Preparation method for composite high-copper tungsten-copper nanopowder

A nano-composite, high-copper technology, applied in the field of powder metallurgy, can solve problems that are not conducive to the development and application of high-quality high-copper tungsten-copper alloys, and achieve the effect of fine particles, simple equipment, and uniform and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A preparation method of high-copper tungsten-copper nanocomposite powder, comprising the following steps:

[0020] Step 1. Prepare copper nitrate, ammonium metatungstate and oxalic acid solutions respectively for later use, wherein the solvents in the three solutions are water-ethanol mixed solutions, and the molar ratio of water and ethanol is 1:0.5~1:2;

[0021] Step 2. Mix the three solutions prepared in step 1 according to the molar ratio of copper nitrate, ammonium metatungstate and oxalic acid as 1: (0.04-0.2): (1-1.5), and then add mass NaOH solution with a concentration of 30~60%, until the pH value of the mixed solution is ≤3, and set aside;

[0022] Step 3: React the mixed solution prepared in Step 2 for 2-4 hours under stirring conditions at a temperature of 60-90°C, then filter and wash the reaction product, and dry it for 18-20 hours at a temperature of 80-95°C. Prepare the precursor;

[0023] Step 4. Calcining the precursor prepared in step 3 at a temper...

Embodiment 1

[0028] A preparation method of high-copper tungsten-copper nanocomposite powder, comprising the following steps:

[0029] Step 1, prepare copper nitrate, ammonium metatungstate and oxalic acid solution respectively, standby; Wherein, solvent is the mixed solution of water-ethanol, and the molar ratio of water and ethanol is 1: 0.5;

[0030] Step 2. Mix the three solutions prepared in step 1 according to the molar ratio of copper nitrate, ammonium metatungstate and oxalic acid as 1: 0.06: 1.05, and then add the NaOH solution with a mass concentration of 40% dropwise to the mixed solution. Until the pH value of the mixed solution is 0.5, set aside;

[0031] Step 3: React the mixed solution prepared in Step 2 for 4 hours at a temperature of 70°C under stirring, then filter and wash the reaction product, and dry it for 20 hours at a temperature of 80°C to obtain a precursor;

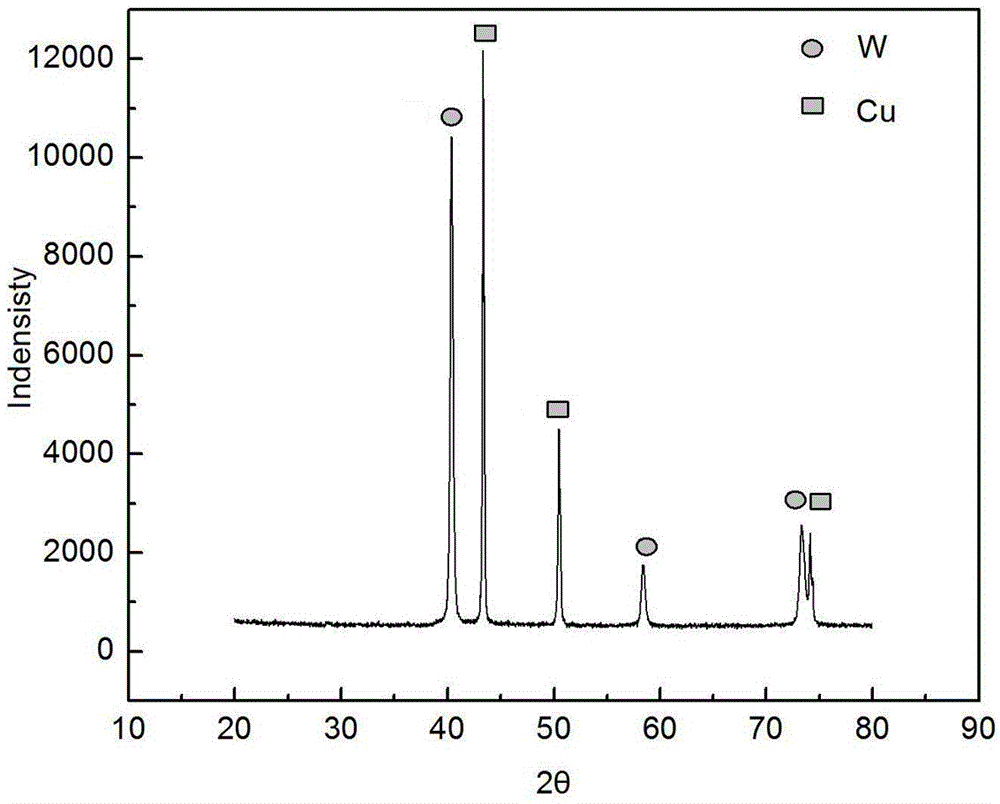

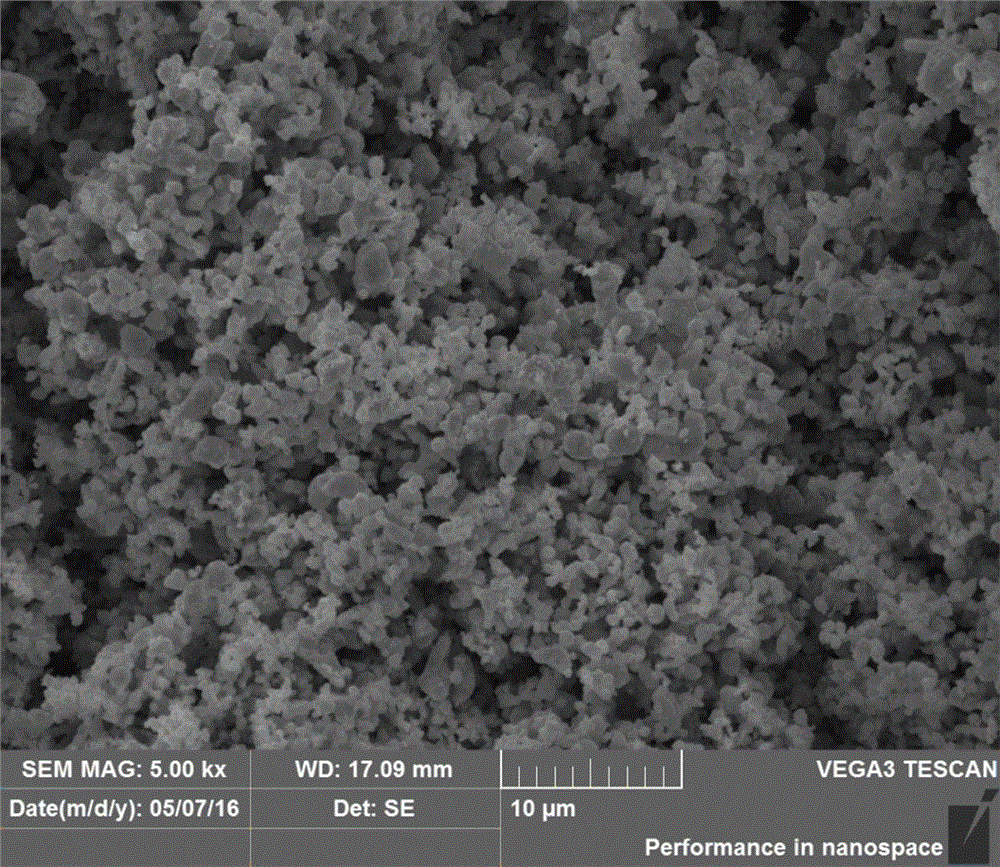

[0032] Step 4. Calcinate the precursor prepared in step 3 at a temperature of 500°C for 2 hours to obtai...

Embodiment 2

[0037] A preparation method of high-copper tungsten-copper nanocomposite powder, characterized in that: comprising the following steps:

[0038] Step 1, preparing copper nitrate, ammonium metatungstate and oxalic acid solutions respectively for subsequent use; wherein, the solvent is a mixed solution of water-ethanol, and the molar ratio of water and ethanol is 1:2;

[0039] Step 2. Mix the three solutions prepared in step 1 according to the molar ratio of copper nitrate, ammonium metatungstate and oxalic acid as 1: 0.15: 1.05, and then add the NaOH solution with a mass concentration of 60% dropwise to the mixed solution. Until the pH value of the mixed solution is 2, set aside;

[0040] Step 3: React the mixed solution prepared in Step 2 for 4 hours at a temperature of 85°C under stirring conditions, then filter and wash the reaction product, and dry it at a temperature of 95°C for 20 hours to obtain a precursor;

[0041] Step 4. Calcinate the precursor prepared in step 3 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com