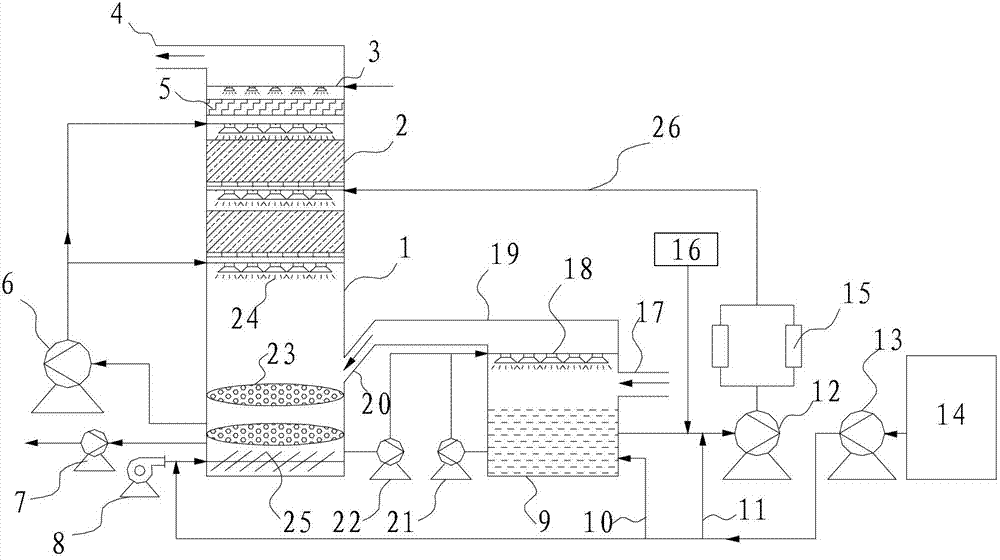

Ammonia flue gas desulfuration and denitration combined process and device

A flue gas and process technology, applied in the direction of separation method, ammonium sulfate, climate sustainability, etc., can solve the problems of reducing oxidation rate and desulfurization efficiency, and achieve the effect of promoting denitrification, improving purity, and promoting natural oxidation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] In a thermal power plant, three 220t / h boilers adopt this desulfurization and denitrification process, and the liquid-gas ratio of the desulfurization tower is 8L / Nm 3 , the pH value of the desulfurization tower is controlled at 5.0-8.0, the pH value of the pre-scrubber is controlled at 2.8-3.8, the supply of lime emulsion is related to the F in the flue gas - The molar ratio is 1.3:1, the height of each layer of filler is controlled at 60cm, the hole size of the air distribution orifice is 3-5mm, and the distance between the two layers of air distribution orifice is 2m; the inlet SO 2 The concentration is 5789mg / m 3 , NO concentration is 352mg / m 3 , the flue gas temperature is 142°C, the outlet SO 2 The concentration is 25mg / m 3 , NO concentration is 12mg / m 3 , the purity of ammonium sulfate is 99.8%, and the particle size range of ammonium sulfate crystals is 1-3mm.

Embodiment 2

[0059] A self-provided power plant, one 300WM unit adopts this desulfurization and denitrification process, and the liquid-gas ratio of the desulfurization tower is 7L / Nm 3 , the pH value of the desulfurization tower is controlled at 6.5-8.0, the pH value of the pre-scrubber is controlled at 3.0-4.0, the supply of lime emulsion is related to the F in the flue gas - The molar ratio is 1.5:1, the height of each layer of filler is controlled at 50cm, the hole size of the air distribution orifice is 3-5mm, and the distance between the two layers of air distribution orifice is 2m; the inlet SO 2 The concentration is 4672mg / m 3 , NO concentration is 421mg / m 3 , the flue gas temperature is 152°C, the outlet SO 2 The concentration is 18mg / m 3 , NO concentration is 15mg / m 3 , the purity of ammonium sulfate is 99.7%, and the crystal particle size range of ammonium sulfate is 1mm-3mm.

Embodiment 3

[0061] In a power plant, two 130t / h boilers adopt this desulfurization and denitrification process, and the liquid-gas ratio of the desulfurization tower is 9L / Nm 3 , the pH value of the desulfurization tower is controlled at 6.8-7.8, the pH value of the pre-scrubber is controlled at 3.5-4.2, the supply of lime emulsion is related to the F in the flue gas - The molar ratio is 1.2:1, the height of each layer of filler is controlled at 50cm, the hole size of the air distribution orifice is 3-6mm, and the distance between the two layers of air distribution orifice is 3m; the inlet SO 2 The concentration is 2983mg / m 3 , NO concentration is 378mg / m 3 , the flue gas temperature is 137°C, the outlet SO 2 The concentration is 16mg / m 3 , NO concentration is 8mg / m 3 , the purity of ammonium sulfate is 99.2%, and the crystal particle size range of ammonium sulfate is 1mm-3mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com