Non-crystalline polyamide resin composition and product thereof

A polyamide resin, amorphous technology, applied in the field of amorphous polyamide resin compositions and molded products, can solve the problems of impaired transparency, difference in refractive index, etc., and achieve the effect of excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] [Amorphous polyamide resin composition]

[0027] The amorphous polyamide resin composition of the present invention contains a resin component containing an amorphous polyamide resin and a glass filler.

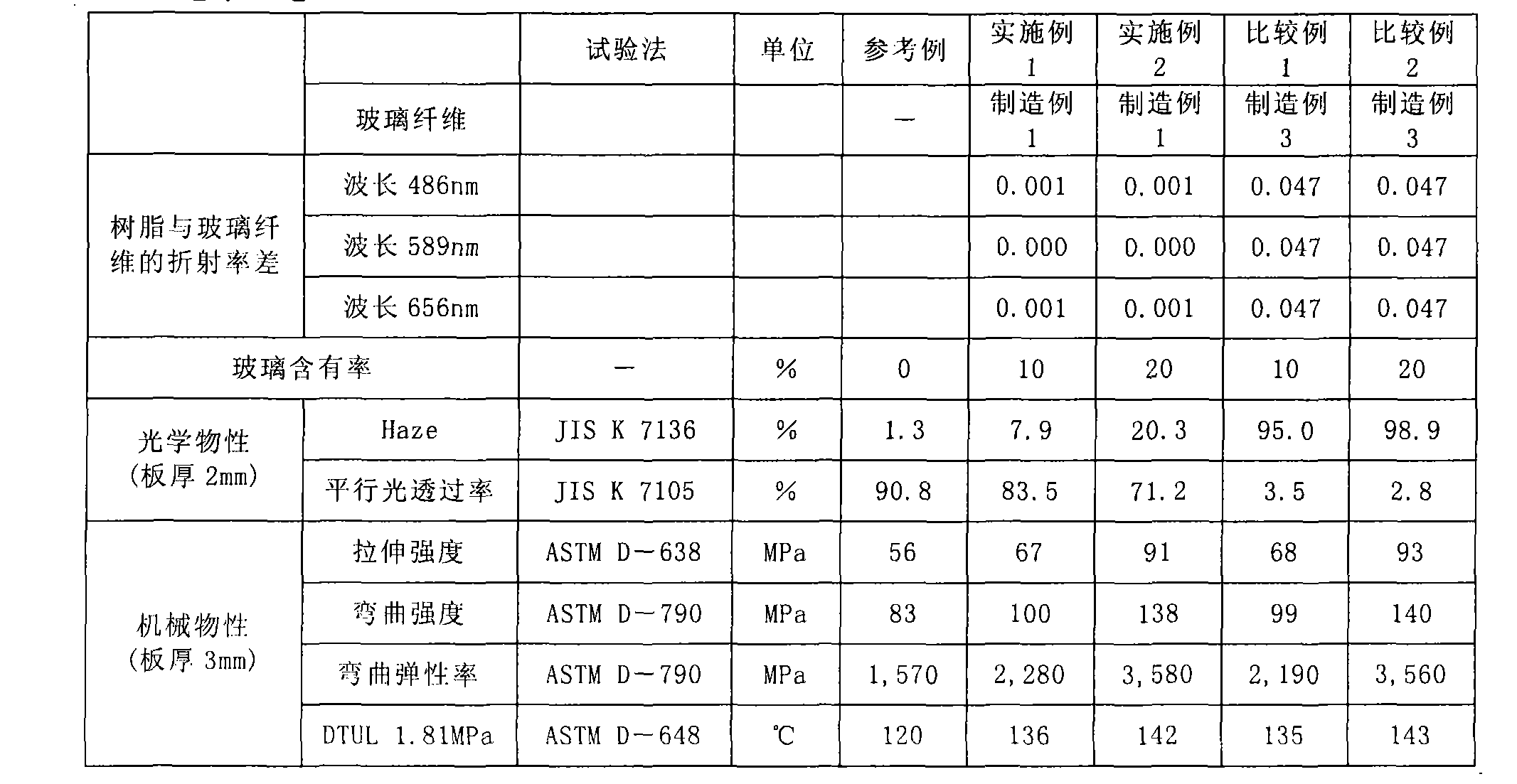

[0028] In addition, in the amorphous polyamide resin composition of the present invention, it is preferable that the difference between the refractive index of the resin component comprising the amorphous polyamide resin and the refractive index of the glass filler is 0.002 or less for light having a wavelength of 589 nm. For light with a wavelength of 486 nm, it is 0.002 or less, and for light with a wavelength of 656 nm, it is 0.002 or less. More preferably, the difference in refractive index for the light of the above three kinds of wavelengths is 0.001 or less. If the difference in refractive index between the resin component containing the amorphous polyamide resin and the glass filler is greater than 0.002 for each of the above three wavelengths of light, the tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com