Patents

Literature

194results about How to "Improve intrinsic coercive force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

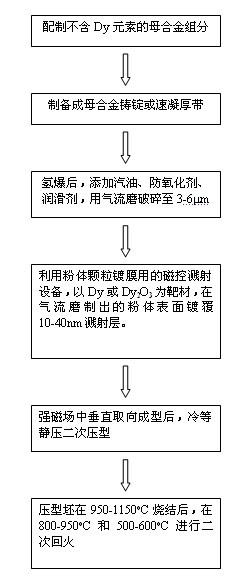

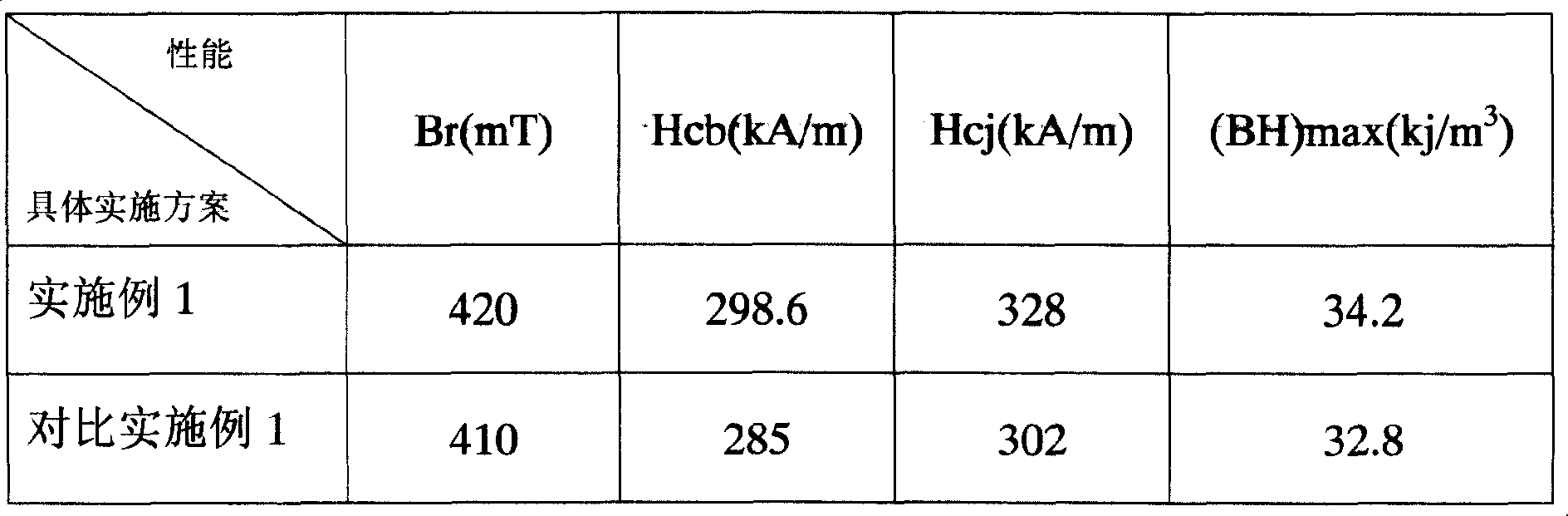

A preparation method of high-performance sintered NdFeB with low dysprosium content

The invention discloses a method for preparing sintered NdFeB with low dysprosium (Dy) content and high performance; the method comprises the following steps of: sputtering and plating the Dy element on the surface of jet mill powder by using the powder plate technology based on magnetron sputtering on the basis of preparing NdFeB powder, and then sufficiently dispersing the Dy element to micron-sized NdFeB crystal particles by dispersing the Dy element at high temperature in the sintering and tempering process, thereby achieving the effect of improving magnetic performance of the sintered NdFeB. Compared with the introduction of the Dy element in the proportioning process of the prior art, the method disclosed by the invention has the advantages: the low dysprosium content and high performance is limited in the nano-size by adopting the physical gas-phase deposition, the consumption quantity of the Dy element during the production process is controlled effectively and the preparationof sintered NdFeB with low dysprosium content and high performance is realized. Compared with the sintered NdFeB of the same components prepared by the traditional casting and powder metallurgy process, both the intrinsic coercivity and the maximum magnetic energy product of the sintered NdFeB rare-earth permanent magnetic material obtained according to the invention are improved obviously; compared with the sintered NdFeB with the same performance prepared by the traditional casting and powder metallurgy process, the dosage of the dysprosium element is reduced remarkably. The method can be widely applicable to producing and manufacturing sintered NdFeB with high performance.

Owner:NANJING UNIV OF SCI & TECH +1

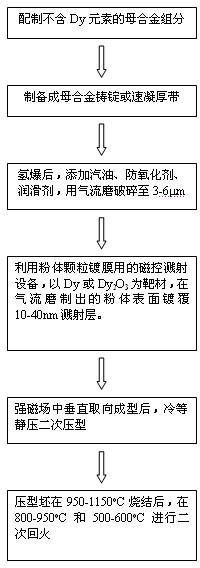

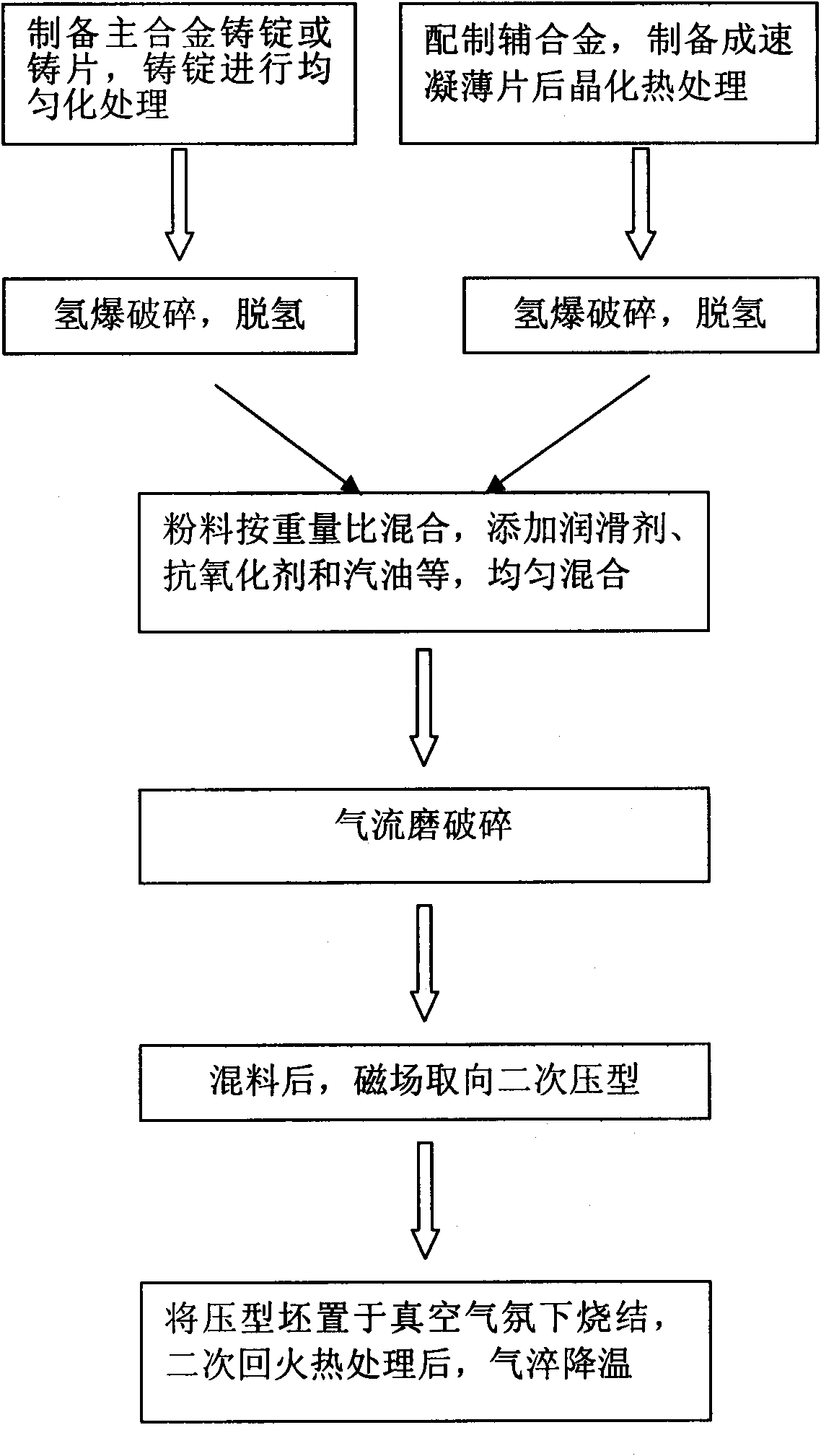

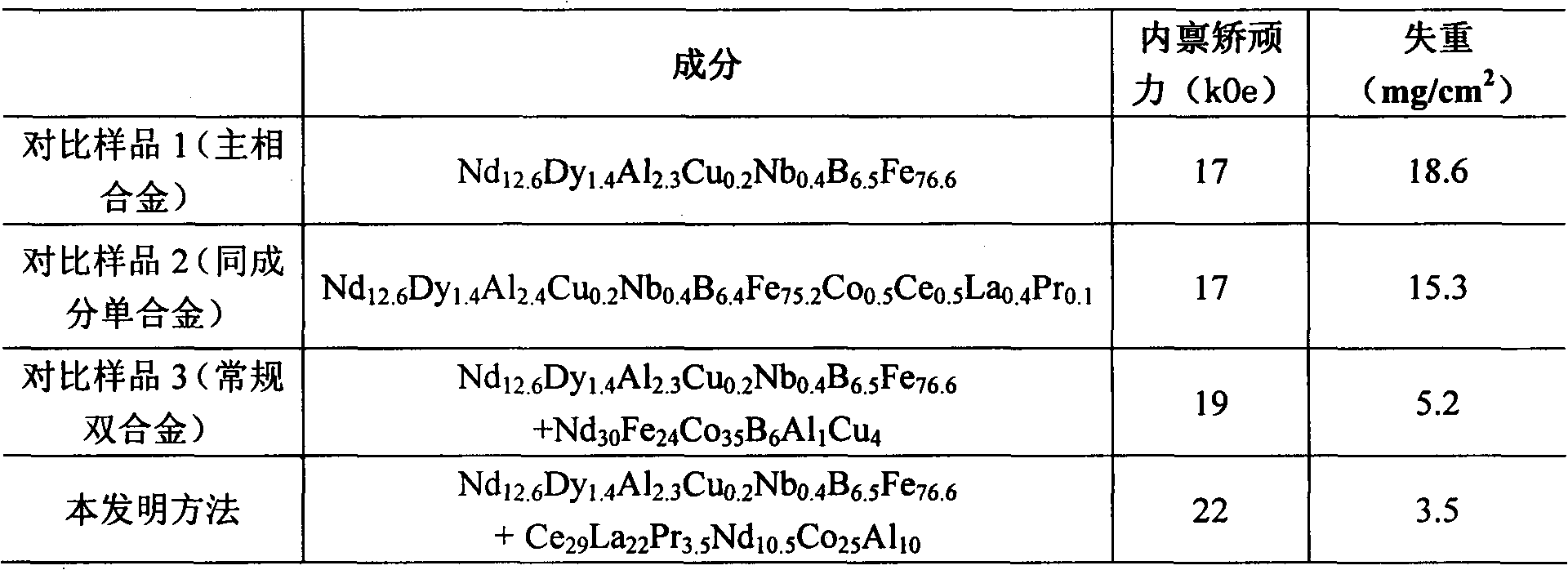

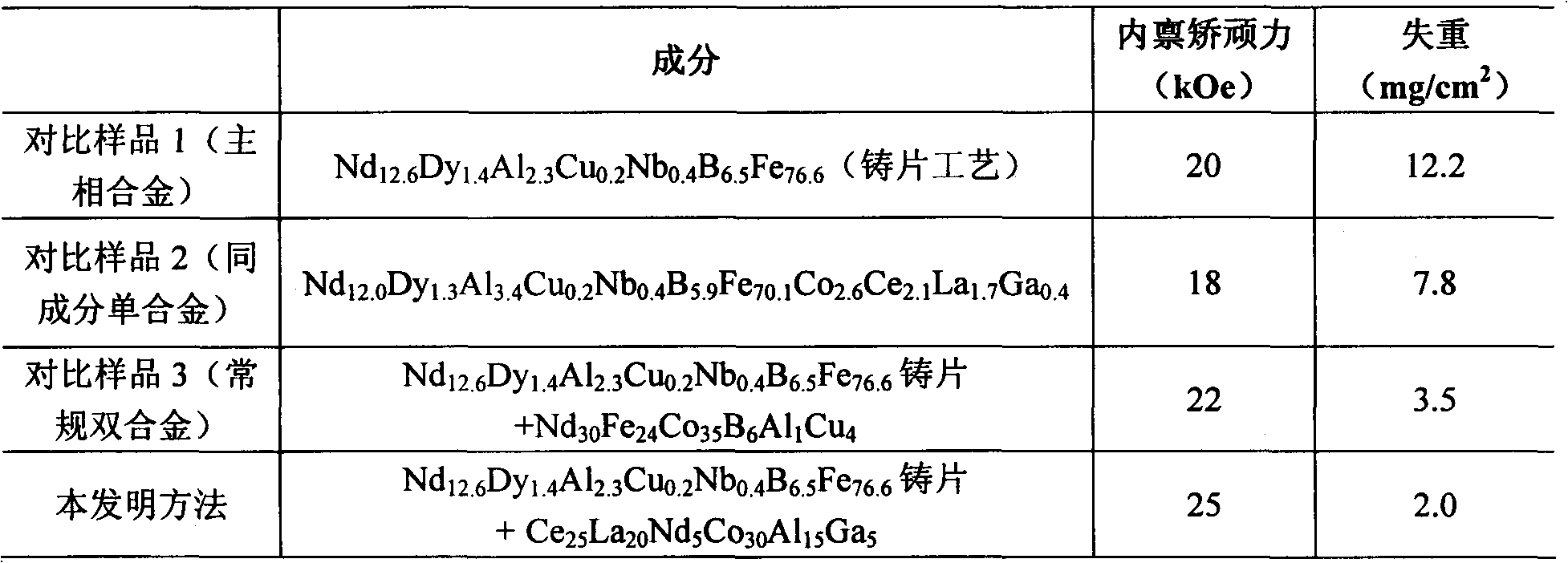

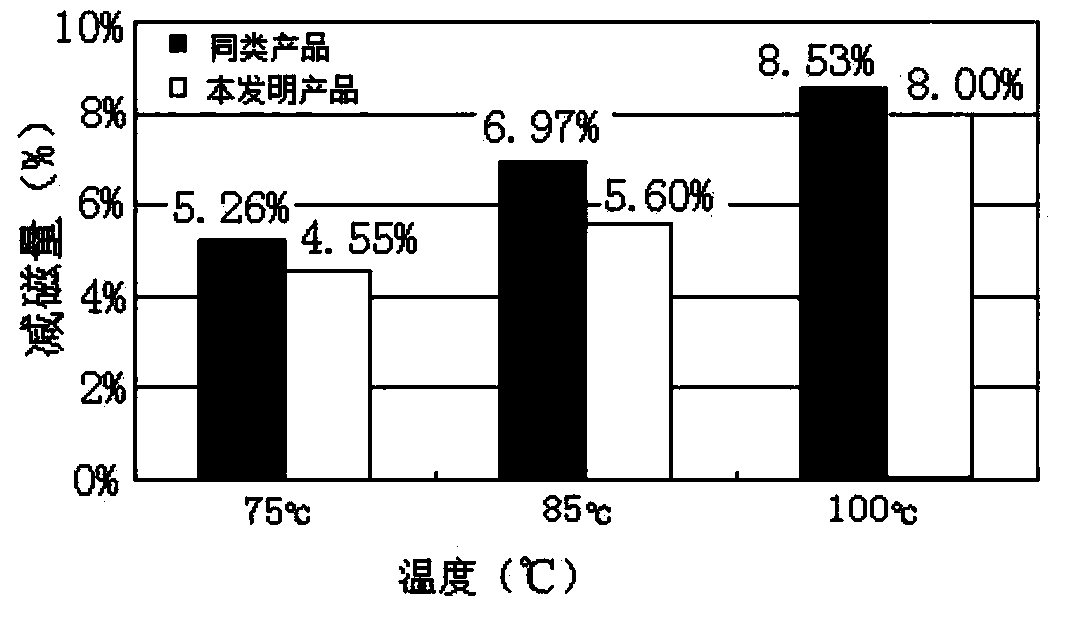

Sintered neodymium-iron-boron preparation method capable of improving intrinsic coercivity and anticorrosive performance

ActiveCN102220538ALow cooling rate requirementsEnhanced Amorphous Formation AbilityInorganic material magnetismAlloyGas quenching

The invention discloses a sintered neodymium-iron-boron preparation method capable of improving intrinsic coercivity and anticorrosive performance. On the basis of a double-alloy preparation process, Ce-enriched multicomponent rare-based alloy with high amorphous forming ability is used as an auxiliary alloy, and the decrystallizatoin of crystal boundary phase structure is realized by gas quenching cooling in a sintering tempering process. In the invention, the intrinsic coercivity is obviously improved, the anticorrosive weight loss is greatly reduced, the magnetic performance and anticorrosive performance are high, and the method can be widely used in the field of production of high-performance anticorrosive sintered neodymium-iron-boron material.

Owner:NANJING UNIV OF SCI & TECH +1

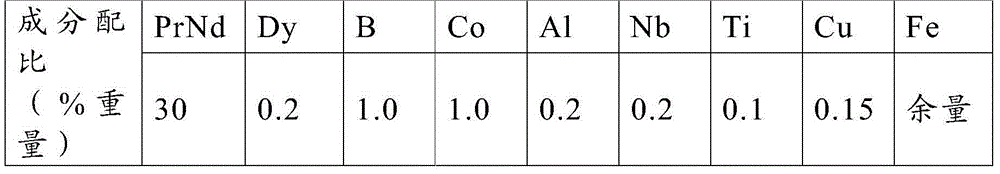

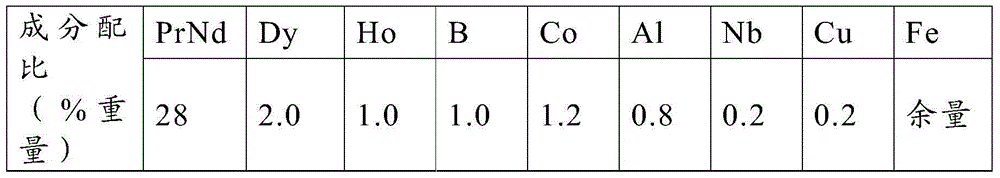

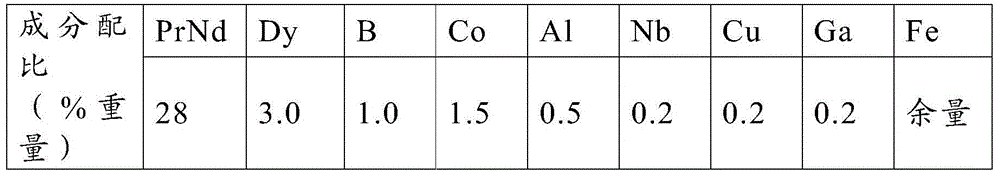

NdFeB magnet and preparation method thereof

ActiveCN104064346AReduce usageImprove intrinsic coercive forceInductances/transformers/magnets manufactureMagnetic materialsHolmiumGranularity

The invention relates to an NdFeB magnet and belongs to the technical field of rare earth magnetic materials. The NdFeB magnet is prepared by sintering a mixture of main phase alloy powder with the granularity of 2-5 <Mu>m, heavy rare earth alloy powder with the granularity of 1-2 <Mu>m and superfine powder with the granularity of 0.1-1.5 <Mu>m, which are mixed at the mass percents of 85-99.8, 0.1-10 and 0.1-5 respectively, the heavy rare earth alloy is one or more of dysprosium hydride and dysprosium-ferrum hydride compound, a holmium hydride and holmium-ferrum hydride compound and terbium hydride and terbium-ferrum hydride compound. The invention further provides a preparation method of the NdFeB magnet. According to the invention, 10-40 percent of heavy rare earth is saved, and the intrinsic coercive field of the NdFeB magnet is increased greatly without reducing the effect of residual magnetism.

Owner:宁波同创强磁材料有限公司

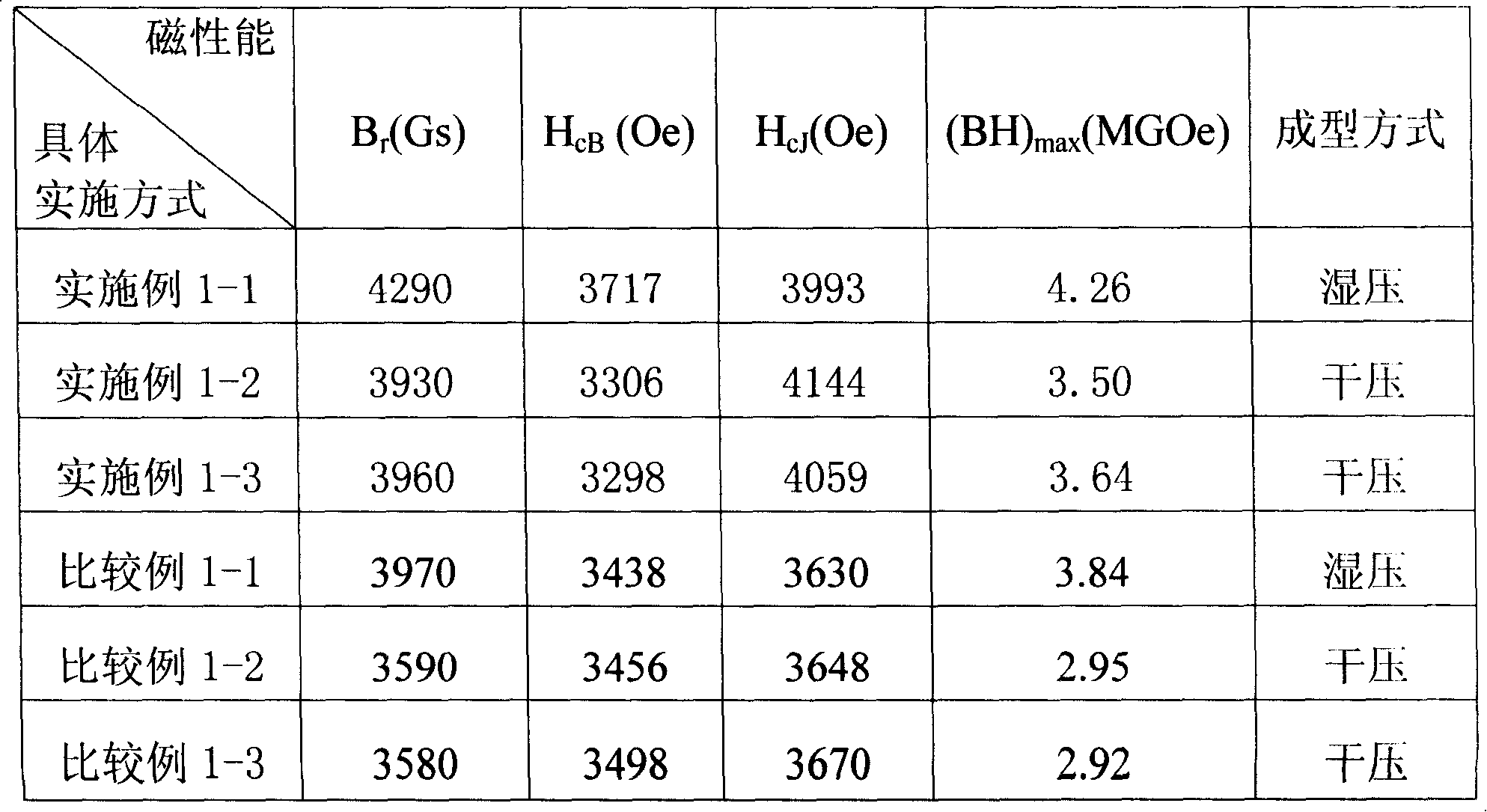

Permanent ferrite magnetic tile and preparation method thereof

InactiveCN101202138AIncrease solid solutionImprove performancePermanent magnetsInorganic material magnetismFiberSilicon oxide

The invention relates to a permanent ferrite magnetic arc and the manufacturing method thereof, belonging to a manufacturing field of a motor permanent ferrite. Weight proportions of main material components and additive components are as the following: main materials: 8.7 to 9.0 percent of strontium oxide; 86 to 87 percent of iron oxide red; additives: 0.6 to 1.0 percent of calcium carbonate; 0.6 to 1.0 percent of aluminum oxide; 0.4 to 0.8 percent of chrome oxide; 0.3 to 0.6 percent of boric acid; 0.3 to 0.5 percent of silicon oxide; 0.2 to 0.4 percent of cobalt oxide; 0.2 to 0.4 percent of lanthanum oxide and 0.1 to 0.3 percent of silicate fiber. The invention is provided with high surplus magnetic induction strength and high intrinsic coercivity so as to enhance a mechanical strength of the magnetic arc.

Owner:CHANGZHOU DIER MAGIC MATERIALS

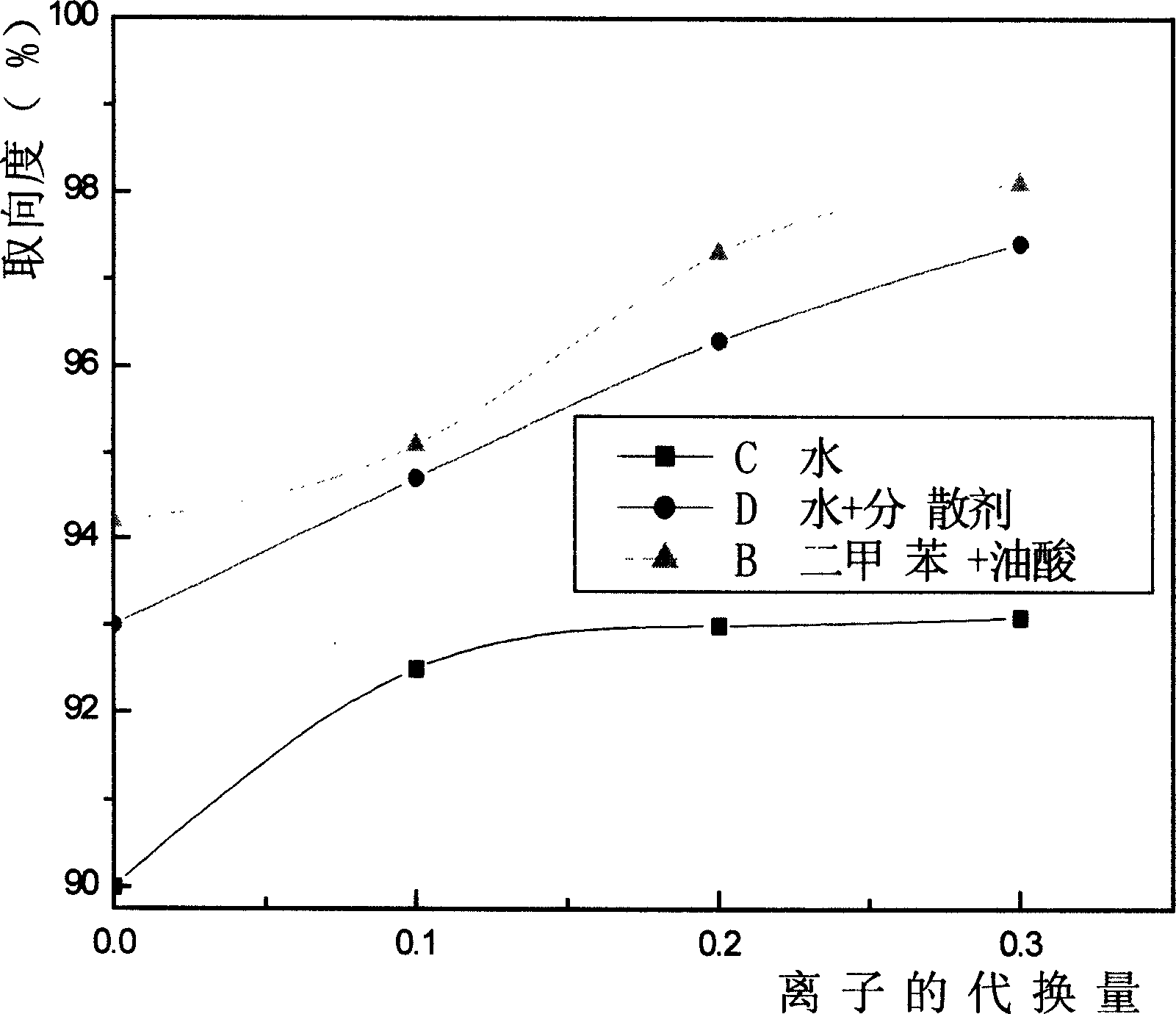

Method for manufacturing dry-pressing formed sintered permanent ferrite

InactiveCN101205137AIncrease productivityEasy to realize automatic moldingMetallurgyPolyethylene glycol

The invention relates to a manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding. The method comprises following working procedures: crushing process, the preparation process of dry pressing the magnetic powder, dry pressing process and sinter process. The organic dispersant added in the crushing process is one or a plurality among polyethylene glycol, calcium stearate and calcium gluconate, and the content of the organic dispersant is 0.1wtpercent-1.5wtpercent; the bond added in the he preparation process of dry pressing the magnetic powder is one or a plurality among PVA, polyethylene glycol, camphor and stearate, and the content of the bond is 0.1wtpercent-1.5wtpercent. 1. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention has the advantages of that the productivity effect is high, the molding mould is simple and the automation molding is easy to be realized; the surface of the molded finished product is lubricous and even, the fettling is not needed, and the workload of the post processing is decreased greatly; 2. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention adopts the unique preparation technique of dry pressing the magnetic powder, and the orientation in the process of magnetic field press is relatively good, and the high Br and high HCJ dry-pressing sintering permanent magnetism ferrite is easy to be gained; 3. The manufacturing method of sintering permanent magnetism ferrite by dry-pressing molding of the invention adopts the pre-sintering material with a better performance of ion substitutional main prescription, and a dry-pressing anisotropic sintering permanent magnetism ferrite with a better magnetism performance can be achieved.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

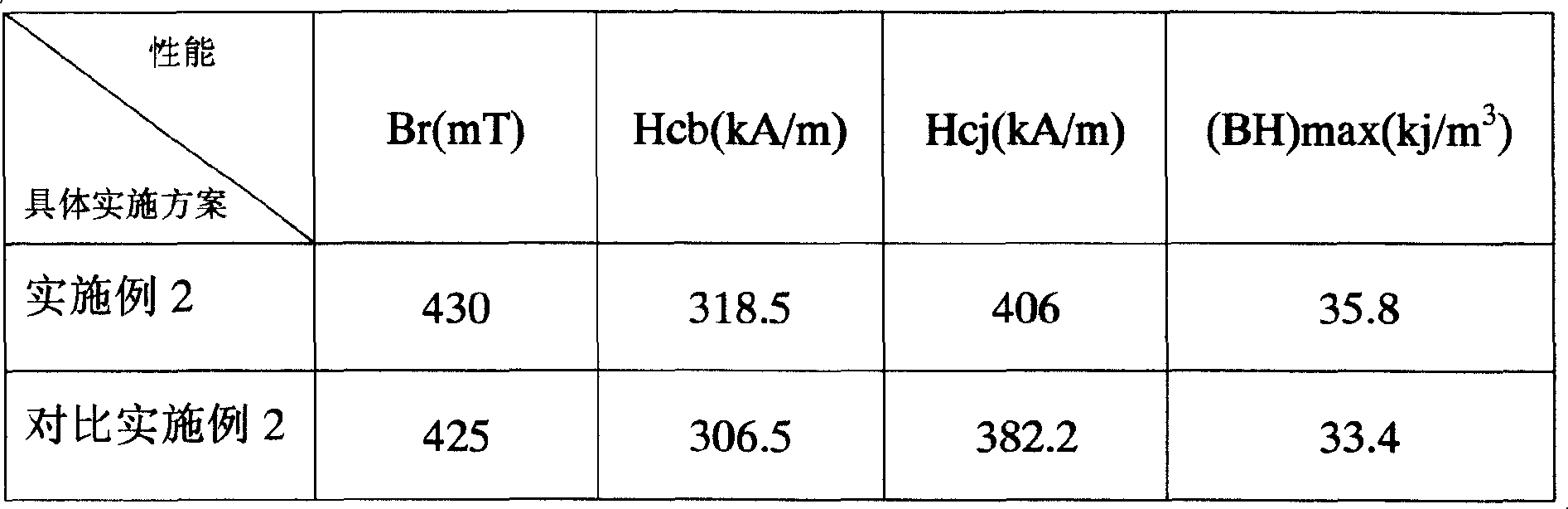

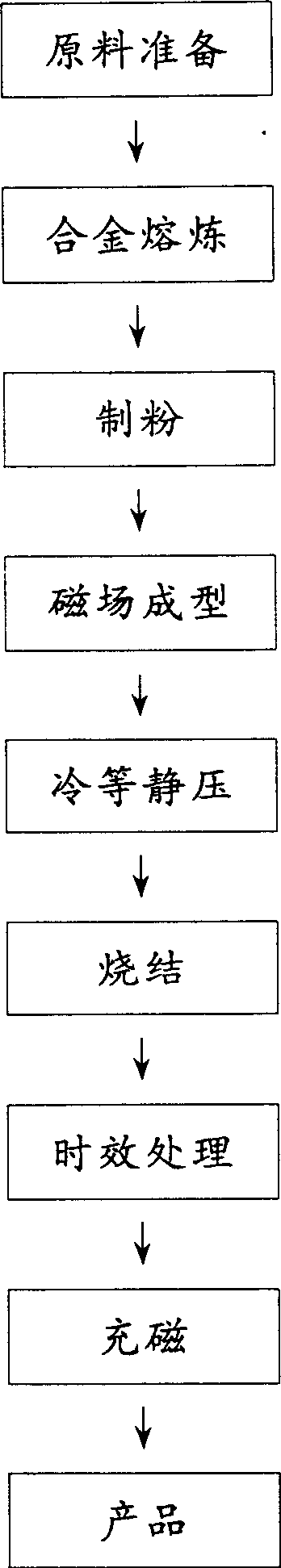

Preparation method of rare earth permanent magnet

ActiveCN104112580APhase and composition stabilityEasily brokenInductances/transformers/magnets manufactureMagnetic materialsRare earthAlloy

A preparation method of a rare earth permanent magnet includes a magnet blank preparing procedure which does not include tempering, a penetrant material coating procedure and a thermal processing procedure. The magnet blank preparing procedure refers to magnet blank preparing through material preparing, alloy smelting, powder crushing, forming and sintering. The penetrant material coating procedure includes preparing penetrant material powder, turning the penetrant material powder into coating solution, coating the magnet blank in the coating solution, and the like. The method has the advantages that rare earth intermetallic compounds are used as diffusion materials, the rare earth intermetallic compounds are stable in phase and component, easy to crush and wide in phase element range, and the phase elements can be adjusted according to magnet performance to form the components of the rare earth intermetallic compounds; the boundary characteristics of crystal boundary and interaction of the crystal boundary and main phase crystal particles can be improved, the internal coercivity of sintered NdFeB magnet is increased, and few residual magnetism and maximum magnetic energy product reduction is achieved.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

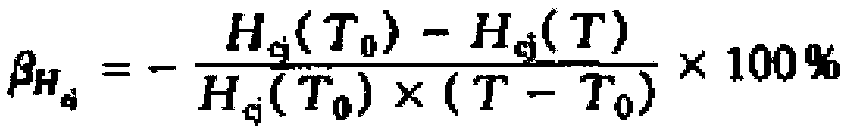

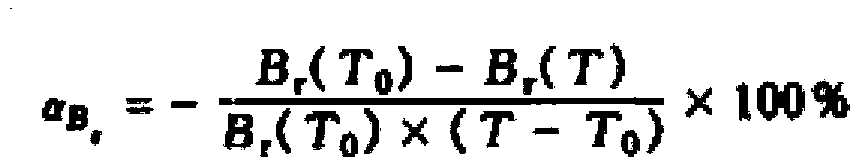

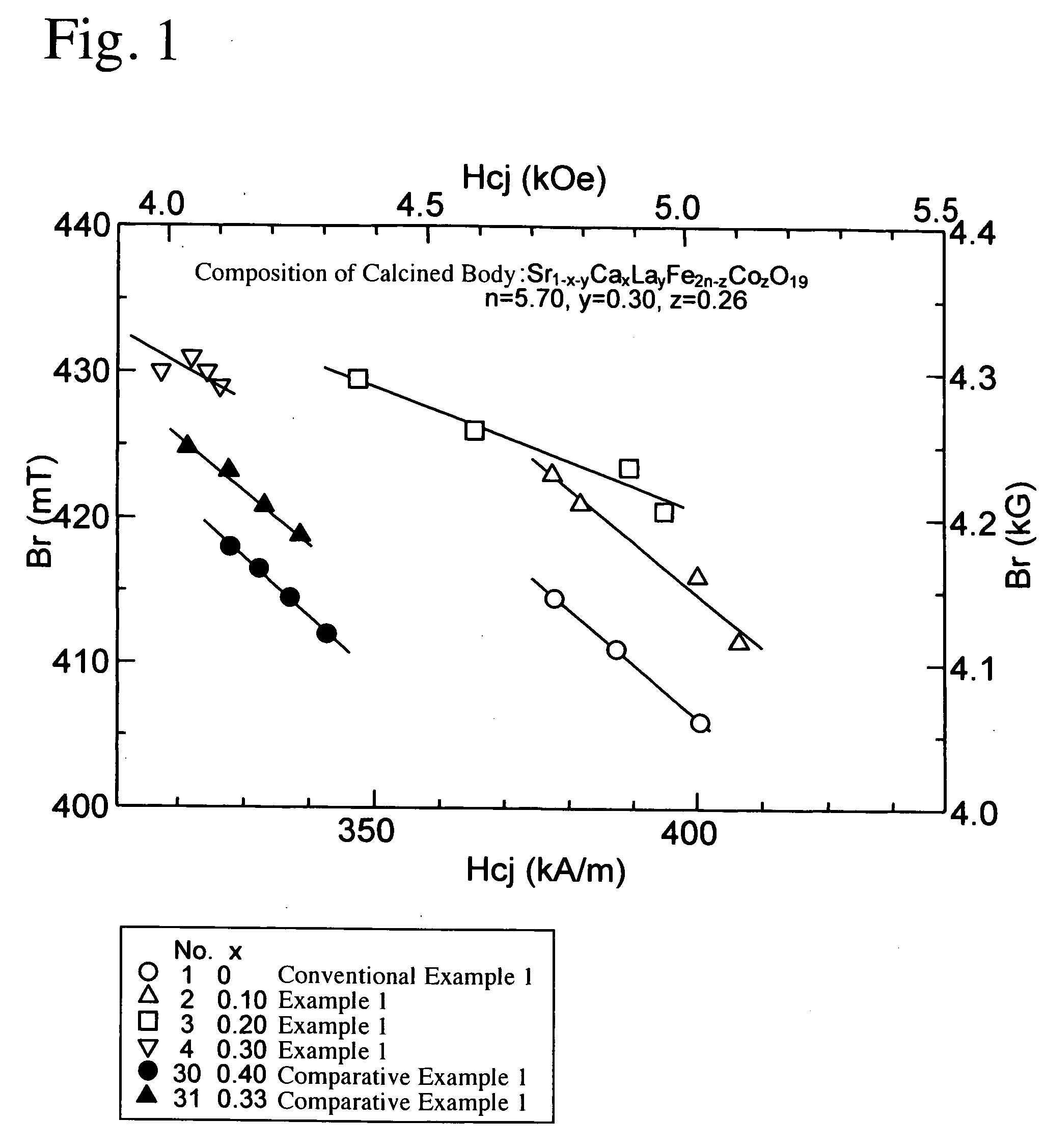

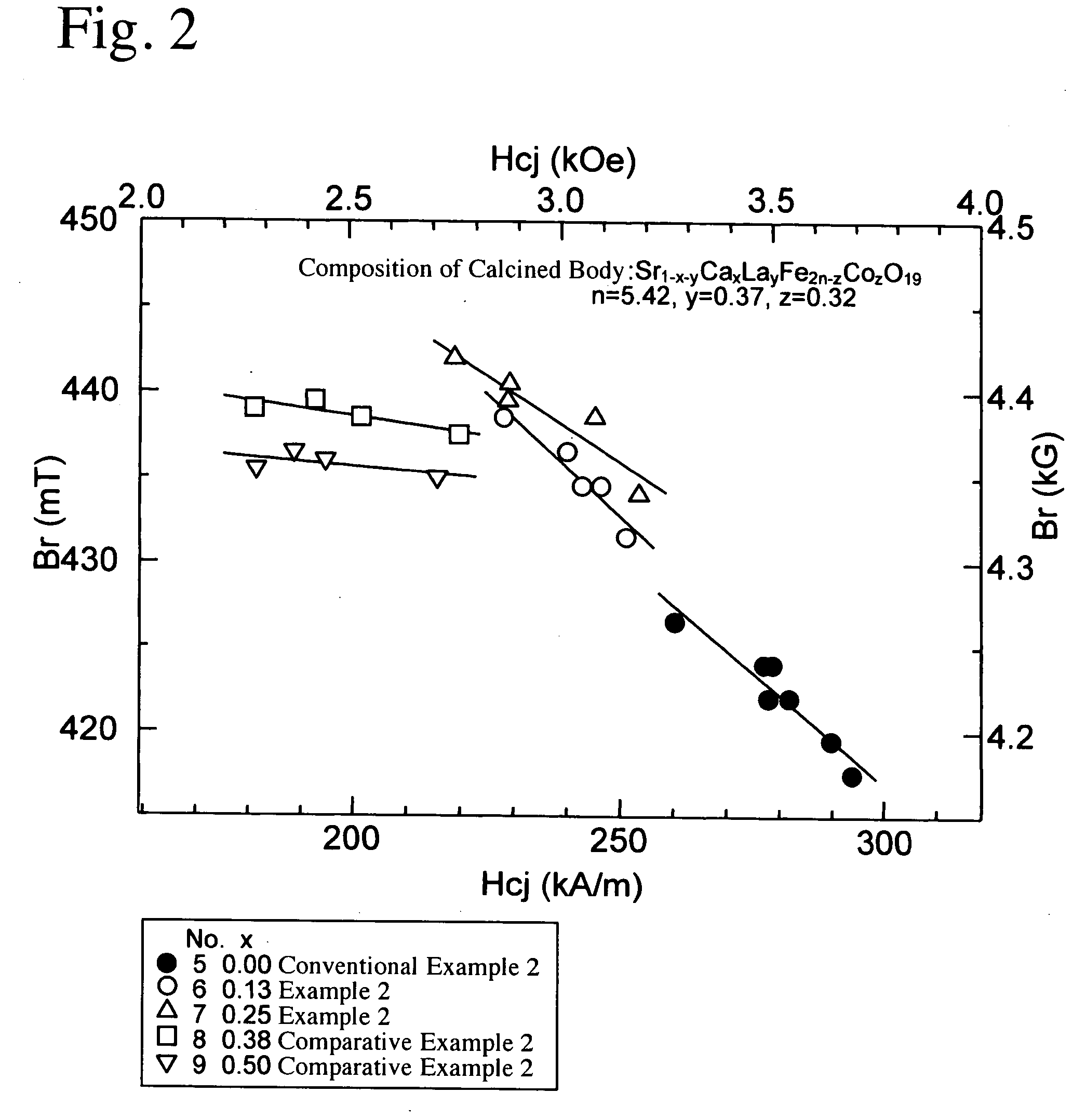

Ferrite sintered magnet

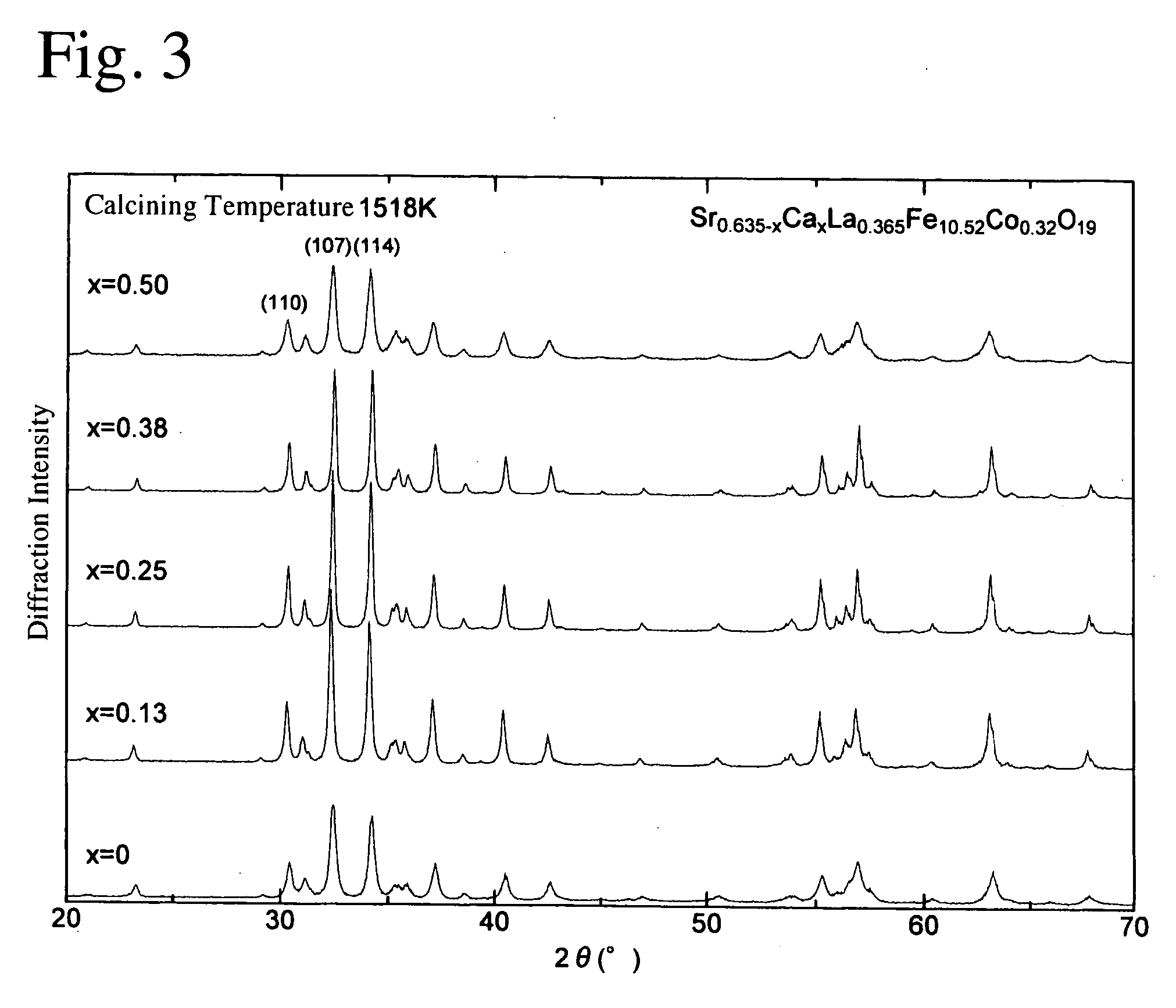

ActiveUS20060284136A1High residual magnetic flux density BrImprove intrinsic coercive forceInorganic material magnetismFerroso-ferric oxidesSintered magnetsFerrite (magnet)

A sintered ferrite magnet having a basic composition represented by the general formula: A1−x−y+aCax+bRy+cFe2n−zCoz+dO19 (atomic ratio), wherein a, b, c and d represent the amounts of an A element, Ca, an R element and Co added in the pulverization step of an oxide magnet material, which are numerals meeting the conditions of 0.03≦x≦0.4, 0.1≦y≦0.6, 0≦z≦0.4, 4≦n≦10, x+y≦1, 0.03≦x+b≦0.4, 0.1≦y+c≦0.6, 0.1≦z+d≦0.4, 0.50≦[(1−x−y+a) / (1−y+a+b)]≦0.97, 1.1≦(y+c) / (z+d)≦1.8, 1.0≦(y+c) / x≦20, and 0.1≦x / (z+d)≦1.2.

Owner:HITACHI METALS LTD

Sintered neodymium-iron-boron magnet and preparation method thereof

ActiveCN102903472AImprove remanenceImprove coercive forcePermanent magnetsInorganic material magnetismMetallurgyMagnetic energy

The invention discloses a sintered neodymium-iron-boron magnet, comprising the following components in percent by weight: 29.5%-32.5% of R, 62.85%-67.54% of Fe, 0.96%-1.15% of B and 2.0%-3.5% of TM, wherein R consists of Nd, Pr and Gd or consists of Nd, Pr and Ho; B represents boron, Fe represents iron, and Tm is one or more in Al, Nb, Cu, Co, Ga and Zr. In addition, the invention also discloses a preparation method of the sintered neodymium-iron-boron magnet, and the sintered neodymium-iron-boron magnet is prepared by adopting a quick-curing piece technology and a forming and pre-pressing process. The invention has the advantages that the largest magnetic energy product and intrinsic coercive force of the sintered neodymium-iron-boron magnet can be furthest improved, and the produced sintered neodymium-iron-boron magnet has high residual magnetism and high coercive force and is lower in cost.

Owner:NINGBO YUNSHENG +4

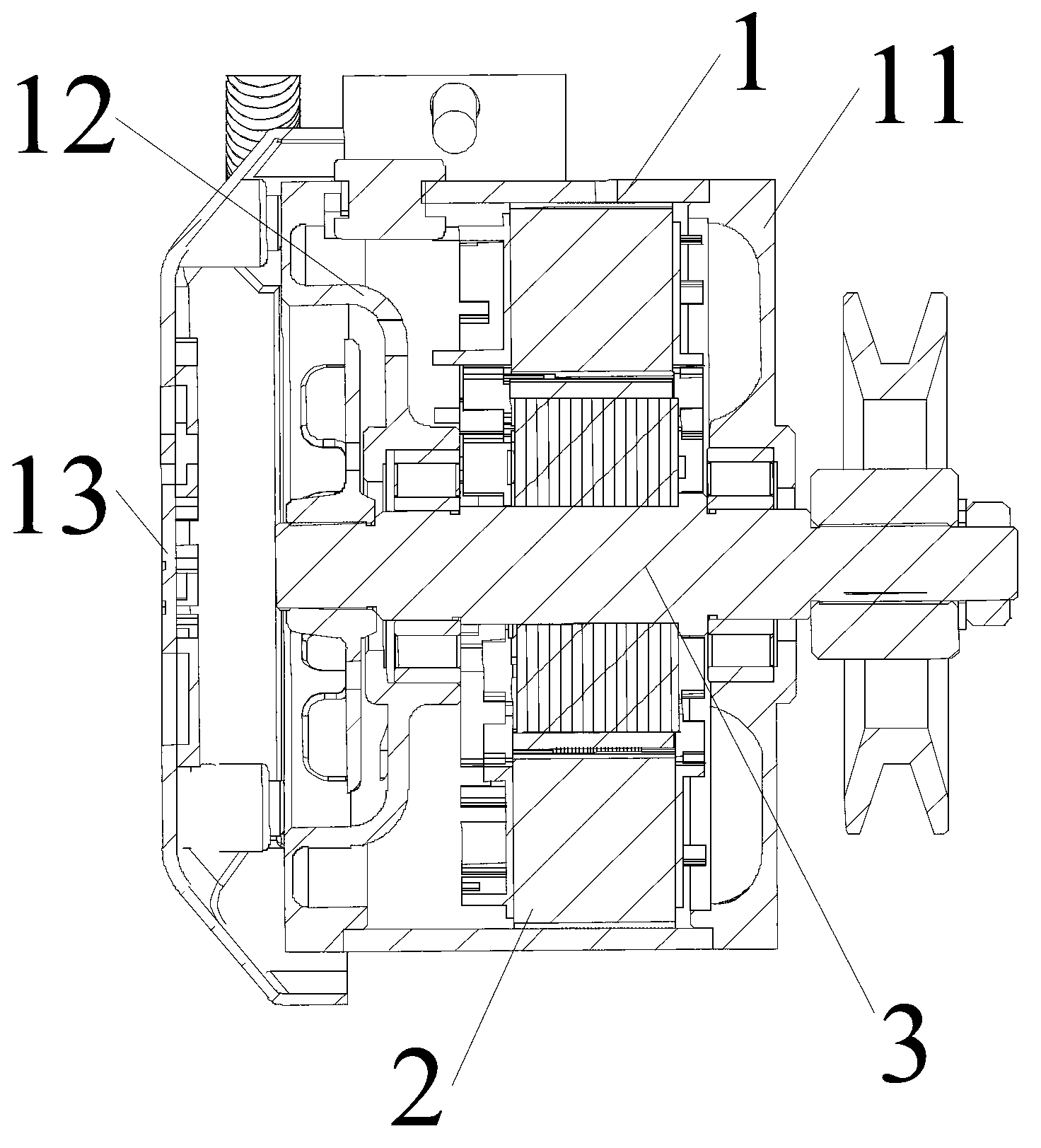

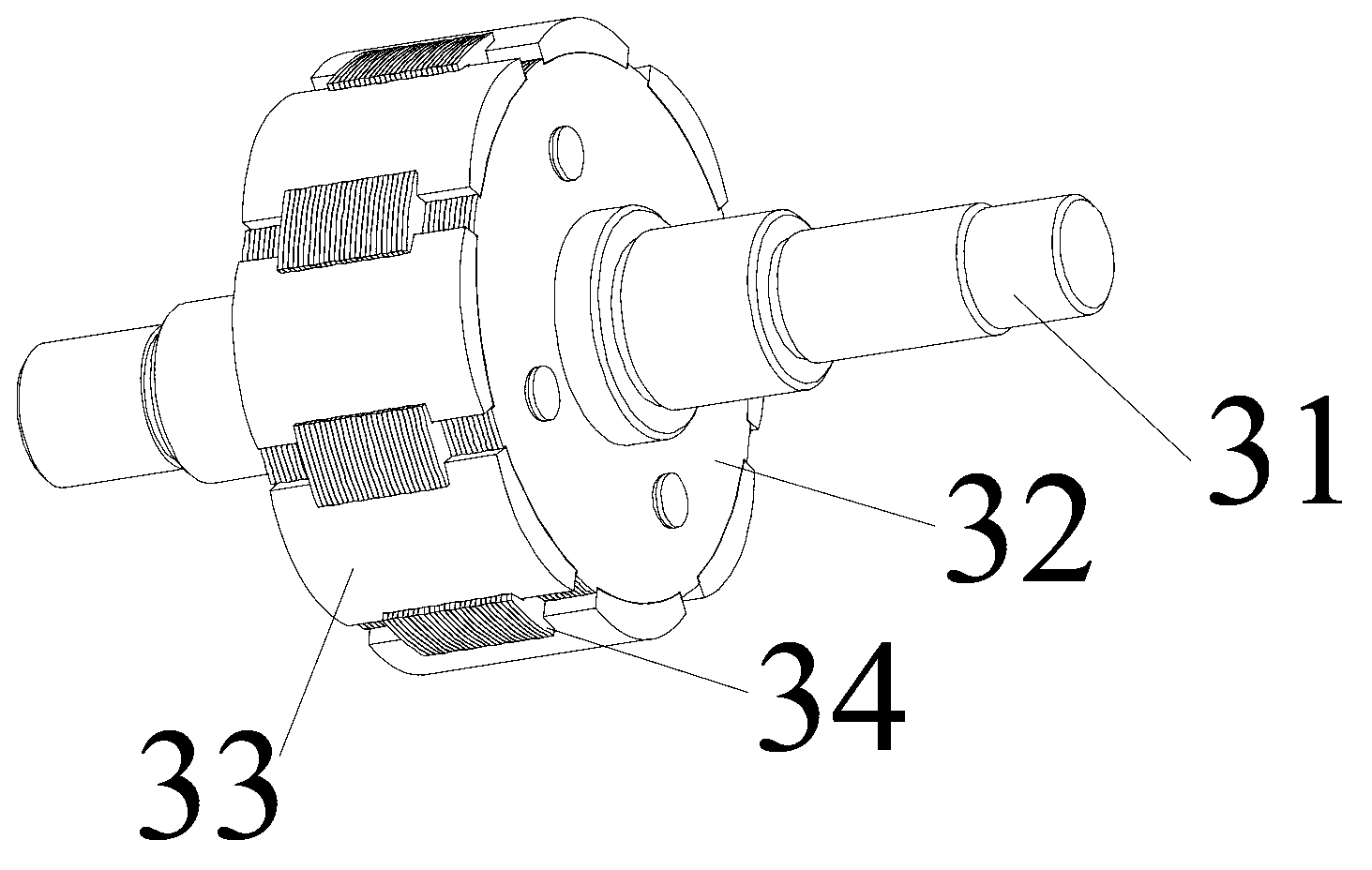

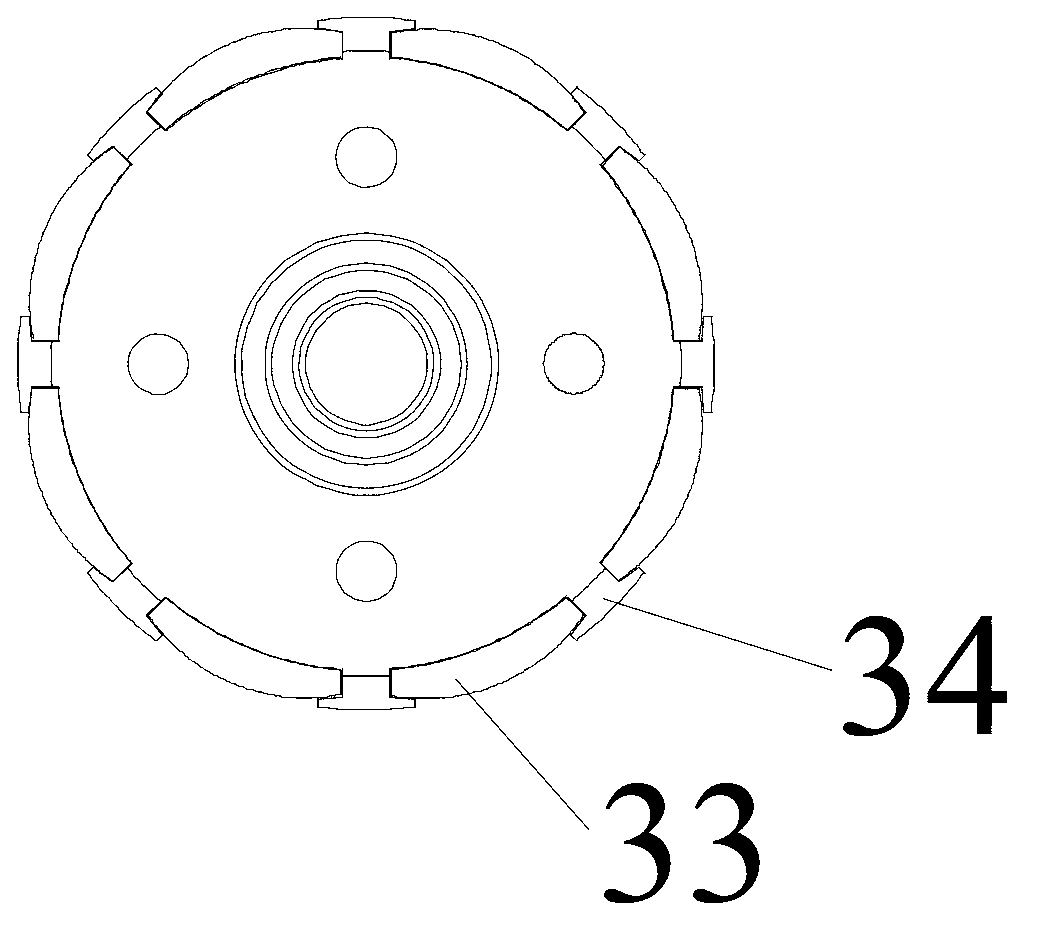

Energy-saving servo motor

InactiveCN103312068AGood energy saving effectEnergy saving effectMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringMagnetic energy

The invention discloses an energy-saving servo motor which comprises a case, a stator assembly and a rotor assembly. The rotor assembly comprises a motor shaft and a rotor iron core, the rotor iron core is fixedly sleeved on the motor shaft, a plurality of silicon steel sheets are laminated to form the rotor iron core, a plurality of steel magnets made of neodymium, iron and boron materials are mounted on the rotor iron core, T-shaped lugs which are distributed circumferentially are arranged on the circumferential surfaces of the silicon steel sheets in the middle of the rotor iron core, the quantity of the T-shaped lugs is identical to that of the steel magnets, the lugs on the silicon steel sheets are laminated to form clamp grooves, and the steel magnets can be embedded into the clamp grooves. Compared with the prior art, the energy-saving servo motor has the advantages that the steel magnets made of the neodymium, iron and boron materials are mounted on the rotor iron core of a rotor of the servo motor, excitation windings are omitted, the neodymium, iron and boron steel magnets are superior in magnetic properties such as high magnetic energy products and high coercivity, the lengths of air gaps can be maximized owing to the high coercivity of the materials, and accordingly an energy-saving effect of the servo motor is improved by 20% as compared with the traditional ferrite motor and other types of motors, and is excellent.

Owner:WUHU WEITE MOTOR

Process for preparing magnetic powder and sintered magnet and product produced thereby

ActiveCN1655295AIncrease the anisotropy constantImprove intrinsic coercive forceInorganic material magnetismInductances/transformers/magnets manufactureMetallurgyFerrite powder

This invention relates to magnetic material field and especially to a process method improvement and its formula to hexagonal magnetic lead ferrite powder and sinter magnetism, wherein the said magnetism or magnetic powder has one-Curie temperature with A,R, B and Fe hexagonal ferrite main phase and the following molecular formula: A1-XRx[(Fe3+aFe2+b)12-yBy]zO19, through adding positive three Co and optimizing the formula and improving the magnetism crystal aeolotropism constant K1.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

High temperature rare earth permanent magnetic material and its preparation method

InactiveCN1494092AImprove intrinsic coercive forceLow temperature coefficient of coercivityInorganic material magnetismMetallurgyRare earth

The invention relates to powder metallurgic method for manufacturing rare earth permanent magnet material Sm2 (Co, Pe, Cu, Zr)17, especially for designing component of 2:17 type SmCo permanent magnet as well as optimizing preparation technique. Thus, application temperature of the material is raised to 400 deg.C so as to meet requirement on the permanent magnet of electric equipment utilized in national defense and arms industry under high temperature environment.

Owner:CENT SOUTH UNIV

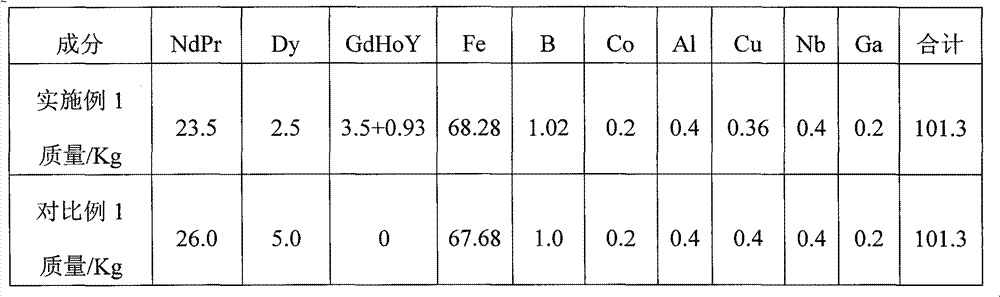

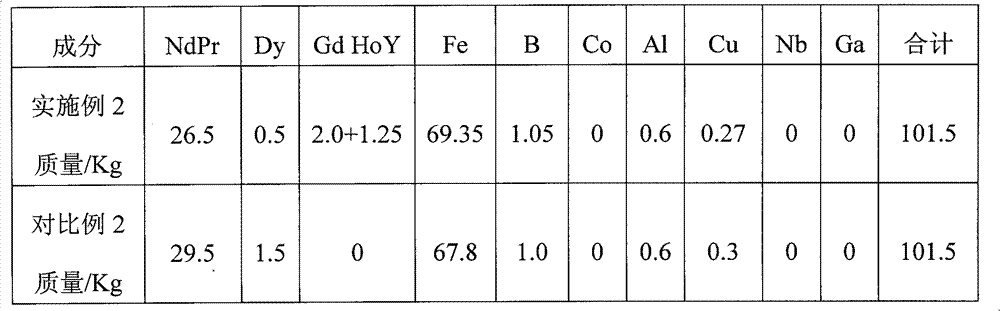

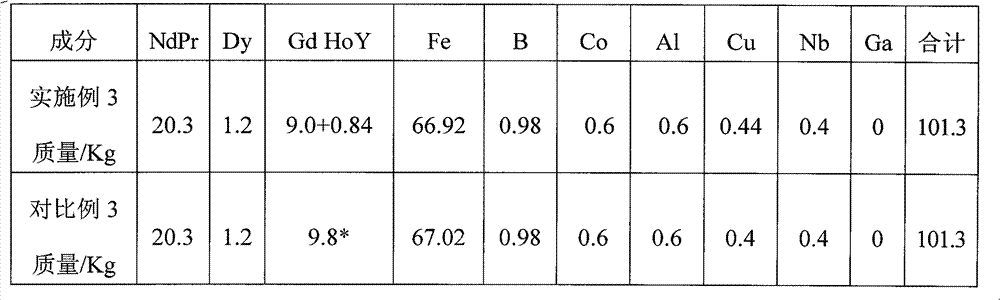

Method for preparing composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium

ActiveCN102956336AImprove remanenceIncrease the maximum energy productInorganic material magnetismRare-earth elementCurie temperature

The invention provides a method for preparing a composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium. The method includes the steps of primary batching, fusion casting, milling, secondary batching, powder mixing, forming, sintering and heat treatment, wherein in the primary batching step, iron alloy added with three rare earth elements of the gadolinium, the holmium and the yttrium is composited, and in the secondary batching step, oxide added with the three rare earth elements of ultrafine gadolinium, holmium and yttrium and cuprous oxide powder are composited. By the method, the relative surplus and cheap gadolinium, holmium and yttrium can be used for partially substituting for rare earth elements of neodymium, praseodymium or dysprosium, and accordingly neodymium, praseodymium or dysprosium consumption can be decreased by 10-30wt.%. Besides, Curie temperature and coercivity force of the prepared neodymium-iron-boron permanent magnet material are increased, corrosion resistance is enhanced, operating temperature and toughness are increased, and processability is improved.

Owner:GANZHOU JIATON ADVANCED MATERIALS

Preparation method of samarium-cobalt (SmCo) system sintered materials

ActiveCN102651263AImprove microstructureGood orientationInductances/transformers/magnets manufactureMagnetic materialsPositive pressureAlloy

The invention relates to a preparation method of samarium-cobalt (SmCo) system sintered materials. The preparation method comprises the steps of alloy smelting, alloy cast strip preparation through rapid quenching, magnetic powder preparation through combination of a hydrogenated disproportionation method and an airflow grinding method, orientation and forming, positive pressure sintering and solid dissolving and aging treatment. The preparation method has the advantages that through the innovation of the ingot casting and powder making process, the microstructure of a magnetic body is optimized to the greatest degree, the magnetic body mainly consists of columnar crystals, the orientation is easy, and in addition, the performance of the magnetic body is stable; and in the hydrogenated disproportionation process of alloy cast sheets, hydrogen enters gap positions in SmCo crystal lattices, and the crystal lattice expansion is caused, so the pulverization is realized under the condition of ensuring the crystal particle integrity, the oxidation in the powder making process is reduced, the magnetic body with low oxygen content is obtained, and the magnetic performance of the magnetic body is ensured.

Owner:NINGBO STAR MATERIALS HI TECH

NdFeB magnet formed by sintering NdFeB recycling waste and preparation method of NdFeB magnet

InactiveCN104575904AImprove performanceReduce weight lossInorganic material magnetismRare earthMixed materials

The invention relates to an NdFeB magnet formed by sintering NdFeB recycling waste and a preparation method of the NdFeB magnet, and belongs to the technical field of a rare earth magnetic material. The NdFeB magnet is formed by a mixed material formed by the recycling waste and a prepared material by a sintering technology, and the mass percentages of the recycling waste and the prepared material are respectively 2%-50% and 50%-98%; the recycling waste is RxMyBzFe(1-x-y-z) (x=29%-32%, y=0-4% and z=0.9%-1.1%), the prepared material is RxMyBzFe(1-x-y-z) (x=29%-35%, y=0-4% and z=0.9%-1.1%), R is one or more elements selected from La, Ce, Pr, Nd, Gd, Ho and Dy, and M is one of more elements selected form Co, Al, Cu, Nb, Zr and Ga. According to the NdFeB magnet and the preparation method, disclosed by the invention, the comprehensive utilization rate and the preparation efficiency of the recycling waste are increased, and the production cost is reduced.

Owner:NINGBO HONGLEI MAGNETICS

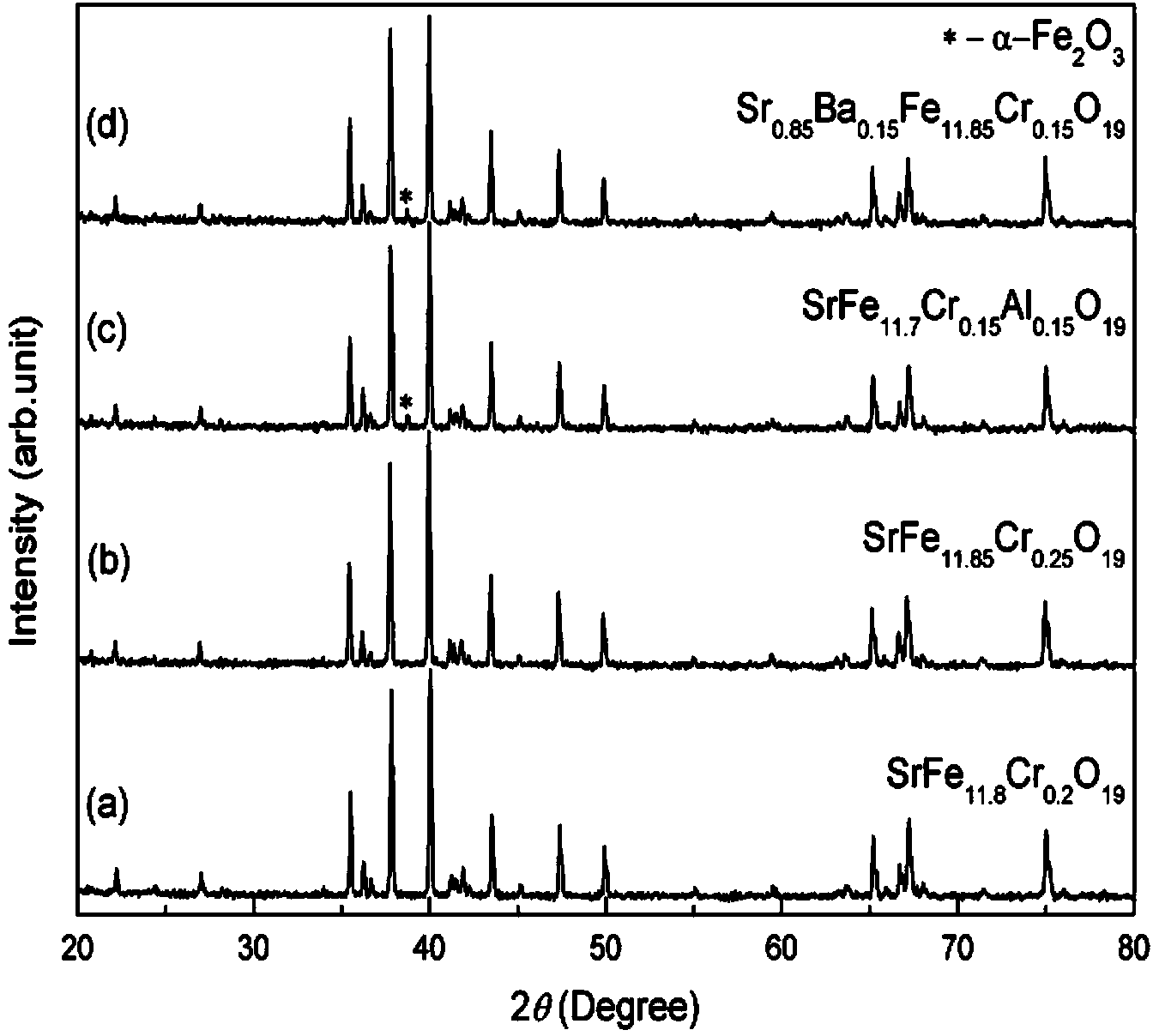

High-performance permanent magnet ferrite material and preparing method thereof

The invention relates to a high-performance permanent magnet ferrite material and a preparing method thereof and belongs to the technical field of magnetic function material preparation. The invention adopts the technical scheme as follows: carrying out preparation according to a main phase molecular formula Sr1-xBaxO.nFe(12-y) / nRy / nO3, wherein x is not smaller than 0 and not bigger than 0.998, n is not smaller than 5.75 and not bigger than 6.15, y is bigger than 0 and not bigger than 0.6, R refers to Cr or Cr and Al, and the content of Cr and Al is smaller than or equal to 0.6 when R refers to Cr and Al; secondarily adding one or more than two of industrial-purity CeO2, Ga2O3 and MoO3. The rest magnetism Br value of the high-performance permanent magnet ferrite prepared by the method is larger than or equal to 390mT, the intrinsic coercivity Hcj value is larger than or equal to 346.1kA / m, and the magnetic energy product (BH)max value is larger than or equal to 28.7kJ / m<3>. The method has the advantages that the high-performance permanent magnet ferrite material with a high performance-to-cost ratio is prepared through the relatively cheap chromium or chromium and aluminum substituted combination additive without adding expensive rare earth and rare metal oxide.

Owner:合肥领远新材料科技有限公司

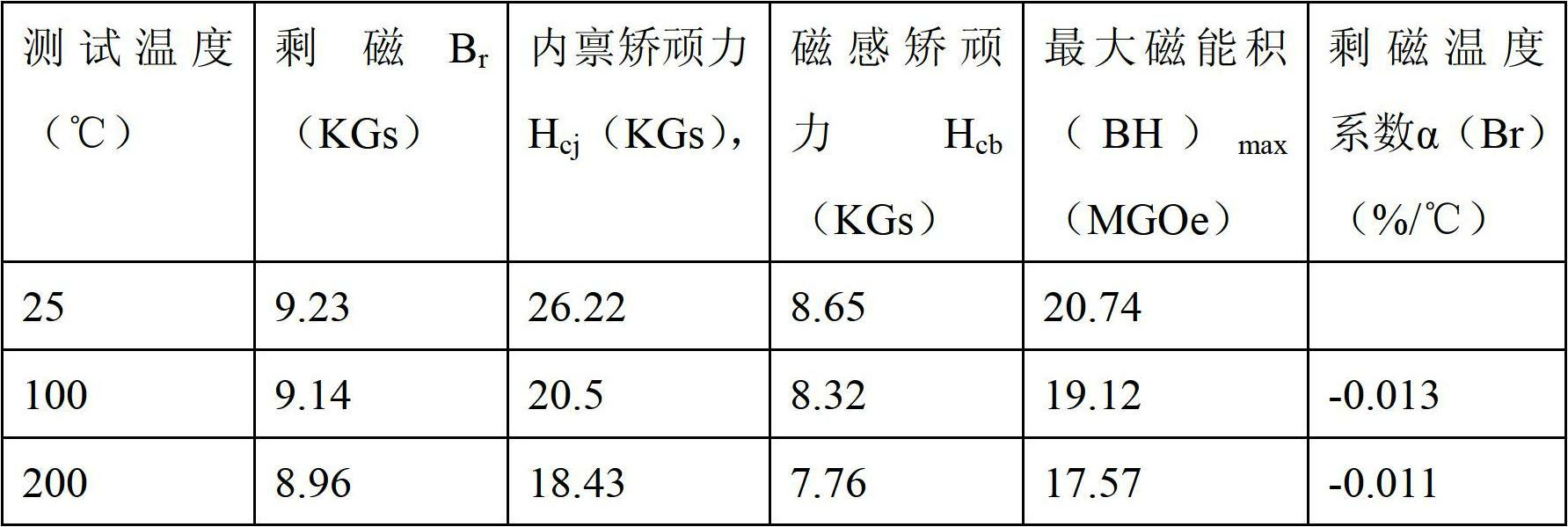

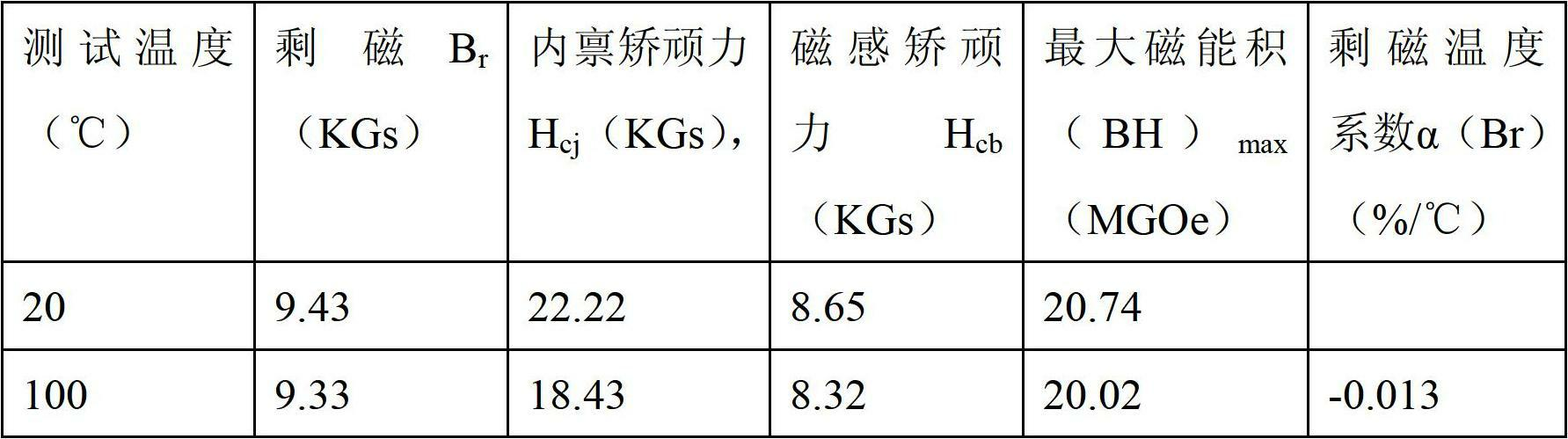

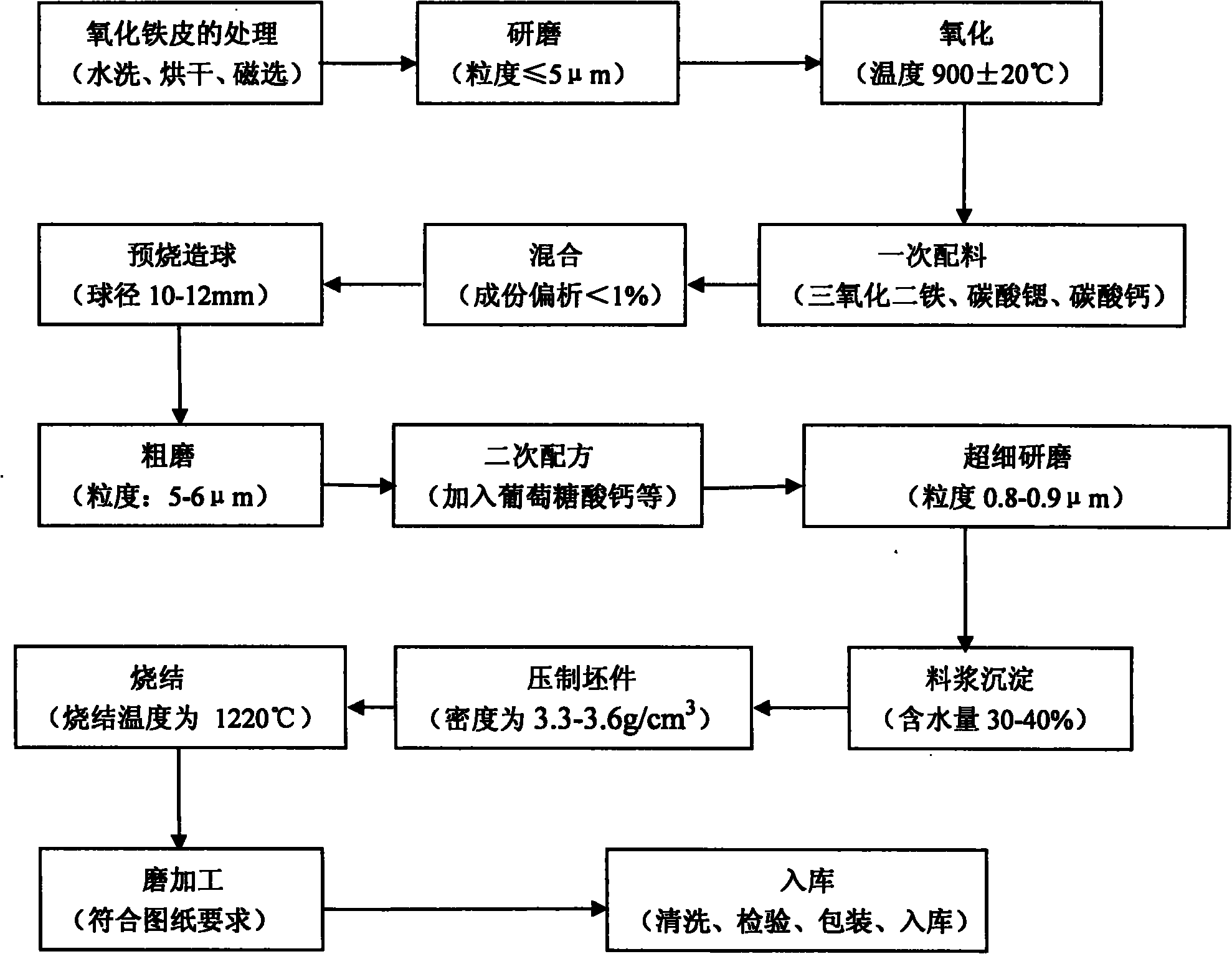

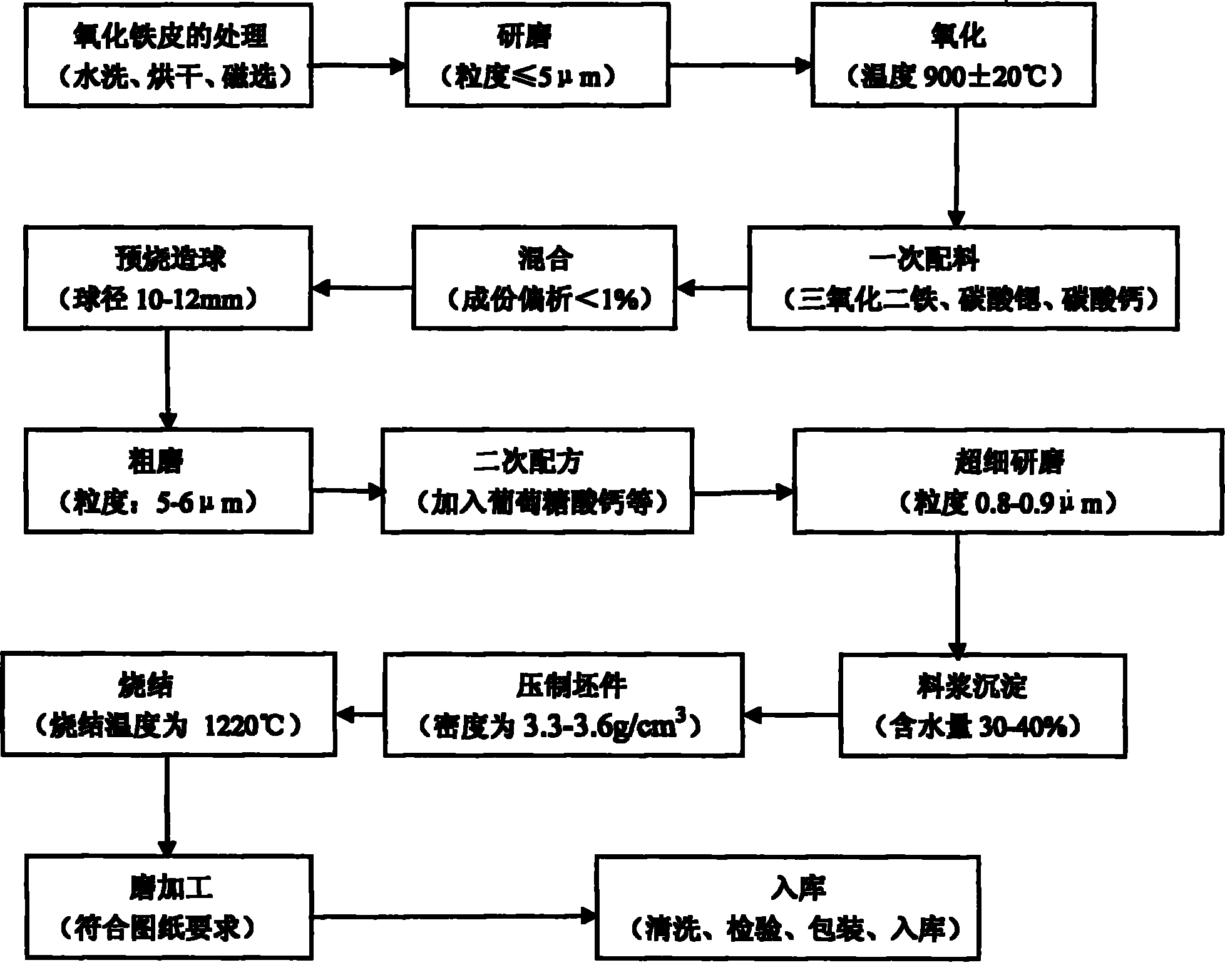

Preparation method for rare earth permanent ferrite magnetic shoe and product

ActiveCN101860091AIncrease the degree of magnetic orientationImproved Grinding MethodMagnetic circuitManufacturing dynamo-electric machinesRare earthUltra fine

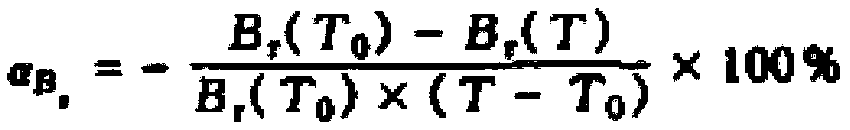

The invention discloses a preparation method for a permanent ferrite magnetic shoe containing a rare earth material and an organic material, and a product. The preparation method comprises the following steps of: treating an iron scale; grinding; oxidizing; primary dosing; mixing; preburning and palletizing; rough grinding; secondary dosing; ultra-fine grinding; slurry precipitation; pressing blanks; sintering; grinding; and warehousing. The preparation method of the invention has the characteristics that: the magnetic orientation degree of crystal grains is improved by adding calcium gluconate and improving a grinding method; and magnetic performance and magnetic characteristics thereof are improved by displacing the components of a conventional strontium ferrite permanent magnet material by adopting an additive mode of secondary dosing. The rare earth permanent ferrite magnetic shoe obtained by the preparation method has the characteristics of high residual magnetic flux density, high intrinsic coercive force and low intrinsic coercive force temperature coefficient.

Owner:马鞍山市鑫洋永磁有限责任公司

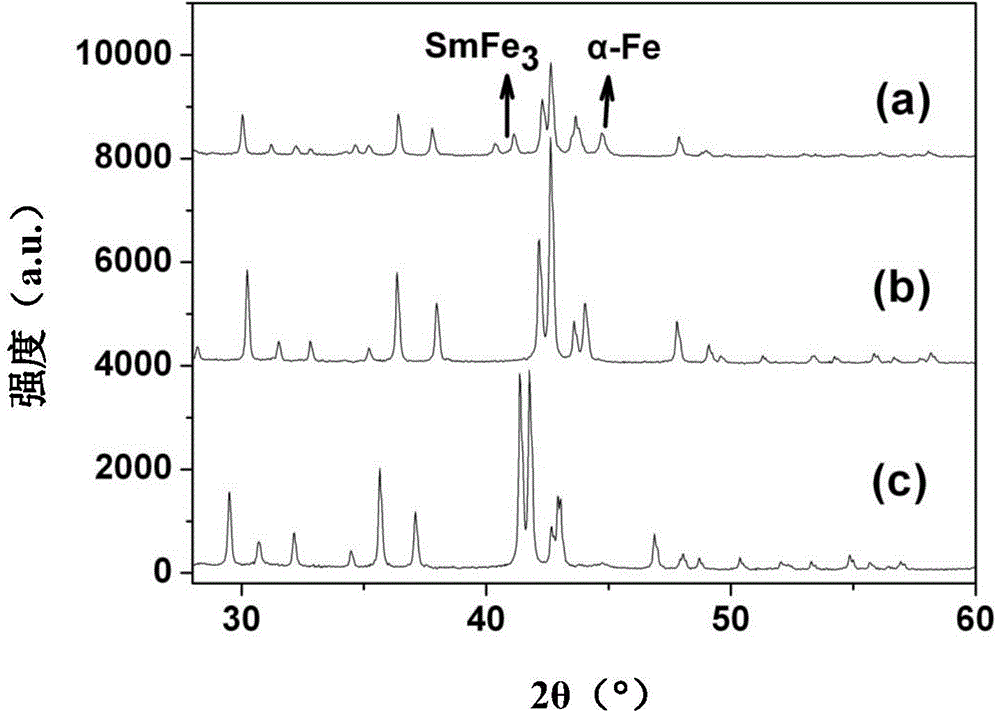

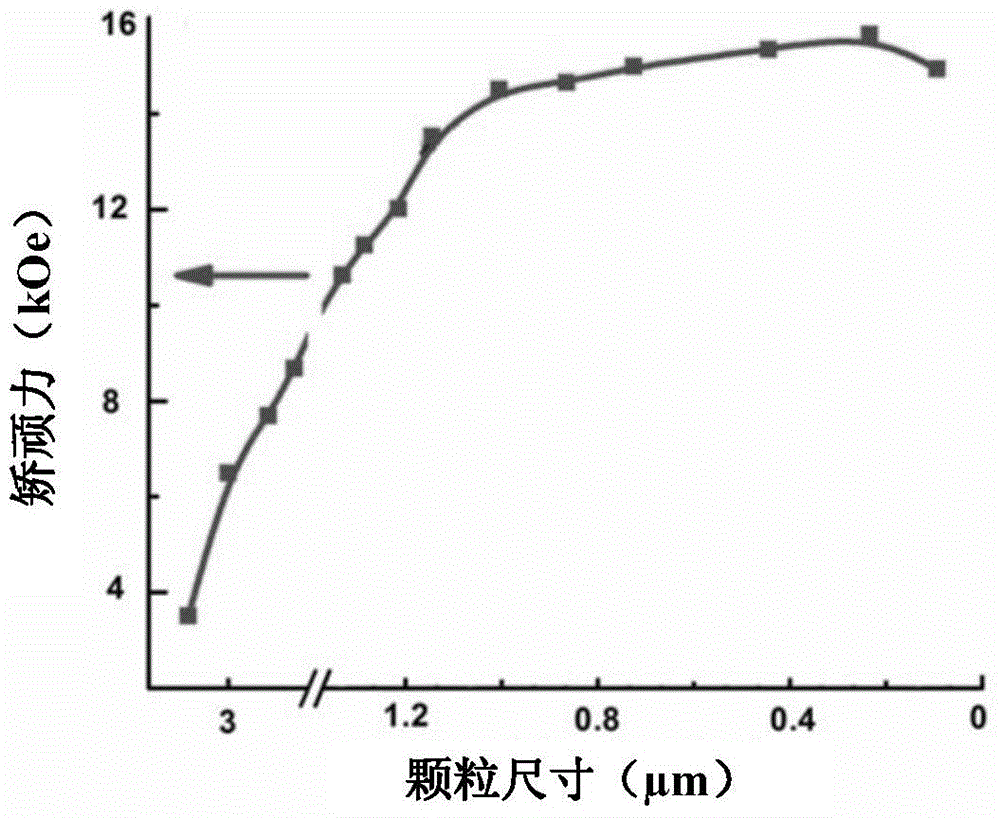

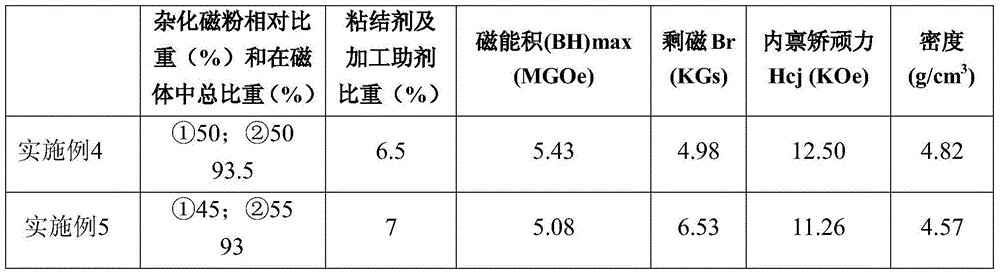

A submicron anisotropic samarium iron nitrogen magnet powder and a method for preparing a hybrid bonded magnet therefrom

ActiveCN106312077AHigh energy productImprove remanenceInductances/transformers/magnets manufactureMagnetic materialsAdditive ingredientSingle crystal

The invention provides a submicron anisotropic samarium iron nitrogen magnet powder and a method for preparing a hybrid bonded magnet therefrom. Samarium-iron alloy is prepared by using a quick setting sheet technology; the samarium-iron alloy is made to perform gas-solid phase reaction in nitrogen or mixed gas of nitrogen and hydrogen to form samarium-iron-nitrogen alloy; then airflow milling and / or ball milling is performed to obtain anisotropic samarium iron nitrogen single-crystal particle magnet powder with a particle size of 0.01-3 [mu]m. Further, the samarium iron nitrogen single-crystal particle magnet powder, as a first ingredient, is mixed with a second ingredient consisting of permanent magnetic ferrite, rapid quenching isotropic neodymium iron boron, anisotropic neodymium iron boron, samarium cobalt and / or neodymium iron nitrogen to form hybrid magnetic powder; processing agents are added; a hybrid bonded magnet is prepared by using a rolling, mould pressing, extrusion or injection method. The prepared samarium iron nitrogen magnet powder are high in magnetic energy product, residual magnetism and intrinsic coercive force, is low in cost and small in particle size; the corresponding hybrid bonded magnet exploits the advantages of different magnetic powder ingredients, is high in shaping degree and mechanical strength and is good in temperature performance.

Owner:NINGXIA MAGVALLEY NOVEL MATERIALS TECH CO LTD

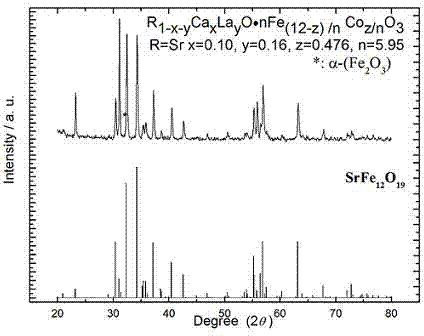

High magnetic-energy-product M type calcium series permanent magnetic ferrite material and preparation method thereof

InactiveCN104496443AHigh magnetic induction coercive forceImprove remanenceCrystal systemChemical structure

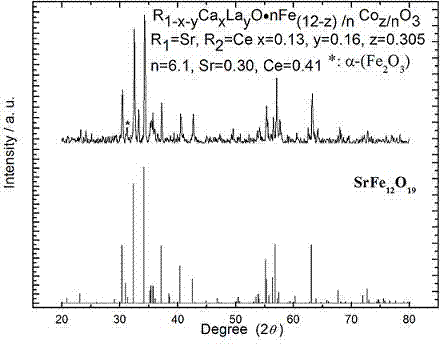

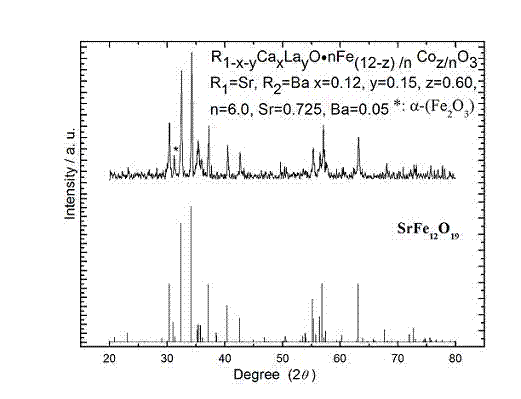

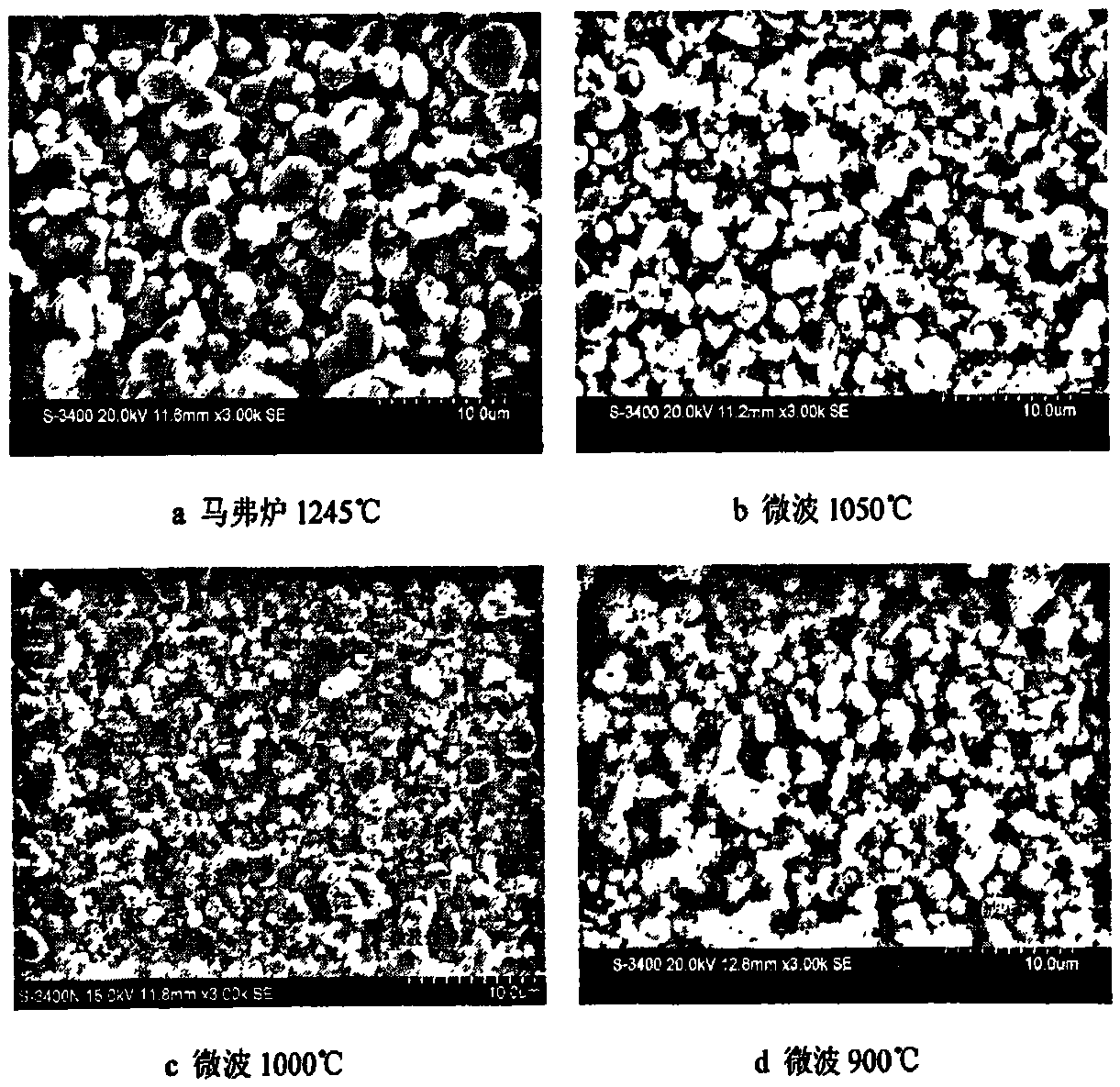

The invention discloses a high magnetic-energy-product M type calcium series permanent magnetic ferrite material and a preparation method thereof. The high magnetic-energy-product M type calcium series permanent magnetic ferrite material is a hexagonal crystal system, and the chemical structural formula is R1-x-yCaxLayO.nFe(12-z) / nCoz / nO3, wherein x is greater than or equal to 0.001 and smaller than or equal to 0.4, y is greater than or equal to 0.001 and smaller than or equal to 0.5, z is greater than or equal to 0.01 and smaller than or equal to 2.0, 1-x-y is greater than 0.2 and smaller than or equal to 0.998, n is greater than or equal to 5.0 and smaller than or equal to 6.5. R is Sr or adopts Sr as the main component, and also contains one, two or three of Ba, lanthanide series Ce, Pr, La, Nd and Sm. When R is Sr and Ba, the content of Sr and Ba is less than or equal to 0.998. In addition to high residual magnetism and intrinsic coercivity, the high magnetic-energy-product M type calcium series permanent magnetic ferrite material provided by the invention also has higher magnetic induction coercivity and maximum magnetic energy product, and is particularly in favor of miniaturization of permanent magnetic ferrite devices.

Owner:ANHUI UNIVERSITY

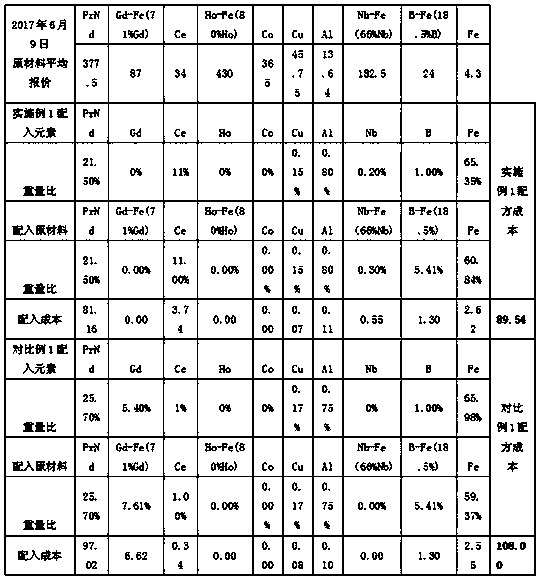

Low-cost N35 NdFeB magnet with high cerium content and sintering method thereof

InactiveCN107610858ALow costReduce consumptionInorganic material magnetismInductances/transformers/magnets manufactureNiobiumCerium

A low-cost N35 NdFeB magnet with high cerium content and a sintering method thereof belong to the technical field of powder metallurgy. The low-cost N35 NdFeB magnet is prepared from the following rawmaterials based on percent by weight according to a sintering process, 12-27% of praseodymium neodymium (Pr-Nd), 7-15% of cerium (Ce), 0-0.5% of niobium (Nb), 0-1% of aluminum (Al), 0-1% of copper (Cu), 0.9-1.1% of boron (B), 0-1.2% of cobalt (Co), 0-0.5% of zirconium (Zr) and 0-3% of gadolinium (Gd) with the balance being iron (Fe). In the scheme, a part of praseodymium neodymium (Pr-Nd) is substituted by cerium (Ce), the magnetic performance index reaches national standard of N35 mark sintering NdFeB, and the material cost can be reduced by 15-25 yuan during production of each kilogram of the corresponding mark magnet.

Owner:DONGYANG ZHONGYUAN MAGNETIC MATERIAL

Preparation method of rare earth doped high-coercivity manganese-bismuth alloy magnetic powder

InactiveCN105689726AIncreased magnetocrystalline anisotropySpread evenlyTransportation and packagingMetal-working apparatusRare-earth elementHigh energy

The invention relates to a preparation method of rare earth doped high-coercivity manganese-bismuth alloy magnetic powder. The preparation method comprises the following steps: dissolving a rare earth complex into anhydrous ethanol, then uniformly soaking manganese-bismuth alloy microparticles into the anhydrous ethanol containing the rare earth complex, then ensuring rare earth elements to diffuse into and enter crystal lattices of manganese-bismuth molecules in an atom form through high-energy ball milling, and ensuring doped elements to be uniformly dispersed into main alloy so as to dramatically improve the magnetocrystalline anisotropy of the magnetic powder. The finally prepared rare earth doped manganese bismuth magnetic powder has the coercivity which is dramatically higher than that of cobalt-manganese-bismuth magnetic powder without containing the rare earth. According to the method, MnBi coarse particles are soaked into mixed liquid of the rare earth complex and the anhydrous ethanol, the rare earth complex uniformly wraps powder particles, the rare earth elements can be uniformly dispersed into the crystal lattices of the manganese-bismuth molecules in the ball milling process, the magnetocrystalline anisotropy of MnBi is improved, and thus the intrinsic coercivity of the MnBi alloy is imroved; and in addition, the process is simple, the operation is easy, and the production cost of high-performance magnetic powder is lowered.

Owner:CHINA JILIANG UNIV

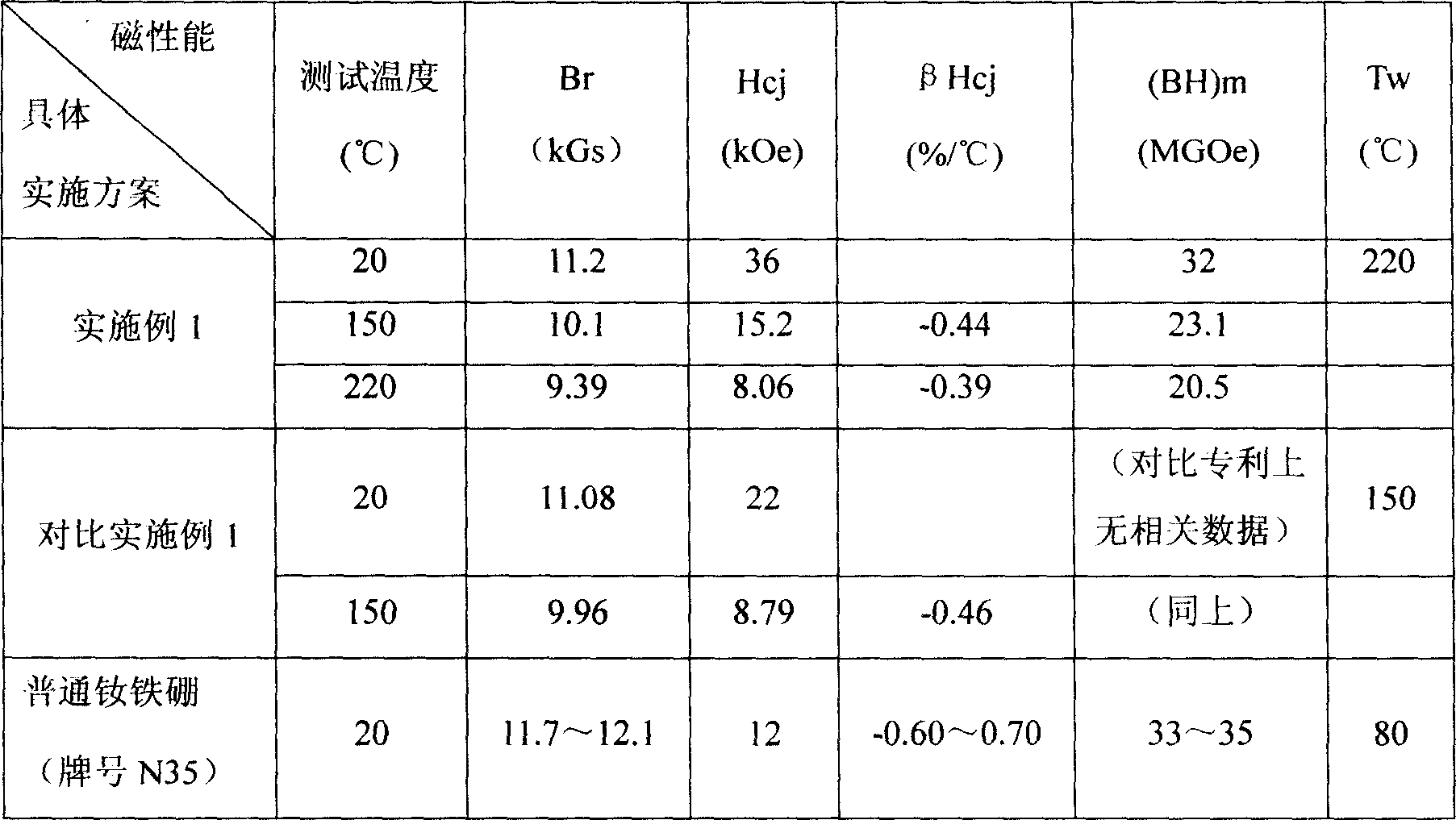

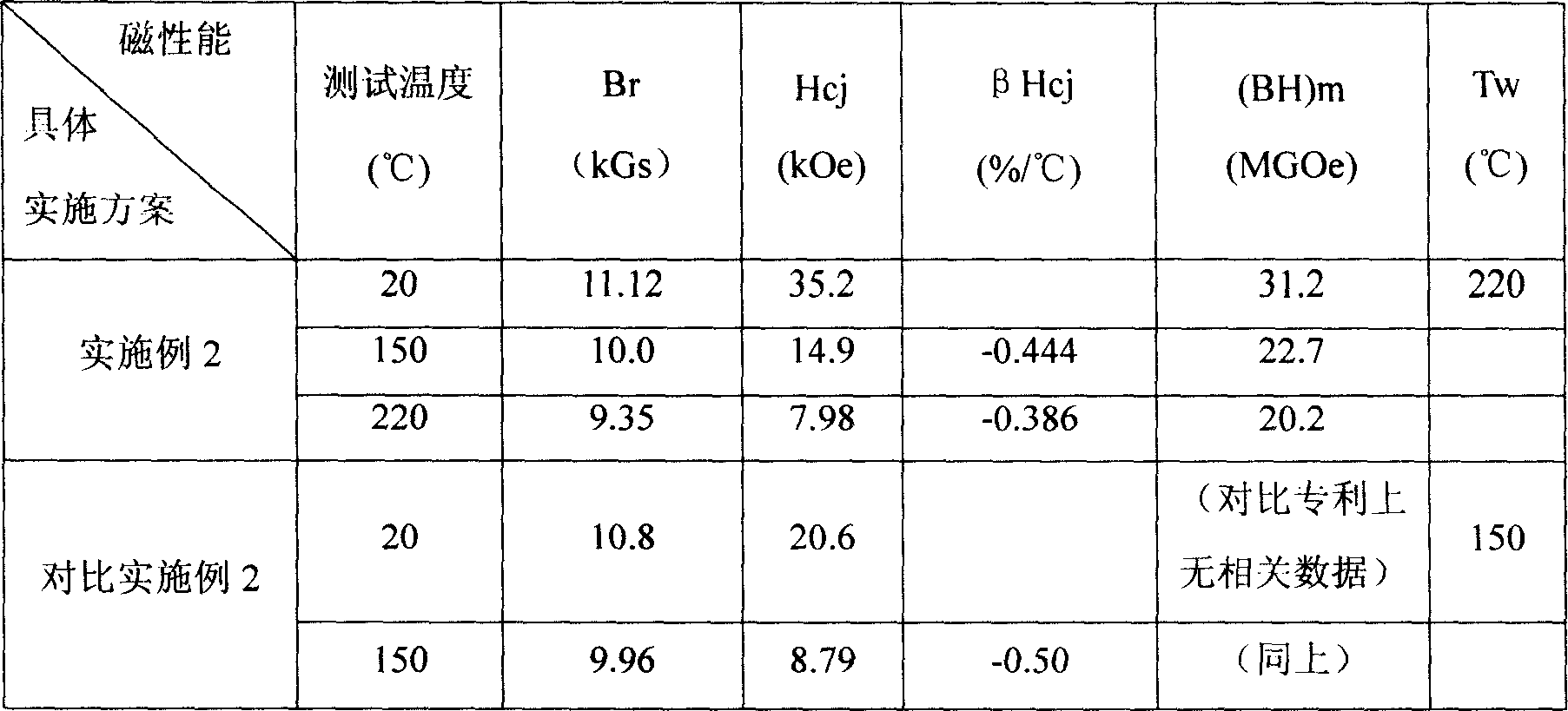

Ultra-high coercive force sintered Nd-Fe-B magnetic material and preparing process thereof

ActiveCN1862717AReasonable distributionMake up for temperature gapsInorganic material magnetismSamarium–cobalt magnetIngot casting

This invention relates to super-high coercive force sintering neodymium iron boron magnet and its preparation method. the alloy molecular general formula is NdxDyyTbzFe(100%-x-y-z-x1-y1-z1-w-w1)Cox1Nby1Cuz1(Ga)wBw1, intrinsic coercive force more than 35k0e(2786kA / m) sintering neodymium iron boron magnet are made through traditional normal ingot casting method. The highest work temperature is 220 degrees centigrade, so the using temperature frees position in traditional sintering neodymium iron boron magnet and sintering samarium cobalt magnet.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

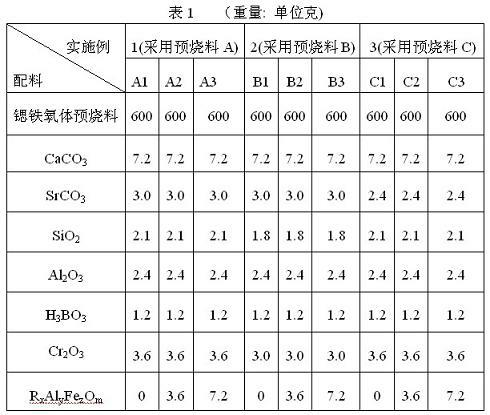

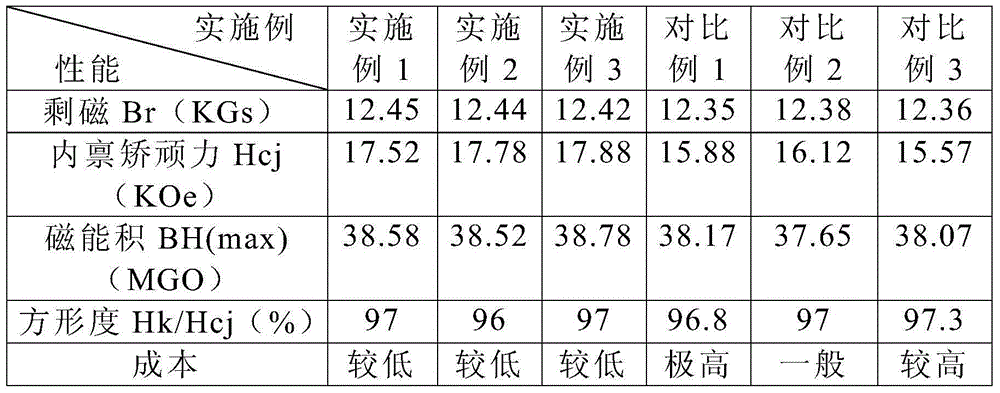

Method for improving coercivity of permanent ferrite

The invention discloses a method for improving coercivity of permanent ferrite by adding an additive without reduction of residual magnetism, which specifically comprises the following steps of: 1), preparing materials, namely, adding two to six of CaCO3, SrCO3, SiO2, Al2O3, H3BO3 and Cr2O3 in secondary process on the basis of iron strontium oxide once pre-sintered material, and adding an additive with formula of RxAlyFezOm, wherein R is mixture of two or more of Pr, Bi, Gd, Nd, Cu, Cr and Co; 2), ball milling; 3), pressing and forming; 4), sintering; and 5), grinding. The invention has the following positive effects that: with respect to the same pre-sintered material, coercivity and intrinsic coercivity of the material are improved by 300-700Oe without reduction of residual magnetism after the additive RxAlyFezOm is added.

Owner:SINOSTEEL ANHUI TIANYUAN TECH

NdFeB magnet sintering method

InactiveCN104576021ASmall particle sizeReduce lossInorganic material magnetismInductances/transformers/magnets manufactureHydrogenGranularity

The invention relates to an NdFeB magnet sintering method, and belongs to the technical field of rare earth magnetic materials. The method comprises the following steps that NdFeB preparing materials are weighed and are subjected to vacuum melting to obtain throwing sheets; cleaning is carried out, NdFeB recovery waste materials are obtained, the throwing sheets and the recovery waste materials are respectively subjected to hydrogen crushing to obtain preparing material coarse powder and recovery waste material coarse powder; the recovery waste material coarse powder is subjected to airflow milling powder preparation to be made into recovery waste material fine powder with the average granularity being 20 to 100mum, and the recovery waste material fine powder is mixed with the preparing material coarse powder according to a ratio being (2 percent to 50 percent) and (50 percent to 98 percent); the mixed materials are subjected to secondary airflow milling to be made into NdFeB micro powder with the average granularity being 2 to 4mum; the micro powder is pressed, formed and pressurized to obtain a blank; the sintering aging processing is carried out, and a NdFeB magnet is obtained. The NdFeB magnet sintering method has the advantages that the powder preparing efficiency is high, the rare earth loss is little, the time of the preparing method is short, and the production cost is low.

Owner:NINGBO HONGLEI MAGNETICS

A magnetic material with high temperature stability and a preparation method thereof

InactiveCN108962528AThree low melting pointsImprove remanenceInorganic material magnetismInductances/transformers/magnets manufactureProper treatmentAlloy

The invention discloses a magnetic material with high temperature stability and a preparation method thereof, which is composed of an alloy material 1, an alloy material 2, an alloy material 3 and aninorganic ceramic material. The weight ratio of the alloy material 1, the alloy material 2, the alloy material 3 and the inorganic ceramic material is 1: 0.03- 0.09:0.003- 0.008:0.011- 0.015. The product obtained by the invention has excellent magnetic properties. In addition, the homogeneity of composition, microstructure and properties of the alloys were ensured by proper treatment, and the quality of the alloys was ensured. The preparation process of the alloy is simple, the cost of raw materials used for preparation is low, the process is simple, and the produced alloy has good properties,which is convenient for industrial production. The permanent magnet material prepared by the invention is suitable for the electric appliance industry.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Plumbite type yttrium permanent magnetic ferrite material and preparation method thereof

The invention discloses a plumbite type yttrium permanent magnetic ferrite material and a preparation method thereof. The plumbite type yttrium permanent magnetic ferrite material is a hexagonal system, the chemical structural formula of which is R1-x-yYxLayO.nFe(12-z) / nCoz / nO3, wherein x is less than or equal to 0.5 but greater than or equal to 0.01, y is less than or equal to 0.75 but greater than or equal to 0.1, z is less than or equal to 0.082 but greater than or equal to 0.07, n is less than or equal to 6.5 but greater than or equal to 5.0, and (1-x-y) is less than or equal to 0.5 but greater than or equal to 0. R is Ca, Ba, Sr or one, two and three of Ce, Pr and Nd and Sm in lanthanide series exclusive of La. Compared with the conventional permanent magnetic ferrite, for the plumbite type yttrium permanent magnetic ferrite material, at the sintering temperature of 1150-1300 DEG C, the remanence Br value reaches 4.2-4.8kGs, the magnetic induction coercive force Hcb value reaches 4.2-5.2kOe, the intrinsic coercive force Hcj value reaches 4.5-6.0kOe, and the magnetic energy product value reaches 5.2-5.7MGOe. The plumbite type yttrium permanent magnetic ferrite material provided by the invention is high in remanence and intrinsic coercive force. When the sintered magnet becomes smaller and thinner, the high residual magnetic flux density is still maintained.

Owner:ANHUI UNIVERSITY

NdFeB magnet and preparation method thereof

ActiveCN104064301ARefine the grain sizeRaise the sintering temperaturePermanent magnetsInductances/transformers/magnets manufactureIngotCopper

The invention provides an NdFeB magnet which comprises, by mass, 29% to 33% of Pr-Nd, 0.97% to 1.5% of B, 0.4% to 0.6% of Dy, 0.2% to 0.8% of Al, 0.6% to 0.8% of Co, 0.01% to 0.5% of Cu, 0.01% to 0.2% of Zr and the balance Fe. The invention further discloses a preparation method of the NdFeB magnet. The method includes the steps that firstly, Pr-Nd alloy, Zr-Fe alloy, B-Fe alloy, Dy-Fe alloy, aluminum, cobalt, copper and iron are molten to prepare an NdFeB cast ingot; secondly, the obtained NdFeB cast ingot is milled into NdFeB powder; finally, the NdFeB powder is sintered into the NdFeB magnet. The NdFeB magnet prepared through the method has a more refined magnet grain size and higher magnet stability.

Owner:BEIJING JINGCI ELECTRIC TECH CO LTD

Nanometer rare earth permanent magnetic material with high-temperature stability and preparation method thereof

InactiveCN103559971AImprove microstructureInhibition of nucleation growthInorganic material magnetismRare-earth elementNiobium

A nanometer rare earth permanent magnetic material with the high-temperature stability is characterized in that a basic expression is RxFe100-x-z-y BzNy, wherein R is one or a plurality of lanthanide series rare earth elements of neodymium, praseodymium and the like, Fe is an iron element, B is an boron element, N is one of elements of niobium, zirconium and the like, x is a number ranging from 15 to 36, z is a number ranging from 2 to 10, and y is a number ranging from 4 to 10. Preferentially, x is a number ranging from 18 to 32, z is a number ranging from 2.6 to 8.5, and y is a number ranging from 4.8 to 9. The invention further provides a preparation method of the rare earth permanent magnetic material. A Co element is not added, and the material has the advantages of being low in cost and high in working temperature and intrinsic coercivity.

Owner:江西江钨稀有金属新材料股份有限公司

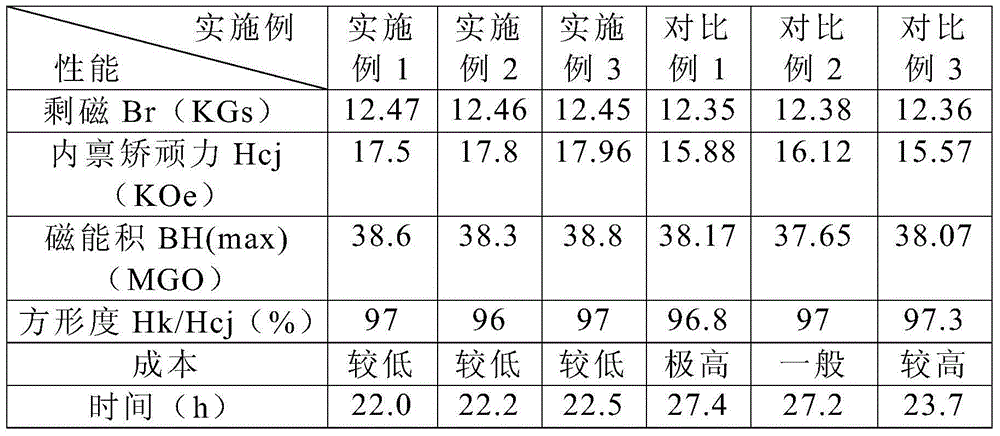

Preparation method for high-coercivity sintered neodymium-iron-boron

ActiveCN103956244AAccurate ingredientsExtend the life cycleInorganic material magnetismDehydrogenationNitrogen gas

The invention discloses a preparation method for high-coercivity sintered neodymium-iron-boron. The method specifically comprises the following steps: batching raw materials proportionally, and preparing a thin alloy sheet by using a medium-frequency vacuum rapid-hardening melt-spinning furnace; performing normal-temperature hydrogen absorption and heating dehydrogenation on the thin alloy sheet in a reaction kettle of a hydrogen decrepitating furnace to prepare coarse particles of which the particle size is 60-80 meshes; milling hydrogen-decrepitated coarse powder by using a jet mill to form fine powder of which the average particle size is 2.0-4.0 mu m; adding one or more rare-earth nano additives into the powder by using a jet method, and performing uniform mixing in the atmosphere of argon shielding; performing oriented molding and isostatic pressing on the mixed powder under the argon shielding through a 1.8-3.0T magnetic field; filling a green neodymium-iron-boron body into a vacuum sintering furnace in a closed glove box full of nitrogen, continuously sintering the green neodymium-iron-boron body for three times, quickly cooling the green neodymium-iron-boron body, and finally, aging the green neodymium-iron-boron body twice to prepare a corresponding neodymium-iron-boron magnet of which the performance meets the national standard. The method is low in cost, simple in process, energy-saving, environmentally-friendly, and high in rare-earth utilization rate.

Owner:SHENYANG SHENGSHI WUHUAN TECH CO LTD

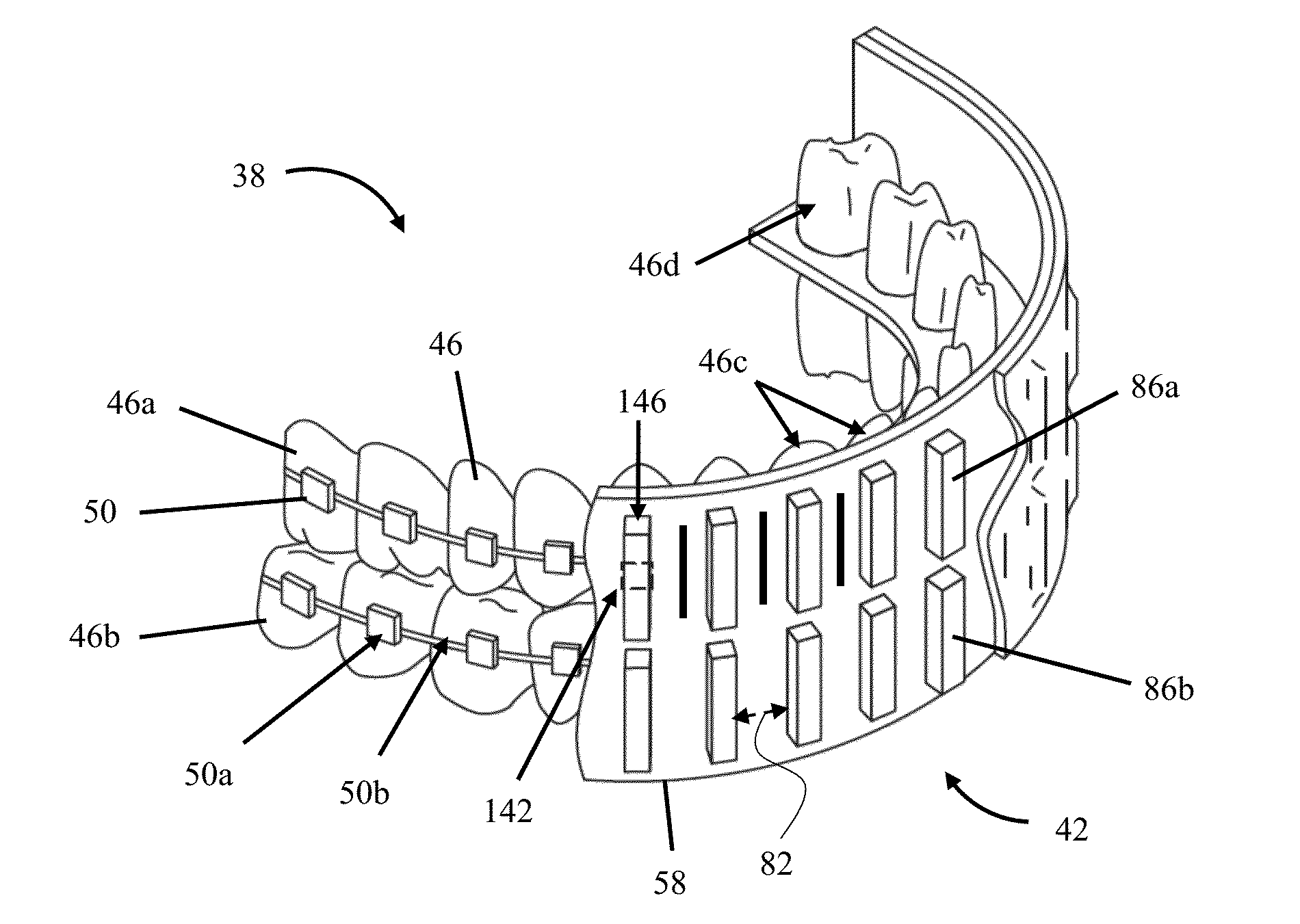

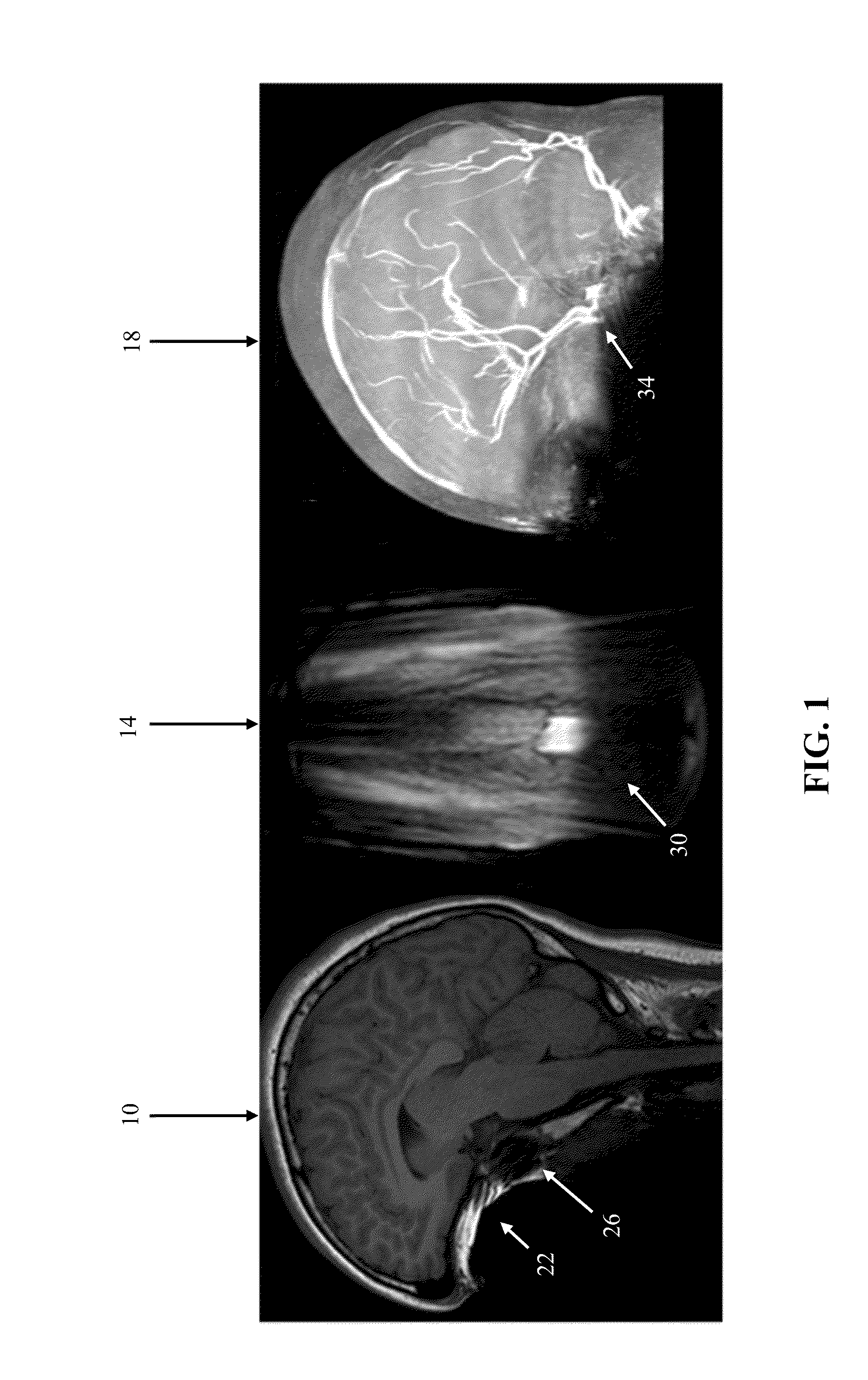

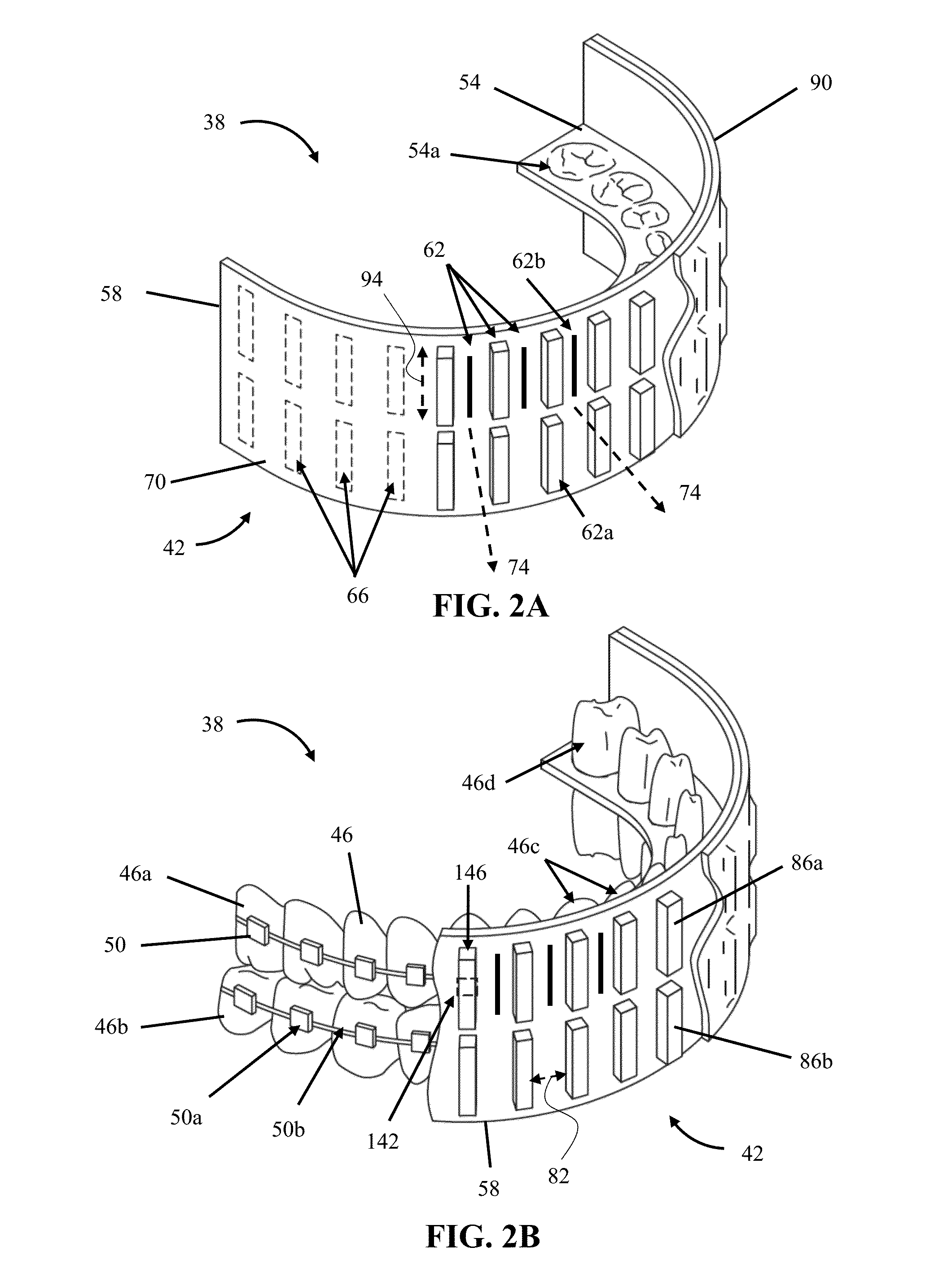

Apparatuses and Methods for Cancellation of Inhomogeneous Magnetic Fields Induced by Non-Biological Materials Within a Patient's Mouth During Magnetic Resonance Imaging

InactiveUS20150200046A1Reduce image lossReduce distortionMedical imagingMagnetic measurementsPresent methodMedicine

This disclosure includes magnetic field correction devices and methods for using the same. Some magnetic field correction devices include an arch-shaped body configured to be worn inside or outside of a user's mouth such that the arch-shaped body follows the contour of the user's teeth or face, where the arch-shaped body has one or more sidewalls and where the sidewalls are configured to receive a plurality of ferromagnetic or magnetic members. Some of the present methods include performing magnetic resonance imaging (MRI) on a user having one or more magnets coupled to an apparatus disposed inside or outside and adjacent to the user's mouth. Others of the present methods include coupling a plurality of magnets to an arch-shaped body configured to be worn by a user, where the magnets are configured to reduce artifacts caused by non-biological materials within the user's mouth during MRI.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Sintered magnetic composite material and preparation method thereof

InactiveCN108335819AInhibit growthEliminate direct contactInorganic material magnetismCopper alloyRaw material

The invention discloses a sintered magnetic composite material and a preparation method thereof. The magnetic composite material is prepared by mixing and sintering a material A, a material B, a material C and a copper alloy D, and the weight ratio of the material A, the material B, the material C to the copper alloy D is 0.05:(1-1.3):(0.003-0.008):(0.05-0.09). The sintered magnetic composite material is simple and convenient in preparation technology and simple in process, raw materials for preparation are low in cost, the produced alloy has good performance, industrial production is facilitated, and the prepared permanent magnet material is applicable to electrical equipment industry.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com