CVD diamond-coated composite substrate containing a carbide-forming material and ceramic phases and method for making same

a carbide-forming material and composite substrate technology, which is applied in the direction of abrasive surface conditioning devices, lapping machines, other chemical processes, etc., can solve the problems of increasing the total manufacturing the production cost of semiconductor wafers, and the total cost of polishing pads, etc., to achieve the effect of improving surface roughness characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

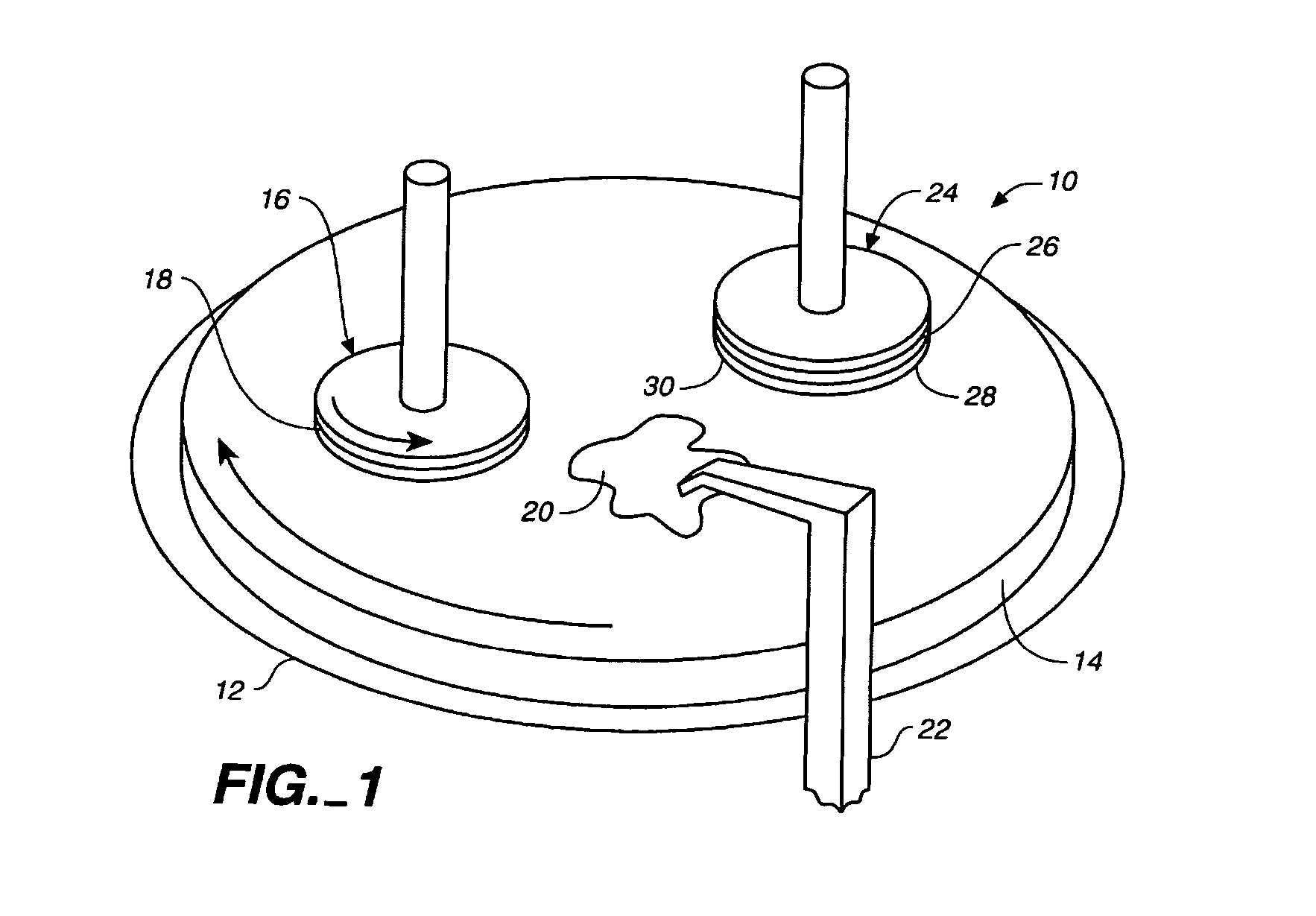

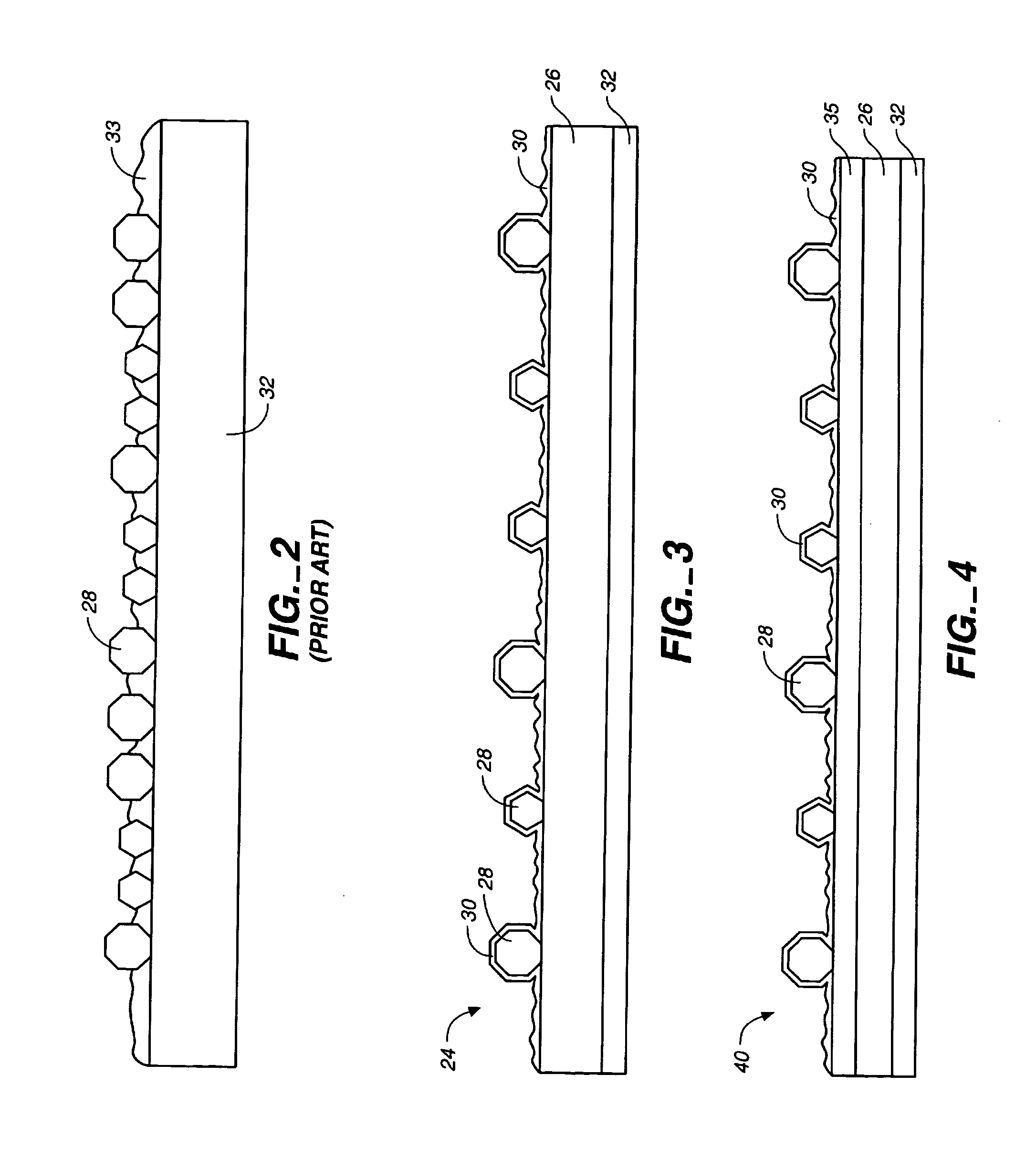

A two (2) inch diameter silicon substrate having a thickness of 0.04 inch (˜1 mm) was placed flat on a support fixture of an HFCVD reactor of the type described and claimed in the above-referenced Garg, et al., U.S. Pat. No. 5,186,973, as modified in the disclosure of U.S. Pat. Nos. 5,833,753 and 5,997,650, the entire contents of which are incorporated herein by reference. A monolayer of synthetic diamond grit having an average particle diameter of about 10 microns was uniformly distributed over the entire exposed surface of the first side of the silicon substrate to achieve an average grit density of 800 grains or grit particles per mm2 and a range from 700 to 900 grains per mm2. The grit from a container was uniformly distributed by using an air dispersion technique in which the grit was dropped at a controlled rate from a fixed height, above the wafer. A moving air current was used to disperse the grit in a lateral direction across the substrate.

The substrate was then placed i...

example 2

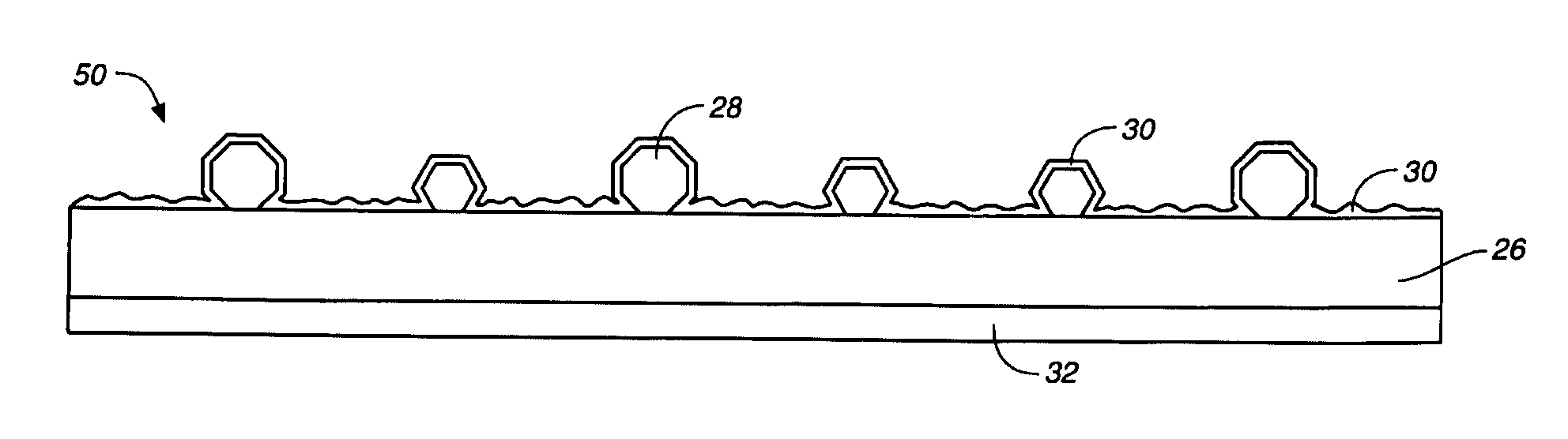

A 2″ diameter by 0.135″ thick round substrate of PUREBIDE R2000 reaction-bonded silicon carbide material which was surface-finished by through feed grinding was seeded with 1-2 micron diamond by mechanically rubbing the surface. The excess diamond was then removed from the surface. Diamond grit (10 micron size) was then dispersed on the surface of the substrate with a density of approximately 420 particles per mm2. The sample was then placed in CVD deposition reactor and a layer of CVD diamond about 8 microns thick was deposited on the surface by the process outlined in Example #1. The sample was then examined and found to have a uniform adherent diamond coating. The bow of the coated substrate was found to be approximately 5+ / −2 microns across the 2-inch diameter substrate. This value was, within measurement error, the same as the bow of the substrate prior to diamond coating. The 10 micron diamond crystals were strongly adhered to the surface. The sample was then hand rubbed on a...

example 3

A 2″ diameter by 0.135″ thick round substrate of PUREBIDE R2000 material with a lapped surface finish was seeded with 1-2 micron diamond by mechanically rubbing the surface. The excess diamond was then removed from the surface. Diamond grit (75 micron size) was then dispersed on the surface of the substrate with a density of 10 particles per mm2. The sample was then placed in CVD deposition reactor and a CVD diamond layer about 15 microns thick was deposited on the surface by the process outlined in Example #1. The sample was then examined and found to have a uniform adherent diamond coating. The 75 micron diamond crystals were strongly adhered to the surface. The sample was then hand rubbed on a polyurethane CMP polishing pad and reexamined. No indications of grit pullout were found.

PUM

| Property | Measurement | Unit |

|---|---|---|

| average grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com