Method for preparing lithium iron manganese phosphate precursor and method for preparing lithium iron manganese phosphate

A technology of lithium iron manganese phosphate and its precursor is applied in the field of preparing nanoscale lithium iron manganese phosphate precursor ferromanganese oxalate or ferromanganese phosphate, which can solve the advantages of ternary high energy density discount and the high cost of ternary materials. and other problems, to achieve the effect of low resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0117] Hereinafter, the present invention will be described in detail with reference to Examples to specifically describe the present invention. However, the embodiments of the present invention may be modified into various other forms and the scope of the present invention should not be construed as being limited to the embodiments described below. The embodiments of the present invention are provided so as to more fully describe the present invention to those skilled in the art.

[0118] If the experimental methods in the following examples do not indicate specific conditions, they are usually the conventional conditions in this field or the conditions suggested by the manufacturer; the raw materials and equipment used, if no special instructions, are available from commercial channels such as the conventional market Raw materials and equipment obtained.

Embodiment A1

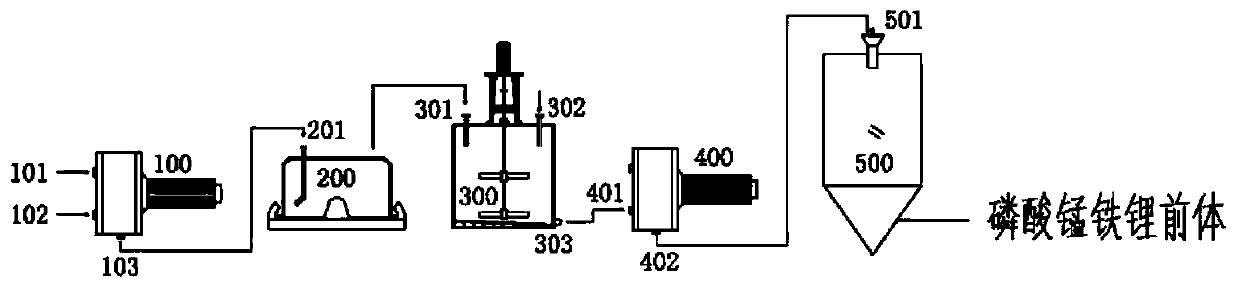

[0120] The lithium manganese iron phosphate precursor is prepared by the following procedure.

[0121] (1) Prepare a mixed solution of 2mol / L ferrous sulfate and manganese sulfate (where the molar ratio of iron to manganese is 5:5), and 2mol / L oxalic acid solution.

[0122] (2) Adopt the parallel flow mode, pump the mixed solution and the oxalic acid solution into the high-gravity rotating bed (vertical high-gravity rotating bed, Hangzhou Keli Chemical Equipment Co., Ltd. company, BZ650-3P) carry out co-precipitation reaction, wherein the reaction temperature in the high gravity rotary bed is 25 ℃, the feed rate of two kinds of raw materials is controlled at 100mL / min respectively, and the rotating speed of high gravity rotary bed is 2000rpm. Obtain the first slurry of ferromanganese oxalate.

[0123] (3) The first slurry of ferromanganese oxalate is centrifugally washed by a centrifuge (Jiangsu Shengli Centrifuge Manufacturing Co., Ltd. PSD / SD1000) to obtain a filter cake of...

Embodiment A2

[0128] The same process as in Example A1 was adopted, except that in step (1), the 2mol / L oxalic acid solution was replaced by a 2mol / L phosphoric acid solution. Finally, ferromanganese phosphate solid is obtained, which is the precursor of lithium iron manganese phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com