High-catalytic-activity amorphous metal oxide hydrogen evolution electrode and preparation method thereof

A high catalytic activity, amorphous metal technology, applied in the field of electrodes, can solve the problems of poor anti-reverse current capability, easy falling off of the catalyst, low catalytic efficiency, etc., and achieve the effect of low polarizability, excellent catalytic activity, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

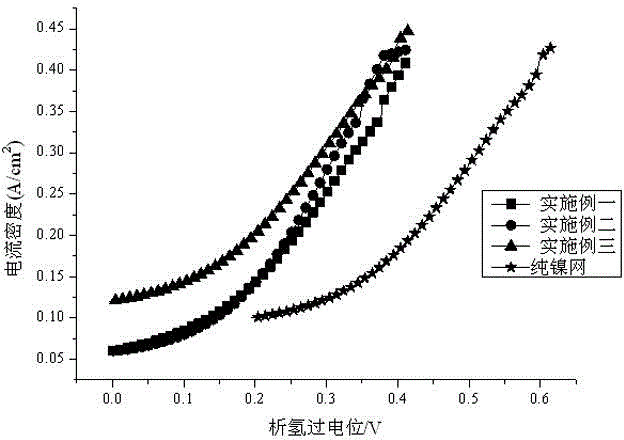

Embodiment 1

[0028] The base nickel mesh was soaked in 20% sodium hydroxide solution for 4 hours, and then cleaned with deionized water. Laser texturing and oxidation treatment are used to form a porous transitional nickel oxide layer to increase the specific surface area of the nickel mesh, which is beneficial to improving the catalytic activity of the hydrogen evolution electrode. Mix 80 g / L of ruthenium acetate, 150 g / L of nickel acetate, and 40 g / L of cerium acetate in ethanol solution according to the weight ratio of ethanol solution of 1:1:0.2 to prepare active coating precursor solution. The precursor solution is coated on the base nickel mesh by dipping and pulling process, and placed in an oven at 250 degrees for 40 minutes for thermal decomposition, so that the above precursor solution is decomposed into amorphous oxide, and then assisted by laser cladding for consolidation. Catalytic electrode 1 was obtained. The process conditions of the above laser cladding are: the las...

Embodiment 2

[0030] The base nickel mesh was soaked in 20% sodium hydroxide solution for 4 hours, and then cleaned with deionized water. Laser texturing and oxidation treatment are used to form a porous transitional nickel oxide layer. Mix 30 g / L ruthenium acetate, 300 g / L nickel acetate, and 70 g / L molybdenum acetate ethanol solution in a weight ratio of 1:1:1 to form an active coating precursor. The precursor solution was coated on the base nickel mesh by dipping and pulling process, placed in an oven at 300 degrees for 40 minutes, and then assisted by laser cladding (the process conditions were the same as in Example 1) for consolidation. Repeat dipping and pulling and thermal decomposition for 5 times to obtain catalytic electrode 2 .

Embodiment 3

[0032]The base nickel mesh was soaked in 20% sodium hydroxide solution for 4 hours, and then cleaned with deionized water. Laser texturing and oxidation treatment are used to form a porous transitional nickel oxide layer. Mix 70 g / L of ruthenium acetate, 50 g / L of molybdenum acetate, 75 g / L of strontium acetate and 90 g / L of cerium acetate ethanol solution according to the weight ratio of ethanol solution 1:1:0.2:0.2, and prepare active coating precursor. The precursor solution was coated on the treated base nickel mesh through the dipping and pulling process, placed in an oven at 350 degrees for 45 minutes, and then assisted by laser cladding (the process conditions were the same as in Example 1) for consolidation. Repeat dipping and pulling and thermal decomposition for 6 times to obtain catalytic electrode 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com