Wide-temperature-range low-loss Mn-Zn ferrite specially used for solar energy inverter, and preparation method thereof

A manganese-zinc ferrite and inverter technology, which is applied in the field of manganese-zinc ferrite and its preparation, can solve the problems of inability to take into account photovoltaic arrays, low utilization rate of a single photovoltaic array, and poor anti-local shadowing ability of the system, achieving The effects of fine and uniform microscopic grains, low pre-sintering and sintering temperatures, and high-temperature saturation magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

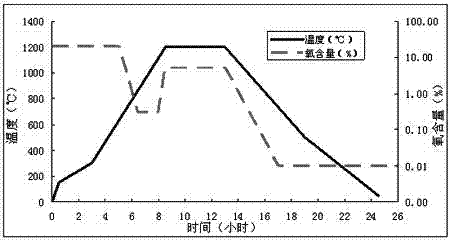

[0030] Weigh 53.7mol% Fe 2 o 3 , 36.5 mol% Mn 3 o 4 and 9.8 mol% ZnO. After mixing the above main components, add them to a sand mill and mix them for 30 minutes. After spray drying, send them to the rotary kiln for pre-calcination at 900°C±10°C for 45 minutes. Then add auxiliary components to the calcined material and put them into a sand mill for crushing. The crushing time is 120 minutes. After crushing, the particle size of the slurry is controlled at 1.0-1.5 μm; The content of material (wt%) is respectively: CaCO 3 : 0.03, Nb 2 o 5 : 0.005, V 2 o 5 : 0.02, Co 2 o 3 : 0.10. In the process of mixing sand milling and crushing sand milling, it is necessary to add pure water equivalent to 35 wt % of the total amount of main components, as well as some dispersants and defoamers (subject to the set particle size range). Finally, 1.5% of PVA equivalent to the weight of the slurry is added to the sanding slurry, and then the manganese zinc ferrite particles are obtaine...

Embodiment 2~6

[0037] As shown in Table 1, except Fe as the main component 2 o 3 The composition ranges from 53.5mol% to 54.5mol% and the composition of ZnO varies from 8.0mol% to 10.0mol%, and the rest is trimanganese tetraoxide. The rest of the process is carried out in the same manner as in Example 1. After the above-mentioned main components are mixed, they are mixed in a sand mill and mixed for 30 minutes. After being sprayed and dried, they are sent to a rotary kiln and pre-fired at a temperature of 900°C ± 10°C. 45 minutes. Then add auxiliary components to the calcined material and put them into a sand mill for crushing. The crushing time is 120 minutes. After crushing, the particle size of the slurry is controlled at 1.0-1.5 μm; The content of material (wt%) is respectively: CaCO 3 : 0.03, Nb 2 o 5 : 0.005, V 2 o 5 : 0.02, Co 2 o 3 : 0.10. In the process of mixing sand milling and crushing sand milling, it is necessary to add pure water equivalent to 35wt% of the total amou...

Embodiment 7~8

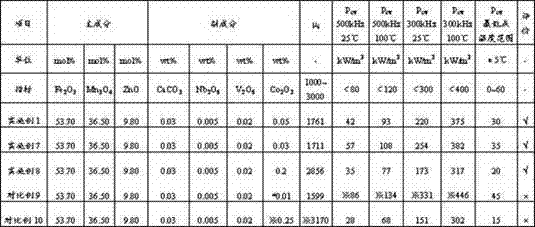

[0057] As shown in Table 2, Fe as the main component 2 o 3 , ZnO, Mn 3 o 4 Content is all identical with embodiment 1, changes the content of the subcomponent cobalt oxide as additive, to its normal temperature initial magnetic permeability μ i , Power loss P at 25°C and 100°C under the conditions of 500kHz, 50mT and 300kHz, 100mT cv characteristics, power loss P cv The lowest point temperature was studied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com