Liquid-phase circulating hydrogenation treatment method capable of reinforcing gas-liquid mass transfer

A liquid-phase circulating hydrogenation and treatment method technology, which is applied in the fields of hydrotreating process, treatment of hydrocarbon oil, petroleum industry, etc., can solve the problems such as the failure to disclose the specific method of dissolving hydrogen, affecting the effect of hydrogenation and removing impurities, and decreasing the solubility of hydrogen. , to achieve the effect of good hydrogenation environment, saving equipment investment and improving impurity removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

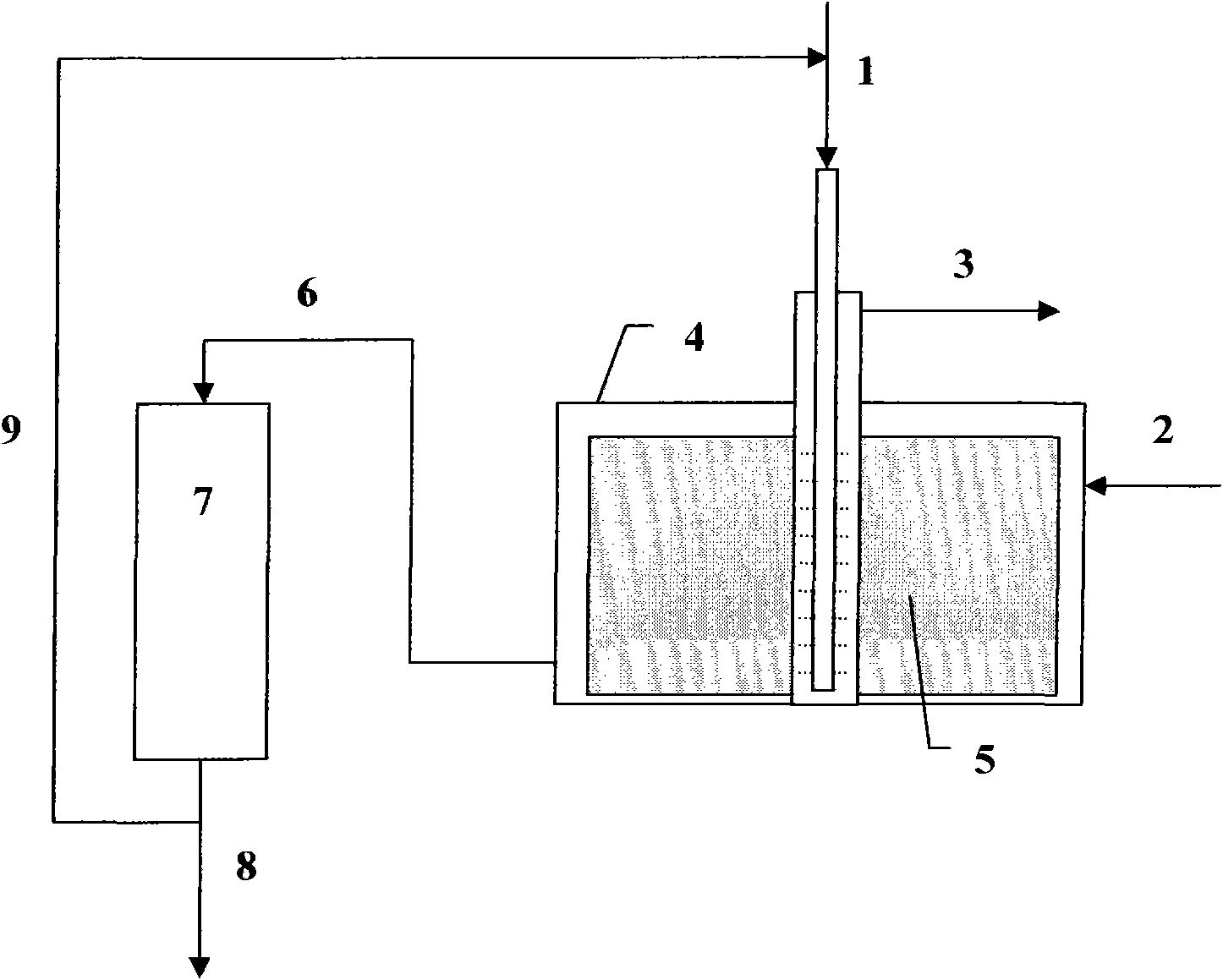

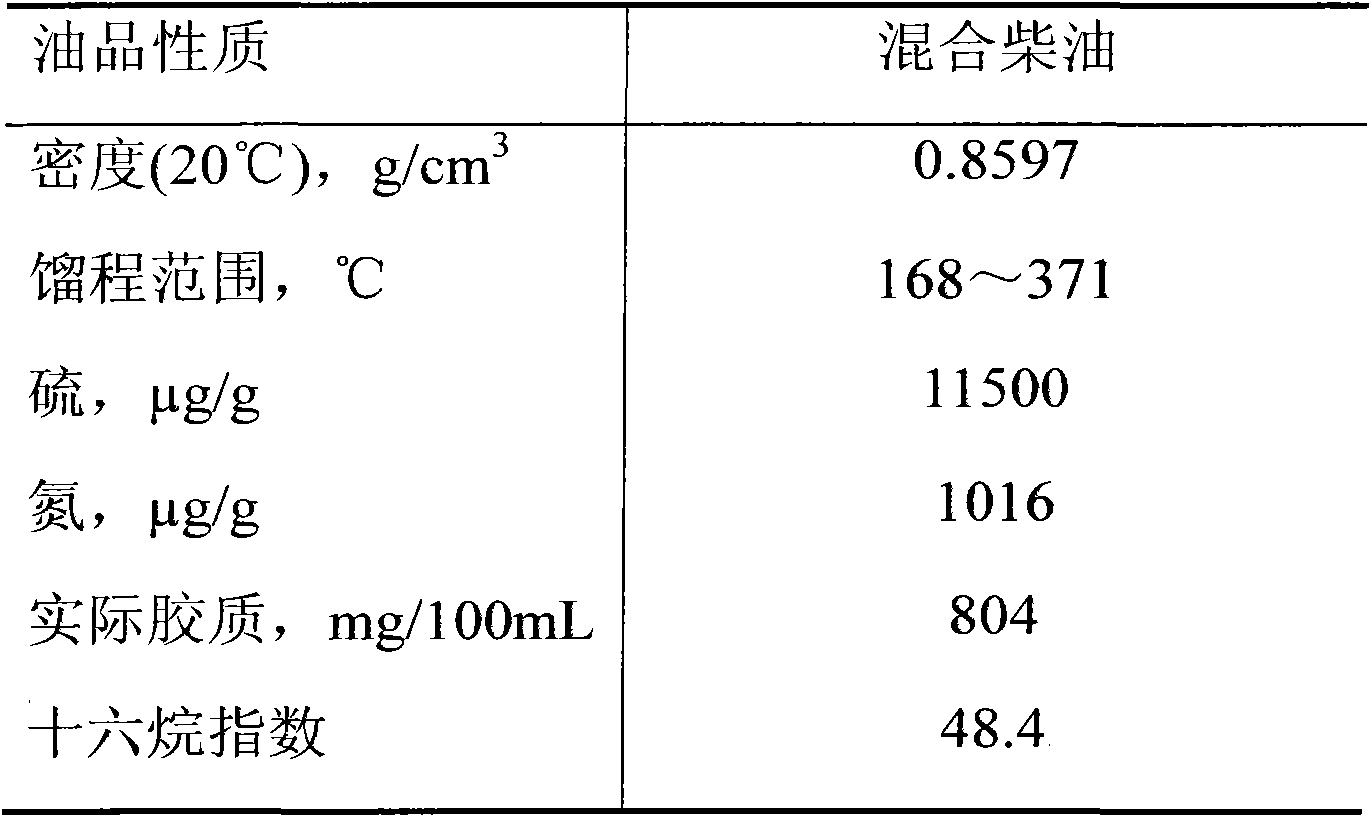

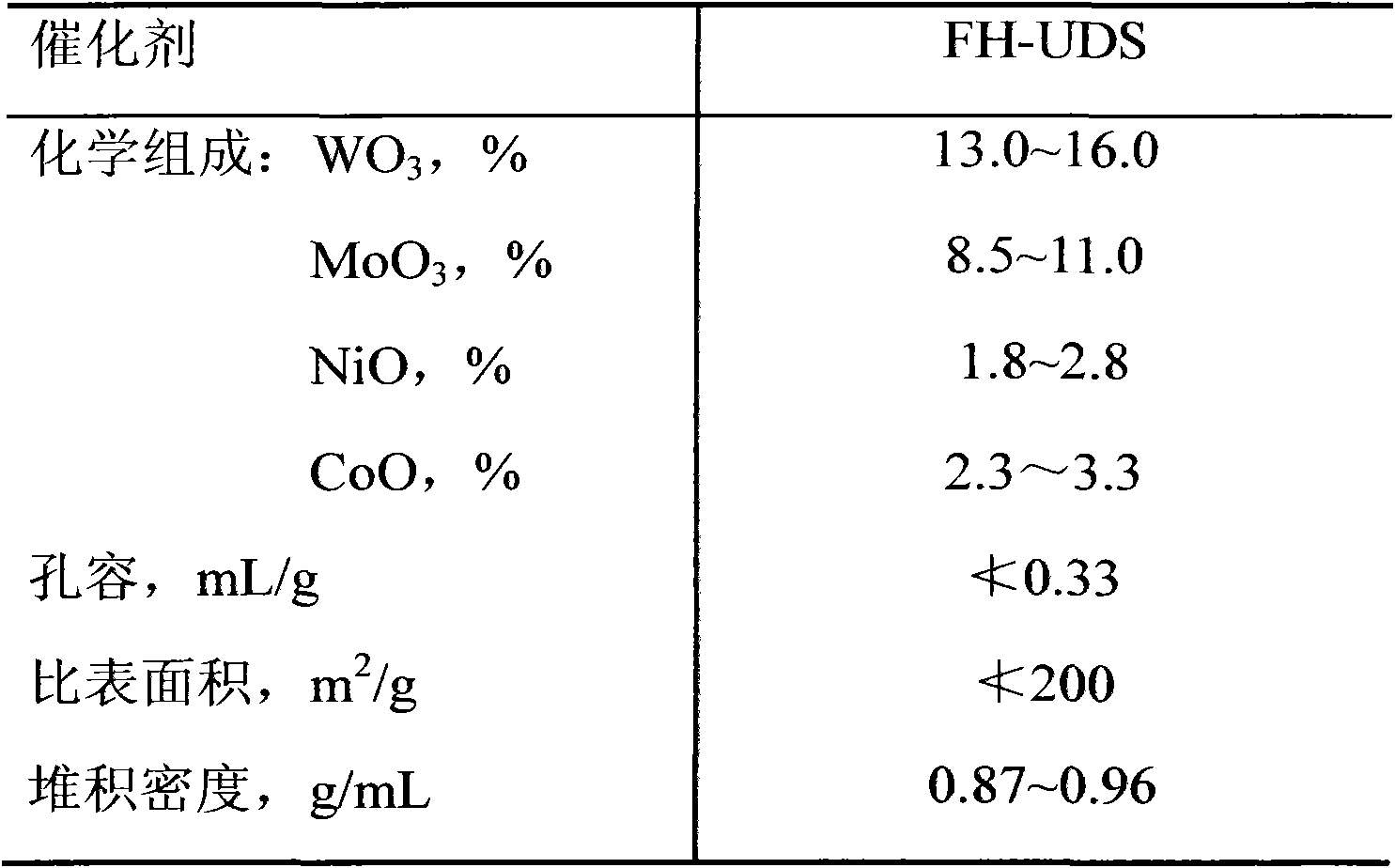

[0027] This example is an implementation of hydrocarbon oil hydrotreating, and the schematic diagram of the operation process refers to the figure 1 .

[0028] The fresh raw material oil 1 and the circulating oil 9 from the hydrogenation reactor enter the supergravity gas-liquid hydrogen dissolving equipment from the center of the rotating shaft, and contact with the fresh hydrogen gas 2 in countercurrent, and the liquid phase material dissolves hydrogen and removes H under the condition of supergravity 2 S, NH 3 and other gas impurities. After passing through the supergravity gas-liquid hydrogen dissolving equipment, the hydrogen containing hydrogen 2 S, NH 3Hydrogen 3 such as gaseous impurities is discharged from the central sleeve of the rotating shaft of the supergravity gas-liquid hydrogen dissolving equipment, and the liquid phase material 6 that fully dissolves hydrogen enters the fixed-bed reactor 7 for catalytic hydrogenation reaction, and part of the oil 8 after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com