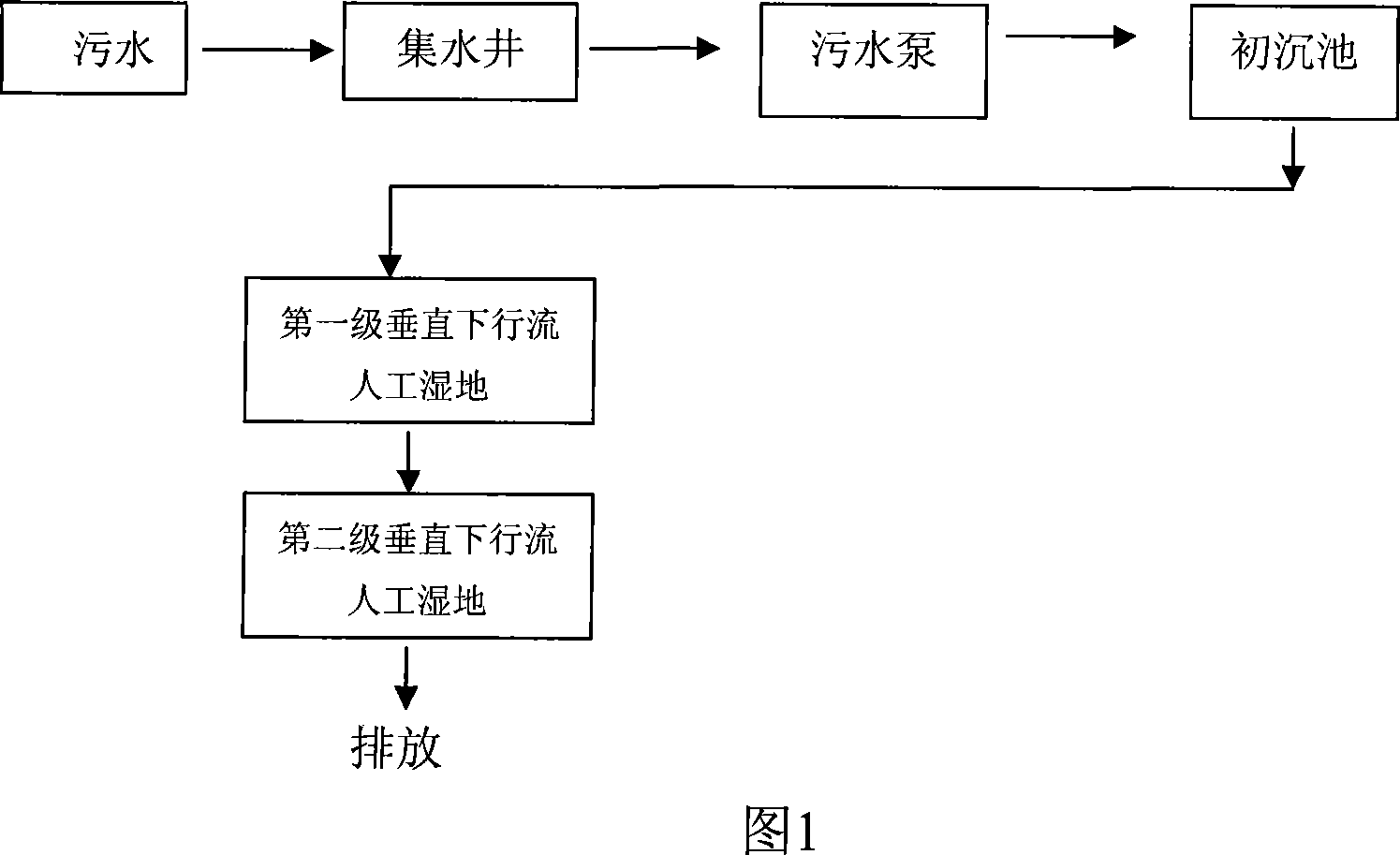

Method of treating sewage by composite vertical down flow artificial wet field and treatment system thereof

A technology of constructed wetlands and treatment systems, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., to improve the removal effect, prevent backwater phenomenon, and improve the removal capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

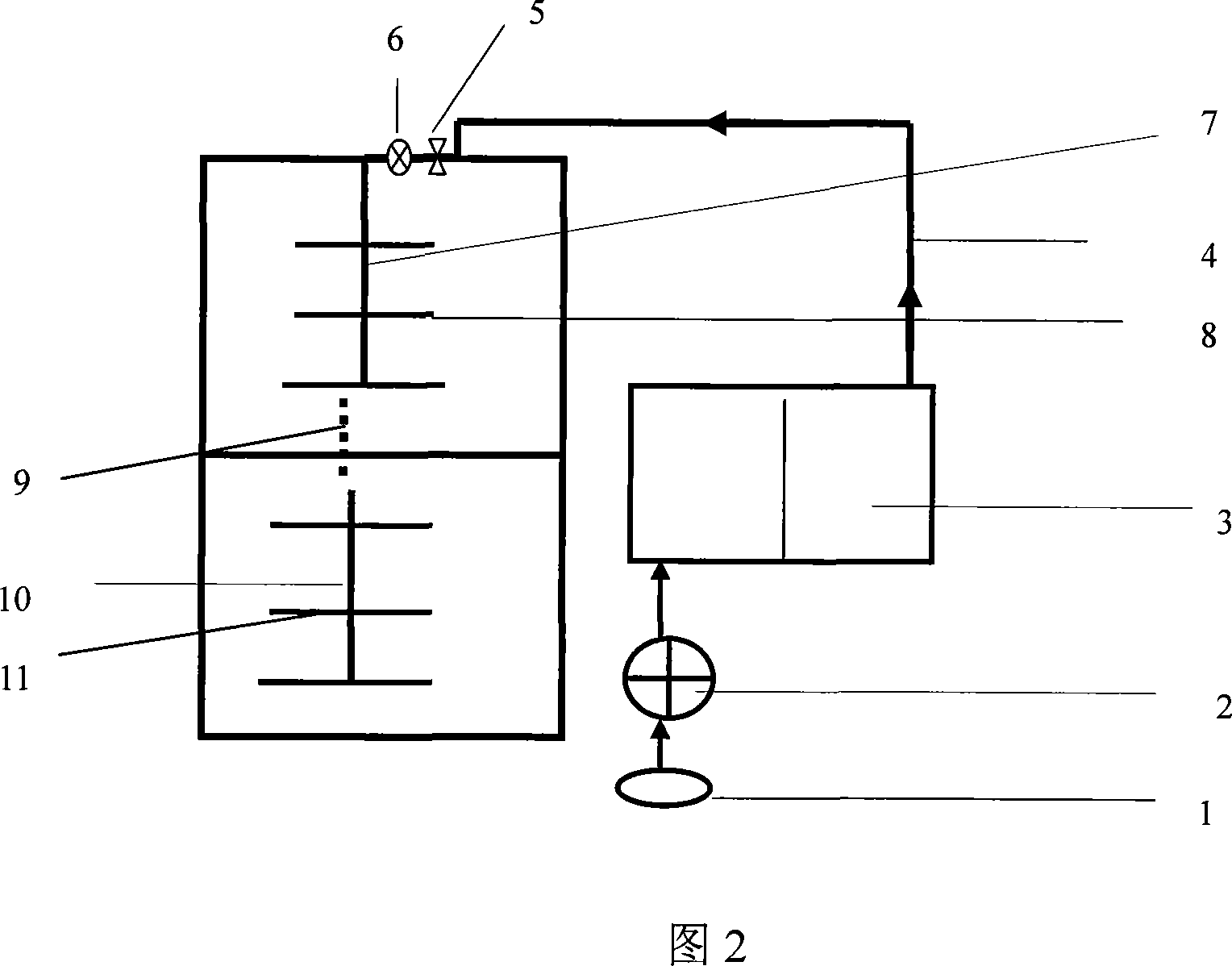

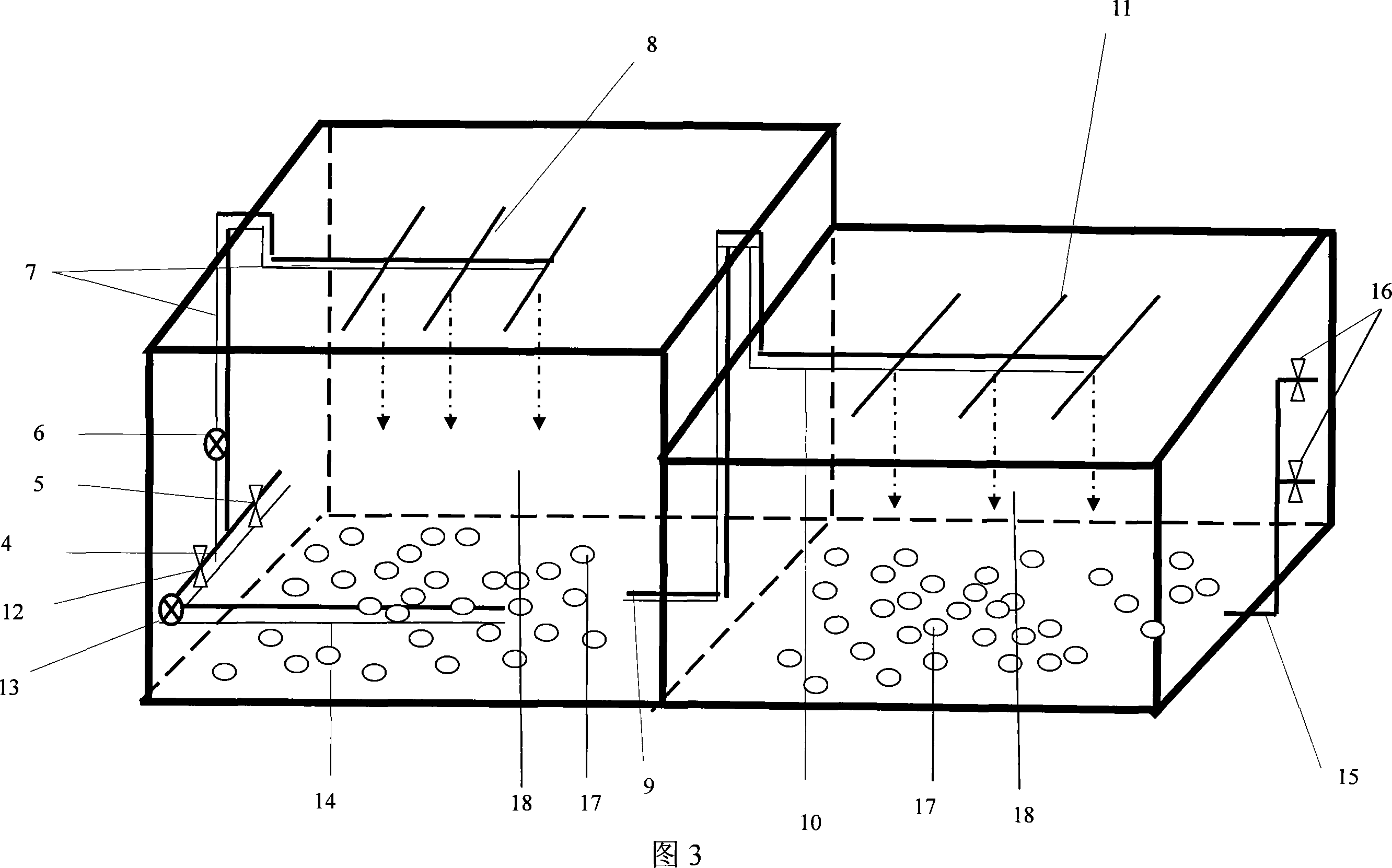

[0029] The composite vertical downflow artificial wetland treatment system of the present invention comprises the primary sedimentation tank 3, the first vertical downflow artificial wetland and the second vertical downflow artificial wetland, the primary sedimentation tank 3, the first vertical downflow artificial wetland, the second Unit structures such as level vertical downflow constructed wetlands are connected by pipes. The primary sedimentation tank 3 is connected to the first-level vertical downflow constructed wetland through the sewage pipe 4, and the second-level vertical downflow constructed wetland is connected to the first-level vertical downflow constructed wetland through the second-level vertical downflow constructed wetland. Water pipe 9 links to each other.

[0030] The vertical downflow constructed wetland system consists of a bed body, a "king" shaped water distribution pipe, and a treatment medium. The bed wall of the bed body is made of non-seepage mater...

Embodiment 2

[0044] In this embodiment, the matrix filled in the matrix layer of the first-stage vertical downflow constructed wetland is melonite (0.5-1.0 cm in diameter). The matrix filled in the matrix layer of the second vertical downflow constructed wetland is also blast furnace slag (0.1-0.5cm in diameter).

[0045] The system treatment effects (mg / L, %) in this embodiment are shown in Table 1, Table 2, Table 3, Table 4 and Table 5. Table 1, Table 2, Table 3, Table 4 and Table 5 respectively show the COD and BOD in sewage after the urban sewage is treated by the composite vertical downflow constructed wetland system 5 , NH 4 + -N, TP, TN concentration changes.

Embodiment 3

[0047] In this example, when the hydraulic load is 0.6m 3 / m 2 At d, the matrix layer of the first-stage vertical downflow constructed wetland is filled with a matrix volume ratio of blast furnace slag (0.1-0.5cm in diameter) and medium-coarse sand (0.05-0.2cm in diameter) fully mixed matrix with a volume ratio of 1:1 , The second-stage vertical downflow constructed wetland matrix layer is filled with coal ash (0.1-2.0cm in diameter) as filler.

[0048] The hydraulic loads were 1.2m 3 / m 2At d, the matrix layer of the first-stage vertical downflow constructed wetland is filled with a matrix volume ratio of 1:3 blast furnace slag (diameter 0.1-0.5cm) and medium-coarse sand (diameter 0.05-0.2cm) fully mixed mixed matrix , The second-stage vertical downflow constructed wetland matrix layer is filled with coal ash (0.1-2.0cm in diameter) as filler.

[0049] The hydraulic loads were 2.4m 3 / m 2 At d, the matrix layer of the first-stage vertical downflow constructed wetland is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com