Method for preparing nanometer manganous-manganic oxide/carbon composite energy storage material

A technology of trimanganese tetraoxide and energy storage materials, which is applied in the field of preparation of nanometer trimanganese tetraoxide/carbon composite energy storage materials, can solve the problems of high energy consumption, high temperature requirement, environmental pollution, etc., and achieve low energy consumption and excellent The effect of supercapacitor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the preparation of nano trimanganese tetraoxide / carbon (20%) composite material

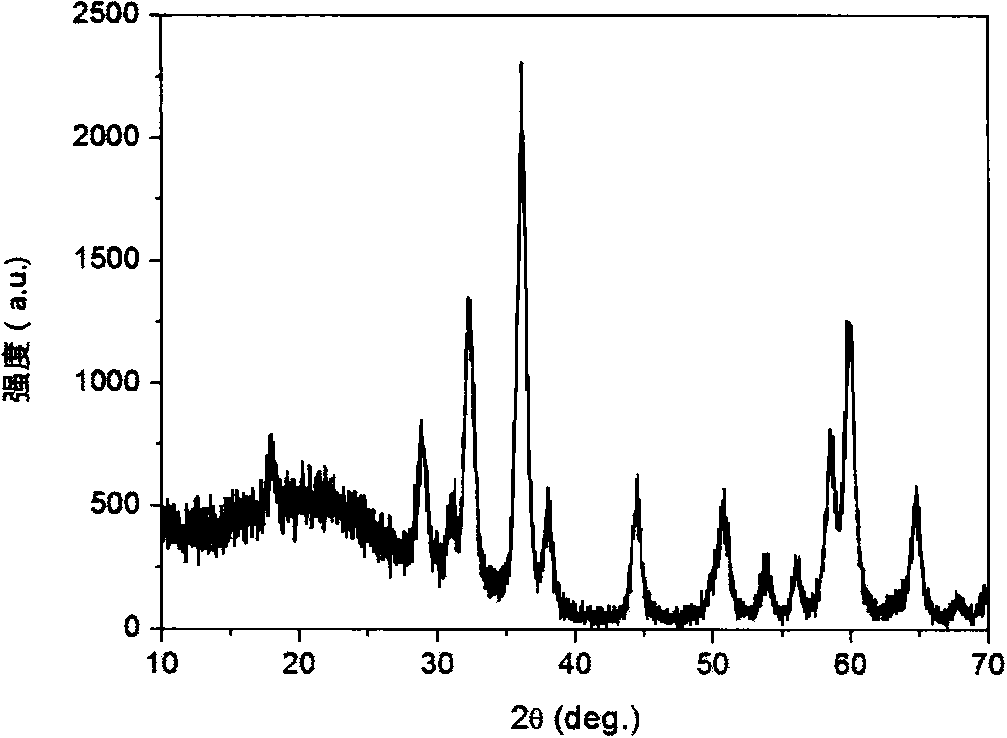

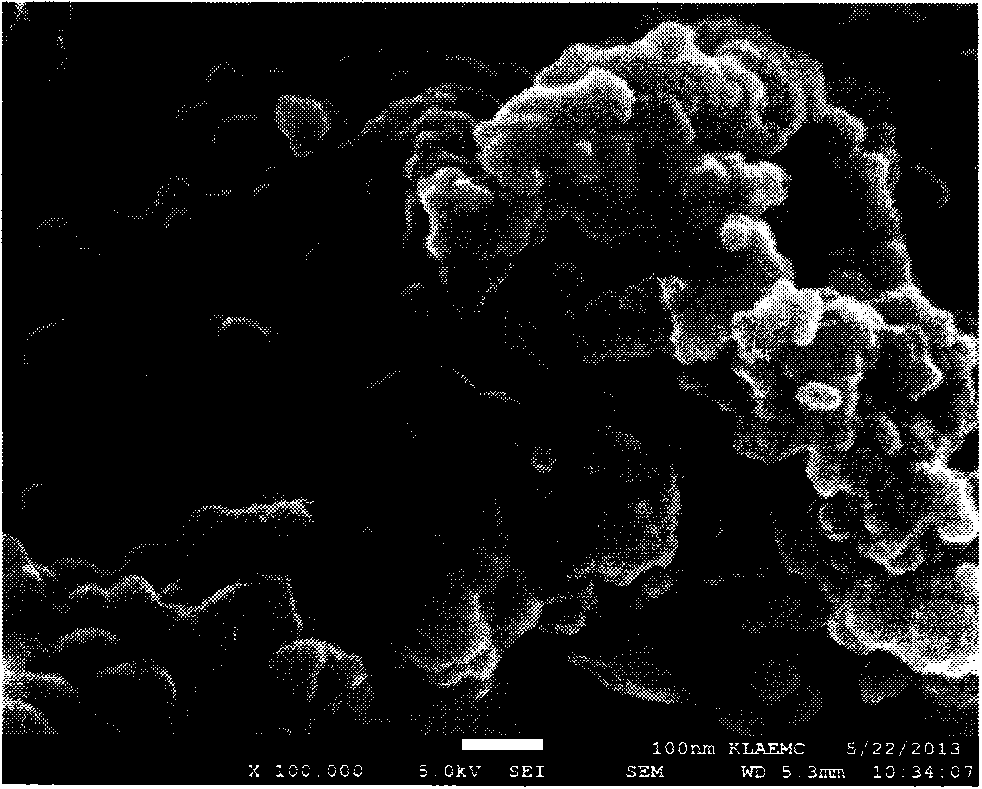

[0017] Slowly add 50 milliliters of oleic acid into 1.5 liters of 0.04 mol / L potassium permanganate solution under stirring. After reacting at room temperature for 24 hours, the obtained solid was filtered, washed and dried. Weigh 0.3 g of the above product, add 100 ml of absolute ethanol, and ultrasonically disperse. Then the solution was transferred to a reaction kettle and reacted at 160° C. for 24 hours. Centrifuge, wash and dry to obtain the product. Product X-ray powder diffraction spectrum ( figure 1 ) is consistent with the standard spectrogram (JCPDS No.24-0734) of manganese ore type trimanganese tetroxide, but a broad diffraction peak of amorphous carbon appears near 20 °; the diffraction peak is wider, indicating that the crystal grains are smaller. The average particle size calculated by the formula is about 11.4nm. From the scanning electron microscope image...

Embodiment 2

[0018] Embodiment 2: the preparation of nanometer trimanganese tetraoxide / carbon (7%) composite material

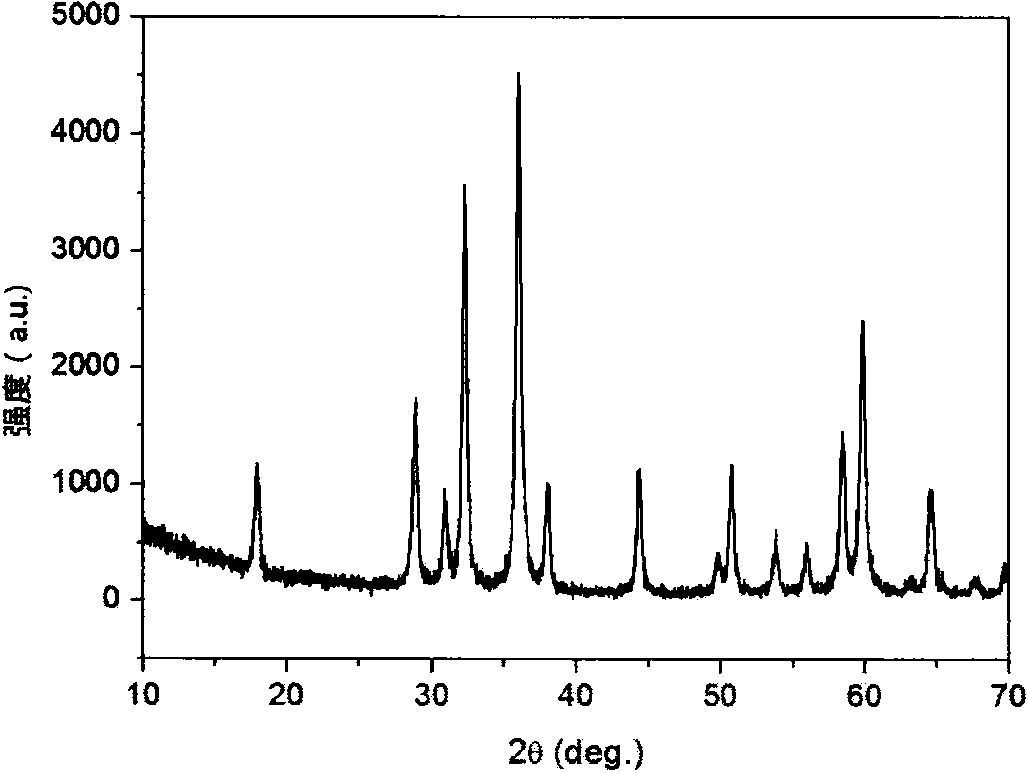

[0019] Weigh 0.3 g of the solid intermediate product obtained in Example 1, add 100 ml of absolute ethanol, and ultrasonically disperse. According to the mass ratio of iodine / manganese dioxide of 1:1, 0.3 g of elemental iodine was added and dissolved. Then the solution was transferred to a reaction kettle and reacted at 160° C. for 24 hours. Centrifugal separation, washing and drying to obtain nanometer trimanganese tetraoxide / carbon composite material. X-ray powder diffraction spectrum ( image 3 ) is consistent with the standard spectrogram (JCPDS No.24-0734) of manganese ore type trimanganese tetroxide; compared with the product of Example 1, the sharpness of the diffraction peak changes shows that crystallinity improves, and the average particle diameter is calculated by Scherrer's formula 27nm. This is because the carbon generated in the reaction is reduced, whic...

Embodiment 3

[0020] Embodiment 3: Electrochemical performance test of trimanganese tetraoxide and trimanganese tetraoxide / carbon composite material

[0021] The electrochemical properties of pure trimanganese tetraoxide and trimanganese tetraoxide / carbon composite were tested at room temperature with a three-electrode system, in which the reference electrode was a saturated calomel electrode and the auxiliary electrode was a platinum electrode. The electrolyte is 1mol / L sodium sulfate solution. The constant current charge and discharge test is carried out with the Blue Electric CT2001A battery test system, and the voltage range is 0-1.0V. The result is as follows:

[0022] (1) by Figure 5 It can be seen that, with a current density of 0.2A / g, the specific capacities of manganese tetraoxide / carbon with 7% and 20% carbon content are 218.2F / g and 207.8F / g, respectively. The curve of voltage versus time has a good mirror symmetry, indicating that the material has good electrochemical rever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com