MnZn ferrite material for broadband anti -electromagnetic-interference and preparation method thereof

An anti-electromagnetic interference, manganese-zinc ferrite technology, applied in inductor/transformer/magnet manufacturing, magnetic materials, shielding materials, etc., can solve the problems of environmental pollution and high manufacturing costs, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A manganese-zinc ferrite material for broadband anti-electromagnetic interference. Its formula is composed of: 42.05 mol% of ferric oxide, 32.51 mol% of manganese tetraoxide, 20.35 mol% of zinc oxide, and 1.68 mol% of copper oxide mol%, calcium oxide 0.41 mol%.

[0031] Its preparation process is:

[0032] (1) Mixing of ingredients: Add the raw materials ferric oxide, manganese tetraoxide and zinc oxide into a conical mixer and mix evenly, then send them into a vibration mill for strong mixing, so that the average particle size of the powder after mixing and vibration grinding is 1.1 μm;

[0033] (2) Granulation: send the mixed material powder into the silo of the granulator, open the granulator, adjust the rolling pressure to 8mPa, so that the rolled material powder particles are cylindrical;

[0034] (3) Pre-burning: The temperature in the high temperature zone of the rotary kiln rises to 900°C, and the feeder is turned on to feed the pellets evenly into the rotary k...

Embodiment 2、 Embodiment 3

[0040] A manganese-zinc ferrite material used for broadband anti-electromagnetic interference, its formula composition according to mole percentage is shown in Table 1:

[0041] Table 1: Manganese zinc ferrite material formula composition

[0042]

Ferric oxide

Trimanganese tetraoxide

Zinc oxide

Copper oxide

Example 2

44.05mol%

34.01mol%

20.23mol%

1.36mol%

0.35mol%

Example 3

46.05mol%

32.51mol%

20.13mol%

1.05mol%

0.26mol%

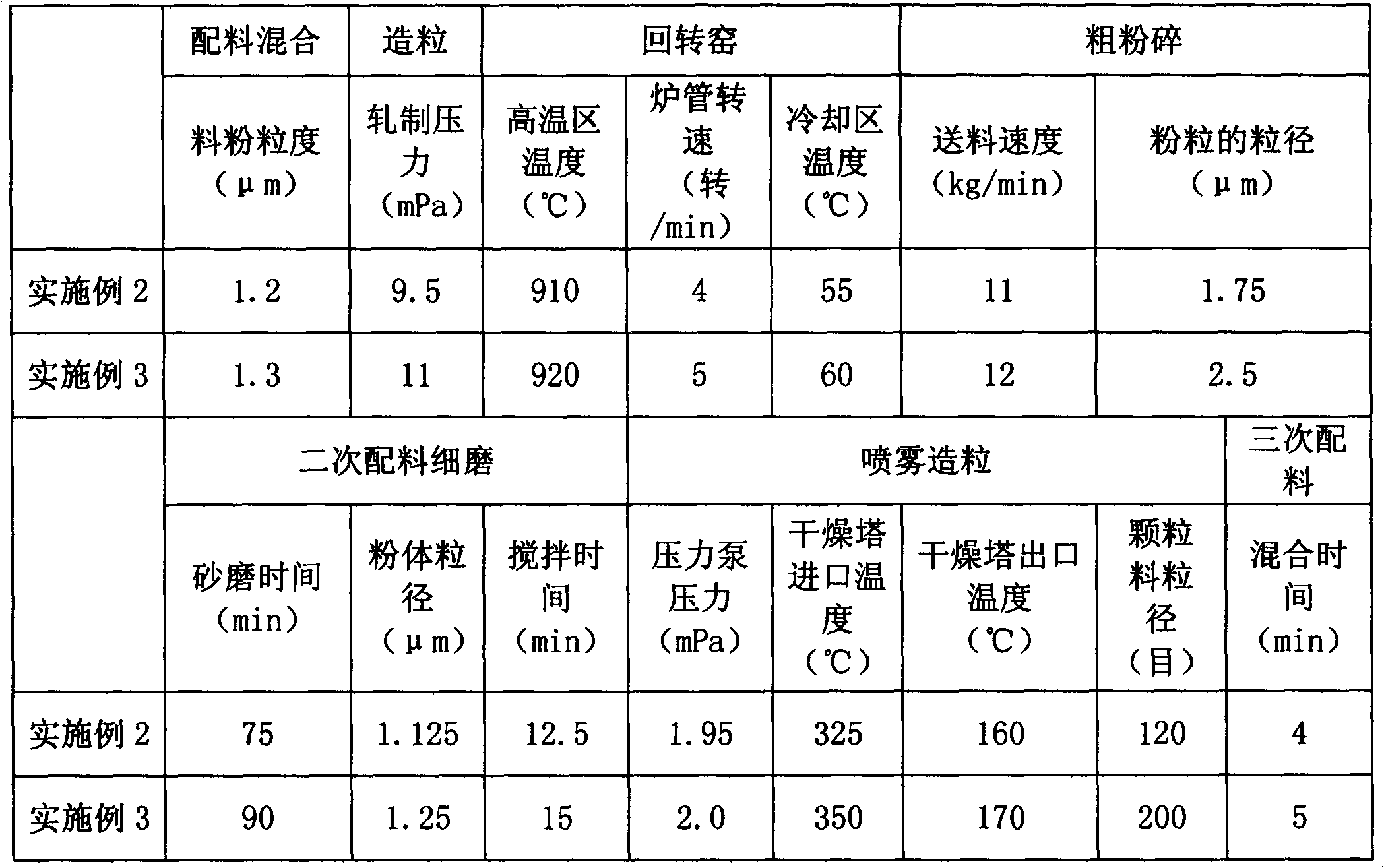

[0043] The production process is basically the same as in Example 1, and the specific process conditions correspond to Table 2 one by one:

[0044] Table 2: Manufacture process of MnZn ferrite material

[0045]

[0046] The dispersant used in the above examples is a special dispersant for magnetic materials, model BWY-507, and the manufacturer is Zhejiang Linan Yueyang Auxiliary Co., Ltd.; the defoamer is n-octanol, with a content greater than or e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com