Method for manufacturing dry-pressing formed sintered permanent ferrite

A permanent magnet ferrite, dry pressing forming technology, applied in the field of magnetic material manufacturing, can solve the problems of difficult automatic forming, product density reduction, complex forming molds, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

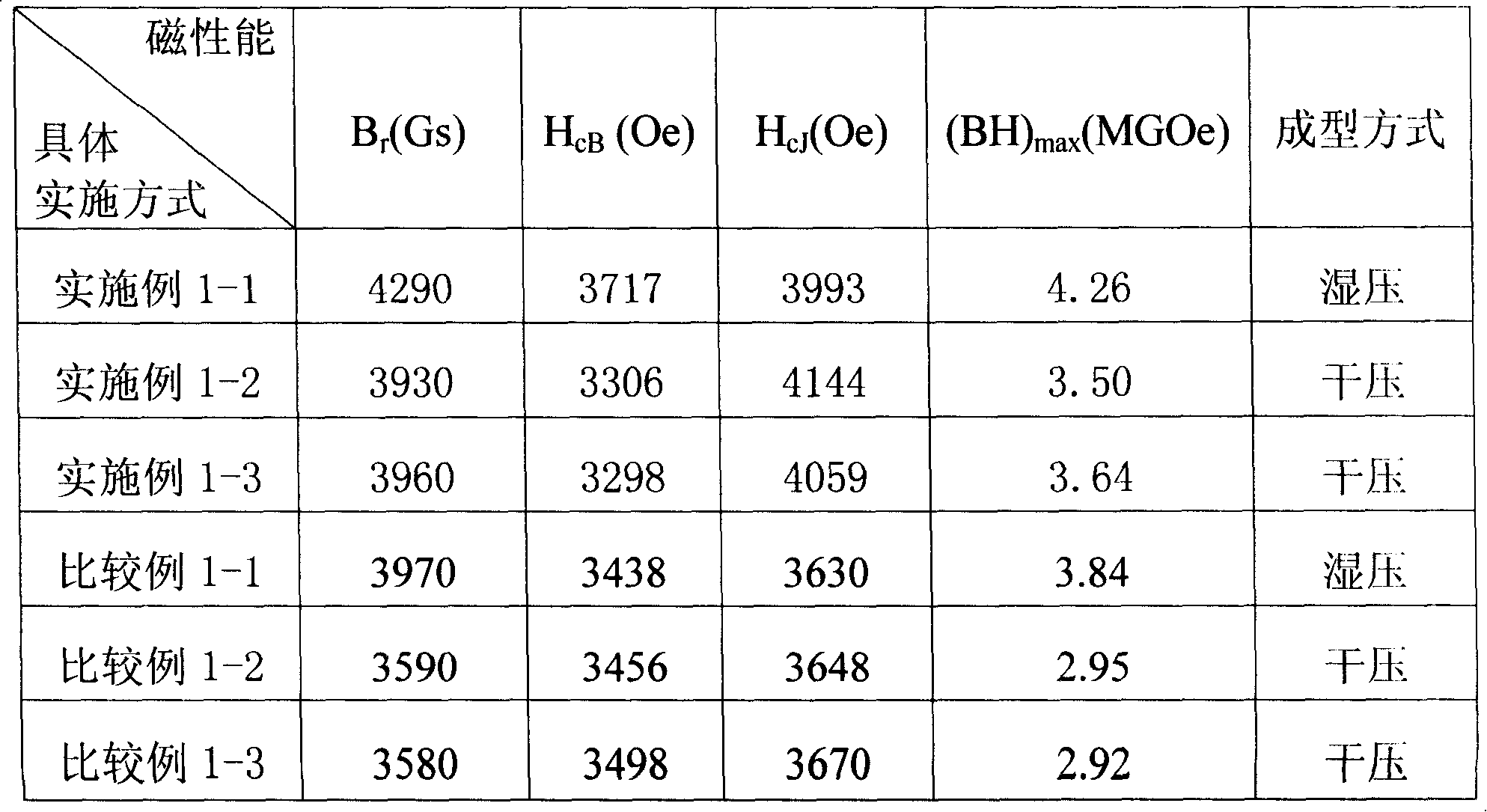

Embodiment 1

[0025] The molecular formula is [Sr 1-x La x [(Fe 3+ a Fe 2+ b ) 12-y co y ]O 19 , where a+b is equal to 1; z is 0.9~1.1; a is 0.97~0.999, b is 0.001~0.03; the range of x and y is: 02 , 0.75wt% CaCO 3 , 18 hours of wet pulverization was carried out in a high-efficiency ball mill, the ratio of ball water to water was set at 1:15:1.2, and the average particle size of the pulverized slurry particles was 0.8 μm.

[0026] Dry the above slurry at a constant temperature of 130°C for 24 hours, weigh 1.6kg of block material, then add 0.8wt% ground camphor powder and 0.5wt% calcium stearate, and fully stir for 5min by a high-speed mixer, A dry-pressed magnetic powder suitable for dry-pressed molding is obtained. The moisture detection content of the dry-pressed magnetic powder is 0.8wt%.

[0027] The above-mentioned dry-pressed magnetic powder is subjected to magnetic field forming, and a forming magnetic field of 10000 Oe is applied in the pressing direction. The obtained mo...

Embodiment 2

[0037] The molecular formula is [Sr 1-x La x [(Fe 3+ a Fe 2+ b ) 12-y co y ]O 19 , where a+b is equal to 1; z is 0.9~1.1; a is 0.97~0.999, b is 0.001~0.03; the range of x and y is: 02 , 0.75wt% CaCO 3 and different contents of polyethylene glycol (PEG800), followed by wet pulverization in a high-efficiency ball mill for 20 hours, and the ratio of material ball to water is set to 1:15:1.2.

[0038] Dry the above slurry at a constant temperature of 130°C for 24 hours, weigh 1.6kg of block material, then add 1.0wt% of ground camphor powder and 0.5wt% of calcium stearate, and fully stir for about 5min with a high-speed mixer , to prepare dry-pressed magnetic powder for dry-pressing. The moisture detection content of the dry-pressed magnetic powder is 0.7wt%.

[0039] The above-mentioned dry-pressed magnetic powder is subjected to magnetic field forming, and a forming magnetic field of 8000 Oe is applied in the pressing direction. The obtained molded body was a cylinder...

Embodiment 3

[0045] The molecular formula is [Sr 1-x La x [(Fe 3+ a Fe 2+ b ) 12-y co y ]O 19 , where a+b is equal to 1; z is 0.9~1.1; a is 0.97~0.999, b is 0.001~0.03; the range of x and y is: 02 , 0.75wt% CaCO 3 , followed by wet pulverization in a high-efficiency ball mill for 20 hours, the ratio of the ball to water was set to 1:15:1.2, and the average particle size of the pulverized slurry particles was 0.8 μm.

[0046] Dry the above-mentioned slurry at a constant temperature of 130°C for 24 hours, weigh 1.6kg / part of block material, first carry out coarse crushing, and then directly add 0.6wt% of ground camphor powder and 0.5wt% of Calcium stearate, for the other part, first dissolve the above-mentioned binder completely in analytical pure alcohol, then add the alcohol solution of the above-mentioned binder to the powdery magnetic powder in the form of spray, and then use a high-speed mixer to The above mixture was fully stirred for about 5 minutes to obtain a dry-pressed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| molding pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com