Patents

Literature

271 results about "Manganous-manganic oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

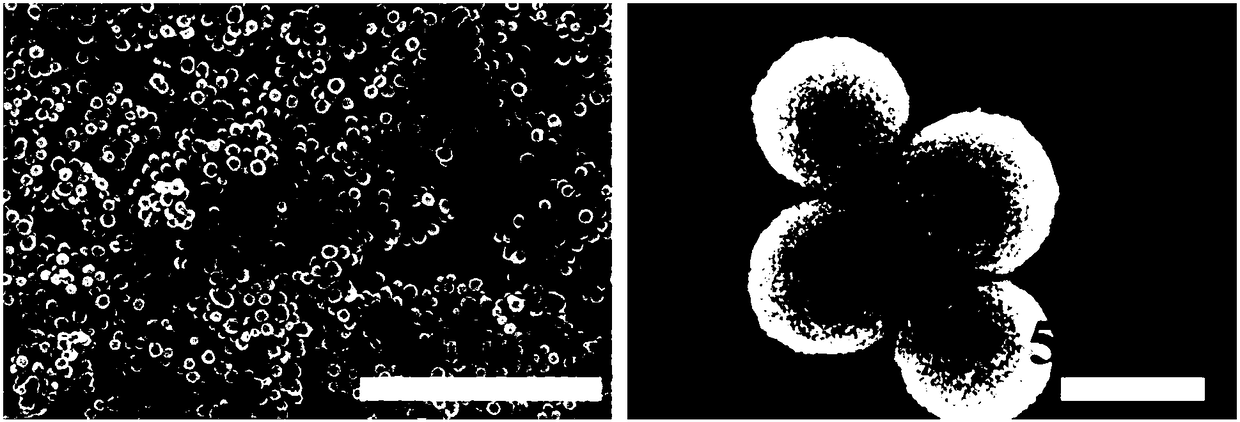

Spherical manganic manganous oxide and its preparation method

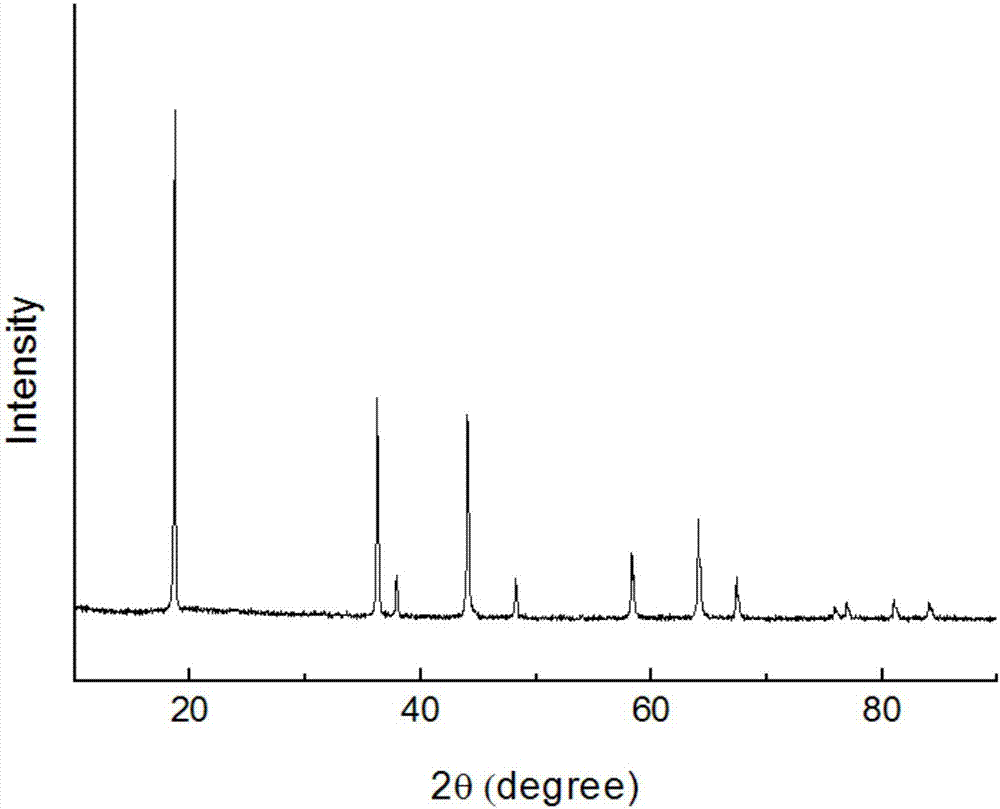

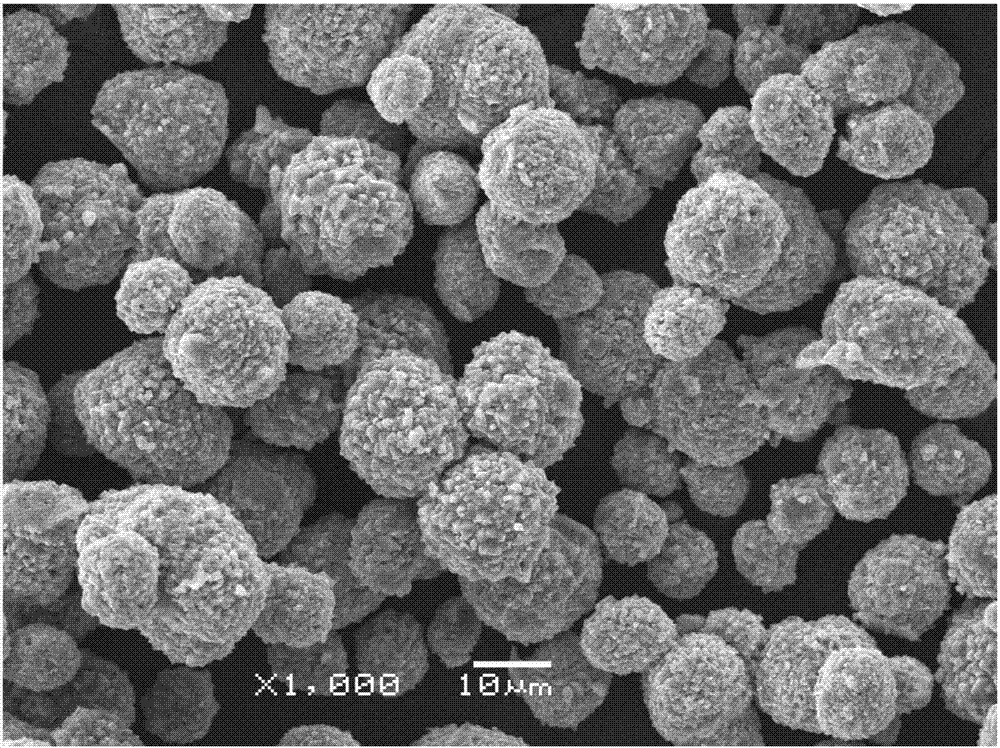

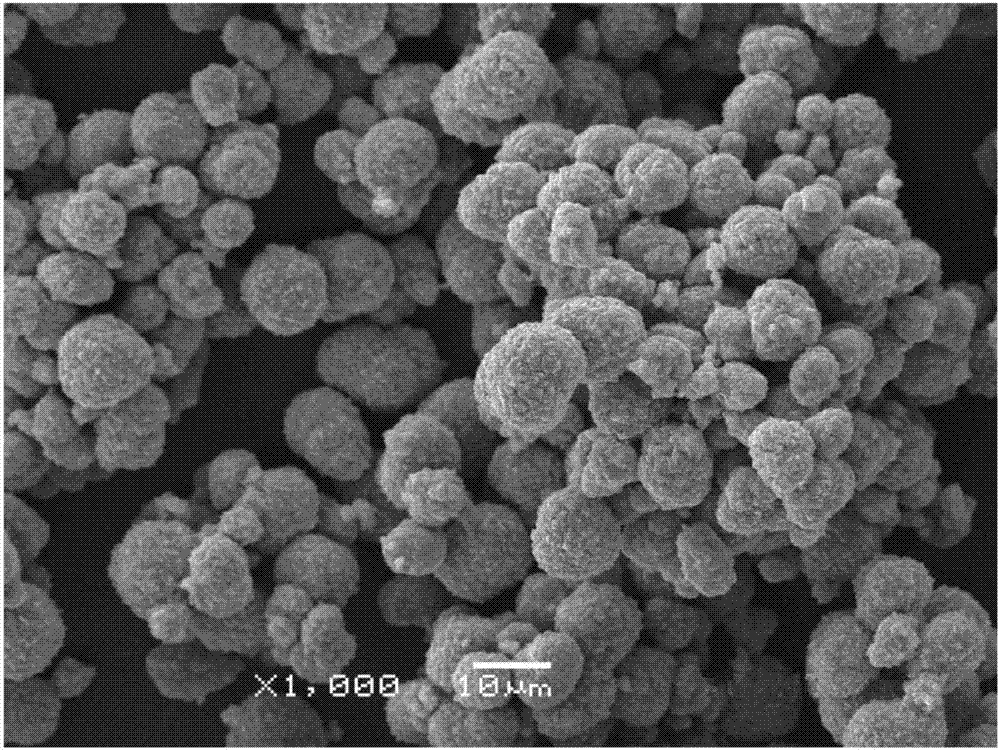

ActiveCN102491422AHigh tap densityIncrease gram capacityManganese oxides/hydroxidesPhysical chemistryManganous-manganic oxide

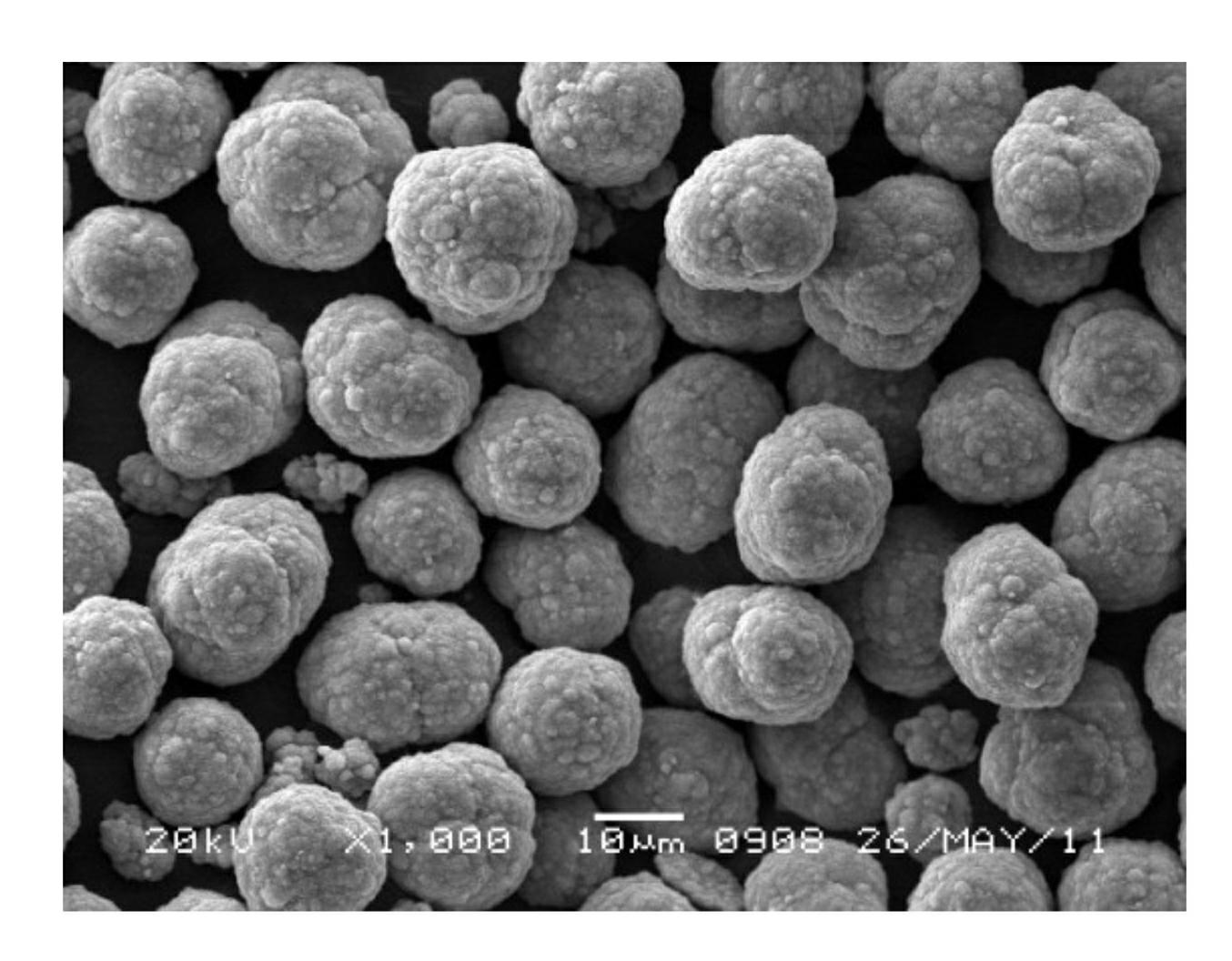

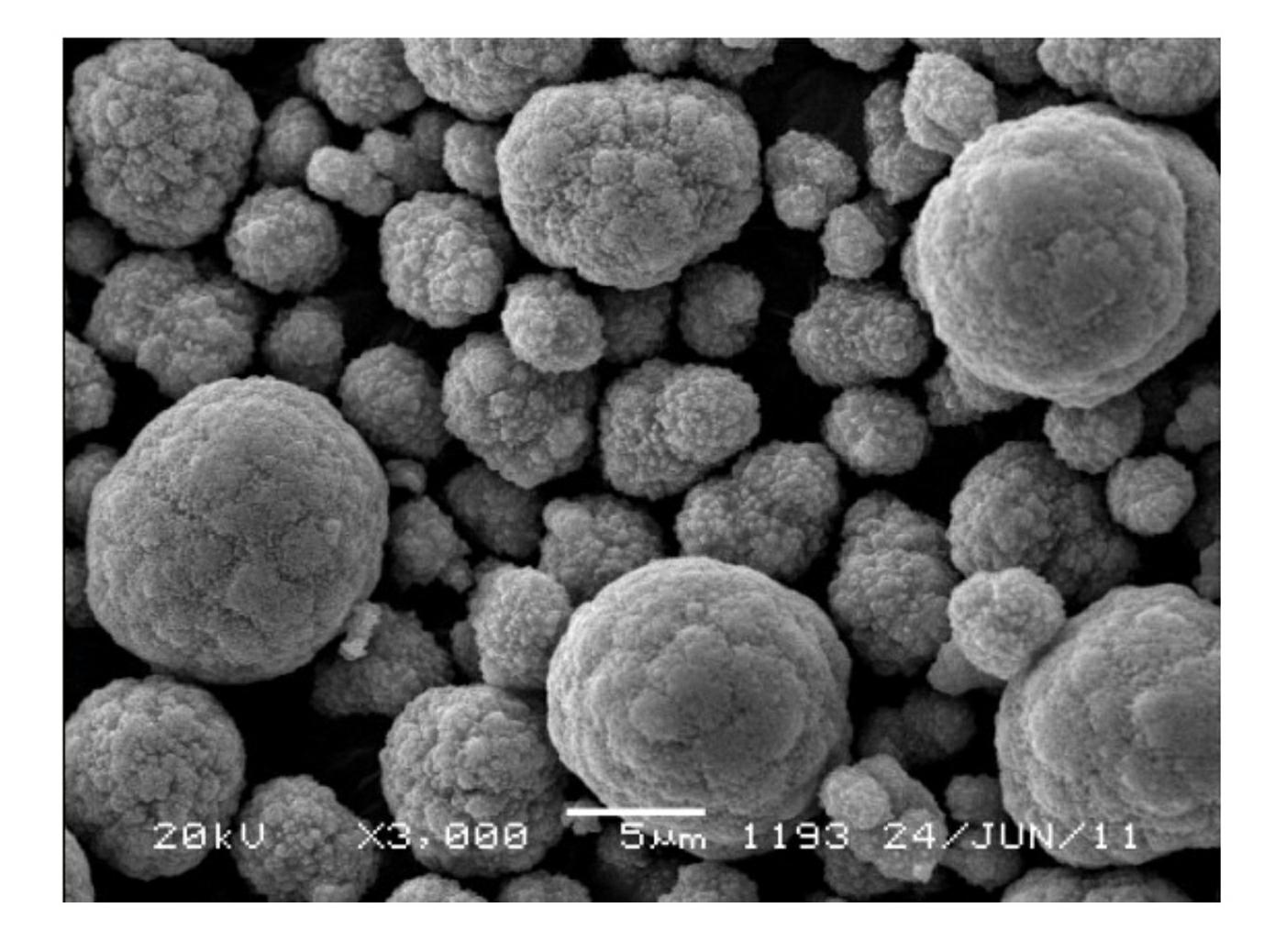

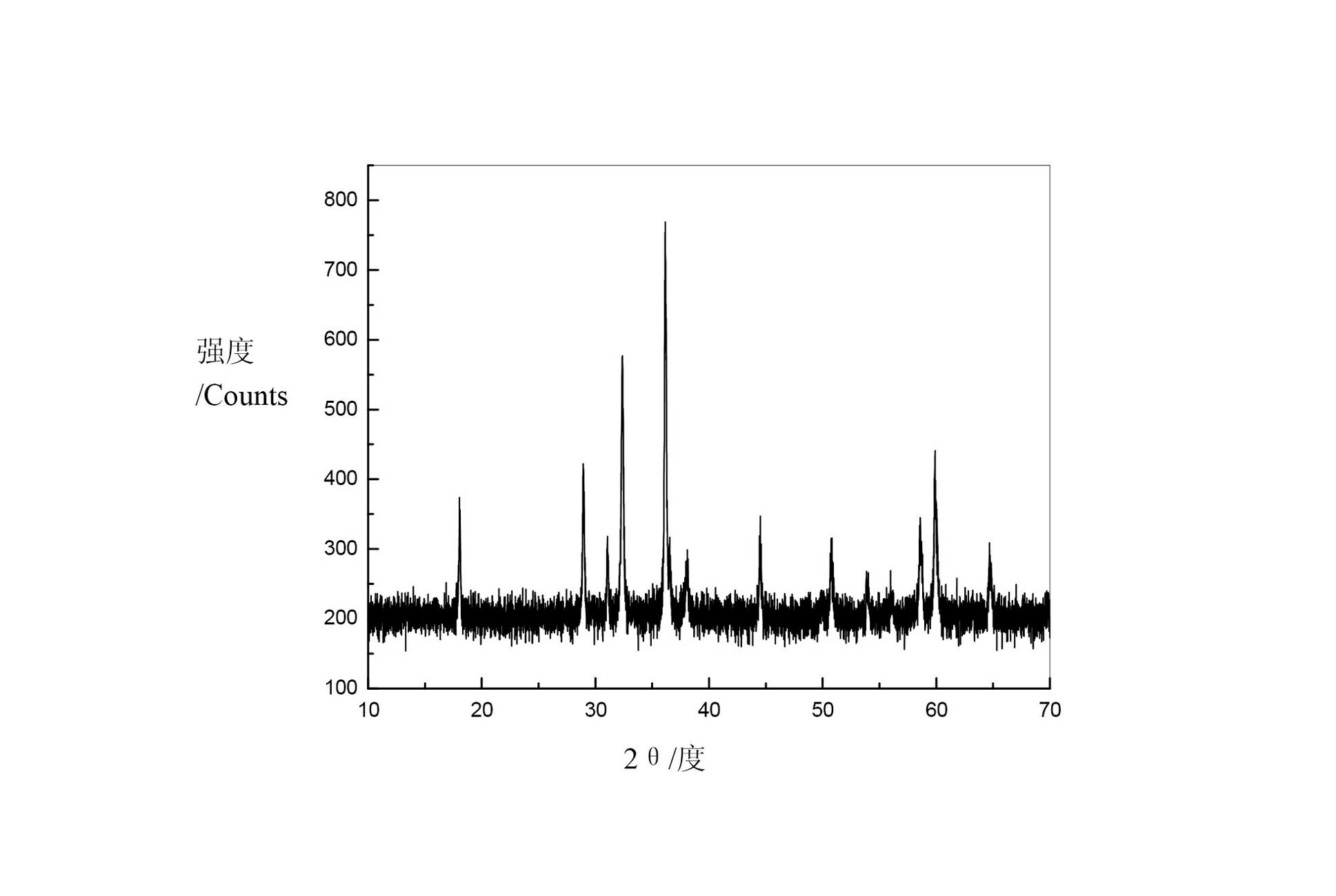

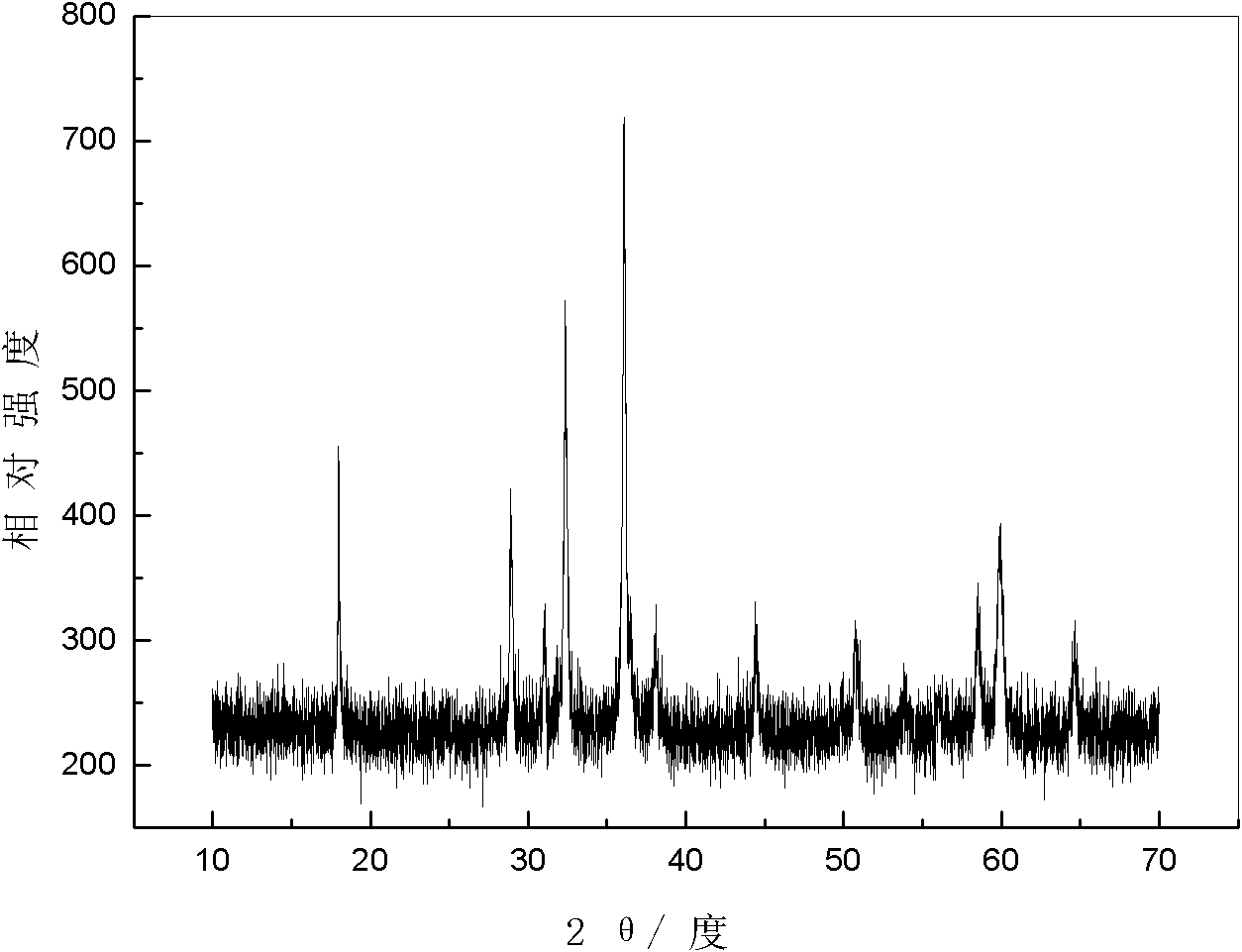

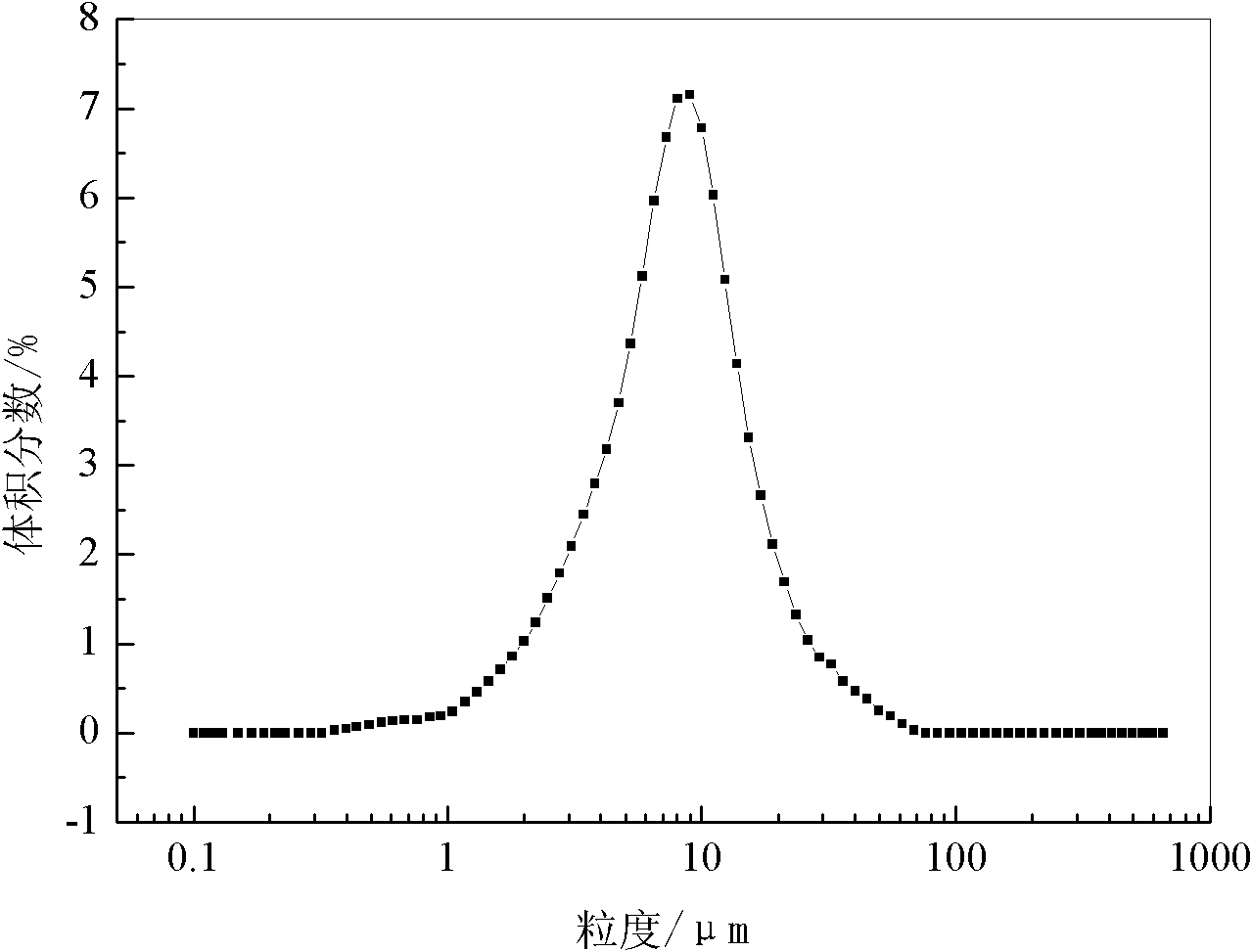

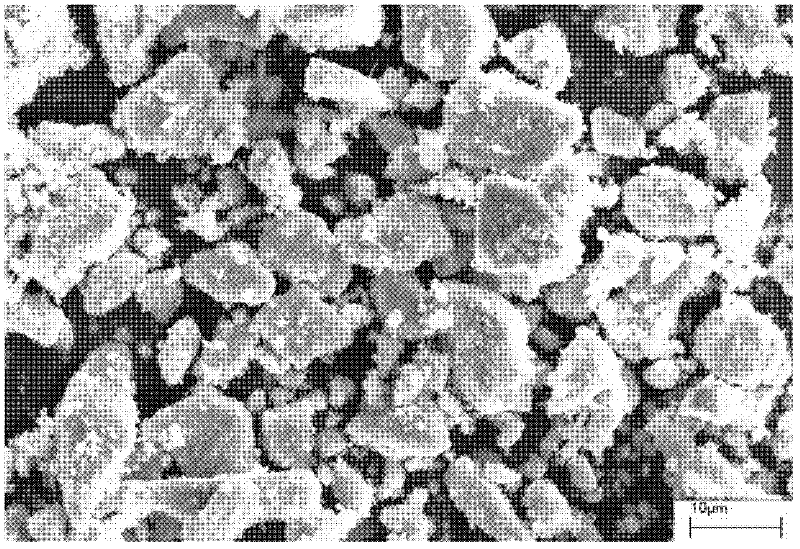

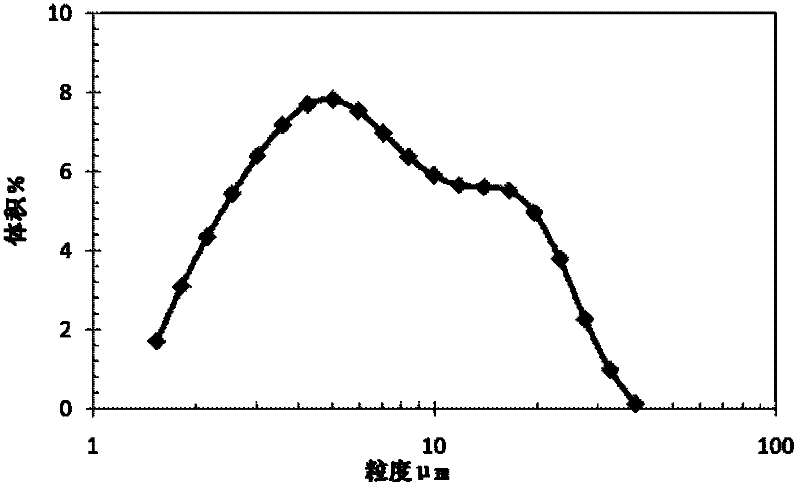

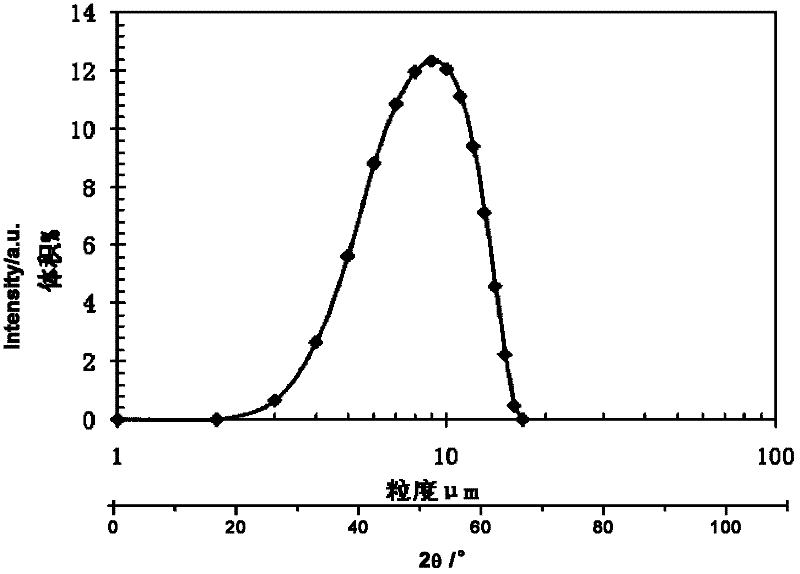

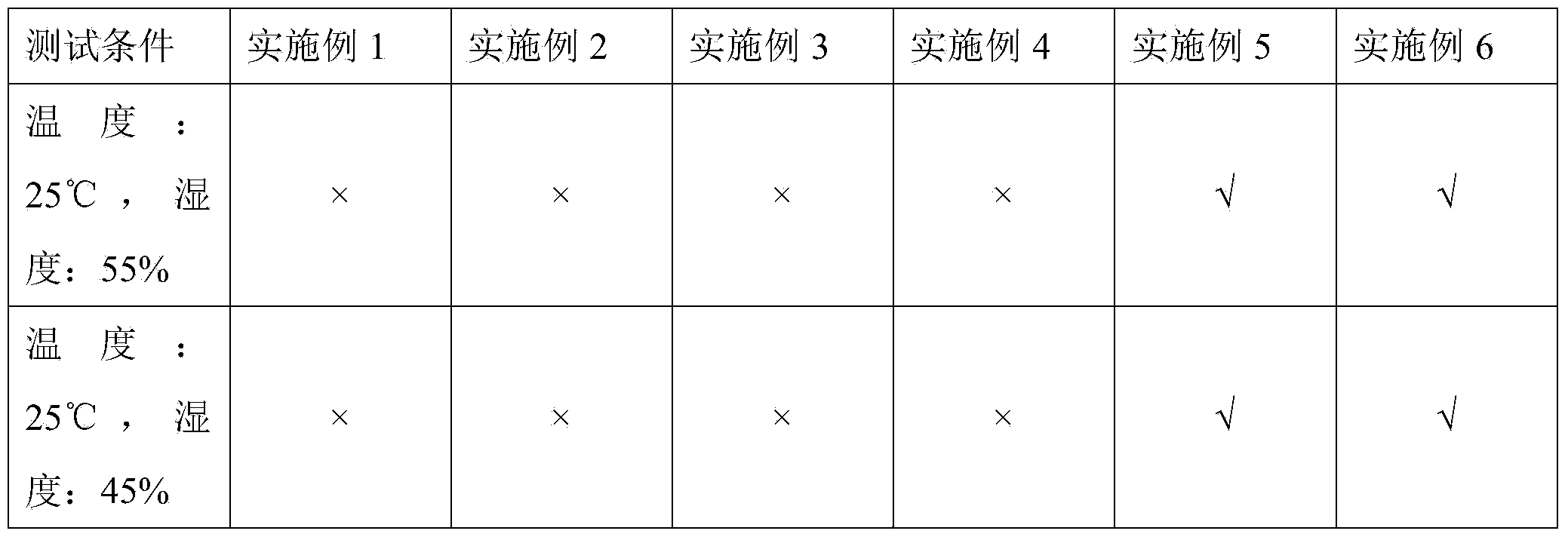

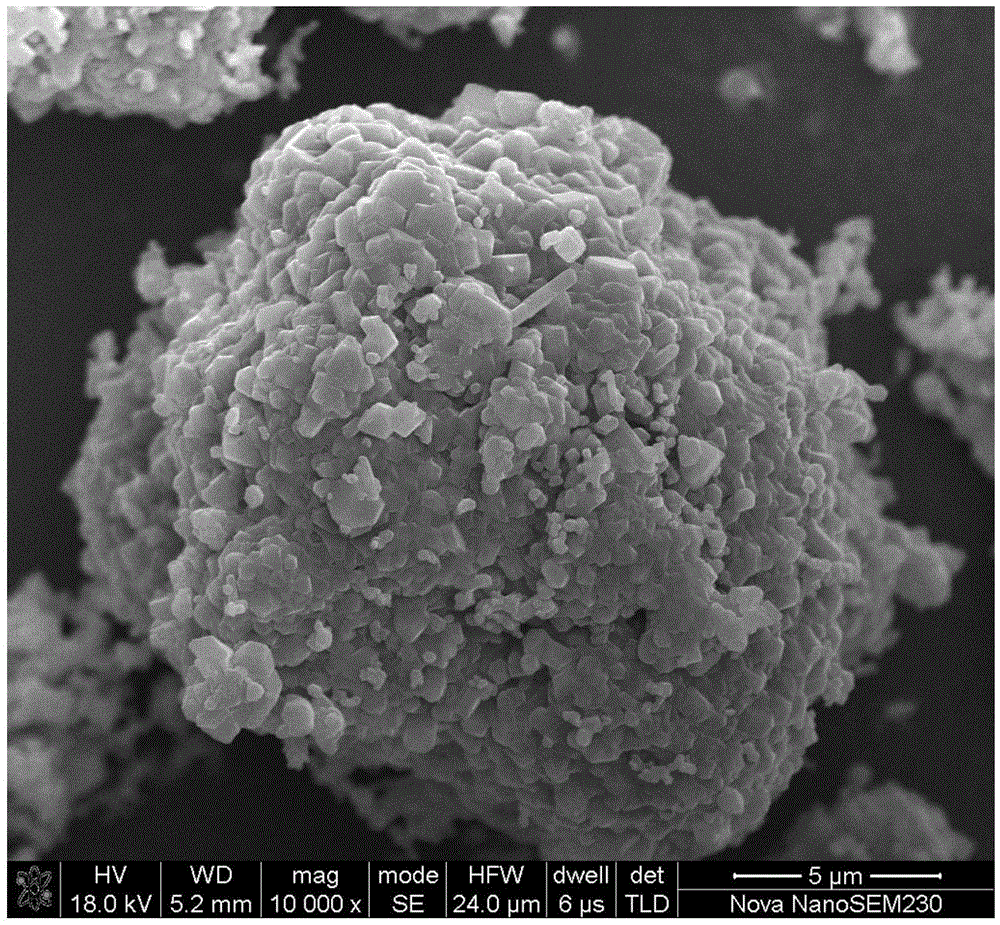

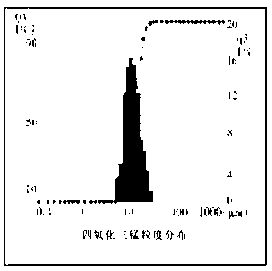

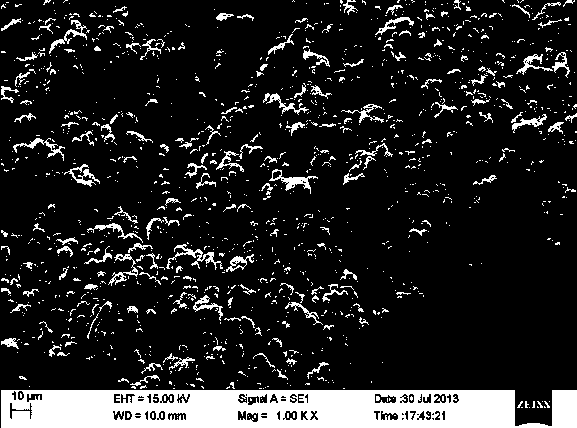

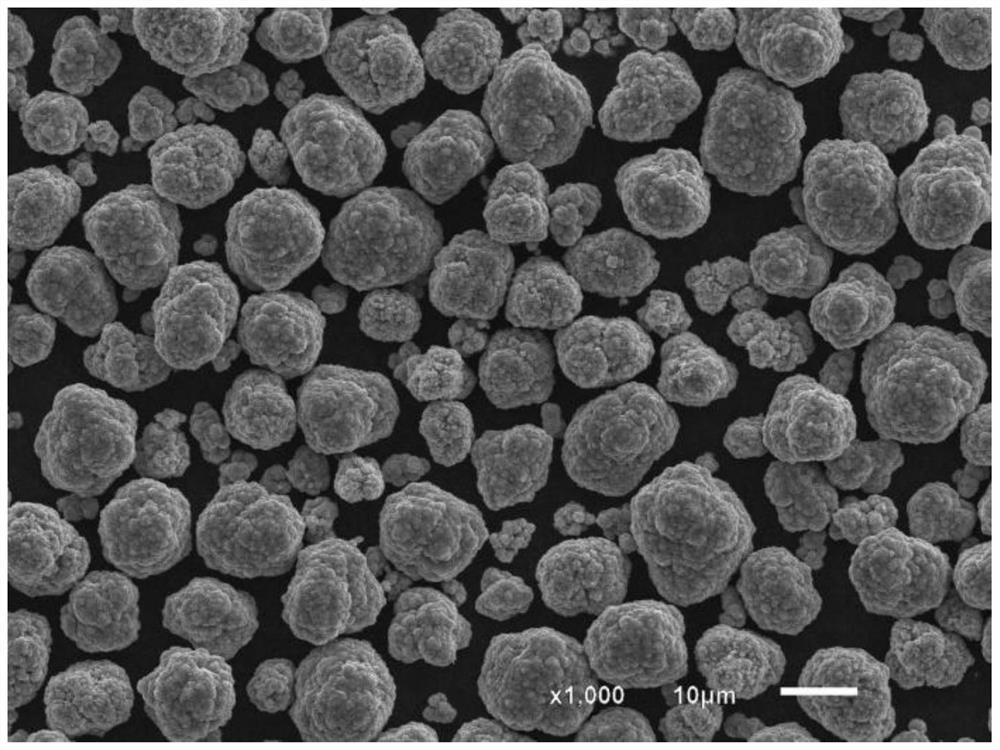

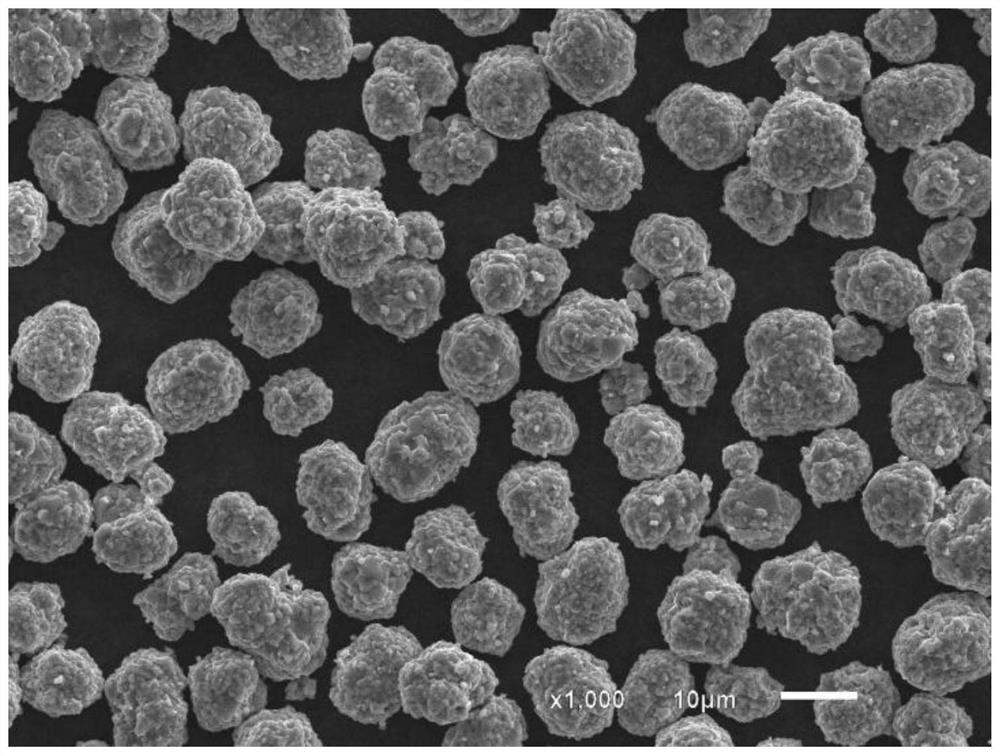

The invention discloses spherical manganic manganous oxide and its preparing method. The spherical manganic manganous oxide has a particle size D50 ranging from 5 micrometers to 20 micrometers and a tap density of greater than or equal to 2.0g / cm<3>. The preparation method of the spherical manganic manganous oxide comprises the steps of: weighing a soluble manganese salt of bivalent manganese, and preparing a manganese salt solution; weighing sodium hydroxide, which is then prepared into a sodium hydroxide solution; adding the obtained manganese salt solution and the sodium hydroxide solution into a reactor continuously according to a mole ratio of manganese ions to sodium hydroxide of (0.5-1.5): 2 for a precipitation reaction, controlling the reaction temperature at 40DEG C-80DEG C and the pH value of the reaction solution at 7.5-13.5, and simultaneously adding an oxidizing agent for oxidation treatment of a generated precipitate; separating an oxidation product, then conducting rinsing and drying, thus obtaining the spherical manganic manganous oxide, which has the advantages of low impurity content, optimized microstructure, high tap density, and good quality, etc.

Owner:贵州大龙汇成新材料有限公司

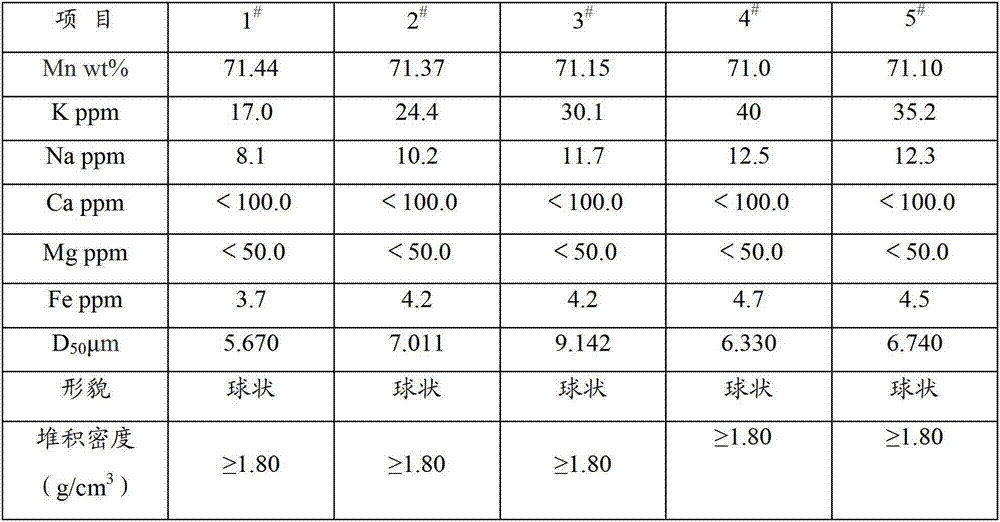

High-proportion manganous-manganic oxide and preparation method thereof

InactiveCN101898796ASmall specific surface areaLess impuritiesManganese oxides/hydroxidesManganous-manganic oxideSlurry

The invention relates to an oxide of manganese and a preparation method thereof, in particular to a high-proportion manganous-manganic oxide and a preparation method thereof. The tap density of the high-proportion manganous-manganic oxide is at least 1.8g / cm<3>, and the specific surface area thereof is 1.5m<2> / g-3.0m<2> / g. The preparation method comprises the following steps of: directly introducing air into a manganese sulfate solution for oxidation, wherein the air flow is controlled to be 800L / h-2500L / h, the oxidation temperature is controlled to be 50-80 DEG C, and the stirring strength in the oxidation process is 75r / min-200r / min; dropwise adding ammonia water in the oxidation process so as to neutralize H<+> generated by oxidization reaction to make the pH value of a reaction system controlled to be 4.5-8.0; repeatedly rinsing manganous-manganic oxide slurry obtained after the reaction is completely ended by using pure water and then drying to obtain the high-proportion manganous-manganic oxide. The high-proportion manganous-manganic oxide not only has higher tap density, smaller specific surface area and even particle size distribution but also has low impurity content and low preparation cost.

Owner:HUNAN HUITONG SCI & TECH

Method for preparing high-purity trimanganese tetraoxide in ammonia medium using manganese sulfate solution

InactiveCN1814551AControl the amount of sedimentFast oxidation reactionManganese oxides/hydroxidesSulfateManganous-manganic oxide

The invention discloses a method to produce high purity manganous-manganic oxide by manganese sulfate solution in ammonia medium. Adding ammonia into manganese sulfate solution that the concentration is 2g.L-1-120g.L-1, controlling the adding speed to make the pH value rising speed at 0-1.00 / minute, using air or oxygen as oxidizing agent to oxide bivalent manganese into manganous-manganic oxide, the reaction temperature is 20-100 degree centigrade, controlling the highest pH value of the solution at the range of 6.0-14.0 in reacting process, and the lowest pH value range at 4.0-9.0. The invention has the advantage of fast reaction, the amount of precipitation of impurity calcium and magnesium could be controlled, and the yield of manganese would be improved, the cost is low.

Owner:郝鹏飞

Method for producing manganese sulfate by high-temperature crystallization process

InactiveCN101224908AReduce manufacturing costImprove product qualityManganese sulfatesManganese sulphateManganese(II) carbonate

The invention provides a method for producing high-purity manganese sulfate by adopting a high temperature crystallization method, which includes that the ore pulp of manganese ore and sulfurous iron ore is heated, removed of iron, removed of heavy metal, neutralized, pressure-filtered to obtain a manganese sulfate solution with the content of 160-200g / L, which is pumped to a manganese sulfate solution for carrying out crystallization and purification; the crystallization and purification includes crystallization, solid-liquid separation, dissolution, pressure filtration and other technologies; the pressure-filtered manganese sulfate solution can be crystallized and purified repeatedly as required. The invention can adopt a large amount of low-grade manganese ore with the manganese content of 10-20 percent as the raw material to produce the high-purity manganese sulfate solution and further deep process various high-purity manganese products, such as: electrolytic manganese dioxide, high-purity manganese carbonate, electronic grade mangano-manganic oxide and manganese monoxide, chemical manganese dioxide, industrial grade manganese sulfate monohydrate, chemical grade manganese sulfate monohydrate, medicine grade manganese sulfate monohydrate, food grade manganese sulfate monohydrate, analytically pure manganese sulfate monohydrate and so on.

Owner:广西双德锰业有限公司

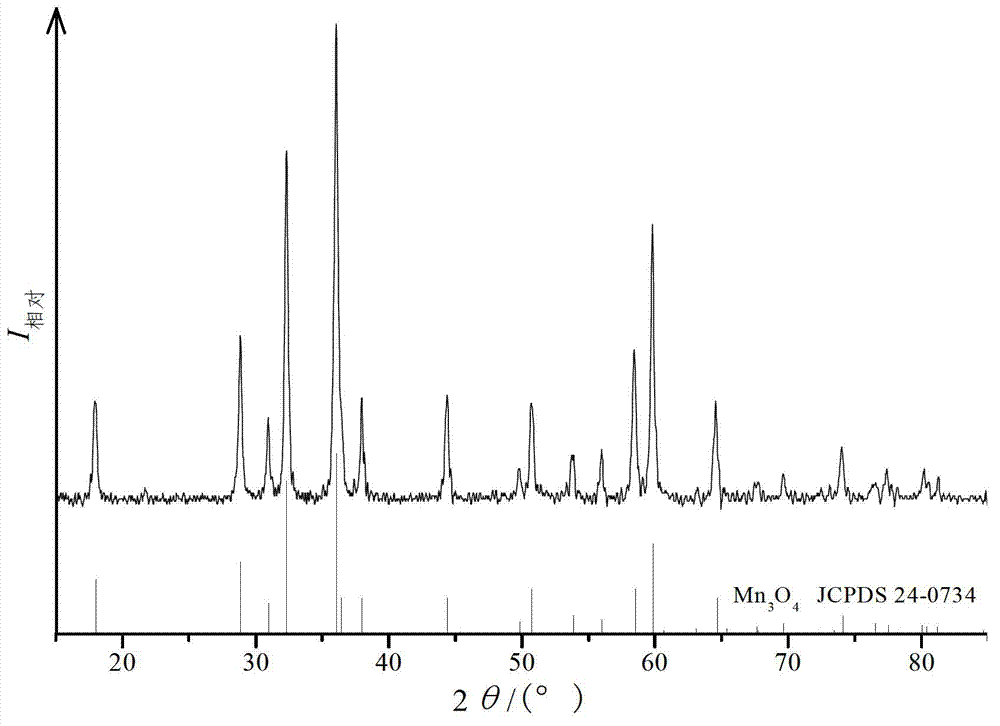

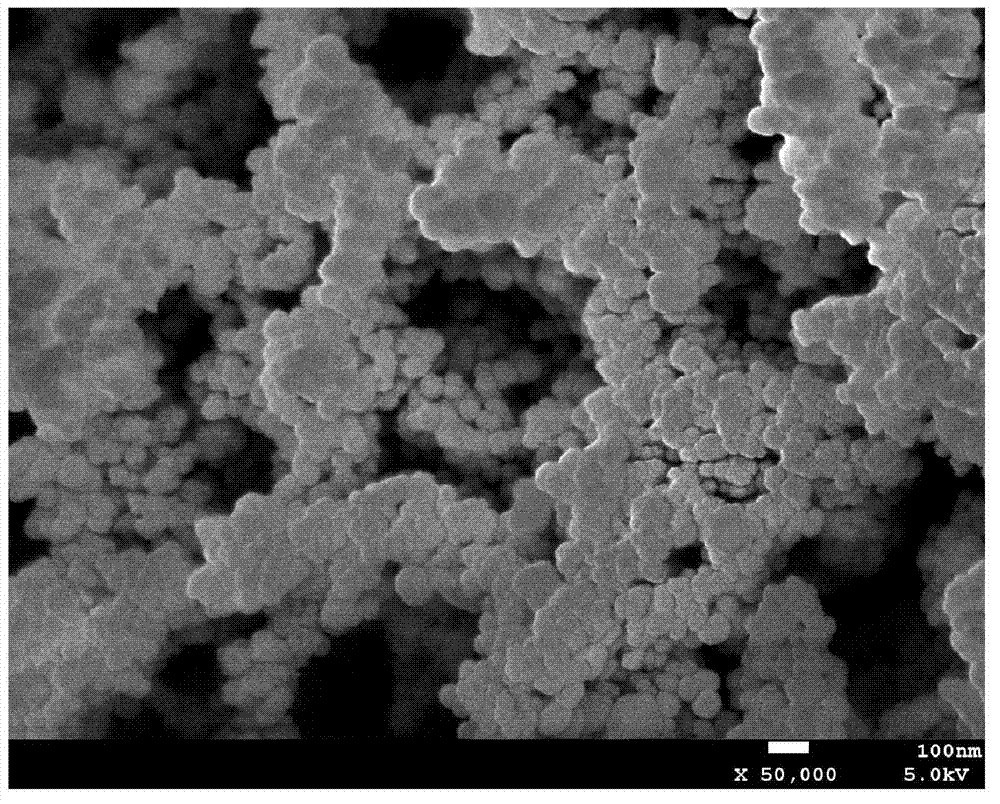

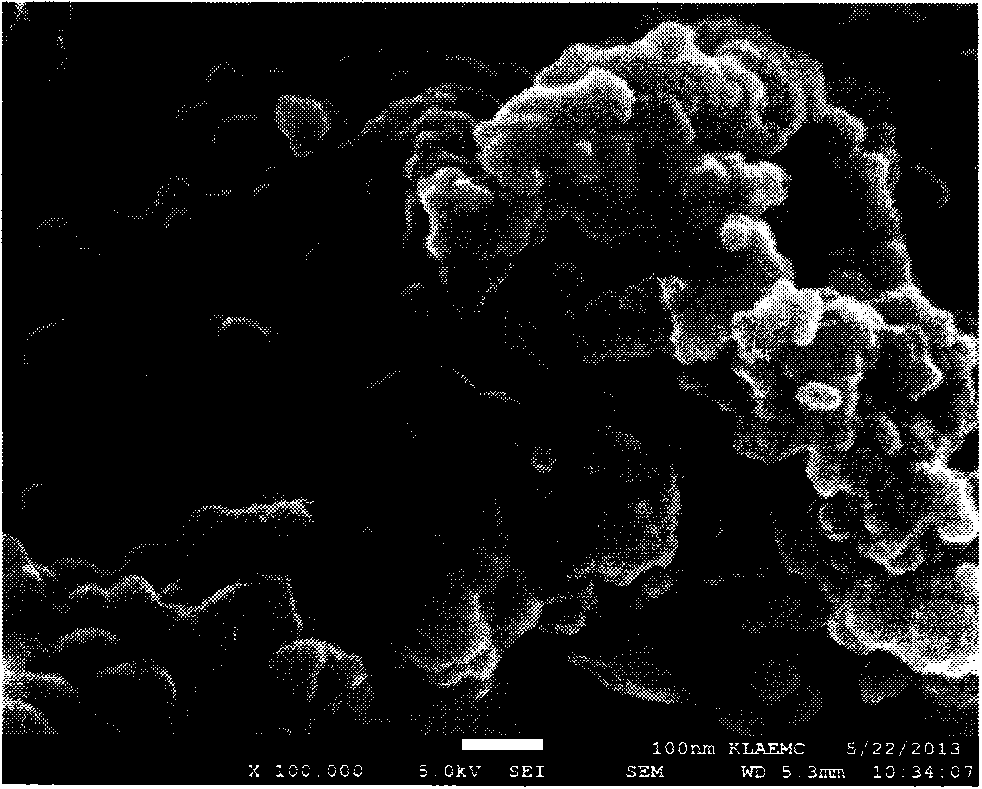

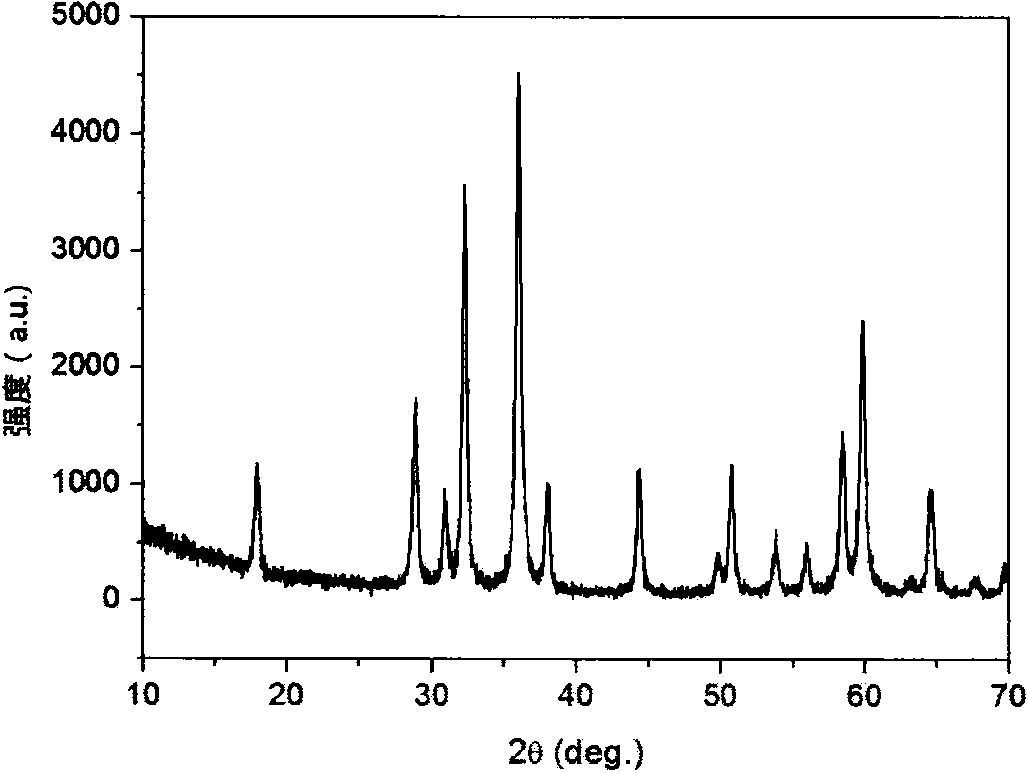

Mesoporous manganese oxide nano granule and preparation method thereof

InactiveCN101597085AImprove protectionSimple preparation processManganese oxides/hydroxidesMANGANESE ACETATESesquioxide

The invention relates to a mesoporous manganese oxide nano material and a preparation method thereof. In the invention, a uniformly distributed mesopore with the aperture of 2 to 10 nanometers and a mixture of oxyhydrogen manganese oxide and manganic manganous oxide or a mangano-manganic octoxide monocrystal granule or a manganese sesquioxide monocrystal granule with the granule particle diameter controlled within the range of 20 to 80 nanometers are prepared by the hydrothermal function of manganese metal, manganese acetate and ammonia and the subsequent calcination control, and the uniformly distributed mesoporous, the mixture of oxyhydrogen manganese oxide and manganic manganous oxide, the mangano-manganic octoxide monocrystal granule and the manganese sesquioxide monocrystal granule play a catalytic action to a toluene combustion reaction. The invention has simple preparation method, loose synthesizing condition, easy repetition and cheap raw materials and can carry out large-scale production.

Owner:HEBEI UNIV OF TECH

Method for preparing lithium manganate used as lithium ion battery anode material by using trimanganese tetroxide

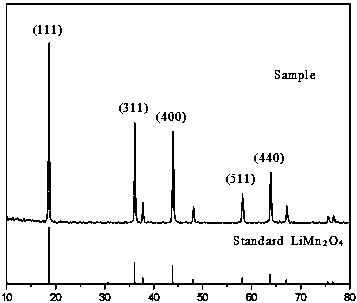

ActiveCN102336441AReduce bring inUniform compositionCell electrodesManganates/permanganatesPhysical chemistryManganate

The invention discloses a method for preparing lithium manganate used as a lithium ion battery anode material by using trimanganese tetroxide, comprising the following steps of: firstly, preparing the trimanganese tetroxide and the lithium salt according to the molar ratio of lithium to manganese 0.5-0.6, uniformly mixing the trimanganese tetroxide and the lithium salt to get the precursor, and then, pre-sintering the precursor; executing ball milling and spray drying after pre-sintering, and then, executing secondary sintering; finally, executing isostatic cool pressing on the products of the secondary sintering process, and crashing and classifying the products to get the lithium manganate used as the lithium ion battery anode material. The method has the advantages of being simple and practical in technical steps, low in cost, easy to realize mass industrial production, excellent in product performance, and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

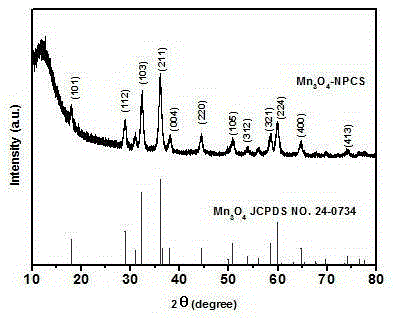

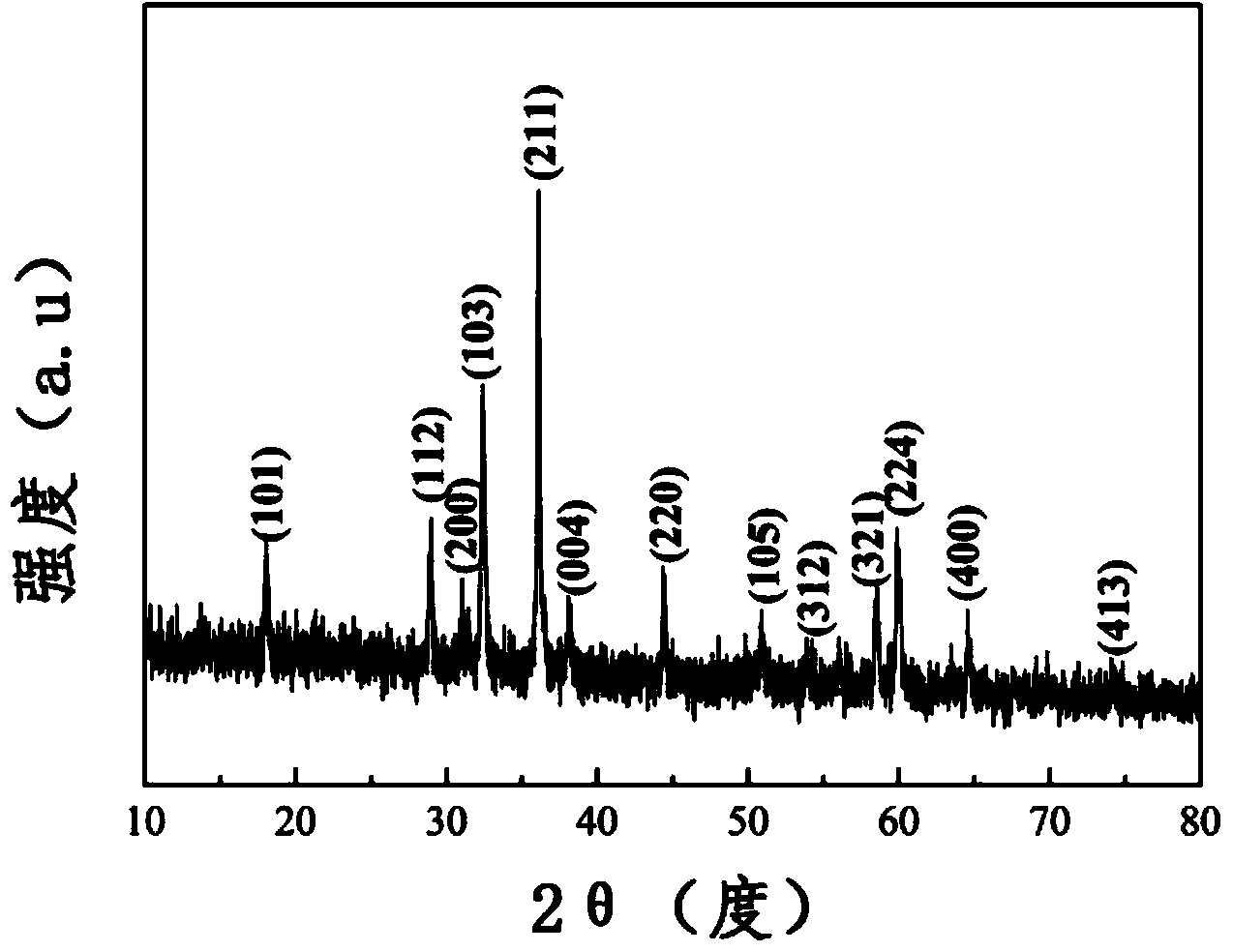

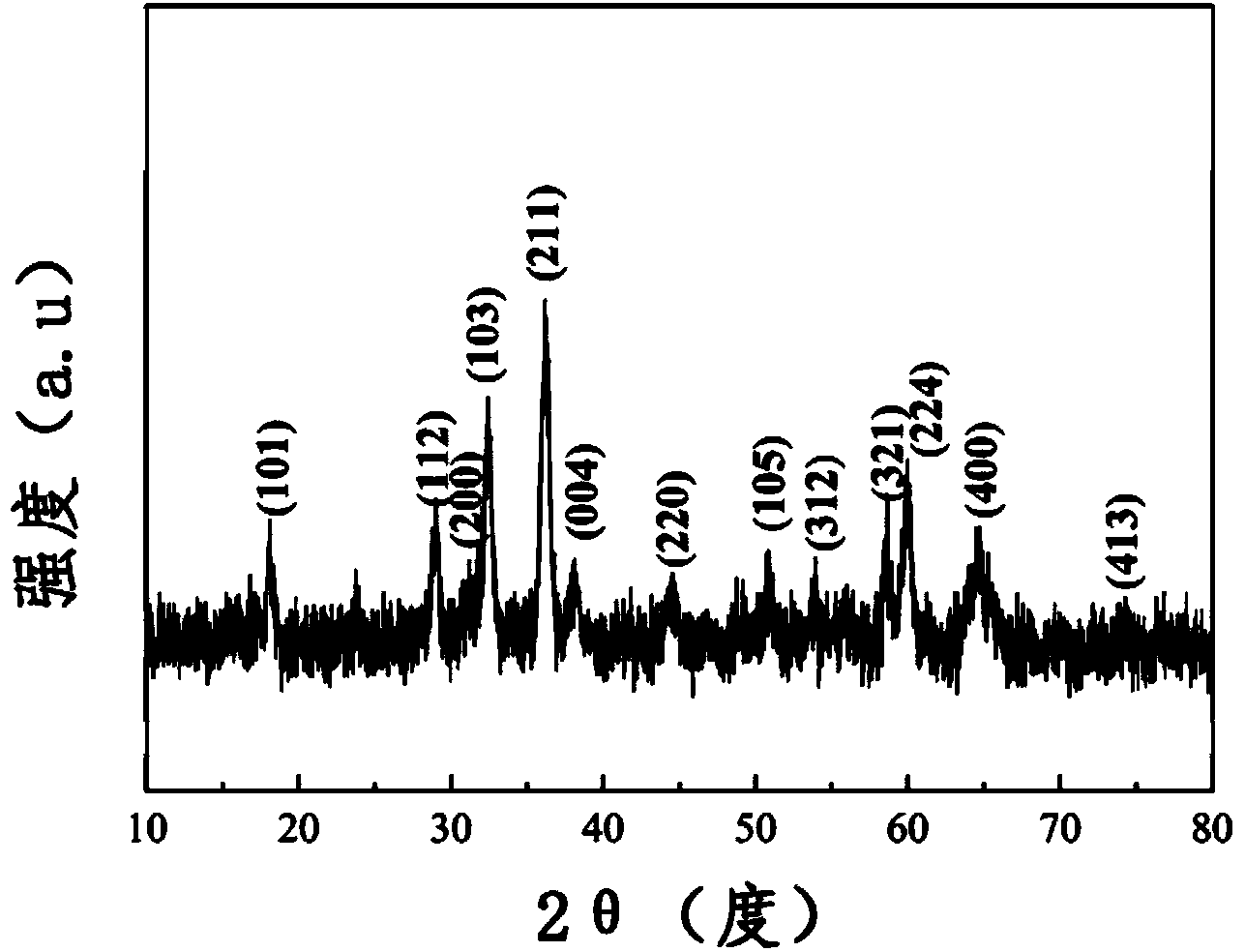

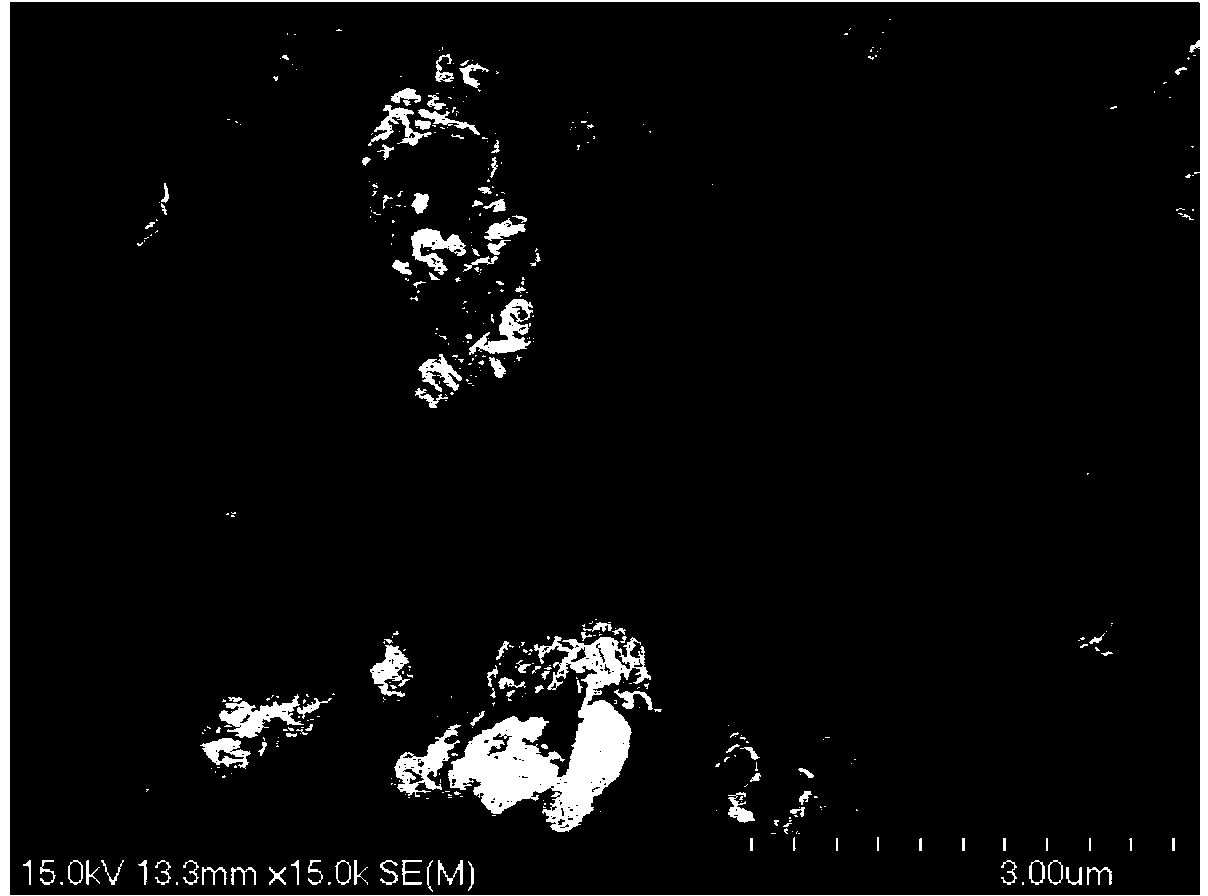

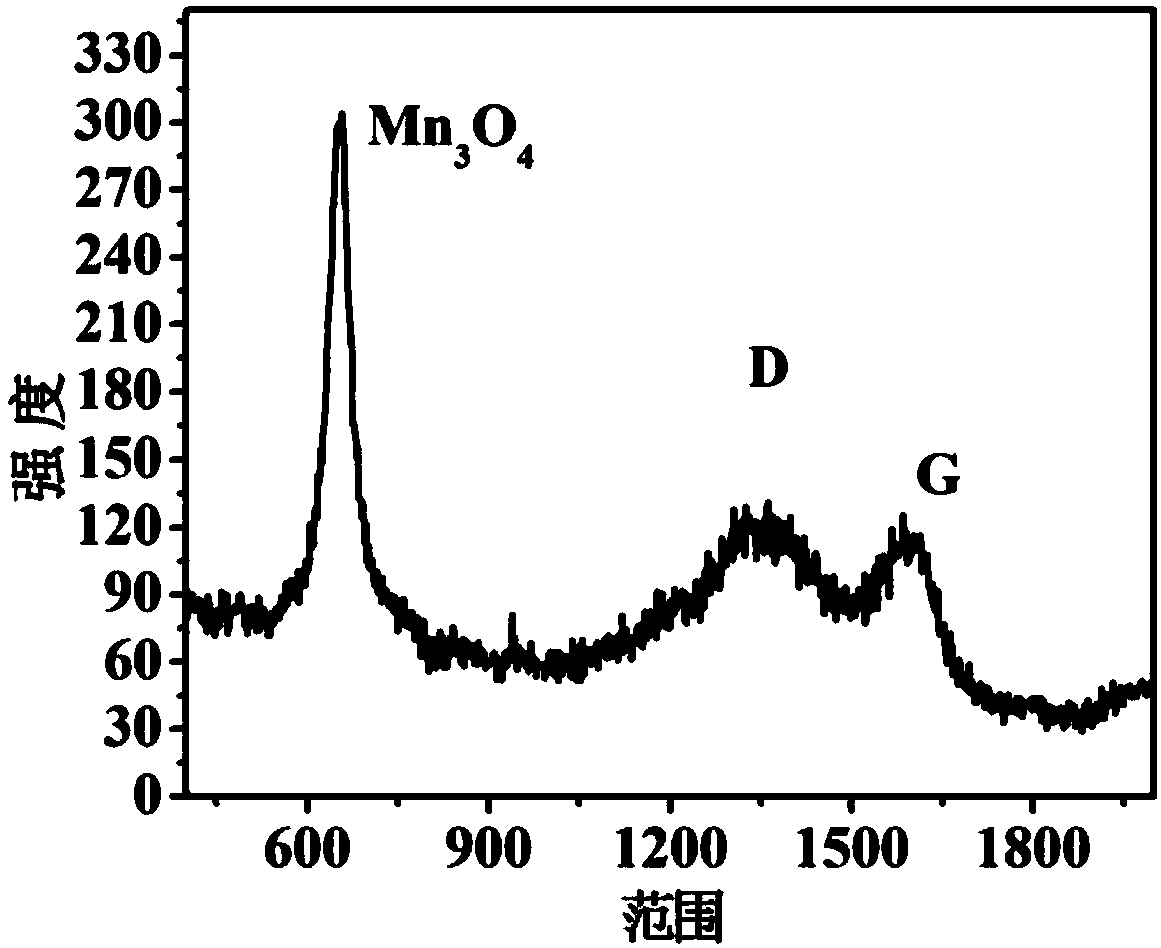

Nitrogen-doped porous carbon ball/manganic manganous oxide nanometer composite electrode material and preparation method thereof

InactiveCN105355874AAbundant and easy to get resourcesLow costMaterial nanotechnologyCell electrodesPorous carbonElectrical battery

The invention discloses a nitrogen-doped porous carbon ball / manganic manganous oxide nanometer composite electrode material and a preparation method thereof. The preparation method comprises that chitosan and its derivative as carbon source and nitrogen source predecessors and porous silica as a hard template are carbonized, then silica is removed so that nitrogen-doped porous carbon balls are obtained, manganic manganous oxide nanometer particles grow on the nitrogen-doped porous carbon balls by a mild solvothermal method, and the nitrogen-doped porous carbon balls with the manganic manganous oxide nanometer particles are subjected to centrifugation washing and drying so that the nitrogen-doped porous carbon ball / manganic manganous oxide nanometer composite electrode material is obtained. The prepared material as a lithium ion battery negative electrode material has a high reversible specific capacity, good cycling stability and excellent multiplying power discharge performances. The preparation method can be operated easily, has mild preparation conditions and no harsh requirement on equipment and is suitable for industrial production. The nitrogen-doped porous carbon ball / manganic manganous oxide nanometer composite electrode material has a wide application prospect in the electrochemistry fields of high performance lithium ion batteries and super capacitors.

Owner:HUBEI ENG UNIV

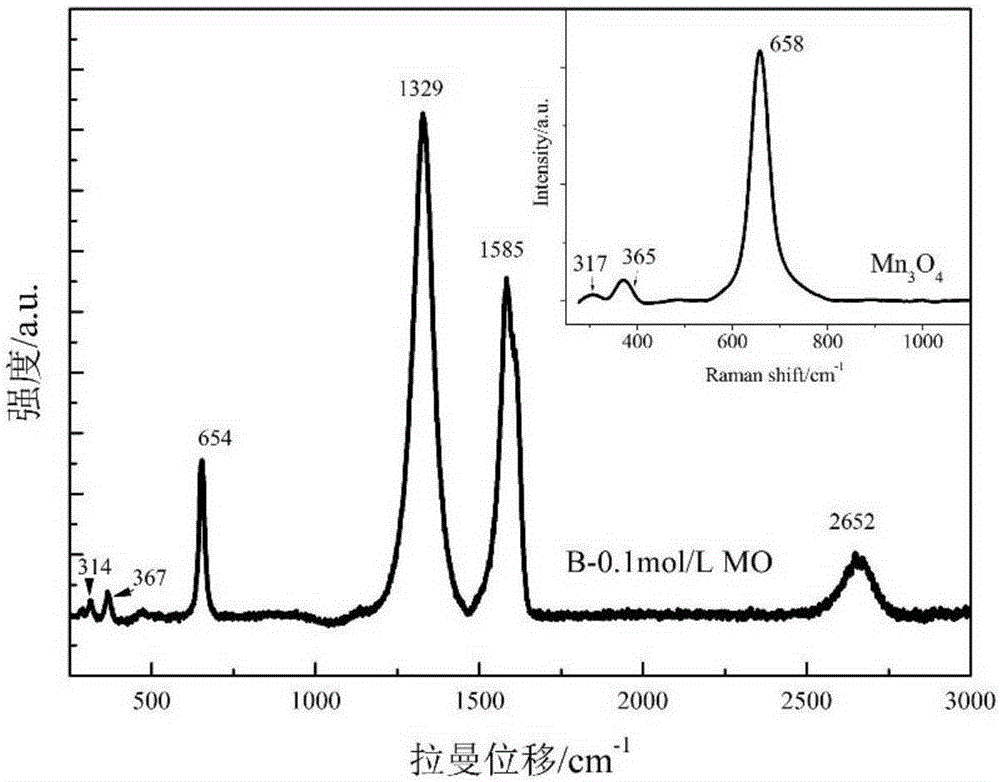

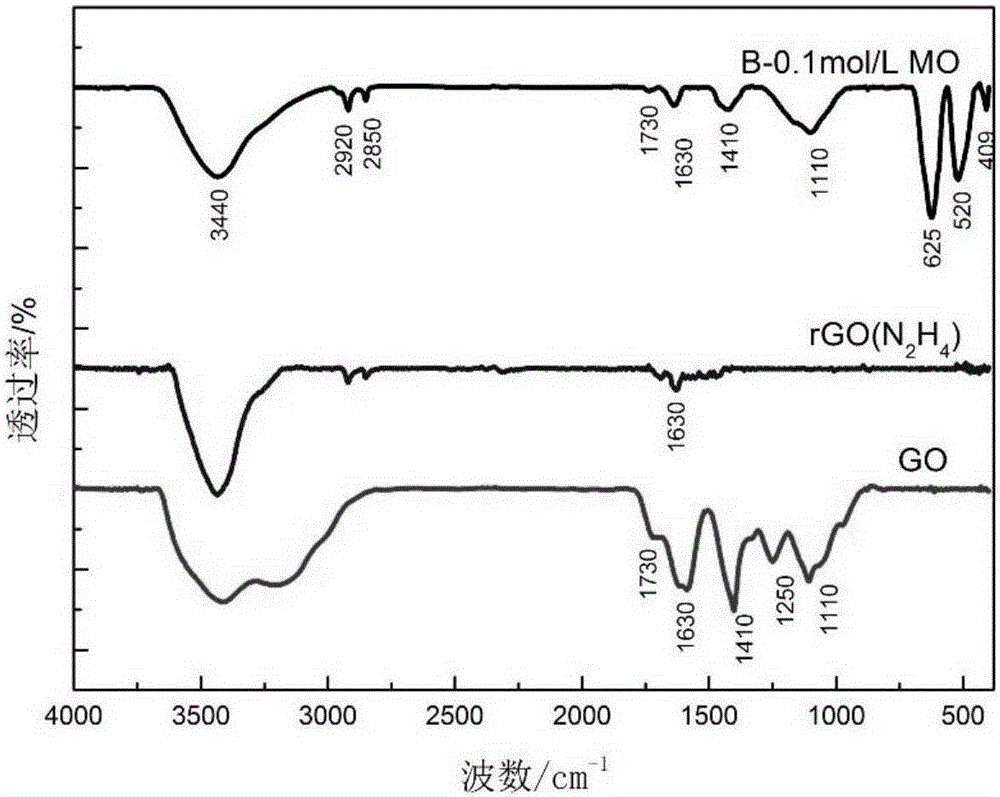

Preparation method of manganous-manganic oxide/graphene composite material

InactiveCN104022262AWide variety of sourcesLow priceCell electrodesSecondary cellsHydrazine compoundFiltration

The invention discloses a preparation method of a manganous-manganic oxide / graphene composite material. The preparation method comprises the following steps: mixing oxidized graphene, manganese sulfate and water together at room temperature, and stirring for 1-10 hours; adding potassium permanganate and continuing stirring for 1-10 hours; dropwise adding 30wt% of hydrogen peroxide, applying ultrasound for 1-10 hours; finally, dropwise adding hydrazine hydrate, and increasing the temperature to the range of 50-150 DEG C for reacting for 10-30 hours; carrying out suction filtration after the reaction is finished, washing the material filtered out with water and drying to obtain the manganous-manganic oxide / graphene composite material; the obtained manganous-manganic oxide / graphene composite material has the characteristics such as high capacity, good electrical conductivity, high cycling stability and good large current discharge performance, and thus being widely applied to the fields of high-performance lithium-ion batteries and the like as a lithium-ion battery anode material.

Owner:ZHEJIANG UNIV OF TECH

Nitrogen-doped carbon-coated manganous-manganic oxide composite material, as well as preparation method and application thereof

InactiveCN108520944AImprove stabilityImprove conductivityCell electrodesSecondary cellsMANGANESE ACETATEManganous-manganic oxide

The invention belongs to the field of materials for lithium ion batteries, and discloses a nitrogen-doped carbon-coated manganous-manganic oxide composite material, as well as a preparation method andapplication thereof. The preparation method comprises the steps of dissolving manganese acetate and ammonium bicarbonate into ethylene glycol, carrying out solvent heat treatment at the temperature of 180 to 220 DEG C, and obtaining manganese carbonate; reacting with dopamine hydrochloride, and obtaining a manganese carbonate / polydopamine composite material; then calcining under an inert atmosphere, and finally oxidizing in a muffle furnace to obtain the nitrogen-doped carbon-coated manganous-manganic oxide composite material. The preparation method provided by the invention is simple and lowin cost; the prepared nitrogen-doped carbon-coated manganous-manganic oxide composite material is stable in structure and good in electrical conductivity, and has excellent rate performance and cyclic stability when being used as a lithium ion battery cathode material.

Owner:SOUTH CHINA UNIV OF TECH

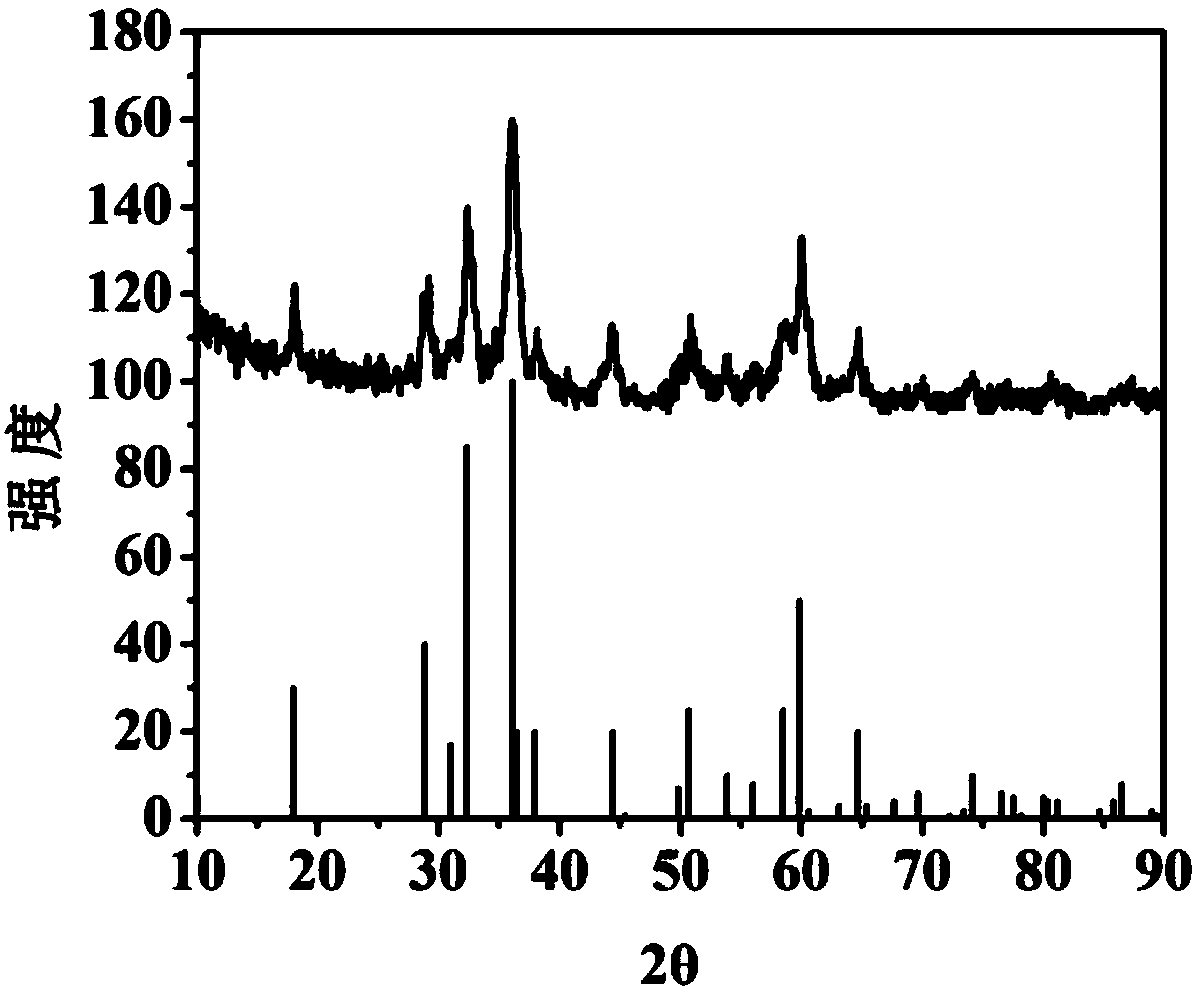

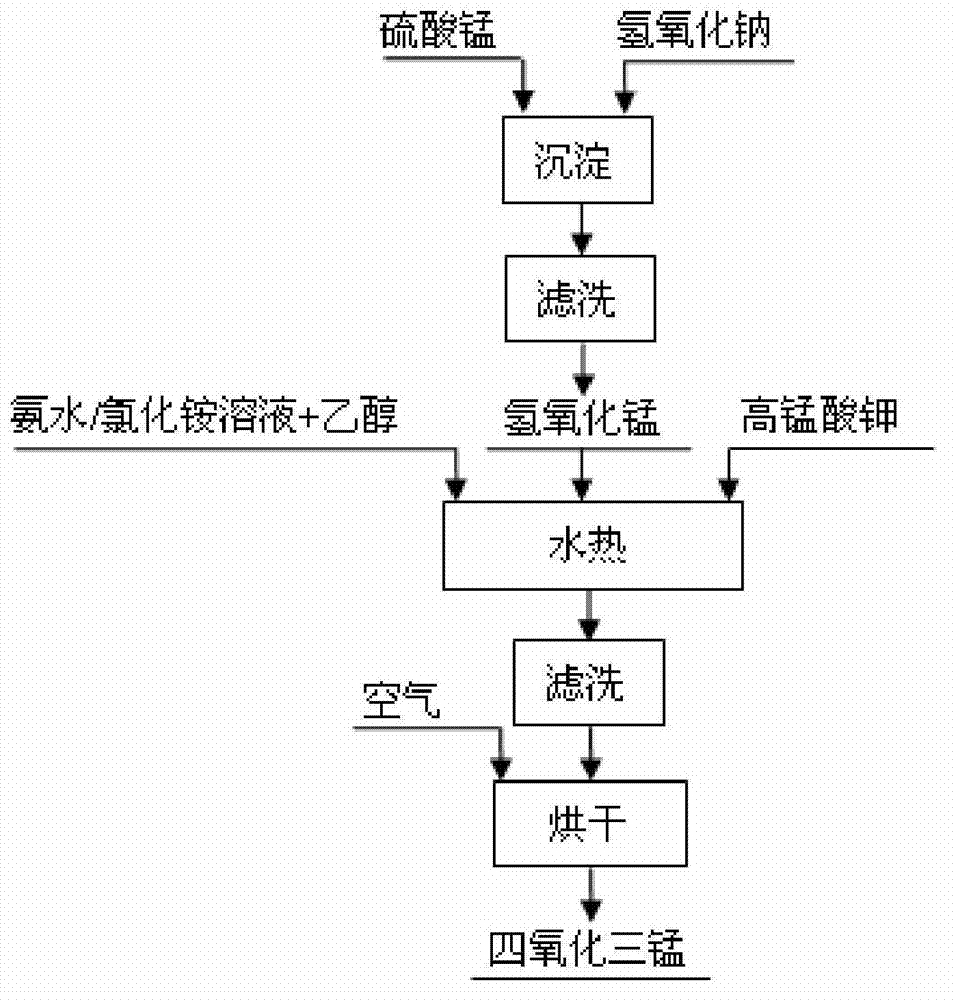

Method for preparing manganous manganic oxide

ActiveCN102786095ALow costIncrease profitManganese oxides/hydroxidesManganous-manganic oxideManganese(II,III) oxide

The invention relates to a method for preparing manganous manganic oxide, belonging to the technical field of chemical production. The technical problem to be solved by the invention is to provide a method for preparing manganous manganic oxide with low production cost. The method comprises the following steps of a, adding manganous hydroxide and potassium permanganate in solvent, mixing the mixtures, and reacting the obtained slurry at 100-200 DEG C for 2-6 h, wherein the dosage of potassium permanganate is as 10-100 percent of a theoretical dosage through which the manganous hydroxide can be oxidized as the manganous manganic oxide; the solvent is mixed solution of ammonium chloride, ammonia and ethanol; the concentration of the NH4Cl in the mixed solution is 5-50 g / L; the concentration of the NH3 H2O in the mixed solution is 5-50 g / L; and the volume concentration of the ethanol in the mixed solution is 10-90 percent; b, cooling the reactant, filtering and washing the cooled reactant with ions for several times, and then filtering and washing the reactant with ethanol; and c, drying the product which is filtered and washed by step b to obtain the manganous manganic oxide.

Owner:四川中创启源新材料科技有限公司

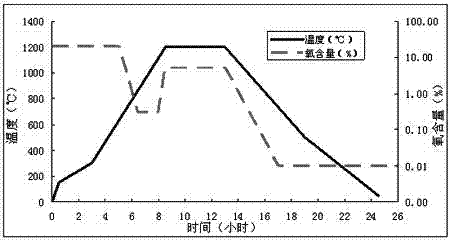

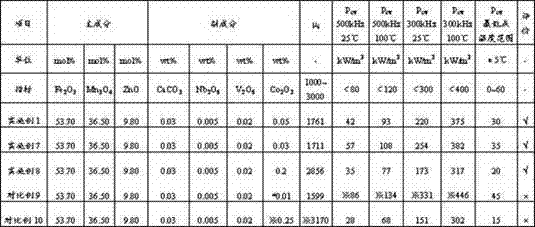

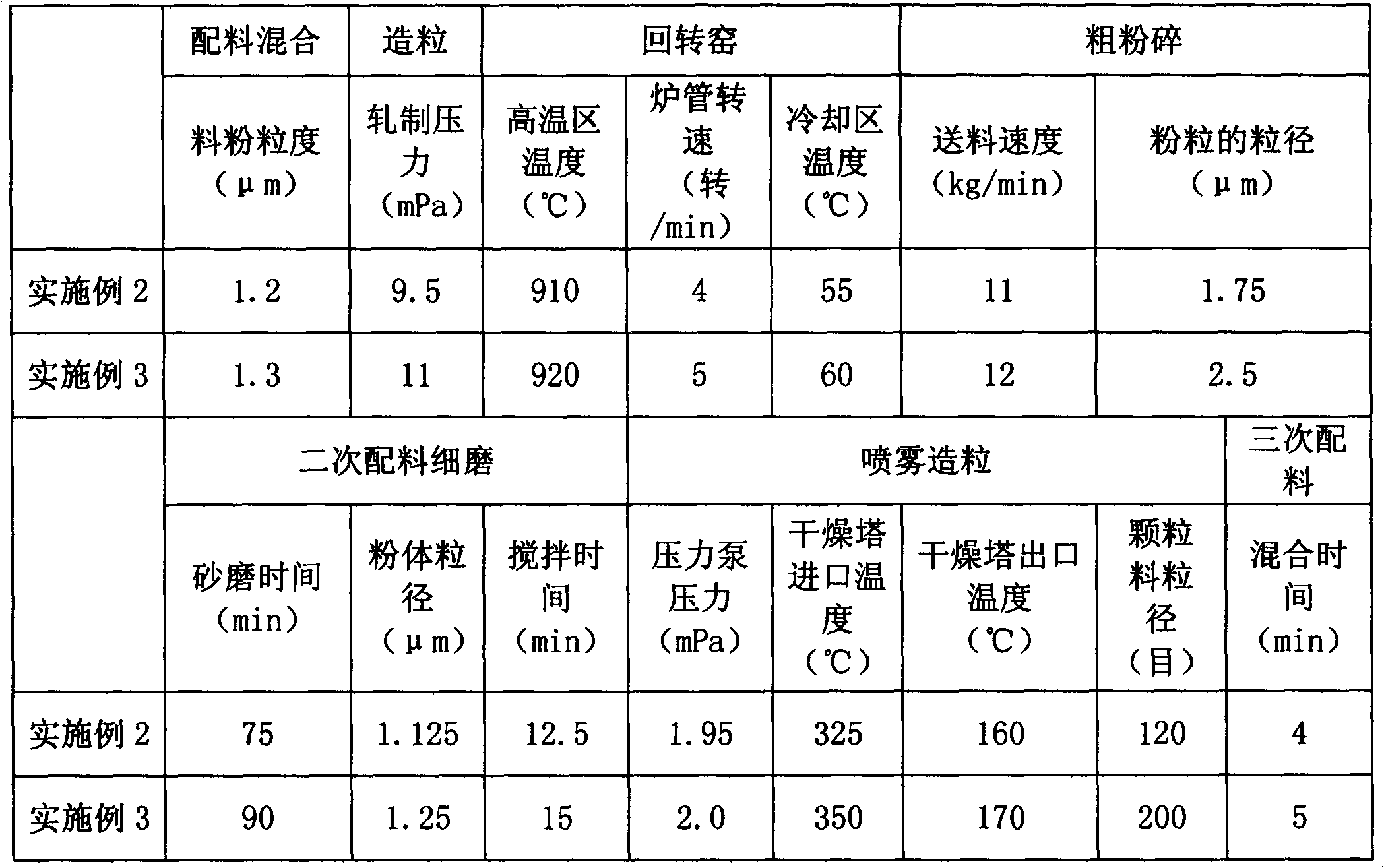

Wide-temperature-range low-loss Mn-Zn ferrite specially used for solar energy inverter, and preparation method thereof

The invention relates to wide-temperature-range low-loss Mn-Zn ferrite specially used for a solar energy inverter, and a preparation method thereof. The Mn-Zn ferrite comprises main components of: 53.5mol%-54.5mol% of iron oxide calculated according to Fe2O3, 8.0mol%-10.0mol% of zinc oxide calculated according to ZnO, and balance of mangano-manganic oxide. The Mn-Zn ferrite also comprises minor components of, by weight: 0.03-0.04% of CaCO3, 0.005-0.01% of Nb2O5, 0.01-0.03% of V2O5, and 0.03-0.2% of Co2O3, calculated according to standard substances of CaCO3, Nb2O5, V2O5, and Co2O3. The Mn-Zn ferrite is prepared with an oxide method, and is sintered under an elevator furnace densification condition. The obtained product has relatively high initial magnetic permeability mui, and low power loss Pcv. With the Mn-Zn ferrite, the loss under a high-frequency transformer operation status is reduced, and the efficiency of the transformer is improved. With the Mn-Zn ferrite, miniature inverterscan be produced with high frequency, small size, and intelligence. Also, a requirement of efficiency improving under a condition of illumination variation can be satisfied. The product is advantaged in high reliability and good stability. With the product, a miniature inverter can be used in environments with large temperature variations, such as deserts and islands.

Owner:海宁瑞思科技有限公司

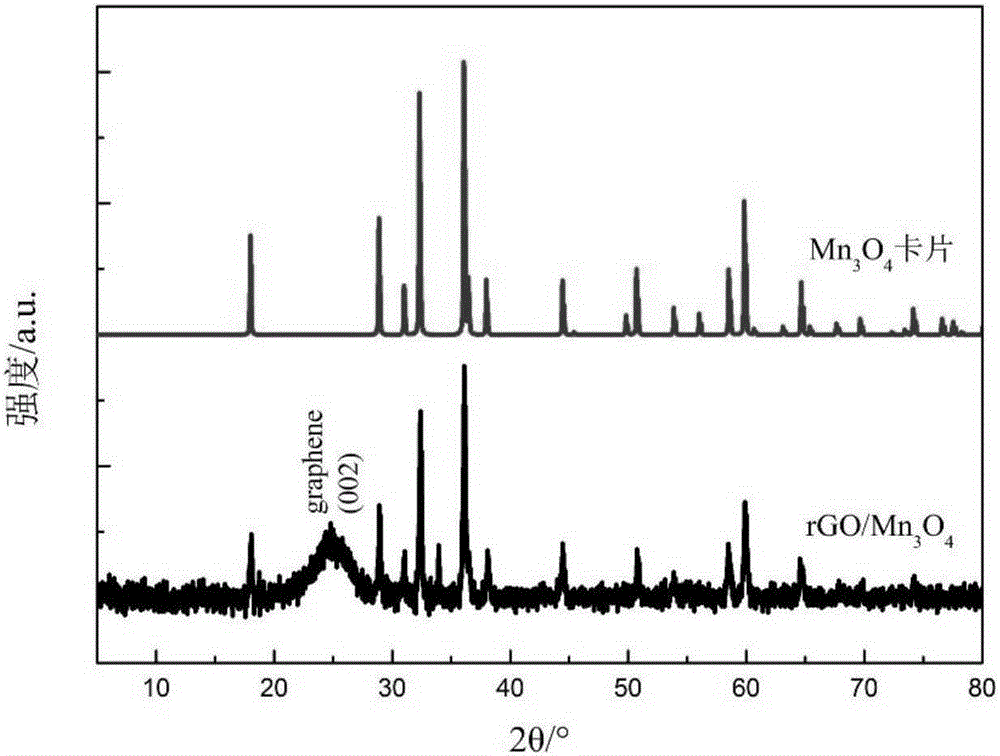

Graphene and manganous-manganic oxide composite material and preparation method thereof

ActiveCN105347334ASimple processEasy to operateHybrid capacitor electrodesManganese oxides/hydroxidesMANGANESE ACETATE TETRAHYDRATEManganous-manganic oxide

The invention relates to a graphene and manganous-manganic oxide composite material and a preparation method thereof. The graphene and manganous-manganic oxide composite material is characterized in that graphite powder, concentrated sulfuric acid, sodium nitrate, potassium permanganate and manganese acetate tetrahydrate are used as matrix materials, the advanced Hummers' method is adopted for preparing oxidized graphene, and a solvothermal method is adopted for further preparing the graphene and manganous-manganic oxide composite material. The preparation method comprises the steps that 1-2 g of the graphite powder and 20-40 mL of the concentrated sulfuric acid are mixed, 100-200 mg of the sodium nitrate is added into the mixture, stirring is performed, a water bath is performed, 1-3 g of the potassium permanganate is added, the oxidized graphene dispersion liquid of the concentration being 4.00-5.00 mg / mL is dispersed in an ethyl alcohol-water mixed solvent, the mass ratio of the oxidized graphene to the manganese acetate tetrahydrate is 1:1-1:30, and then a reaction is performed for 8-12 h at the temperature of 160-200 DEG C. The method is easy to operate and low in cost, has no special requirement for equipment, and can be applied in the fields of supercapacitors, batteries, automobiles, military facilities and the like.

Owner:WUHAN UNIV OF TECH

Preparation method of bulky-grain spinel lithium manganate material

InactiveCN102420326AEvenly dopedGood grain shapeCell electrodesManganese(II) carbonateManganous-manganic oxide

The invention discloses a preparation method of a bulky-grain spinel lithium manganate material, which belongs to the field of electrochemical materials. The bulky-grain spinel lithium manganate material is prepared through carrying out high-temperature sintering on a raw material such as manganese dioxide or manganese carbonate as with a doped element M to be converted into uniformly-doped bulky-grain mangano-manganic oxide, using the bulky-grain mangano-manganic oxide as the raw material of a Mn source, mixing the bulky-grain mangano-manganic oxide with an original material of Li, and sintering the obtained mixture. The mangano-manganic oxide prepared by the invention has a good crystalline grain shape; the grain size is in normal distribution; after the bulky-grain mangano-manganic oxide is used as the raw material of the Mn source and mixed with the original material of the Li, a bulky-grain lithium manganate product with a low surface area can be obtained without the obtained miture at a temperature which exceeds 900 DEG C; and the problem that oxygen loss is caused when the bulky-grain lithium manganate is prepared by high sintering exceeding 900 DEG C is solved. The lithium manganate prepared by the method has uniform granularity; the average grain size of the lithium manganate can be controlled in a range of 5-15 mum through the process; the specific surface area is between 0.2 m<2> / g and 0.6 m<2> / g; crystalline grains are complete; and the high-low temperature cycle service is excellent. The method provided by the invention has a simple process and low cost, and is applicable to industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Anti-static zirconia ceramic and preparation process thereof

ActiveCN104341150AGood chemical stabilityHigh hardnessManganous-manganic oxideYttria-stabilized zirconia

The invention discloses an anti-static zirconia ceramic. The anti-static zirconia ceramic is prepared from the following raw materials in parts by mole: yttria-stabilized zirconia, sodium oxide, aluminum oxide, calcium oxide, nickel oxide, chromium sesquioxide, manganous-manganic oxide and conductive carbon black. The preparation process of the anti-static zirconia ceramic comprises the following steps: 1) sufficiently carrying out ball milling on the yttria-stabilized zirconia; 2) mixing the ball-milled yttria-stabilized zirconia, sodium oxide, aluminum oxide, calcium oxide, nickel oxide, chromium sesquioxide, manganous-manganic oxide and conductive carbon black and then sufficiently sanding and mixing; 3) adding a binder in above mixture, and pelleting; and 4) placing above spherical particle in a die at room temperature to perform compression forming, hot-pressing to degrease and sintering; after sintering, naturally cooling to room temperature. The zirconia ceramic product produced by the invention is good in chemical stability, high in hardness, high temperature resistant, abrasion resistant, corrosion resistant, strong in insulation, and obvious in anti-static performance advantage, and has good application prospect.

Owner:李正国

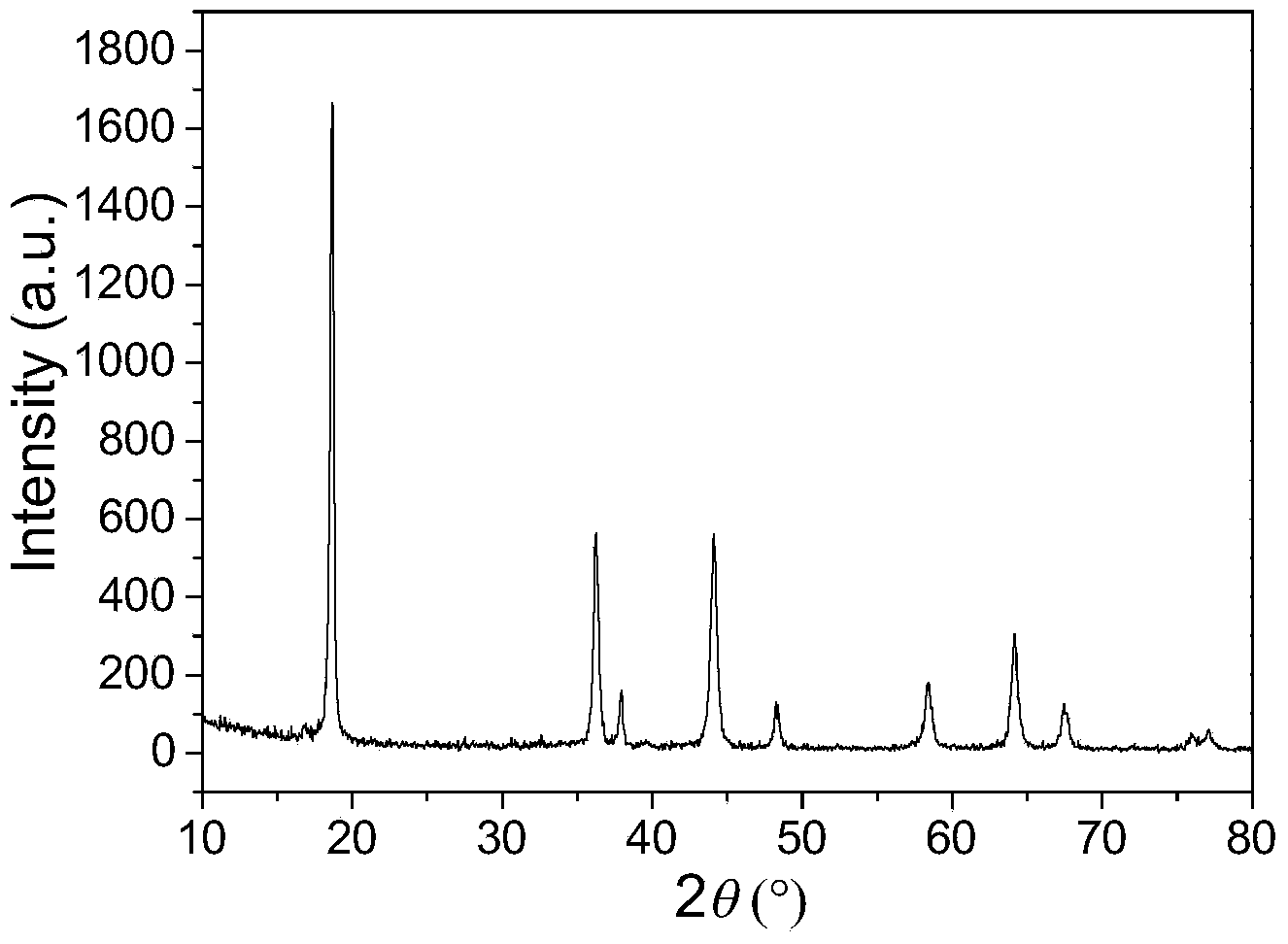

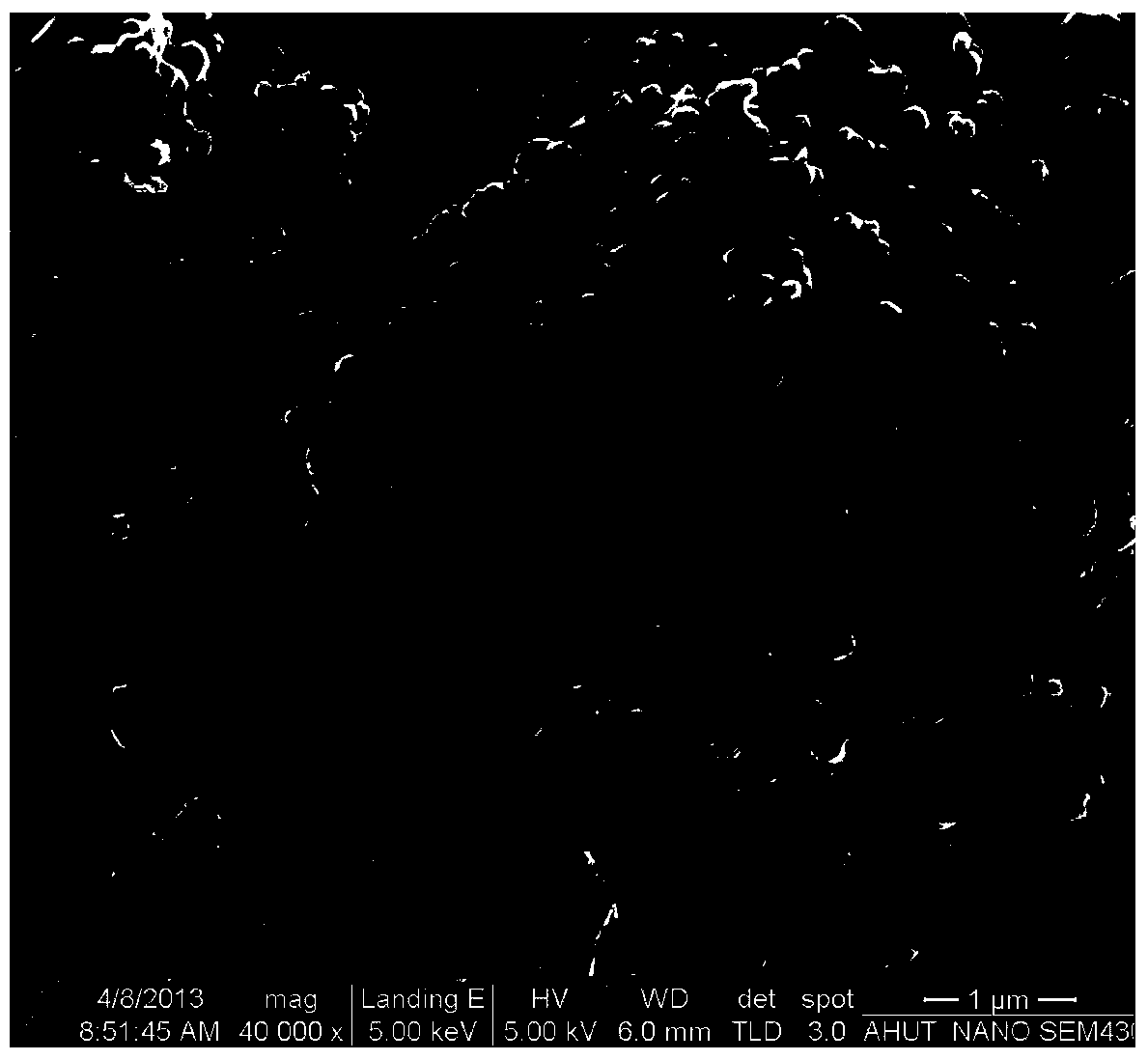

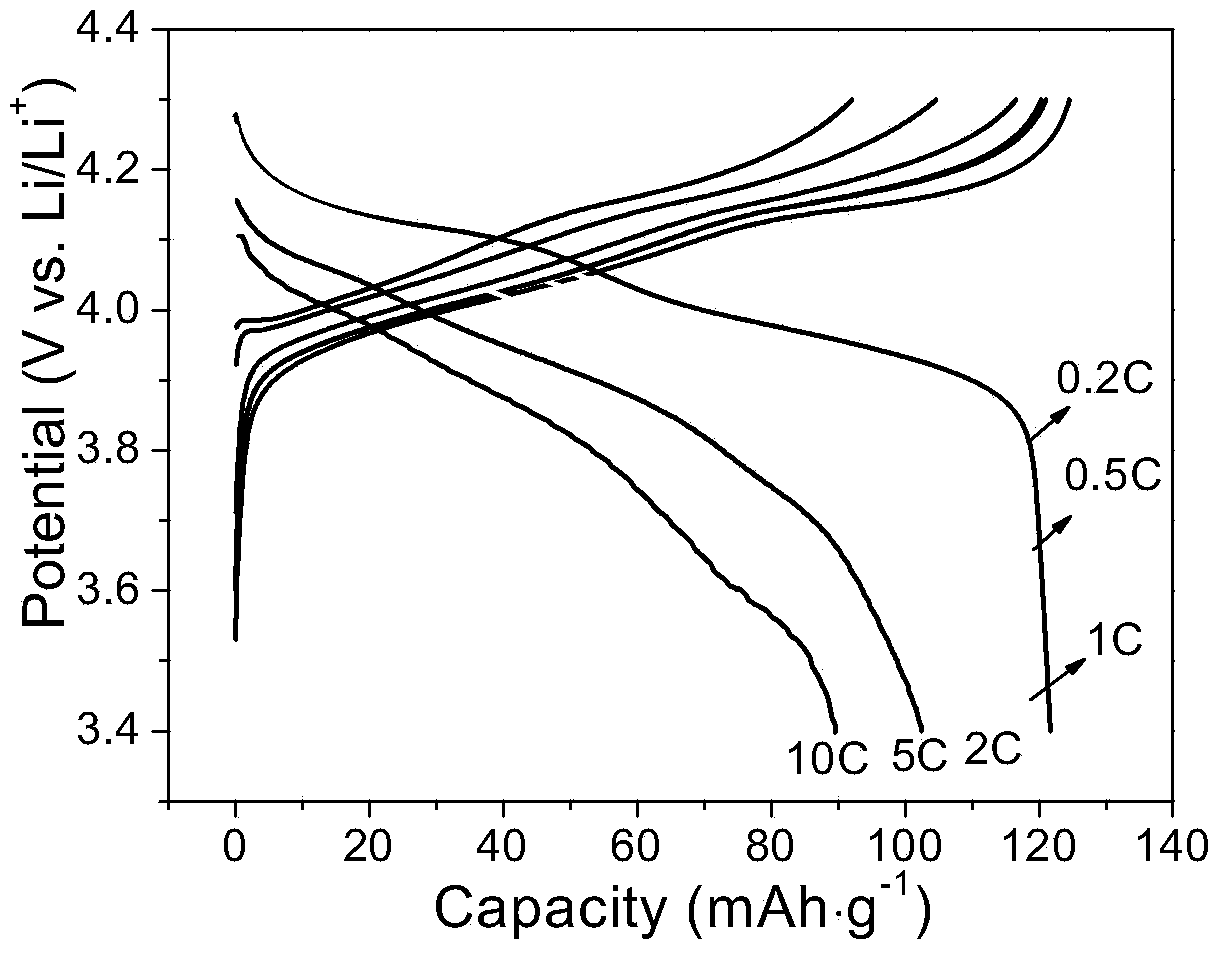

Doping modification method of spinel lithium manganate anode material

ActiveCN104319393APrecise control of stoichiometryPromote crystallizationCell electrodesManganateManganous-manganic oxide

The invention discloses a doping modification method of spinel lithium manganate anode material, and belongs to the field of nanotechnology. The method mainly comprises the following steps: respectively adding a saline solution of lithium-ion and doping ion into a citric acid solution, regulating pH values, adding ethylene glycol into the solution, heating and stirring the solution so as to form sol, mixing manganous-manganic oxide with the sol, performing ball milling, and performing microwave dehydration and subsequent heat treatment on products subjected to ball milling so as to obtain the doped spinel lithium manganate anode material. The method has the advantages that the prepared spinel lithium manganate anode material has high specific capacity, good rate capability and excellent cycling performance, meanwhile the technology is simple, the cost is low, the efficiency is high, and the method can be directly applied to industrial production.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

MnZn ferrite material for broadband anti -electromagnetic-interference and preparation method thereof

ActiveCN102690112AReduce manufacturing costExcellent broadband anti-interference characteristicsShielding materialsInorganic material magnetismSesquioxideManganous-manganic oxide

The invention discloses anti-broadband-electromagnetic-interference MnZn ferrite material which comprises, by molar percentage, 42.05-46.05 % of iron sesquioxide, 32.51-35.51 % of manganous manganic oxide, 18.55-20.35 % of zinc oxide, 1.05-1.68 % of copper oxide and 0.25-0.45 % of calcium oxide. A preparation method includes weighing and mixing, granulating, calcinating, coarsely grinding, secondarily weighting and fine grinding, spray granulating, and thirdly weighting and inspecting and packaging. Preparation cost of soft magnetic ferrite anti-interference material is reduced effectively. The MnZn ferrite material has fine broadband interference resistance from low frequency to high frequency and integrates the characteristics of NiZn and MgZn materials, and the materials can replace NiZn material and MnZn simultaneously. The MnZn ferrite material does not contain metal elements such as nickel, cadmium and cobalt, so that the environment cannot be polluted, and the MnZn ferrite is more environment-friendly than the NiZn material.

Owner:NANTONG HUAXING MAGNETIC MATERIAL

Preparation method for spherical doped lithium manganate

InactiveCN107240692AImprove structural stabilityImprove cycle performanceCell electrodesSecondary cellsAir atmosphereLithium hydroxide

The invention relates to a preparation method for spherical doped lithium manganate. The preparation method comprises the following steps of (1) weighing doped element soluble salt and solute manganese salt with divalent manganese and preparing with water to form a mixed solution containing doped element ions and divalent manganese ions; (2) preparing a sodium hydroxide solution; (3) continuously adding the mixed solution and the sodium hydroxide solution into a reactor, performing a coprecipitation reaction, and meanwhile, adding sufficient oxidizing agent to the reaction liquid to perform oxidation treatment on precipitates, and next, performing rinsing by water and drying to obtain spherical-doped manganous-manganic oxide; and (4) weighing lithium carbonate or lithium hydroxide spherical doped manganous-manganic oxide to be fully mixed, and performing high-temperature roasting in the oxygen or air atmosphere to obtain spherical doped lithium manganate. The spherical doped lithium manganate prepared in the invention is low in impurity content and uniform in doped element molecule scale, and capable of solving the problem of relatively poor cycling performance of lithium manganate.

Owner:GUANGXI GUILIU CHEM CO LTD +1

Trimanganese tetroxide preparation method and trimanganese tetroxide prepared therethrough

InactiveCN103570072AGood dispersionOmit the precipitation stepManganese oxides/hydroxidesPyrrolidinonesManganous-manganic oxide

The invention provides a trimanganese tetroxide preparation method. The preparation method comprises the following steps: 1, mixing and dissolving a manganese source, cetyltrimethylammonium bromide, polyvinylpyrrolidone and an alkaline precipitating agent to obtain an aqueous solution; 2, introducing an oxidative atmosphere or adding H2O2 to the aqueous solution obtained in step 1 for reacting to obtain a manganese-containing solid oxide; and 3, sequentially washing and drying the manganese-containing solid oxide obtained in step 2 to obtain a trimanganese tetroxide product. The invention also provides trimanganese tetroxide. The preparation method has the advantages of simplicity, simple operation, environmental protection, and the trimanganese tetroxide product has the advantages of regular morphology and good dispersibility.

Owner:BYD CO LTD

Method for doping and cladding double modifying for lithium manganate in one step

ActiveCN105576218AImprove structural stabilityImprove cycle performanceElectrode thermal treatmentSecondary cellsManganous-manganic oxideManganate

The invention provides a method for doping and cladding double modifying for lithium manganate in one step. In a product obtained by virtue of the method, during the heat treatment process of an aluminum source on the surface of manganous-manganic oxide, partial aluminum can enter the outer layer lithium manganate to form a LiMn2-xAlxO4 solid solution, and the rest aluminum exists in an oxide form, so that the double modification of doping and cladding on the lithium manganate can be achieved. The aluminum oxide can effectively isolate the direct contact between the lithium manganate and electrolyte; the LiMn2-xAlxO4 solid solution has a structure more stable than that of LiMn2O4 under the condition that the passing of lithium ions is not obstructed. The double-functional modification effectively inhibits the dissolution of bivalent manganese, so that the cycling performance and the high temperature performance of the lithium manganate are improved.

Owner:CENT SOUTH UNIV

Preparation method and application of crystalline-state beta-MnOOH nanowire

InactiveCN102041553ALow costSimple processSemi-permeable membranesPolycrystalline material growthPorous substrateNanowire

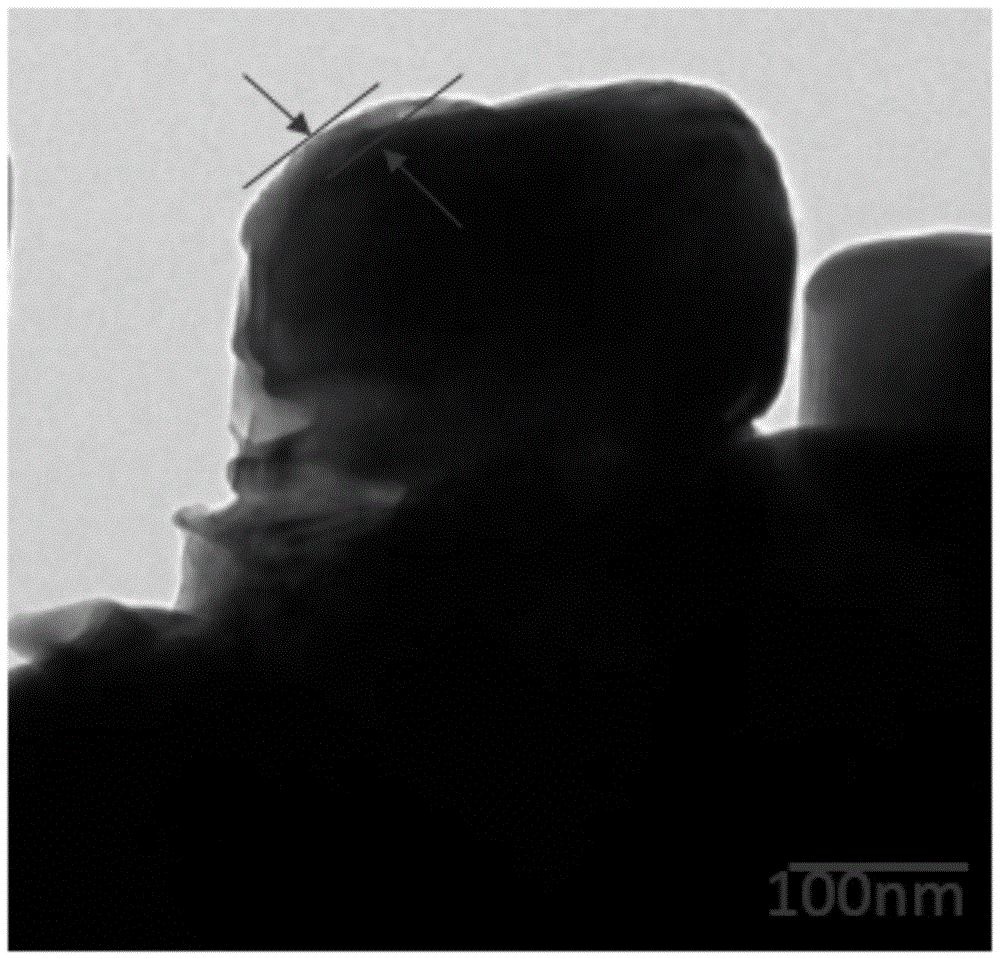

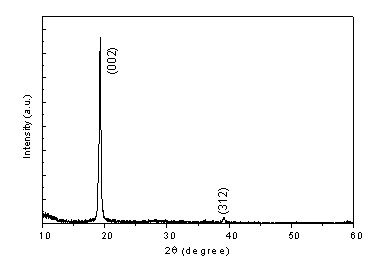

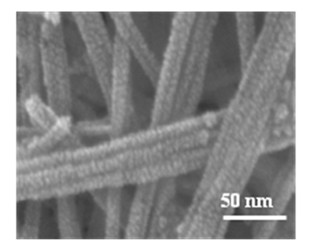

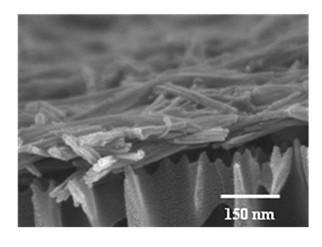

The invention discloses a preparation method and application of a crystalline-state beta-MnOOH nanowire. The preparation method of the crystalline-state beta-MnOOH nanowire comprises the following steps of: mixing 0.4-0.6 mM of manganous saline solution with 0.8-1.0 mM of aqueous alkali, which have same volumes, under magnetic stirring at normal temperature; and standing for 1-2 days to generate crystalline-state beta-MnOOH nanowire precipitates, wherein the crystalline-state beta-MnOOH nanowire is used for preparing a mesoporous separation membrane with the thickness of 120-600 nanometers and has a very good beta-MnOOH crystalline structure and a mean diameter of 25 nanometers; easily carrying out ultrasonic dispersion for 5-10 minutes, filtering 2-10 ml of dispersion liquid on a porous substrate to form a mesoporous membrane with the thickness of 120-600 nanometers, wherein the mesoporous membrane can effectively separate granules of 10 nanometers from a water solution, and the flow velocity reaches up to 15,120 L / m<2>hbar; annealing the crystalline-state beta-MnOOH nanowire in the air at 350-450 DEG C for 1 hour, and then converting into a trimanganese tetroxide nanowire with high specific surface area of 70 m<2> / g, which is used for catalyzing and degrading dye molecules.

Owner:ZHEJIANG UNIV

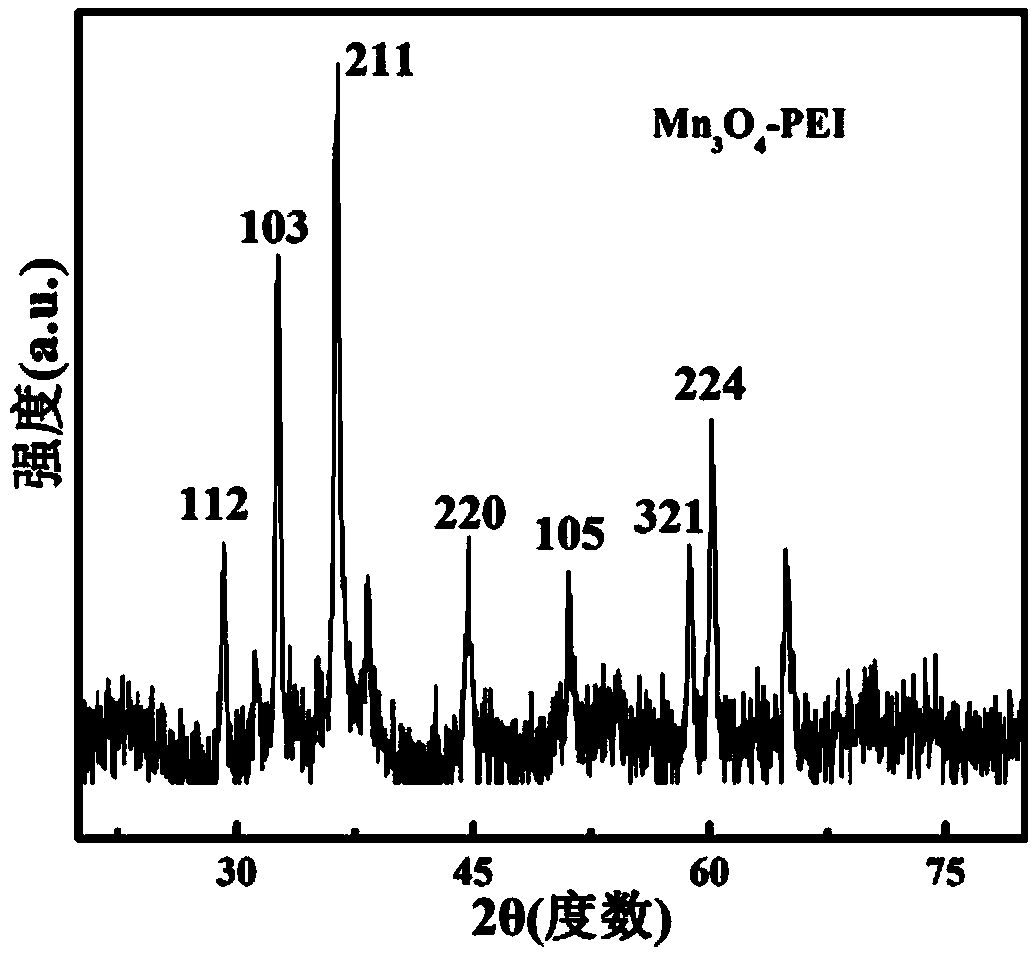

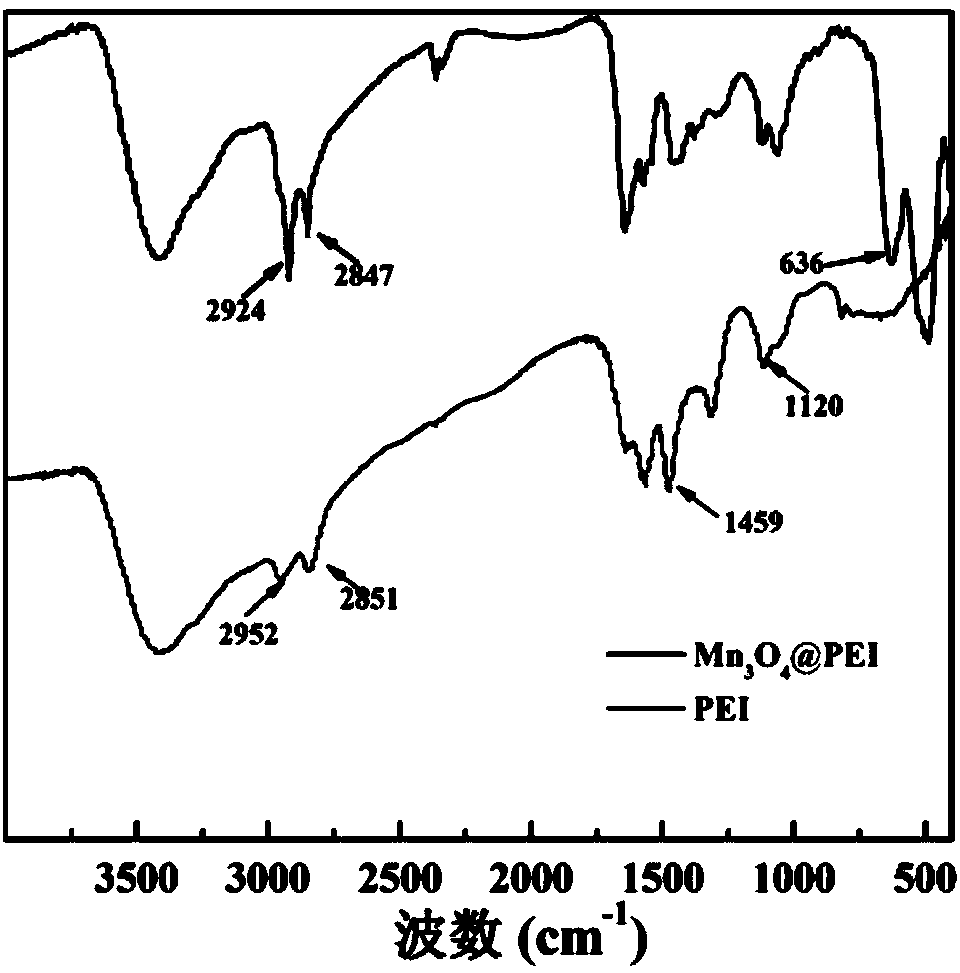

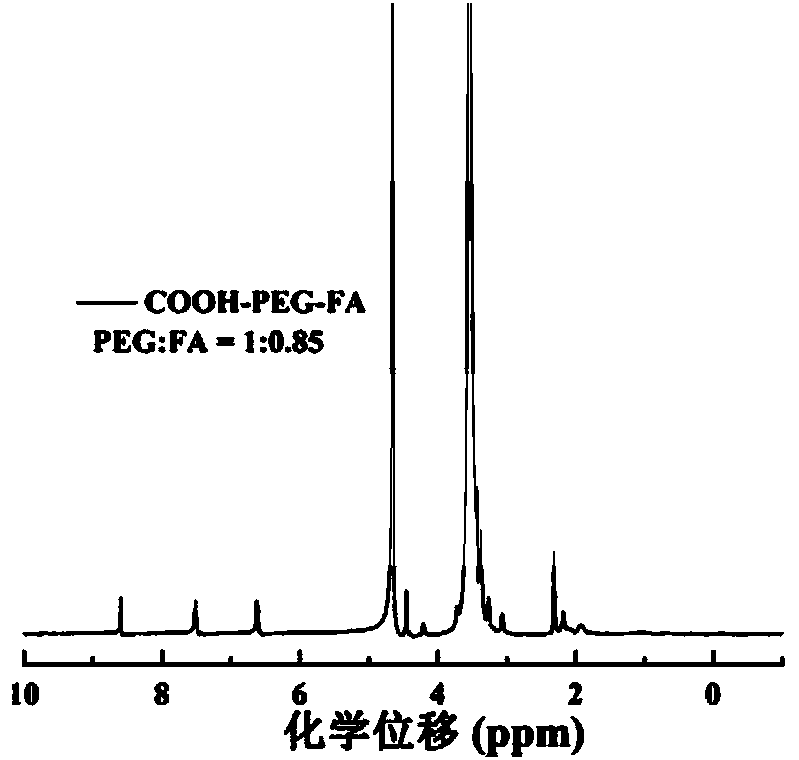

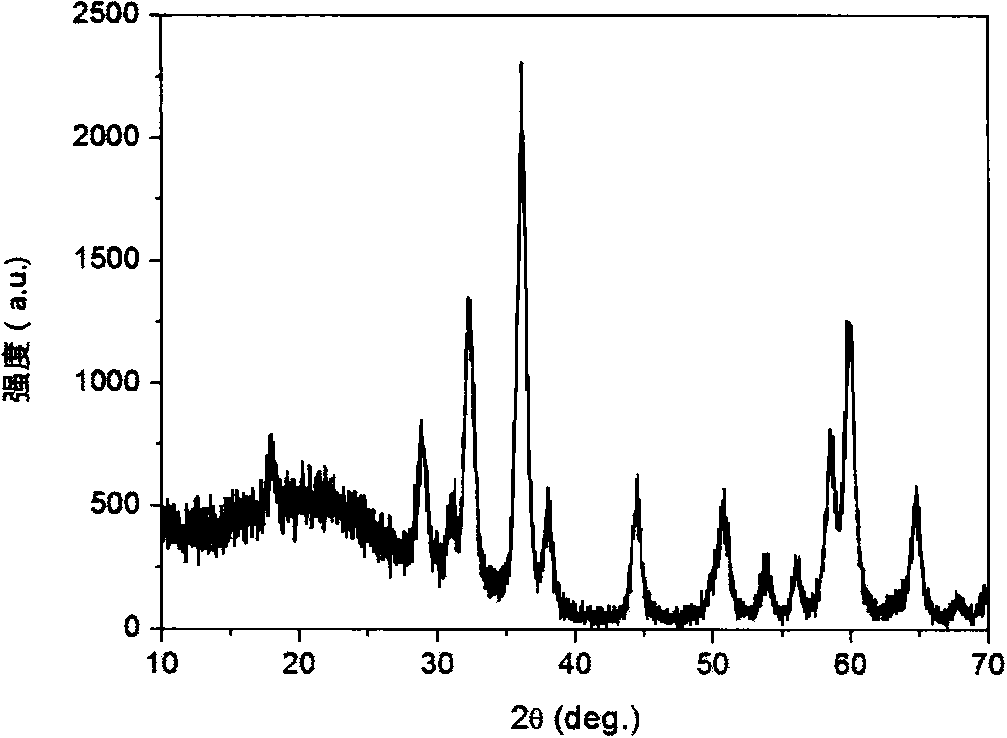

Method for preparing multifunctional manganous manganic oxide nano-particle nuclear magnetic resonance contrast agent mediated by polyethyleneimine

InactiveCN104274842ASimple operation processMild reaction conditionsEmulsion deliveryIn-vivo testing preparationsCancer cellManganous-manganic oxide

The invention relates to a method for preparing a multifunctional manganous manganic oxide nano-particle nuclear magnetic resonance contrast agent mediated by polyethyleneimine. The method comprises the following steps: preparing PEI modified Mn3O4 nano-particles by using a solvothermal method, and then separating and purifying the nano-particles; then, marking tracer molecule fluorescein isothiocyanate FI on the nano-particles; modifying polyethylene glycol PEG molecules on the amino of PEI; and finally, modifying targeted reagent folic acid FA molecules on the PEI through PEG modification and performing complete acetylation treatment to obtain the contrast agent. The contrast agent prepared in the invention can trace the phagocytosis condition of the cancer cells to nanoparticles in a cellular level, has a significant targeting function on a high-expression cancer cell strain of an FA receptor and can be used for achieving early diagnosis of cancer, meanwhile, since the preparation method of the contrast agent is simple and easy and the raw materials are cheap and easy to obtain, the contrast agent can be produced in large batches.

Owner:DONGHUA UNIV

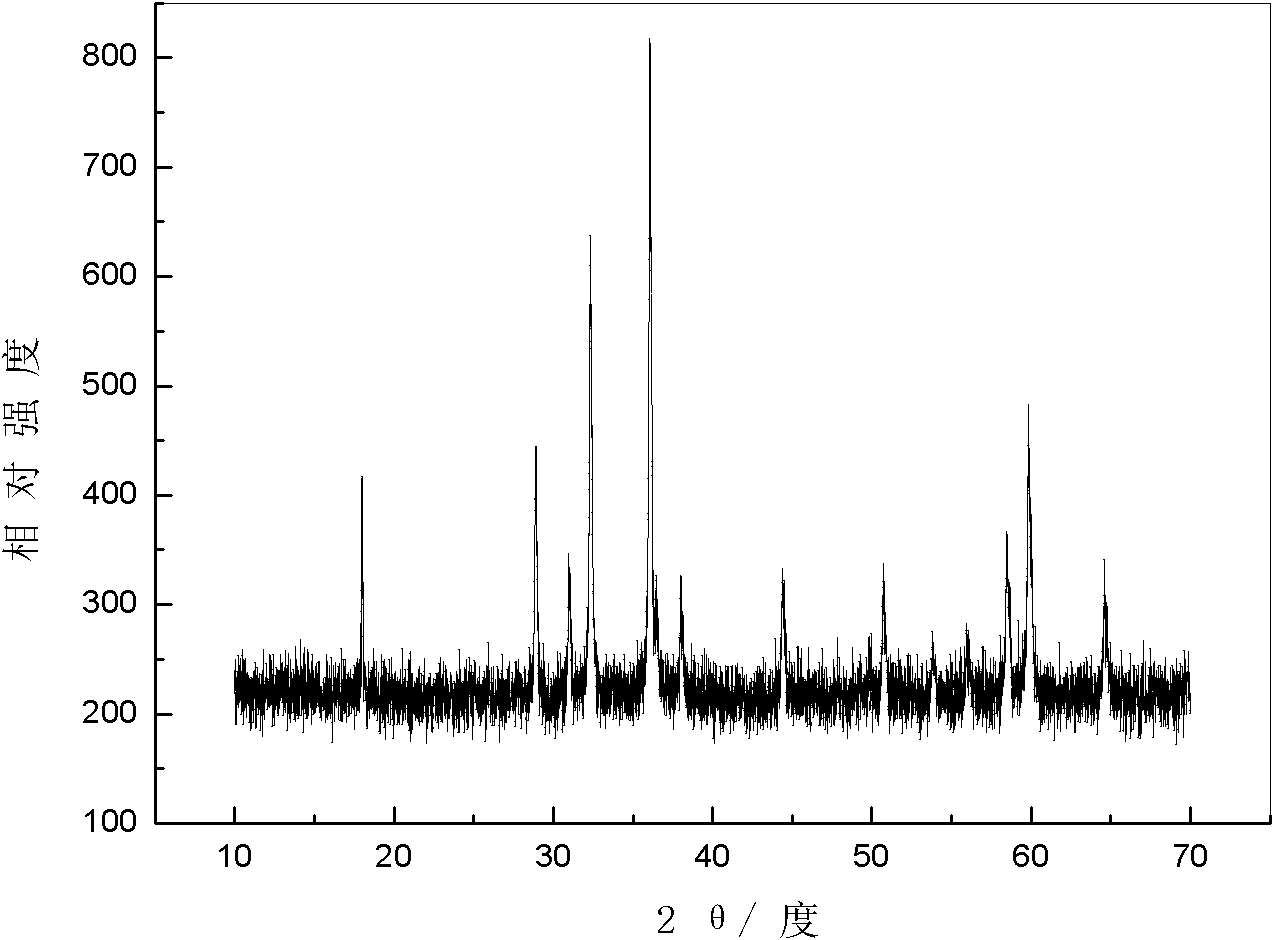

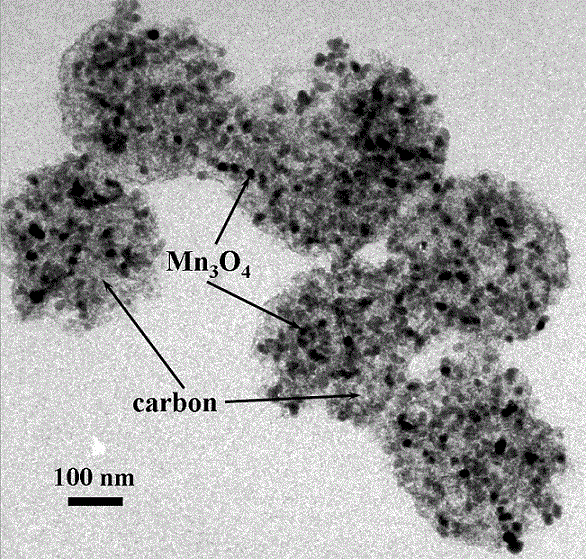

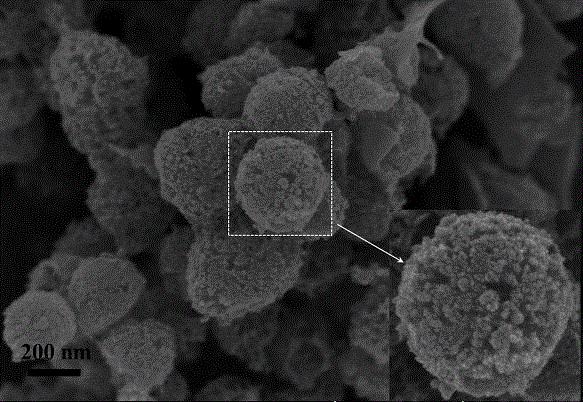

Method for preparing nanometer manganous-manganic oxide/carbon composite energy storage material

InactiveCN103440996AReduce energy consumptionExcellent supercapacitor performanceMaterial nanotechnologyHybrid capacitor electrodesCapacitanceCarbon composites

The invention discloses a method for preparing a nanometer manganous-manganic oxide / carbon composite energy storage material. The method comprises the steps that potassium permanganate is reacted with oleic acid in the ratio of 100:1 (g / L) in an aqueous solution, obtained solid substances are dispersed in alcohol solvent, single substance iodine is added into the aqueous solution according to the mass ratio of 0-2:1, and the solid substances are dissolved. The solution reaction time is 12 hours-48 hours in a reaction kettle at the temperature of 120 DEG C to 200 DEG C. After centrifugal separation, washing and drying are conducted, the manganous-manganic oxide / carbon composite energy storage material is obtained. The method can be conducted on the low temperature and non-alkaline conditions and is simple in technology and low in energy consumption. Meanwhile, the super capacitive property of the manganous-manganic oxide / carbon composite energy storage material obtained according to the method is remarkably improved.

Owner:TIANJIN POLYTECHNIC UNIV

Manganous-manganic oxide preparation method for battery positive pole material lithium manganate and product thereof

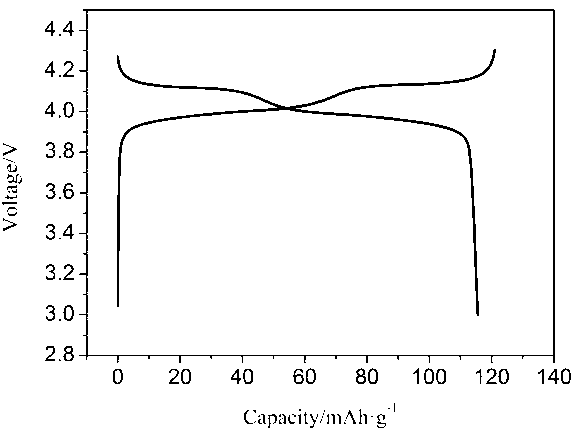

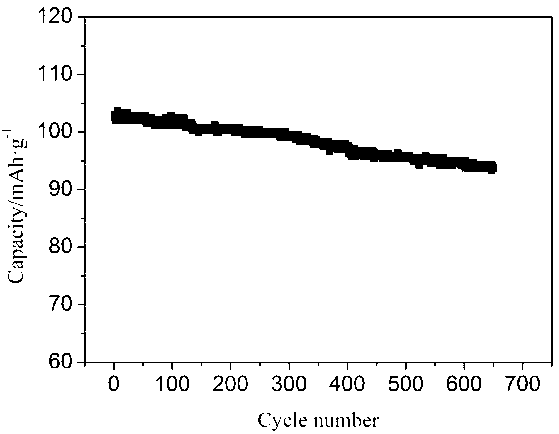

ActiveCN102842708AImprove Capacitive PerformanceIncrease compaction densityCell electrodesHydrogenGram

The invention discloses a manganous-manganic oxide preparation method for battery positive pole material lithium manganate and a product thereof. After high pure manganese metal powder is crushed in a dry method to a certain particle size distribution, and air is added into a reactor for oxidation after water and ammonium salts are added. In an early stage of reaction, air flow is 20-100 cubic meters per hour; after five hours of the reaction, the air flow is regulated to 40-300 cubic meters per hour; after twelve hours of the reaction, the air flow is regulated to 20-100 cubic meters per hour; and when the reaction is finished, a stirring rate is controlled to be 250-450 revolutions per minute. Time needed for the reaction is 18-28 hours, and a potential of hydrogen (pH) value at a finishing point of the reaction is controlled to be 6.4 + / -0.2. After the reaction is finished completely, a manganous-manganic oxide product can be prepared after being washed and dried. The manganous-manganic oxide product prepared by means of the method is 15-30 micrometers in a particle diameter, 1.0-4.0 square meters per gram in specific surface area, and 2.0-3.0 grams per cubic centimeter in tap density. With the manganous-manganic oxide preparation method, the lithium manganate positive pole material has the advantages of being good in capacity performance, high in compaction density, goof in cycle performance and the like.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

Method for producing high-capacity lithium manganate by using manganous manganic oxide

InactiveCN103613143ASimple production processShort processing cycleCell electrodesManganates/permanganatesLithium carbonatePhysical chemistry

The invention discloses a method of producing high-capacity lithium manganate by using manganous manganic oxide. The method comprises the following steps: uniformly mixing manganous manganic oxide and lithium carbonate which are raw materials by a dry method according to a molar ratio of lithium to manganese being 0.48-0.58 and the weight percentage of an additive corresponding to a finished product being 0.1-1%; preparing a semi-finished product; and then, producing the high-capacity lithium manganate by process methods of sintering and post-treatment. The method disclosed by the invention is simple in process and simple and convenient to operate, and can produce high-capacity lithium manganate within a short time, so that the capacity of a lithium manganate positive electrode material can be improved by over 10%, and the method is worth popularizing and applying.

Owner:HENAN FUSEN NEW ENERGY TECH

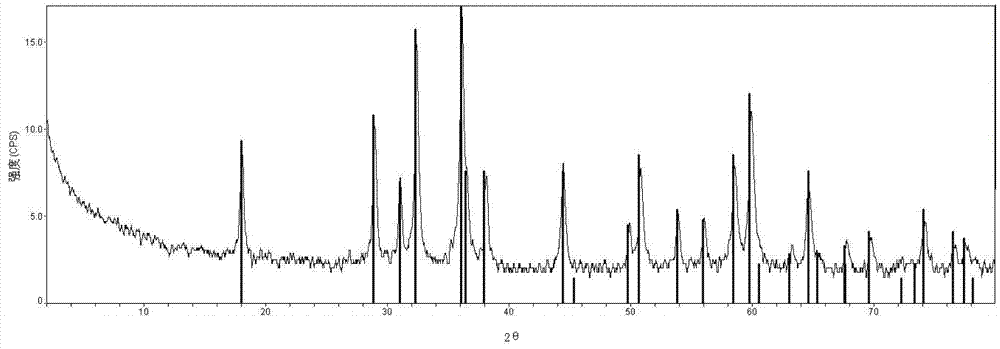

Bulk-phase doped manganous-manganic oxide as well as preparation method and application thereof

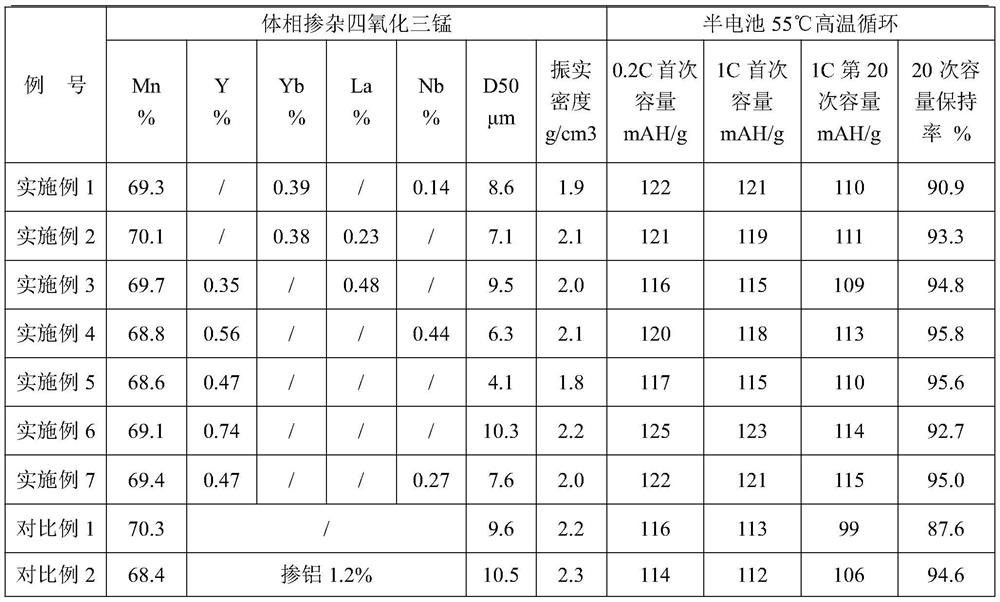

PendingCN112390292AIncrease gram capacityIncrease compaction densitySecondary cellsPositive electrodesElectrical batteryNiobium

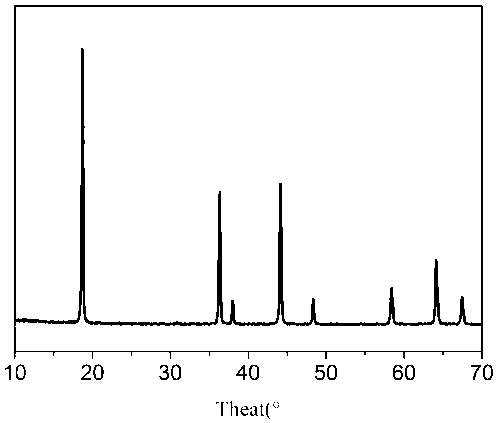

The invention discloses bulk-phase doped manganous-manganic oxide. The bulk-phase doped manganous-manganic oxide is doped with at least one element of yttrium, ytterbium, lanthanum and niobium, wherein the doping amount of the doping element is 0.1%-1.0%, the particle size D50 of manganous-manganic oxide is 3-20 microns, and the tap density is greater than or equal to 1.5 g / cm<3>. The preparationmethod comprises the steps: under a stirring condition, continuously adding a divalent manganese salt and a soluble doped salt solution and ammonia water into a reactor to carry out a coprecipitationreaction, and adding an oxidant to carry out oxidation treatment, so as to obtain the bulk-phase doped manganous-manganic oxide. The manganous-manganic oxide or the manganous-manganic oxide prepared by the preparation method is used as a precursor and mixed with a lithium source, and the mixture is roasted to obtain a lithium ion battery positive electrode material lithium manganate. In the manganous-manganic oxide disclosed by the invention, the doping elements are in uniform bulk phase distribution in microcosmic particles, so that the gram volume of lithium manganate can be improved, the compaction density of the lithium manganate can be improved, and the high-temperature performance and the cycle performance of a lithium manganate product can be remarkably improved.

Owner:GUIZHOU DALONG HUICHENG NEW MATERIAL CO LTD

Method of preparing high-purity manganomanganic oxide by pyrolyzing manganese sulfate at high temperature

InactiveCN1927727ABreak down completelyReduce manufacturing costManganese oxides/hydroxidesSulfatePhysical chemistry

Owner:GUANGXI UNIV

Low-density high-strength petroleum fracturing propping agent ceramsite and preparation method thereof

InactiveCN102618251ATake advantage ofReduce occupancyFluid removalAdditive ingredientManganous-manganic oxide

The invention discloses low-density high-strength petroleum fracturing propping agent ceramsite and a preparation method thereof. According to used raw materials, a weight ratio of glass phase-enriched low bauxite to brown fused alumina dust wastes in a ceramsite inner core is (80-20):20:80; and a weight ratio of corundum-enriched low bauxite to brown fused alumina dust collection micro powder to brown fused alumina tailings to titanium dioxide to manganous-manganic oxide in a ceramsite shell is (70-80):(10-8):(10-12):(5-2):(5-3), wherein the Al2O3content in the low bauxite is 60 to 65 percent; main ingredients of brown fused alumina smelting wastes are Al2O3, K2O, Na2O, SiO2 and Fe2O3; the content of Al2O3 in the brown fused alumina dust collection micro powder is 80 to 85 percent; and the Al2O3content in the brown fused alumina tailings is 72 to 80 percent.

Owner:龚亚云

Preparation method of lithium manganese oxide spinel positive material

InactiveCN103219509AHigh magnificationImprove cycle performanceCell electrodesSesquioxidePhysical chemistry

The invention relates to a preparation method of a lithium manganese oxide spinel positive material, and particularly relates to a preparation method of a lithium manganese oxide spinel positive material with high rate and high cycle performance, which belongs to the field of energy materials. The preparation method comprises the steps of preprocessing manganese dioxide which is taken as raw materials to obtain a lattice-doped precursor containing one, two or three of manganese dioxide, manganese sesquioxide and trimanganese tetroxide, and controlling the valence state of the precursor to improve the stability and the performance of the lithium manganese oxide structure.

Owner:SICHUAN UNIV

Method for producing high purity manganous-manganic oxide with little iron and chromium

High purity electrolytic metal manganese sheet is used as a raw material, and a non iron or chromium base pressure-resistant and wear-resistant material, such as a pressure-resistant ceramic is used as a pressure roller of a roller mill. The electrolytic metal manganese sheet is fragmented into electrolytic metal manganese powder, sieved through a copper screen to obtain electrolytic metal manganese powder with a fineness of -140 mesh or -160 mesh, and put into a reaction tank together with water in a ratio of 1:6 for reaction. The reaction tank employs a non iron or chromium base anti-corrosion and wear-resistant material, such as epoxy resin, rubber and titanium, etc., as an inner liner non iron or chromium base anti-corrosion and wear-resistant material, such as epoxy resin, rubber and titanium, etc., and a stirring slurry of the reaction tank is coated with a non iron or chromium base anti-corrosion and wear-resistant material, such as epoxy resin, rubber and titanium, etc. after the reaction, high purity manganous-manganic oxide with little iron and chromium can be obtained, wherein an iron content is not greater than 0.02%, and a chromium content not greater than 0.001%.

Owner:伍宏斌

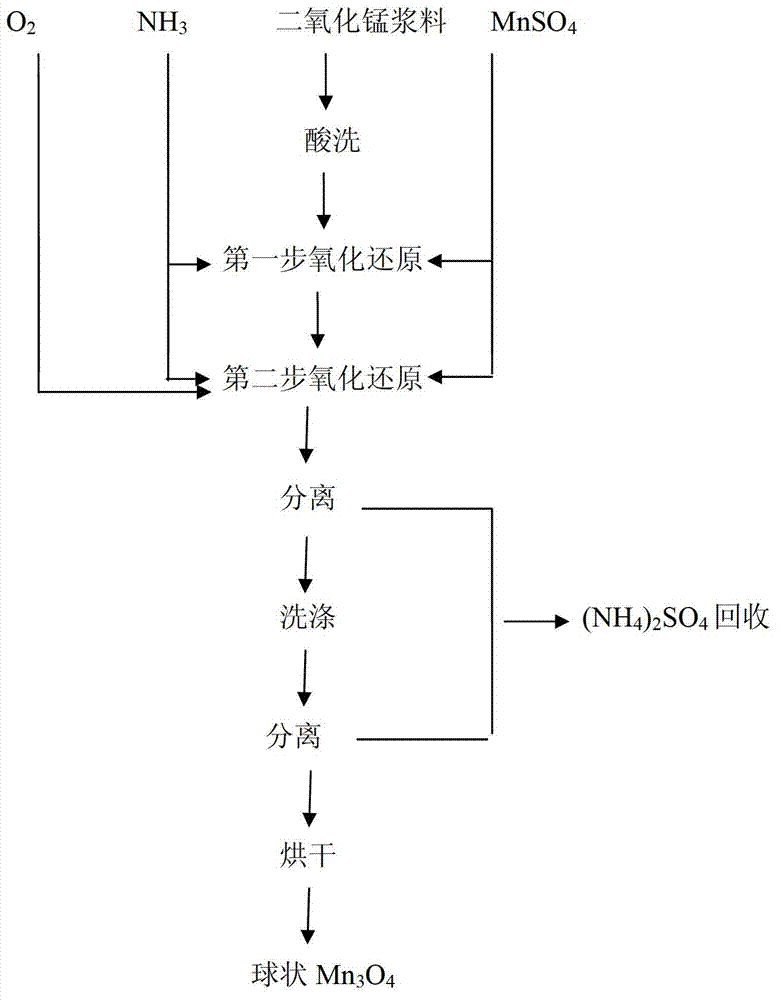

Preparation method of manganous-manganic oxide and manganous-manganic oxide

ActiveCN102765760AReduce contentMeet the indicator requirementsManganese oxides/hydroxidesLithiumSulfate

The invention provides a preparation method of manganous-manganic oxide and the manganous-manganic oxide. The preparation method comprises the following steps of adjusting the pH value of manganese dioxide powder slurry to be 2.0-2.5, stirring the slurry at the temperature of 60-70 DEG C and conducting solid-liquid separation; adding manganese dioxide after scouring in manganese sulfate solution with the concentration of 100-200g / L; warming the solution at nitrogen atmosphere to the temperature in the scope of 55-60DEG C; leading in NH3 holding solution with the pH value in the scope of 7.5-8.0, and maintaining, stirring and reacting for 0.8-1.2 hours after the pH value of the holding solution is stable; replacing nitrogen atmosphere by using oxygen atmosphere, leading in NH3 holding solution with the pH value in the scope of 7.0-7.5, adding 250-350g / L of MnSO4 solution, reacting until concentration of Mn+ is smaller than 500ppm, stopping the reaction, conducting solid-liquid separation, washing solid phase, and drying to obtain globular Mn3O4 products. The preparation method can use electrolytic manganese dioxide (EMD) tail powder to serve as raw materials, obtained manganous-manganic oxide products are approximately spherical and high in purity, and requirements for lithium-ion secondary battery are met.

Owner:SHENZHEN MODERN SKY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com