Method for improving coercivity of permanent ferrite

A technology of permanent magnet ferrite and coercivity, applied in the field of improving the coercivity of permanent magnet ferrite, can solve problems such as decline, and achieve the effects of low cost, improved magnetic performance, and enhanced competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

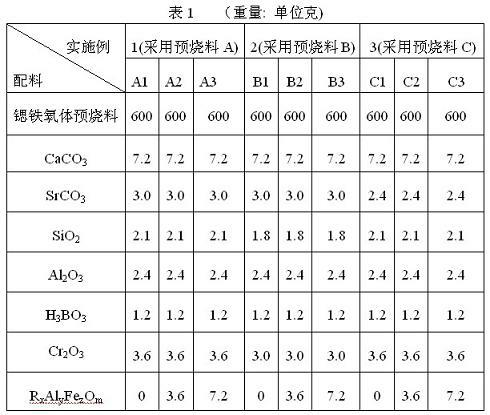

[0018] 1), ingredients: as shown in Table 1.

[0019] 2) Ball milling: use a roller mill for secondary ball milling, the steel balls used are bearing steel balls with a diameter of 5-10 mm, and the ball milling time is 15-20 hours; the mass percentage of material, balls and water is 1:15 : 2; The particle size of the secondary ball mill is tested with a laser particle size analyzer, and its D50 is controlled within the range of 0.80~0.95μm;

[0020] 3) Compression molding: Press the slurry after ball milling with a magnetic material hydraulic press. The diameter of the pressed blank is 30-40 mm, the height is 15-25 mm, and the density is 3.1-3.3 g / cm 3 ;The water content of the slurry before pressing is controlled at 33~38%;

[0021] 4) Sintering: Use a program-controlled box-type electric furnace to sinter the blank. The specific sintering process is as follows: 180°C / 1.0h+380°C / 1.0h+600°C / 1.0h+850°C / 1.0h+1100°C / 1.0h +1175°C / 1.5h.

Embodiment 2

[0028] Example 2: Pre-sintered material B was used for sintering, and the sintering process was 180°C / 1.0h+380°C / 1.0h+600°C / 1.0h+850°C / 1.0h+1100°C / 1.0h+1185°C / 1.5h. Other steps are the same as in Example 1. The specific properties of the product prepared by using calcined material B are shown in Table 3 below:

[0029] Table 3 Specific properties of products prepared from calcined material B

[0030] Sample type Br(kGs) Hcb(kOe) Hcj(kOe) (BH)m(MGO) B1 4.123 2.552 2.658 4.158 B2 4.111 3.089 3.302 4.067 B3 4.126 3.143 3.343 4.105

[0031] The calcined material B is according to the formula in Table 1, and the sintering temperature of the three formulas of B1, B2 and B3 is 1185°C. It can be seen from Table 3 that compared with B1, the remanence of formula B2 is only slightly reduced by 12Gs, while the coercive force of the material is increased by 537Oe, and the intrinsic coercive force is increased by 644Oe; compared with B1, the...

Embodiment 3

[0033] Example 3: Pre-sintered material C is used for sintering, and the sintering process is 180°C / 1.0h+380°C / 1.0h+600°C / 1.0h+850°C / 1.0h+1100°C / 1.0h+1175°C / 1.5h. Other steps are the same as in Example 1. The specific properties of the product prepared by using calcined material C are shown in Table 4 below:

[0034] Table 4 Specific properties of products prepared from calcined material C

[0035] Sample type Br(kGs) Hcb(kOe) Hcj(kOe) (BH)m(MGO) C1 3.943 3.154 3.306 3.852 C2 3.930 3.543 3.764 3.775 C3 3.935 3.637 3.925 3.781

[0036]Pre-sintered material C follows the formula in Table 1, and the sintering temperature of the three formulas of C1, C2 and C3 is 1175°C. It can be seen from Table 4 that compared with C1, the remanence of formula C2 is only slightly reduced by 13Gs, while the coercive force of the material is increased by 389Oe, and the intrinsic coercive force is increased by 458Oe; compared with C1, the remanent m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com