Preparation method of manganous-manganic oxide/graphene composite material

A technology of trimanganese tetraoxide and composite materials, which is applied in the field of preparation of trimanganese tetraoxide/graphene composite materials, and can solve the constraints on the commercial application of trimanganese tetraoxide, low conductivity and poor rate performance of trimanganese tetraoxide, etc. problem, to achieve the effect of high-current discharge performance, low price, and high capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 0.16g graphite oxide, 3g manganese sulfate, 150mL deionized water to a 250mL beaker, stir uniformly for 4 hours, then add 3g potassium permanganate, and stir uniformly for 4 hours. Slowly add 32 mL of 30 wt% hydrogen peroxide into the beaker dropwise, and sonicate for 3 hours. The product was placed in an oil bath at 100°C, 8 mL of hydrazine hydrate was added dropwise, and the mixture was stirred for 24 hours. After the product was washed with water and suction filtered, it was dried at 60° C. for 12 hours to obtain the manganese tetroxide / graphene composite material.

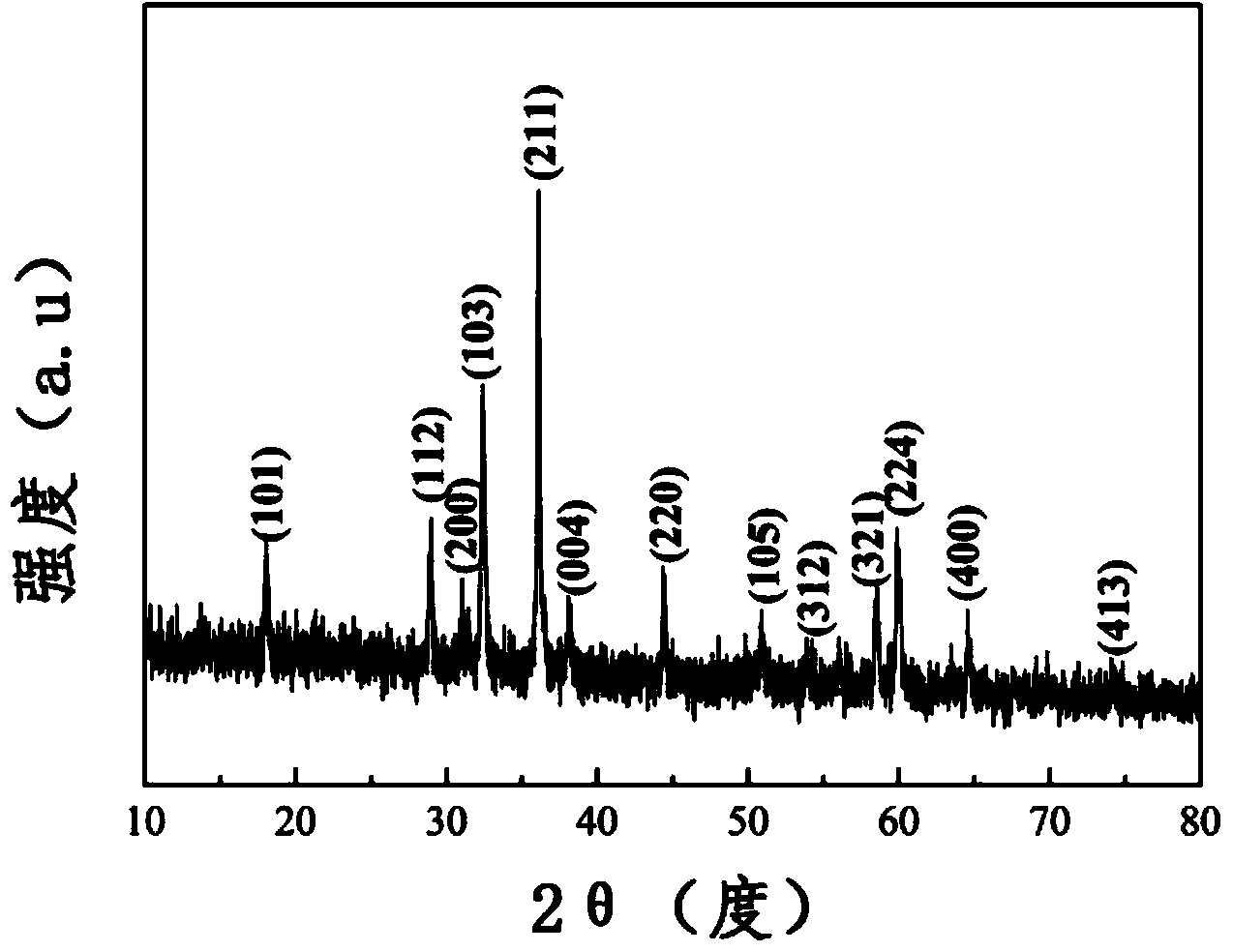

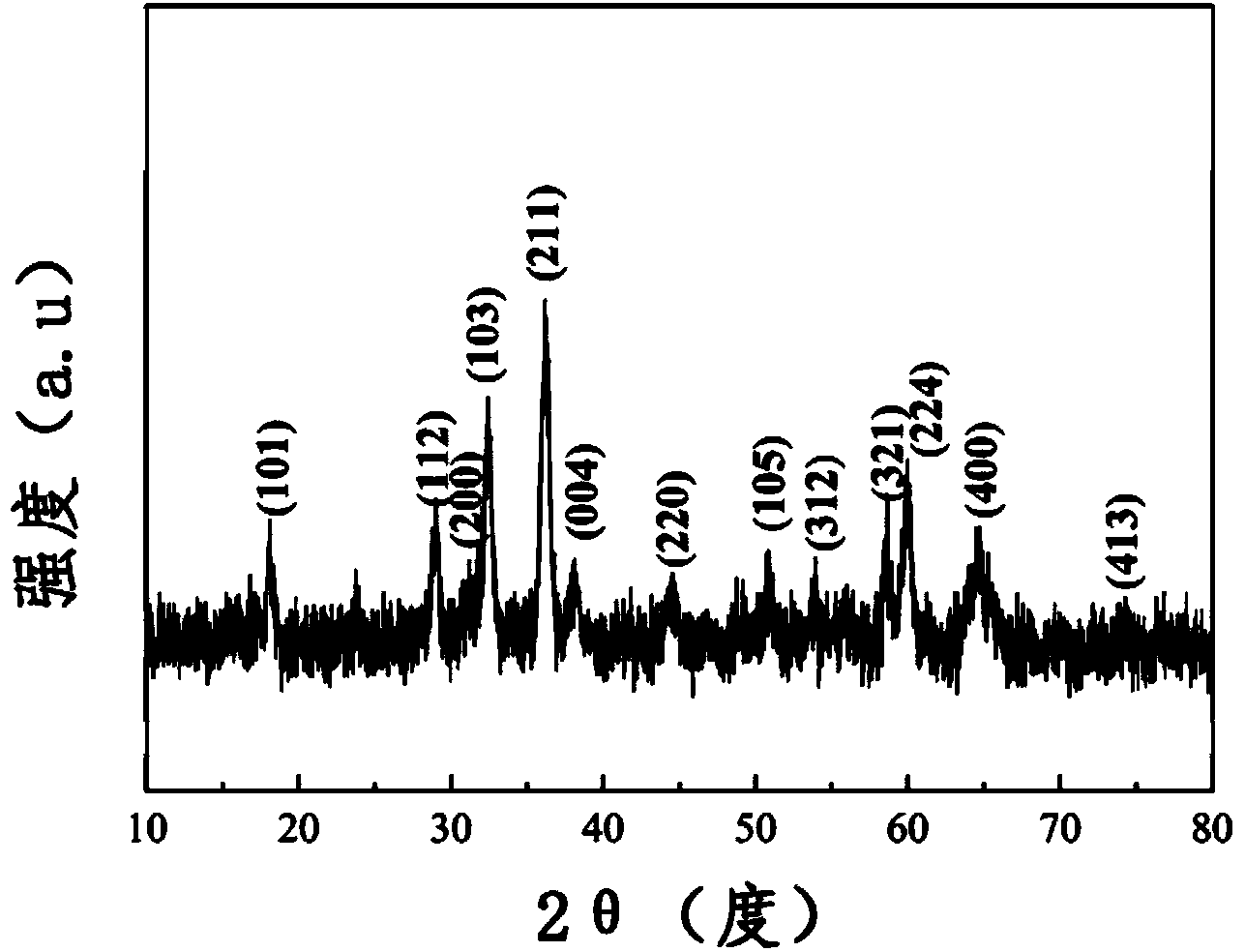

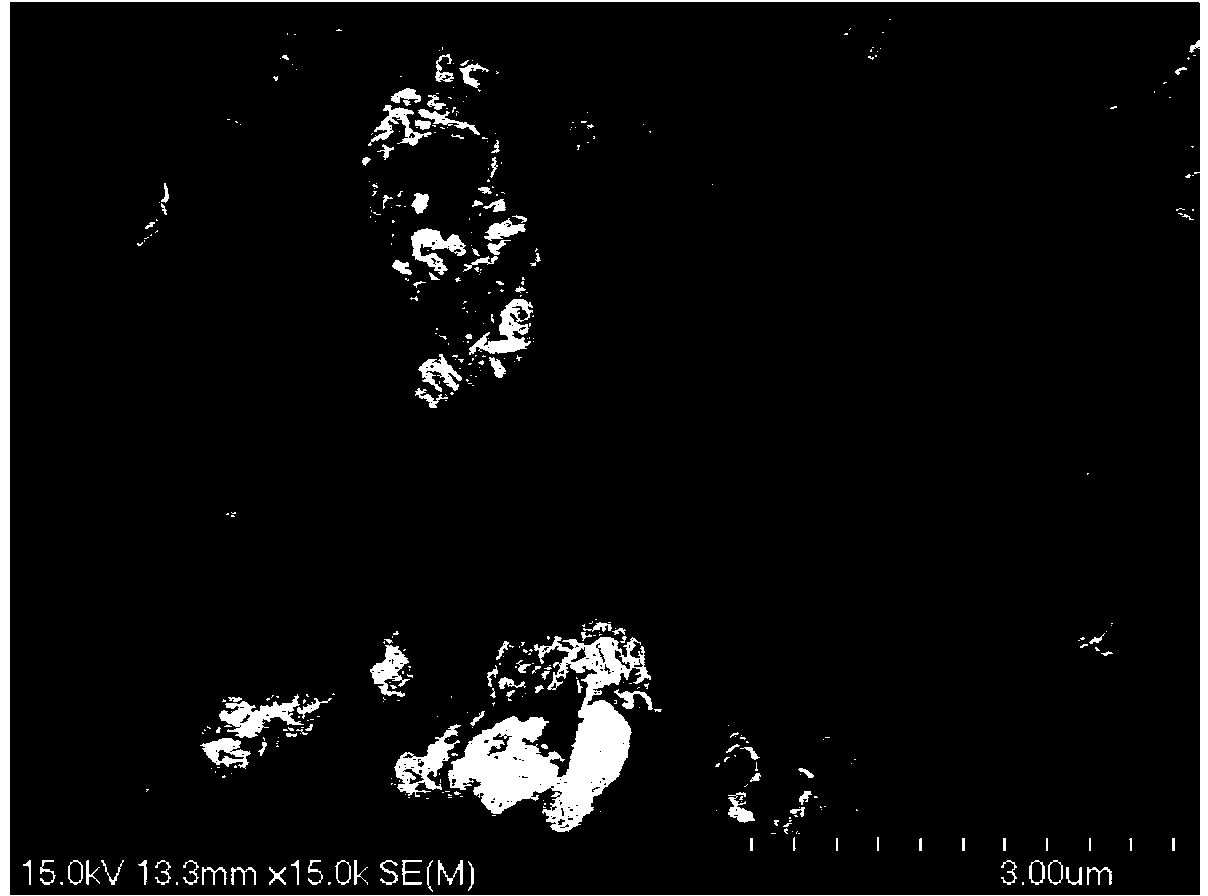

[0036] figure 1 It is the XRD diffractogram of the material, according to the standard card, it can be seen that the obtained product is manganese tetroxide, and there is no impurity phase. image 3 For the SEM photo of the material, it can be seen that the graphite oxide has been exfoliated into a graphene sheet-like structure, and a large number of manganese tetroxide particles are distributed on...

Embodiment 2

[0040] Add 0.25g graphite oxide, 3g manganese sulfate, 150mL deionized water to a 250mL beaker, stir uniformly for 4 hours, then add 3g potassium permanganate, and stir uniformly for 4 hours. Slowly add 45 mL of 30 wt% hydrogen peroxide into the beaker dropwise, and sonicate for 3 hours. The product was placed in an oil bath at 100°C, 10 mL of hydrazine hydrate was added dropwise, and the mixture was stirred for 24 hours. After the product was washed with water and suction filtered, it was dried at 60° C. for 12 hours to obtain the manganese tetroxide / graphene composite material.

[0041] The XRD pattern of the composite product is similar figure 1 , similar in appearance image 3 . Use the prepared manganese tetroxide / graphene composite material to make electrodes according to the method of Example 1, assemble into a simulated lithium ion battery, and the first charge-discharge capacity reaches 1500mAhg -1 , 800mAg -1 The discharge capacity is close to 300mAhg -1 .

Embodiment 3

[0043] Add 0.2g graphite oxide, 5g manganese sulfate, and 150mL deionized water to a 250mL beaker, stir uniformly for 4 hours, then add 5g potassium permanganate, and stir uniformly for 4 hours. Slowly add 44 mL of 30 wt% hydrogen peroxide into the beaker dropwise, and sonicate for 3 hours. The product was put into an oil bath at 100°C, 6 mL of hydrazine hydrate was added dropwise, and the mixture was stirred for 24 hours. After the product was washed with water and suction filtered, it was dried at 60° C. for 12 hours to obtain the manganese tetroxide / graphene composite material.

[0044] The XRD pattern of the composite product is similar figure 1 , similar in appearance image 3 . Use the prepared manganese tetroxide / graphene composite material to make electrodes according to the method of Example 1, assemble into a simulated lithium ion battery, and the first charge-discharge capacity reaches 1600mAhg -1 , 800mAg -1 The discharge capacity is close to 300mAhg -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge and discharge capacity | aaaaa | aaaaa |

| Charge and discharge capacity | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com