImprove desulfurizationPromote denitrificationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSal ammoniacHigh concentration

The invention relates to a hydrogenation catalyst with active metal component concentration in gradient increase and distribution and a preparation method thereof. The preparation method comprises the following steps of: mixing compounds of metal in VIB and / or VIII family with deionized water or ammonia to prepare a metal impregnating solution by using Al2O3 or Al2O3 containing SiO2, TiO2 and ZrO2 as a vector; preparing the hydrogenation catalyst by using a saturated impregnation method; gradually adding denser metal solution for saturated impregnation of the vector by preparing more dilute solutions of metal in VIB and / or VIII family or deionized water; or impregnating the vector first with the metal impregnating solution with low concentration and then with the metal impregnating solution with high concentration by preparing metal solutions of different concentrations; drying for 1 to 8 hours at 80 DEG C to 150 DEG C; and baking for 2 to 6 hours in an air of 300 DEG C to 650 DEG C. The catalyst has the advantages of high desulfurization, denitrification, residual carbon removing activity and stability, simple preparation and lower preparation cost and is suitable for the field of heavy oil hydrogenation.

Owner:PETROCHINA CO LTD

Hydrotreating catalyst of containing molecular sieve, and preparation method

This invention provides a hydrogenation catalyst containing molecular sieve, which is composed of nickel oxide 1-10 wt. %, molybdena oxide and tungsten oxide 10-50 wt. %, and carrier. The catalyst is prepared by introducing nickel, molybdena and tungsten into the carrier containing molecular sieve. The catalyst has such advantages as high desulfurization and denitrification activity, and high ring-opening activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

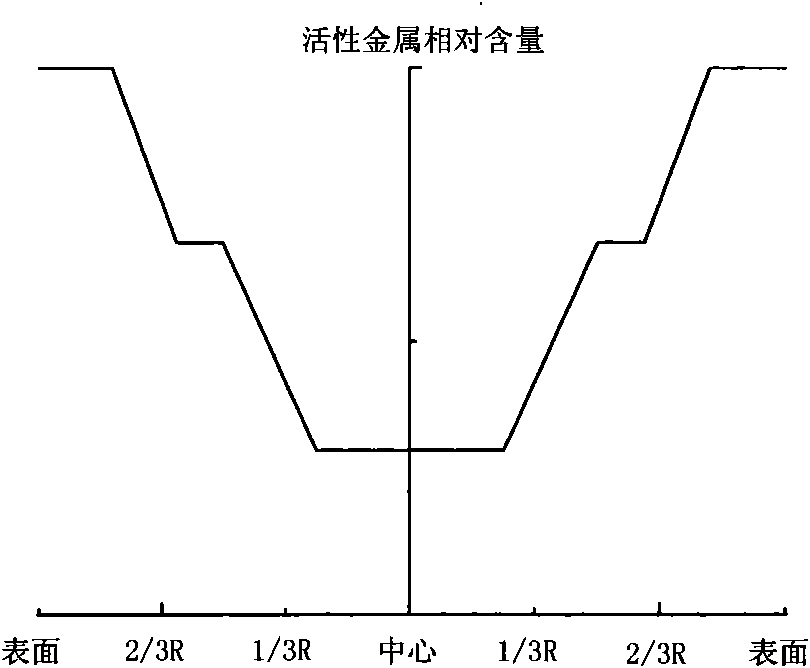

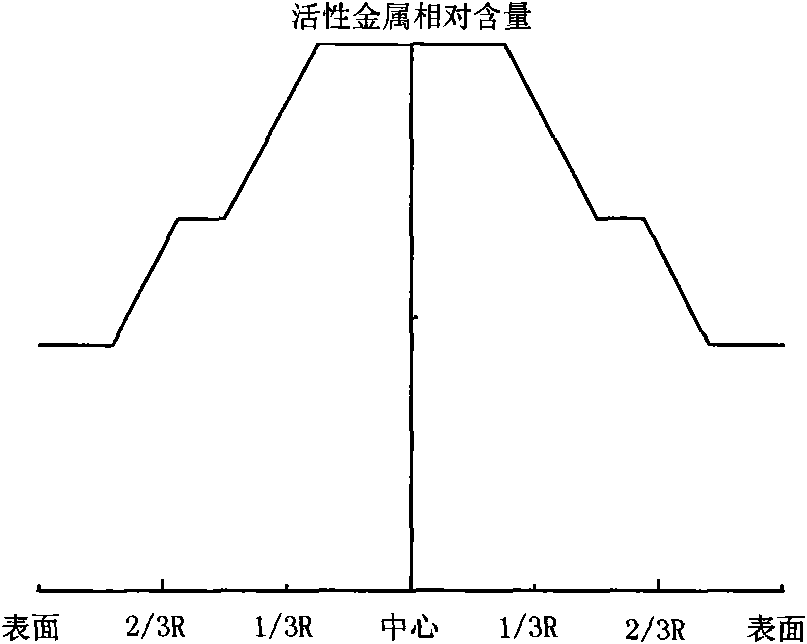

Hydrogenation catalyst with gradient-decreasing-distributed active metal constituent concentration and preparation method thereof

ActiveCN101927196AGood demetallizationGood charcoal removalCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsSal ammoniacAmmonia

The invention relates to a hydrogenation catalyst with gradient-decreasing-distributed active metal constituent concentration and a preparation method thereof. The preparation method comprises the following steps: by using Al2O3 or Al2O3 containing SiO2, TiO2 and ZrO2 as the carrier, mixing molybdenum and / or tungsten compounds and / or nickel and / or cobalt compounds with deionized water or ammonia water to obtain a metal dipping solution; preparing a thicker metal dipping solution dipping carrier, and gradually adding deionized water or ammonia water to dilute the metal dipping solution saturated spray carrier, or preparing metal dipping solutions with at least two different concentrations; and drying at 80-150 DEG C for 1-8 hours, and roasting in the air at 300-650 DEG C for 2-6 hours. The catalyst contains 1.0-10.0 wt% of molybdenum and / or tungsten oxides and / or 0.2-5.0 wt% of cobalt and / or nickel oxides. The hydrogenation catalyst has favorable activities of demetallization, carbon residue removal, devulcanization and denitrification, has the advantages of high stability, simple preparation and low cost, and is used for hydrogenating heavy-weight oil.

Owner:PETROCHINA CO LTD

Catalytic composition for hydrotreating of hydrocarbons and method for hydrotreating

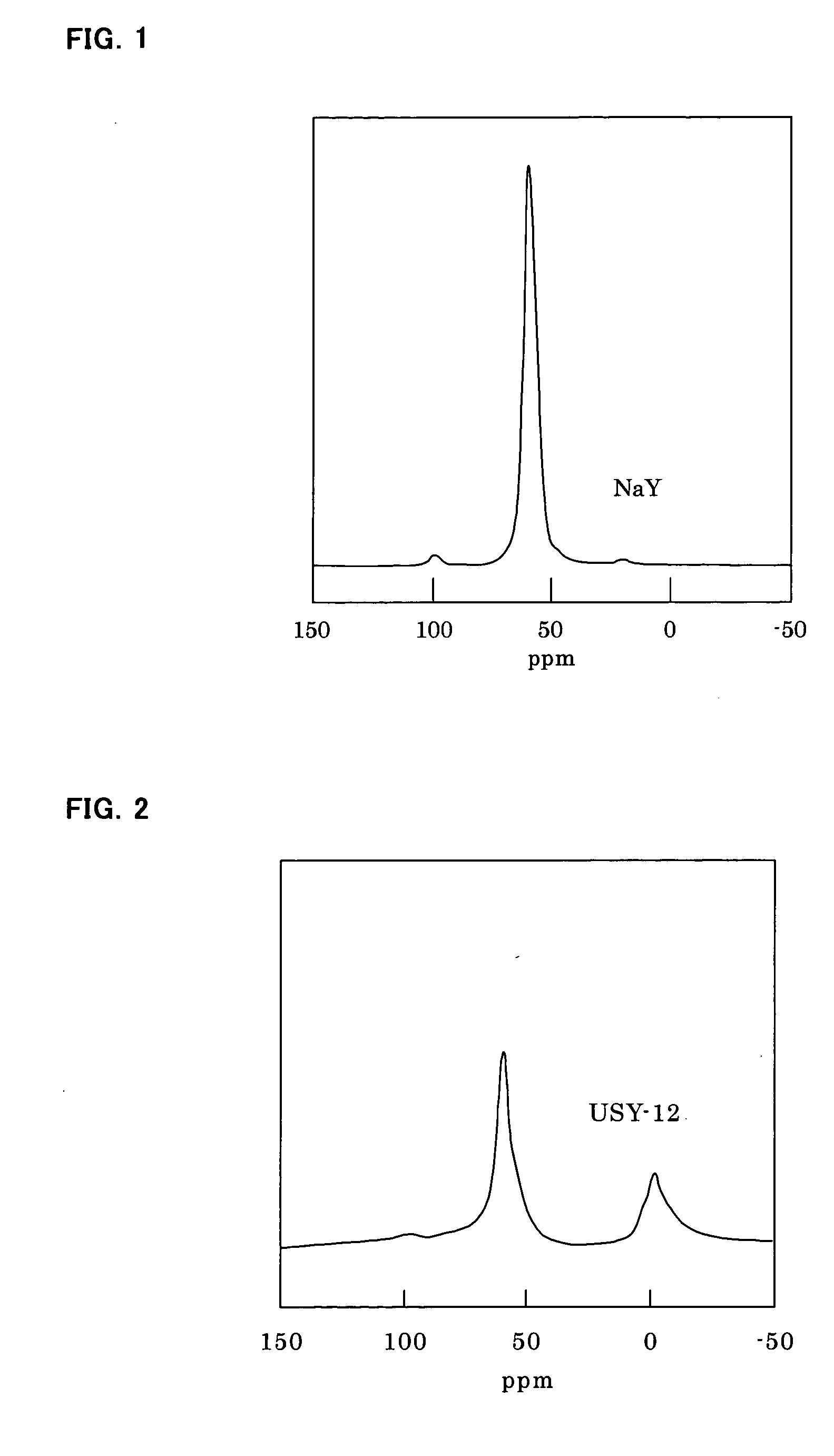

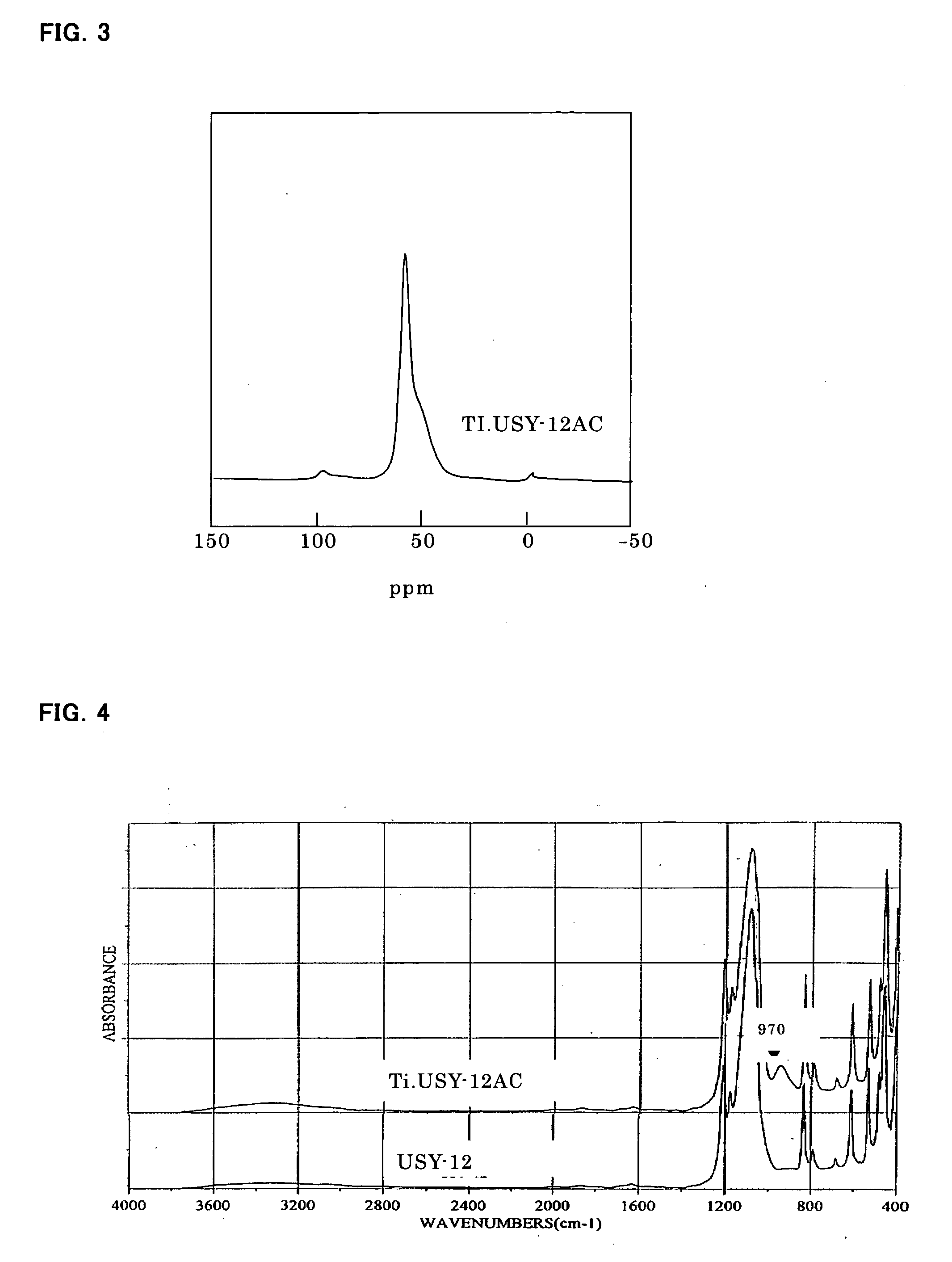

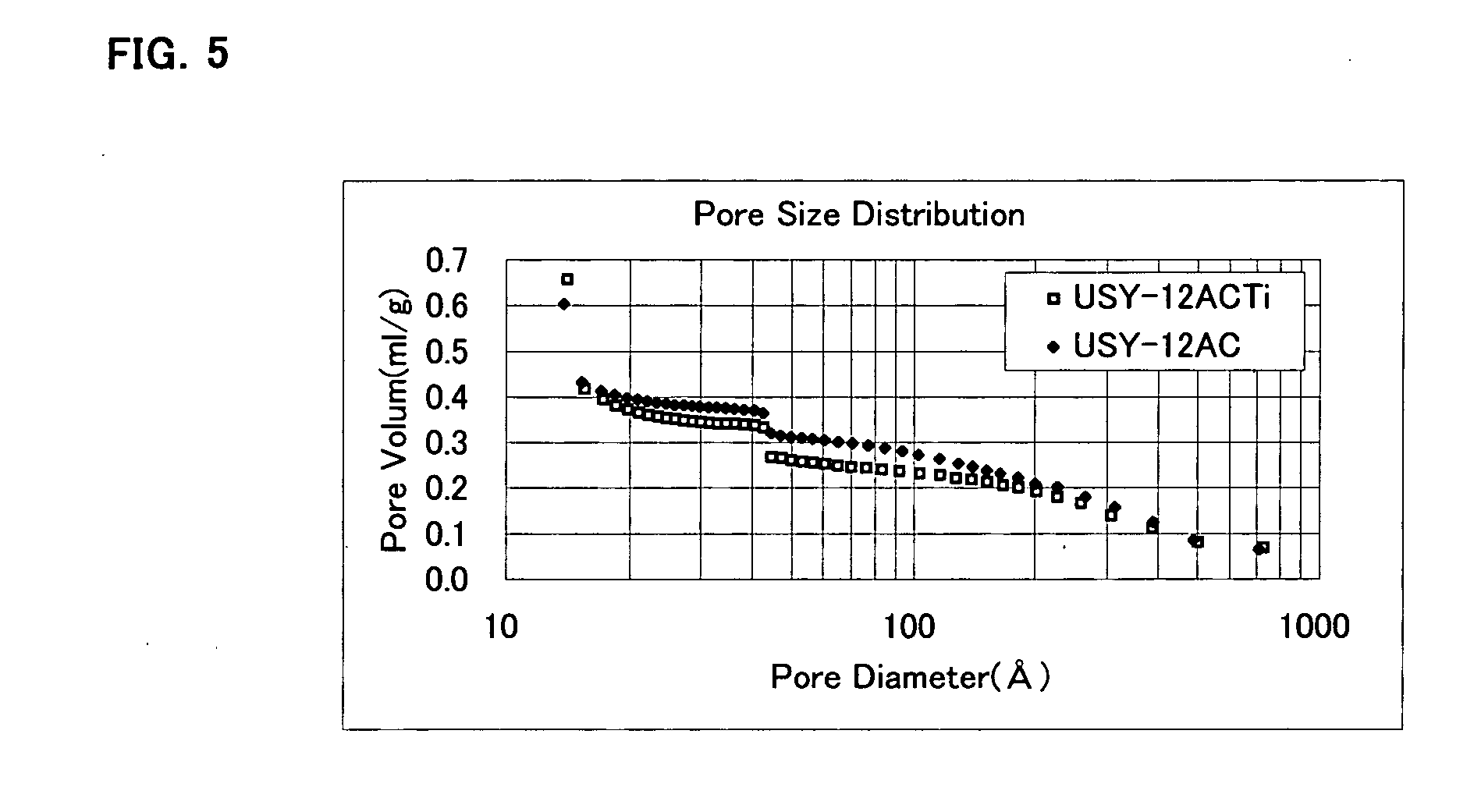

InactiveUS20090283443A1Improve rendering capabilitiesPoint becomes highMolecular sieve catalystsHydrocarbon oil crackingTitaniumCrystallinity

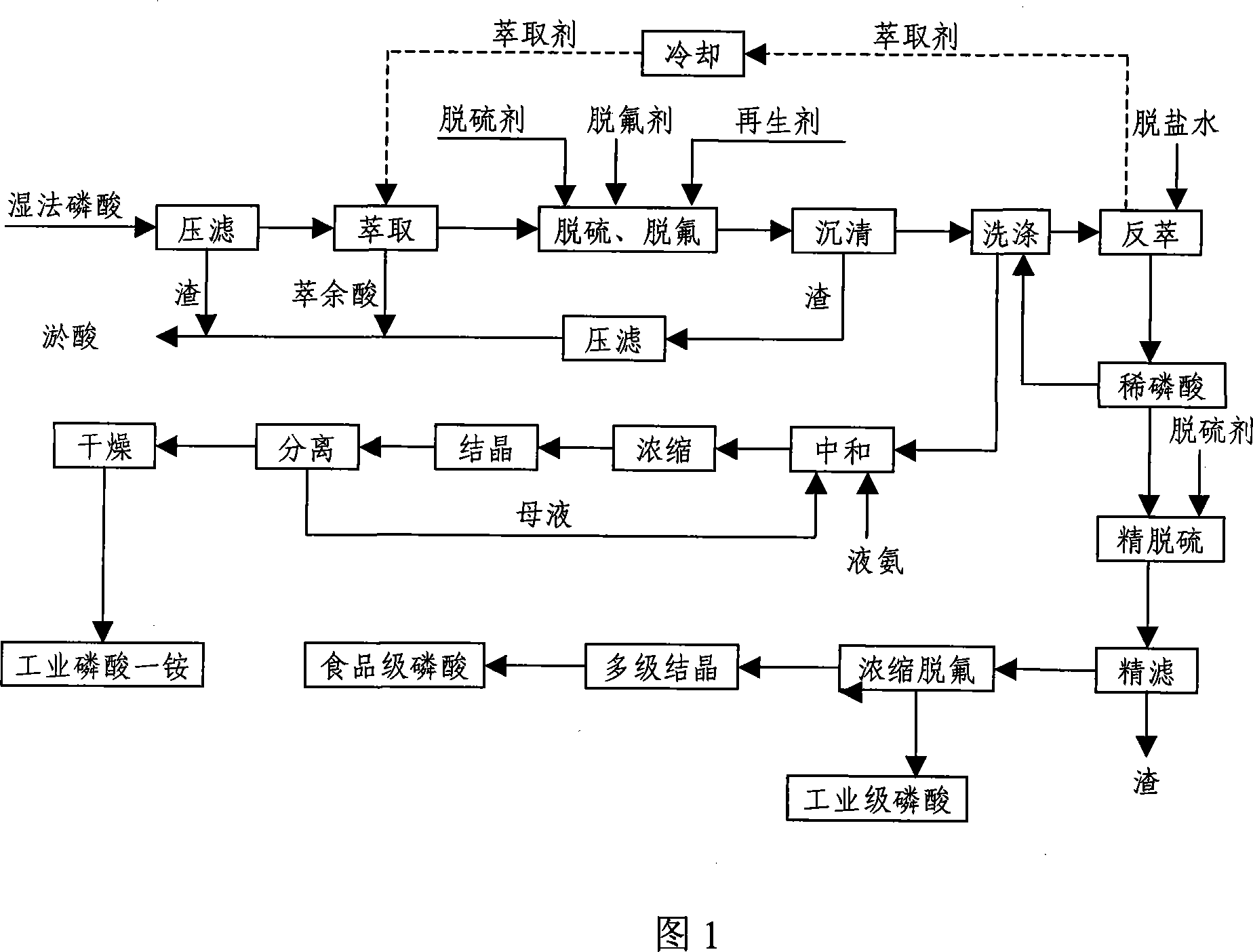

A catalytic composition for hydrotreating of hydrocarbons in which a metallic component for hydrogenation is carried on a carrier comprising zeolite Y with aluminum and titanium inserted therein and a porous inorganic oxide, the zeolite Y having the following characteristics: (a) unit cell dimension (UD) in a range from 24.25 to 24.60 Å, (b) crystallinity of 95% or more, (c) specific surface area (SA) of 500 m2 / g or more, (d) total pore volume (PVt) of a group of pores each having a diameter of 600 Å or below in a range from 0.45 to 0.70 ml / g, (e) pore volume (PVm) of a group of pores each having a diameter in a range from 100 to 600 Å in a range from 0.10 to 0.40 ml / g, (f) pore volume (PVs) of a group of pores each having a diameter in a range from 35 to 50 Å in a range 0.03 to 0.15 ml / g, and (g) percentage of 4-coordinate aluminum atoms against total aluminum atoms in the zeolite of 60 atom % or more.

Owner:JGC CATALYSTS & CHEM LTD +1

Method for producing technical grade ribose phosphate, food grade ribose phosphate and industry ammonium diacid phosphate using wet-process ribose phosphate

The invention discloses a method of using wet phosphoric acid to prepare industrial grade phosphoric acid, food grade phosphoric acid and industrial ammonium diacid phosphate, which is characterized in using wet phosphoric acid as the material, and preparing industrial grade phosphoric acid and food grade phosphoric acid respectively by using a series of compound purifying technologies such as chemical sedimentation and extracting by organic solvent and concentration and recrystallization and other technologies; meanwhile, the invention uses a part of purified diluted phosphoric acid to prepare industrial ammonium diacid phosphate. The invention has the advantages of reasonable cascade utilization of the wet phosphoric acid, high additional value of phosphorus, and further exploitation of the lower industrial and food grades phosphate.

Owner:中化重庆涪陵化工有限公司

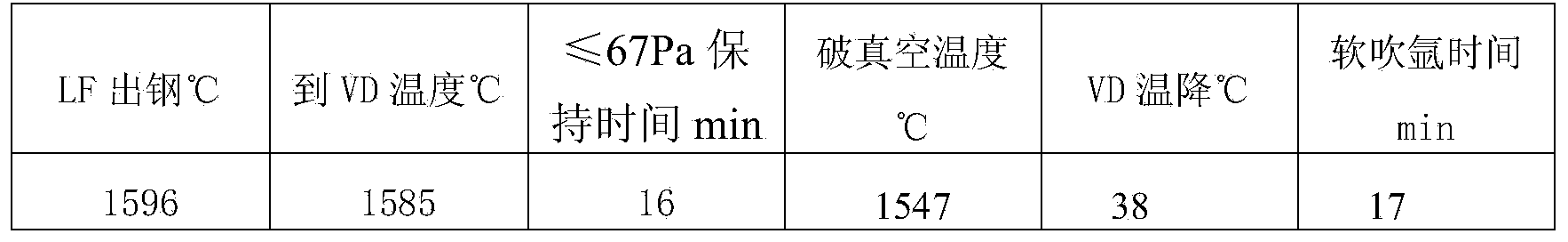

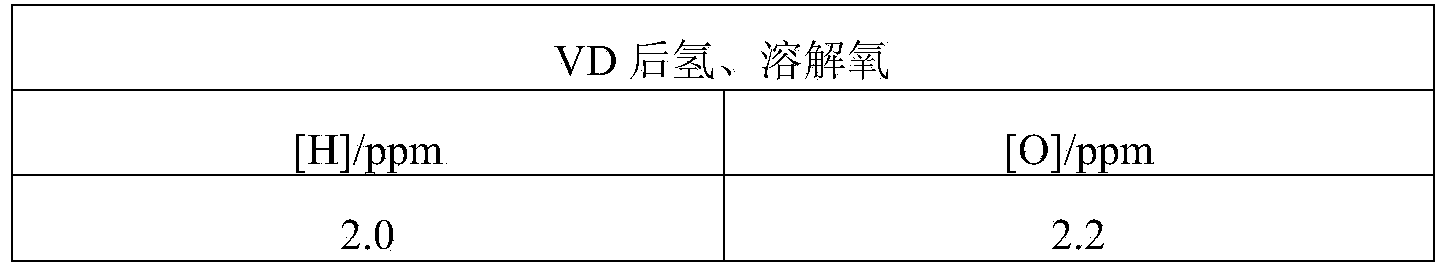

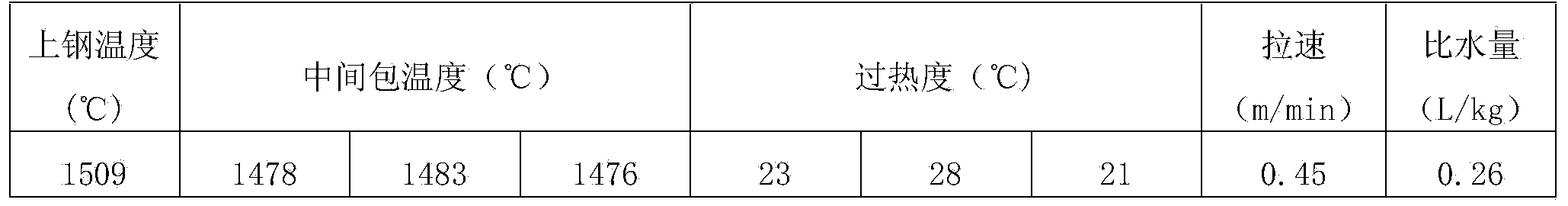

Method for preparing bearing steel

ActiveCN104178698AHarm reductionInhibit peroxidationProcess efficiency improvementElectric furnaceNon-metallic inclusionsOxygen content

The invention relates to a method for preparing bearing steel. The method comprises the following steps of smelting, and alloying; carrying out continuous casting; rolling; carrying out slow cooling, and the like. The chemical components in the bearing steel are controlled in percentage by weight as follows: 0.95%-1.05% of C, 0.20%-0.30% of Si, 0.30%-0.35% of Mn, 0.02%-0.05% of Mo, 1.45%-1.48% of Cr, 0.015%-0.035% of AlS, less than or equal to 0.05% of Cu, less than or equal to 0.025% of S, less than or equal to 0.025% of P, less than or equal to 0.05% of Ni, less than or equal to 12*10<-6> of [O], less than or equal to 2*10<-6> of [H] and the balance of Fe and inevitable impurities. According to the bearing steel produced through the method disclosed by the invention, the total oxygen content of a steel product can be stably controlled below 8 ppm, non-metallic inclusions are low in content and uniformly distributed, and good casting blank structure homogeneity, steel quality stability and anti-fatigue property and casting blank segregation grade reduction are achieved.

Owner:SHANDONG IRON & STEEL CO LTD

Distillate hydrogenation catalyst and its preparation method

ActiveCN1769383AImprove denitrification activityReasonable hydrogenation reactionHydrocarbon oils refiningDistillates petroleumPetroleum

The invention discloses the hydrotreatment catalyst and preparing method. The catalyst comprises molecular screen, modified aluminum oxide, active metal and organic auxiliary agent. The method comprises the following steps: using the aluminum oxide modified by titanium and silicon as carrier, after soaking the catalyst carrier in the active metal and organic auxiliary agent, drying at the 200íµ, and getting the catalyst. The said catalyst can be used for hydrotreating process of fraction of petroleum, especially for hydrodesulphurization and hydrodenitrification process of middle distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

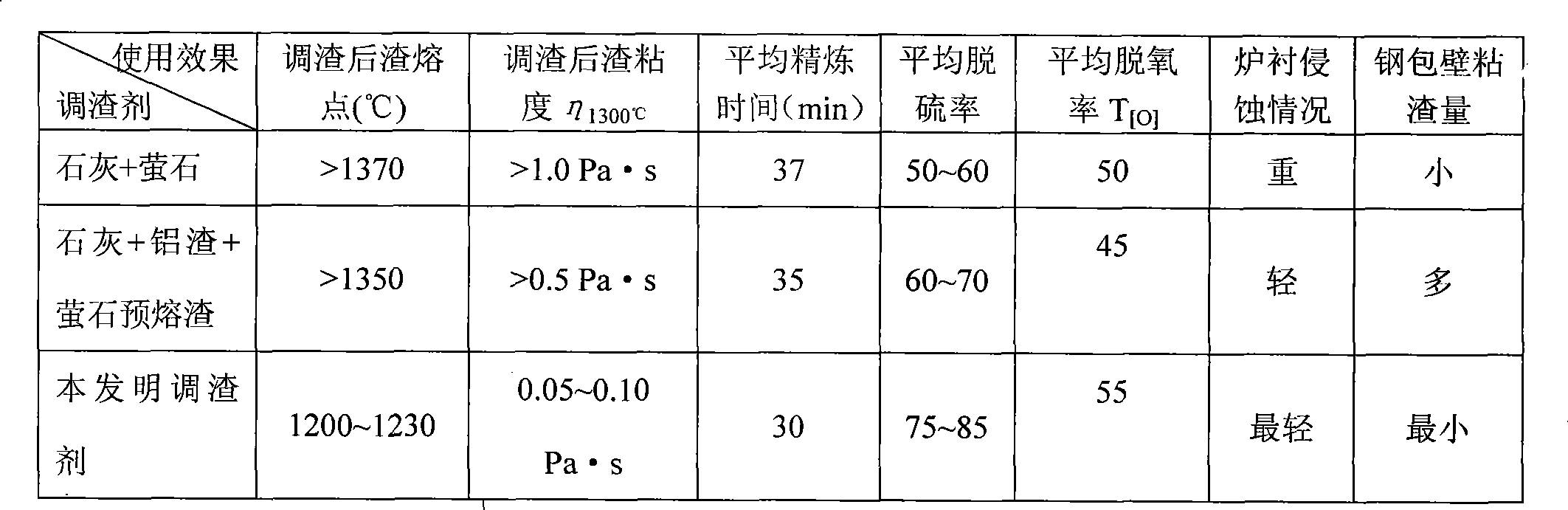

Ladle refining slag modifier, preparation method and slag modifying method

InactiveCN101519712AStrong fluxing effectImprove flux effectProcess efficiency improvementSteelmakingImpurity

The invention belongs to the technical field of steelmaking and refining, and discloses a ladle refining slag modifier, a preparation method and a slag modifying method. The slag modifier comprises the following chemical components in percentage by mass: 30 to 60 percent of CaO, 30 to 60 percent of Al2O3, 2 to 10 percent of MgO2, 2 to 10 percent of B2O3, and less than 8 percent of impurities. The slag modifying method using the slag modifier comprises that: the slag modifier is hoisted to the front of a refining furnace after a steelmaking furnace discharges steels, and then is directly fed into ladles, or the slag modifier can also be fed into the furnace along with other slags at a refining station; the components of modifying slag are determined according to the ladle residue amount and components, desulfuration amount and steel deoxidation product amount; and the modifying slag for controlling the ladle slag comprises the following components according to the adding amount: 48 to 54 percent of CaO, 26 to 32 percent of Al2O3, 6 to 8 percent of MgO, 2 to 4 percent of B2O3, and 0 to 8 percent of SiO2, wherein the modifying slag is better if the content of the SiO2 is lower. The slag modifier has the capabilities of quickly manufacturing the slag, improving desulfuration and deoxidation of the refining slag and accommodating and absorbing deoxidation products, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

Convertor tapping washing fining furnace fast desulfurization method

The invention relates to a method for rapidly desulfurizing a slag washing and refining furnace for converter tapping, which belongs to the steelmaking technical field and is used to solve the problem that the converter tapping is rapidly refined and desulfurized. The method comprises two steps of steel ladles slag-washing and LF refining and is characterized in that pre-melted slag and white lime 3-5Kg / t are added according to the ratio of 7-12Kg / t in the step of the steel ladles slag-washing, the pre-melted slag is added according to the ratio of 3-5Kg / t in the step of LF refining, and fluxing medium is added according to the following ratio: lime 3-5Kg / t, calcium carbide 2-4Kg / t and ferrosilicon powder 2-4Kg / t, the components of the pre-melted slag is combined according to following weight units: CaO 46-52, Al2O3 38-45, CaF2 5-7, SiO2<=10, Fe2O3 <=2, H2O<= 0.5, and the pre-melted slag melting point <=1350DEG C. The invention can increase the rear furnace slug washing of a high converter under the condition that aluminum is added to deoxidize in refining and refining slag is rapidly produced under the weak oxidation condition, and the requirements for producing low sulphur steel are satisfied.

Owner:HANSTEEL

Slag adhesion preventing fluorine-free slag modifier for ladle refining, preparation method and using method

InactiveCN101519713AIncrease contentIncrease surface tensionProcess efficiency improvementSteelmakingPhosphor

The invention belongs to the field of steelmaking, and particularly discloses a fluorine-free slag modifier for preventing a ladle refining device from adhering slag, a preparation method and a using method. The slag modifier consists of active lime, bauxite and boric anhydride; and the slag modifier comprises the following chemical components in percentage by mass: 75 to 85 percent of CaO, 10 to 20 percent of Al2O3, 5 to 15 percent of B2O3, 0 to 8 percent of MgO, and the balance of impurities, wherein SiO2 is less than 7.0 percent, H2O is less than 0.05 percent, and the total amount of sulfur and phosphor is less than 0.01 percent. During use, in order to prevent a ladle from adhering the slag, the slag modifier is fed into the ladle in the later period of discharging steel from a steelmaking furnace, and in order to prevent an RH dip pipe or a CAS-OB dip cover and the like from dipping into the ladle device to adhere slag, the slag modifier is fed at a refining station. The slag modifier can effectively control the refining device from slag adhesion and improve the service life of a fireproof material, is favorable for reducing the contents of the sulfur, oxygen and impurities in the steel, and is simple to prepare and convenient to store, transport and use.

Owner:JIANGSU UNIV

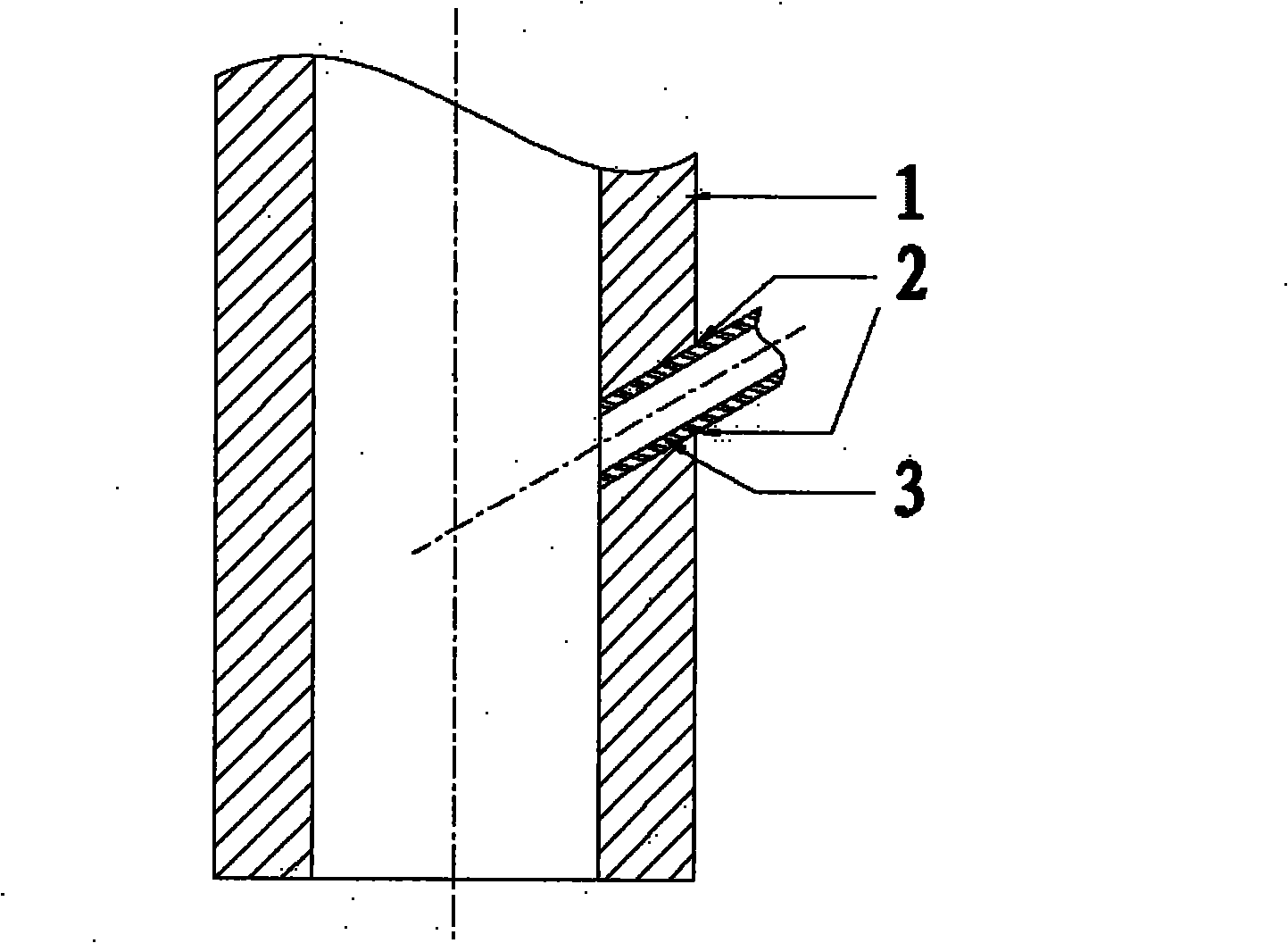

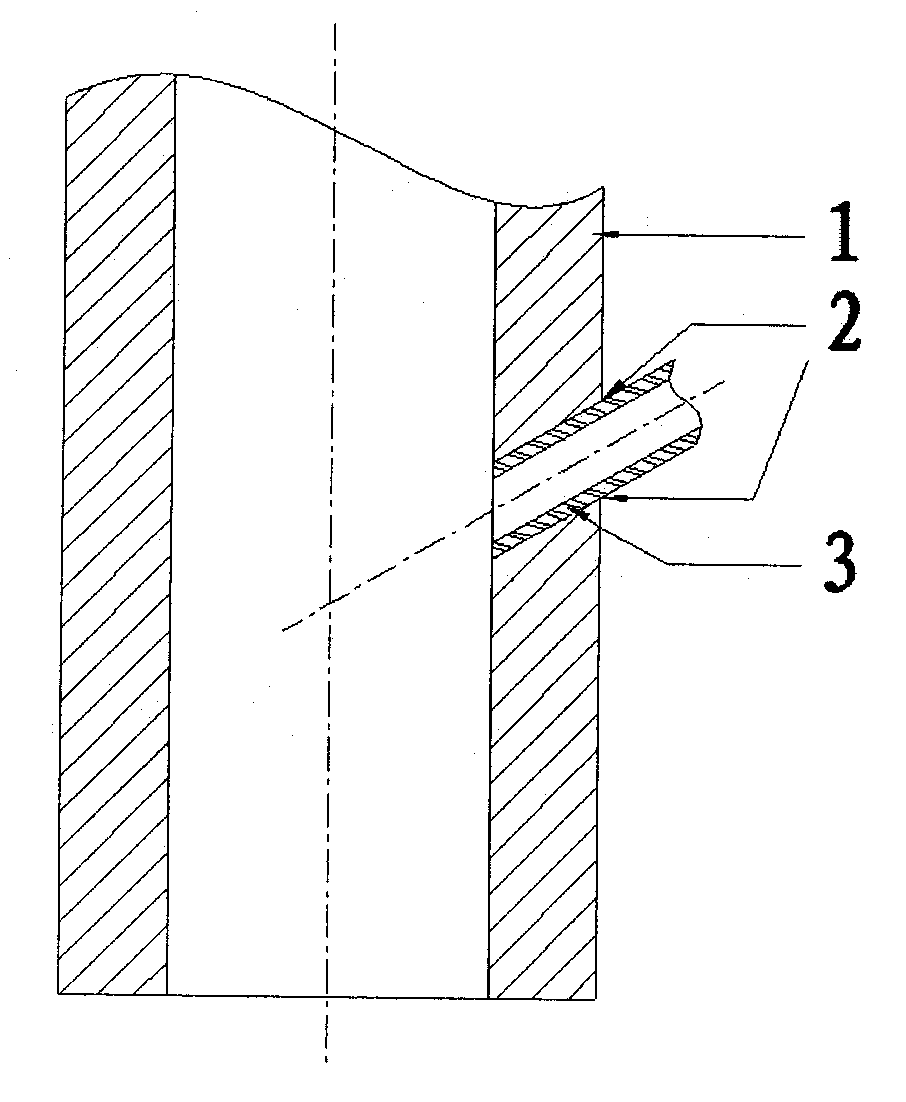

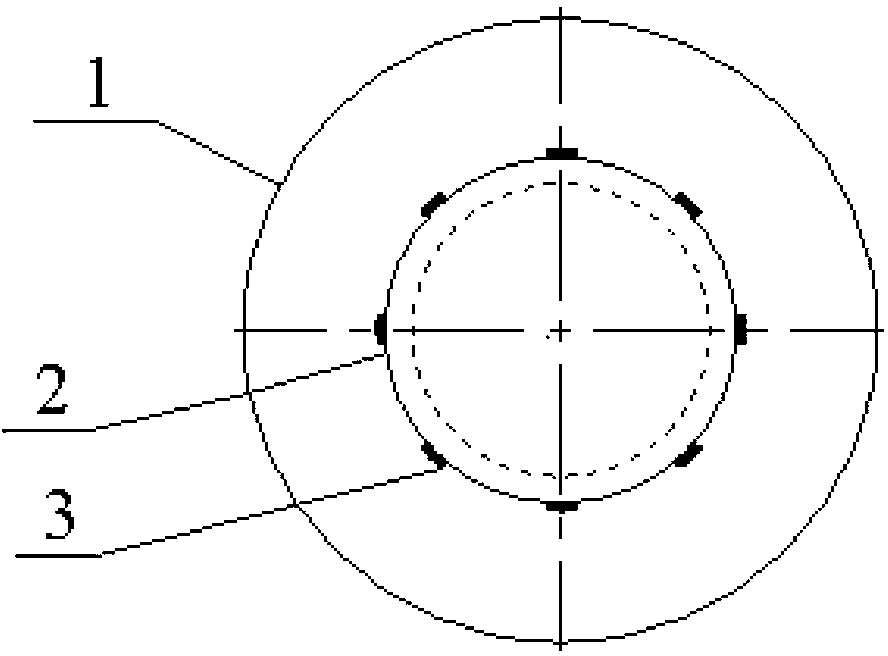

RH injection refining device and application thereof

The invention provides an RH injection refining device and application thereof. The device comprises an RH ascending pipe and an RH descending pipe; pipe walls of the RH ascending pipe and the RH descending pipe are provided with through holes which are connected with an external air supply or a feeding device by spraying pipes. A method of removing small inclusions by using the device comprises:after deoxidation alloying, blowing inert gas into the descending pipe by using the spraying pipes, wherein the gas flow is 10-500L / min and air pressure is 1.0-15atm; or blowing carbonate power into steel liquid, wherein the particle size of the powder is less than 3mm, the feeding rate is 1-100kg / ton steel, the carrier is Ar, N2 or CO2 inert gas, the gas flow is 10-800L / min, and air pressure is 1.0-20atm. The invention has the characteristics of simple equipment, convenient operation, reasonable process, low cost, and good effect. The invention has the advantages of effectively removing small inclusions from steel, regulating alloying elements, manufacturing dispersion steel of small oxide, and achieving the aims of decarburization, desulfurization, dephosphorization, steel slag modification and the like.

Owner:ANGANG STEEL CO LTD

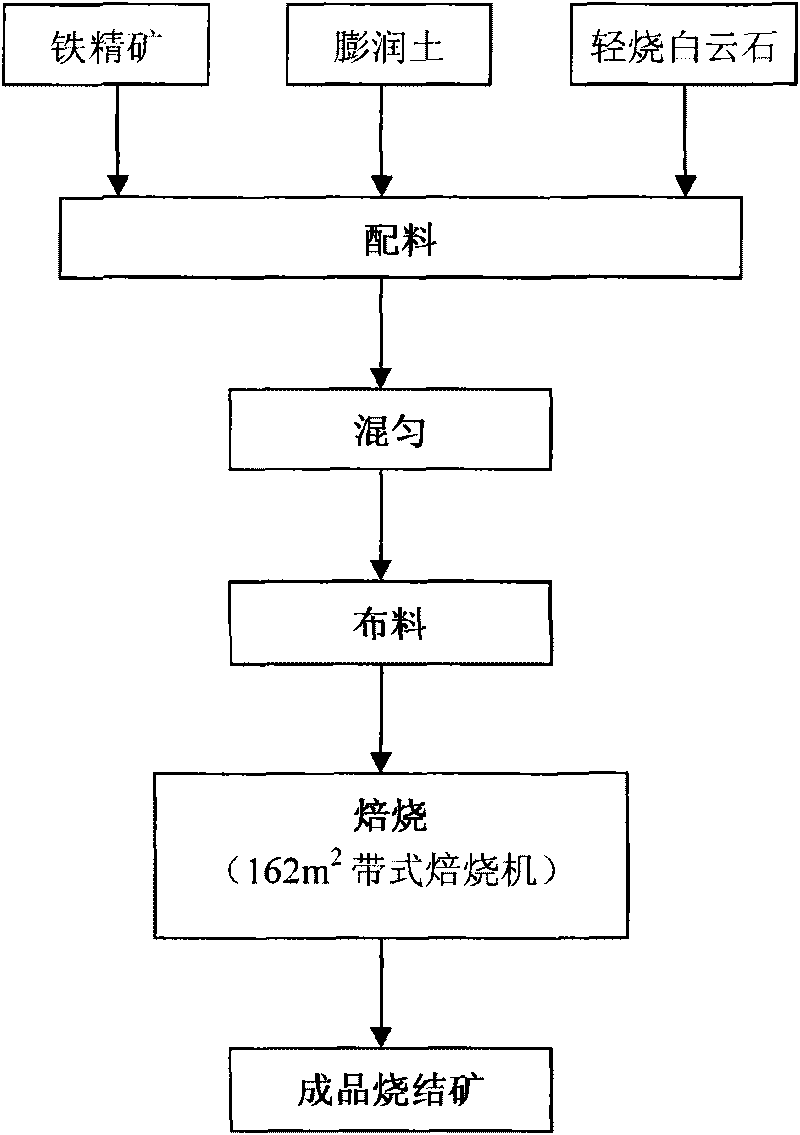

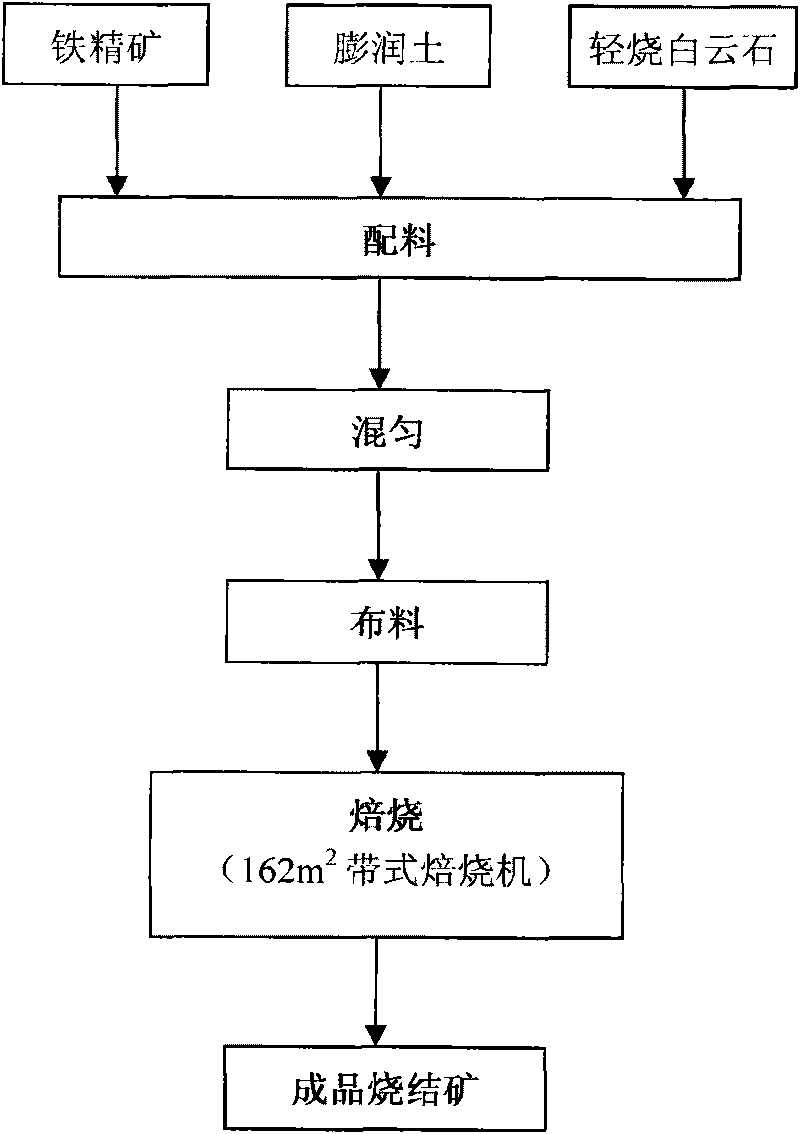

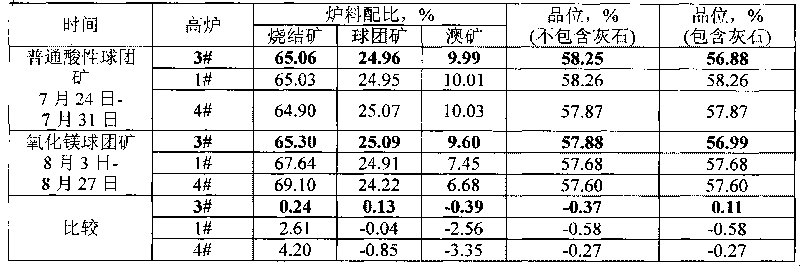

Fluorine-containing magnesium oxide pellet ore

The invention relates to a fluorine-containing magnesium oxide pellet ore which comprises the following raw materials: an iron material, bentonite and caustic calcined dolomite. The iron material is the mixed iron ore concentrate of Baotou steel Baiyun'ebo iron ore concentrate and common iron ore concentrate; the proportion of the Baiyun'ebo iron ore concentrate in the iron material is larger than 0 and not larger than 60wt percent, the bentonite accounts for 1.0-1.2wt percent relative to the raw materials, and the caustic calcined dolomite accounts for 3-4wt percent relative to the raw materials, wherein in the caustic calcined dolomite, CaO content is larger than 40wt percent, MgO content is not smaller than 28wt percent, SiO2 content is smaller than 8.0wt percent, and the proportion of granularity of 200 meshes is not smaller than 80wt percent; and MgO / SiO2 content in the fluorine-containing magnesium oxide pellet ore is not larger than 0.5. The invention fully utilizes Baotou steel Baiyun'ebo iron ore resources and can reduce the dosage of the bentonite and improve the reducibility and dropping temperature of the pellet ore by adjusting the pellet ore alkalinity and magnesium oxide content through adopting the dolomite; compared with acid pellet ore, the magnesium oxide pellet ore improves the reducibility and a low-temperature reduction degradation index, reduces the expansion ratio, and can meet the production requirement of a large blast furnace though with slightly reduced compressive strength of the pellet ore.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

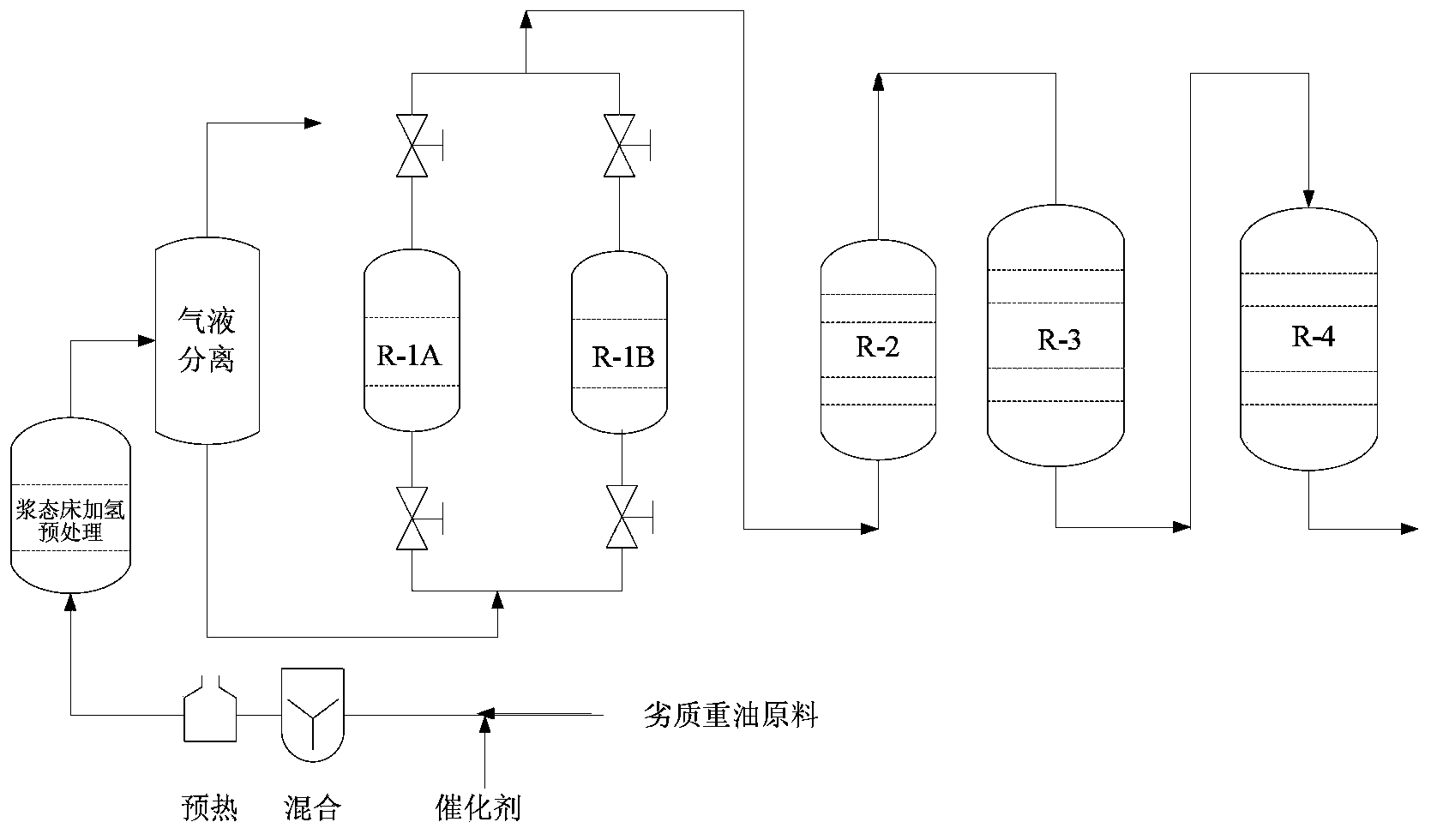

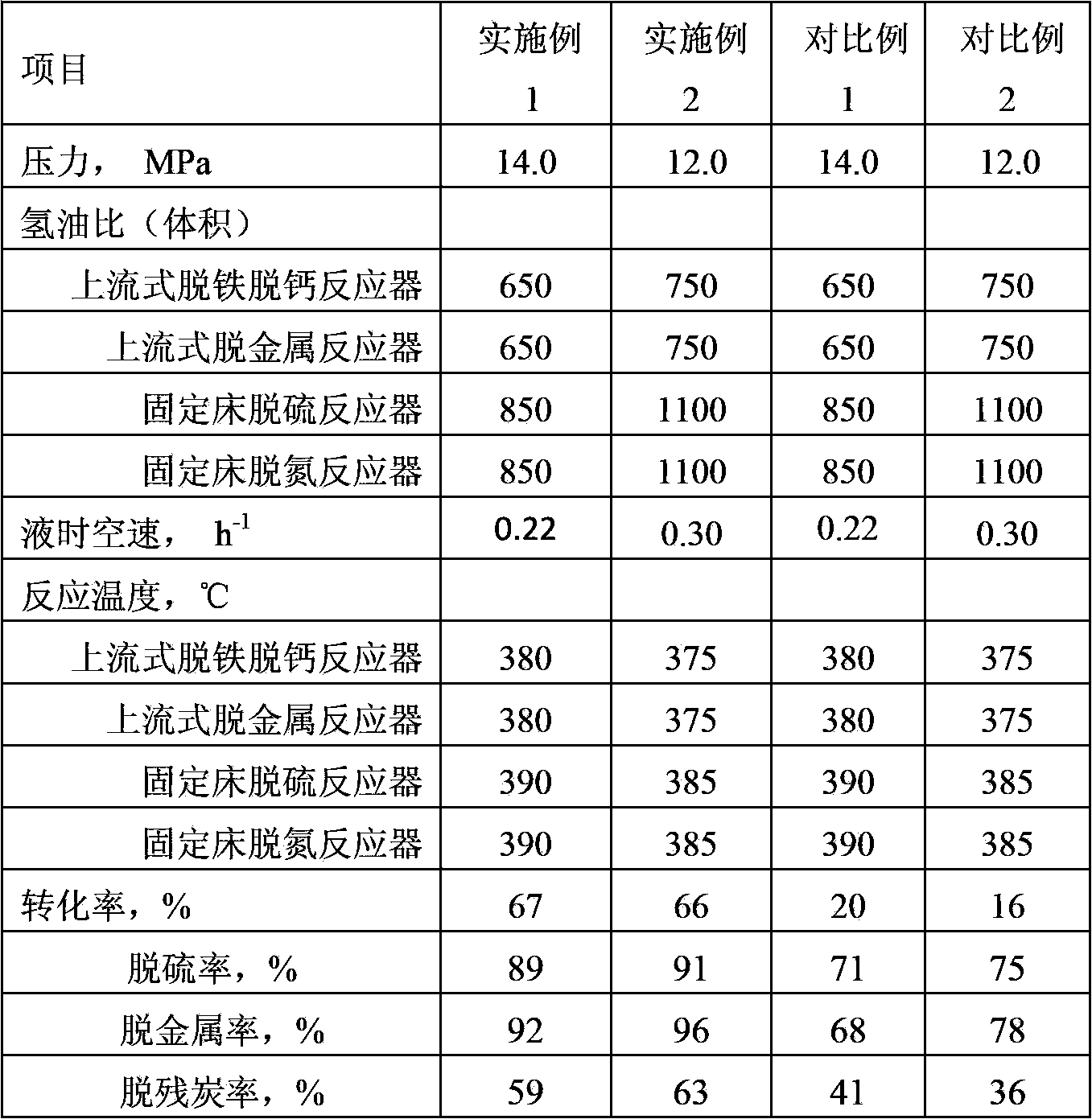

Hydrotreating combined process for inferior heavy oil and residual oil

ActiveCN103540350AHigh demetallizationImprove desulfurizationTreatment with hydrotreatment processesSlurry reactorFuel oil

The invention relates to a hydrotreating combined process for inferior heavy oil and residual oil. The hydrotreating combined process comprises the following steps of: firstly pretreating the heavy oil and / or residual oil raw material in a slurry reactor; carrying out gas-liquid separation, and hydro-upgrading the liquid-phase product in a fixed bed, wherein the hydro-pretreating part of the slurry reactor comprises a straight cylinder type slurry reactor pretreatment reactor and a slurry reactor hydro-catalyst, and the reactors used in the fixed bed hydro-upgrading part sequentially and mainly include two parallel up-flow type deferrization-decalcification reactors, one up-flow type demetalization reactor, one fixed bed desulfurization reactor and one fixed bed denitrification reactor. By adopting the hydrotreating combined process provided by the invention, not only are the hydrotreating and impurity removal capacities of the catalyst improved, but also the running cycle of the device is prolonged. The hydrotreating combined process provided by the invention can be applied to treating the inferior heavy oil and residual oil, which are high in sulfur content, metal content, and asphalt content; the conversion ratio is 30-80%; the raising rate of the pressure drop of the reactors can be effectively reduced so as to achieve the long-period running of the device.

Owner:PETROCHINA CO LTD

Iron ore pellet and its preparation method

The invention discloses an iron ore pellet preparing method, Which comprises the following steps: putting 2-4wt% forsterite and 0. 2-0. 8wt% agglomerant in iron ore; mixing up water (the water content of mixture: 6-11wt%); making ball and drying; preheating at the temperature of 900-1000 deg. c for 15-25min; roasting at the temperature of 1260-1320deg. c for 20-40min; mixing up 20-40% jevigating, 5-10% polyacrylamide, 0-5% polypropylene, 0-5% sodium humate, 20-40% twaterproof putty powder, 3-5% caoline and 5-10% copperas in mass fraction to obtain agglomerant. The invention can improve the strength of green-ball and the heat endurance.

Owner:WUHAN UNIV OF SCI & TECH

Dual-circulation single-tower desulfurization systems and process thereof

The invention discloses dual-circulation single-tower desulfurization systems and a process thereof. A liquid collecting disc arranged in a desulfurization tower divides a desulfurization area into an upper circulation desulfurization area and a lower circulation desulfurization area. The lower circulation desulfurization area, a lower circulation neutralization oxidation pond and a lower circulation pump altogether form a lower circulation desulfurization system. The upper circulation desulfurization area, an upper circulation neutralization oxidation pond and an upper circulation pump altogether form an upper circulation desulfurization system. The dual-circulation desulfurization systems which are relatively independent are formed in the desulfurization tower, and desulfurization of flue gas is completed by the two dual-circulation desulfurization systems together. The dual-circulation single-tower desulfurization systems which operate relatively independently are arranged within one desulfurization tower, so that high desulfurization efficiency is guaranteed, and the slurry circulation amount and the system power consumption are reduced, besides, the integral arrangement of the single tower reduces the occupied area and saves investment. The dual-circulation single-tower desulfurization systems are particularly applicable to desulfurization of flue gas produced by burning high sulfur coal, and the desulfurization efficiency can achieve more than 99%.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

Diesel oil deep-hydro-desulfurizing-dearomatizing method

InactiveCN1488715AEasy to operateImprove desulfurizationRefining to eliminate hetero atomsCounter currentMaterial flow

The present invention relates to a diesel oil counter-current overhydro-desulfurizing and dearenizing method. The lies in that it uses low-temperature diesel oil fraction, specially the diesel oil fraction obtained by cooling said invented liquid-phase product as cooling raw material of reaction system. As compared with existent technology said invention can effectively regulate the gas-liquid flow distribution in the diesel oil counter-current hydrogenation treatment reactor, and can effectively reduce flow rate of material flow which is easy to produce flooding area, can make equipment operation more stable and can effectively raise product quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

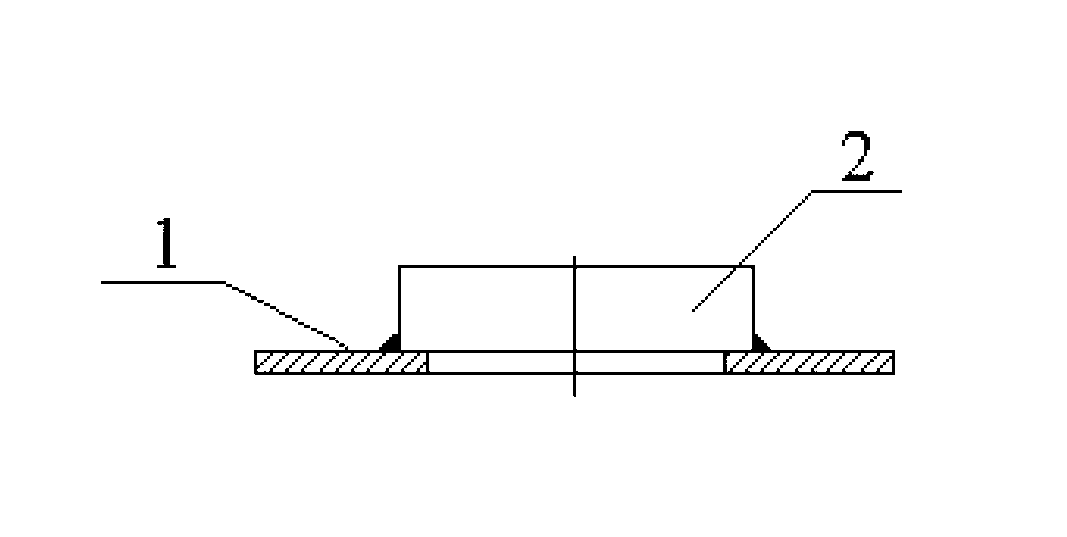

Process for industrially producing ultrapure Inconel 690 (I-690) alloy electroslag remelting ingot of 3 tons

ActiveCN103008621AReduce the chance of passingReasonable selection of cooling water temperatureIncreasing energy efficiencyMagnesiumSulfur content

The invention belongs to the technical field of electroslag remelting and relates to an improvement of a process for industrially producing Inconel 690 (I-690) alloy electroslag remelting ingots, in particular to a process for industrially producing an ultrapure low-segregation I-690 alloy electroslag remelting ingot of 3 tons. An electrode bar smelted by a vacuum induction furnace is phi430mm in dimension, and a crystallizer is phi503 / phi527mm*2400mm in dimension. Remelting process parameters are shown as follows: according to the requirements of I-690 alloy components, a five-component premelting slag system with a new proportion is adopted by the remelting, wherein the five-component premelting slag system comprises the five components: calcium fluoride, calcium oxide, aluminum oxide, magnesium oxide and titanium dioxide, and the total content of unstable oxide impurities, such as manganese oxide, ferrous oxide and silicon oxide, is less than 0.5 percent. Before the remelting is performed, an electrode is used after being baked at 700 DEG C for 8 hours, a slag charge is used after being baked at 680 DEG C for 8 hours, and argon shield is adopted during a remelting process. According to the process, the oxygen content of I-690 alloy after the remelting is performed can be reduced to 20 parts per million (ppm) or below, and thus, the goal of no oxygenation or less oxygenation is achieved after the remelting is performed. Moreover, sulfur content is reduced to 5ppm or below; the oxide inclusion grade is lower than 1, and the alloy after the remelting is performed is even in structure component, and therefore, the high-quality remelting alloy is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

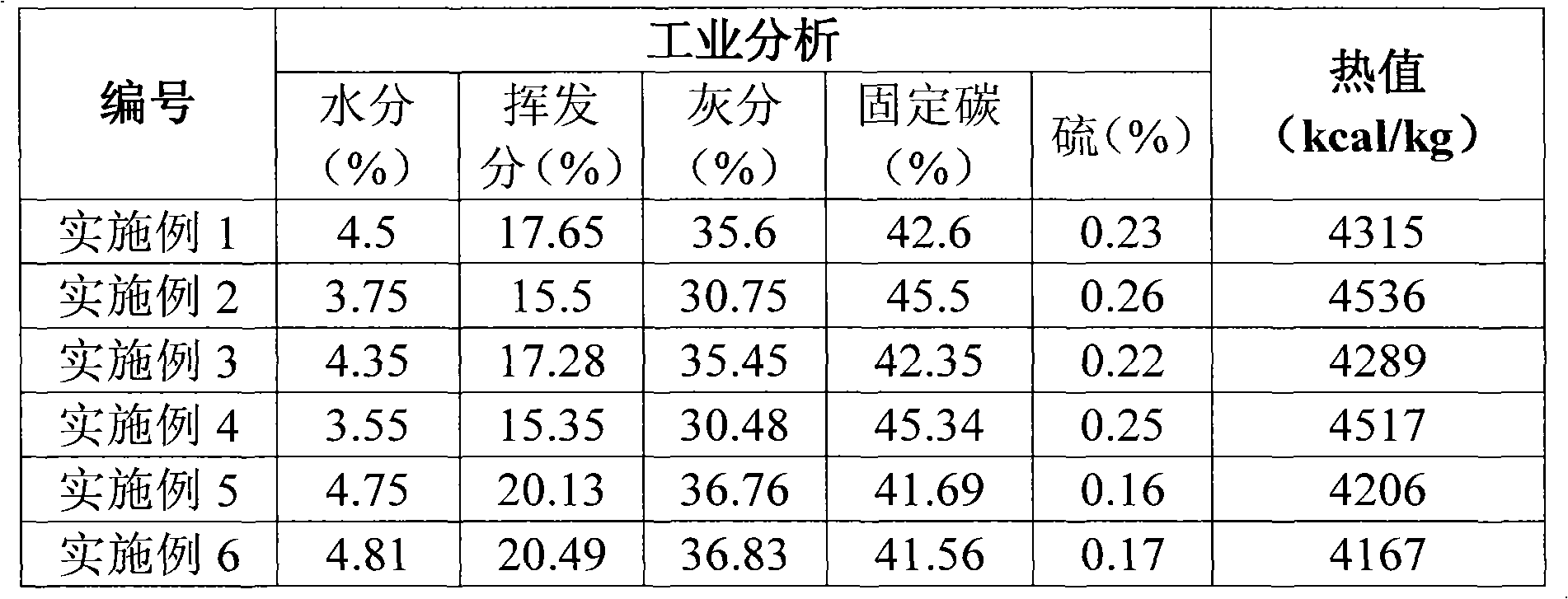

Biomass moulded coal and preparation method thereof

InactiveCN101985575ALow calorific valueLow volatileBiofuelsSolid fuelsFixation agentSodium hydroxide

The invention provides a method for preparing biomass moulded coal by using biomass and inferior smokeless pulverized coal as raw materials. The biomass moulded coal is prepared by uniformly mixing the biomass, the inferior smokeless pulverized coal and additives (a sulfur fixation agent, a biomass binder, an oxidant and a waterproofing agent), and performing low-pressure compression moulding by a wet method, wherein the sulfur fixation agent is calcined lime CaO; the biomass binder is light yellow dope prepared by treating bagasse by using 1 to 2 percent sodium hydroxide solution; the oxidant is potassium permanganate; and the waterproofing agent is tar or a binder. The biomass moulded coal comprises following raw materials in part by mass: 40 to 65 parts of inferior smokeless pulverized coal, 25 to 55 parts of biomass and 5 to 10 parts of additive. The biomass moulded coal has the advantages of low cost, low ignition point, high burn-off rate and integrative desulfurization and water proofing performance, and has great significance of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

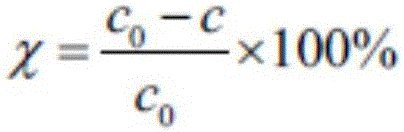

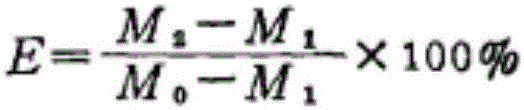

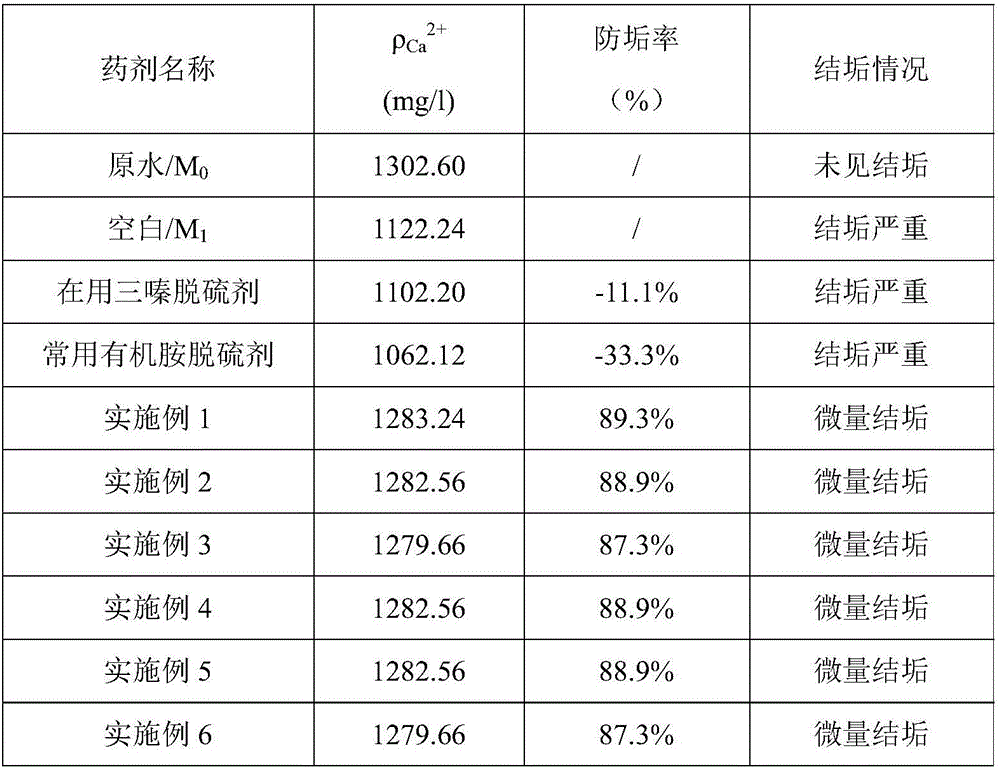

Oil field scale prevention desulfurizing agent and preparing method thereof

ActiveCN106554804AImprove desulfurizationGood antifouling effectHydrocarbon oils refiningTreatment apparatus corrosion/fouling inhibitionTemperature controlPhosphate

The invention relates to the field of chemical desulphuration, and discloses an oil field scale prevention desulfurizing agent and a preparing method thereof. The oil field scale prevention desulfurizing agent is prepared in the manner that a modifying agent, a synergist and a dispersing agent are added in a main agent, and the main agent is obtained in the manner that organic amine and a formaldehyde solution serve as raw materials and are subjected to polymerization, dehydration and refining. The preparing method comprises the steps that the organic amine is stirred under a certain temperature condition, the formaldehyde solution is dripped, the temperature control reaction is conducted after dripping is finished, and the main agent is obtained after decompression dehydration under a certain vacuum degree and temperature condition; then the reaction temperature is controlled, and a modifying agent is dripped in the main agent, and the reaction is conducted; and finally, the synergist and the dispersing agent are sequentially added in a reaction product, and stirring is conducted till uniform mixing. The oil field scale prevention desulfurizing agent has a nitrogen-containing triazine structure, the efficient desulfuration effect can be guaranteed, the phosphate functional group is introduced in molecules, and meanwhile excellent scale prevention performance is achieved. Thus, the oil field scale prevention desulfurizing agent has good desulfuration and scale prevention performance at the same time, and the oil field scale prevention desulfurizing agent is suitable for the desulfuration process of oil field fluid production.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Composite active carbon desulfurizer and preparation method thereof

InactiveCN103736391AReduce dosageImprove desulfurizationDispersed particle separationEnvironmental resistanceSodium bicarbonate

A composite active carbon desulfurizer is prepared from the following raw materials by weight: 100-120 parts of bamboo charcoal, 30-34 parts of quicklime, 10-12 parts of weathered coal, 3-4 parts of sodium hydroxide, 12-14 parts of sodium bicarbonate, 10-12 parts of ammonium bicarbonate, 30-35 parts of gypsum, 40-45 parts of fresh reed roots, 35-39 parts of zeolite, 5-6 parts of sodium tripolyphosphate, 4-5 parts of carboxymethylcellulose sodium, 2-3 parts of sodium laurate, 4-5 parts of auxiliary agents, and a proper amount of water. By using zeolite, fresh reed roots, weathered coal, gypsum and the like, after high temperature carbonization, the desulfurizer of the invention not only has adsorption and ion exchange effects, but also has antibacterial effect, saves the using amount of bamboo charcoal, and improves economic benefits and environmental protection benefits; by using a plurality of alkaline compounds, rapid and thorough desulfurization is realized; the desulfurizer of the invention can adsorb SO2, SO3, H2S, organic sulfur, n-butyl sulfur of waste gas and waste water, is wide in application, and causes no secondary pollution.

Owner:WUHU ZHONGLU IND

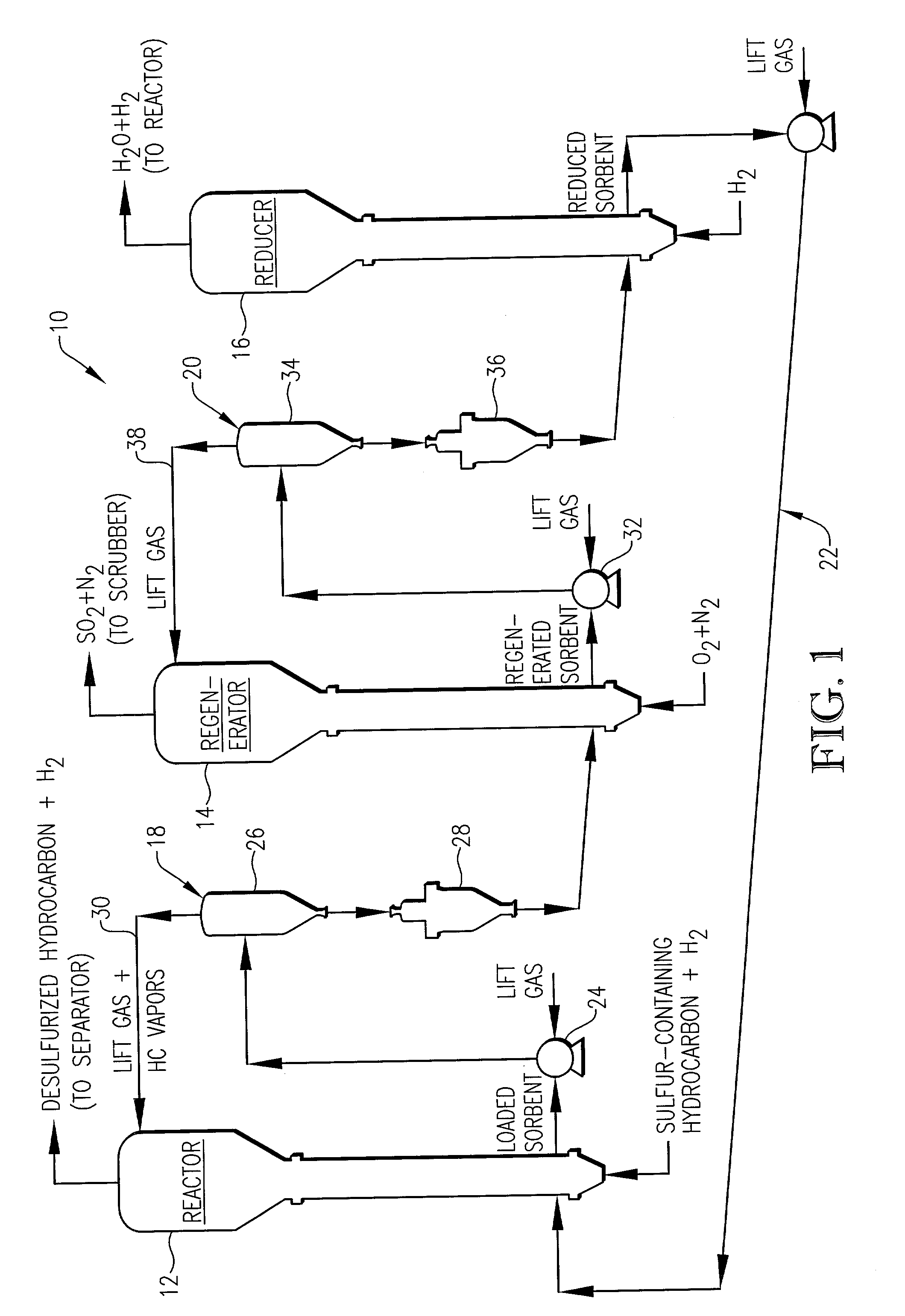

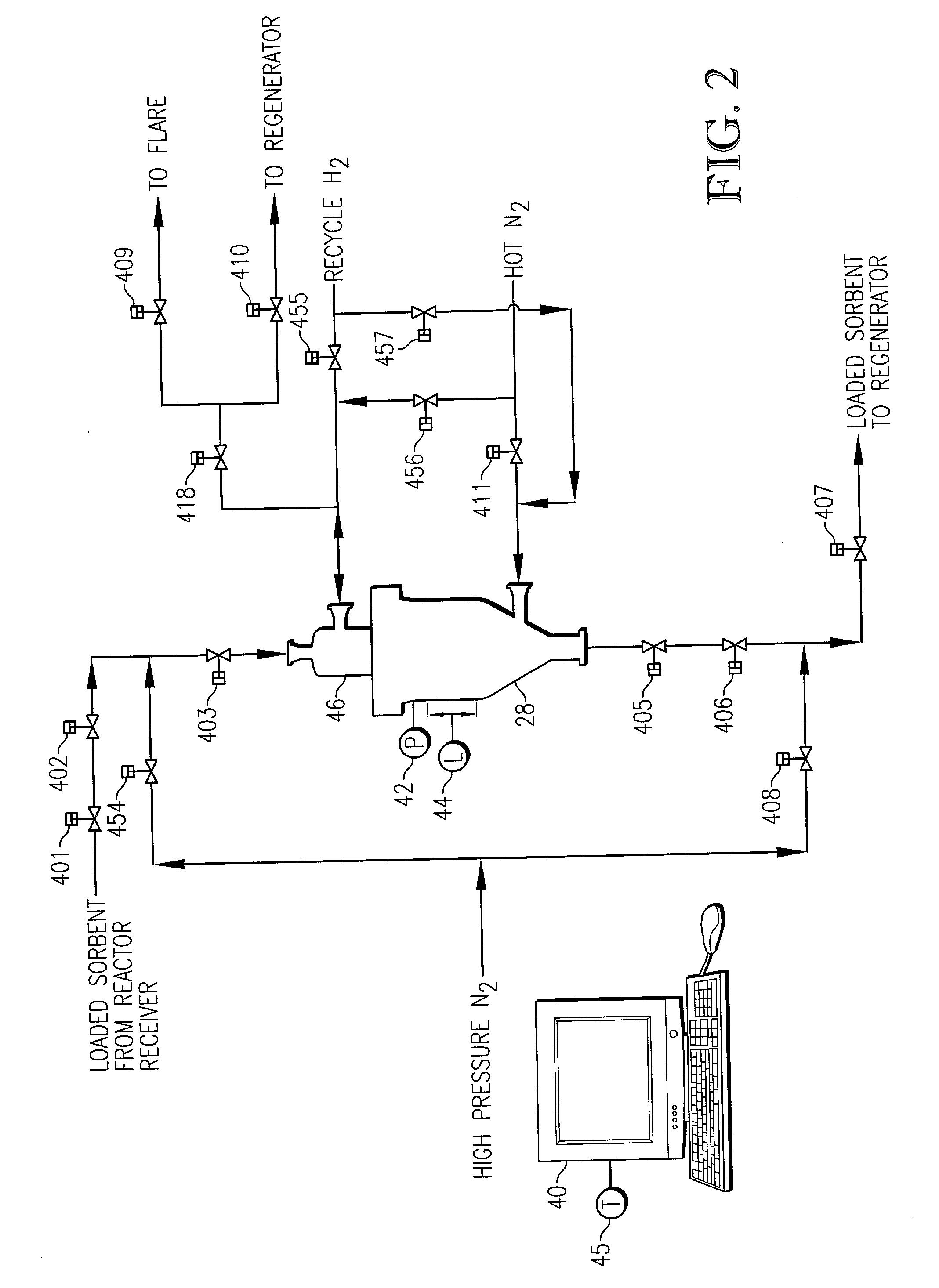

Desulfurization system with novel sorbent transfer mechanism

InactiveUS7172685B2Minimizes octane loss and hydrogen consumptionImprove desulfurizationGas treatmentOther chemical processesParticulatesFluidized bed

A hydrocarbon desulfurization system employing regenerable solid sorbent particulates in a fluidized bed desulfurization reactor. The sulfur-loaded sorbent particulates are continuously withdrawn from the reactor and transferred to a regenerator. A novel solids transport mechanism provides for the safe and effective transfer of the sulfur-loaded sorbent particulates from the high pressure hydrocarbon environment of the reactor to the low pressure oxygen environment of the regenerator.

Owner:CHINA PETROCHEMICAL CORP

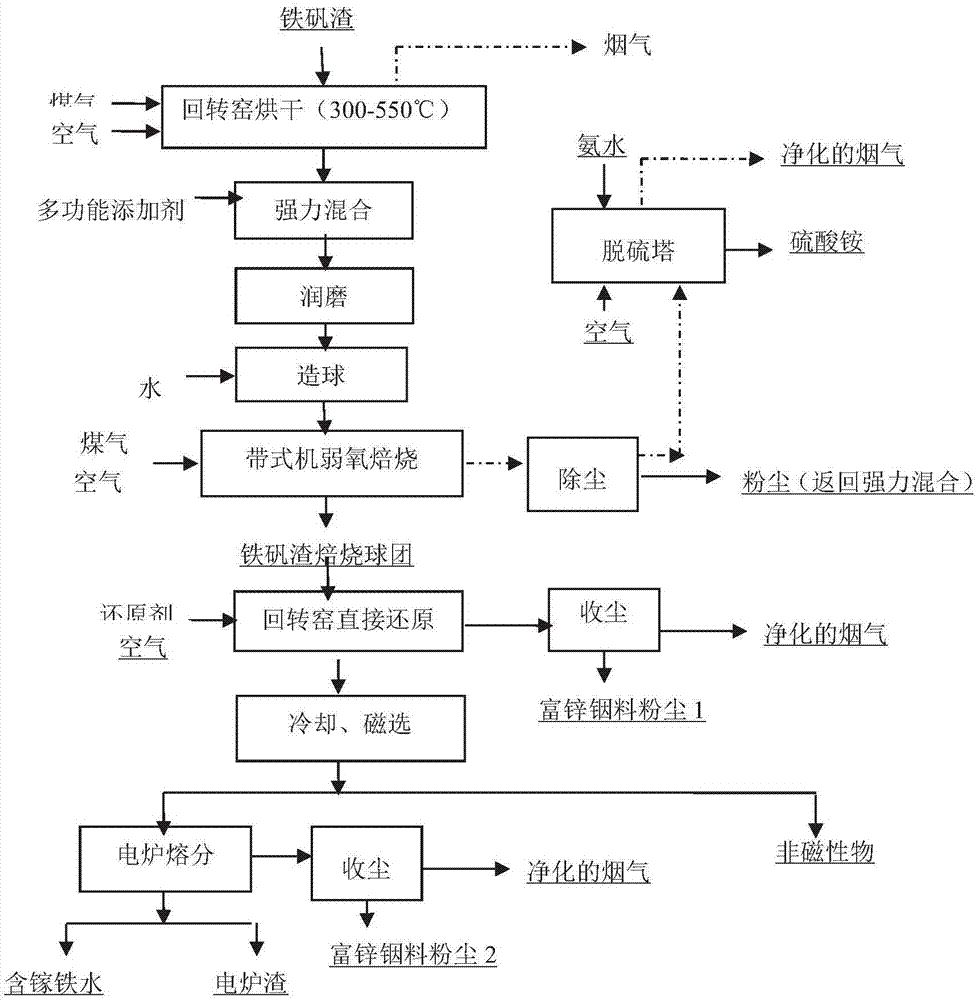

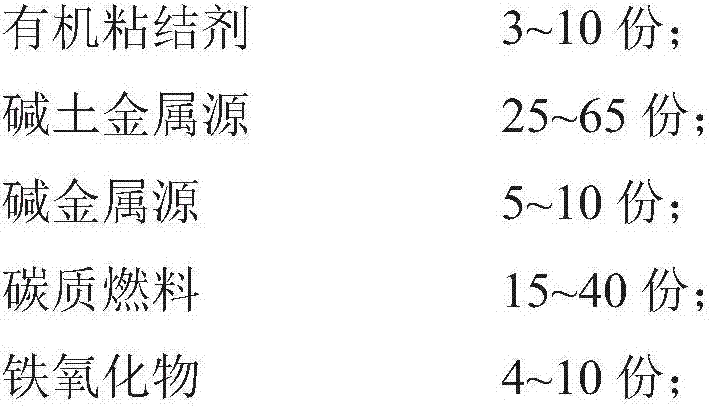

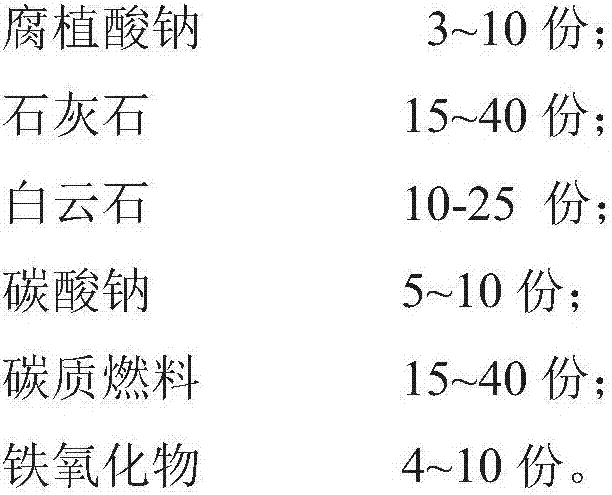

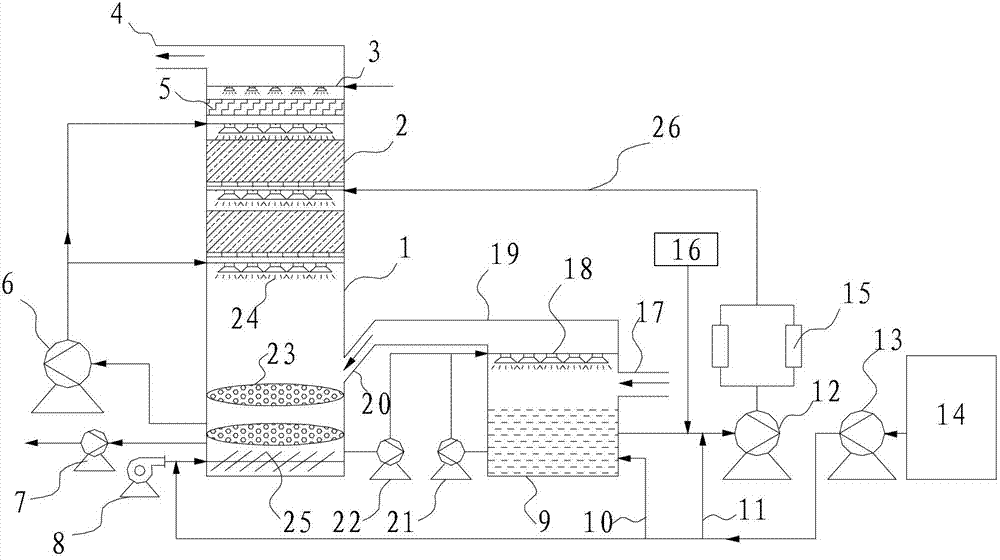

Method for recycling zinc, indium, iron and gallium from iron vanadium slag

ActiveCN107254585AHas multiple functionsHigh strengthProcess efficiency improvementAlkaline earth metalIndium

The invention discloses a method for recycling zinc, indium, iron and gallium from iron vanadium slag. The method specifically comprises the steps of uniform mixing of an additive with the iron vanadium slag, grinding, pelletizing, oxidized roasting desulfurization, direct reduction, melt separation and the like. In the pelletizing process, the special additive is adopted, and the additive comprises an organic binding agent, an alkali earth metal source, an alkali metal source, carbonaceous fuel and ferric oxide. It is verified through a great number of researches and tests that, through the additive, the pellet roasting desulfurization and solidification effects can be enhanced and improved, the roasted pellet strength is improved, the roasted pellet reducibility is improved, the pellet reduction expansion rate is lowered, and a qualified furnace material is provided for pyrogenic-process efficient separation and extraction of multiple types of valuable elements, such as, the iron, gallium, zinc, indium and sulphur.

Owner:CENT SOUTH UNIV

Ammonia flue gas desulfuration and denitration combined process and device

InactiveCN103041678APromote denitrificationImprove denitrification efficiencyUsing liquid separation agentPerfluorocarbons/hydrofluorocarbons captureFomesChemistry

The invention discloses an ammonia flue gas desulfuration and denitration combined process and device. The process comprises the following steps: liquid ammonia is fed into a desulfurization tower, flue gas to be processed is sprinkled and pre-washed and then fed into the desulfurization tower for sprinkling desulfuration and denitration, and the flue gas subjected to sprinkling desulfuration and denitration is demisted and dried and then discharged out of the desulfurization tower; cleaning solution in a prewashing tower and for sprinkling and washing comes from serous fluid in a tower kettle of the desulfurization tower, and meanwhile, liquid ammonia is injected into the prewashing tower to adjust the pH value of the cleaning solution to be 2-4.5; and the cleaning solution in the prewashing tower is led out and added with lime milk, liquid ammonia is injected into the cleaning solution added with lime milk to adjust the pH value to be 6.0-7.5, and then the mixture is filtered and returned to a sprinkling layer of the desulfurization tower to sprinkle and wash the flue gas. The flue gas denitration efficiency, the natural oxidation rate of (NH4)2SO3 and the purity of the by-product (NH4)2SO4 are all improved to a larger extent; and corrosion of the serous fluid to the desulfuration system is eliminated and the service life of the desulfuration equipment is prolonged.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com