Patents

Literature

90results about How to "Overcome surface tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

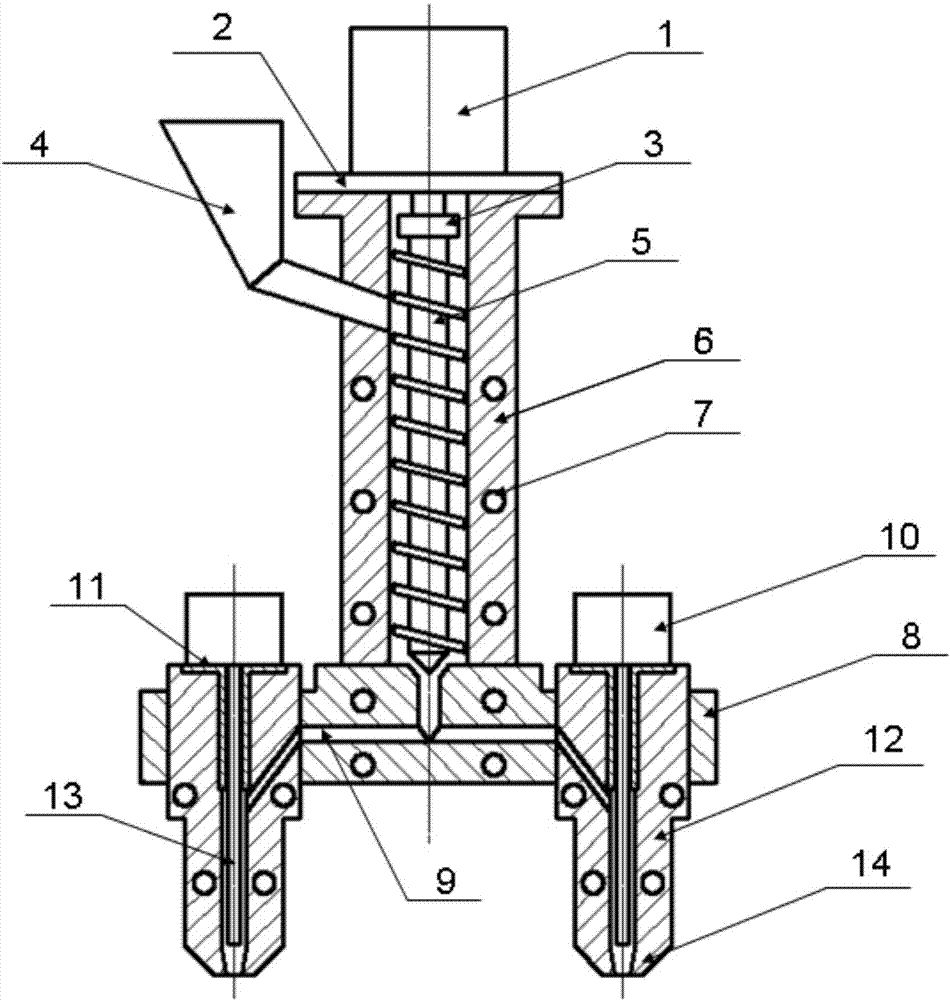

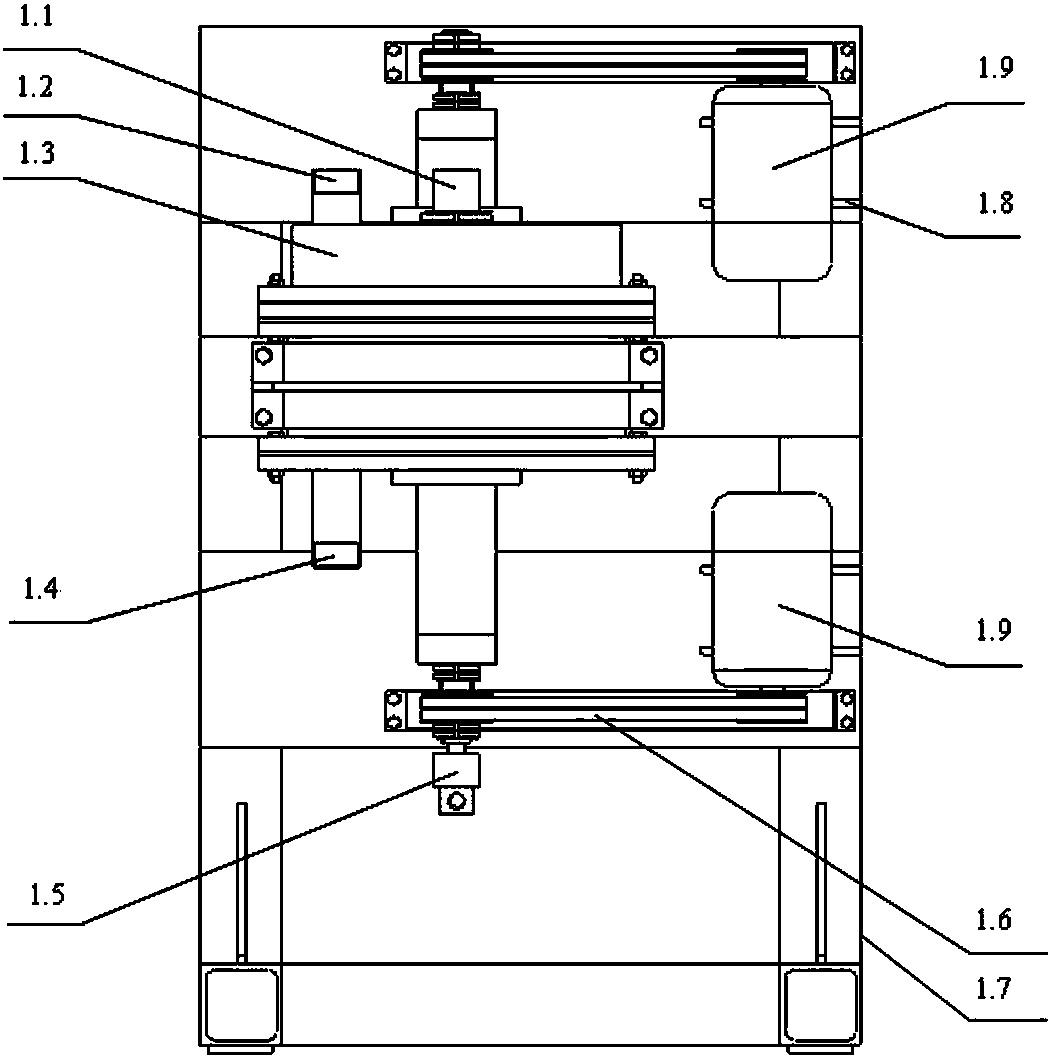

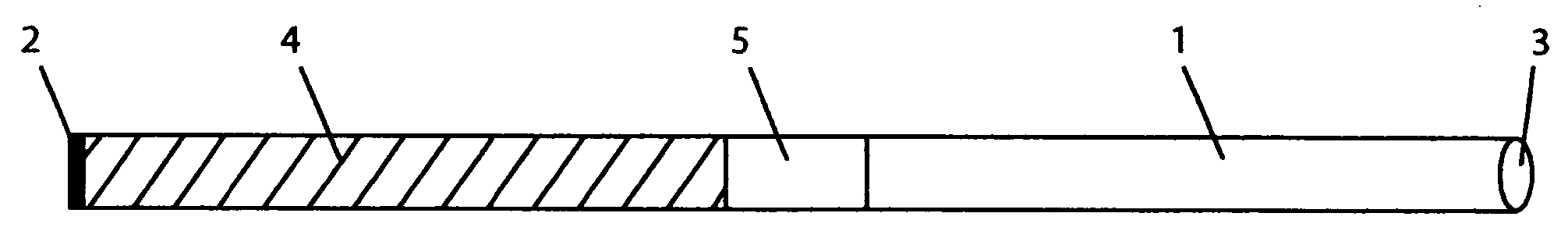

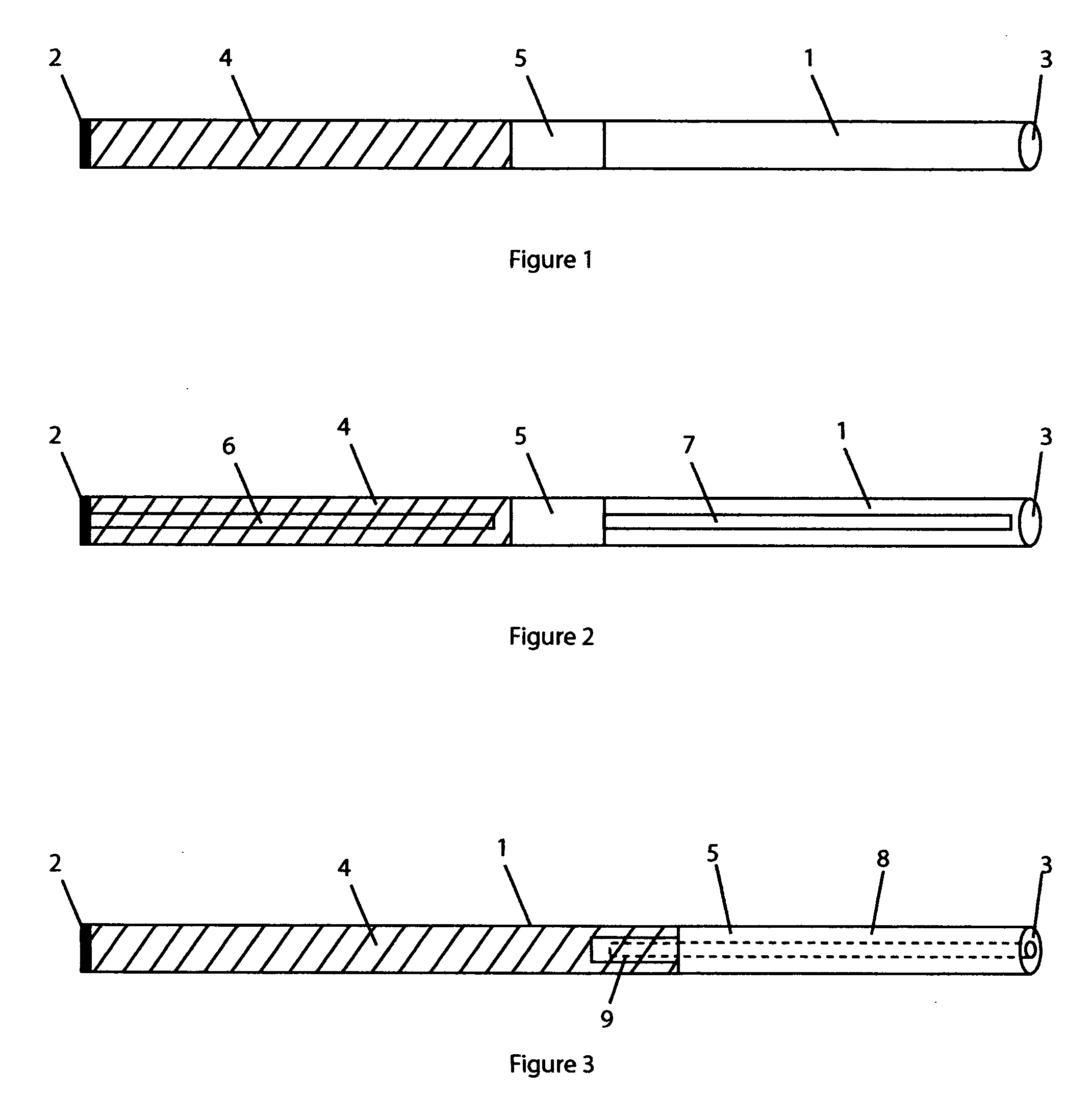

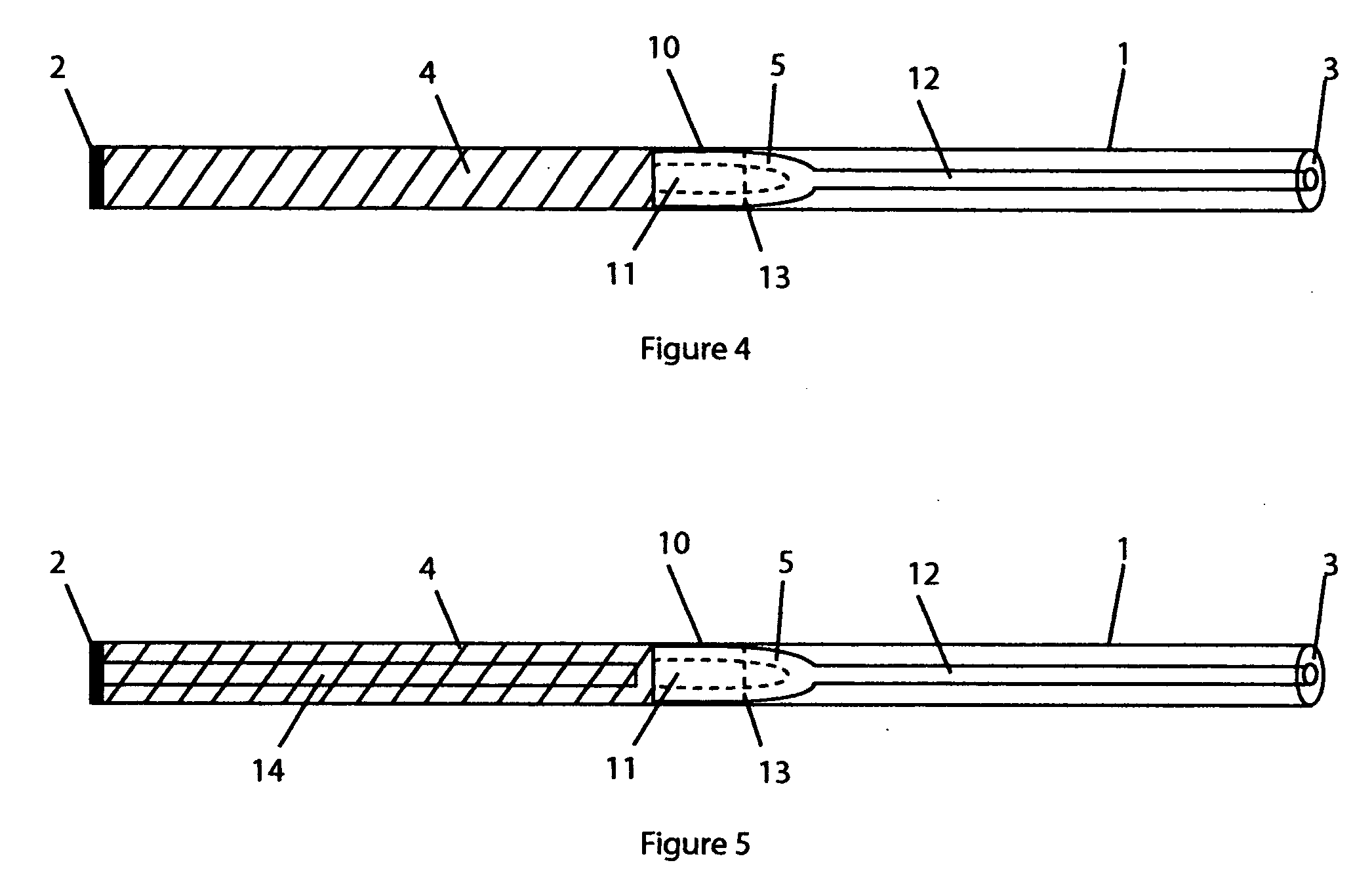

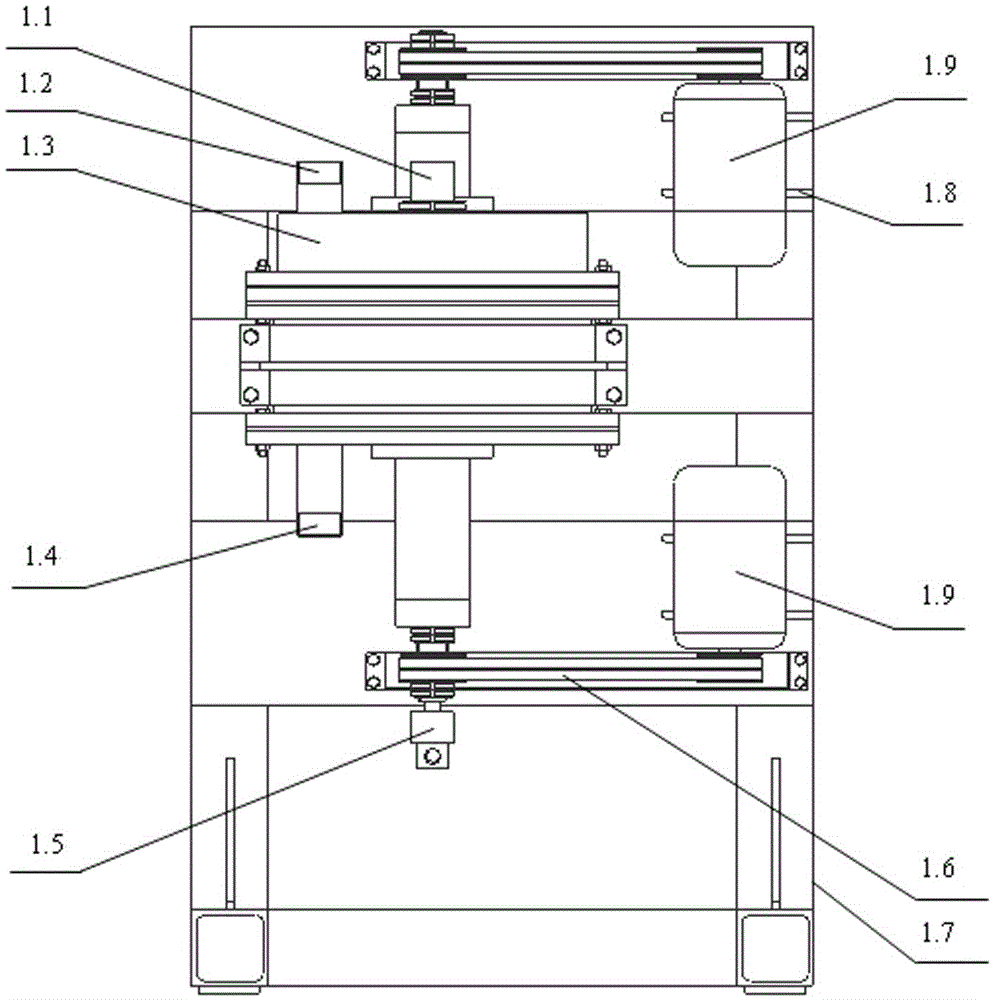

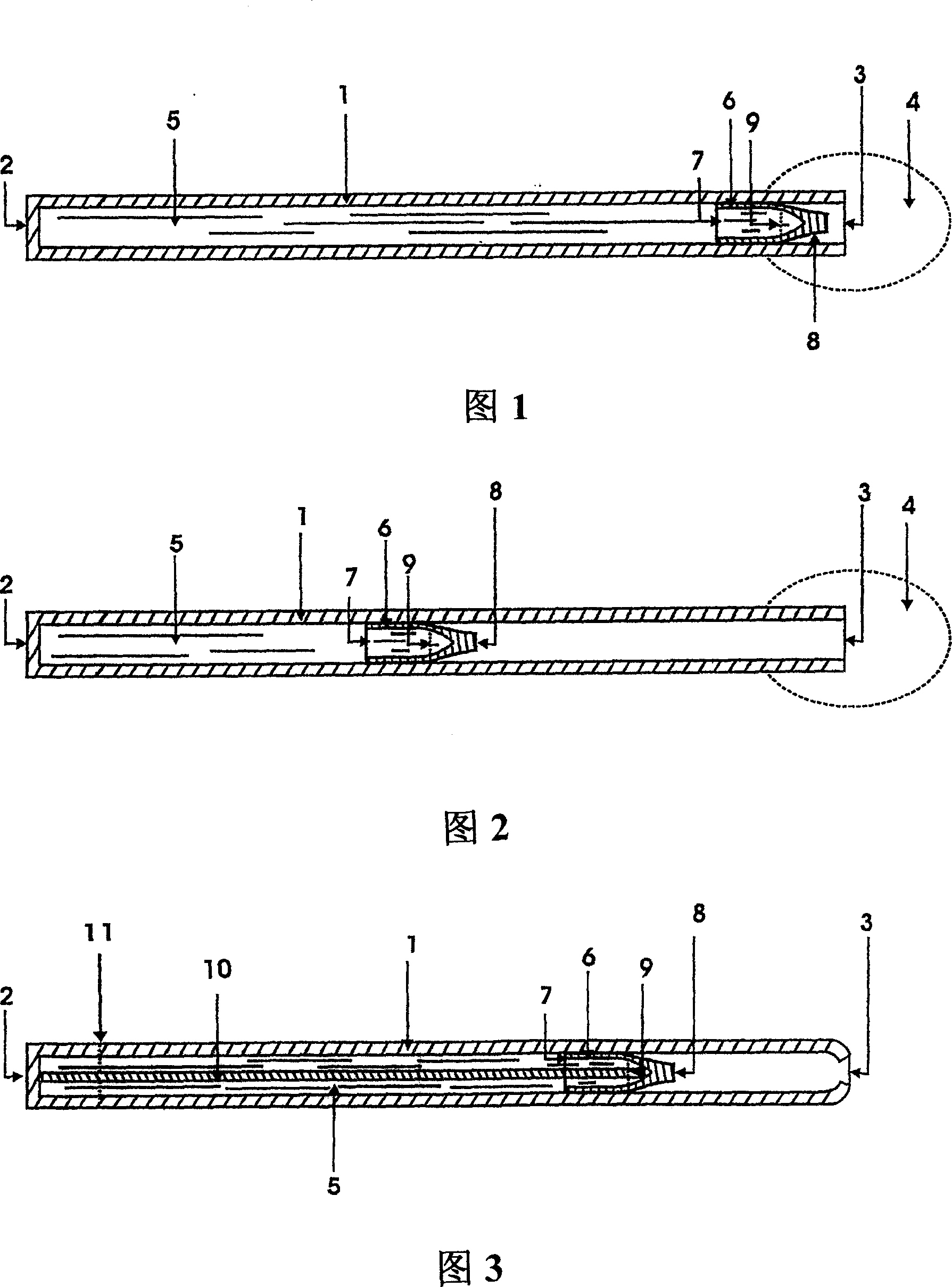

Melt differential three-dimensional printer

ActiveCN103692653ABurn out preventionConvenient Quantitative ManagementManufacturing driving meansAdditive manufacturing with liquidsHot runnerMotor drive

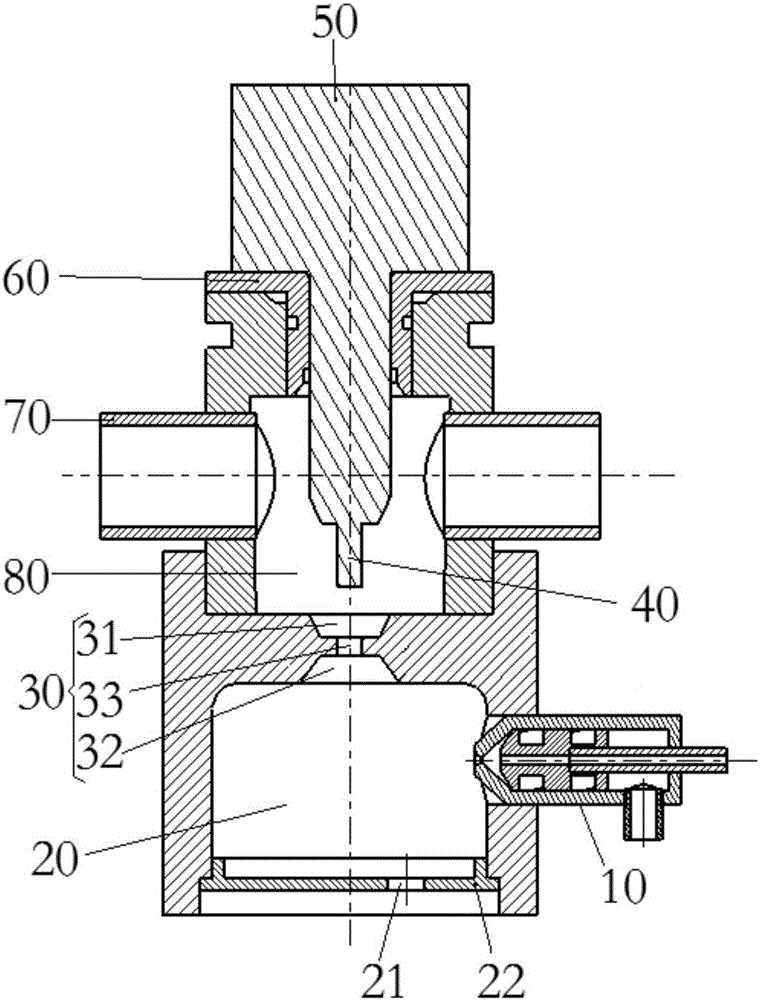

The invention discloses a melt differential three-dimensional printer. The melt differential three-dimensional printer mainly comprises a material melting unit, a micro-droplet jetting unit, a cylindrical-coordinate system molding unit and a rack, wherein a servo motor drives a screw rod to rotate in the material melting unit; a heater, which is fixedly arranged inside a machine cylinder, ensures that granules are entirely plastified through temperature regulation; a molten material is transmitted by the screw rod to the micro-droplet jetting unit; in the micro-droplet jetting unit, the molten material is transmitted into a valve body through a hot runner in a runner plate; a linear servo motor drives a valve needle to do reciprocating motion in the valve body so as to quantitatively and intermittently squeeze the molten material out of a nozzle to form melt micro-droplets; in the cylindrical-coordinate system molding unit, the molten micro-droplets are injected to a bearing table for cooling and deposition molding; the servo motors in the left-right direction and in the vertical direction are respectively engaged with the corresponding screw rod to rotate so as to drive the material melting unit and the micro-droplet jetting unit to move along the left-right direction and the vertical direction; a circumference servo motor drives the bearing table with a worm gear to rotate through a worm rod so as to realize three-dimensional movement under a cylindrical-coordinate system.

Owner:BEIJING UNIV OF CHEM TECH

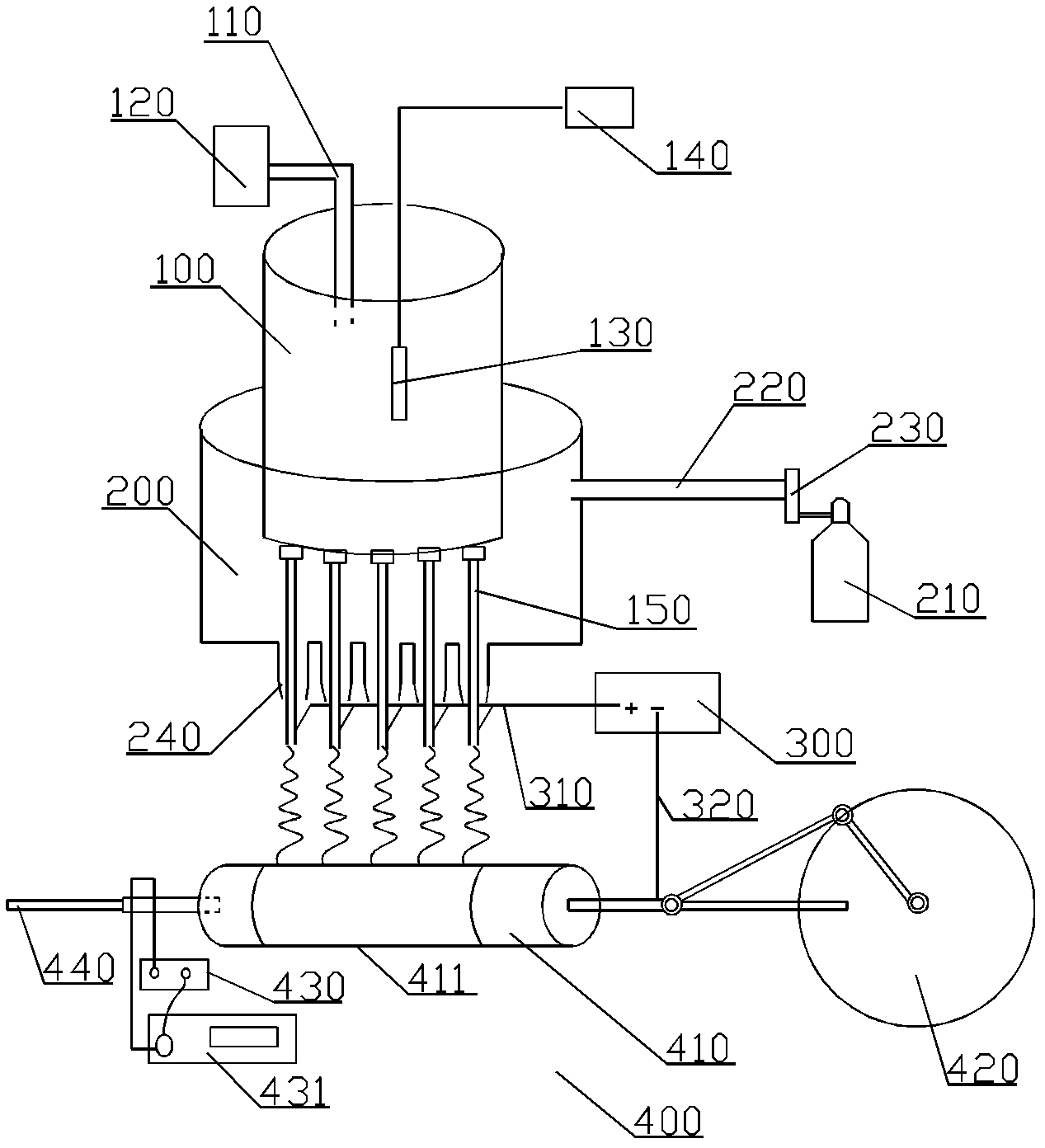

Device and method for preparing polysulfonamide nanometer fiber nets by means of airflow-electrostatic combination

ActiveCN102534822AOvercome surface tensionLarge specific surface areaStretch-spinning methodsFiberElectrospinning

The invention discloses a device and a method for preparing polysulfonamide nanometer fiber nets by means of airflow-electrostatic combination. The device comprises a liquid storage tank, an air chamber, an electrostatic generator and a receiving device, a plurality of spinnerets are arranged at the bottom of the liquid storage tank, the air chamber is arranged outside the liquid storage tank, air outlets in the number equal to that of the spinnerets at the bottom of the liquid storage tank are arranged at the bottom of the air chamber, the spinnerets are arranged inside the air outlets, an electrode with multiple pins are led from the positive electrode of the electrostatic generator to be connected with the spinnerets, and a lead is led from the negative electrode of the electrostatic generator to be connected with the receiving device. The method includes steps of combining the airflow method and the electrostatic spinning method effectively to prepare the polysulfonamide nanometer fiber nets. By the device and the method for preparing the polysulfonamide nanometer fiber nets, the specific surface area of the polysulfonamide nanometer fibers is enlarged greatly, the problem of blockage of existing electrostatic spinning needles due to inflow of the airflow is alleviated greatly, and spinning efficiency is improved. Besides, nanometer fibers can be prepared at the normal temperature directly, so that production procedures are simplified and production cost is saved.

Owner:SHANGHAI UNIV OF ENG SCI

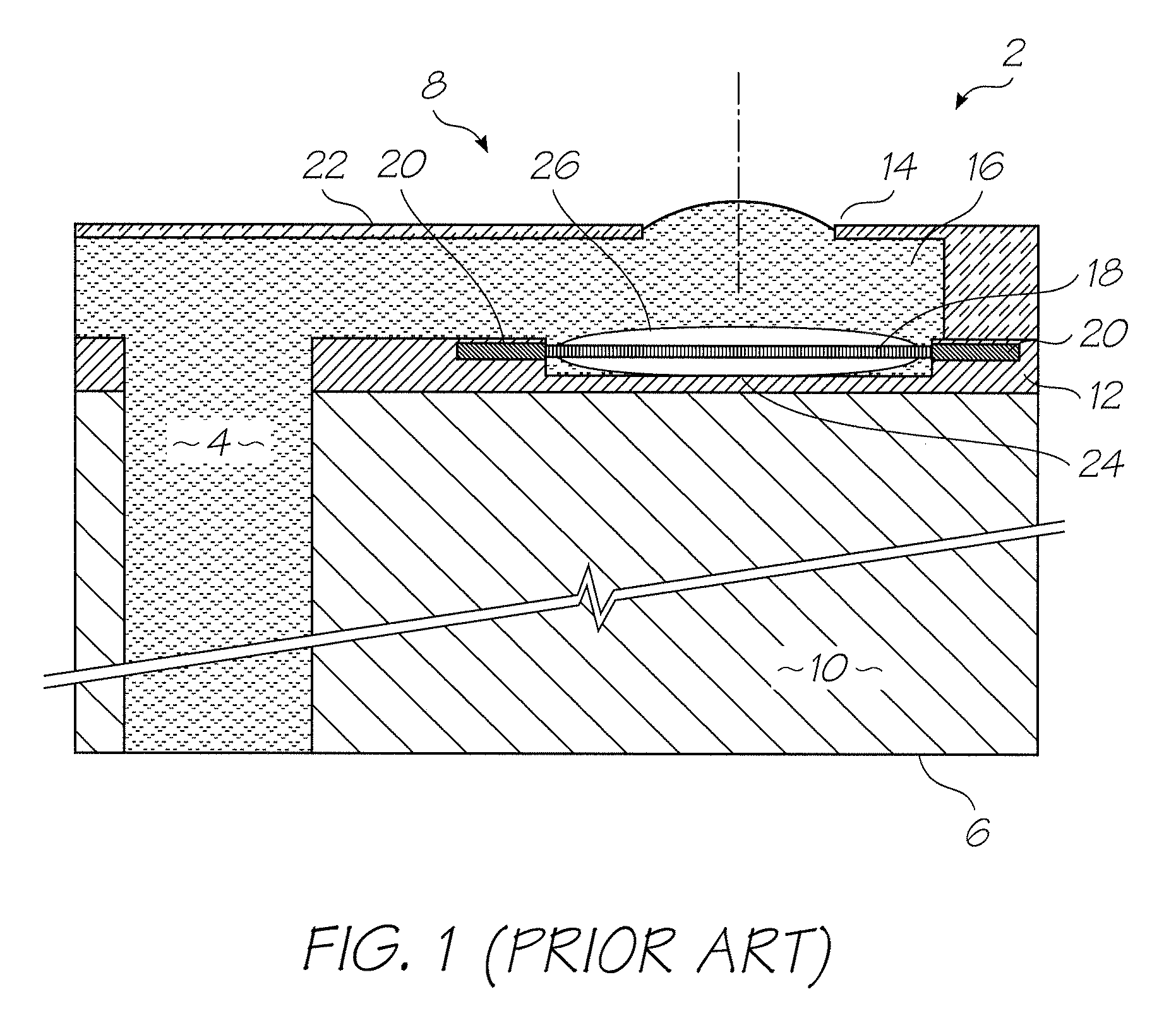

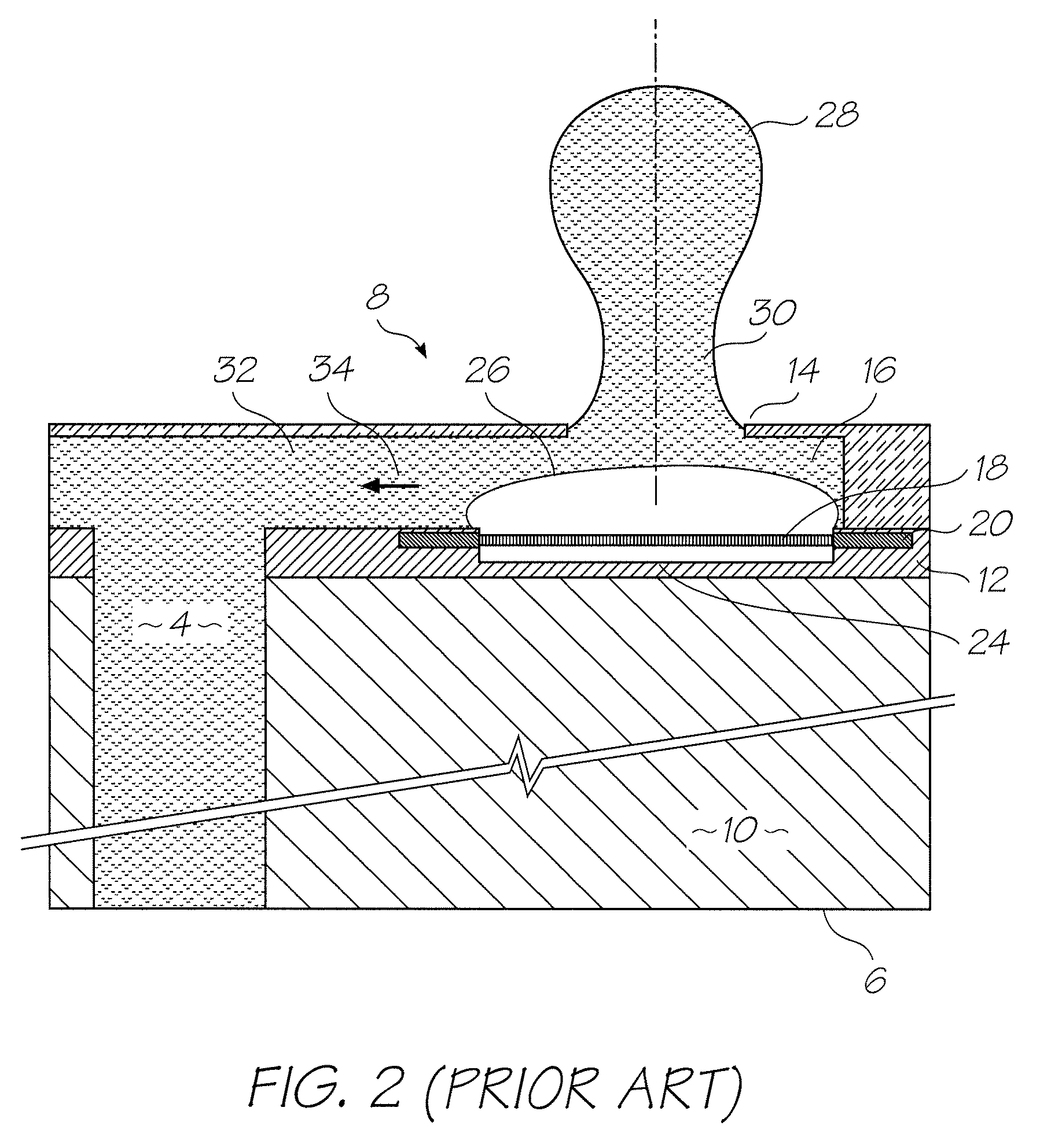

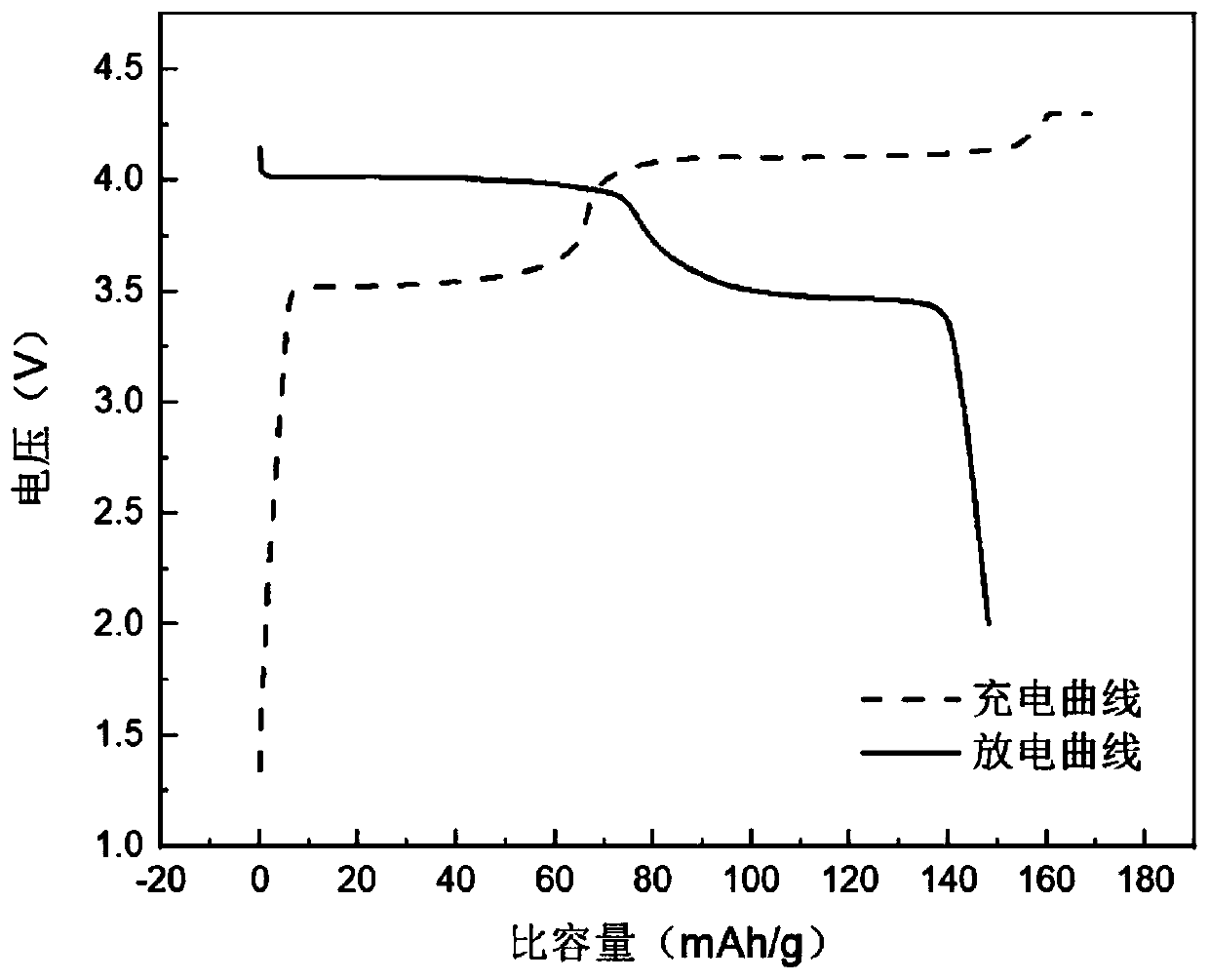

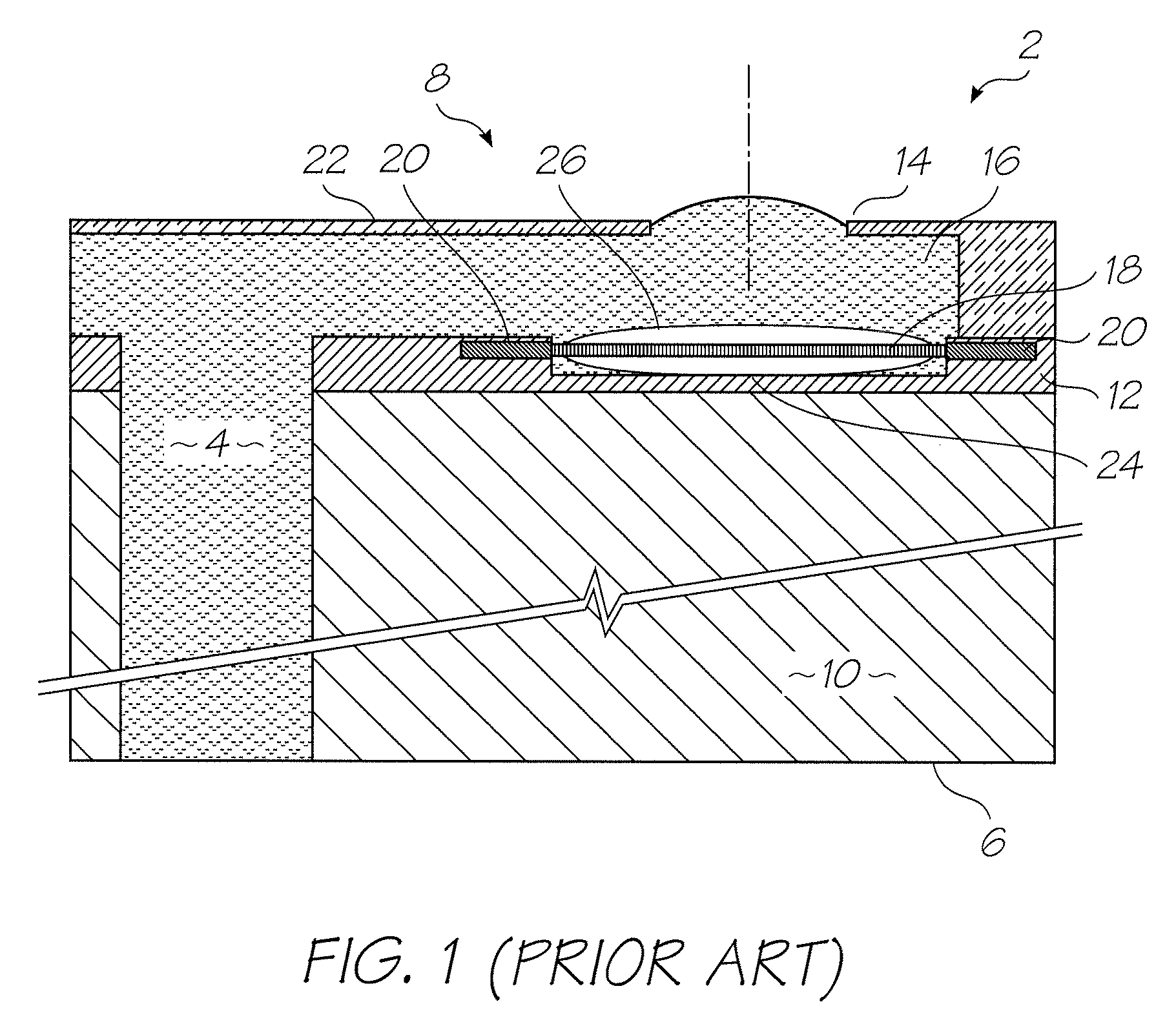

Printhead with heaters offset from nozzles

ActiveUS20090040276A1Fluidic drag resisting flow outOvercome surface tensionPrintingSpray nozzleEngineering

A thermal inkjet printhead of the roof shooter type that slightly offsets the nozzle aperture centroid from the heater element centroid to correct drop trajectory misdirection caused by vapor bubble asymmetries.

Owner:MEMJET TECH LTD +1

Polymer superfine fibre wet electrostatic spinning method

InactiveCN101445963AEasy to shapeOvercome surface tensionArtificial filament recoveryArtificial filament washing/dryingPolymer dissolutionFiber

The invention relates to a polymer superfine fibre wet electrostatic spinning method which comprises the steps as follows: polymer is dissolved in organic solvent to prepare uniform spinning solution with the weight percentage of 2-60 percent; an outlet of a spinneret is immersed in a spinning medium completely to ensure that fibre solidifying process is carried out in liquid spinning medium; a fibre collector can be arranged in the spinning medium or air medium; the temperature of the spinning medium is 0-65 DEG C; and the spinning solution is sprayed from a spinneret orifice immersed in the spinning medium under the static voltage of 1kV to 200kV to form jet current to be solidified and collected. The method improves the recovery ratio and the recycling ratio of solvent, is good for increasing the variety of spinnable polymer and developing the application range of superfine fibre by electrostatic spinning and has very wide industrialized application prospect.

Owner:DONGHUA UNIV

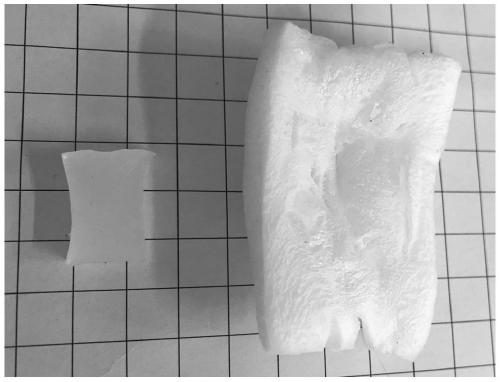

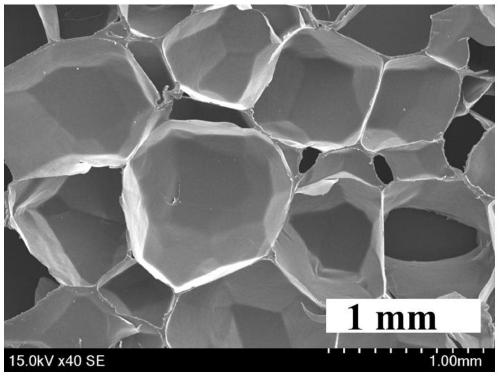

Method for preparing foam material by microwave hydrogel foaming

ActiveCN110256718AReduce surface tensionOvercome surface tensionMicrowaveSynthetic Polymeric Macromolecules

The invention discloses a method for preparing a foam material by microwave hydrogel foaming. The method includes: heating a hydrogel with a microwave to obtain the foam material. Water content of the hydrogel is 5wt%-60wt%, and preferably 10wt%-35wt%. The hydrogel is a directly-prepared hydrogel or a hydrogel obtained by partly dewatering the directly-prepared hydrogel and has cross-linked networked macromolecules, and the macromolecules comprise one or more of natural macromolecules and derivatives thereof and synthetic macromolecules. A novel method and a novel thought are provided for preparing a porous material from the hydrogel. By means of microwave foaming, water in the hydrogel can be evaporated and expanded quickly in a heating process, and accordingly foam pores can be formed in the hydrogel to form the porous material. Further, stability and controllable moisture absorption of the foam material can be realized through adjustment of hydrophilic and hydrophobic groups in the hydrogel or surface coating.

Owner:SICHUAN UNIV

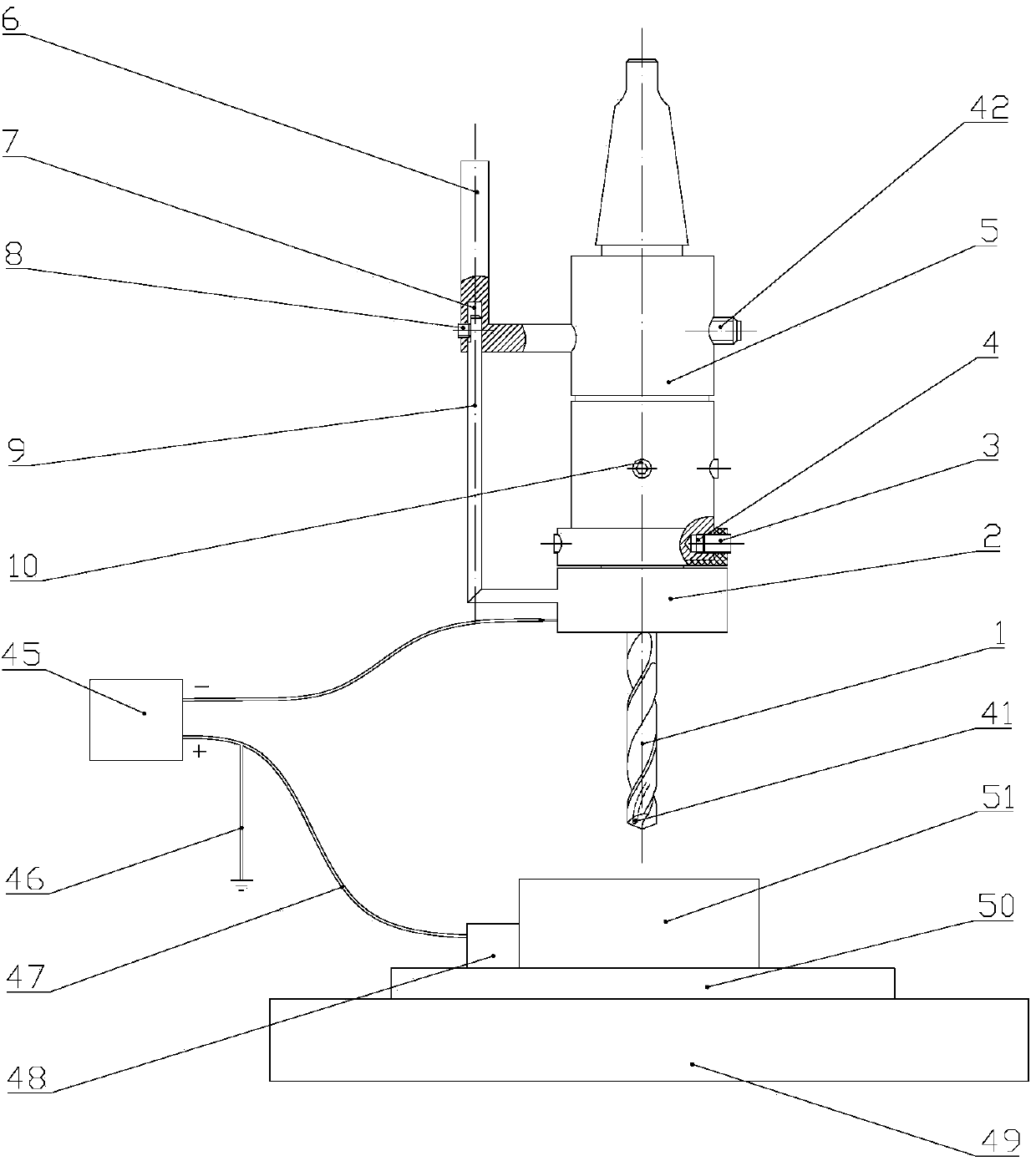

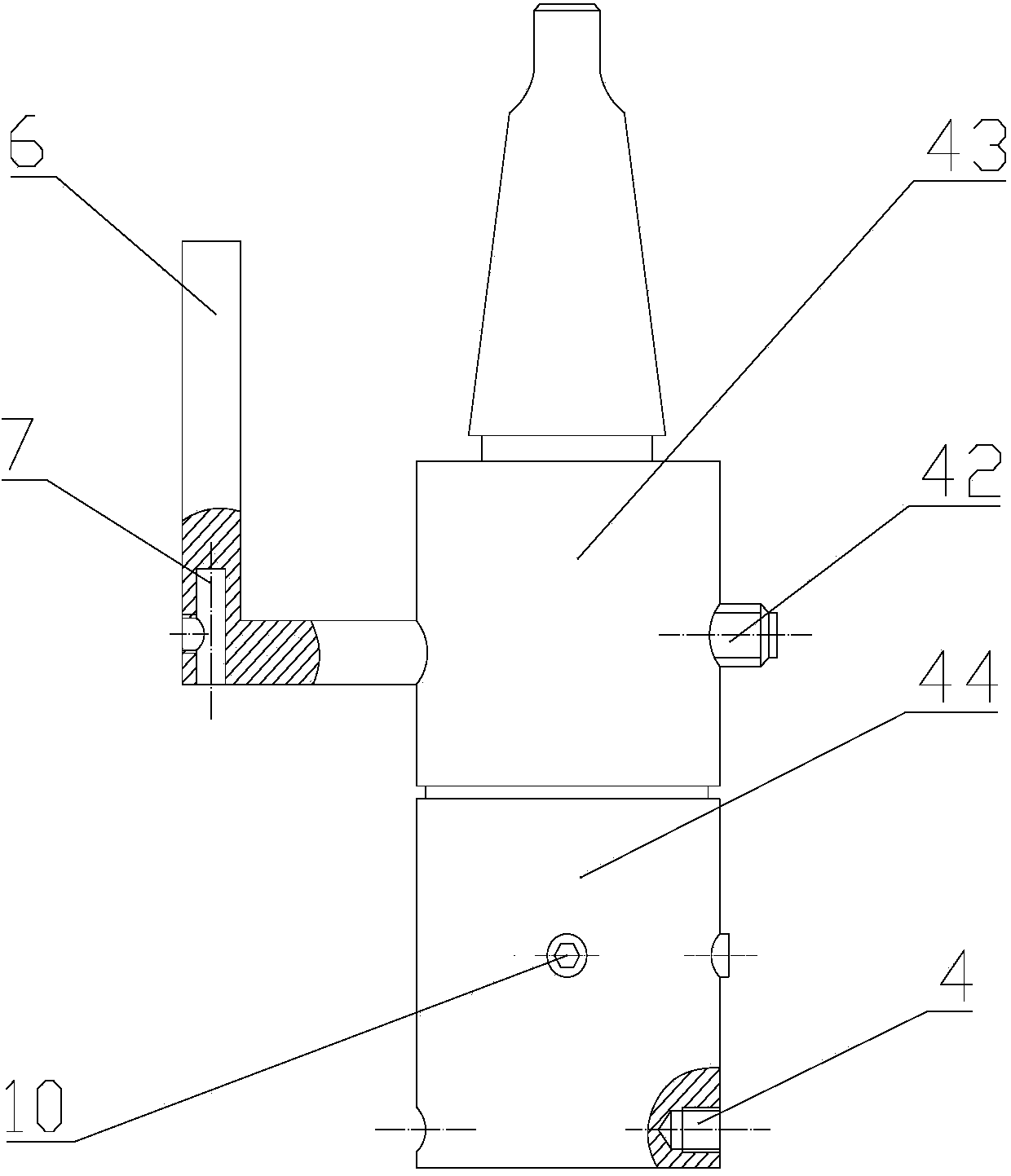

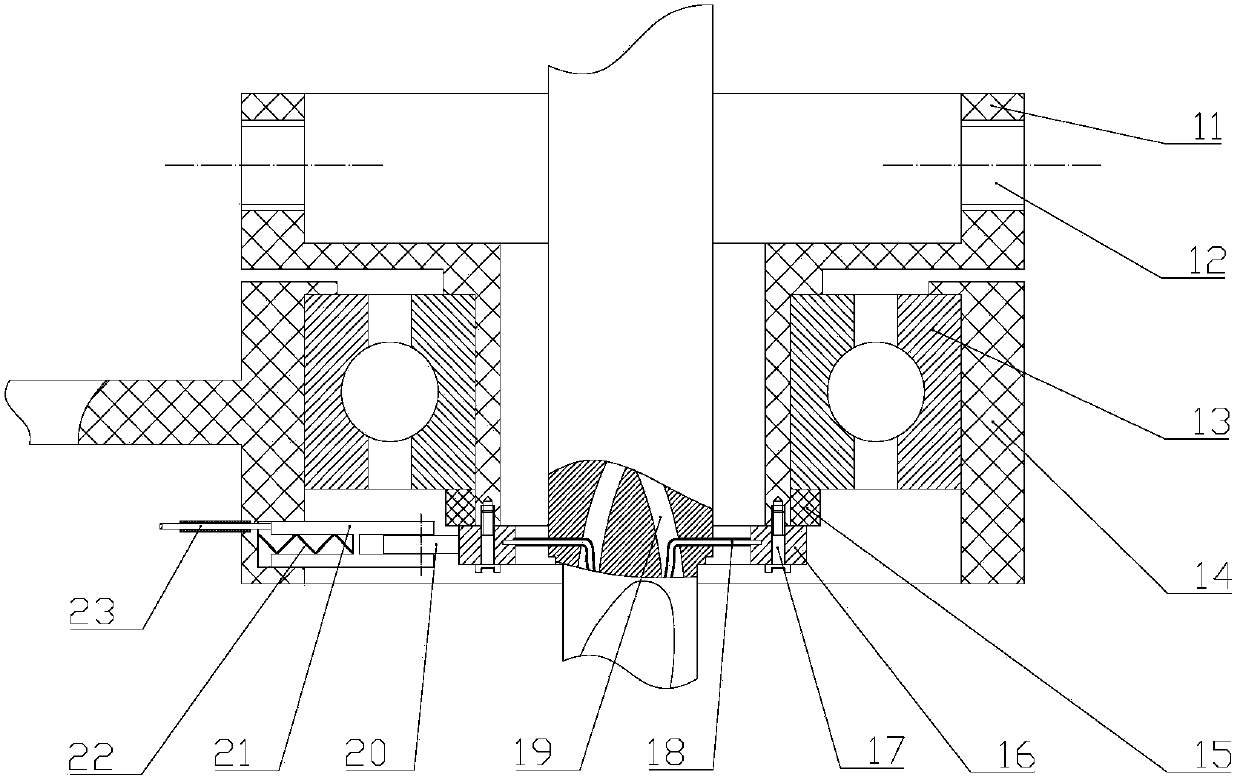

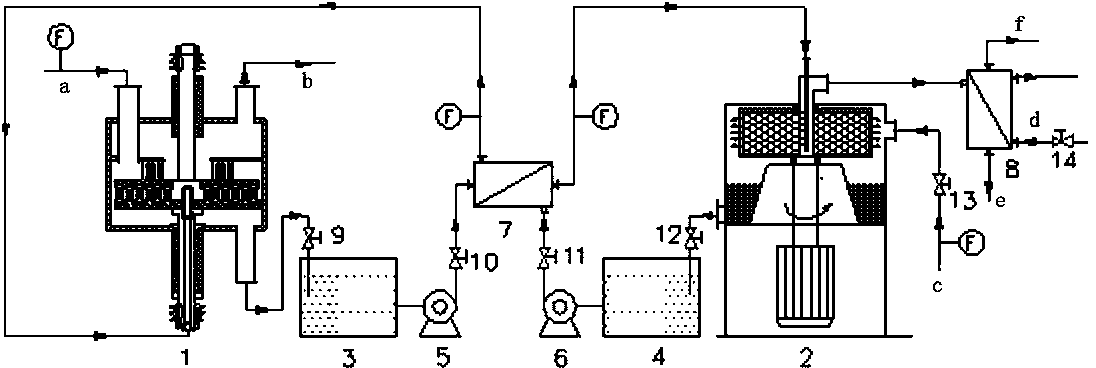

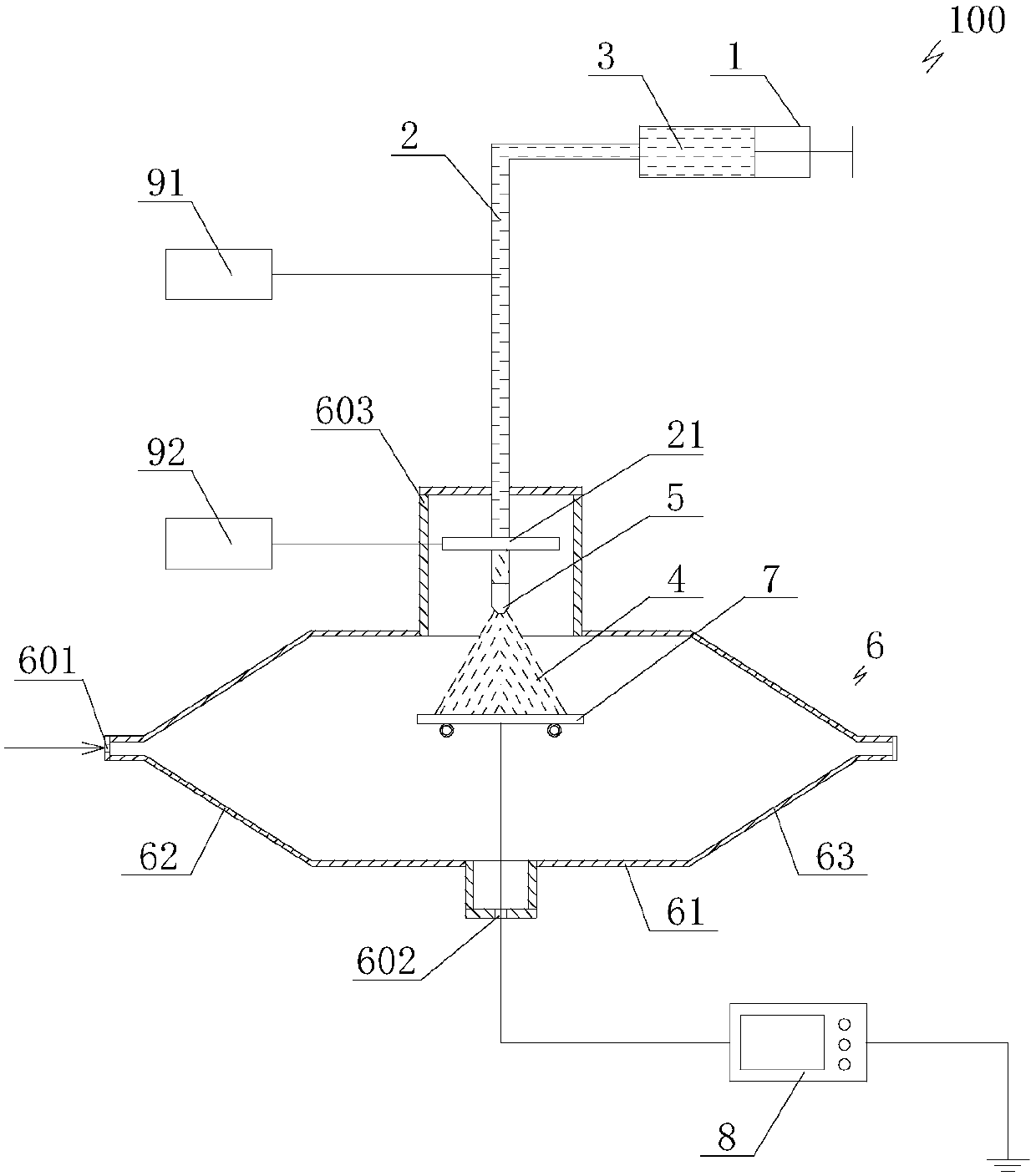

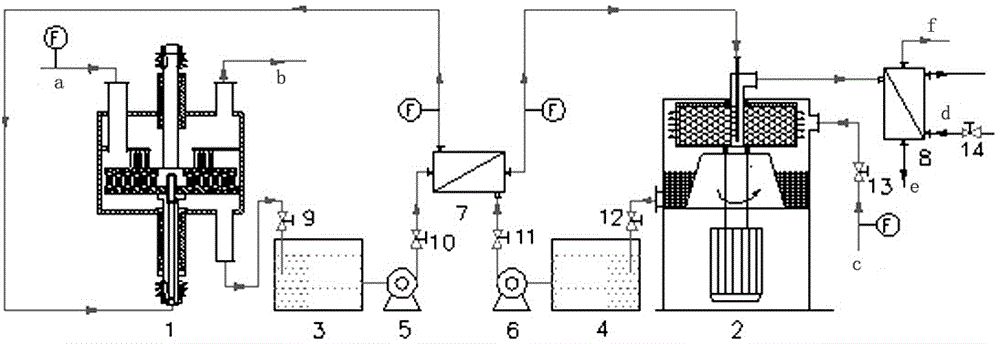

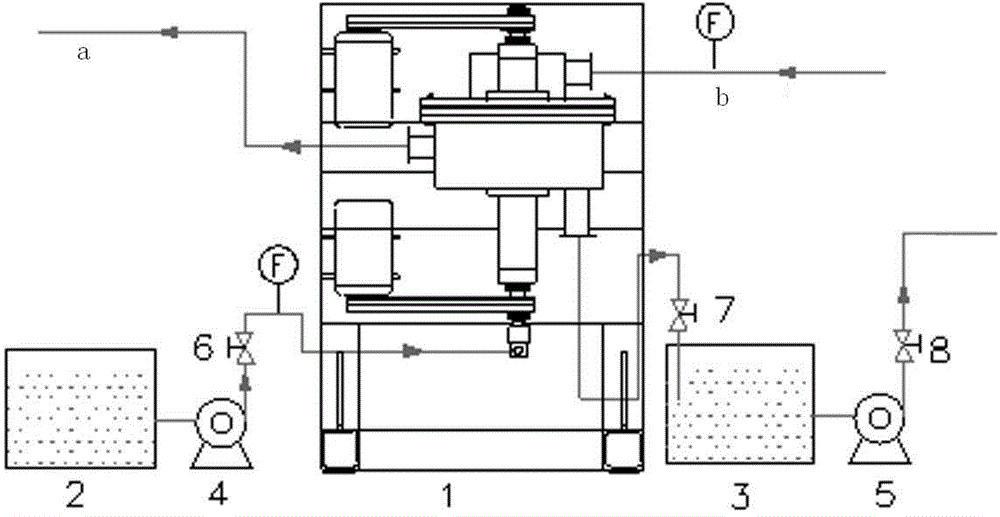

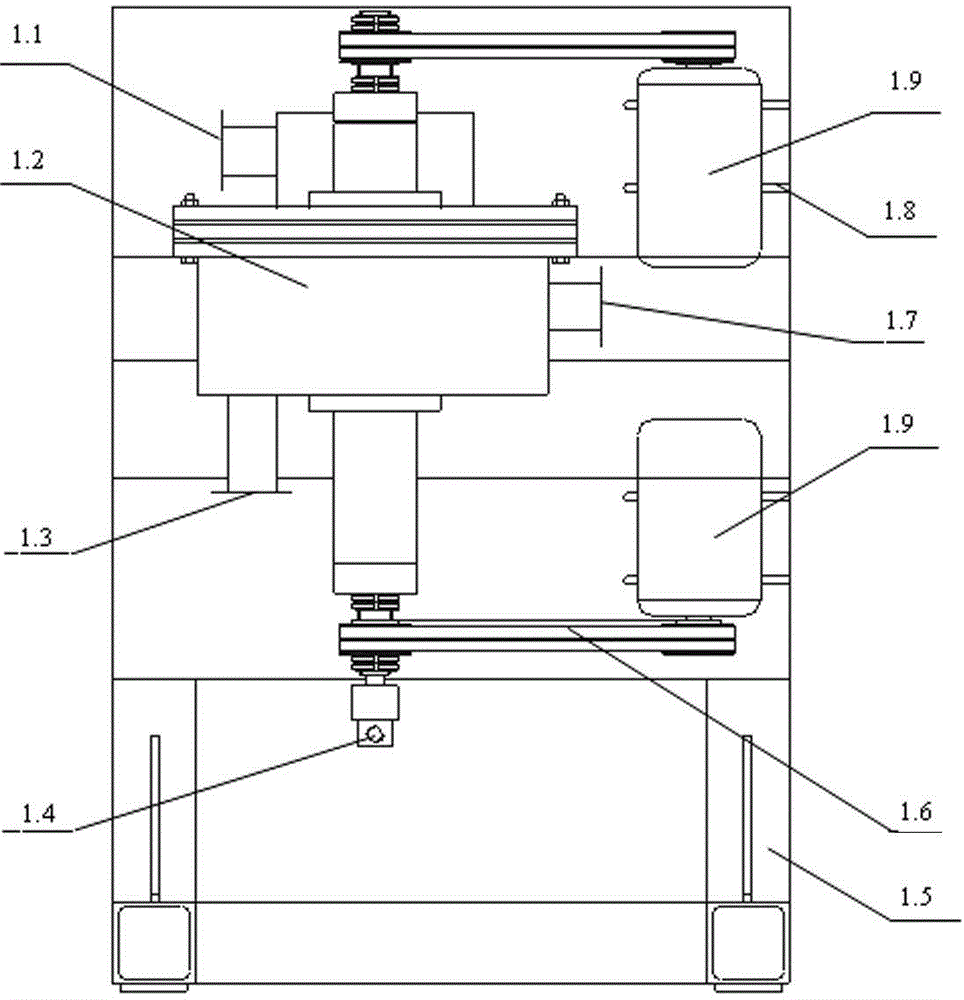

System for nanofluid minimal quantity lubrication electrostatic atomization controllable jet flow inner cooling technology

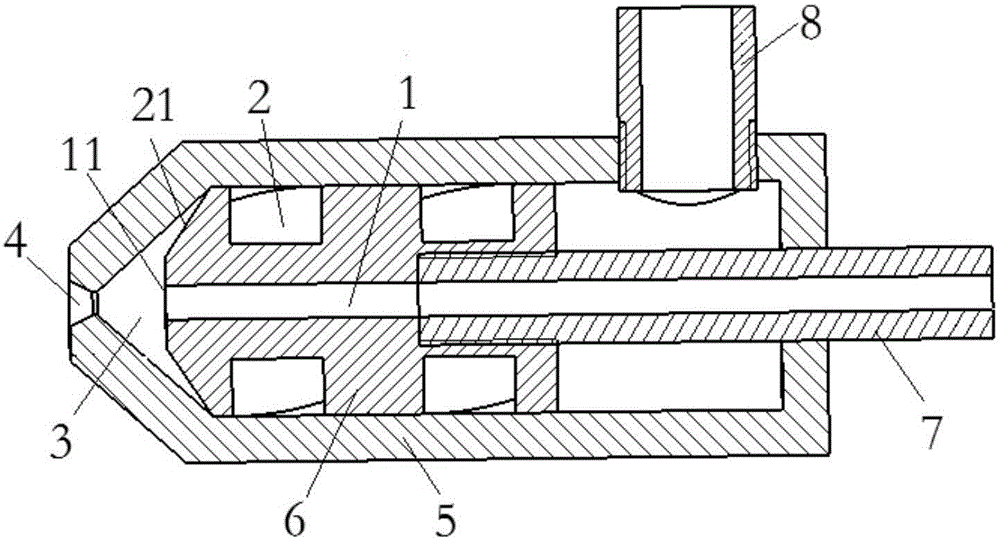

ActiveCN104191376AIncrease profitOvercome surface tensionGrinding/polishing safety devicesHigh-voltage direct currentHigh pressure

The invention relates to a system for the nanofluid minimal quantity lubrication electrostatic atomization controllable jet flow inner cooling technology. According to the system for the nanofluid minimal quantity lubrication electrostatic atomization controllable jet flow inner cooling technology, based on the electrostatic atomization principle, minimal quantity lubrication cutting fluid fog droplets can be controllably distributed during jetting, the evenness of a fog droplet spectrum can be improved, the deposition efficiency can be improved, the fluid effective utilization rate can be increased, the motion law of the fog droplets can be effectively controlled, in this way, pollution to the environment is reduced, and better health security is provided for workers. The system comprises an adjustable high-voltage direct-current power supply, an inner-cooled cutter converter, a high-voltage electricity converting device and an integrated spray nozzle. A minimal quantity lubrication system supplies minimal quantity lubrication cutting liquid to an inner-cooled drill bit through the inner-cooled cutter converter. The adjustable high-voltage direct-current power supply conducts positive electricity to a needle electrode of the integrated nozzle through the high-voltage electricity converting device, the adjustable high-voltage direct-current power supply makes negative electricity be grounded and transmits the negative electricity to a workpiece through an electromagnetic connector, and then a corona charging field is formed in the needle electrode-workpiece area; in this way, corona charging is conducted on the minimal quantity lubrication cutting fluid, and then electrostatic atomization function is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Flue gas desulfurization device and process

ActiveCN103480259AOvercome viscosityOvercome surface tensionDispersed particle separationChemistryFlue-gas desulfurization

The invention belongs to the technical field of flue gas desulfurization, and particularly relates to a flue gas desulfurization process and device, which aim to solve the problems of an existing flue gas desulfurization process and device. The flue gas desulfurization device comprises a retrograde rotation packed bed absorber, a rotation packed bed desorber, a barren liquid storage groove, a rich liquid storage groove, a barren liquid circulation pump, a rich liquid circulation pump, a heat exchanger and a condenser. The flue gas desulfurization process comprises an absorption process and a desorption process. The device provided by the invention is small in size, has a wide in treatment gas quantity range, and is simple in structure and easy to operate. The process has the advantages of high desulfurization rate, low energy consumption, simple process, low investment and running expense, running stability, convenience in starting and stopping and the like.

Owner:ZHONGBEI UNIV

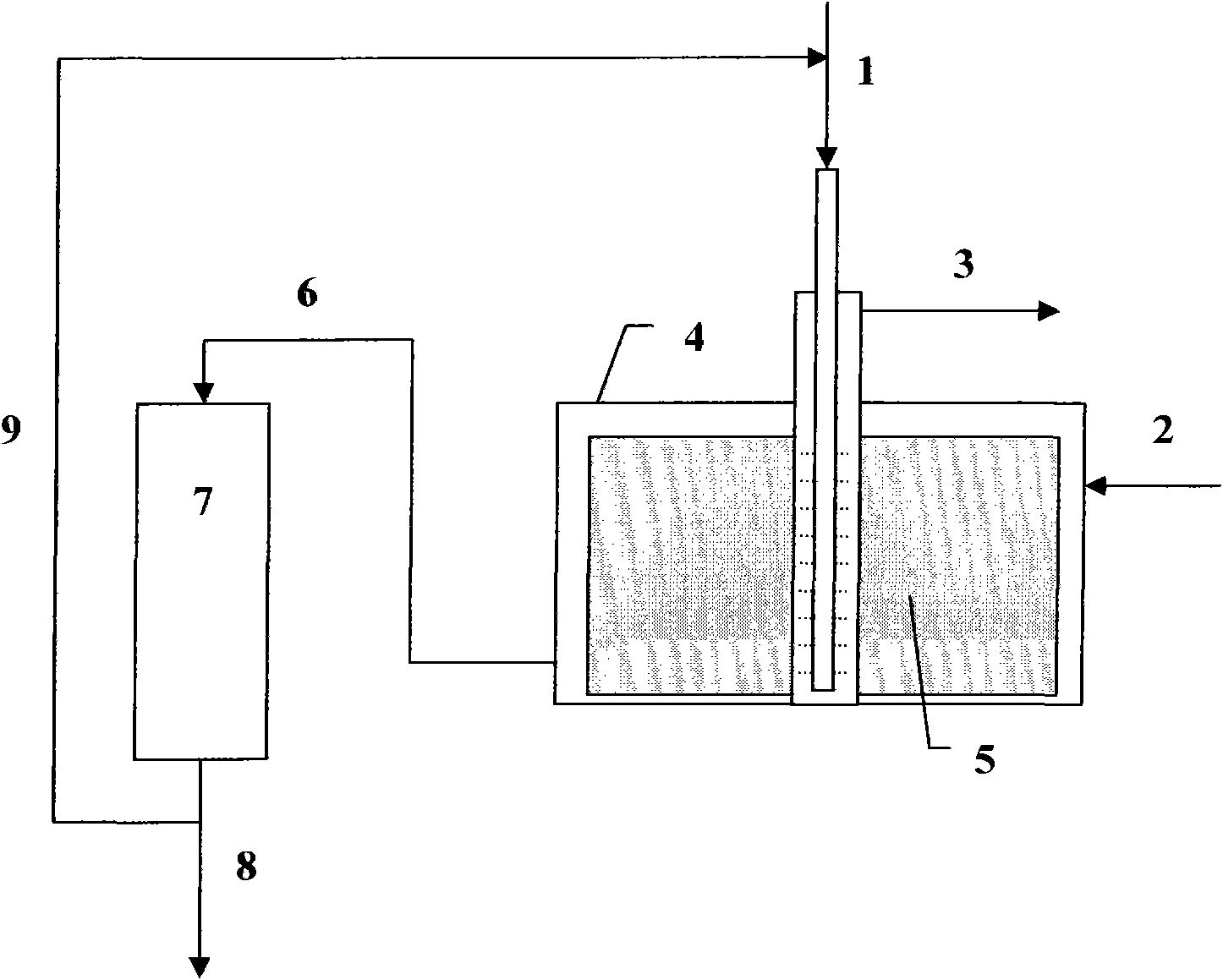

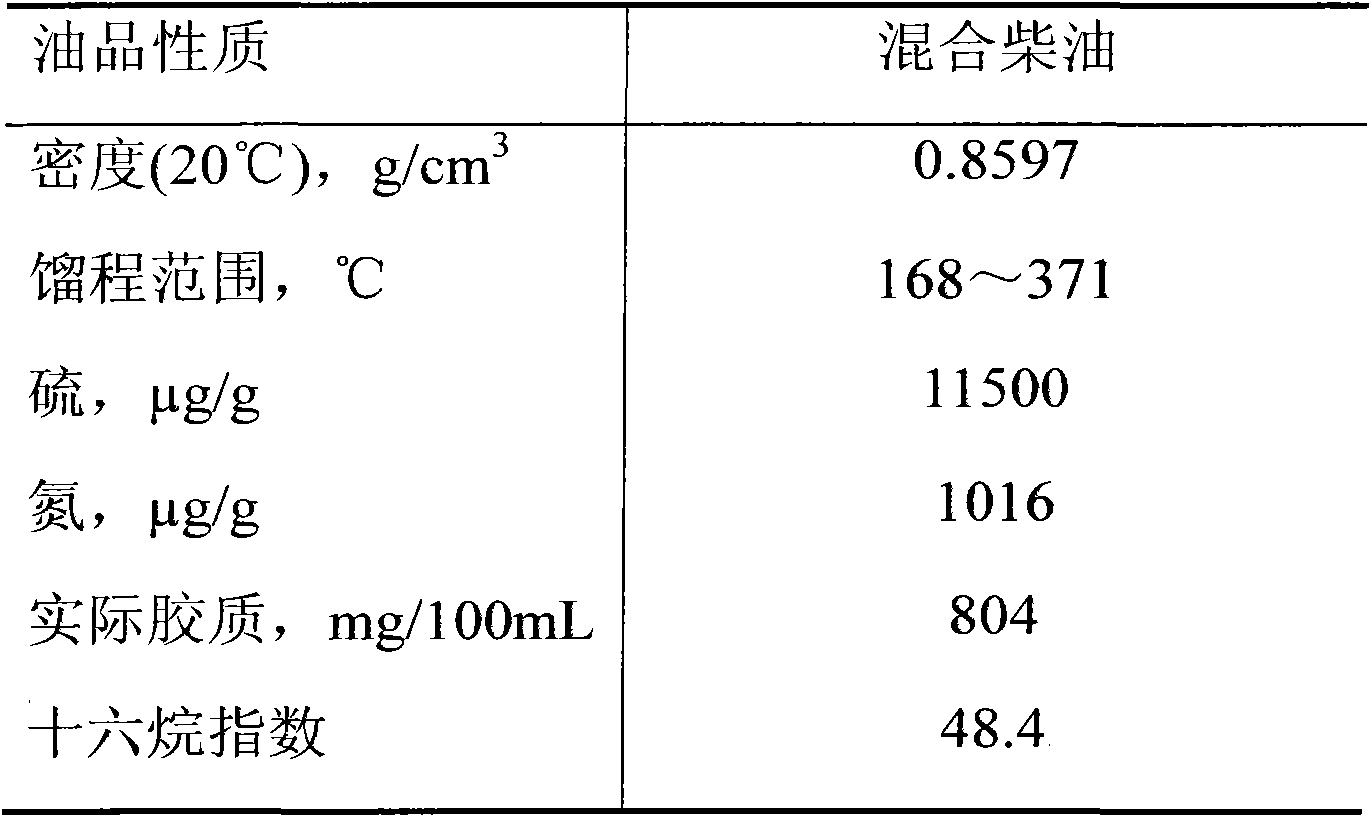

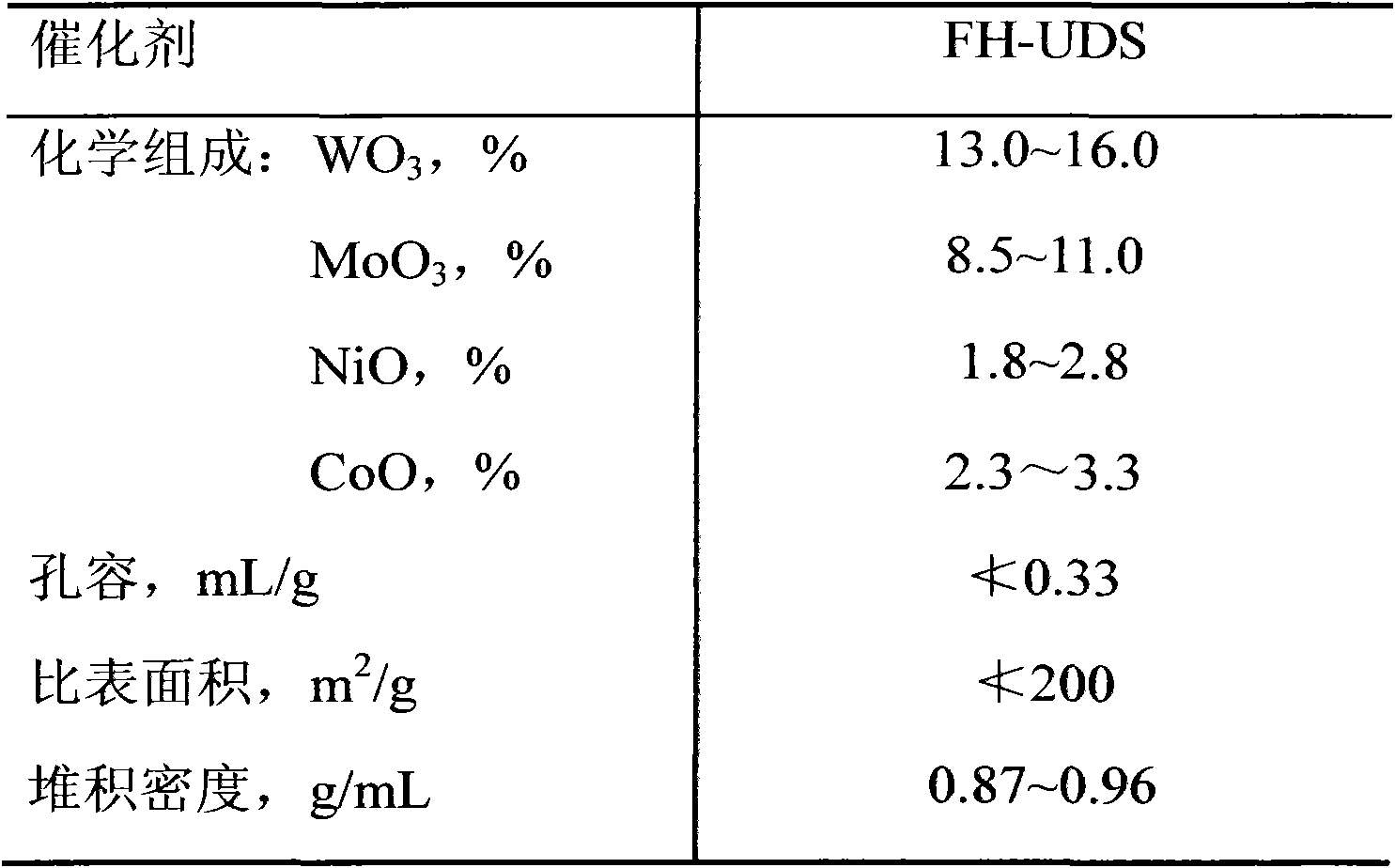

Liquid-phase circulating hydrogenation treatment method capable of reinforcing gas-liquid mass transfer

ActiveCN102311791AEasy to operateLess investmentTreatment with hydrotreatment processesHydrocarbon oils refiningHydrodesulfurizationMixed materials

The invention discloses a liquid-phase circulating hydrogenation treatment method capable of reinforcing gas-liquid mass transfer. The process flow adopted by the method comprises: part of hydrogenation circulating oil and a fresh raw material are mixed to form a liquid-phase mixed material to be filled into supergravity gas-liquid hydrogen dissolution equipment together with hydrogen; through the drive of the high-speed rotation of a feeding rotor, gas-liquid countercurrent full contact is formed; the mixed liquid-phase material in which hydrogen is dissolved is discharge out from the bottom of the supergravity gas-liquid hydrogen dissolution equipment and contacted with a catalyst to undergo a hydrogenation reaction, and part of a liquid phase obtained after reaction is circulated. Compared with the prior art, the method has the advantages that: the rotation of the feeding rotor in the gas-liquid hydrogen dissolution equipment forms a supergravity field, so the gas-liquid mass transfer efficiency is increased greatly, and the liquid phase material can fully dissolve hydrogen; meanwhile, gas impurities such as H2S and NH3 in a reaction system can be removed efficiently, so that the hydrodesulfurization, denitrification, aromatic saturation, cracking and other reactions are promoted.

Owner:CHINA PETROLEUM & CHEM CORP +1

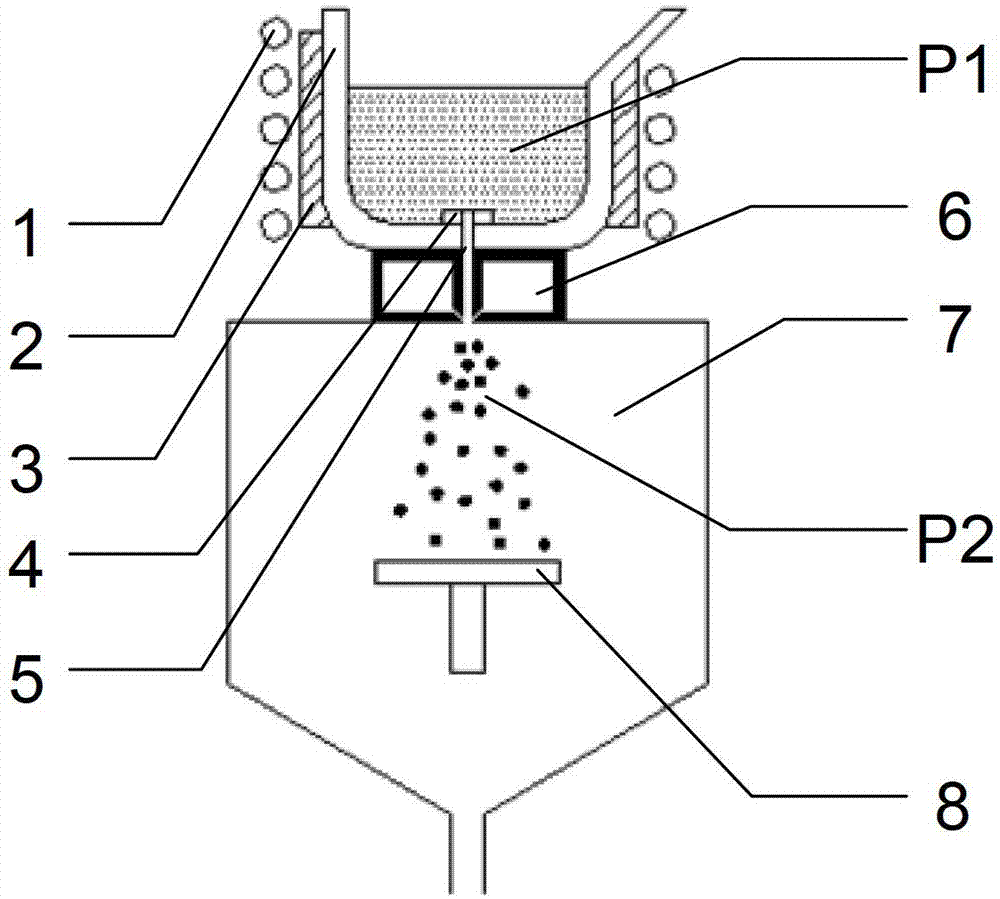

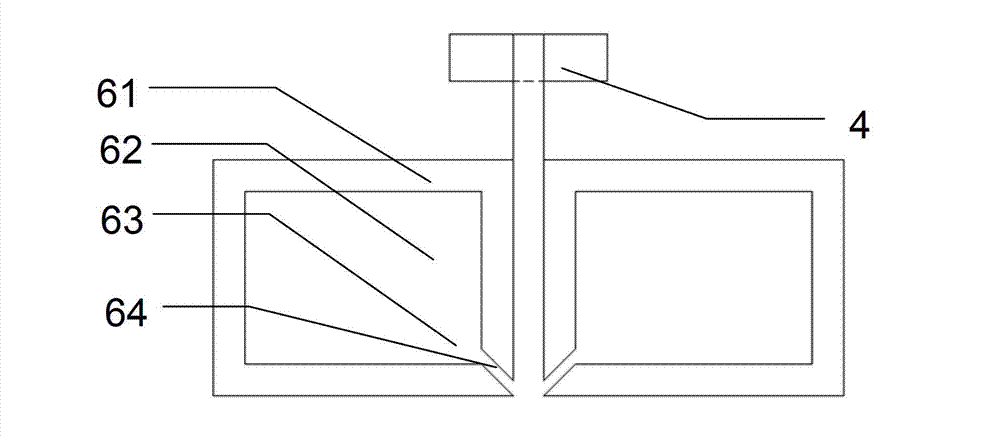

Preparation method for silicon powder

InactiveCN103043665AReduce contentMeet the requirements of pickling and impurity removal processSilicon compoundsSlagAtmospheric pressure

The invention discloses a preparation method for silicon powder, relates to a process of removing boron by industrial silicon and a preparation method for high-purity superfine silicon powder. The invention provides the preparation method for the silicon powder capable of remarkably reducing the content of the boron. The silicon powder can be used as an ideal low-boron material for a later process, namely pickling and impurity-removing process of purifying solar polycrystalline silicon by a metallurgy method. The preparation method comprises the following steps of: (1), adopting a metallurgical-grade silicon material as the material, putting the material silicon to a crucible, electromagnetically heating up the silicon material to melt the silicon material by an inductive coil; (2), adding a slag former to control the heating power when the silicon material is molten, so that the temperature of the molten silicon is kept to 1550 DEG C to 1850 DEG C in a reaction process, stewing the molten silicon to remove the slag former on the upper layer of the molten silicon after slagging and refining; and (3), controlling the temperature of the molten silicon to 1500 DEG C to 1700 DEG C, and then opening the valve and starting an atomizer; guiding the molten silicon to the atomizer by a guide tube, adjusting the air pressure of the air outlet of the atomizer so that the molten silicon is sprayed out of the atomizer in the forms of mists to enter an atomizing chamber; and collecting the silicon powder by a supporting rotary plate.

Owner:XIAMEN UNIV

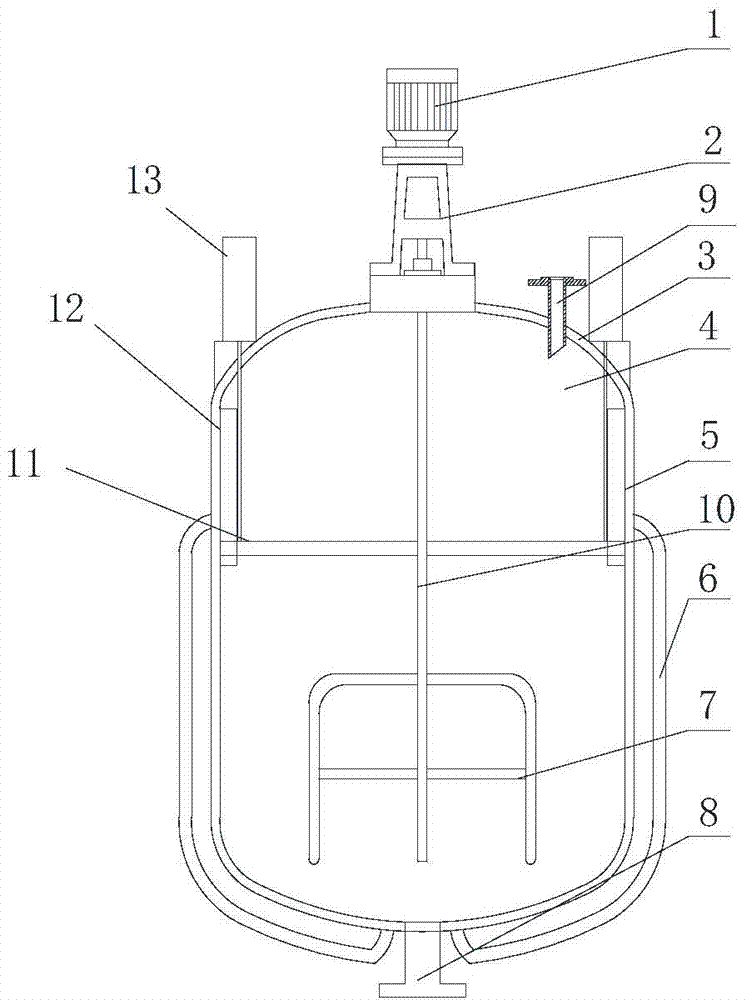

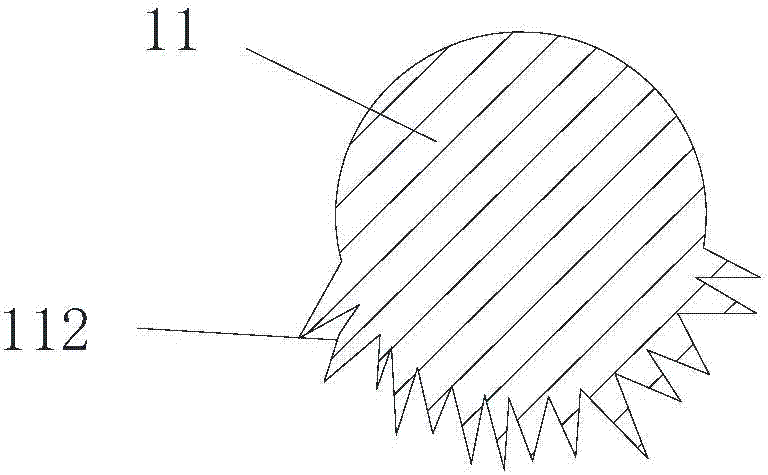

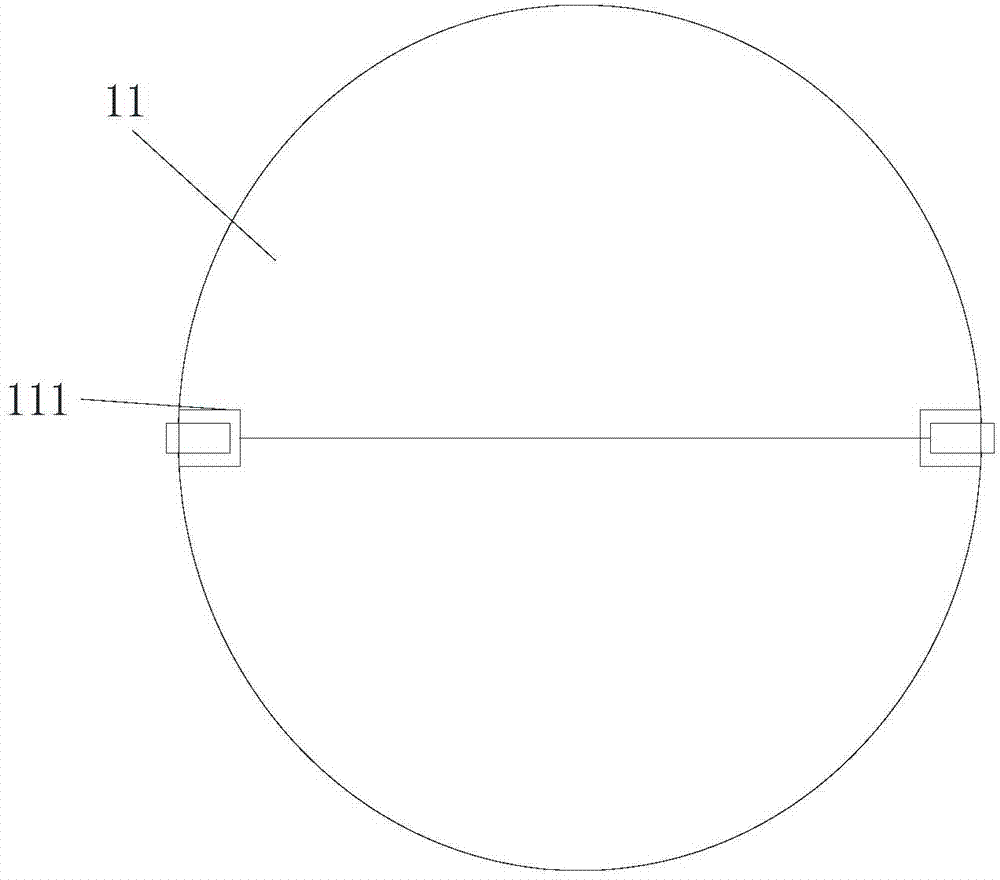

Reaction kettle

InactiveCN104492365ASimple structureGuaranteed stabilityChemical/physical/physico-chemical stationary reactorsFoam dispersion/preventionChemical reactionEngineering

The invention relates to a reaction kettle, and particularly relates to a reaction kettle capable of eliminating foam generated in chemical reactions. The reaction kettle comprises a kettle body, wherein a discharge opening is formed in the lower end of the kettle body; a jacket is arranged on the periphery of the kettle body in an enclosing manner; the top of the kettle body is connected with a kettle cap; a feeding opening is formed in the kettle cap; a support is arranged at the center of the kettle cap; a stirring motor is connected with the top of the support, and is connected with a stirring shaft extending into the kettle body; and a stirrer is arranged on the stirring shaft. The reaction kettle is characterized in that a defoaming device is arranged inside the kettle body, and is a defoaming screen connected on the kettle body; and a burr part is arranged on the surface of the defoaming screen. According to the reaction kettle, the structure of the defoaming screen is improved, and after the burr part arranged on the lower surface of the defoaming screen is in contact with foam, the surface tension of the foam can be quickly broken, so that foam can be quickly eliminated.

Owner:CHANGZHOU LONGDAO E COMMERCE

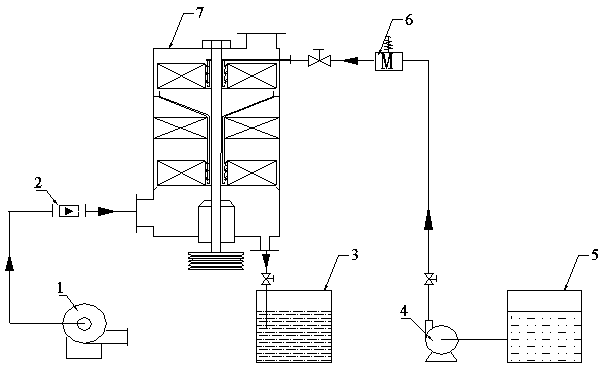

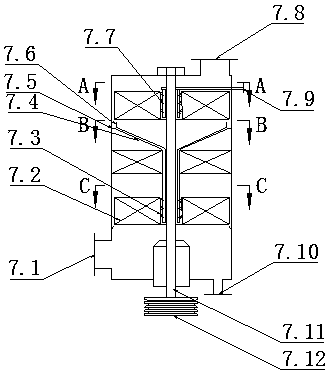

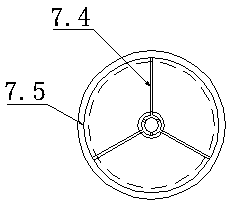

Device and method for magnesium process flue gas desulfurization

InactiveCN108187478AEnhanced mass transfer processImprove reaction rate and desulfurization rateDispersed particle separationFilling materialsGas pipeline

The invention discloses a device and method for magnesium process flue gas desulfurization. The device comprises a multi-stage cross flow-reverse flow rotating filling bed absorption device, wherein an exhaust pipe is arranged on the top of the rotating filling bed absorption device; a liquid discharge pipe is arranged at the bottom; a liquid inlet pipe is connected with the side surface of the upper side; an air inlet pipe is connected with the side surface of the lower side; a rotating shaft is arranged inside the rotating filling bed absorption device; two filling material rotors or more are arranged on the rotating shaft; a filling material stator is arranged between the two adjacent rotors; a liquid distributor is arranged in the center of the filling material rotor and is connected with the liquid inlet pipe; the lower end of the rotating shaft extends to the outside of an absorption device to be connected with a frequency modulation motor; the gas inlet pipe of the rotating filling bed absorption device is connected with a SO2-containing smoke gas pipeline; a liquid inlet pipe of the rotating filling bed absorption device is connected with a magnesium hydrate storage groove;the liquid discharge pipe is connected with a magnesium bisulfite storage groove. The method has the advantages that a magnesium hydroxide desulfurizer is used for wet process desulfurization; the purification degree, and the speed in the desulfurization process and the desulfurization efficiency are improved; the smoke gas ultra-low discharge standard can be reached by single piece of equipment.

Owner:ZHONGBEI UNIV

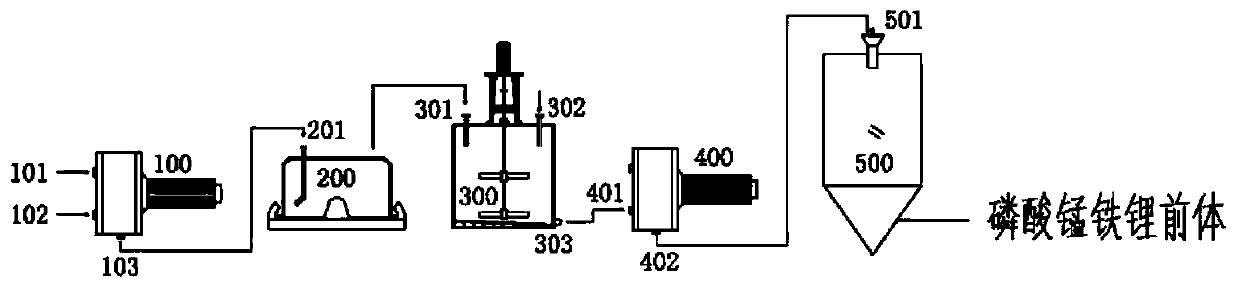

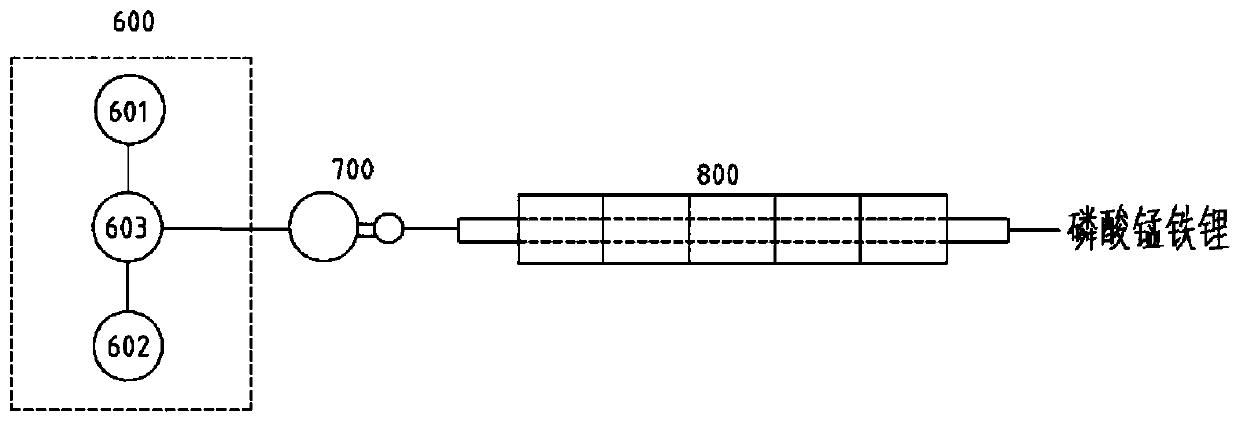

Method for preparing lithium iron manganese phosphate precursor and method for preparing lithium iron manganese phosphate

PendingCN110980682AFine and uniform particle sizeFast manufacturingMaterial nanotechnologyOrganic compound preparationCarbon coatingOXALIC ACID DIHYDRATE

The invention relates to a method for preparing a lithium iron manganese phosphate precursor and a method for preparing lithium iron manganese phosphate. The method for preparing the lithium iron manganese phosphate precursor comprises the following steps: (1) preparing a liquid material A and a liquid material B, wherein the liquid material A is a mixed solution of a manganese salt and an iron salt, and the liquid material B is an oxalic acid or phosphoric acid solution; (2) carrying out a coprecipitation reaction on the liquid material A and the liquid material B in a supergravity rotating bed to obtain a first slurry; (3) washing and filtering the first slurry to obtain a filter cake; (4) mixing the filter cake with water, adding a carbon source, and uniformly stirring to obtain a second slurry; (5) homogenizing the second slurry; and (6) drying the homogenized second slurry to obtain the lithium iron manganese phosphate precursor. The particle size of the lithium iron manganese phosphate precursor prepared by the method is smaller and more uniform than that of a precursor prepared by a traditional method using a reaction kettle, the preparation speed is increased, and carbon coating is uniform.

Owner:JIANGSU LITHITECH CO LTD

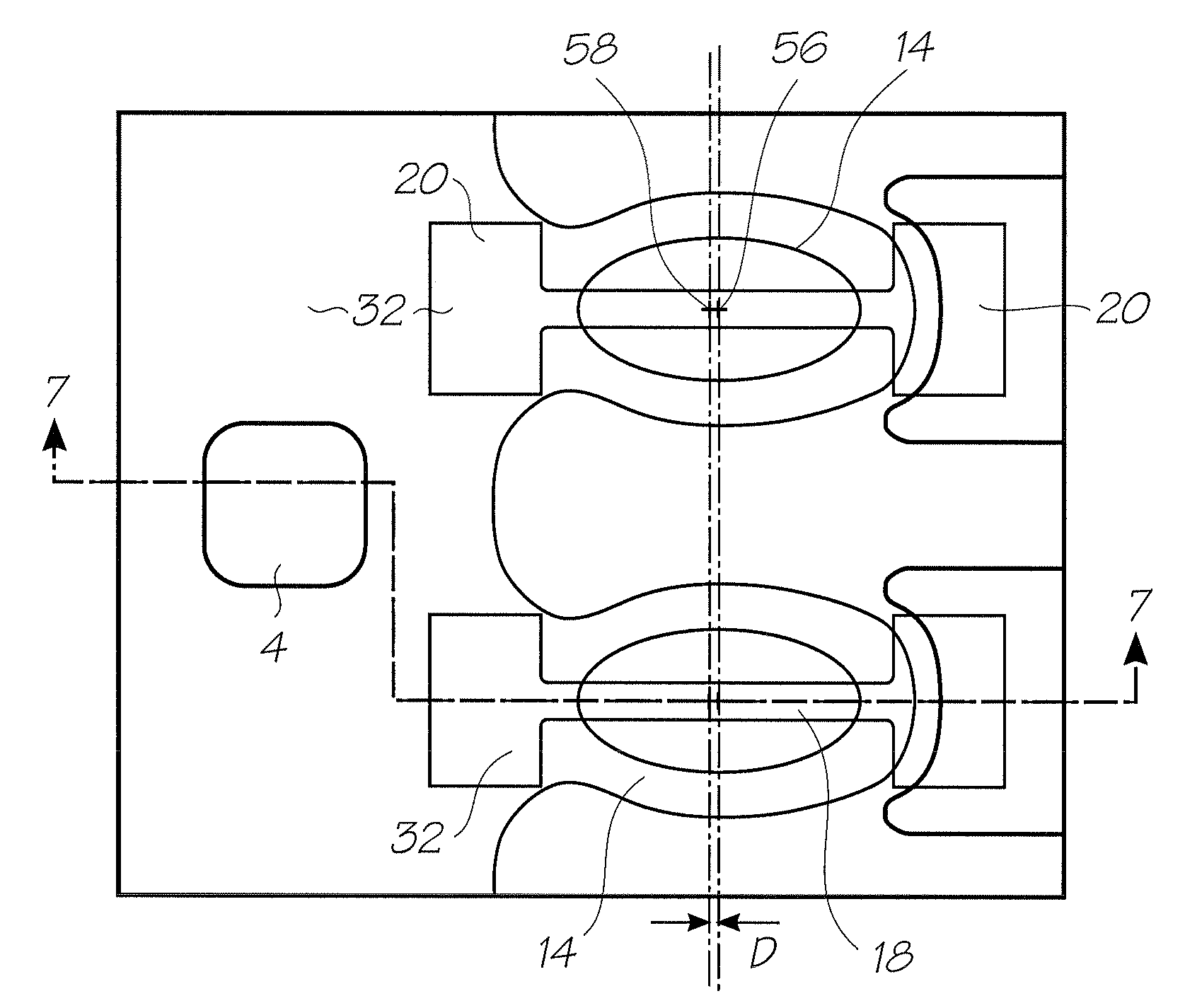

Printhead with heaters offset from nozzles

ActiveUS7780271B2Fluidic drag resisting flow outOvercome surface tensionPrintingVapor bubbleSpray nozzle

A thermal inkjet printhead of the roof shooter type that slightly offsets the nozzle aperture centroid from the heater element centroid to correct drop trajectory misdirection caused by vapor bubble asymmetries.

Owner:MEMJET TECH LTD +1

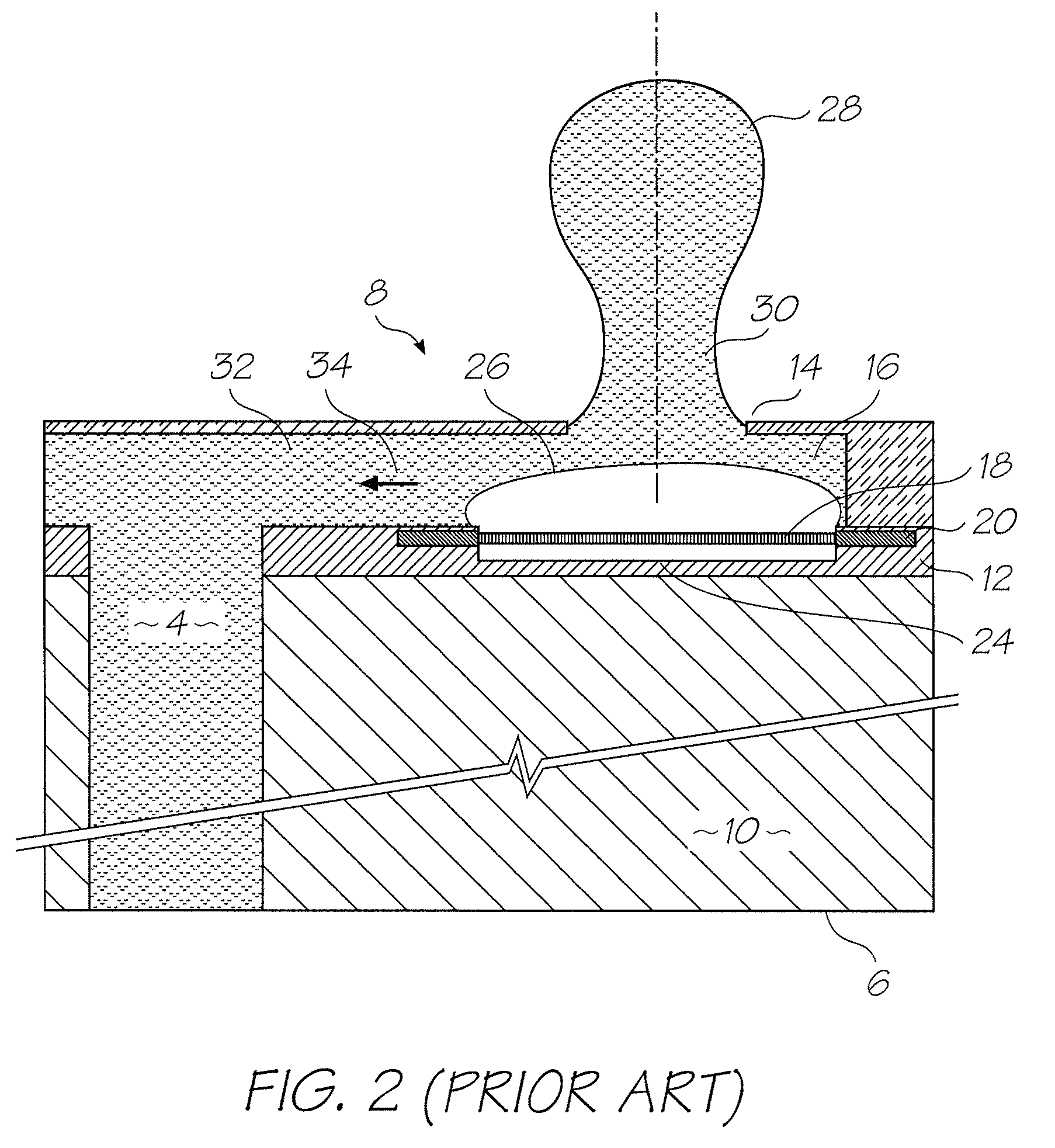

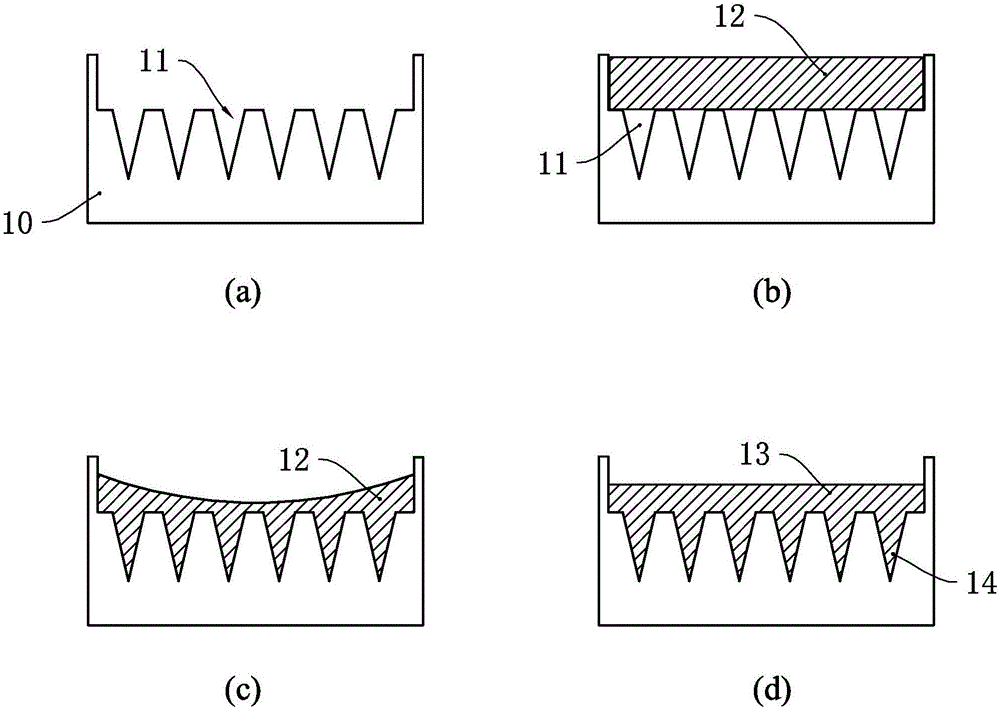

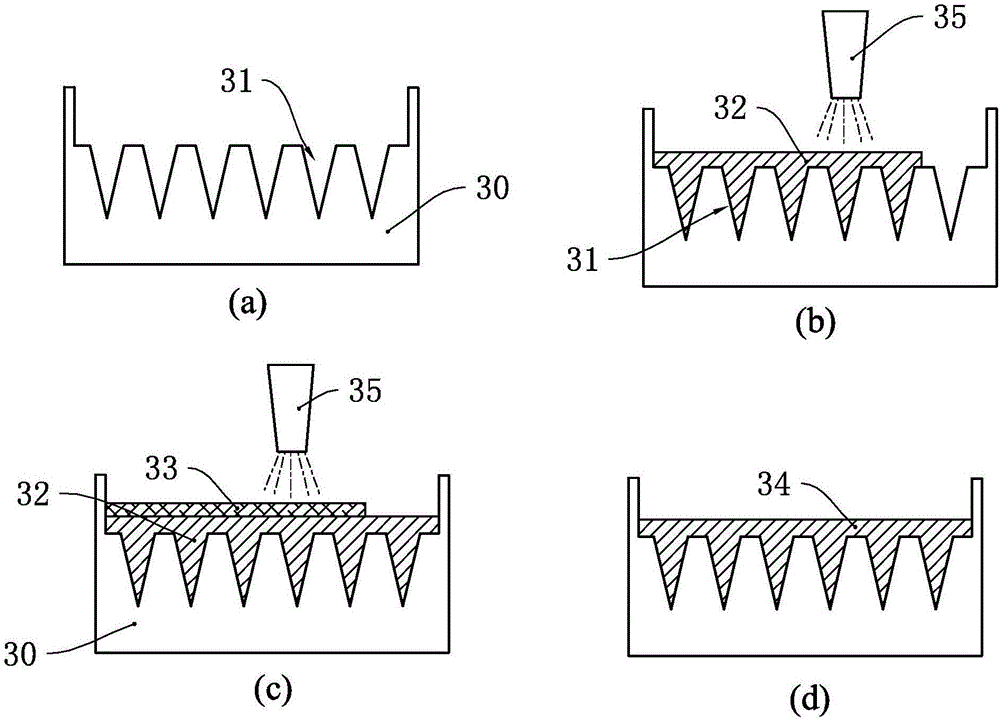

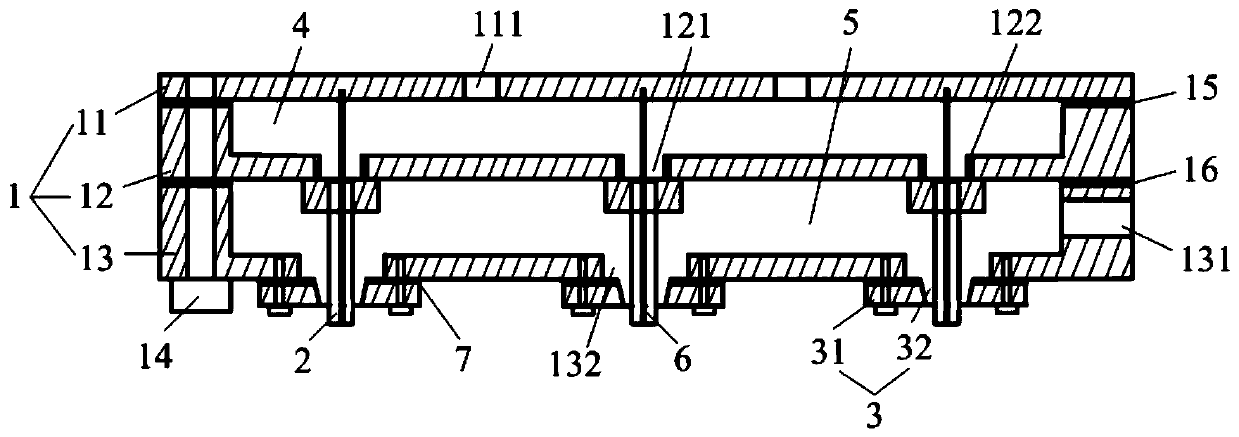

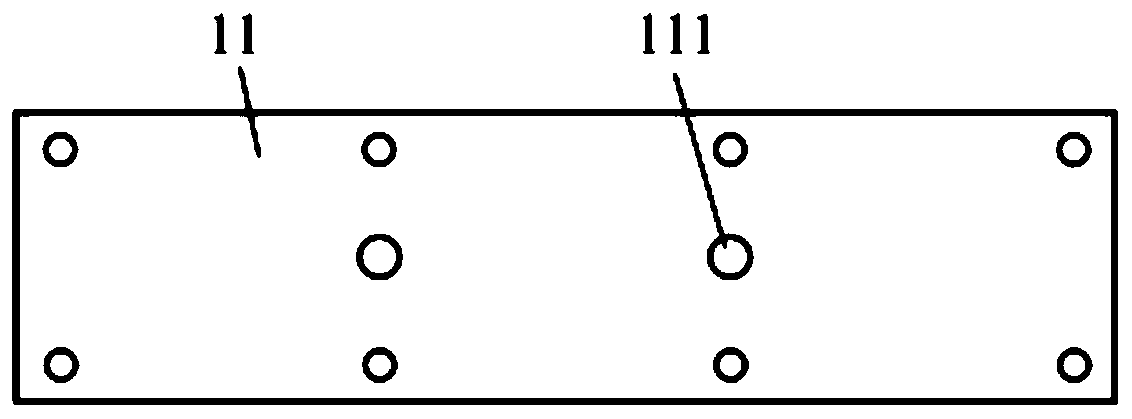

Manufacture method for soluble microneedle

InactiveCN106727273ASimple processImprove production efficiencyCosmetic preparationsToilet preparationsManufacturing technologyPolymer science

The invention provides a manufacture method for a soluble microneedle. The manufacture method comprises the following steps: manufacturing a microneedle mould, wherein the microneedle mould is provided with a plurality of micropore cavities; in addition, using high-pressure spraying equipment to inject macromolecular solution to the micropore cavities; filling the macromolecular solution into each micropore cavity; after the macromolecular solution is dried, taking out a solidified microneedle from the microneedle mould. Optimally, a high-pressure atomizing unit is used for injecting atomized macromolecular solution to the micropore cavities, or high-pressure burst firing equipment is used for injecting the drops of the macromolecular solution to the micropore cavities. When the method disclosed by the invention is applied to manufacture the microneedle, ways including vacuumizing, centrifugal force loading and the like are not required, the manufacture technology of the microneedle is simple, and a superior rate for microneedle manufacture can be improved.

Owner:YOUWE ZHUHAI BIOTECH CO LTD

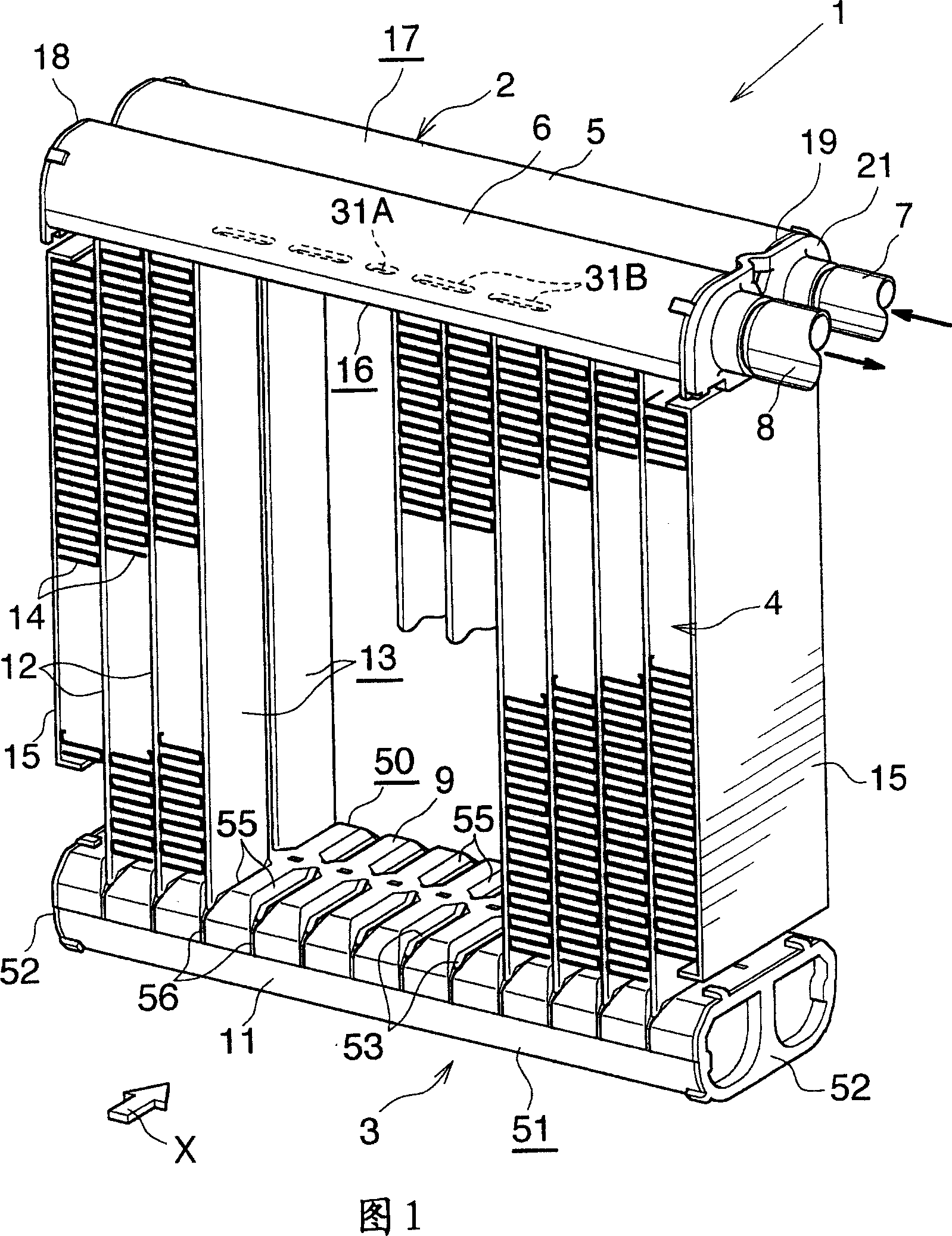

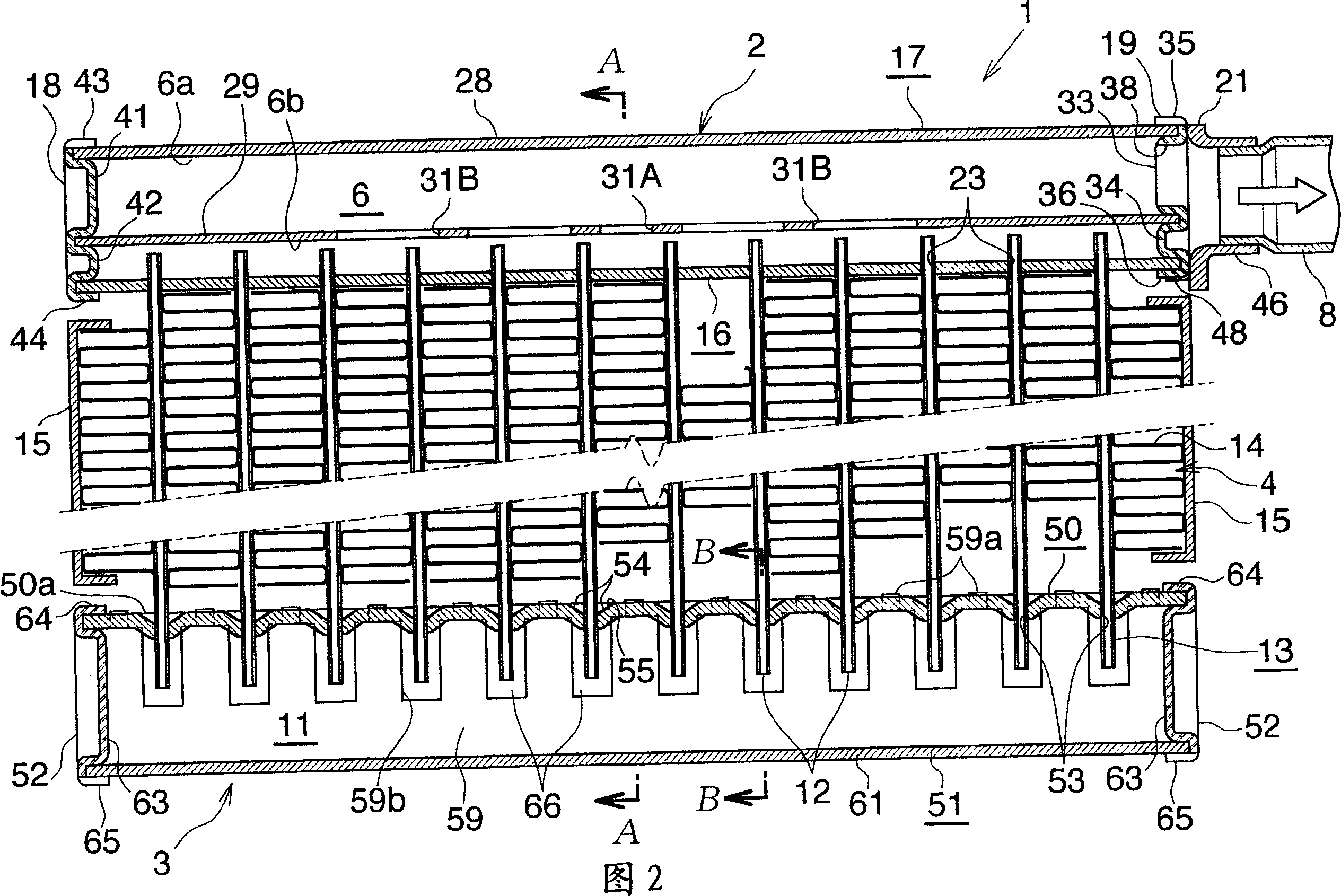

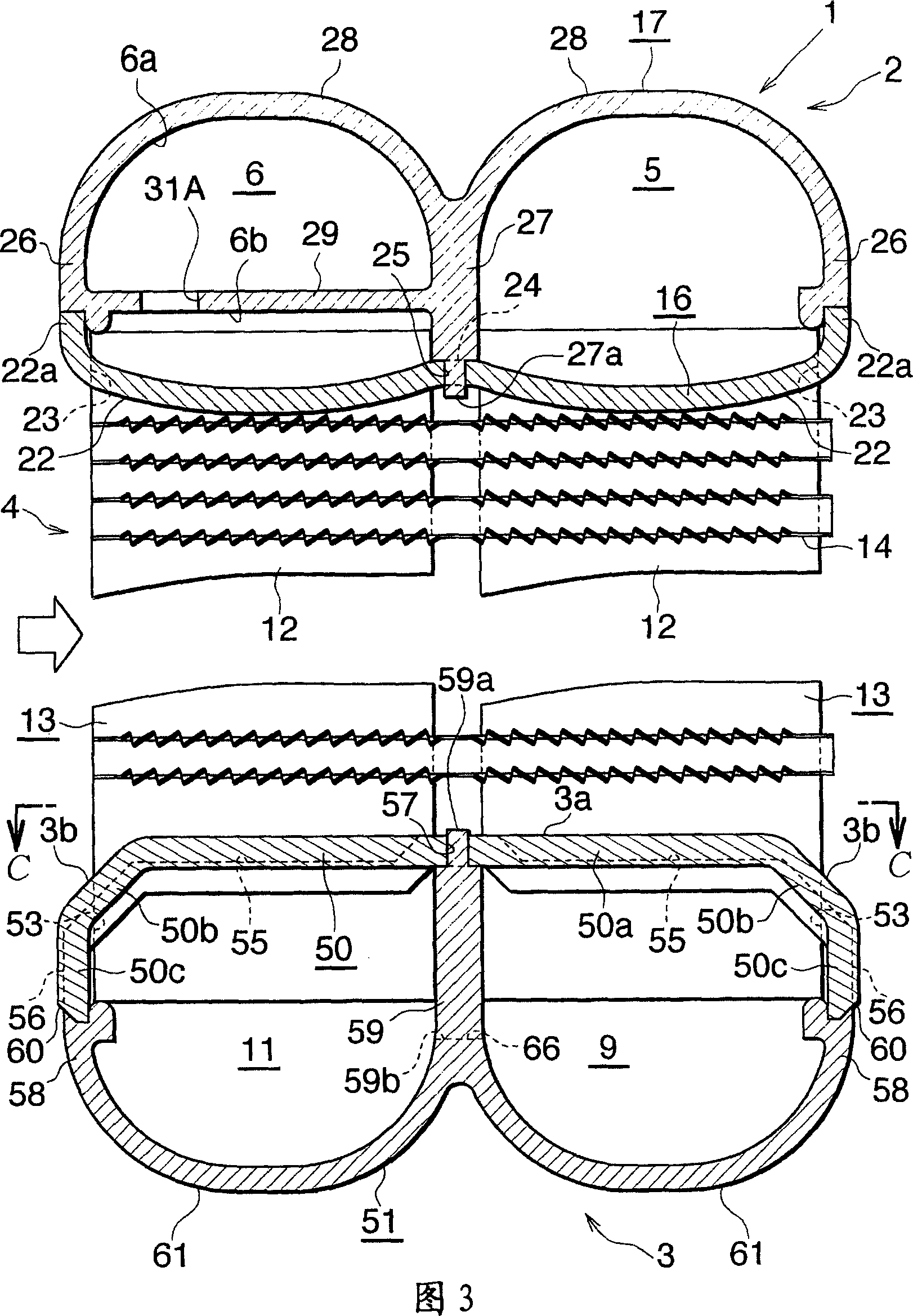

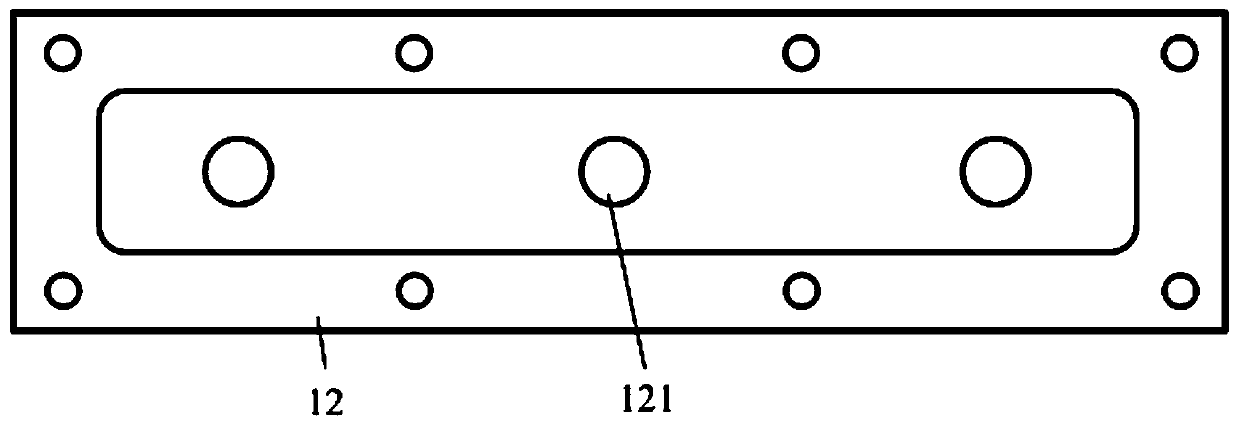

Heat exchanger

InactiveCN1981176AImprove drainage efficiencyAvoid gatheringAir-treating devicesSafety devices for heat exchange apparatusPlate heat exchangerEngineering

A heat exchanger for use as an evaporator 1 comprises a heat exchange core having a plurality of heat exchange tubes 12 arranged in a left-right direction at a spacing, and a refrigerant turn tank 3 as a lower tank disposed toward a lower end of the heat exchange core. The heat exchange tubes 12 are inserted through respective tube insertion holes 53 formed in the turn tank 3 and joined to the tank 3. The turn tank 3 has drain grooves 56 each extending from a forwardly or rearwardly outer end of each of the tube insertion holes 53 for discharging condensation water to below the turn tank 3 therethrough. Each of the drain grooves 56 has a bottom extending gradually downward as the bottom extends away from the tube insertion hole 53. When the exchanger is used as the evaporator 1, the top surface of the turn tank 3 can be drained of water with an improved efficiency.

Owner:KEIHIN THERMAL TECH CORP

Novel method and device for preparing polymer particles

ActiveCN107715789AAvoid the influence of the preparation processOvercome surface tensionGranulation by liquid drop formationEnergy based chemical/physical/physico-chemical processesPolymer scienceOrganic solvent

The invention relates to a novel method and device for preparing polymer particles. The method includes the following steps that, a conductive organic solvent is pumped into an insulated capillary tube through an injection pump, the capillary tube is sealed and penetrate through a shuttle-shaped pneumatic conveying container which can be sealed, the outlet end of the capillary tube is communicatedwith a nozzle, under the strong electric field effect generated by a high voltage source, the organic solvent is dispersed to form charged droplets, under the traction force effect of electric fieldforce, gravity and flowing gas in the container, the charged droplets are uniformly spread on a grounded collection plate in the shuttle-shaped pneumatic conveying container, and the charged dropletsare grounded through the collection plate so as to remove static electricity, and solid polymer particles are formed. The novel method for preparing the polymer particles is convenient to operate, thedevice for preparing the polymer particles is simple in structure, and the particle size and shape of the obtained products, namely the polymer particles, are uniform, the performance is stable, andthe method and the device are conducive to application and popularization.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

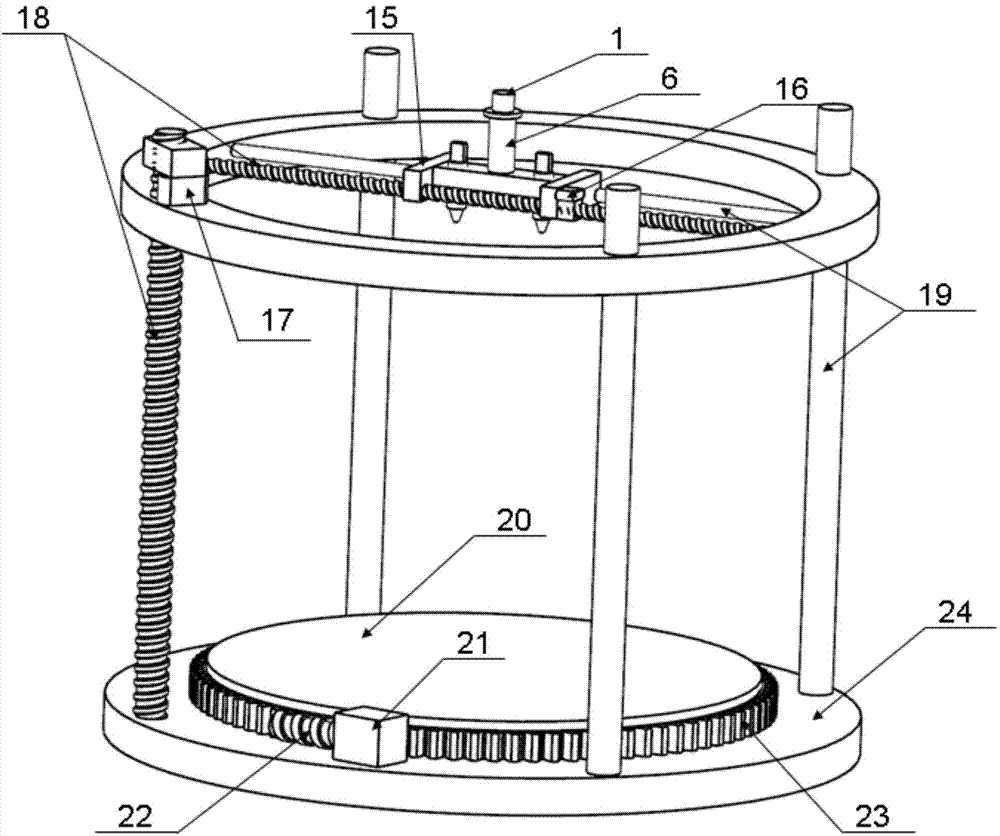

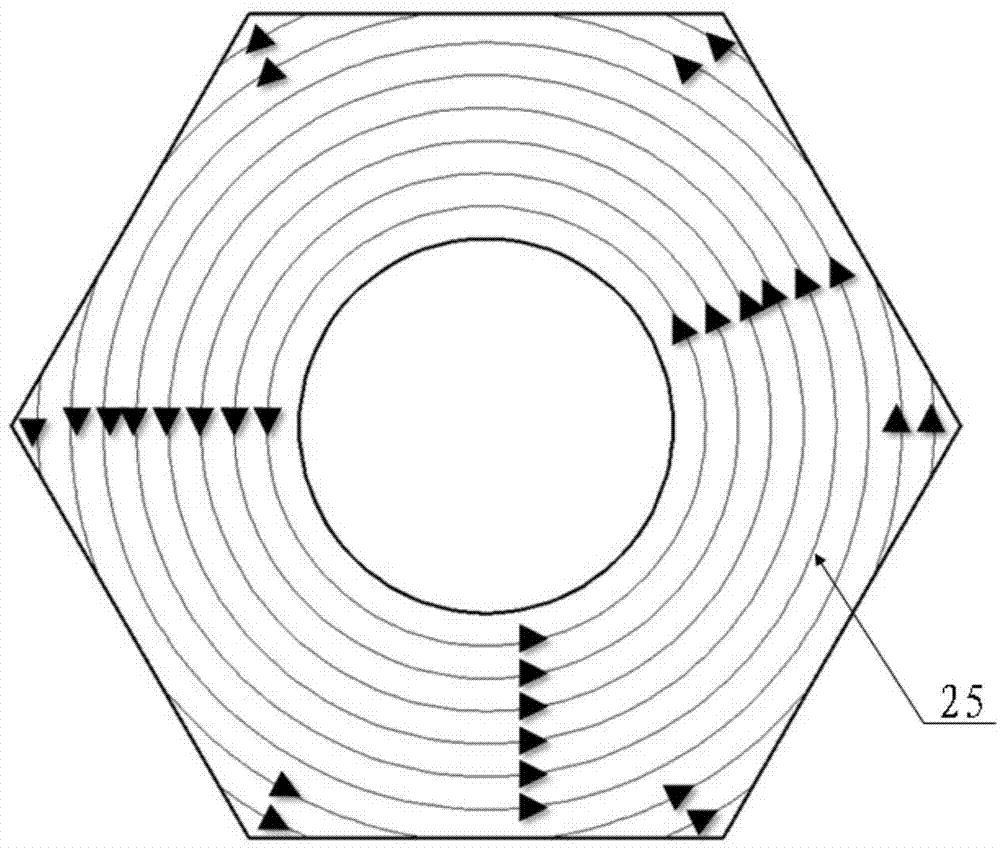

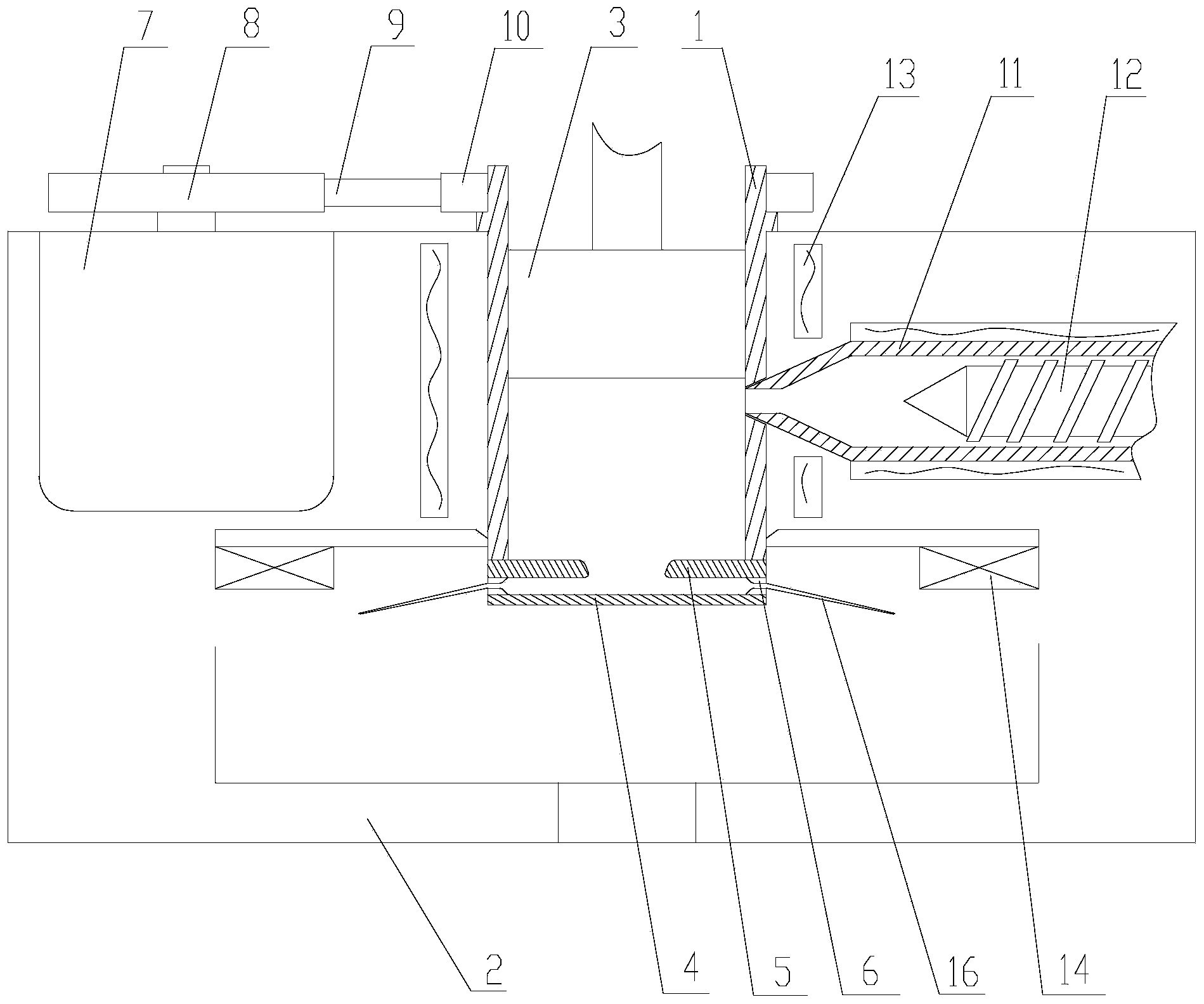

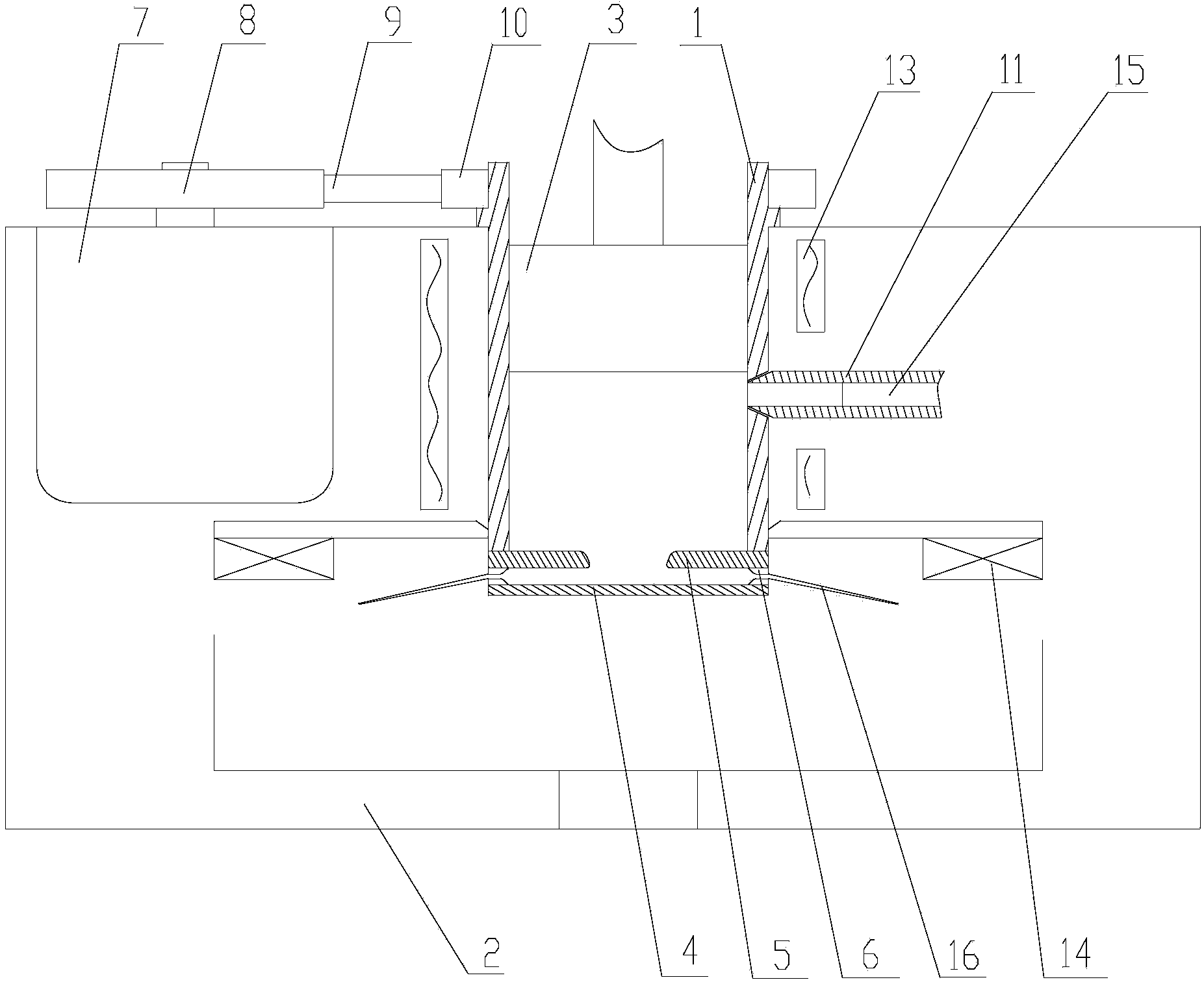

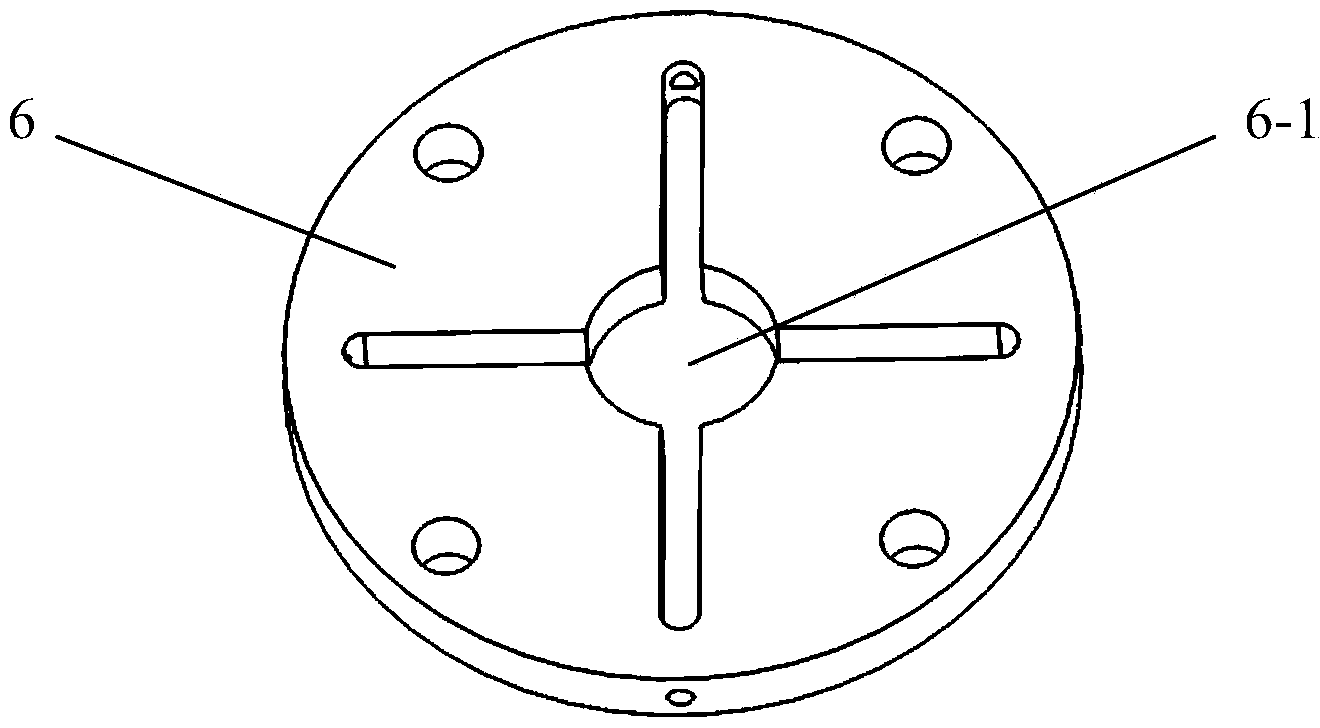

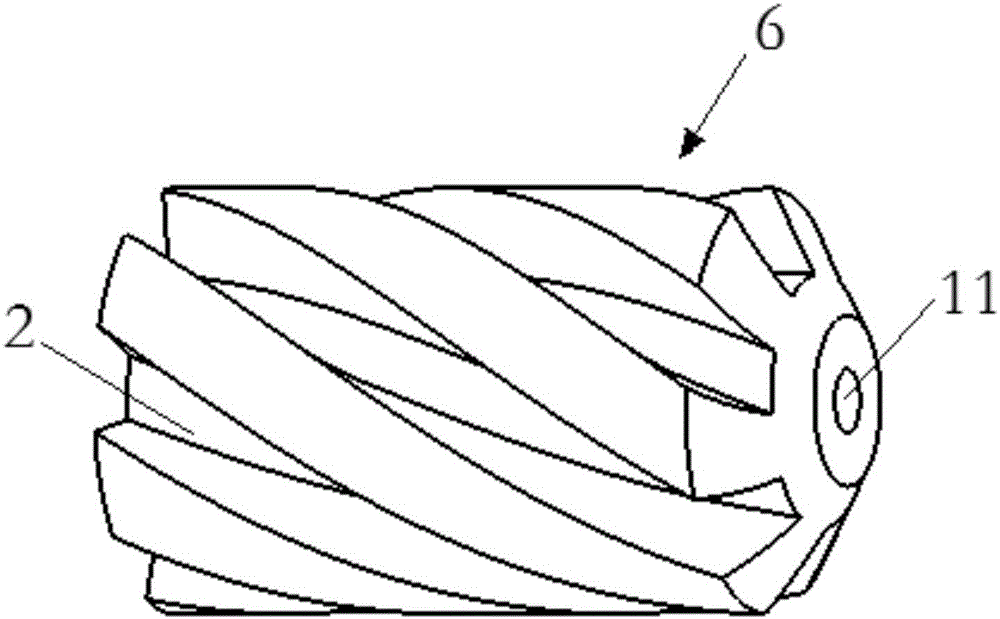

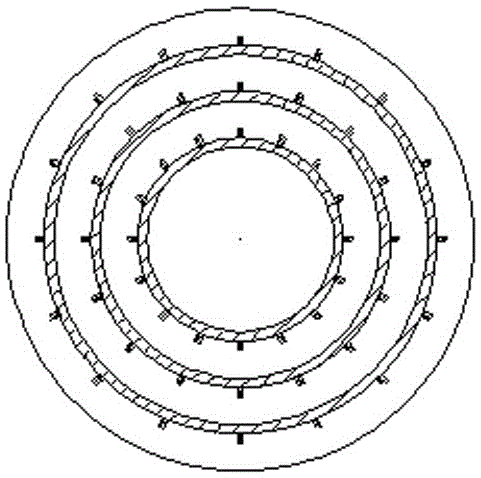

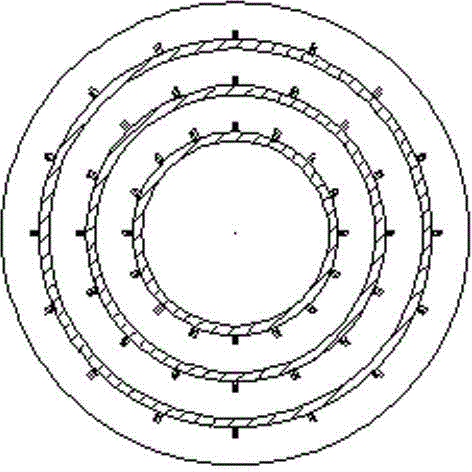

Super-centrifugal and swirl high viscosity spinning method and device for producing nano-fibers

The invention discloses a super-centrifugal and swirl high viscosity spinning method and device for producing nano-fibers. The device comprises a storage tank, a fiber receiver, a rotating drive mechanism and a conveying mechanism; the fiber receiver is arranged below the storage tank; the rotating drive mechanism is disposed around the storage tank; the conveying mechanism is arranged outside the storage tank; a plunger rod is disposed in the storage tank; a retaining plate is disposed at the bottom of the storage tank; a feed plate is arranged above the retaining plate; a nozzle plate is disposed between the feed plate and the retaining plate; a spout of the nozzle plate is arranged within the fiber receiver. The method includes the steps: material is conveyed to the nozzle plate by forced extraction; under the coupled action of strong extrusion and super-centrifugal force, the material overcomes capillary pressure and spouts out from the spout to primarily form fiber; under further action of the super-centrifugal force and swirl air pressure, the fiber is urged to continuously decrease in diameter until arriving the fiber receiver to form nano-fiber. The nano-fibers produced by the method and device are good in performance and uniform in diameter.

Owner:SOUTH CHINA UNIV OF TECH

Nano composite solder with high retention rate and preparation method thereof

ActiveCN109590636AImprove service performanceOvercome surface tensionWelding/cutting media/materialsSoldering mediaHigh energySolder matrix

The invention discloses a nano composite solder with high retention rate and a preparation method thereof. The preparation method comprises the steps of providing a solder matrix, a nano-reinforcing phase and a cavity; cleaning the solder matrix, the nano-reinforcing phase and the cavity, and then performing surface treatment; mixing the obtained solder matrix with the nano-reinforcing phase to obtain a mixture, and placing the obtained mixture into the cavity to make the mixture into the a bulk material or a preformed sheet; and closing the cavity containing the bulk material or the preformedsheet, and melting and solidifying the bulk material or the preformed sheet under the external high-energy auxiliary action to obtain the nano composite solder with high retention rate. The compositesolder has a uniform and stable material structure, and has greatly improved strength, elongation, thermal conductivity and electrical conductivity, moreover can control a treatment process to promote the oriented alignment of the nano-reinforced phase to achieve targeted anisotropic strengthening of the composite solder, and has high material utilization rate and simple process, and the increaserange can reach 40-100% compared with the solder matrix.

Owner:HOERSON ELECTRONICS TECH +1

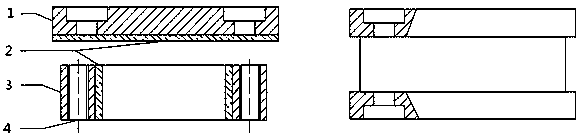

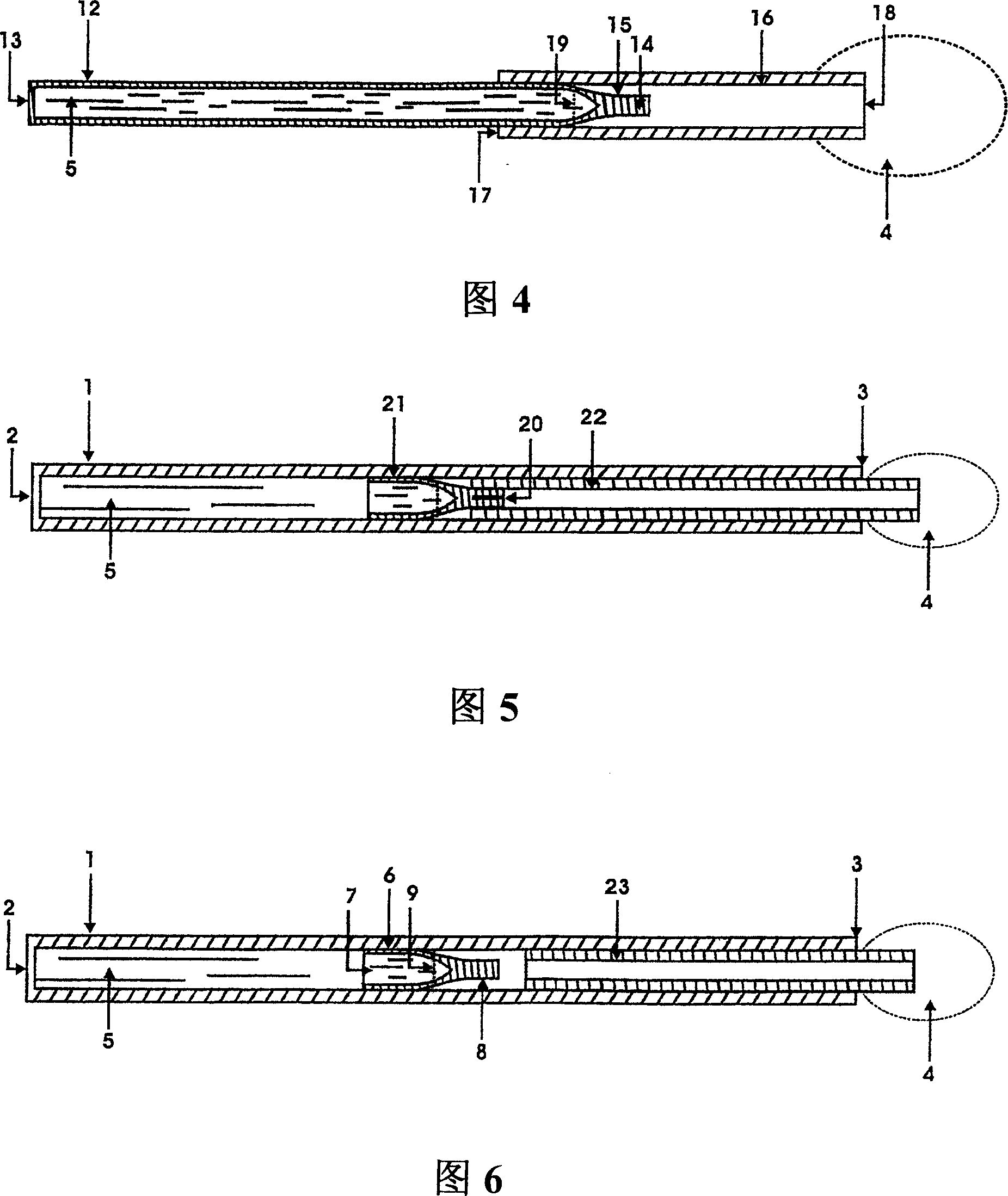

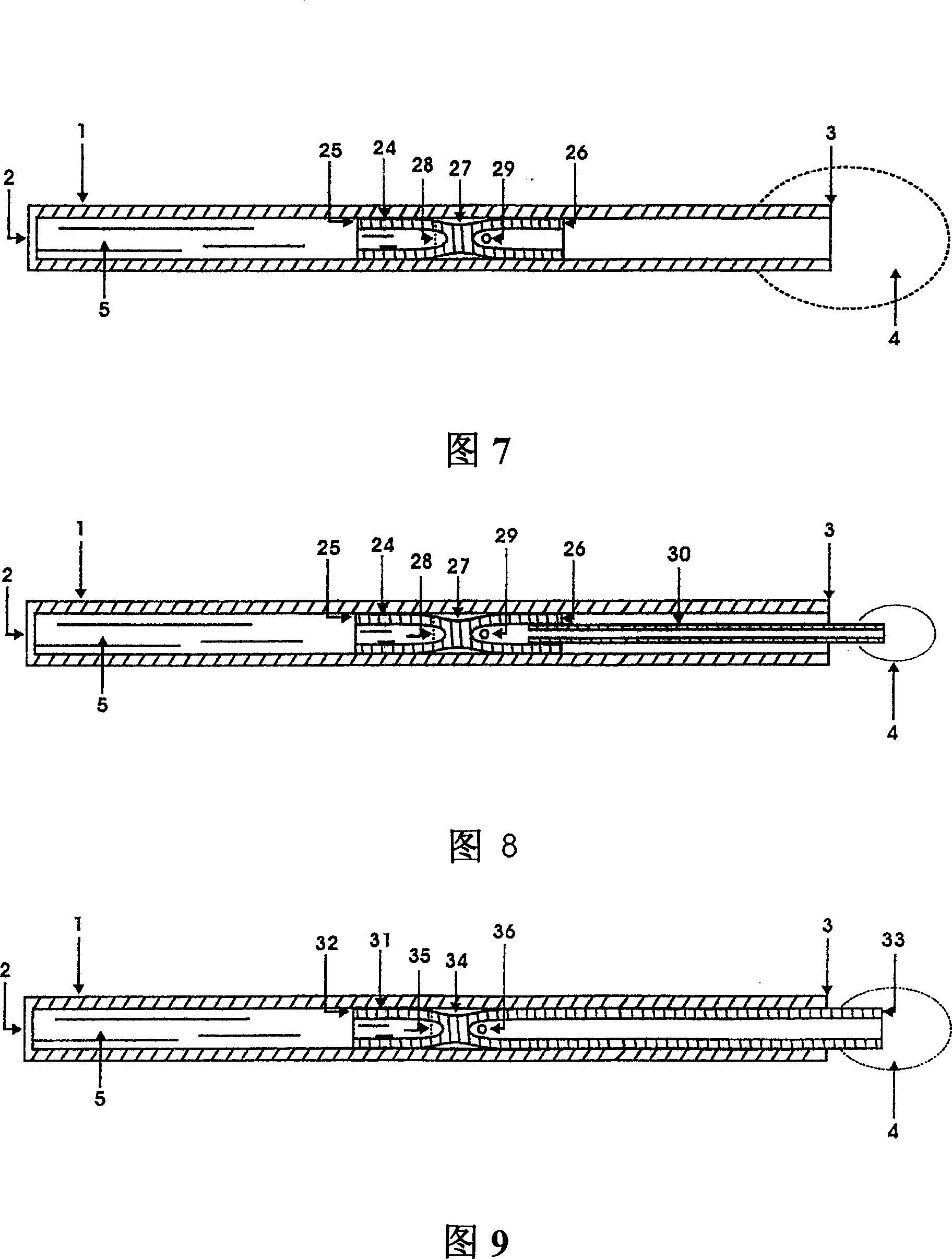

Droplet Generation Method Based on Microchannel

ActiveCN104324769BGenerated smoothlyQuick buildMixing methodsMixersMechanical engineeringEngineering

Owner:MACCURA MEDICAL INSTR CO LTD

Foamed asphalt generation device

InactiveCN106436531AOvercome surface tensionOvercome viscous forceRoads maintainenceSpray nozzleProduct gas

The invention relates to a foamed asphalt generation device, comprising a foaming chamber body and an atomizing nozzle, wherein the foaming chamber body is provided with an asphalt inlet, the asphalt inlet is arranged to introduce asphalt to be foamed, the atomizing nozzle is arranged to eject atomized liquid to the asphalt to be foamed, and comprises a liquid passageway and a gas passageway, the liquid passageway is provided with a liquid outlet, the liquid outlet is arranged to output liquid, the gas passageway is provided with a gas outlet, the gas outlet is arranged to output gas, the gas passageway spirally extends along the circumferential direction of the liquid passageway to one end, provided with the liquid outlet, of the liquid passageway, so that liquid outputted from the liquid outlet can move along the circumferential direction of the liquid outlet under the action of the gas outputted from the gas outlet. The liquid ejected from the liquid outlet can overcome surface tension and viscous force of the liquid under the combined action of centrifugal force and inertia force, so as to improve the atomizing effect of the liquid, and therefore the atomized liquid can contact with the asphalt more uniformly so as to improve foaming quality of the asphalt.

Owner:XCMG CONSTR MACHINERY

Adjustable angle eye dropper

InactiveUS20050070856A1Enhanced capillary actionOvercome surface tensionMedical applicatorsIntravenous devicesEngineeringMechanical engineering

Owner:TSAUR GARRY

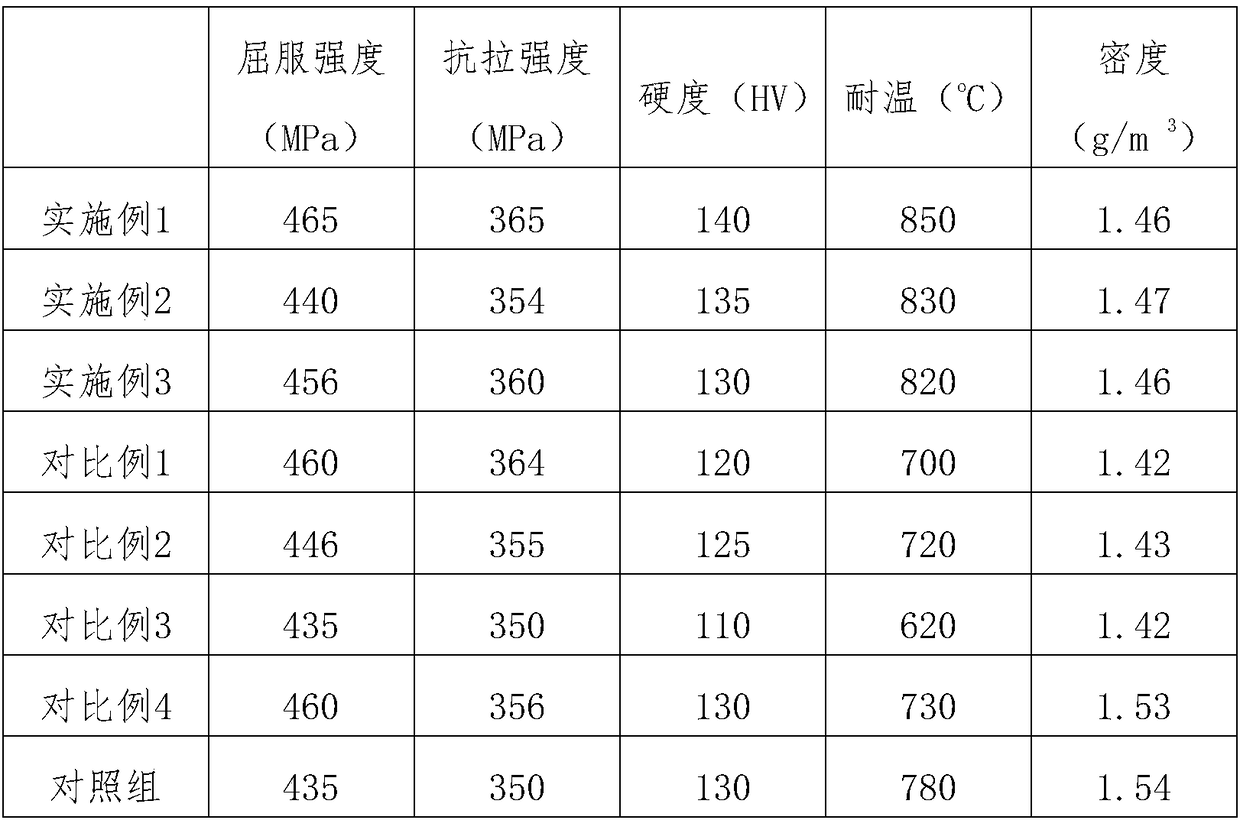

Preparation method of high-performance alkene-magnesium alloy

The invention belongs to the technical field of alloy materials, and particularly relates to a preparation method of high-performance alkene-magnesium alloy. The preparation method comprises the following steps: (1) adding modified graphene powder in a solution of an organic silicon surfactant, soaking, drying, and obtaining mixed graphene powder; (2) smelting the magnesium powder and alloy element powder under inertial gas to obtain metal liquid; (3) adding the mixed graphene powder into the metal liquid, ultrasonically treating and stirring, obtaining molten alloy, removing the slag, pouring, and obtaining an alloy ingot; and (4) performing the heat treatment for the alloy ingot, and obtaining the alkene-magnesium alloy. The modified graphene powder is prepared by utilizing zirconium, hydrofluoric acid and nitrogen to modify the graphene. By adopting the preparation method of the high-performance alkene-magnesium alloy provided in the invention, the problem that the graphene is low in dispersity and easy to agglomerate can be solved, the close combination of the graphene and other elements can be realized, and the prepared alkene-magnesium alloy is high in homogeneity and excellent in performances.

Owner:贵州航天风华精密设备有限公司

Method for preparing lactide through high-gravity technology

InactiveCN106749160AOvercome viscosityOvercome surface tensionOrganic chemistryDepolymerizationLactide

The invention discloses a method for preparing lactide through a high-gravity technology. The method comprises the following steps: injecting lactic acid aqueous solution into a high-gravity reactor, and removing free water under carrier gas desorption or a vacuum condition; adding catalyst into anhydrous lactic acid of which the free water is removed, generating polymerization reaction at a certain temperature after even mixing, then, injecting into the high-gravity reactor, further removing reaction water under the carrier gas desorption or the vacuum condition to obtain oligolactic acid; raising the temperature of the reaction liquid to a depolymerization temperature, injecting the reaction liquid into the high-gravity reactor, steaming the lactide from the reaction liquid under the vacuum condition, and cooling to obtain lactide crystal. In the process, a free water removal temperature is 60-100 DEG C, a reaction water removal temperature is 100-140 DEG C, and lactide steaming temperature is 160-220 DEG C. Compared with a traditional vacuum reaction process, the method disclosed by the invention has the advantages of high water removal efficiency, simple production process, high lactide yield and easiness in industrialization.

Owner:NANJING UNIV OF TECH +1

A flue gas desulfurization device and process

ActiveCN103480259BOvercome surface tensionEnhanced mass transferDispersed particle separationDesorptionLiquid circulation

The invention belongs to the technical field of flue gas desulfurization, and particularly relates to a flue gas desulfurization process and device, which aim to solve the problems of an existing flue gas desulfurization process and device. The flue gas desulfurization device comprises a retrograde rotation packed bed absorber, a rotation packed bed desorber, a barren liquid storage groove, a rich liquid storage groove, a barren liquid circulation pump, a rich liquid circulation pump, a heat exchanger and a condenser. The flue gas desulfurization process comprises an absorption process and a desorption process. The device provided by the invention is small in size, has a wide in treatment gas quantity range, and is simple in structure and easy to operate. The process has the advantages of high desulfurization rate, low energy consumption, simple process, low investment and running expense, running stability, convenience in starting and stopping and the like.

Owner:ZHONGBEI UNIV

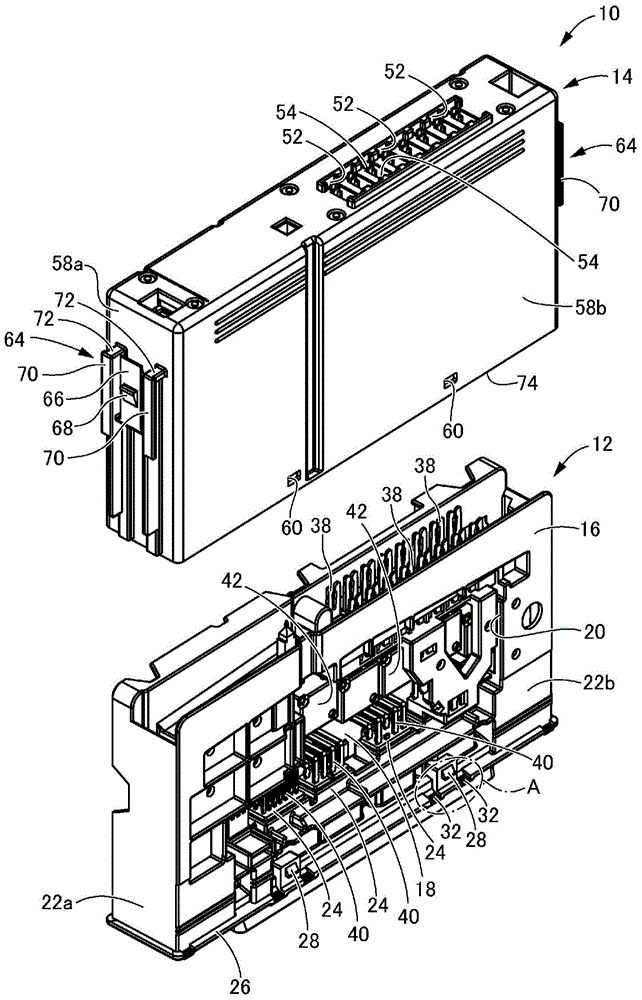

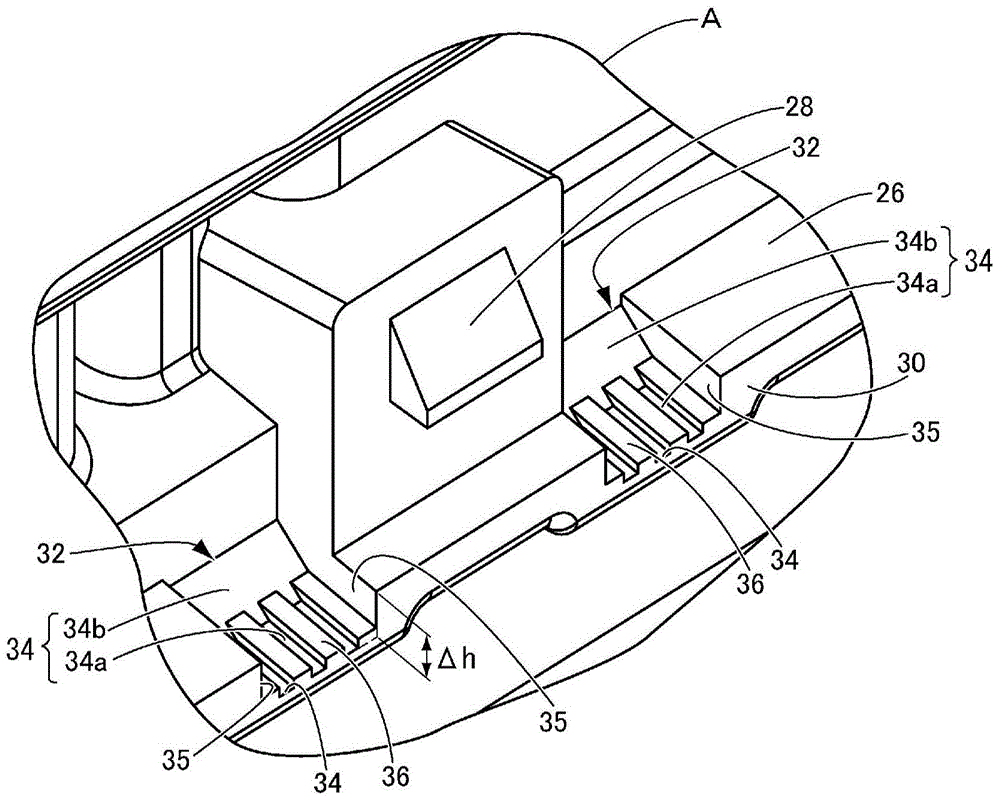

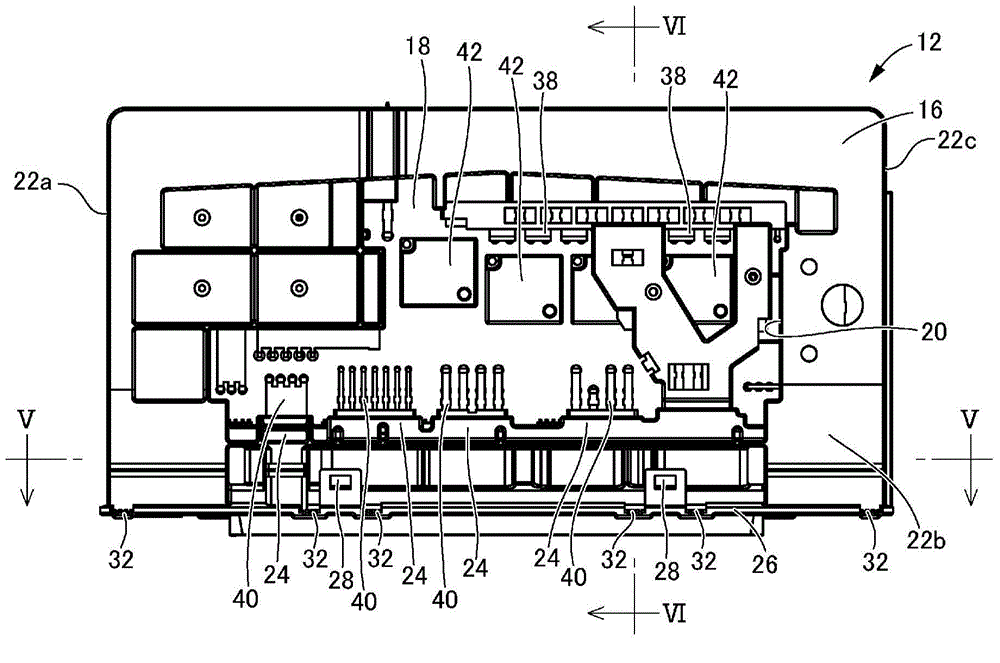

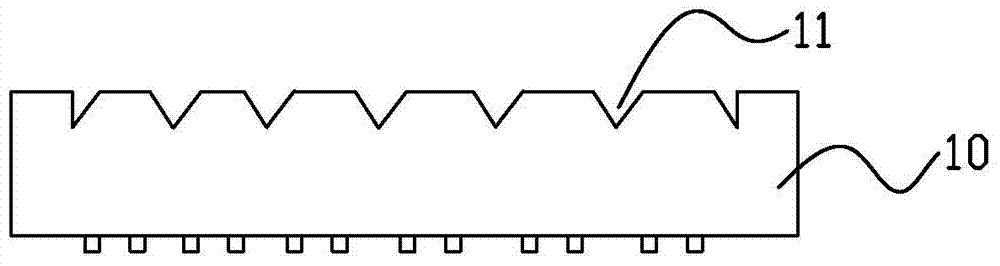

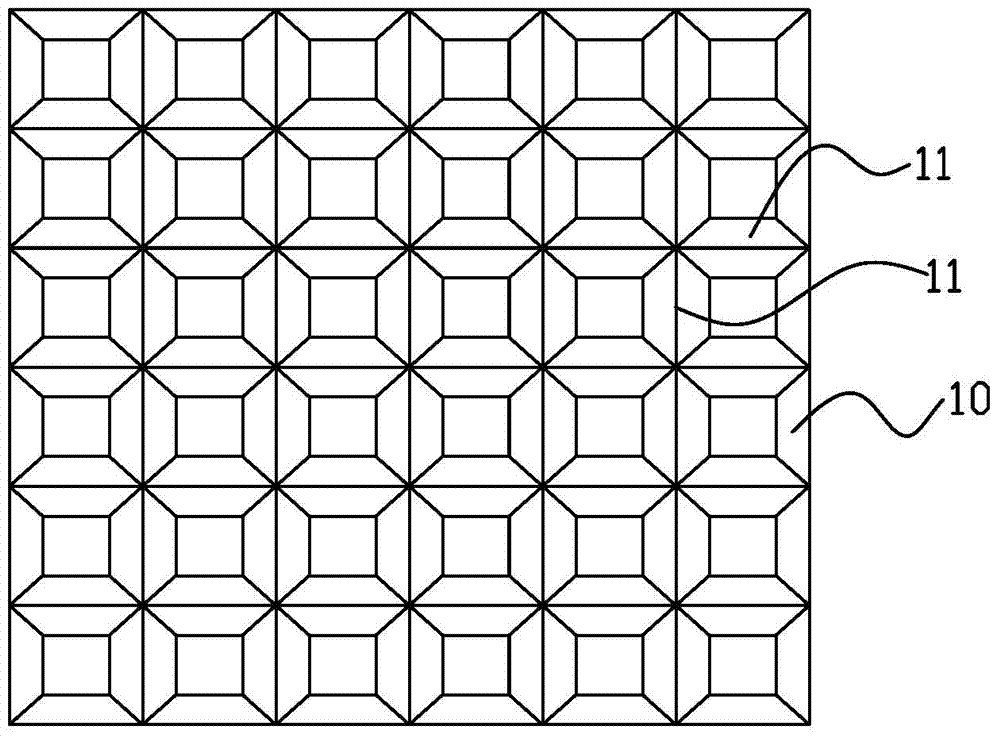

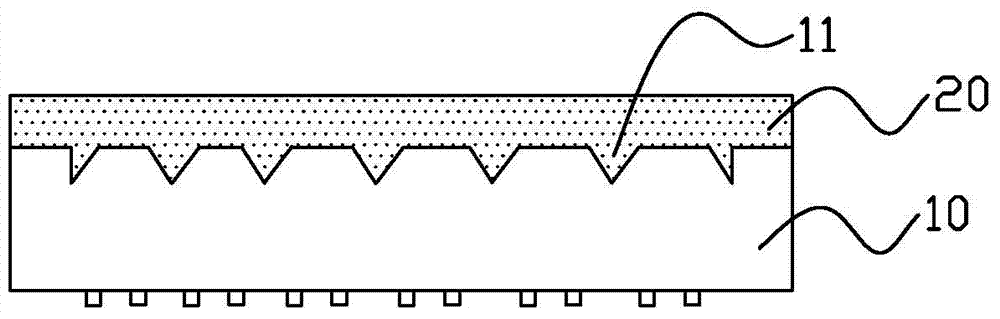

Electrical junction box

ActiveCN104685740AOvercome surface tensionImprove drainage capacityElectrical apparatusElectric/fluid circuitRough surfaceElectrical junction

Provided is an electrical junction box with a novel structure, said electrical junction box having a downward-opening, box-shaped cover that is externally fitted from above to a main body equipped with an internal circuit, wherein drainage in a gap between a flange and a peripheral wall end face disposed on the main body is improved. A recess (32) that is recessed downward is disposed on a portion of the surface of the flange (26), and opens to a protruding end face (30) of the flange (26). A drainage hole (76) is formed between the recess (32) and the peripheral wall end face (74) of the cover (14). Meanwhile, forming surfaces (34) of the drainage hole (76) are configured to include rough surface parts (36).

Owner:SUMITOMO WIRING SYST LTD

Device and method for removing sulfur dioxide in waste gas

ActiveCN103463936BOvercome surface tensionEnhanced mass transferDispersed particle separationAir quality improvementGas phaseTower

The invention belongs to the field of waste gas desulfurization, and particularly relates to a device and a method for removing sulfur dioxide contained in a waste gas. The device and the method can be used for solving the problems of the traditional waste gas desulfurization technology. The device for removing the sulfur dioxide contained in the waste gas comprises an inverse shearing rotation packed bed, a barren solution storage tank, a pregnant solution storage tank, a barren solution circulation pump and a pregnant solution circulation pump, wherein an inverse rotation packed bed absorber is in a parallel flow structure; a gas and a liquid which are positioned in the inverse shearing rotation packed bed contact in a parallel flow way. The method for removing the sulfur dioxide contained in the waste gas comprises the following step: fast transferring SO2 contained in the waste gas to a desulfurization absorbing agent by carrying out multistage parallel flow contact on the desulfurization absorbing agent and the SO2-containing waste gas through multilayer inverse rotation packings and body resistance parts. The device disclosed by the invention has the advantages of small size, width treatment tolerance range, simple structure and easiness for operation. Compared with the traditional tower, the process disclosed by the invention has the advantages of high desulfurization rate, less gas-phase pressure drop, low energy consumption, low investment and operation cost, stability in operation, convenience for start and stop, and the like.

Owner:JIANGSU ZEYU ENVIRONMENTAL ENG

LED chip packaging method and LED packaging structure using same

ActiveCN104269491ASimple processOvercome surface tensionSemiconductor devicesEngineeringLed packaging

The invention provides an LED chip packaging method. The method comprises the following steps that an epitaxial wafer of an LED chip is made, and the top of the epitaxial wafer is cut to form a groove; a thin film is arranged on the top of the epitaxial wafer; the thin film and the epitaxial wafer are cut along the groove to form multiple LED chips, and a chamfer is formed on the top of each cut LED chip; the cut LED chips are heated, so that the thin film is molten and wrapped on the LED chips, and a packaging layer is formed when curing is conducted after the thin film is cooled. The invention further provides an LED packaging structure using the LED chip packaging method. The LED chip packaging method and the LED packaging structure using the LED chip packaging method have the advantage that the process is simple.

Owner:LEEDARSON IOT TECH INC

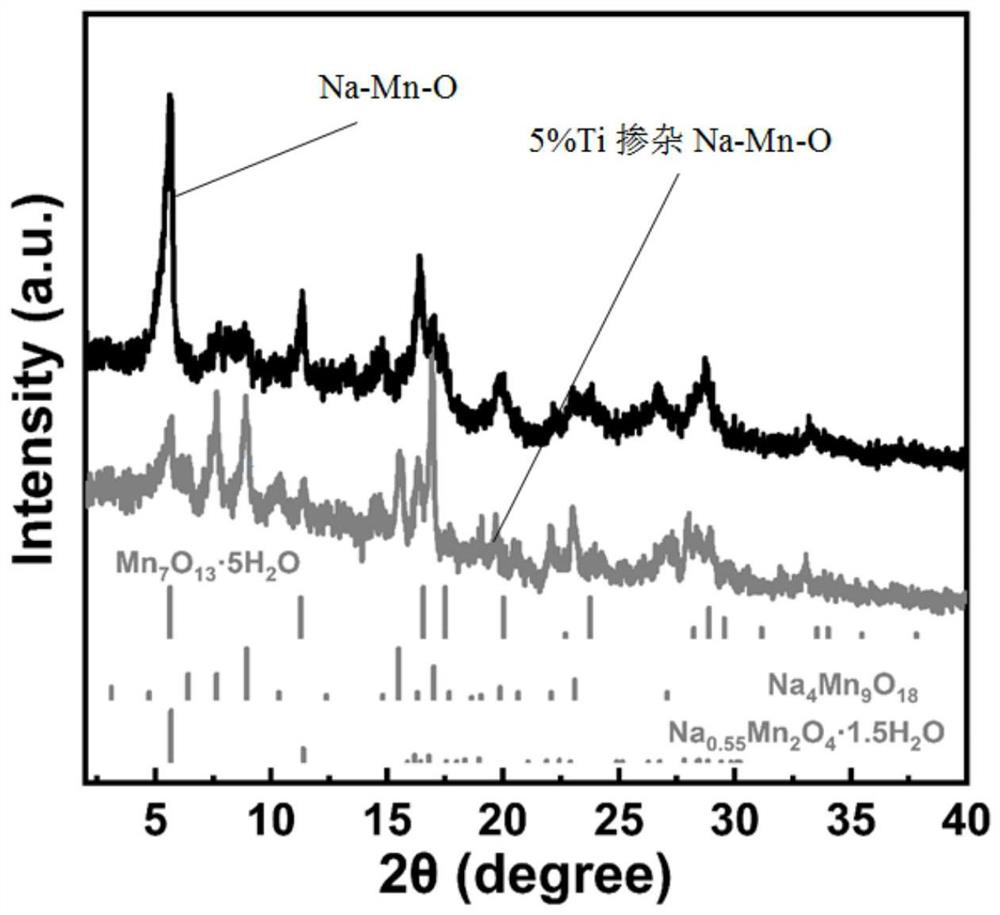

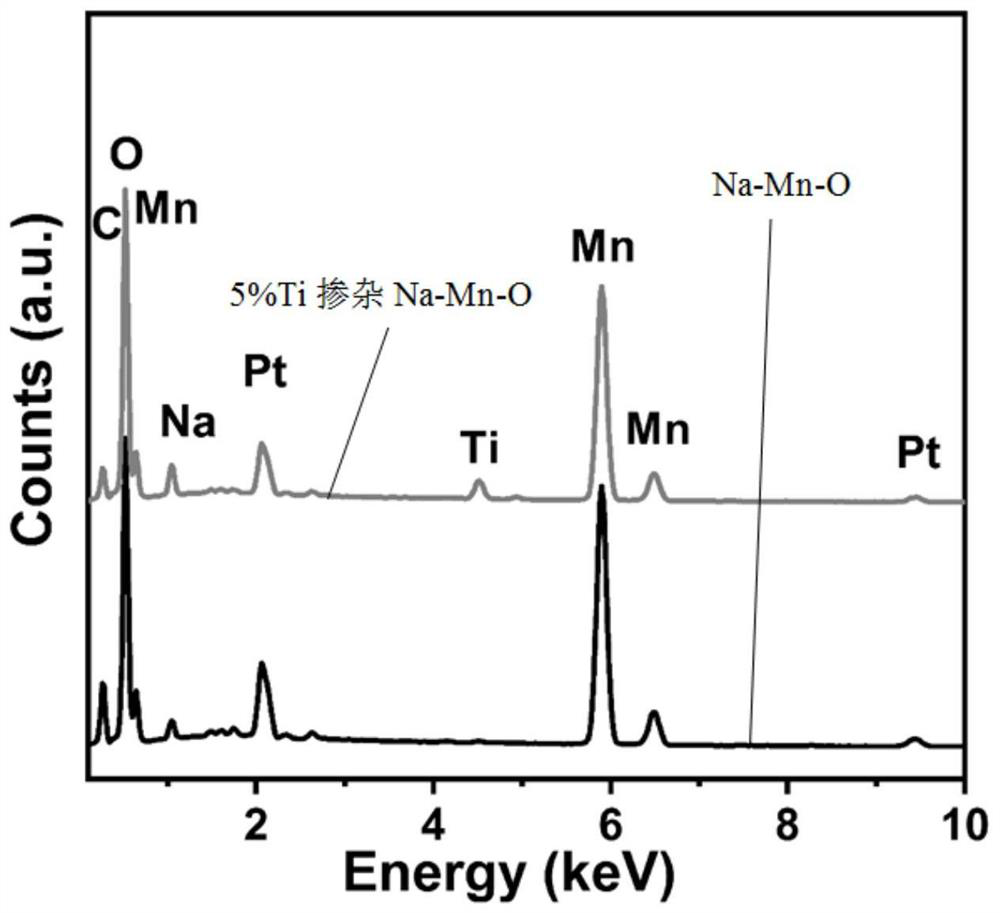

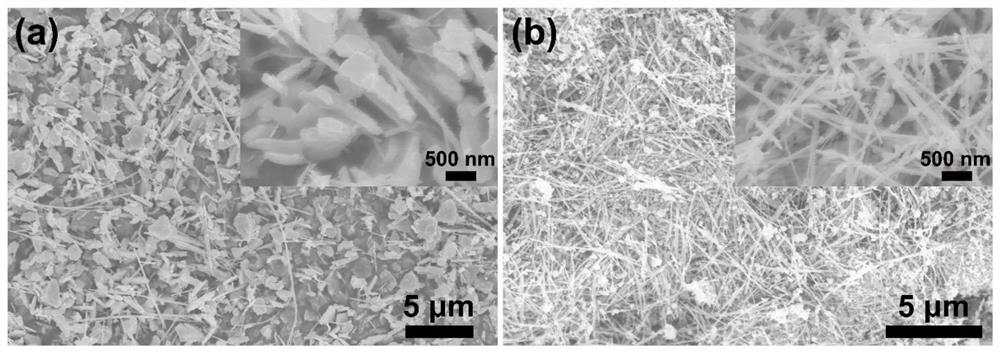

Magnesium ion battery cathode material of novel microstructure and preparation method thereof

ActiveCN111916700AExcellent reversible capacity and rate performanceEasy to prepareMaterial nanotechnologyDrying solid materials without heatTitanium oxideSodium oxide

The invention discloses a magnesium ion battery positive electrode material of a novel microstructure and a preparation method thereof, and belongs to the technical field of battery materials. The invention solves the problems of low reversible capacity, poor rate capability and the like of the electrode material of the existing magnesium ion battery positive electrode. The preparation method comprises the following steps: dissolving manganese oxide in a high-concentration sodium hydroxide solution environment, carrying out hydrothermal reaction and centrifugation, directly freeze-drying the product to prepare a nanosheet and nanowire blended NaMnO electrode material, and adding titanium oxide in the same preparation process to prepare the Ti-doped NaMnO electrode material. The obtained nanosheet and nanowire blended NaMnO electrode material has higher tap density, reversible capacity, rate capability and good cycling stability, and the reversible capacity, the rate capability and thecycling stability are further improved by doping the designed Ti-doped NaMnO electrode material.

Owner:HARBIN UNIV OF SCI & TECH

Enclosed opening means

InactiveCN101018676AOvercome surface tensionClosuresMedical applicatorsMechanical engineeringEngineering

Owner:曹荣华

Tip-induced electrostatic spinning nozzle and tip-induced electrostatic spinning device

PendingCN110670156AIncrease the cross-sectional areaIncrease supplySpinnerette packsStretch-spinning methodsPolymer scienceNanofiber

The invention discloses a tip-induced electrostatic spinning nozzle which comprises a nozzle body, a spinning needle and an airflow assisted nozzle. A liquid cavity and an air cavity are formed in thenozzle body, a liquid inlet, a liquid outlet, an air inlet and an air outlet are formed in the nozzle body, the liquid inlet and the liquid outlet are communicated with the liquid cavity, and the airinlet and the air outlet are communicated with the air cavity. The airflow assisted nozzle is fixedly arranged at the air outlet and communicated with the air cavity; the spinning needle is fixedly arranged at the liquid outlet and communicated with the liquid cavity; a free end of the spinning needle penetrates the air cavity and extends out of the airflow assisted nozzle; a conductive needle isarranged in the spinning needle. Besides, the invention further discloses a tip-induced electrostatic spinning device. The large-diameter spinning needle can be used without greatly increasing operating voltage, the production efficiency of nanofibers can be improved, and the tip-induced electrostatic spinning nozzle is good in spinning quality and high in safety.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com