Thin film magnet, cylindrical ferromagnetic thin film and production method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

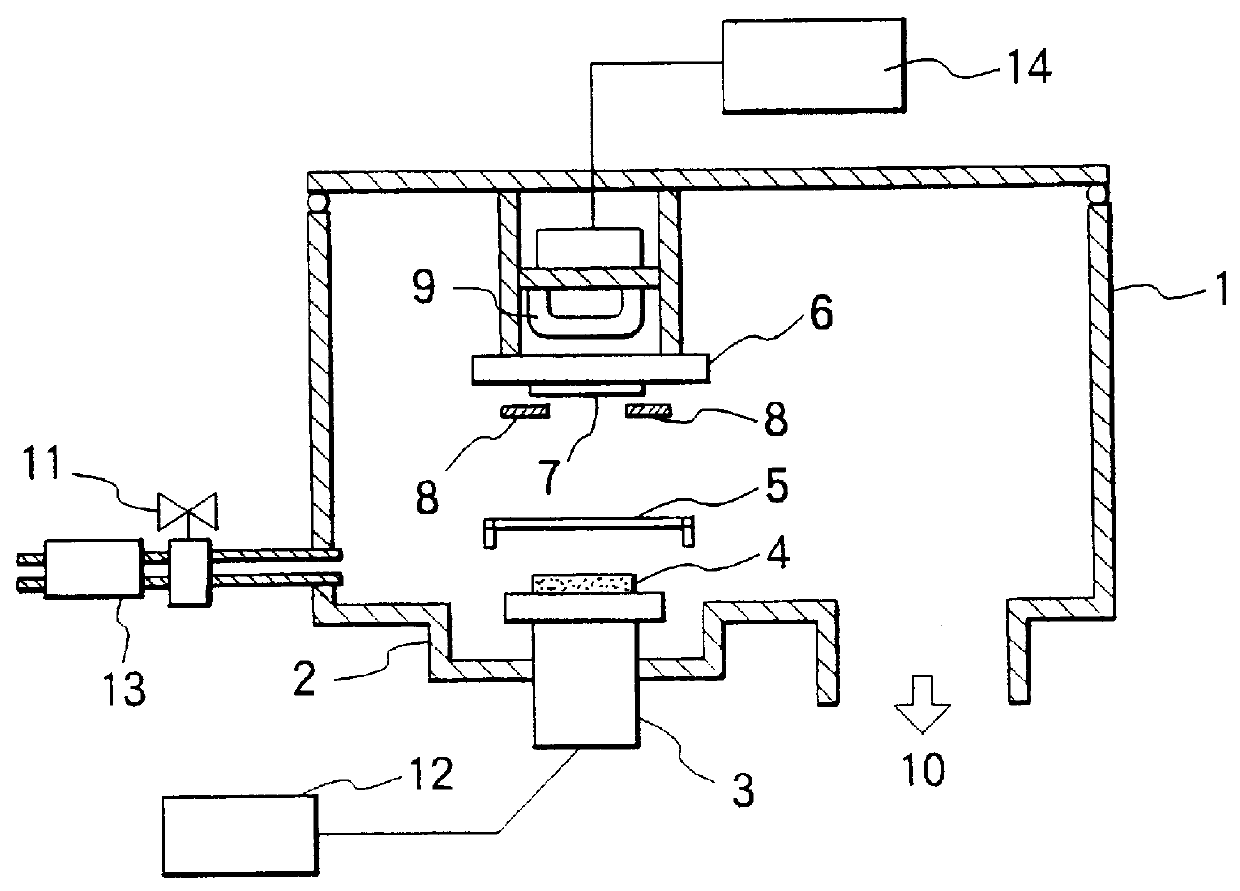

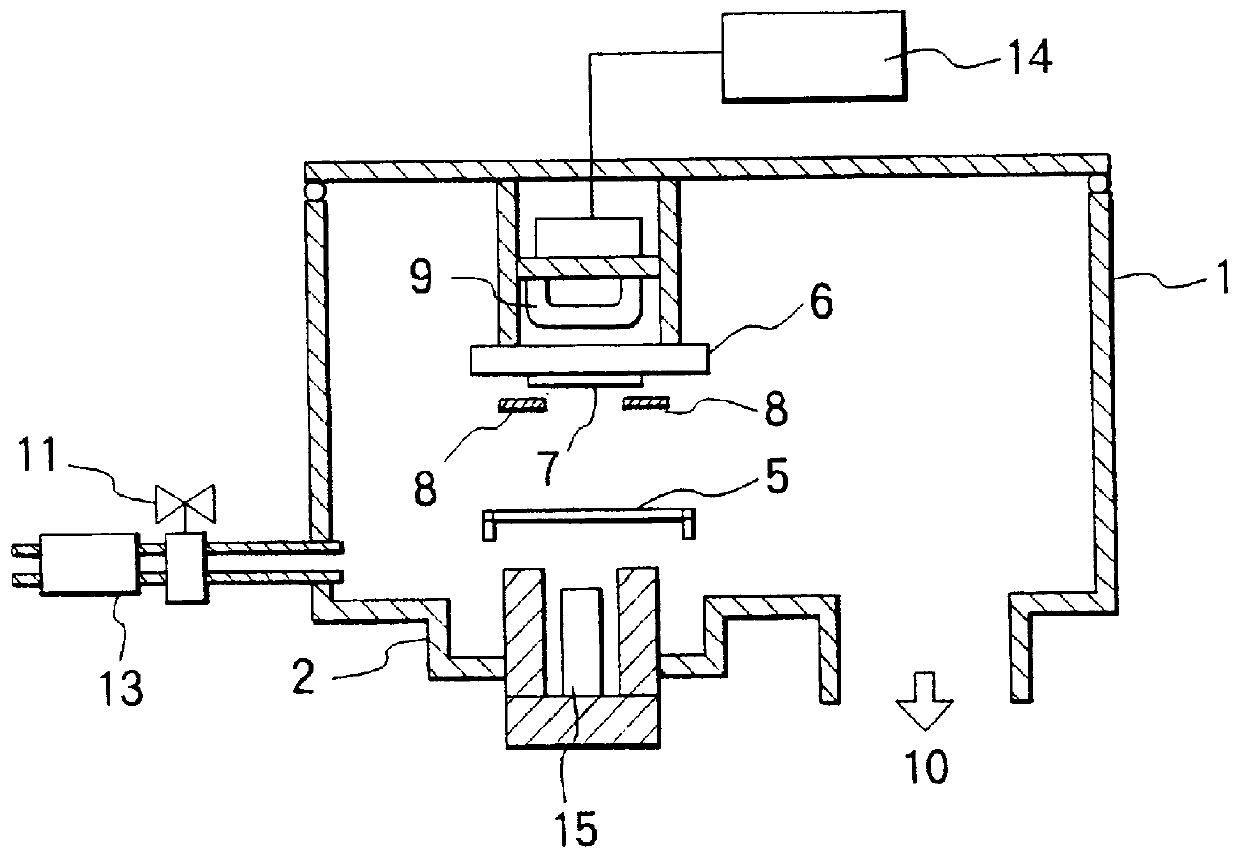

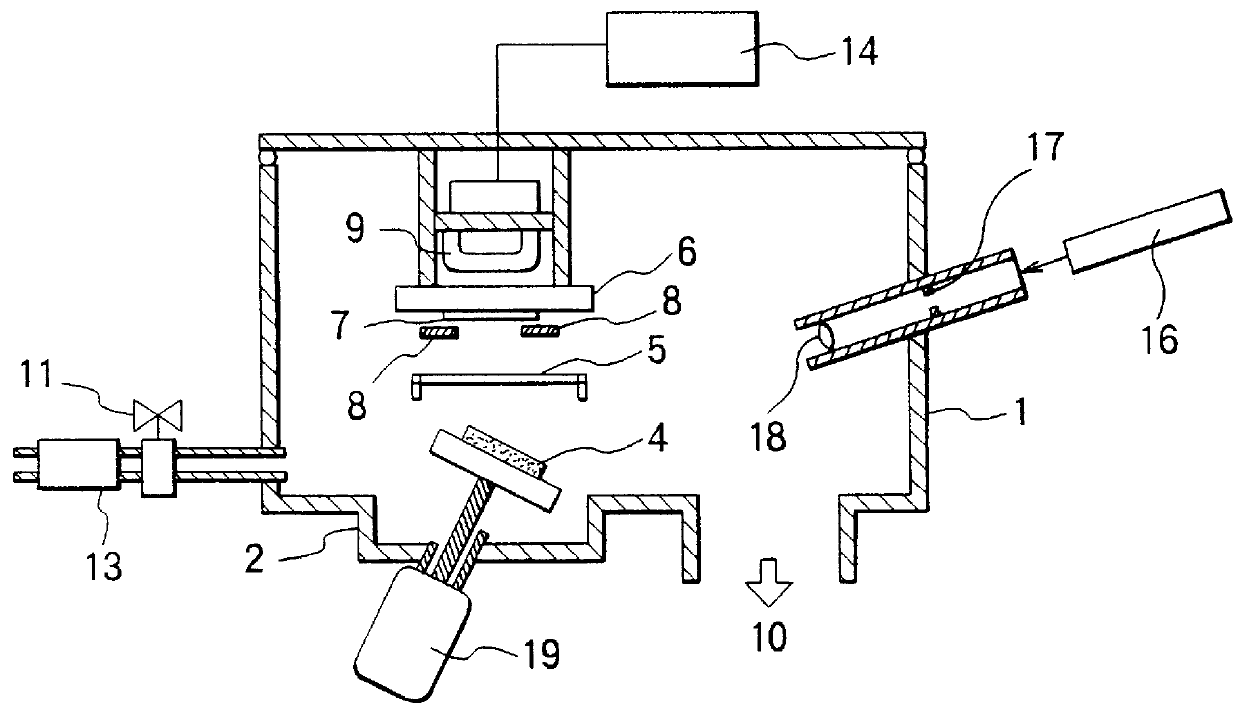

In the film deposition apparatus shown in FIG. 4, Nd--R (R is Tb, Ho, or Dy) serving as the target 4a, Fe metal as the target 4b, and an FeB alloy as the target 4c were attached to the cathode electrodes 3a, 3b, and 3c, respectively. The target 4a was made in such a manner that R metal chips having dimensions of 5 mm.times.5 mm.times.1 mm (thickness) was disposed on a 3 inch diameter Nd metal target. A 12 mm.times.12 mm.times.0.5 mm (thickness) quartz glass substrate was attached to the rotating substrate holder 20. The inside of the vacuum chamber 1 was then evacuated to a pressure less than 1.times.10.sup.-4 Pa via the pumping system 10. The substrate 7 was then heated by the heater 9 up to 590.degree. C.

After the temperature of the substrate 7 became stable, Ar gas was introduced into the vacuum chamber 1, and the gas pressure was maintained at 8 Pa. Substrate holder 20 was rotated by the motor 21. While maintaining the shutters 5a, 5b, and 5c in a closed state, voltages were app...

example 2

The film deposition apparatus shown in FIG. 4 was used, and Nd--Tb, M .[.fie--Co,.]. .Iadd.(Fe--Co, .Iaddend.Fe--Ni, or Fe--Co--Ni alloy), and an FeB alloy were employed as the targets 4a, 4b, and 4c, repectively. (Nd.sub.0.93 Tb.sub.0.07).sub.y M.sub.1-y-z B.sub.z thin film magnets having a thickness of about 2 .mu.m were formed on quartz glass substrates according to a procedure similar to that in Example 1 wherein the substrate temperature, the Ar gas pressure, and the deposition rate were 590.degree. C. 8 Pa, and 8 .mu.m / hr, respectively.

Table 6 shows the resultant magnetic characteristics measured perpendicular to the film plane for obtained thin film magnets. As can be seen from Table 6, the films show magnetic characteristics which are basically similar to those of the (Nd.sub.0.93 Tb.sub.0.07).sub.y Fe.sub.1-y-z B.sub.z thin film magnets described above with slight differences in the magnetic characteristics being observed depending on the changes in the Co and Ni compositio...

example 3

The film deposition apparatus shown in FIG. 4 was used. Nd-Tb, Fe metal, and an FeB alloy were employed as the targets 4a, 4b, and 4c, respectively, and (Nd.sub.1-x Tb.sub.x).sub.y Fe.sub.1-y-z B.sub.z thin film magnets having a thickness of about 2 .mu.m were formed on quartz glass substrates in a manner similar to that in Example 1, wherein the substrate temperature, the Ar gas pressure, and the deposition rate were 510.degree. to 590.degree. C. 8 Pa, and 8 .mu.m / hr, respectively.

FIG. 7 shows the magnetic characteristics of the thin film magnets obtained as a function of the substrate temperature upon. From FIG. 7, it can be seen that if a substrate temperature in the range from 530.degree. to 570.degree. C. is employed, it is possible to obtain particularly high coercive force and thus a large maximum energy product greater than at lease 140 kJ / m.sup.3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com