Patents

Literature

623 results about "Strontium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strontium oxide or strontia, SrO, is formed when strontium reacts with oxygen. Burning strontium in air results in a mixture of strontium oxide and strontium nitride. It also forms from the decomposition of strontium carbonate SrCO₃. It is a strongly basic oxide.

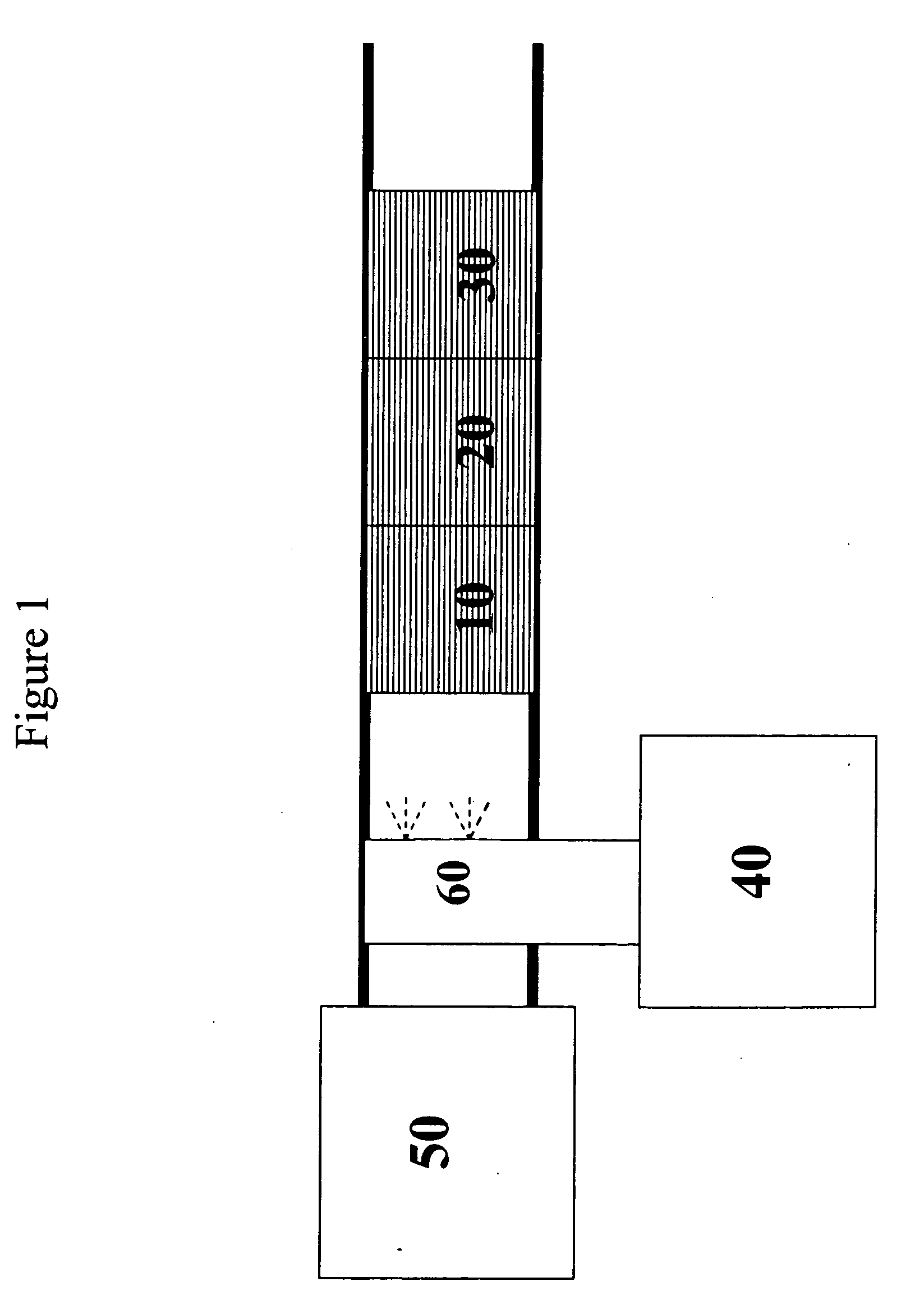

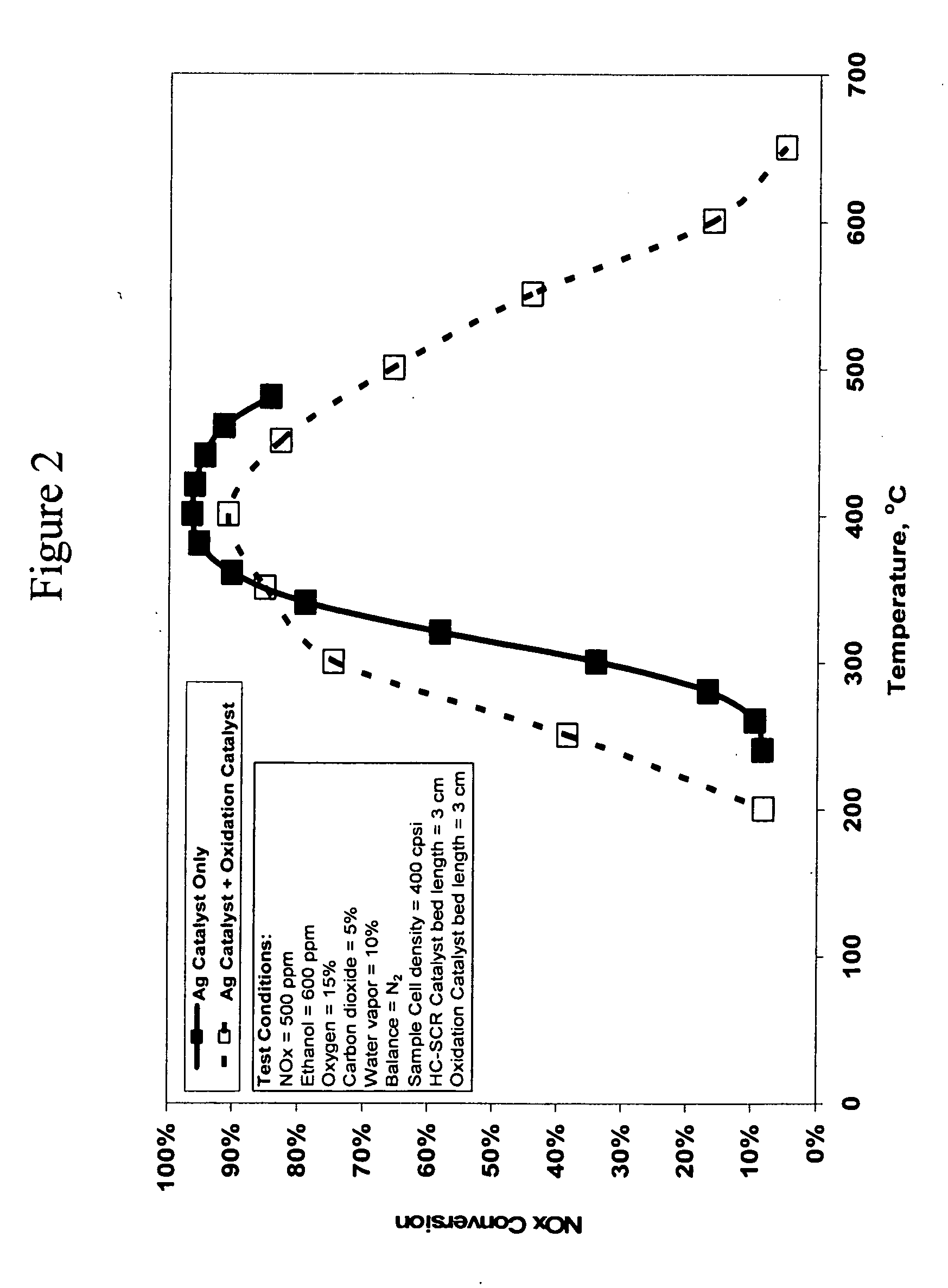

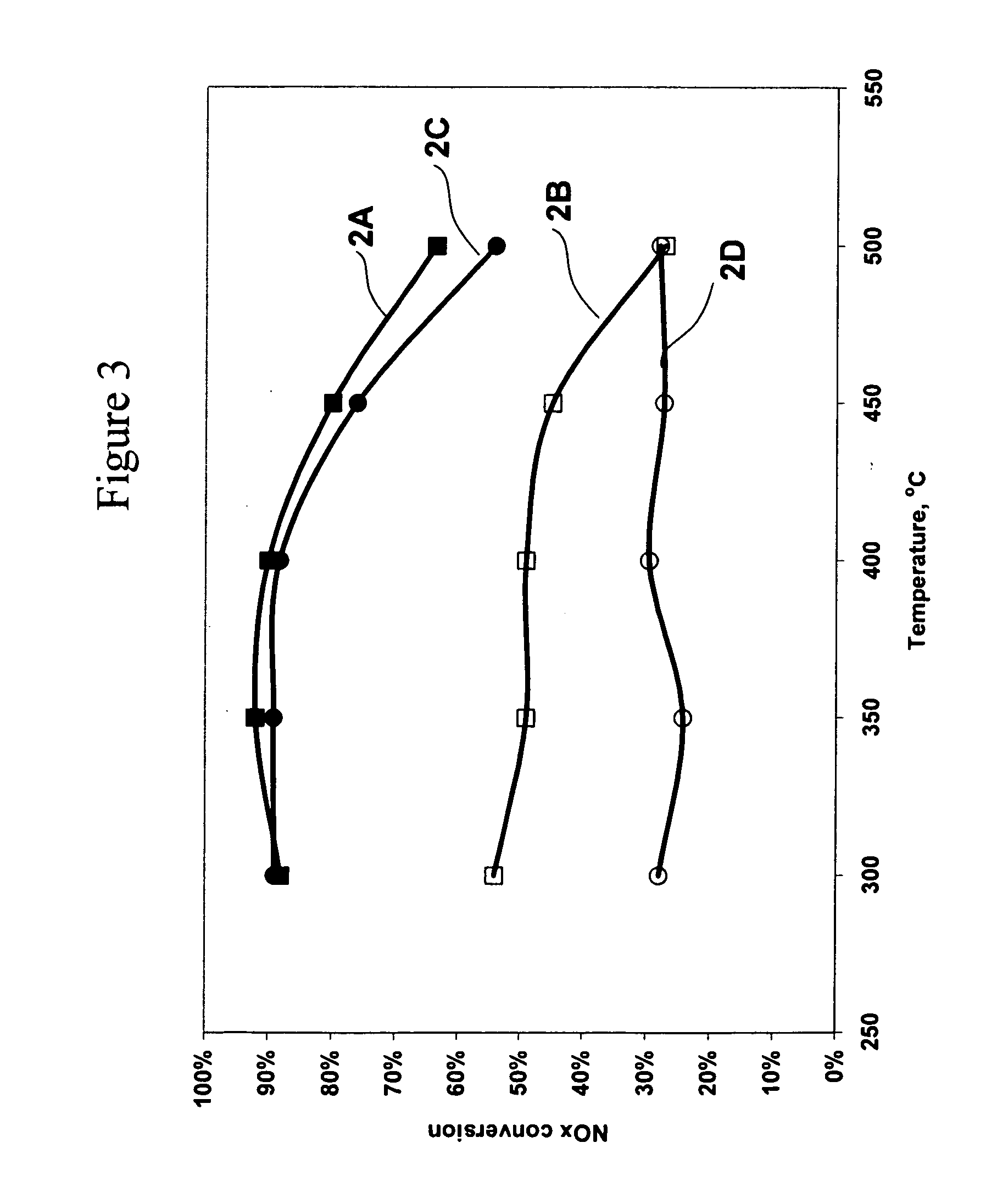

Catalyst and method for reducing nitrogen oxides in exhaust streams with hydrocarbons or alcohols

A catalyst system and a method for reducing nitrogen oxides in an exhaust gas by reduction with a hydrocarbon or oxygen-containing organic compound reducing agent are provided. The catalyst system contains a silver catalyst and a modifier catalyst, where the modifier catalyst contains a modifier oxide, where the modifier oxide is selected from the group consisting of iron oxide, cerium oxide, copper oxide, manganese oxide, chromium oxide, a lanthanide oxide, an actinide oxide, molybdenum oxide, tin oxide, indium oxide, rhenium oxide, tantalum oxide, osmium oxide, barium oxide, calcium oxide, strontium oxide, potassium oxide, vanadium oxide, nickel oxide, tungsten oxide, and mixtures thereof. The modifier oxide is supported on an inorganic oxide support or supports, where at least one of the inorganic oxide supports is an acidic support. The catalyst system of the silver catalyst and the modifier catalyst provides higher NOx conversion than either the silver catalyst or the modifier catalyst alone.

Owner:CATALYTIC SOLUTIONS INC

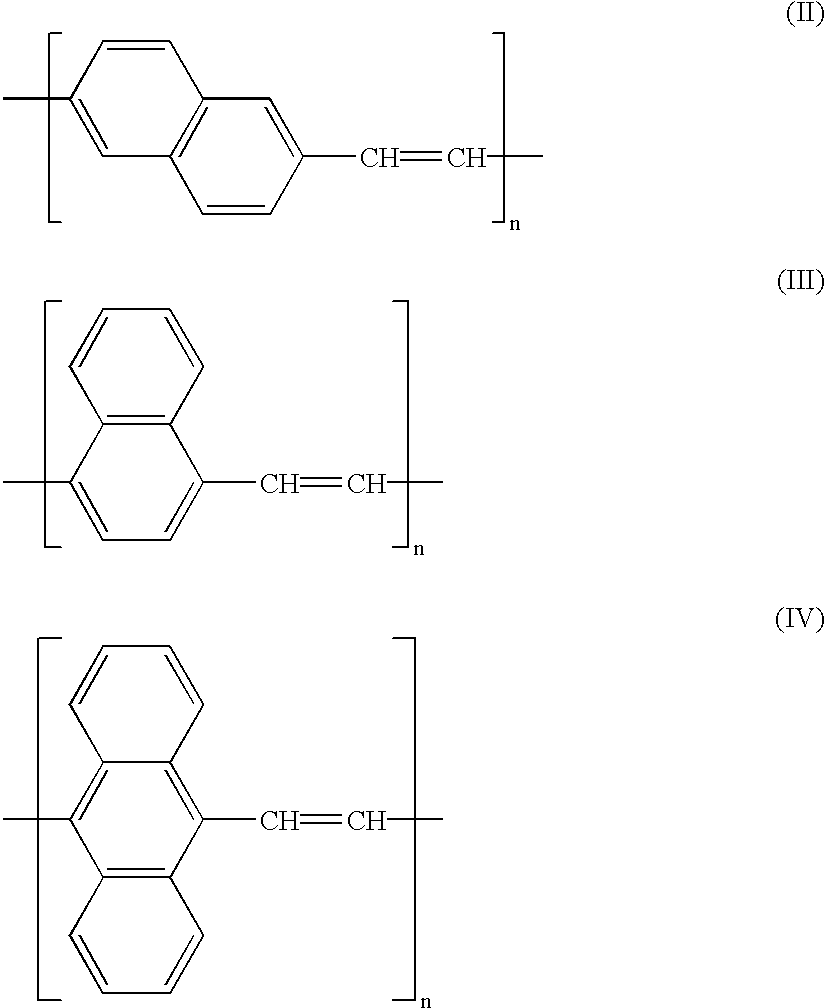

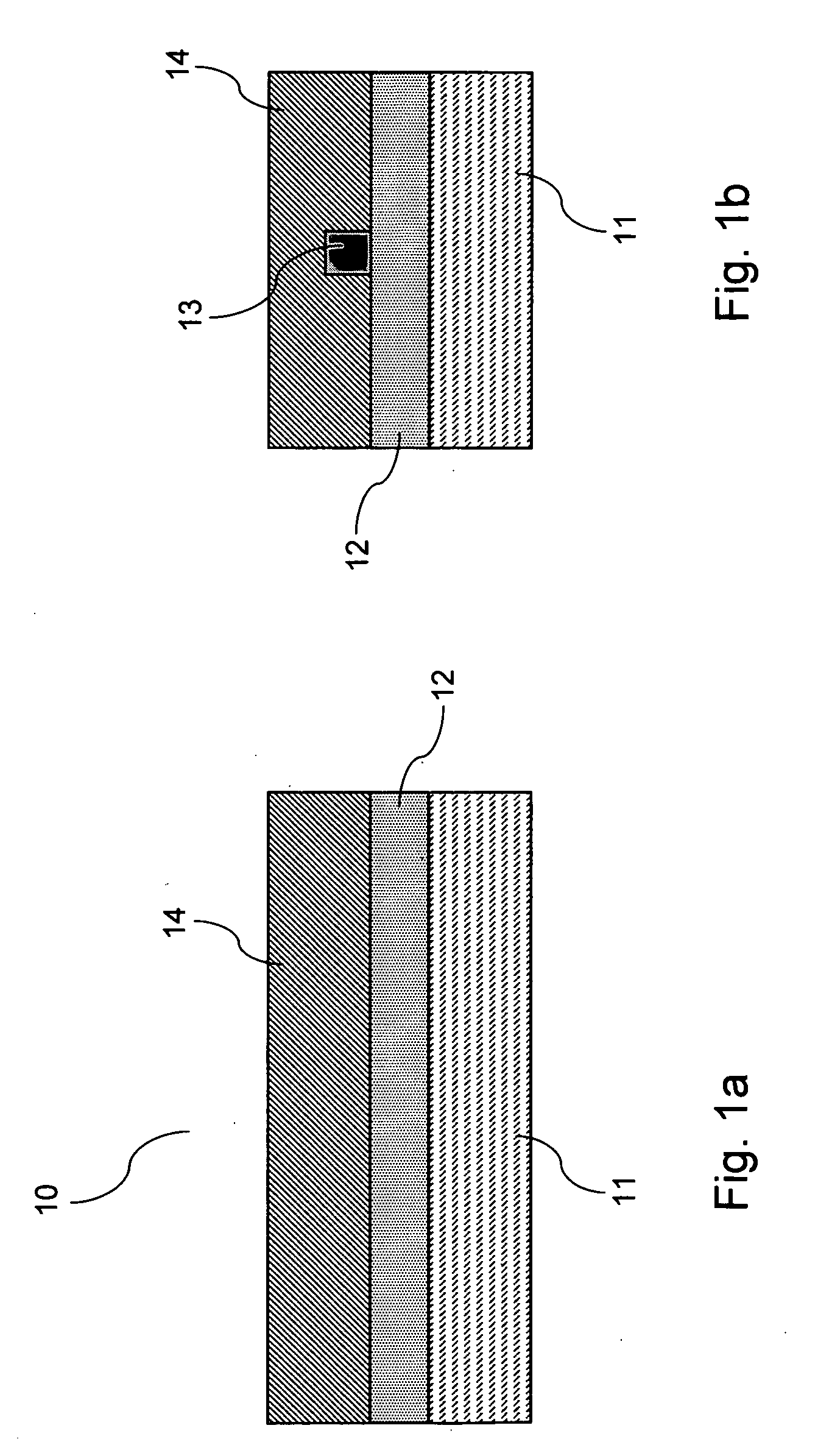

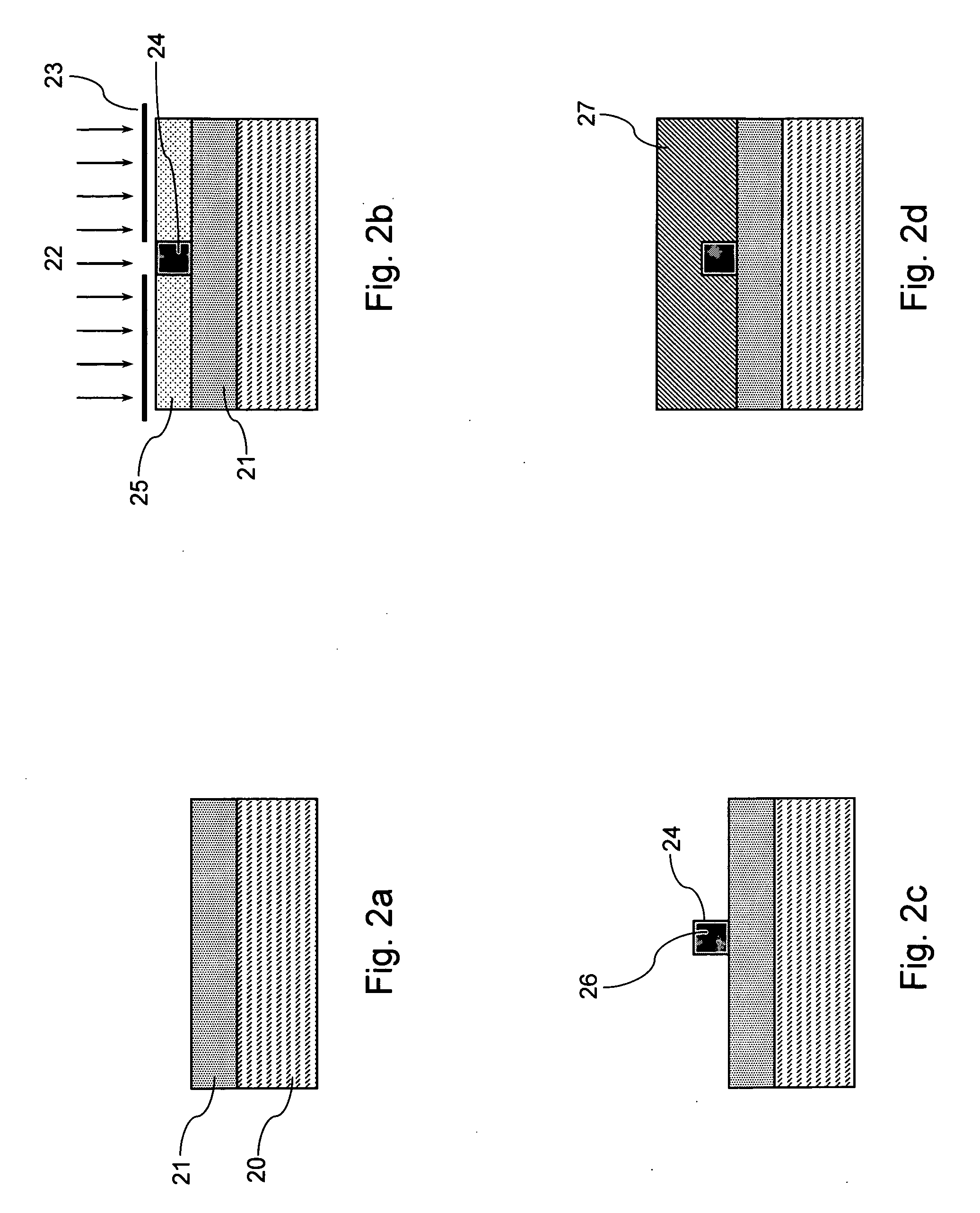

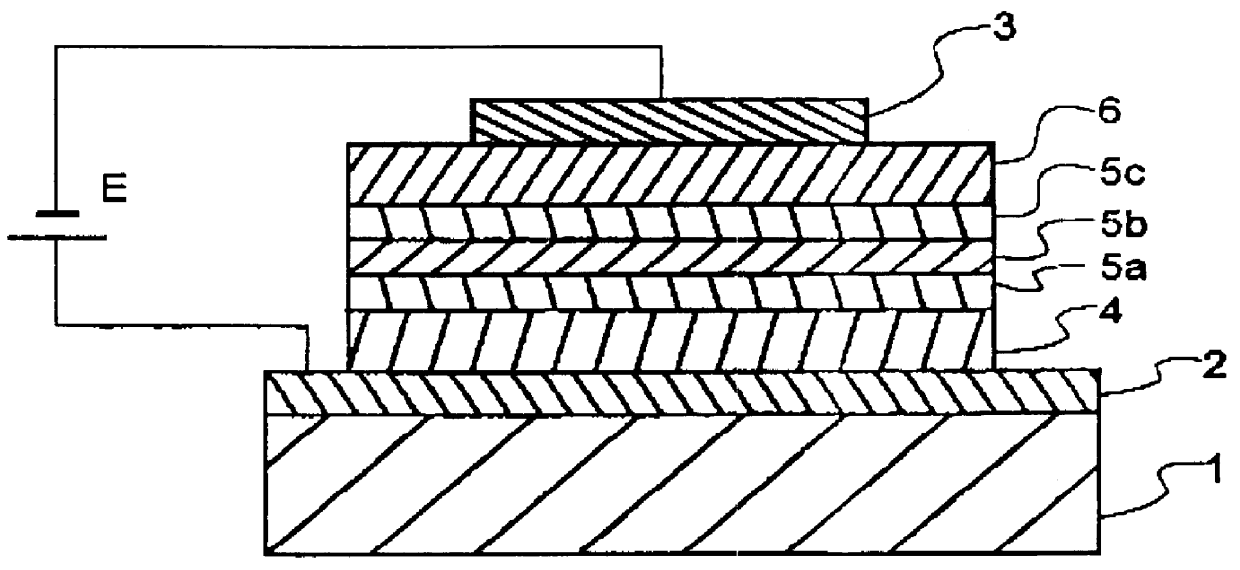

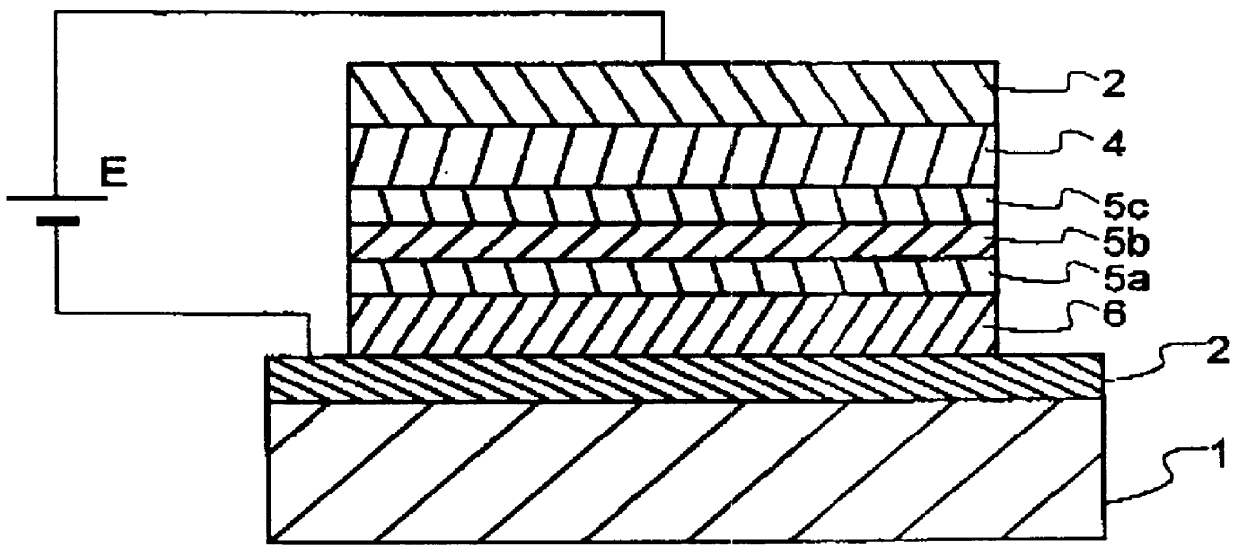

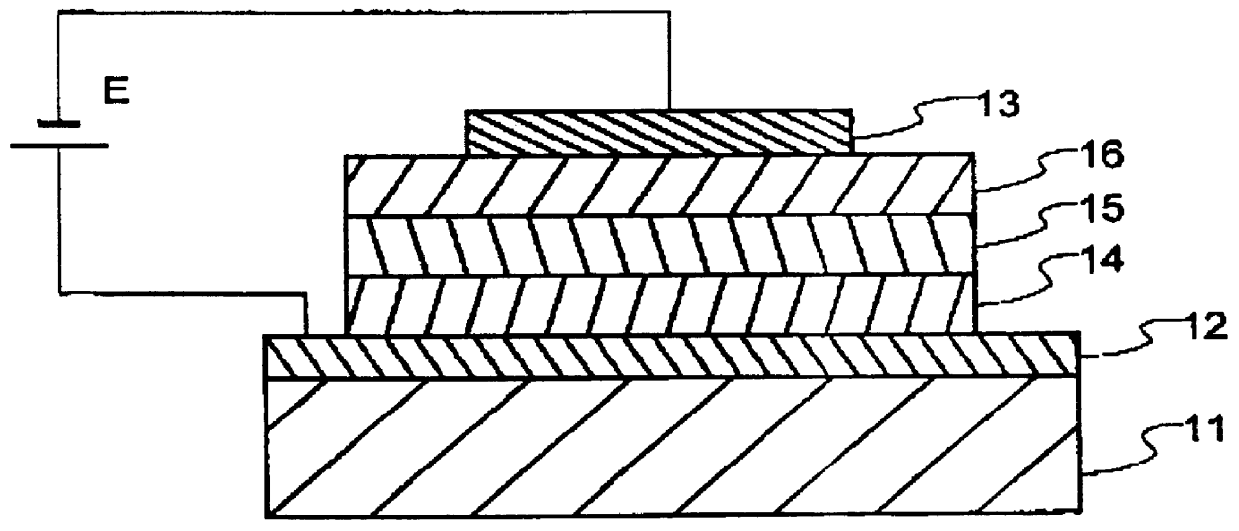

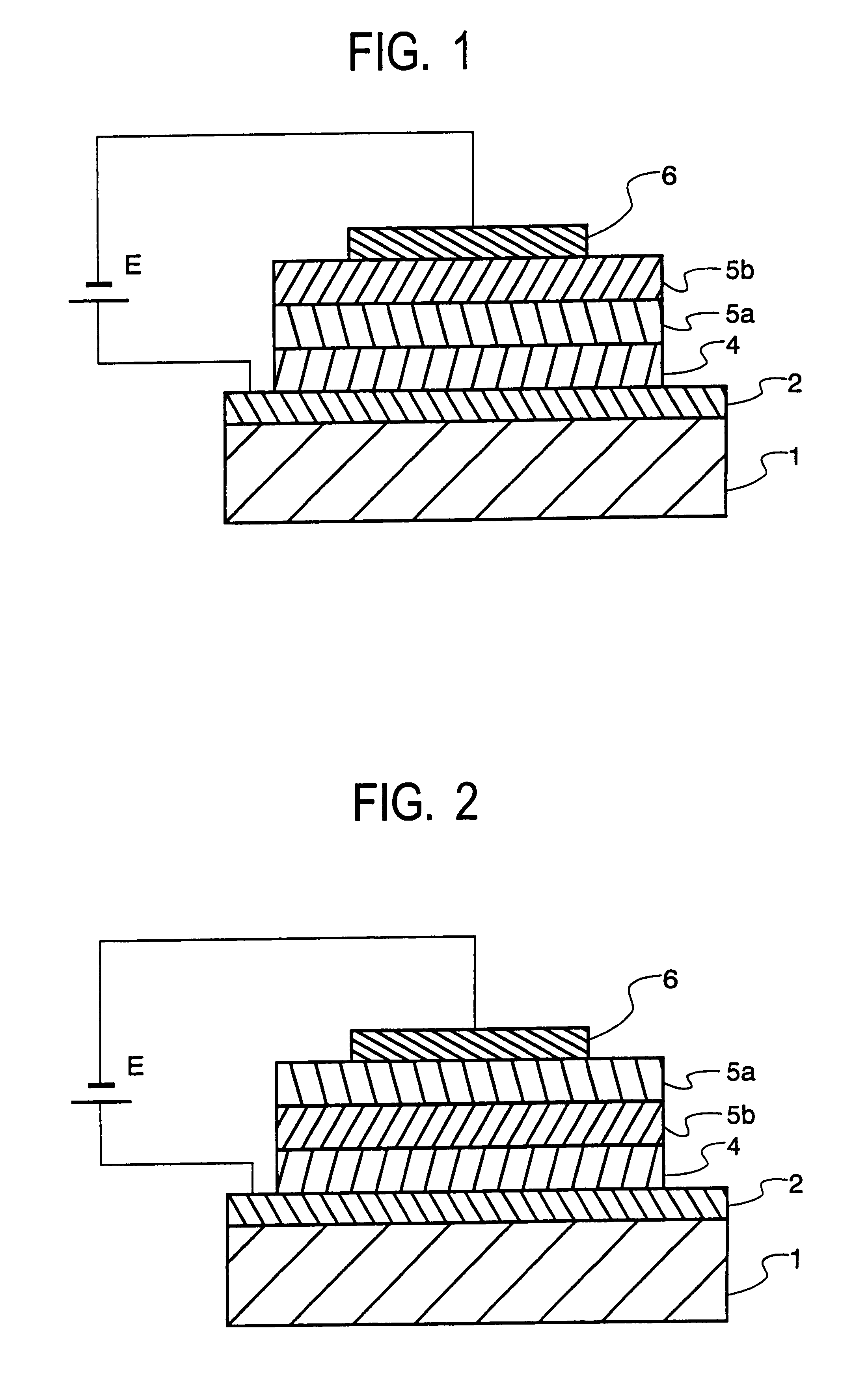

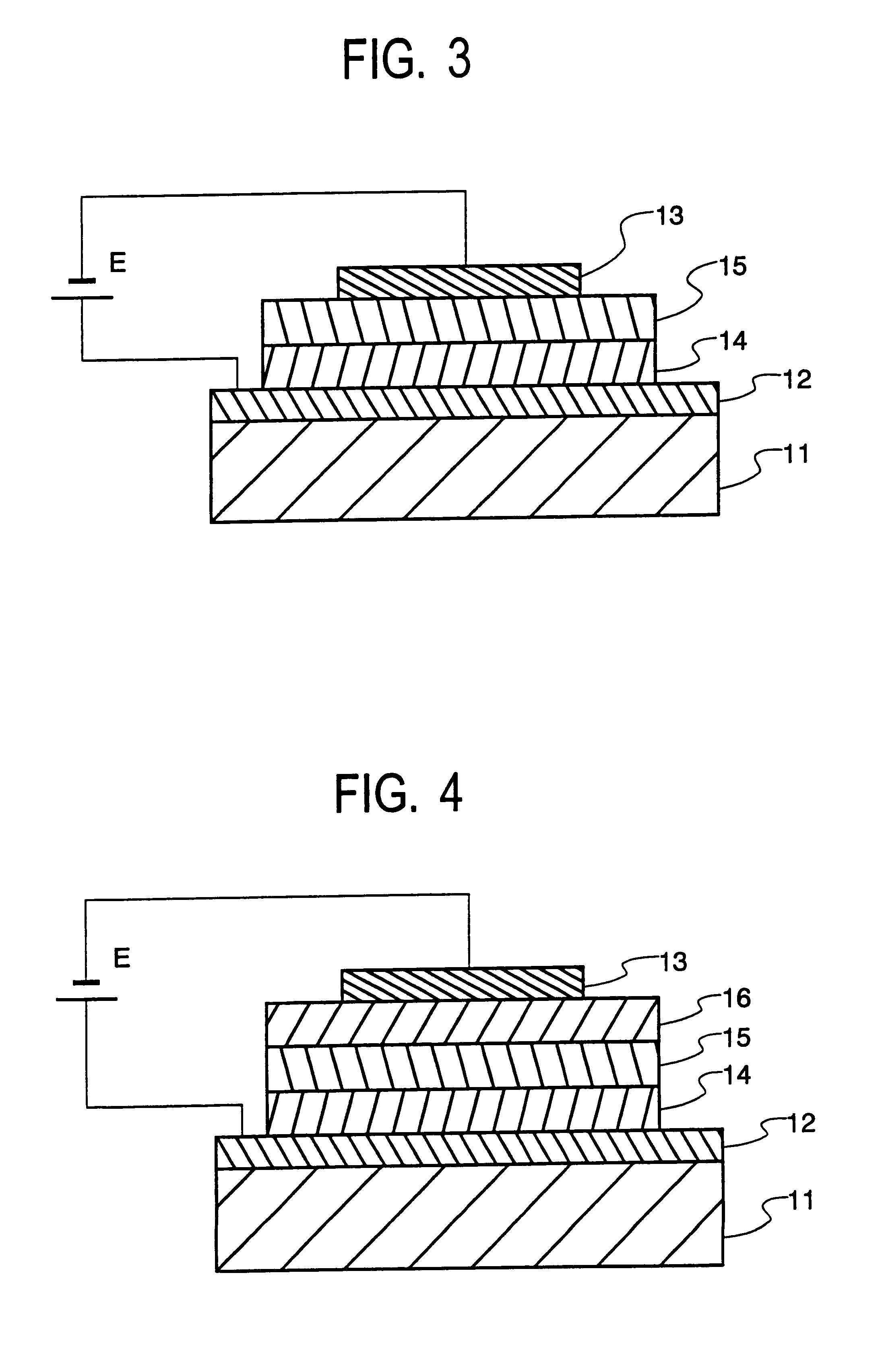

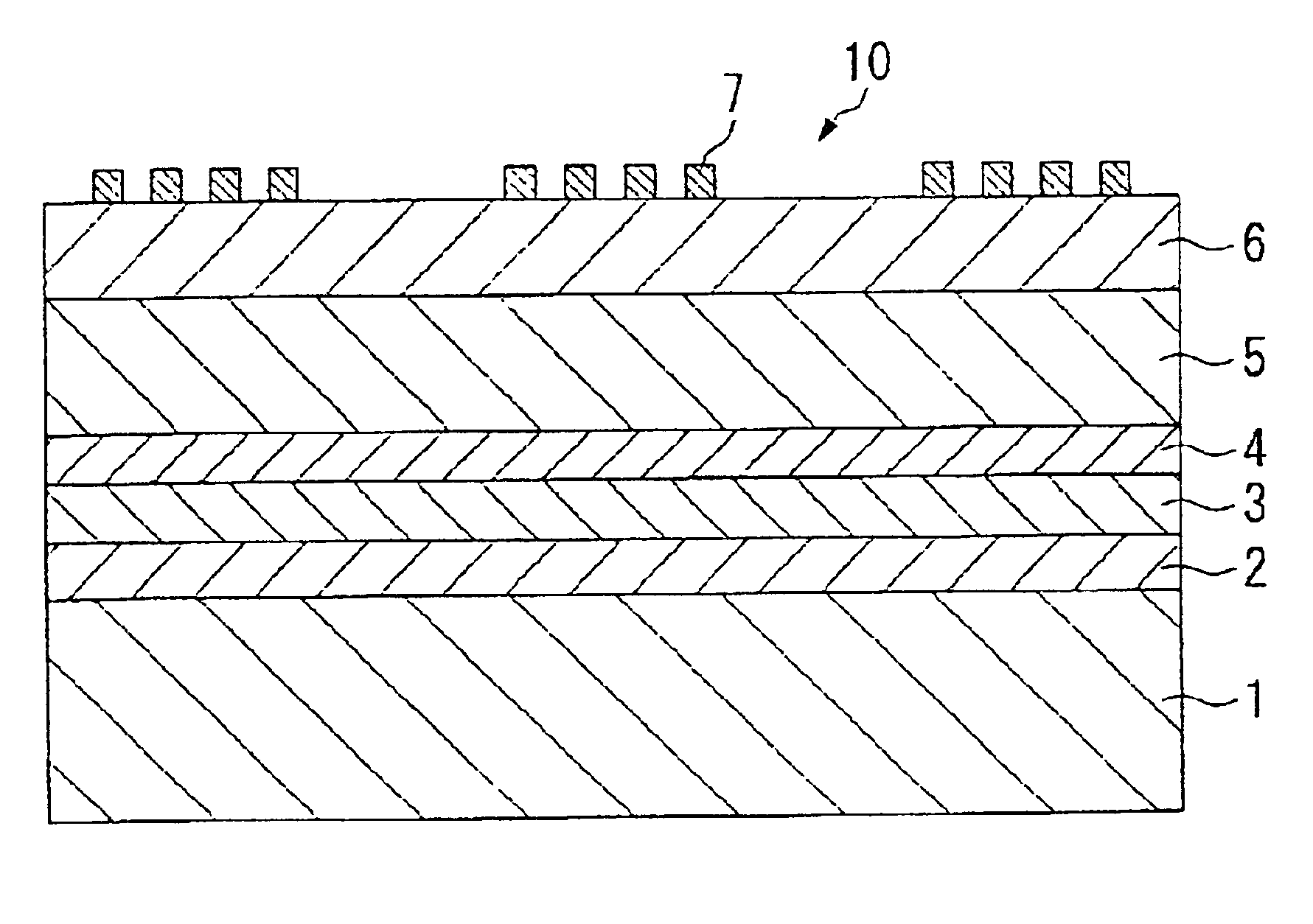

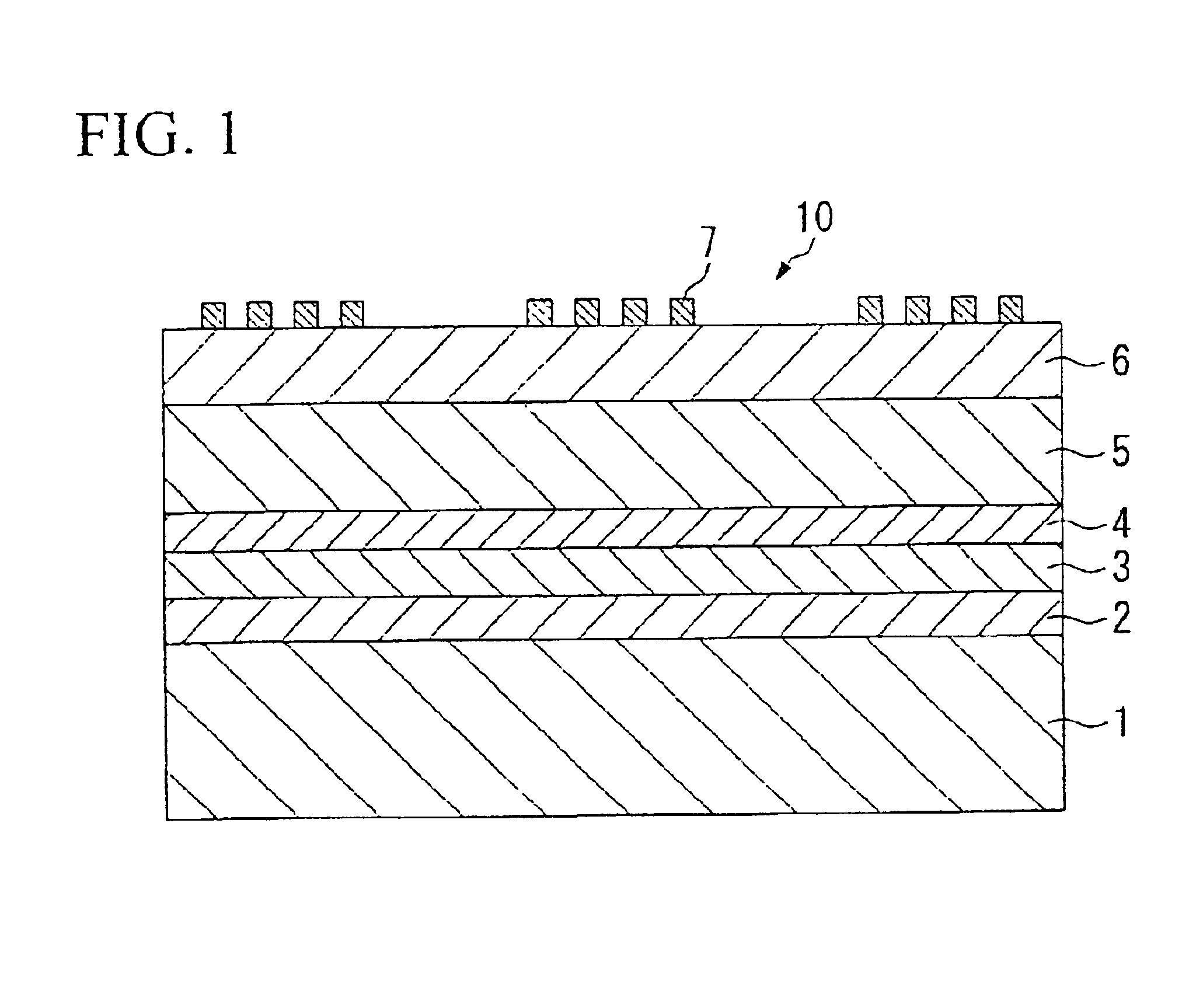

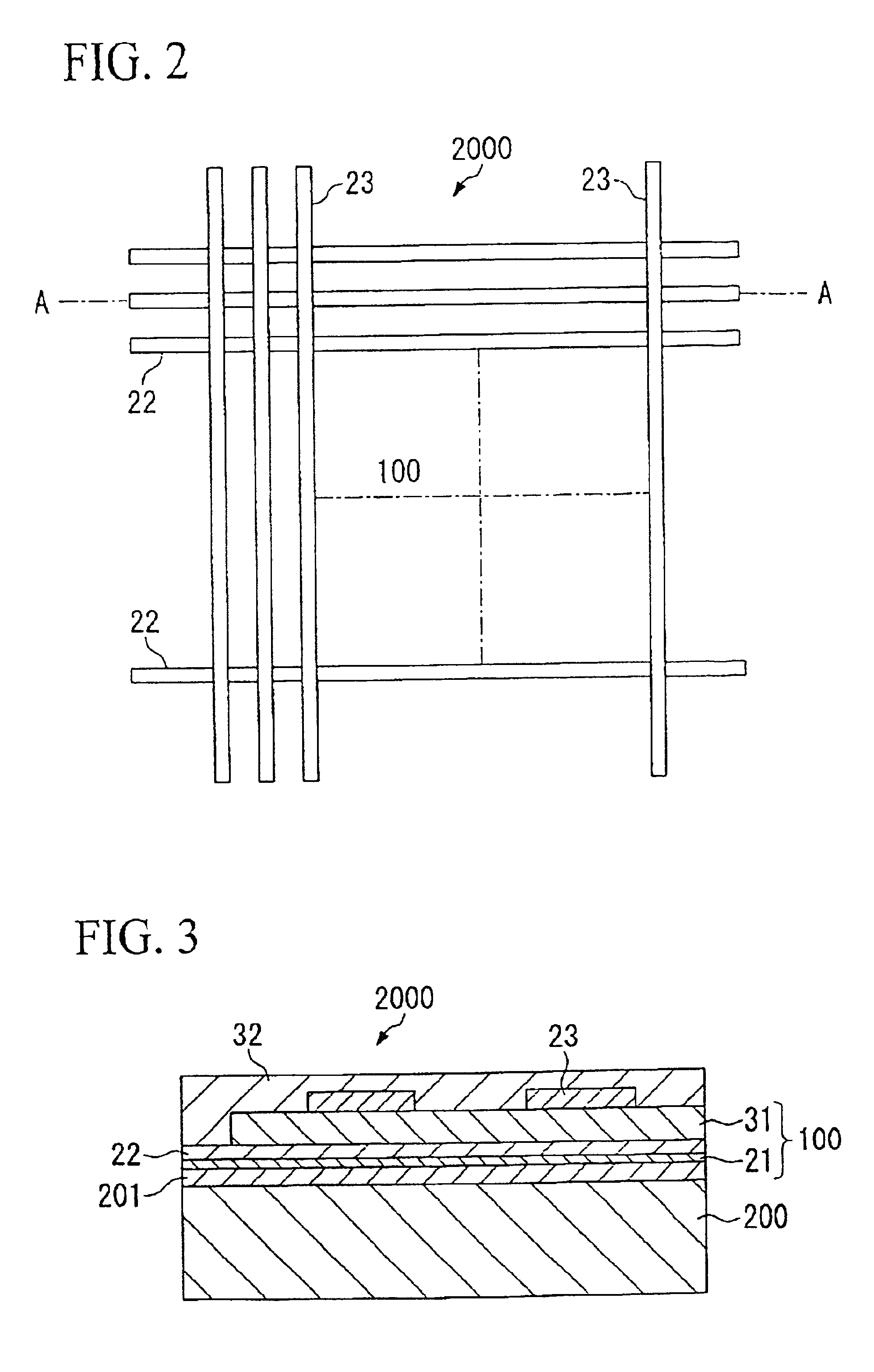

Organic electroluminescent device having a conjugated polymer and an inorganic insulative electron injecting and transporting layer

InactiveUS6404126B1Improve efficiencyLong lastingDischarge tube luminescnet screensElectroluminescent light sourcesRubidium oxideLithium oxide

An organic electroluminescent device having high efficiency, a long life time, and low cost, includes a substrate, a hole injecting electrode and an electron injecting electrode formed on the substrate, an organic material-containing organic layer between the electrodes, and an inorganic insulative electron injecting and transporting layer between the light emitting layer and the electron injecting electrode. The organic layer includes a light emitting layer containing a conjugated polymer, and the inorganic insulative electron injecting and transporting layer comprises three components. The first component is at least one oxide selected from the group consisting of lithium oxide, rubidium oxide, potassium oxide, sodium oxide, and cesium oxide. The second component is at least one of strontium oxide, magnesium oxide, and calcium oxide. The third component consists of silicon oxide, germanium oxide, or mixtures thereof.

Owner:TDK CORPARATION

Optical glass

InactiveCN1450010AHigh coefficient of thermal expansionPrecise without migrationOptical elementsLithium oxideSilicic acid

The present invention relates to an optical glass using silicic acid group as main body, said optic glass has high expansion coefficient, high Young modulus, excellent weatherability and high transmissivity in the infrared wave zone. Said glass composition contains (mole%) 36-66% of silicon dioxide, 0-12% of aluminium oxide, 0-6% of boric oxide, 0-10% of magnesium oxide, 0-16% of calcium oxide, 0-16% of strontium oxide, 0-16% of baria, 0-8% of zinc oxide, 0-32% of lithium oxide, 0-25% of sodium oxide, 0-25% of potassium oxide, 0-20% of cesium oxide, 0-6% of phosphorus pentoxide, 0-8% of scandium oxide and others.

Owner:PICVUE OPTOELECTRONICS INT

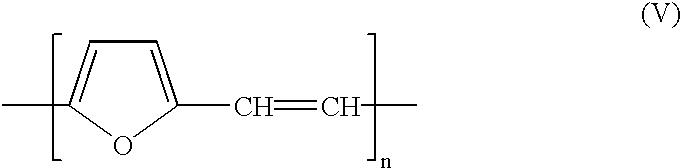

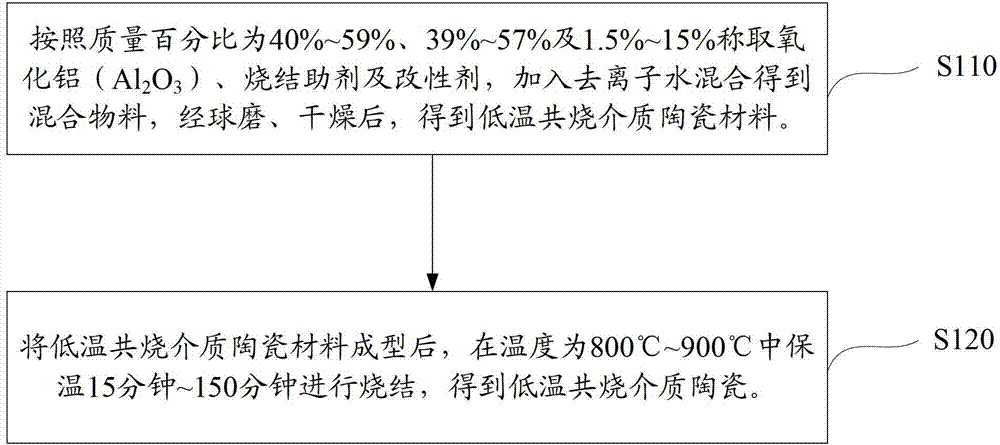

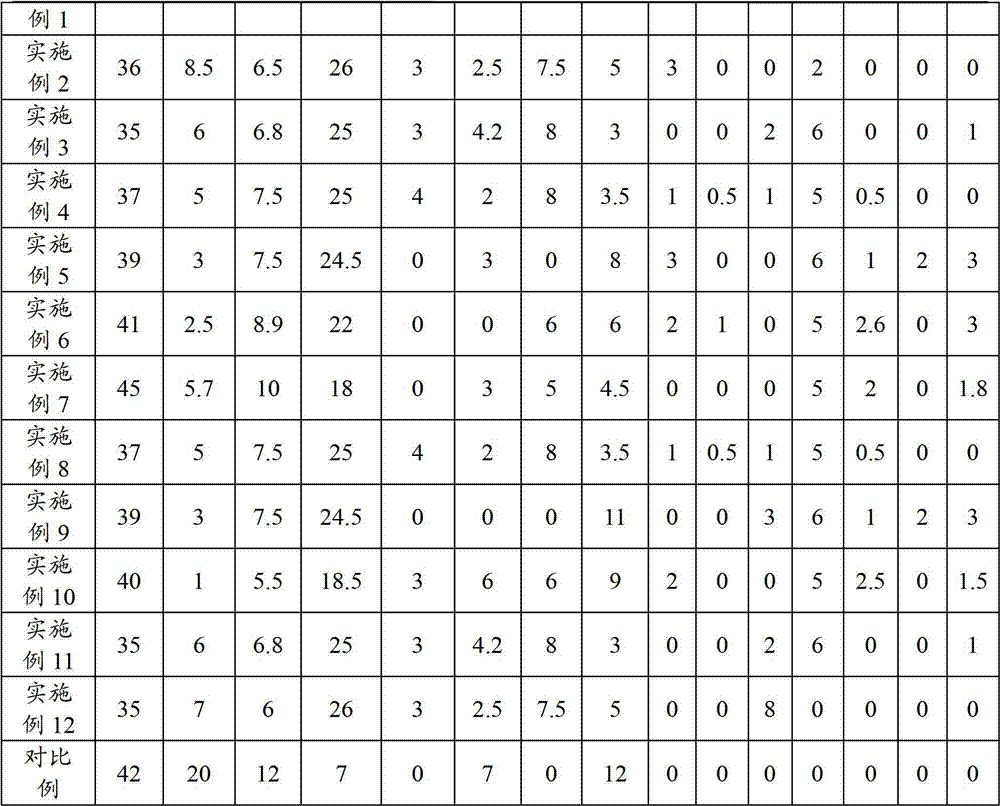

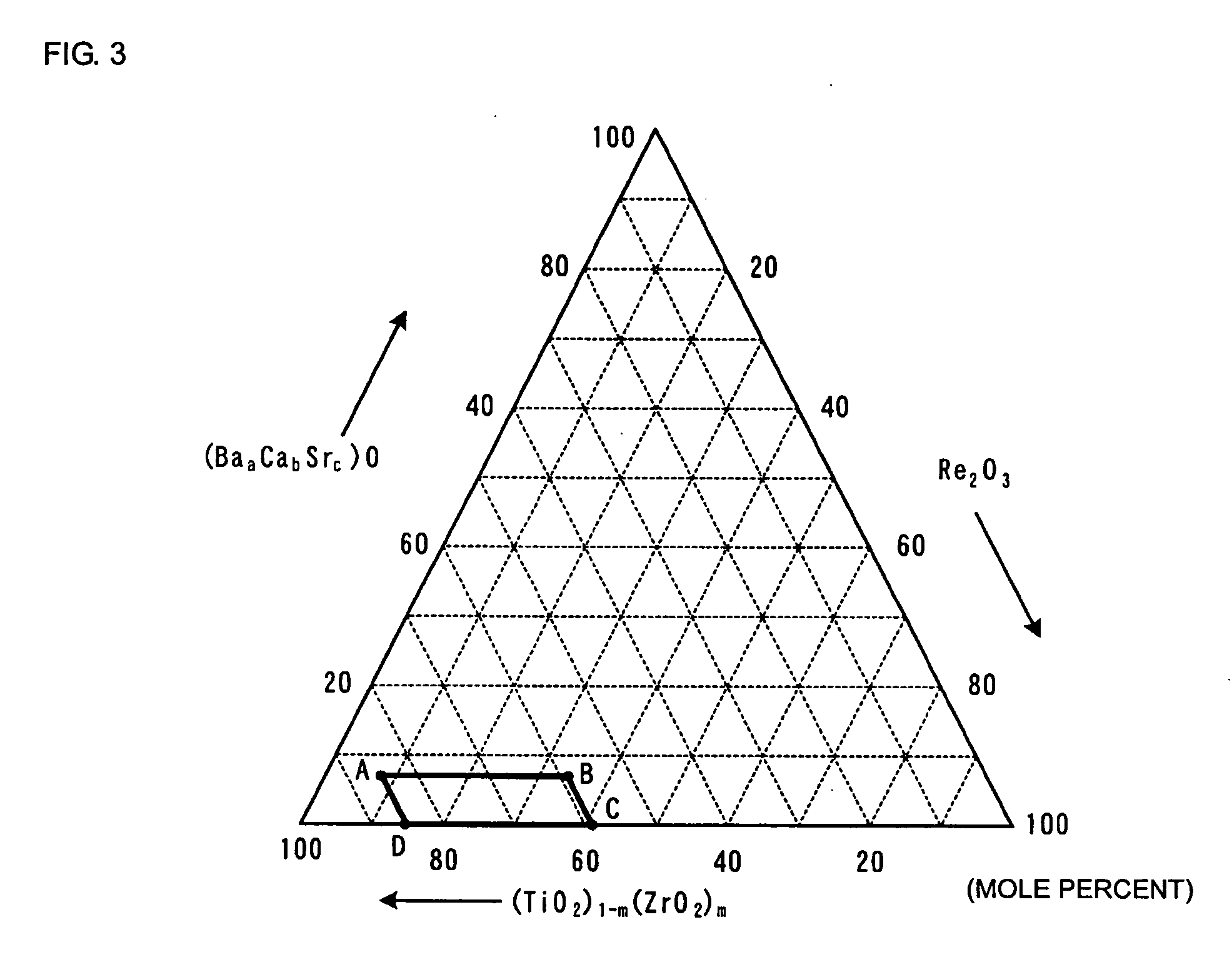

Method, sintering aid and materials for preparation of low-temperature cofired medium ceramic and application

A sintering aid for a low-temperature cofired medium ceramic material is composed of, by weight, 31%-45% of silicon dioxide, 1%-10% of boron oxide, 5.1%-10% of zinc oxide, 18%-30% of aluminum oxide, 11%-24% of alkaline earth metallic oxide and 5%-15% of oxide with the general formula of R2O3, wherein R refers to at least one of lanthanum, cerium, praseodymium, neodymium, samarium, europium and dysprosium, and the alkaline earth metallic oxide refers to one of magnesium oxide, calcium oxide, barium oxide and strontium oxide. Adding the sintering aid into the low-temperature cofired medium ceramic material enables the prepared low-temperature cofired medium ceramic to have excellent thermal mechanical performance and dielectric performance. In addition, the invention provides the low-temperature cofired medium ceramic material and application thereof and a method for preparing the low-temperature cofired medium ceramic.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Permanent ferrite magnetic tile and preparation method thereof

InactiveCN101202138AIncrease solid solutionImprove performancePermanent magnetsInorganic material magnetismFiberSilicon oxide

The invention relates to a permanent ferrite magnetic arc and the manufacturing method thereof, belonging to a manufacturing field of a motor permanent ferrite. Weight proportions of main material components and additive components are as the following: main materials: 8.7 to 9.0 percent of strontium oxide; 86 to 87 percent of iron oxide red; additives: 0.6 to 1.0 percent of calcium carbonate; 0.6 to 1.0 percent of aluminum oxide; 0.4 to 0.8 percent of chrome oxide; 0.3 to 0.6 percent of boric acid; 0.3 to 0.5 percent of silicon oxide; 0.2 to 0.4 percent of cobalt oxide; 0.2 to 0.4 percent of lanthanum oxide and 0.1 to 0.3 percent of silicate fiber. The invention is provided with high surplus magnetic induction strength and high intrinsic coercivity so as to enhance a mechanical strength of the magnetic arc.

Owner:CHANGZHOU DIER MAGIC MATERIALS

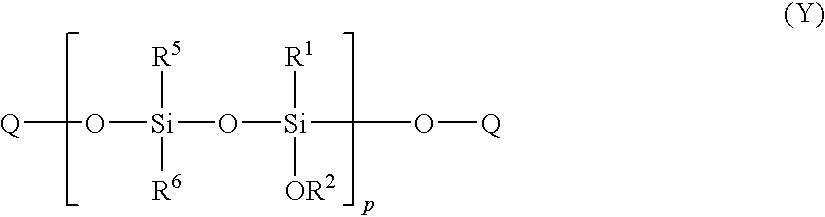

Process for producing polysiloxanes and use of the same

A process for the preparation of an organosilicon condensate which comprises reacting together a silicon containing compound having at least one silanol group and a silicon containing compound having at least one —OR group or at least one silanol group (or a compound having both groups) in the presence of strontium oxide, barium oxide, strontium hydroxide or barium hydroxide and optionally a solvent such as water, methanol, ethanol, 1-propanol, 2-propanol, 1-butanol and 2-butanol, acetone or toluene.

Owner:ZETTA RES & DEV LLC RPO SERIES

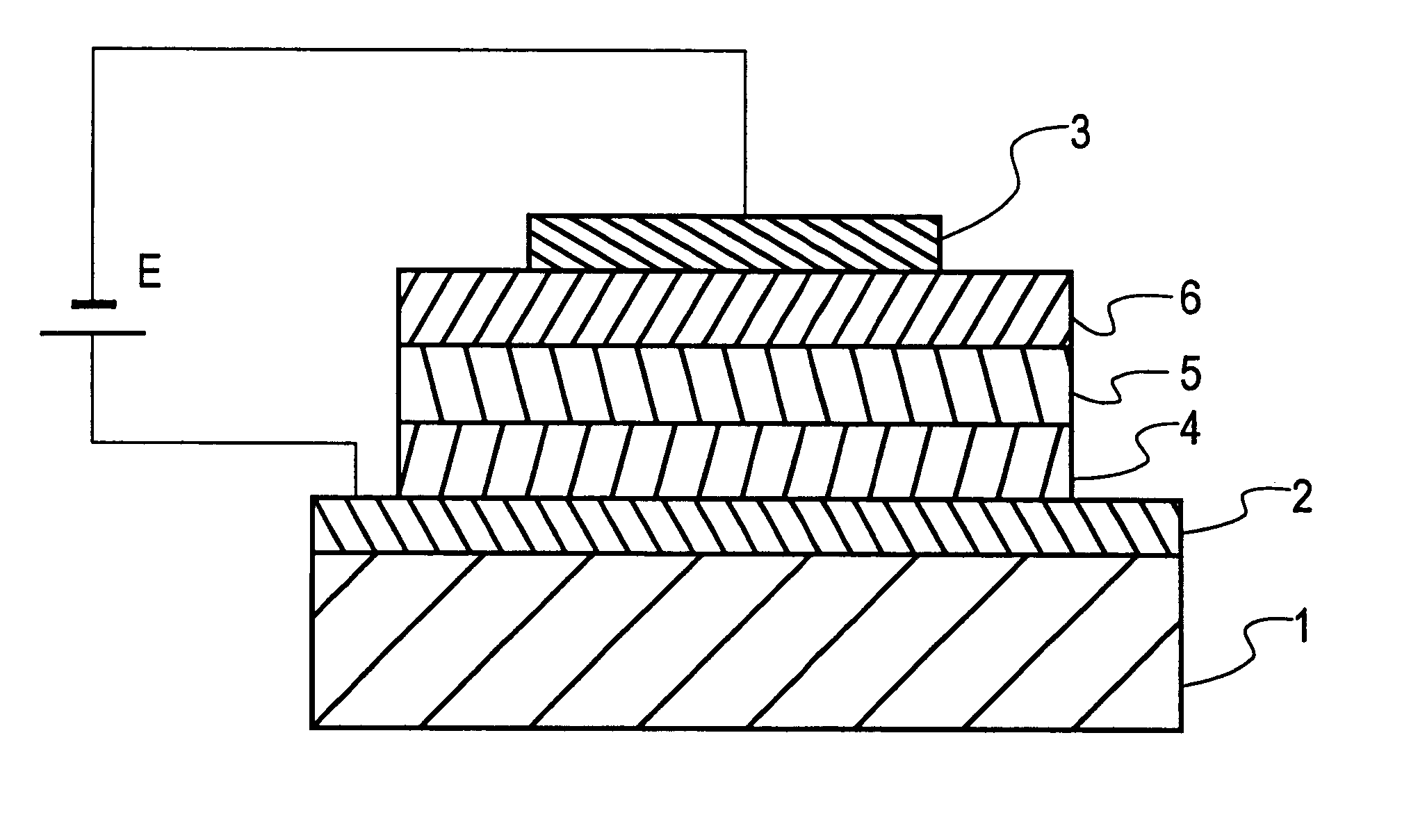

Organic electroluminescent device

InactiveUS6166488AImprove stabilityProlong lifeDischarge tube luminescnet screensElectroluminescent light sourcesRubidium oxideLithium oxide

An object of the invention is to achieve an organic EL device which is resistant to a deterioration of an inorganic-organic interface, has performance equivalent or superior to that of a prior art device comprising hole and electron injecting and transporting layers using an organic substance, possesses an extended life, weather resistance and high stability, and is inexpensive. This object is accomplished by the provision of an organic EL device which comprises a substrate, a hole injecting electrode and a cathode formed on the substrate, and an organic substance-containing light emitting layer located at least between these electrodes, wherein an inorganic insulating electron injecting and transporting layer is located between the light emitting layer and the cathode, and an inorganic insulating hole injecting and transporting layer is located between the light emitting layer and the hole injecting electrode. The inorganic insulating electron injecting and transporting layer comprises as a main component one or two or more oxides selected from the group consisting of strontium oxide, magnesium oxide, calcium oxide, lithium oxide, rubidium oxide, potassium oxide, sodium oxide and cesium oxide, and the inorganic insulating hole injecting and transporting layer comprises as a main component an oxide of silicon and / or an oxide of germanium. The main component has an average composition represented by (Si1-xGex) Oy where 0< / =x< / =1, and 1.7< / =y< / =1.99. The light emitting layer comprises a layer made up of a host substance on a side thereof contiguous to the inorganic insulating electron injecting and transporting layer and / or the inorganic insulating hole injecting and transporting layer. A layer containing a dopant in addition to the host substance is located on the side of the light emitting layer that faces away from the layer made up of the host substance or between them.

Owner:TDK CORPARATION

Hydrogen-storing material with low-cerium and production thereof

ActiveCN1817447AHigh oxygen storage performanceIncrease the areaMetal/metal-oxides/metal-hydroxide catalystsHydrogenCerium

An O2-bearing low-Ce RE material with high performance and multiple purposes is a composite oxide consisting of cerium oxide, zirconium oxide and assistant chosen from lanthanum oxide, strontium oxide and yttrium oxide. It is prepared through codeposition and calcining at 500-600 deg.C. It can be used as the carrier and assistant of the catalyst for cleaning the tail gas of car.

Owner:SINOCAT ENVIRONMENTAL TECH

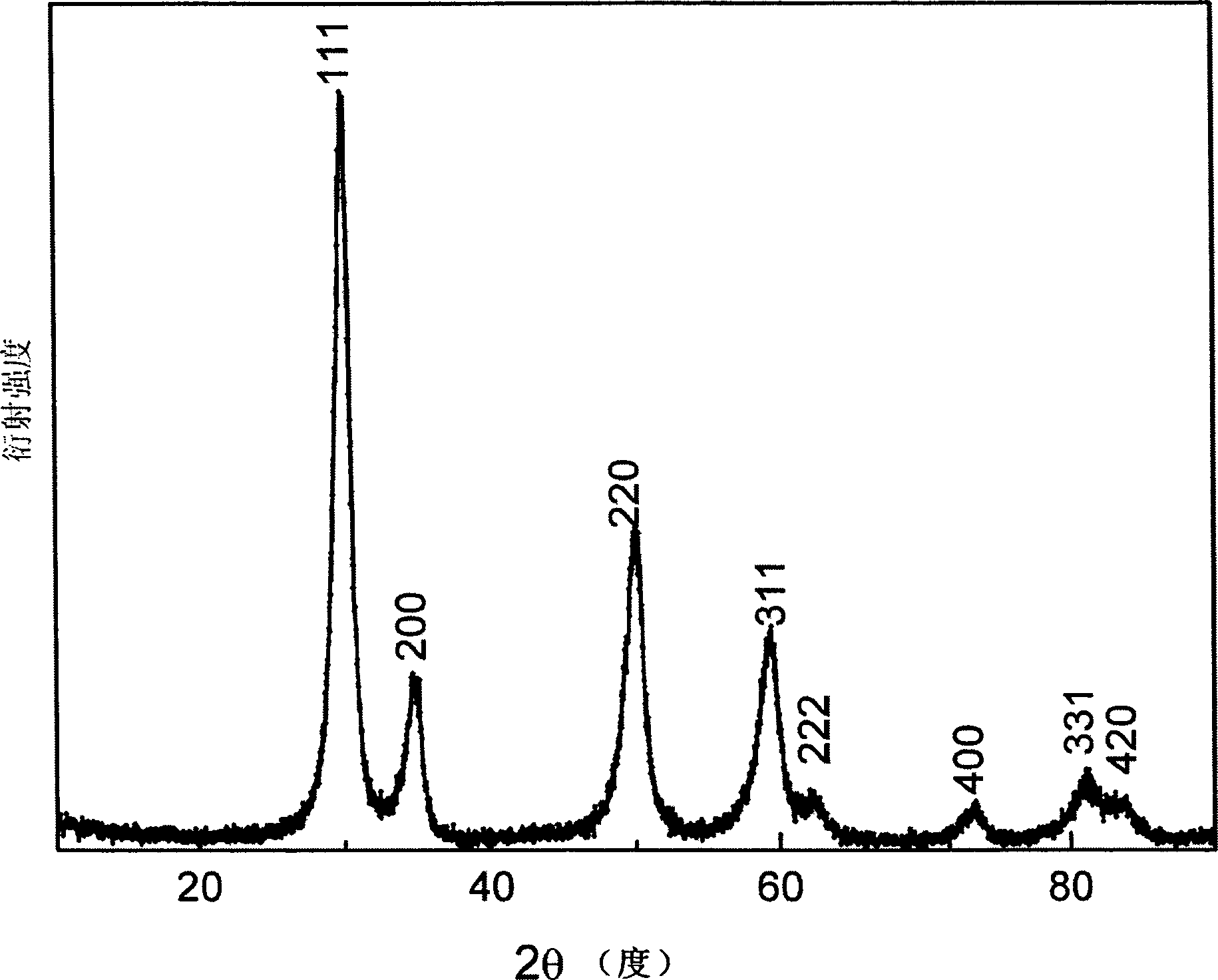

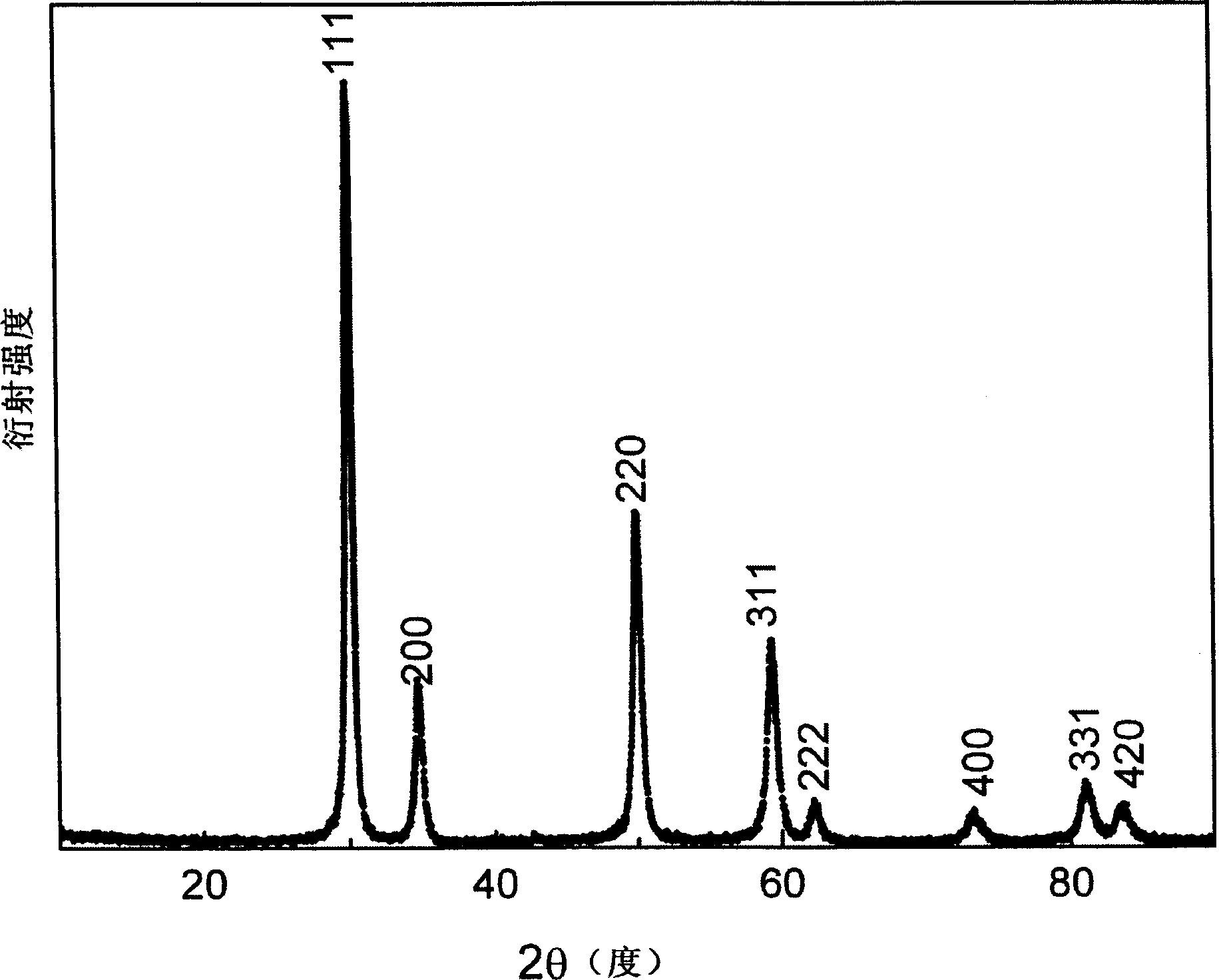

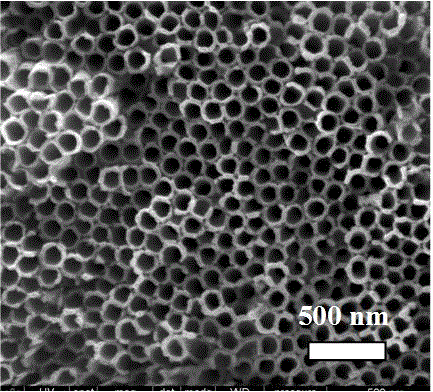

Preparation method of iron strontium oxide magnetic nanoparticles and magnetic damping rubber thereof

ActiveCN101913855AStrong magnetismGood compatibilityPigment treatment with organosilicon compoundsMagnetic dampingMolten salt

The invention discloses a preparation method of iron strontium oxide magnetic nanoparticles and a magnetic damping rubber thereof, which solves the problem that the existing magnetic damping rubber fails to meet the requirements for excellent physical-mechanical properties and good magnetic damping effect simultaneously. In the preparation method of the iron strontium oxide magnetic nanoparticles, a chemical coprecipitation method is organically combined with a molten salt method to obtain surface-modified nano-grade iron strontium oxide in a regular shape, and then the obtained iron strontium oxide is used for preparing the magnetic damping rubber. The invention has the following advantages: the magnetic particles have nano-scale particle size and excellent magnetic property, and can be uniformly dispersed in a rubber matrix; a nitrile-butadiene rubber is taken as the matrix, thus having excellent oil resistance; and the magnetic damping rubber has excellent mechanical property.

Owner:ZHONGBEI UNIV

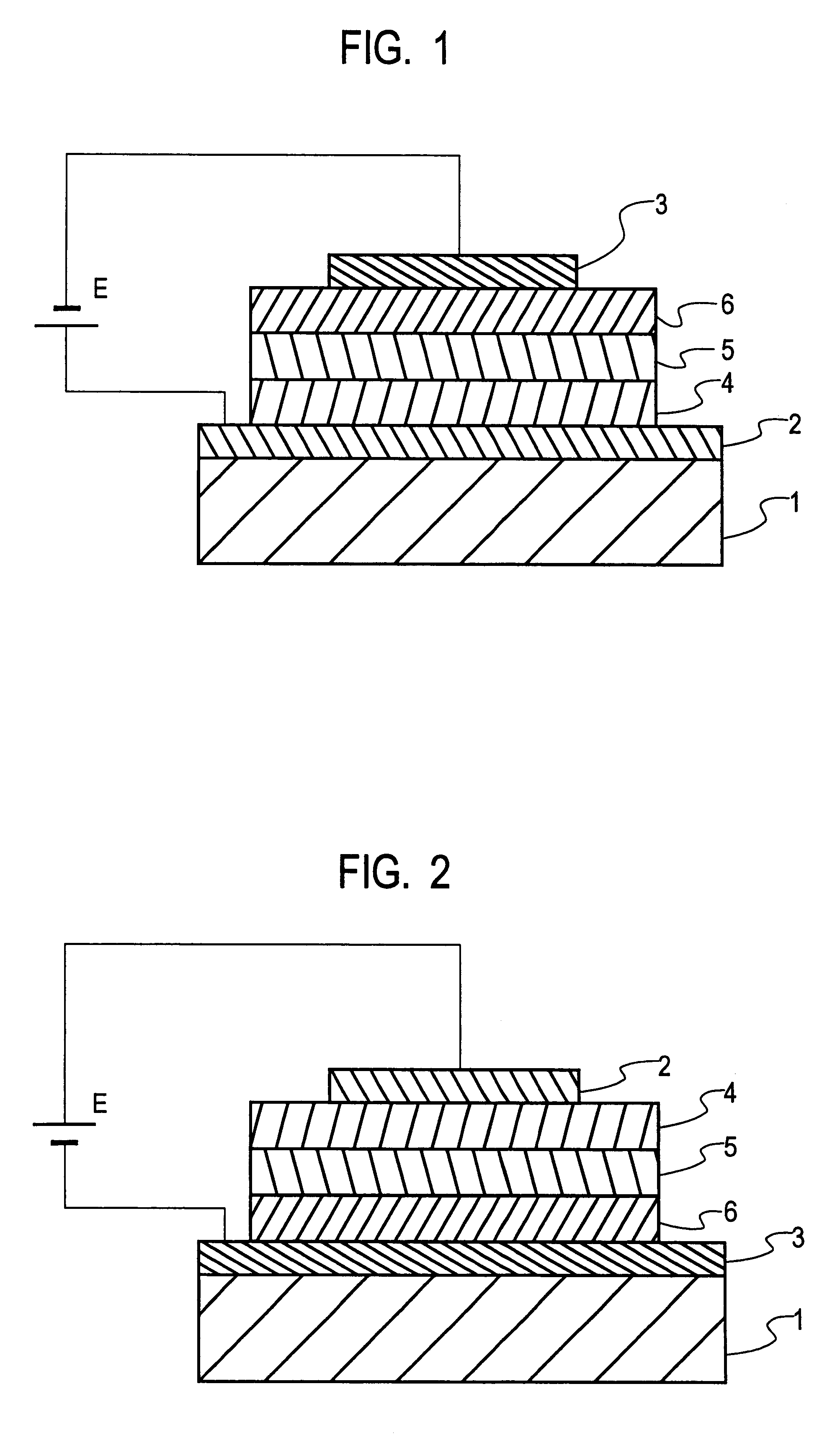

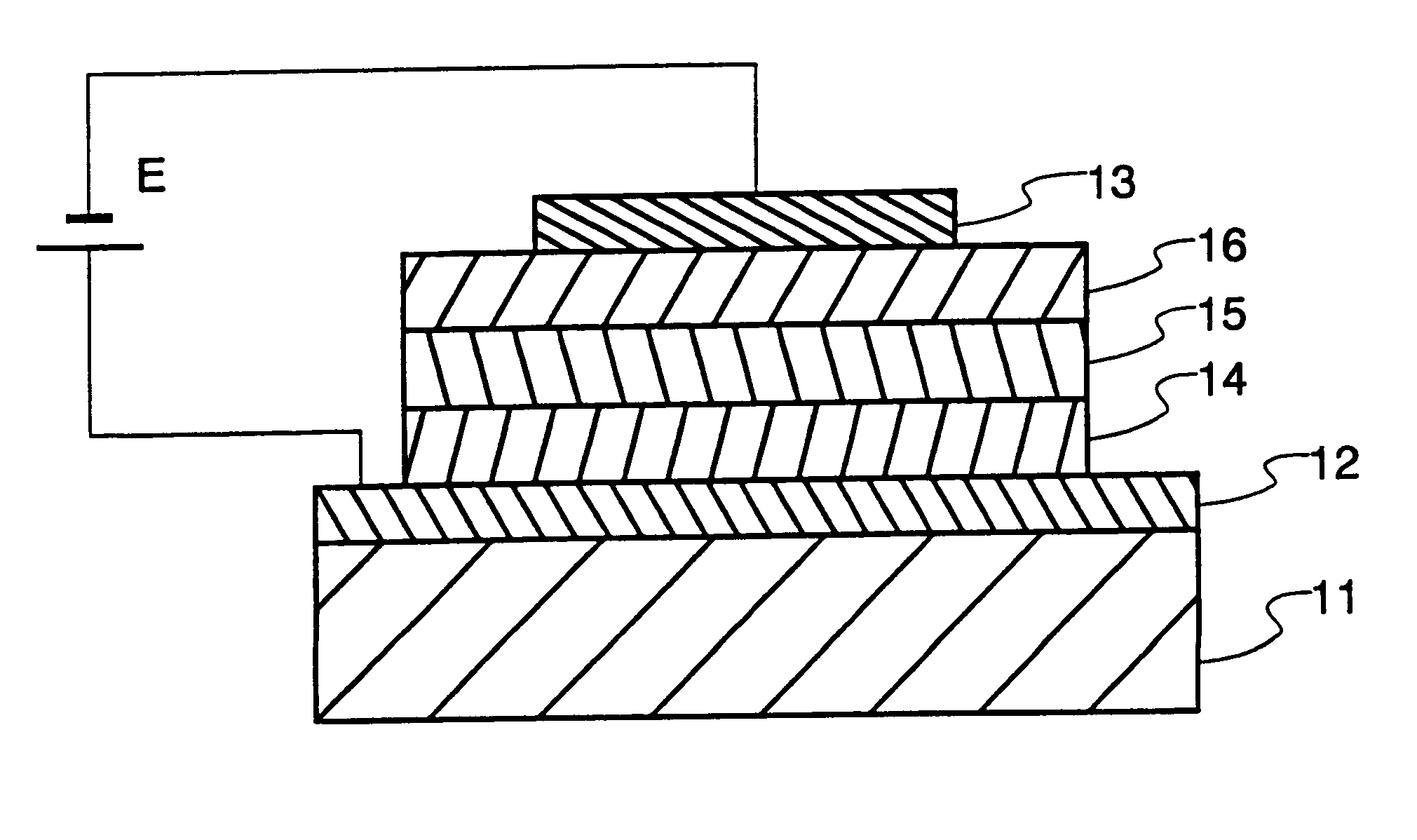

Organic electroluminescent device

InactiveUS6303239B1Improve stabilityImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesRubidium oxideLithium oxide

An object of the invention is to achieve an organic EL device which has an extended life, weather resistance, high stability, and high efficiency, and is inexpensive as well. This object is accomplished by the provision of an organic EL device comprising a substrate, a pair of a hole injecting electrode and a cathode formed on the substrate, and an organic layer located between these electrodes and taking part in at least a light emission function, wherein between the organic layer and the cathode there is provided an inorganic insulating electron injecting and transporting layer comprising a first component comprising at least one oxide selected from the group consisting of lithium oxide, rubidium oxide, potassium oxide, sodium oxide and cesium oxide, a second component comprising at least one oxide selected from the group consisting of strontium oxide, magnesium oxide and calcium oxide, and a third component comprising silicon oxide and / or germanium oxide.

Owner:TDK CORPARATION

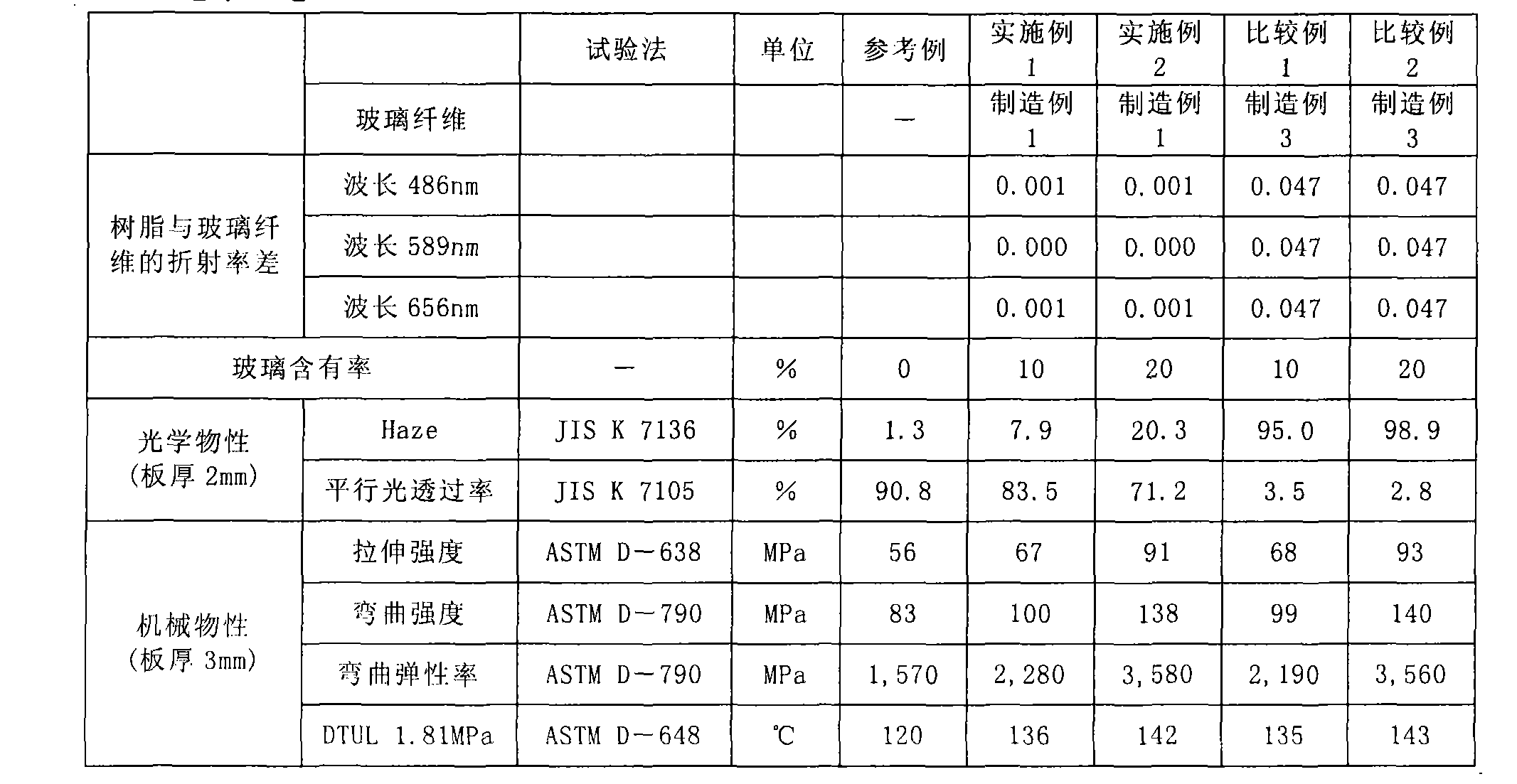

Amorphous polyamide resin composition and molded product

Provided are an amorphous polyamide resin composition having high transparency, and is excellent in heat resistance and stiffness, and a molded product thereof. The glass filler contains, expressed in terms of oxides by mass %, 68 to 74% of silicon dioxide (SiO2), to 5% of aluminum oxide (Al2O3), 2 to 5% of boron oxide (B2O3), 2 to 10% of calcium oxide (CaO), 0 to 5% of zinc oxide (ZnO), 0 to 5% of strontium oxide (SrO), 0 to 1% of barium oxide (BaO), 1 to 5% of magnesium oxide (MgO), 0 to 5% of lithium oxide (Li2O), 5 to 12% of sodium oxide (Na2O), and 0 to 10% of potassium oxide (K2O), where a total amount of lithium oxide (Li2O), sodium oxide (Na2O), and potassium oxide (K2O) is 8 to 12%.

Owner:ASAHI FIBER GLASS CO LTD

Glass-ceramic composition, glass-ceramic sintered body, and monolithic ceramic electronic component

InactiveUS20060287184A1Improve electrical insulation reliabilityReduced insulation performanceCeramic layered productsPrinted circuit manufactureStrontium titanateLithium oxide

A glass-ceramic composition contains first ceramic particles principally containing forsterite; second ceramic particles principally containing at least one selected from the group consisting of calcium titanate, strontium titanate, and titanium oxide; and borosilicate glass particles containing about 3% to 15% lithium oxide, about 20% to 50% magnesium oxide, about 15% to 30% boron oxide, about 10% to 45% silicon oxide, about 6% to 20% zinc oxide, 0% to about 15% aluminum oxide, and at least one additive selected from the group consisting of calcium oxide, barium oxide, and strontium oxide on a weight basis. The content of the borosilicate glass particles is about 3% or more; the lower limit of the content of the additive is about 2%; and the upper limit of the additive content is about 15%, about 25%, or about 25% when the additive is calcium oxide, barium oxide, or strontium oxide, respectively, on a weight basis.

Owner:MURATA MFG CO LTD

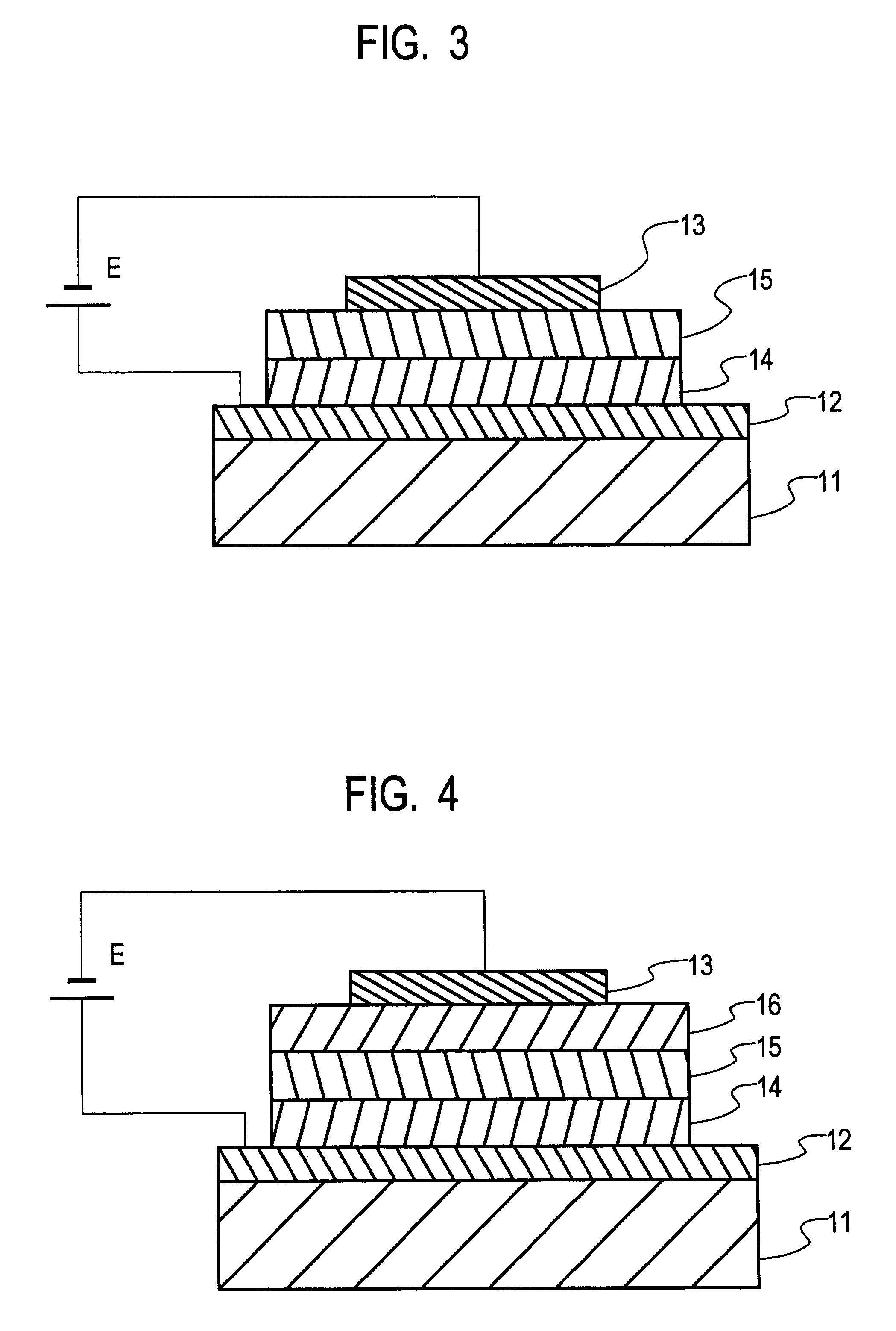

Organic electroluminescent device

InactiveUS6198219B1Improve performanceImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesLithium oxideRubidium oxide

The invention provides an organic EL device comprising a substrate, a hole injecting electrode and a negative electrode formed on the substrate, an organic layer containing an organic material between the electrodes, the organic layer including a light emitting layer having at least a light emitting function, and an electron injecting and transporting layer containing an electron transporting organic material and an inorganic insulative electron injecting and transporting layer formed of an inorganic material between the negative electrode and the light emitting layer. The inorganic insulative electron injecting and transporting layer contains at least one oxide selected from the group consisting of lithium oxide, rubidium oxide, potassium oxide, sodium oxide, cesium oxide, strontium oxide, magnesium oxide, and calcium oxide as a main component, and silicon oxide, germanium oxide or a mixture of silicon oxide and germanium oxide as a stabilizer. This construction ensures better performance than prior art devices having electron injecting and transporting layers using organic materials, a high efficiency, long life, weather resistance, and high stability.

Owner:TDK CORPARATION

Glass ceramic coating produced on metal carrier and its producing method

InactiveCN1899997AImprove ductilityNot easy to fall offCatalyst carriersCatalyst protectionCopper oxideAluminium oxide

The present invention belongs to the field of automobile tail gas purifying technology, and is especially glass ceramic coating on metal or alloy carrier of automobile tail gas purifying treater and its preparation process. The oxides of the glass coating include silica in 25-65 wt% and boron oxide in 5.0-27 wt%, except the mixture of other 3-9 oxides selected from 17 kinds of oxides, including sodium oxide, potassium oxide, lithium oxide, aluminum oxide, calcium oxide, etc. The glass coating on the metal carrier can raise the mechanical strength and reaction activity of the catalyst effectively, and this results in saving in active component and lowered cost.

Owner:JILIN UNIV

Alkali-free aluminoborosilicate glass, and uses thereof

InactiveUS20020013210A1Improve heat resistanceFavorable processing rangeNon-linear opticsSemiconductor devicesAlkali freeSilicate glass

The invention relates to an alkali-free aluminoborosilicate glass having a coefficient of thermal expansion alpha20 / 300 of between 2.8.10-6 / K and 3.6.10-6 / K, which has the following composition (in % by weight, based on oxide): silicon dioxide (SiO2)>58-65, boric oxide (B2O3)>6-11.5, aluminum oxide (Al2O3)>20-25, magnesium oxide (MgO) 4-<6.5, calcium oxide (CaO)>4.5-8, strontium oxide (SrO) 0-<4, barium oxide (BaO) 0.5-<5, with strontium oxide (SrO)+barium oxide (BaO)>3, zinc oxide (ZnO) 0-<2, and which is highly suitable for use as a substrate glass both in display technology and in thin-film photovoltaics.

Owner:SCHOTT AG +1

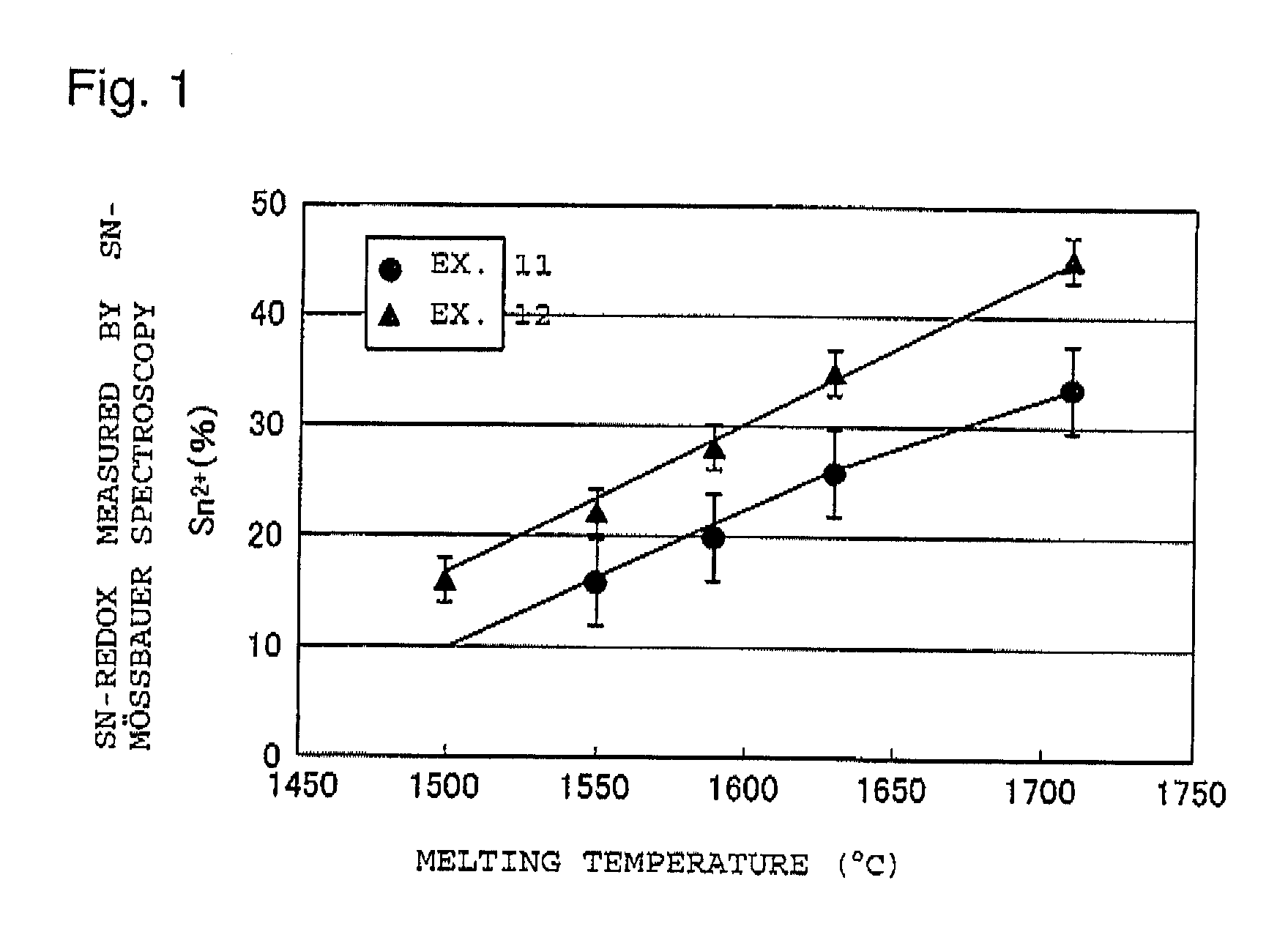

Process for producing alkali free glass and alkali free glass plate

InactiveUS20080127679A1Small coefficient of thermal expansionLess bubbleGlass furnace apparatusGlass productionTO-18Platinum

To provide a process for producing and alkali free glass for effectively suppressing bubbles, and an alkali free glass produced by the process, which is suitable as a glass substrate for flat panel displays and has few bubbles.A process for producing an alkali free glass containing substantially no alkali metal oxide, which comprises melting a glass starting material having a matrix composition of the following composition, and subjecting the molten glass to a treatment process of removing bubbles under reduced pressure, stirring or transferring under a condition where the molten glass is in contact with a platinum member, wherein the starting material is prepared so as to contain SnO2 in an amount of from 0.01 to 2.0% per 100% of the total amount of the above matrix composition; the starting material is melted under heating at from 1,500 to 1,650° C.; then bubbles contained in the molten glass are permitted to rise to the surface of the molten glass, together with oxygen bubbles generated by a reduction reaction in which SnO2 in the molten glass is reduced to SnO; and in the above treatment process, the oxygen bubbles generated at the interface between the molten glass and the platinum member are permitted to be absorbed by an oxidation reaction in which SnO is oxidized to SnO2, under a condition where the molten glass is from 1,300 to 1,500° C.Composition as represented by the mass percentage:SiO258.4 to 66.0%,Al2O315.3 to 22.0%,B2O3 5.0 to 12.0%,MgO 0 to 6.5%,CaO 0 to 7.0%,SrO 4 to 12.5%,BaO 0 to 2.0%,MgO + CaO + SrO + BaO 9.0 to 18.0%.

Owner:ASAHI GLASS CO LTD

Load type calcium oxide catalyst, its preparation method and uses

The present invention provides one kind of supported calcium oxide catalyst and its preparation process and usage in preparing biological diesel oil. The supported calcium oxide catalyst has the co-catalyst of strontium oxide, zinc oxide or lanthanum oxide, carrier of magnesia, silica, alumina or magnesia-alumina, calcium oxide supporting amount of 2-30 wt% of the carrier and co-catalyst supporting amount of 0-16 wt% of the carrier. The supported calcium oxide catalyst has simple preparation process, high repeatability, high reaction activity for preparing biological diesel oil, insolubility in methanol system and easy separation from the reaction system.

Owner:CHINA PETROLEUM & CHEM CORP +2

Color stable phosphors

ActiveUS20110279011A1Discharge tube luminescnet screensLamp detailsZinc hydroxideMagnesium phosphate

An LED lamp includes a light source configured to emit radiation with a peak intensity at a wavelength between about 250 nm and about 550 nm; and a phosphor composition configured to be radiationally coupled to the light source. The phosphor composition includes particles of a phosphor of formula I, said particles having a coating composition disposed on surfaces thereof;((Sr1−zMz)1−(x+w)AwCex)3(Al1−ySiy)O4+y+3(x−w)F1−y−3(x−w) Iwherein the coating composition comprises a material selected from aluminum oxide, magnesium oxide, calcium oxide, barium oxide, strontium oxide, zinc oxide, aluminum hydroxide, magnesium hydroxide, calcium hydroxide, barium hydroxide, strontium hydroxide, zinc hydroxide, aluminum phosphate, magnesium phosphate, calcium phosphate, barium phosphate, strontium phosphate, and combinations thereof; andA is Li, Na, K, or Rb, or a combination thereof;M is Ca, Ba, Mg, Zn, or a combination thereof; and0<x≦0.10, 0≦y≦0.5, 0≦z≦0.5, 0≦x≦x.

Owner:GE LIGHTING SOLUTIONS LLC

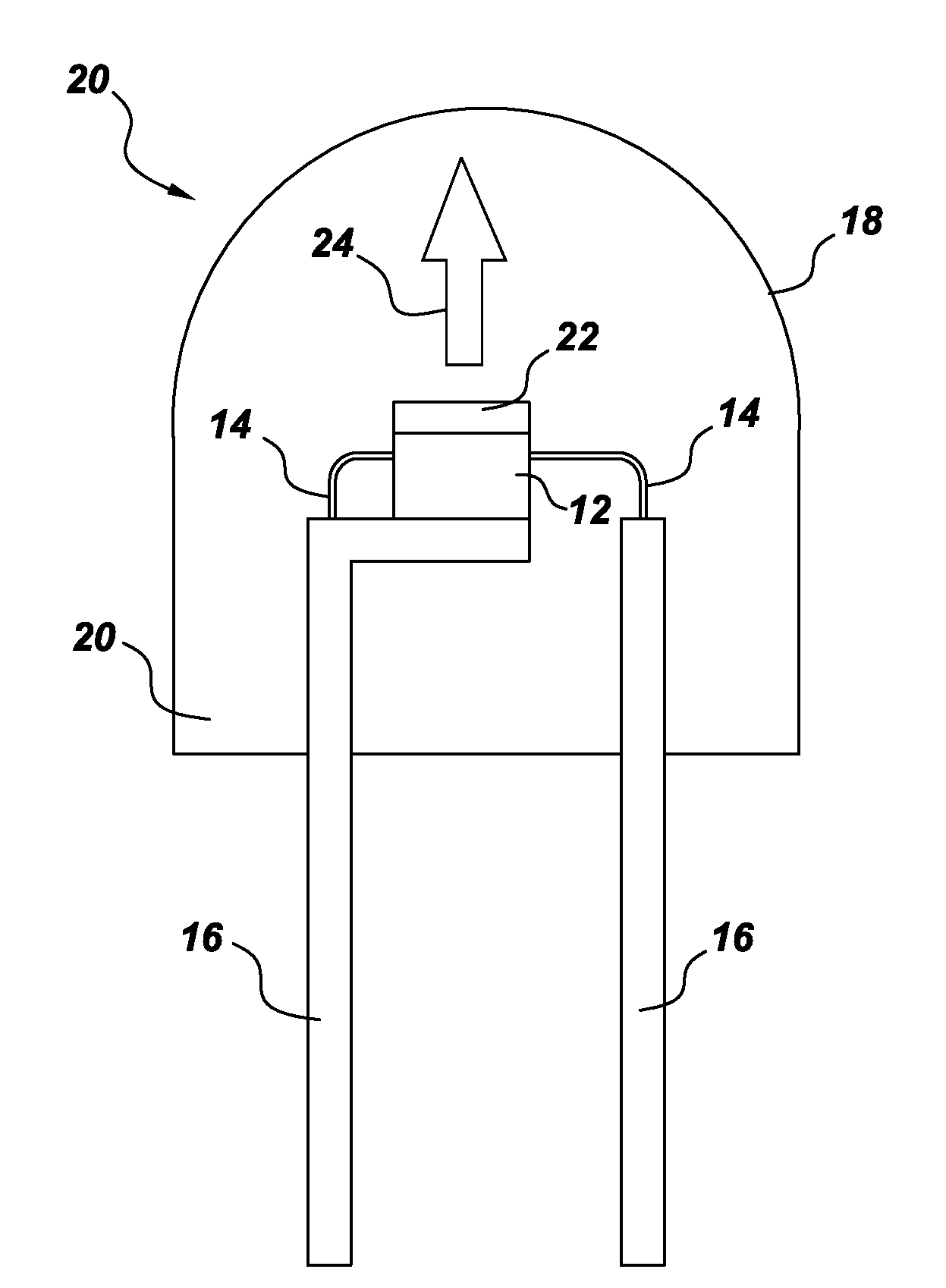

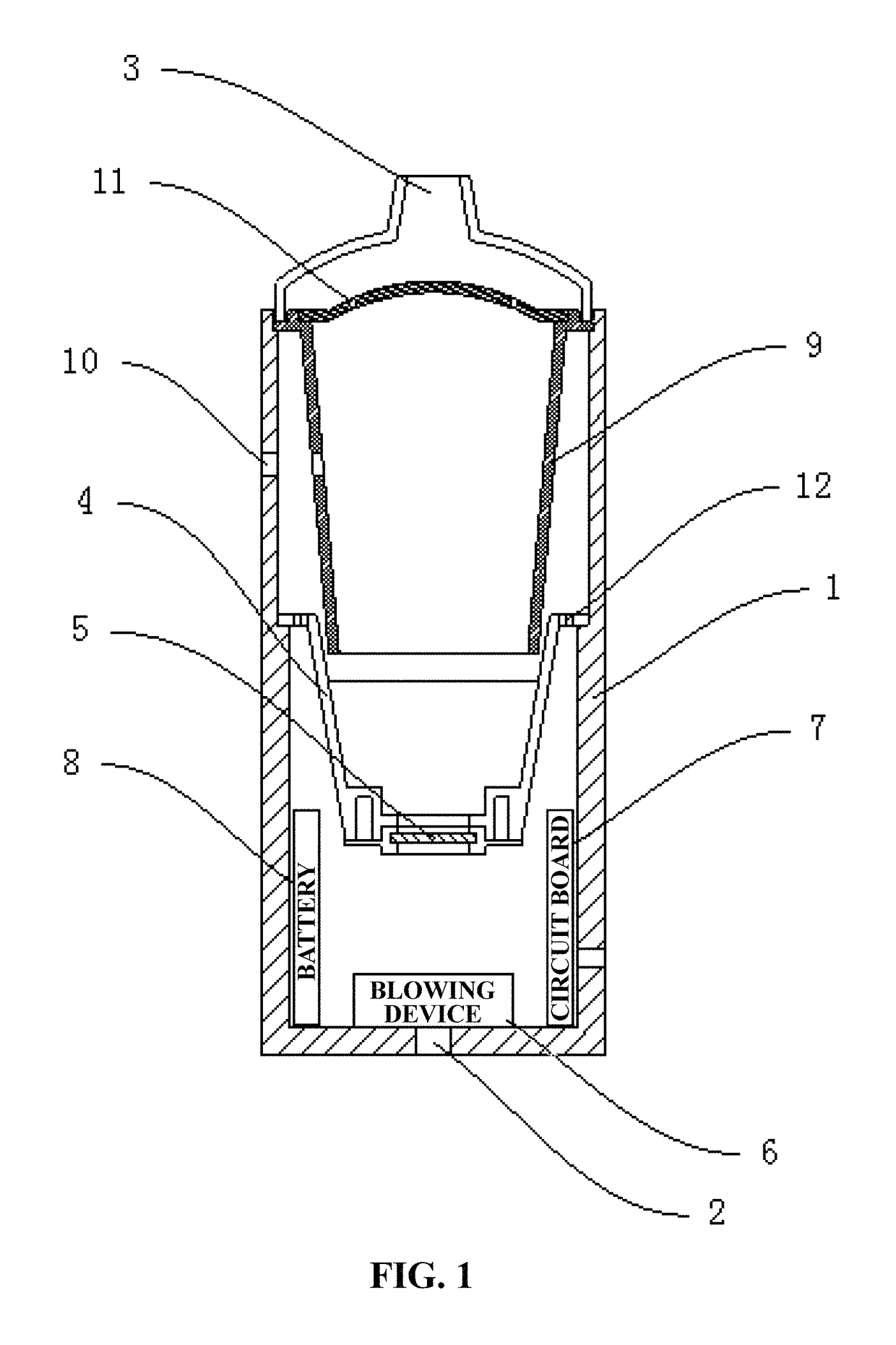

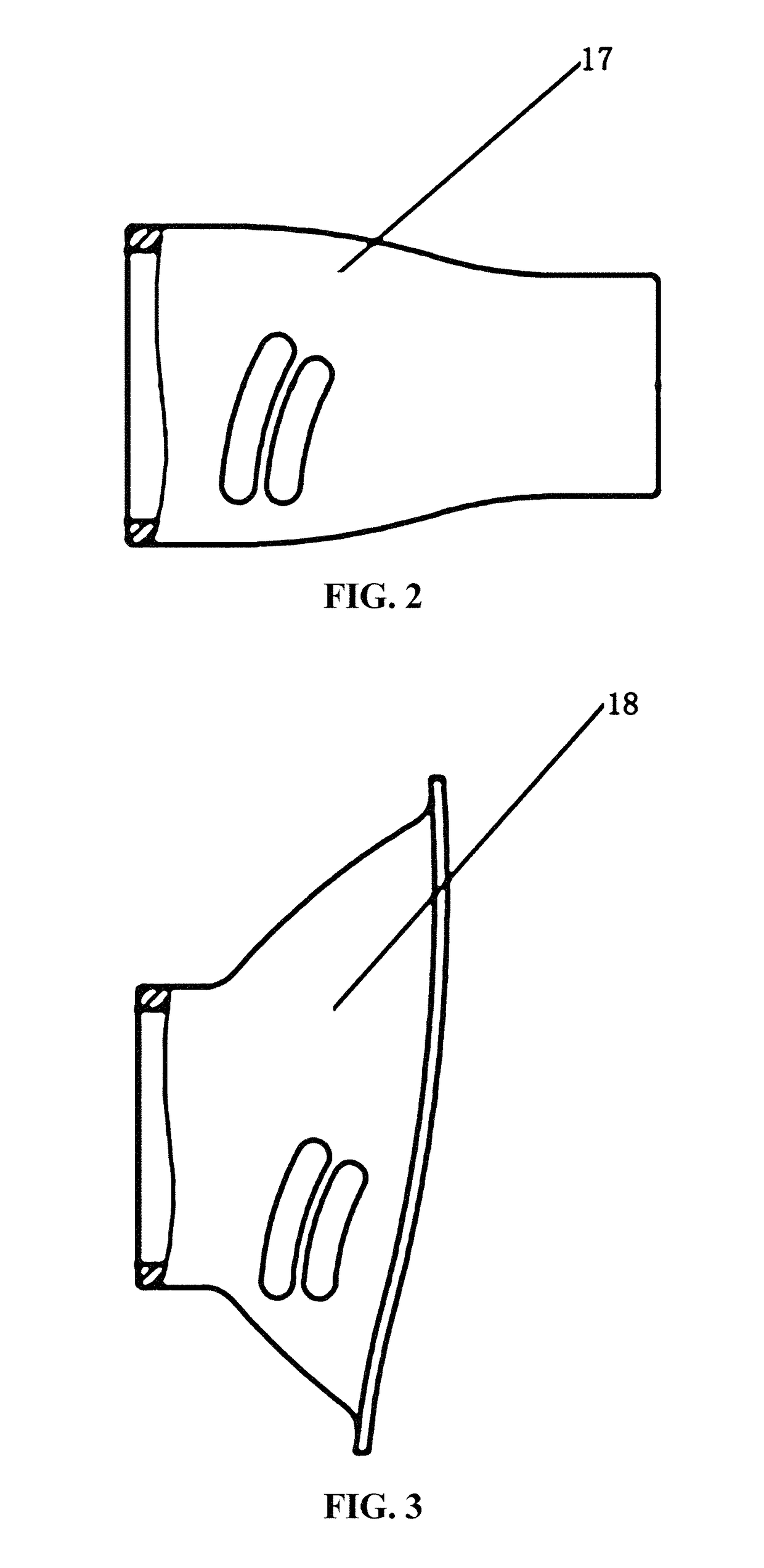

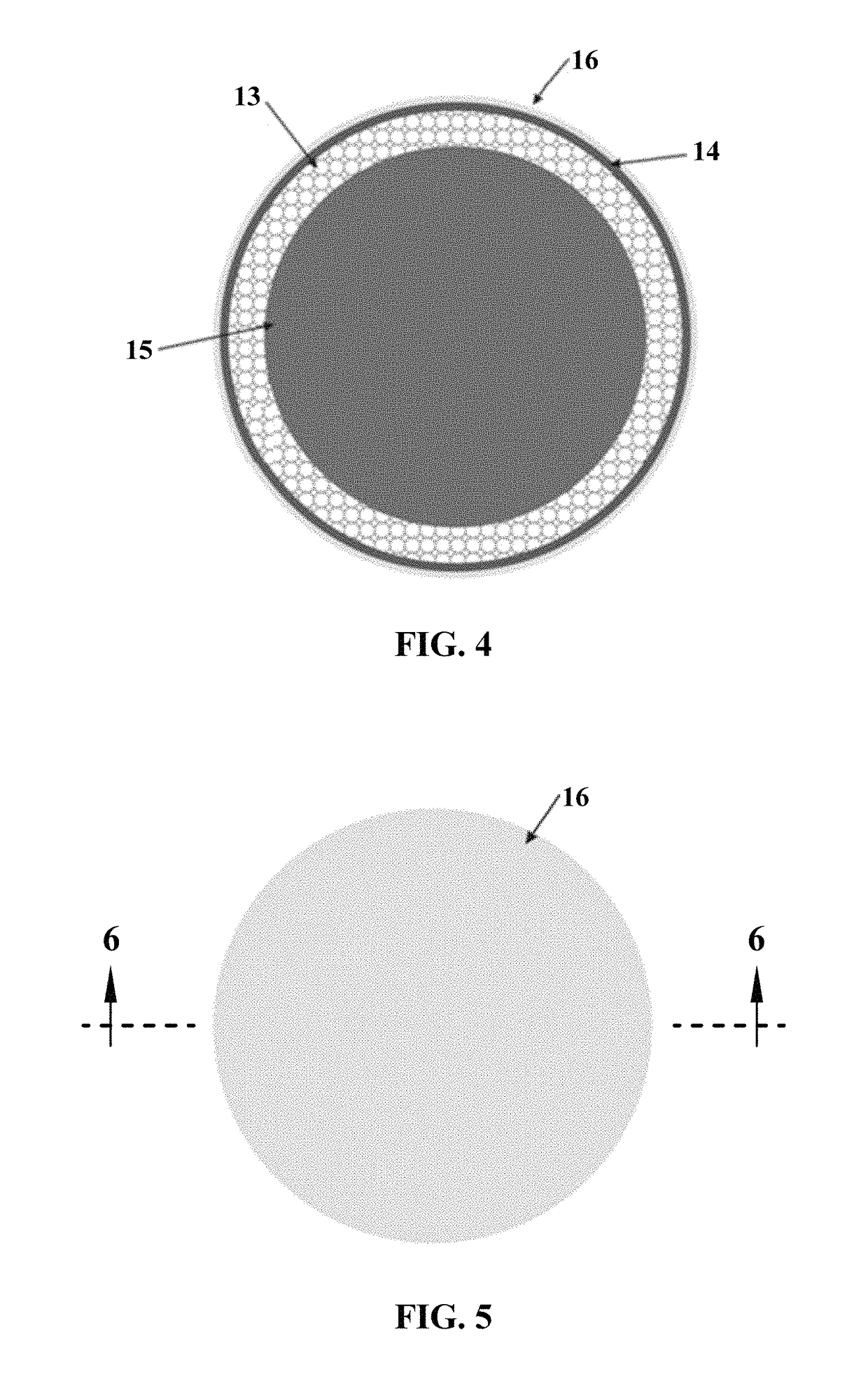

Handheld high frequency ultrasonic nebulizer for whole respiratory tract drug delivery

Owner:CHANGZHOU ZHENGYUAN MEDICAL TECH +1

Non-crystalline polyamide resin composition and product thereof

The invention provides a non-crystalline polyamide resin composition with enough transparency and excellent rigidity, mechanical performance, physical performance and heat resistance, and a product thereof. The composition adopts glass filler which is represented by the mass percentage based on oxide, contains 68-72 percent of silicon dioxide (SiO2), 2-5 percent of aluminum oxide (Al2O3), 2-5 percent of boron oxide (B2O3), 2-10 percent of calcium oxide (CaO), 0-5 percent of zinc oxide (ZnO), 0-5 percent of strontium oxide (SrO), 0-1 percent of barium oxide (BaO), 1-5 percent of magnesium oxide (MgO), 0-5 percent of lithium oxide (Li2O), 5-12 percent of sodium oxide (Na2O) and 0-10 percent of potassium oxide (K2O), wherein the total amount of lithium oxide, sodium oxide and potassium oxideis 8-12 percent.

Owner:ASAHI FIBER GLASS CO LTD

Catalyst for preparing alcohol through hydrogenation of acetic acid and preparation method

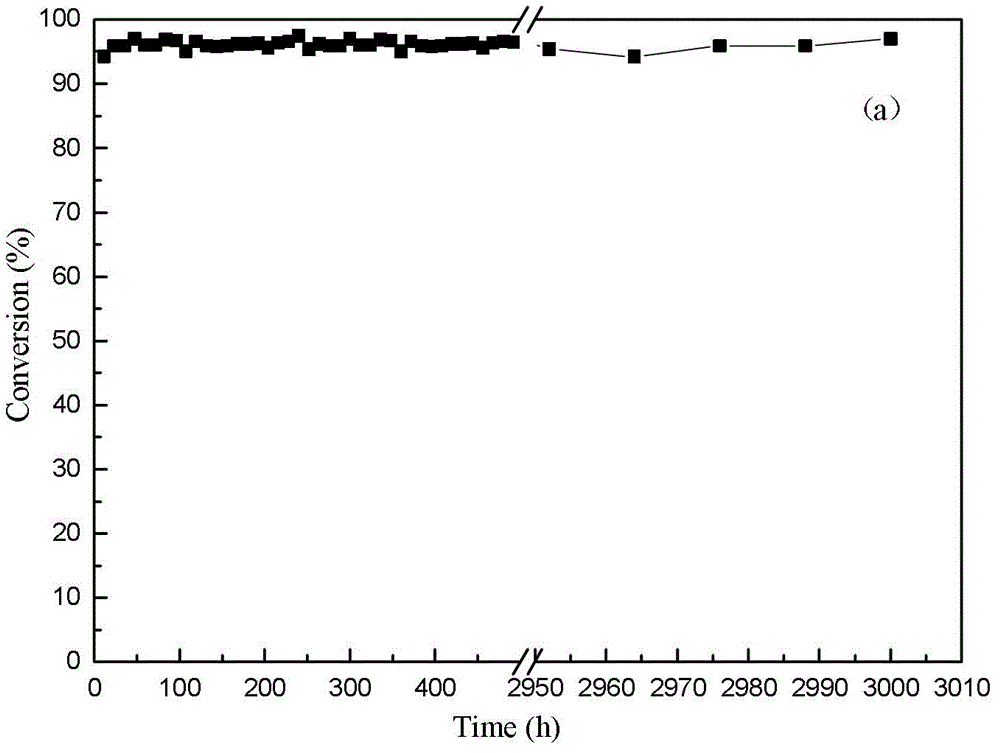

ActiveCN103331158AExtended service lifeImprove catalytic performanceOrganic compound preparationHydroxy compound preparationPlatinum oxidePalladium oxide

The invention discloses a catalyst for preparing alcohol through hydrogenation of acetic acid, and a preparation method of the catalyst. The catalyst is a multicomponent load catalyst and comprises ingredients a, b and c, and a carrier, wherein the ingredient a is one or more of calcium, potassium, sodium, barium, strontium, calcium oxide, potassium oxide, sodium oxide, barium oxide and strontium oxide; the ingredient b is one or more of tin, cobalt, molybdenum, nickel, iron, tin oxide, cobalt oxide, molybdenum oxide, nickel oxide and iron oxide; the ingredient c is one of platinum, palladium, ruthenium, rhodium, platinum oxide, palladium oxide, ruthenium oxide and rhodium oxide; the carrier is silicon dioxide, cerium dioxide, titanium dioxide, graphite, aluminum oxide or active carbon; and the mass ratio of the ingredient a to the ingredient b to the ingredient c to the carrier is (1-20):(0.5-2):(0.5-1):100. The multicomponent load catalyst is prepared by a multistep impregnation method, and used for preparing alcohol through the hydrogenation of acetic acid, and results prove that the catalyst is excellent in catalytical performance, long in service life and high in reaction stability.

Owner:SHANGHAI HUAYI GRP CO

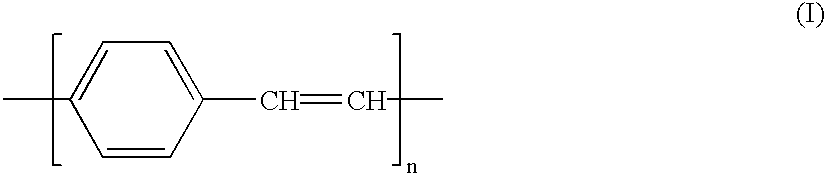

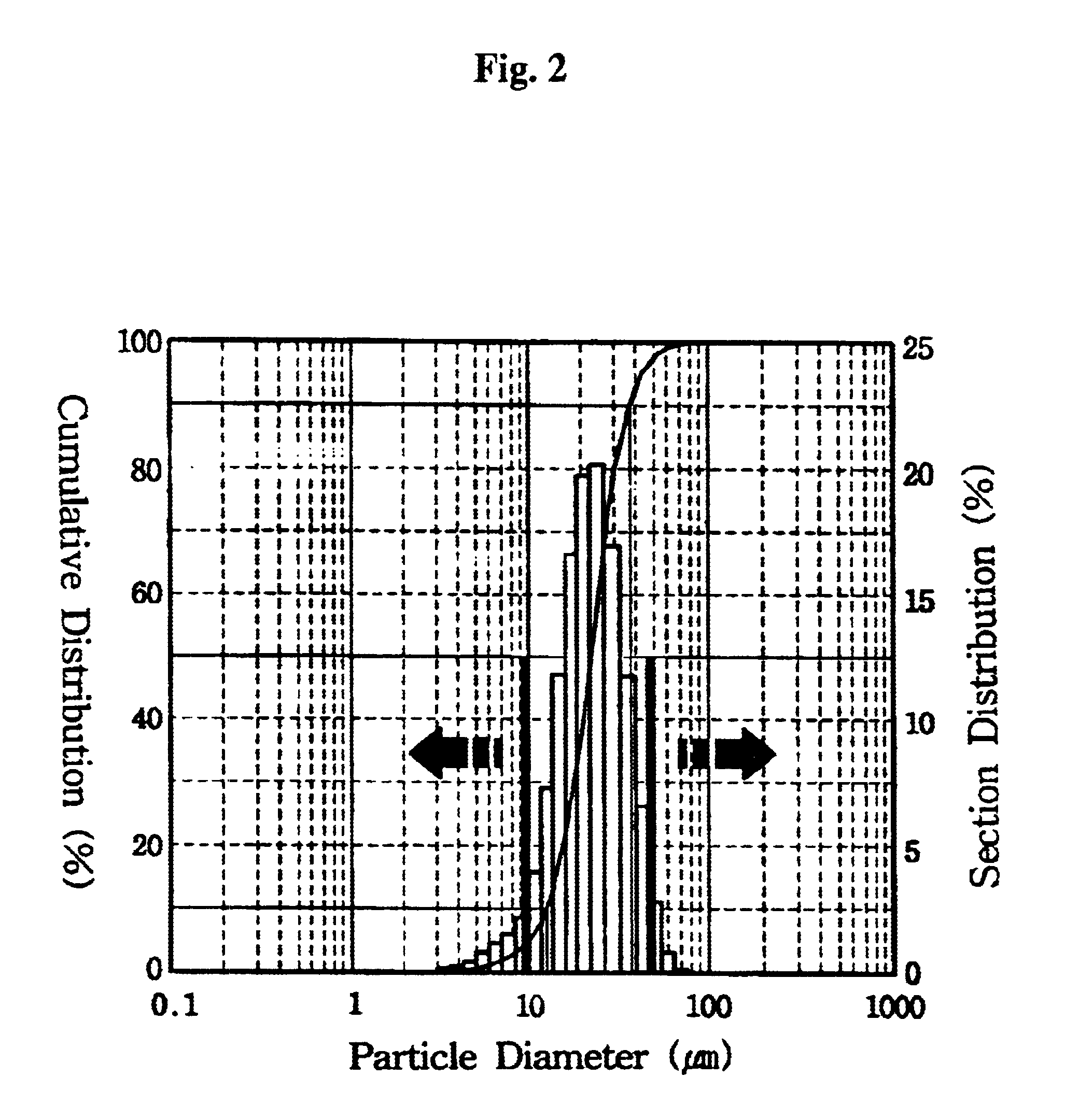

Process of making a phosphorescent fiber

InactiveUS6692667B2Liquid surface applicatorsMonocomponent polypropylene artificial filamentChemical structureFiber

A method of making phosphorescent fiber having phosphorescent particles composed, by weight, of 55-62.5% of strontium oxide, 35-42.5% of aluminum oxide, 1-9% of dysprosium oxide and 0.5-1.5% of europium oxide encapsulated with a wall material. The encapsulated particles are mixed and pelletized at a weight ratio of 15-25:85-75 with polymer capable of fiber formation to give a master batch, which is then compounded at a weight ratio of 30-70:70-30 with a polymer mixture, in combination with a softener and a dispersing agent. Polymer mixture consists of two polymers. One is the same polymer used to produce a master batch, the other is a polymer in the same chemical structure but different in physical properties such as melt index and tenacity. The compounded chip is melt-spun at 190-290° C. through a melt extruder. The fibers with the encapsulated phosphorescent particles exhibit such excellent physical properties as to be applicable to various textile products and show a high degree of luminescence.

Owner:GLOYARN +1

Electrocoat composition and process replacing phosphate pretreatment

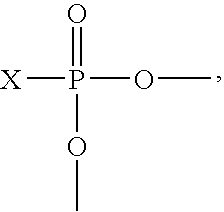

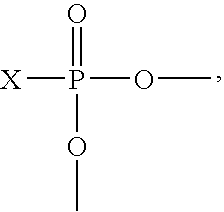

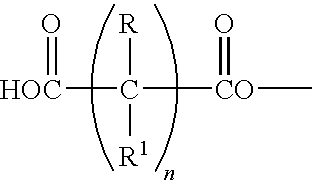

ActiveUS20100167072A1Strong resistanceImprove anti-corrosion performanceElectrolysis componentsVolume/mass flow measurementPhosphateManganese oxide

An aqueous coating composition comprises a metal oxide selected from the group consisting of bismuth oxide, vanadium oxide, manganese oxide, cobalt oxide, zinc oxide, strontium oxide, yttrium oxide, molybdenum oxide, zirconium oxide, lanthanum oxide, oxides of the lanthanide series of elements and combinations thereof and an electrodepositable binder, the binder comprising (a) a phosphorous-containing groupin which X is a hydrogen, a monovalent hydrocarbon, an alkyl group such as an aminoalkyl group, or an oxygen atom having a single covalent bond to the phosphorous atom, and each oxygen atom has a covalent bond to a hydrogen atom, an alkyl group, an aryl group, an alkylaryl group, an arylalkyl group, or the resin, with the caveat that at least one oxygen atom has a covalent bond to resin; (b) a carboxylate group separated by from 2 to 4 carbons from an ester group; and (c) a tridentate amine ligand. The coating composition can be electrodeposited on a metal substrate to provide superior corrosion resistance.

Owner:BASF COATINGS GMBH

Far infrared magnetic fiber and producing method thereof

ActiveCN101067225AHemodynamically significantPromote new metabolismFilament/thread formingMonocomponent polypropylene artificial filamentFiberPolymer science

The present invention relates to one kind of far infrared magnetic fiber and its production process, and features that the base material for producing the far infrared magnetic fiber is dacron, polypropylene or nylon with mixed superfine powder of ferric oxide, barium oxide, strontia, silica, calcium oxide and manganese oxide, accounting for 2-8 wt%. The production process of the far infrared magnetic fiber includes the steps of: preparing the mixed superfine powder, mixing the mixed superfine powder, the polymer slicing and assistant through smelting and stirring, pelletizing the mixture in a double screw pelletizing machine to form agglomerate, heating the agglomerate to form melt, extruding with a screw extruder and a metering pump through a orifice, condensating and curing, and stretching to form far infrared magnetic fiber.

Owner:南京天脉健康科技发展有限公司

Unleaded glass powder used for electronic paste and preparation method thereof

The invention provides an unleaded glass powder used for electronic paste and a preparation method thereof. The unleaded glass powder is composed of the following components by mass ratio: 10-60% of diboron trioxide, 2.5-30% of silicon dioxide, 30-75% of bismuth trioxide, 0.1-5% of sodium oxide, 0.1-3% of calcium oxide, 0.5-10% of strontium oxide, 1.5-20% of titanium dioxide, 0.5-8% of zirconium oxide, 0.1-5% of stannic oxide, 0.5-6% of aluminium oxide, 0.5-5% of antimonous oxide and 0.1-5% of calcium fluoride, the components are fully mixed to be uniform and then heated to 1050-1250 DEG C, and heat preservation is carried out for 30-120min, so that raw material is fully melted into glass metal, the glass metal is poured into deionized water to be quenched into glass granules, and ball milling into 320-400 meshes is carried out, thus obtaining the unleaded glass powder. The invention provides an unleaded glass powder with low softening temperature, good chemical stability, appropriate expansion coefficient, acid-base resistance, good abrasive resistance, wide sintering temperature range, low manufacturing cost and no toxic heavy metal oxide, and the unleaded glass powder has wide application range.

Owner:KUNMING UNIV OF SCI & TECH

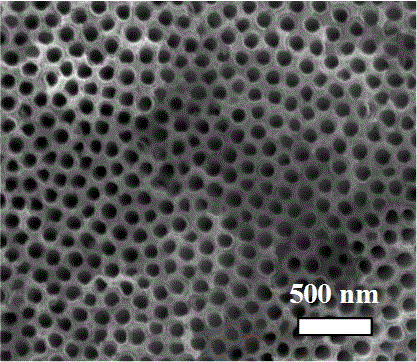

Medical titanium with a trace element slow-release function or titanium alloy implant material as well as preparation method and application of same

InactiveCN102908661AImprove biological activityIncrease success rateSurface reaction electrolytic coatingSuperimposed coating processElectrolytic agentTitanium metal

The invention relates to medical titanium with a trace element slow-release function or a titanium alloy implant material as well as a preparation method and an application of the medical titanium. The invention adopts the technical scheme that the preparation method comprises the following steps: putting a polished titanium-containing metal sheet into an electrolyte as an anode for anodic oxidation; flushing and drying the titanium-containing metal sheet subjected to anodic oxidation, carrying out heat treatment for 1-3 hours at a temperature of 100-500 DEG C, naturally cooling and ultrasonically cleaning and drying; and putting the dried titanium-containing metal sheet into one of or mixed solution of more than any two strontium hydroxide, strontium acetate, zinc acetate or magnesium acetate, carrying out hydrothermal reaction for 0.5-12 hours in a closed container at a temperature of 100-300 DEG C, naturally cooling, taking out, cleaning and drying, and carrying out heat treatment for 1-3 hours at a temperature of 450-550 DEG C to obtain the medical titanium with the trace element slow-release function or the titanium alloy implant material. The medical titanium or the titanium alloy implant material as well as the preparation method and the application thereof have the beneficial effects that the preparation method is simple and reliable, the loading quantity and the release amount of trace elements of the medical titanium in a nano tube are controllable, the medical titanium and the biological activity on the alloy surface can be better promoted, and the application prospect is good in the medical implant material.

Owner:WUHAN UNIV OF SCI & TECH

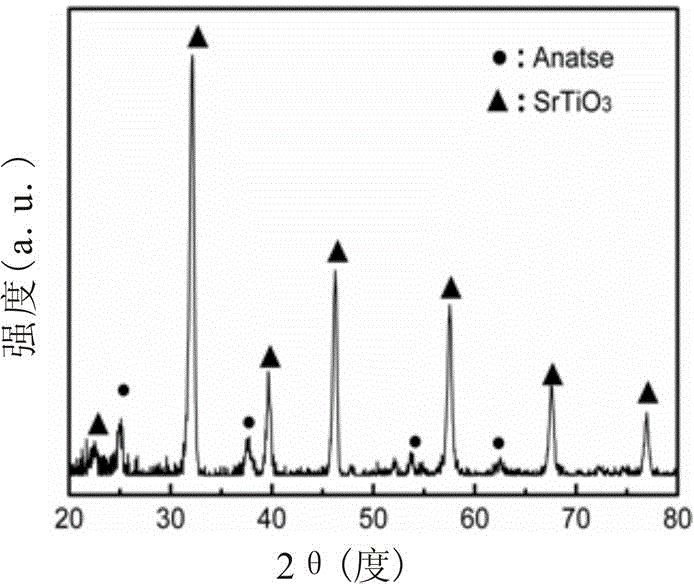

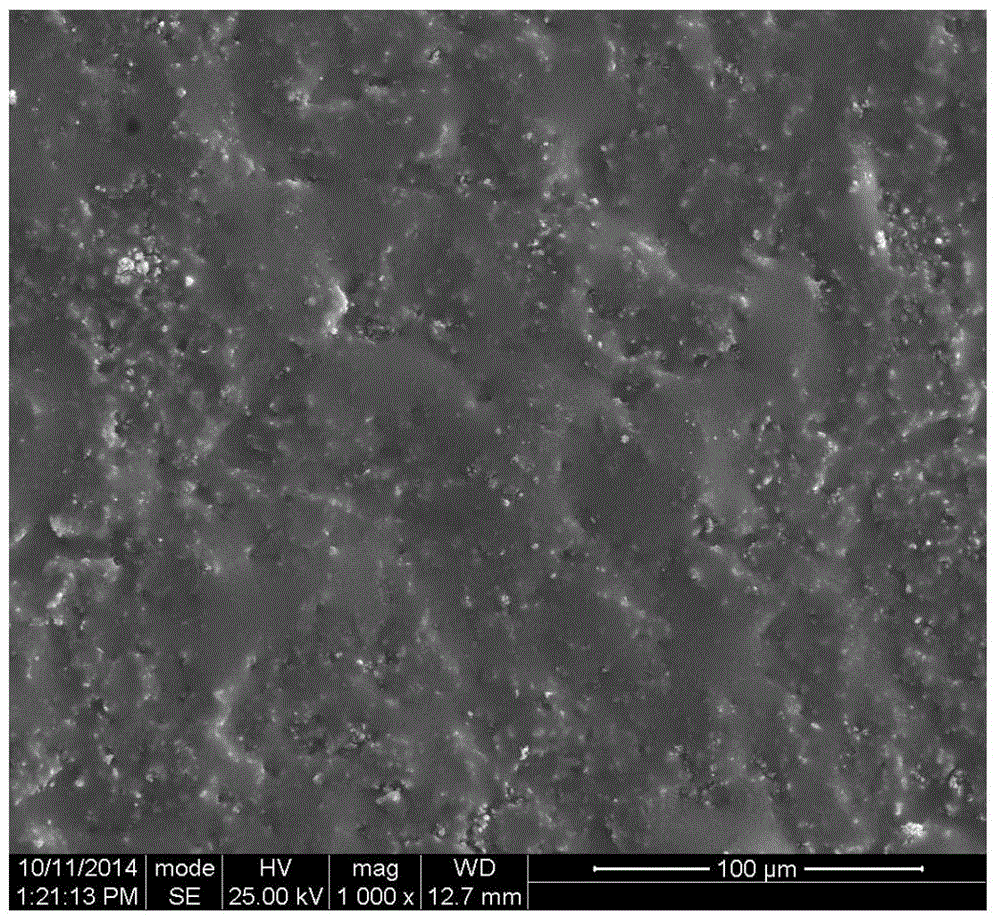

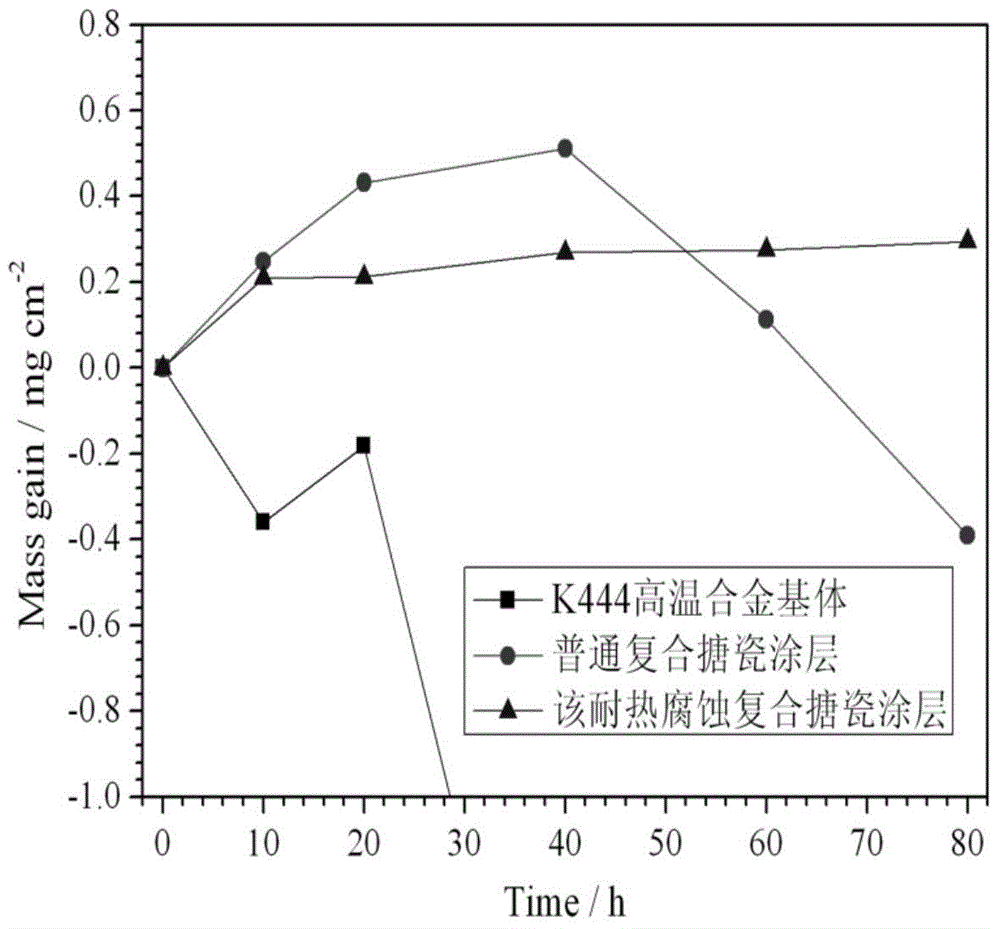

Heat-corrosion-resistant composite enamel coating and preparation method thereof

The invention aims at providing a heat-corrosion-resistant composite enamel coating and a preparation method thereof. The heat-corrosion-resistant composite enamel coating is characterized by comprising an enamel matrix and ceramic particles, wherein the ceramic particles are corundum with the size of less than 5 mum, and the addition amount of the ceramic particles accounts for 15-30 wt% of the weight of the composite enamel coating; and the enamel matrix comprises the following components: 58-62 wt% of silicon dioxide, 10-13 wt% of zirconia dioxide, 5-8 wt% of aluminum oxide, 5-7 wt% of calcium oxide, 4-6 wt% of diboron trioxide, 2-4 wt% of strontium oxide, 2-4 wt% of titanium dioxide, 2-6 wt% of sodium oxide and / or potassium oxide and 0-2 wt% of nickel oxide. The heat-corrosion-resistant composite enamel coating has no problems of continuous dissolving of an alloy matrix caused by easy occurrence of excessive interface reaction between the conventional enamel coating and high temperature alloy matrix during high temperature service, and overhigh content of low-melting-point components and poor diffusion infiltration resistance of the conventional enamel coating, and has excellent comprehensive resistance against heat corrosion and thermal circulation spalling.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

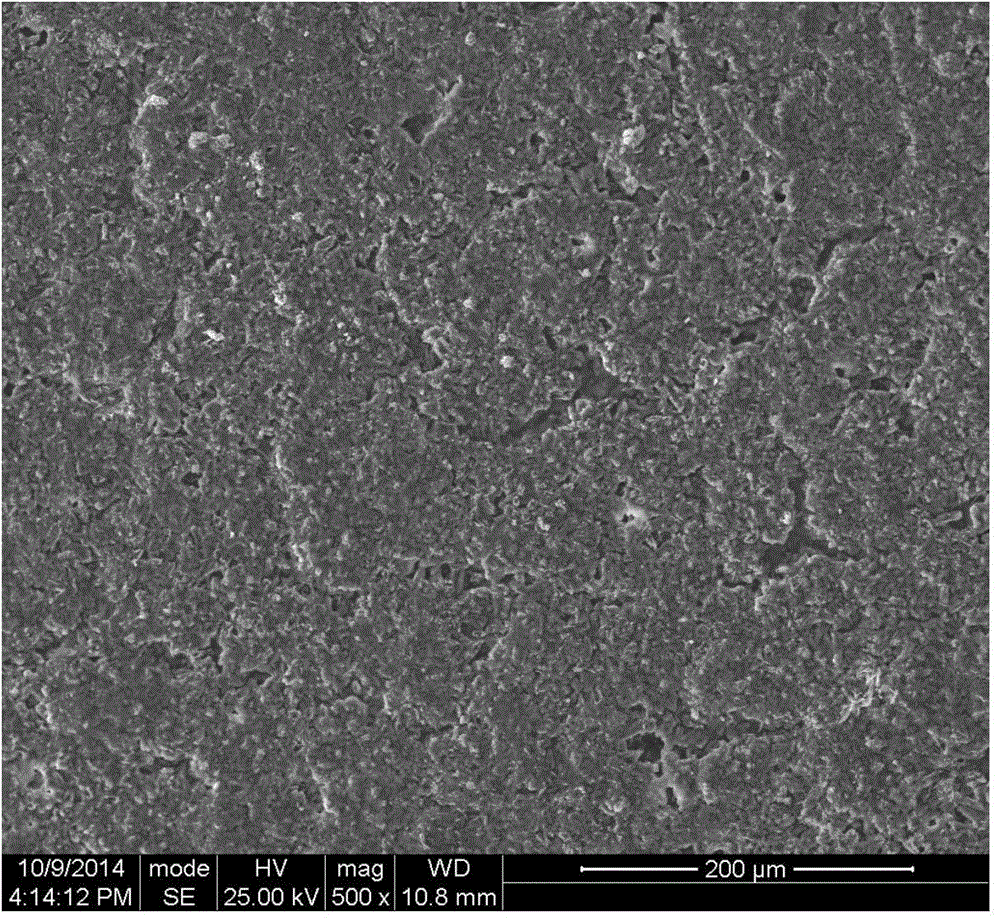

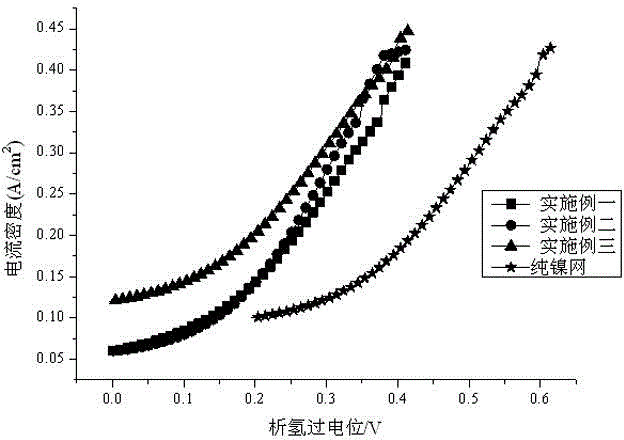

High-catalytic-activity amorphous metal oxide hydrogen evolution electrode and preparation method thereof

The invention discloses a high-catalytic-activity amorphous metal oxide hydrogen evolution electrode and a preparation method thereof. The electrode comprises an active coating made from an amorphous metal oxide, which is selected from any one or more of amorphous nickel oxide, amorphous ruthenium oxide, amorphous molybdenum oxide, amorphous cerium oxide, and amorphous strontium oxide. The preparation method comprises: step1, pre-treating a nickel screen to form a porous transition nickel oxide layer; step2, preparing an active coating precursor solution and coating the nickel screen with the precursor solution; and step3, performing thermal decomposition and laser-cladding assisted solidification to obtain the hydrogen evolution electrode. The preparation method is simple and is low in thermal decomposition temperature. The prepared hydrogen evolution electrode is high in catalytic activity and is not prone to polarize in a high current density. A catalyst firmly combines with a matrix and is not prone to fall off. The hydrogen evolution electrode has excellent anti-reverse-current performance. Compared with a conventional nickel screen, in a high current density of 4000A / m<2>, the electrode can reduce the hydrogen evolution overpotential by 250 mV. In a situation of frequent startup and shutdown, the voltage of an electrolytic bath is stable, and the fluctuation amplitude is small.

Owner:派新(上海)能源技术有限公司

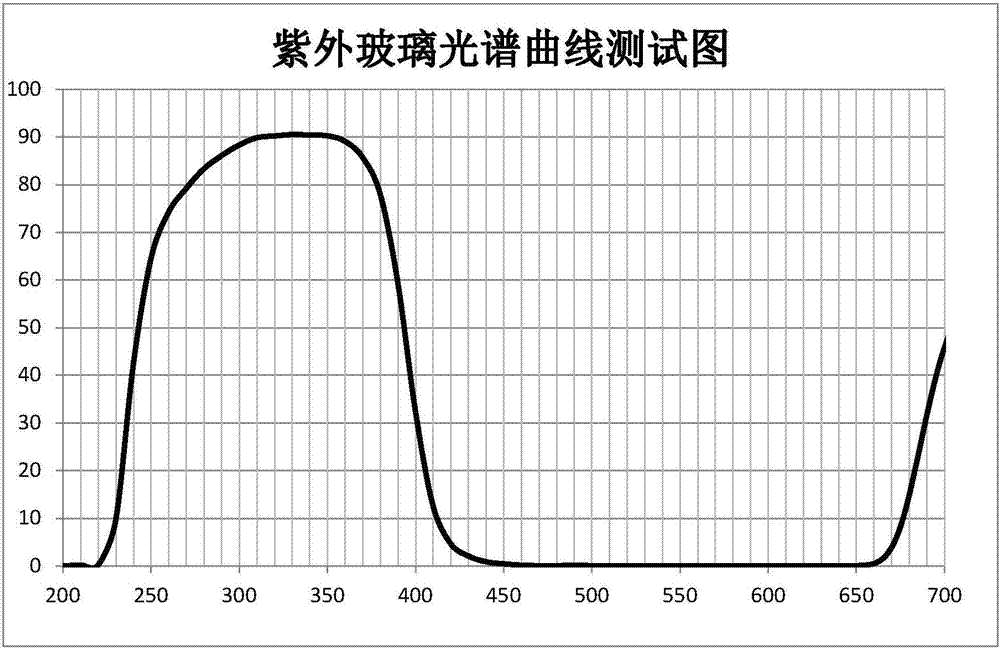

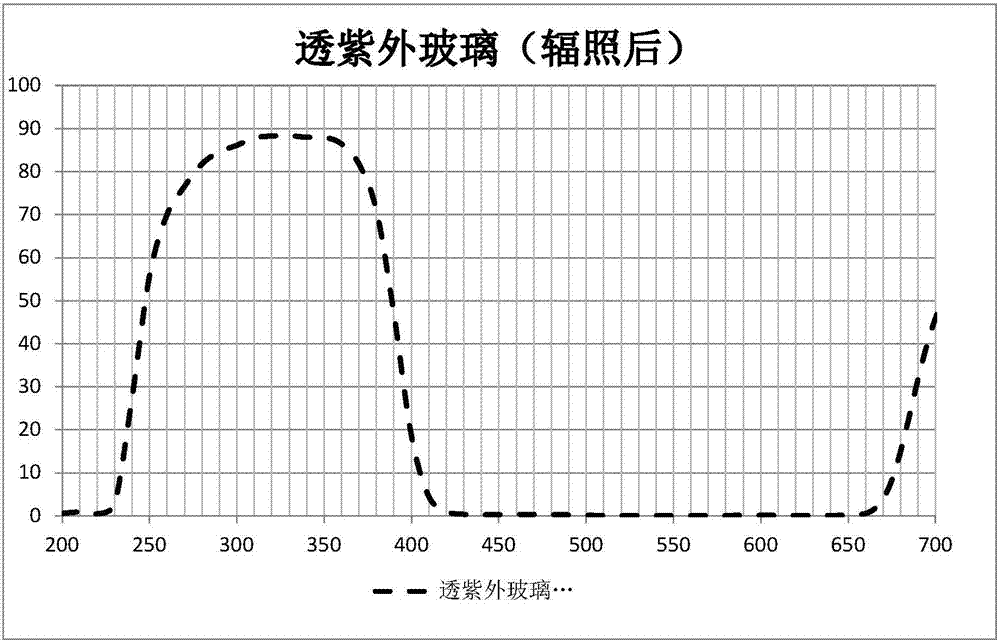

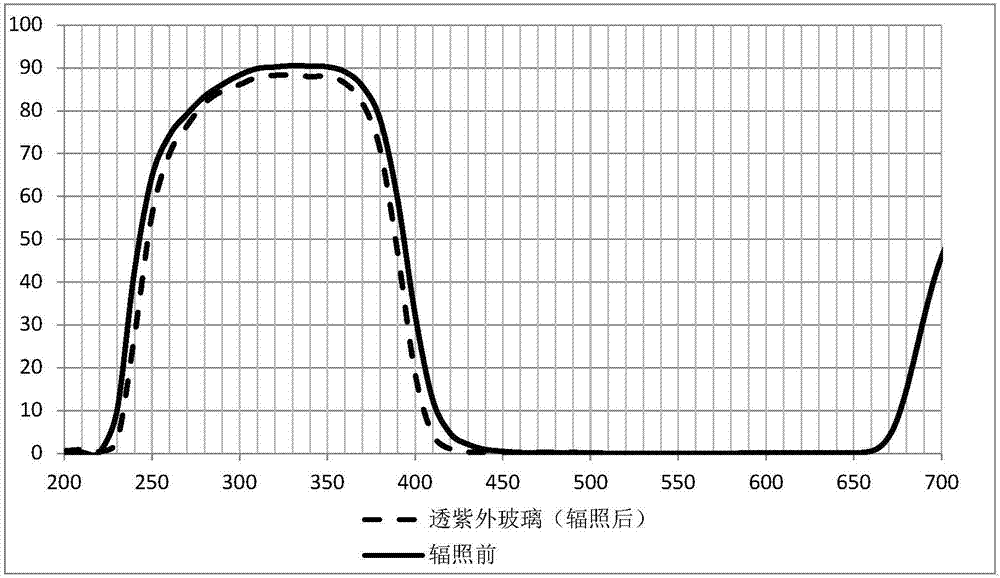

Ultraviolet-radiation-resistant optical glass high in ultraviolet band transmittance

The invention provides ultraviolet-radiation-resistant optical glass high in ultraviolet band transmittance. The optical glass is prepared from, by weight, 60-70 parts of phosphoric acid, 13-15 parts of boric acid, 8-12 parts of aluminum oxide, 4-6 parts of barium carbonate, 4-6 parts of potassium carbonate, 3-5 parts of calcium carbonate, 1-1.8 parts of a coloring agent A, 2-2.8 parts of a coloring agent B, 0.5-1 part of a reducing agent and 0.5-1 part of a stabilizing agent, wherein the stabilizing agent is composed of cerium oxide and strontium oxide, a ratio of strontium oxide to cerium oxide is 2:1, the coloring agent A refers to cobalt oxide, the coloring agent B refers to nickel oxide, a ratio of nickel oxide to cobalt oxide is 1:2, and tartaric acid serves as the reducing agent. The optical glass has advantages that a great ultraviolet radiation resistance function of the ultraviolet glass is achieved while ultraviolet band transmittance of the ultraviolet glass is increased, and the technical problem that the peak transmittance, which is required to be 85% or above in practical application, of current ultraviolet glass at an ultraviolet band is only about 80% is solved.

Owner:GUOGUANG OPTICAL GLASS CO LTD

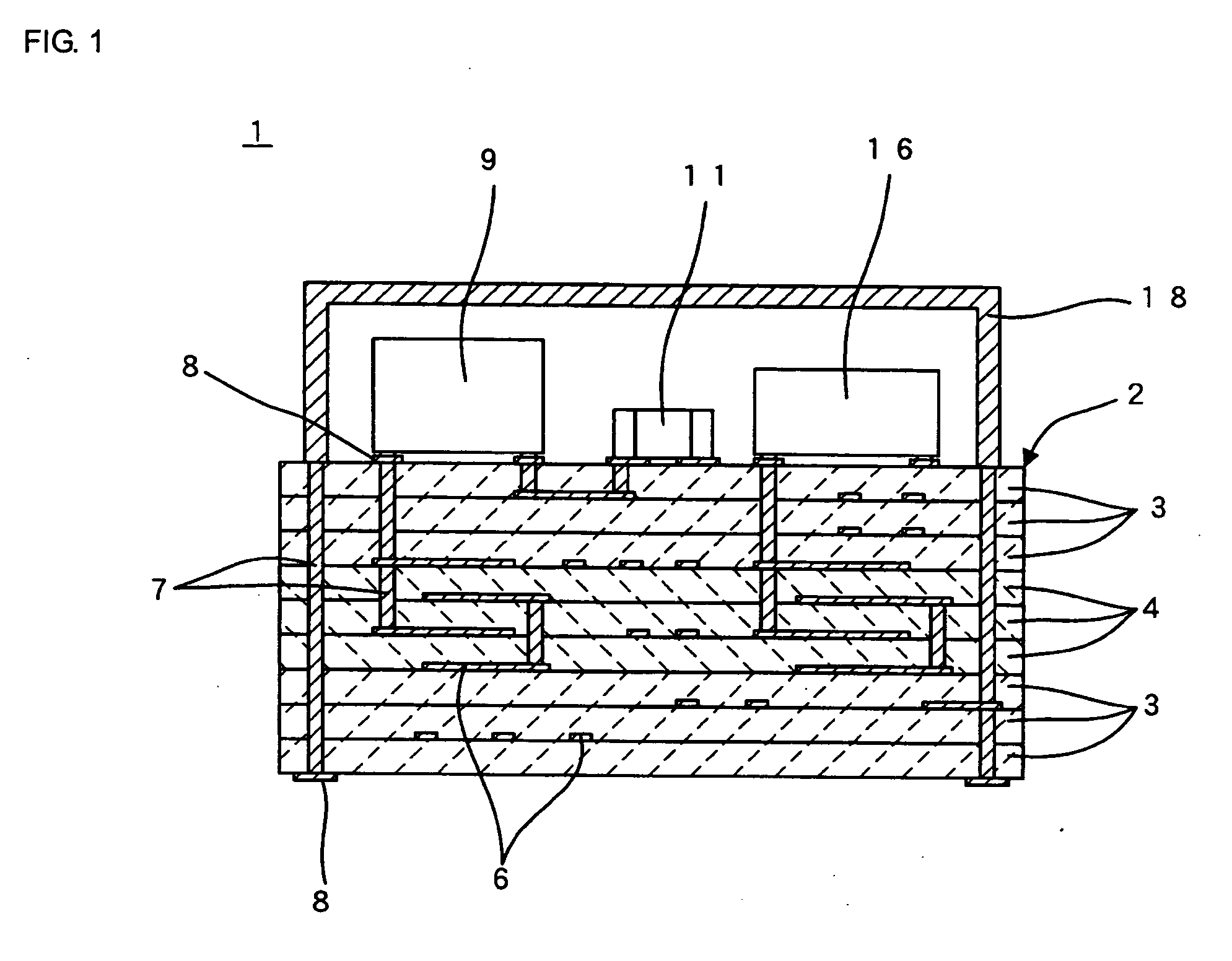

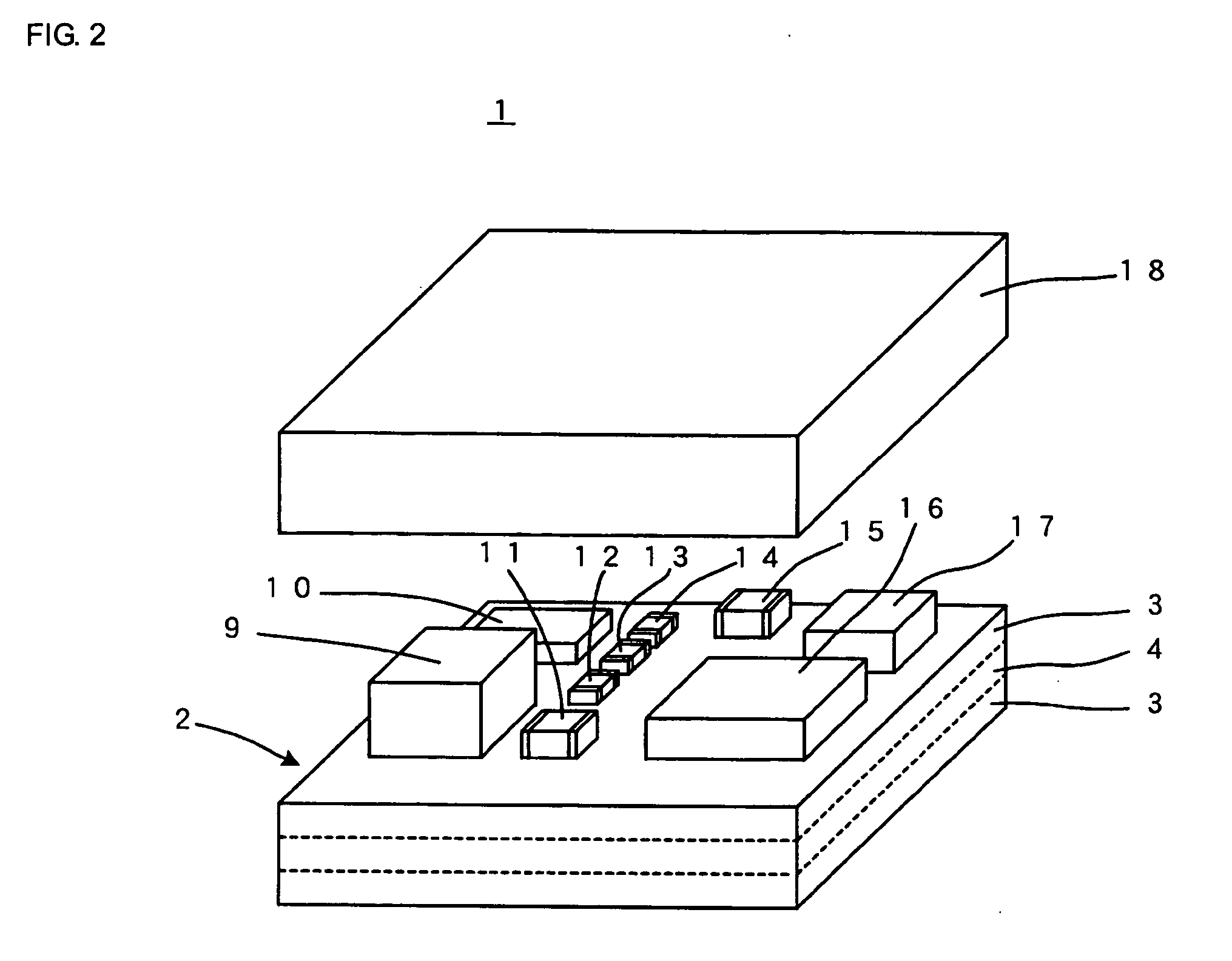

Electronic device and electronic apparatus

InactiveUS6849861B2Improve performanceQuality improvementImpedence networksSolid-state devicesStrontium titanateThin layer

Performance of an electronic device is highly improved by epitaxially growing a perovskite-type oxide thin film on an inorganic amorphous layer or an organic solid layer in a desired direction; and furthermore, a high performance electronic device is provided by incorporating the electronic device into an integrated circuit, wherein oxide thin layers are formed on the inorganic amorphous layer or the organic solid layer, and the perovskite-type oxide thin film is grown epitaxially on the oxide layer, the oxide thin layers being able to be at least one of strontium oxide, magnesium oxide, cerium oxide, zirconium oxide, yttrium stabilized zirconium oxide, and strontium titanate; and as the perovskite-type oxide thin film, the perovskite-type oxide thin film being a piezoelectric or ferroelectric material, for example, is used.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com